Overhead two-core user lead-in cable

A technology for introducing cables and users. It is applied in the direction of cable/conductor manufacturing, twisted/quad-stranded cables, circuits, etc. It can solve the problems of increasing construction difficulty, limited tensile strength, and easy damage. , to achieve the effects of improving fluidity, improving processing performance and improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

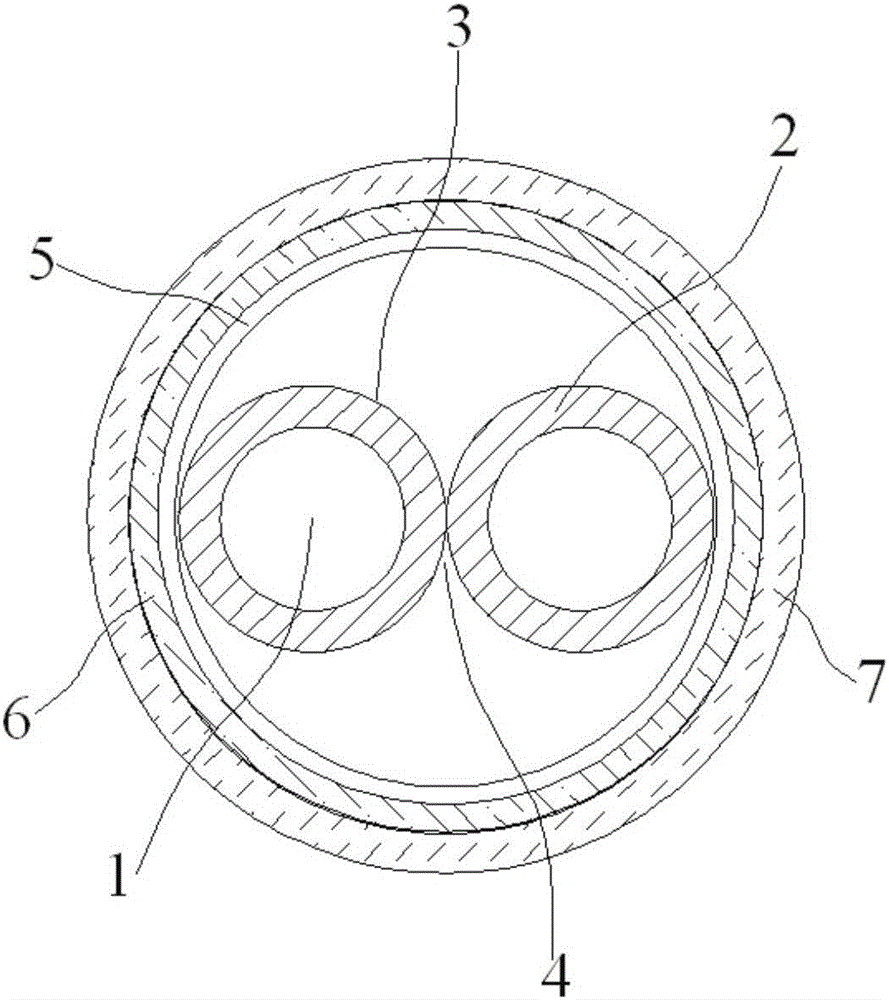

[0030] Embodiments 1 to 3: An overhead two-core user lead-in cable, including two copper-magnesium alloy conductors 1, the outer surface of the copper-magnesium alloy conductor 1 is covered with a polyethylene layer 2 to form a wire 3, and the two wires 3 Twisting to form a twisted wire pair 4, an aluminum foil 5 is wrapped around the outer surface of the twisted wire pair 4, a polyvinyl chloride layer 6 is wrapped on the outer surface of the aluminum foil 5, and a polyethylene sheath layer 7 is wrapped around the outer surface of the twisted wire pair 4. The outer surface of the polyvinyl chloride layer 6;

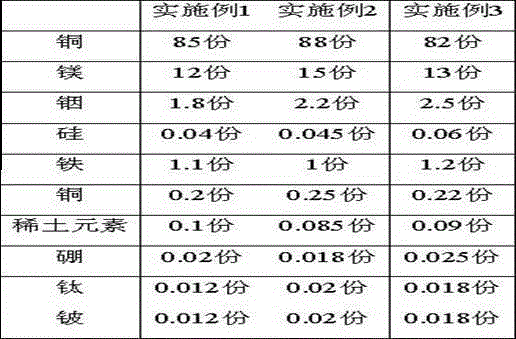

[0031] The copper-magnesium alloy conductor 1 is composed of the following components by weight, as shown in Table 1:

[0032] Table 1

[0033]

[0034] ;

[0035] The rare earth element is composed of lanthanum, cerium and scandium, and the lanthanum, cerium and scandium are mixed in a ratio of 10:4:1 by weight to form the rare earth element.

[0036] The above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com