A method for producing non-oriented high silicon steel by cold rolling

A technology of continuous cold rolling and high-silicon steel, which is applied in the field of metallurgy, can solve problems such as production process capacity constraints, and achieve the effect of improving capacity and continuous rolling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

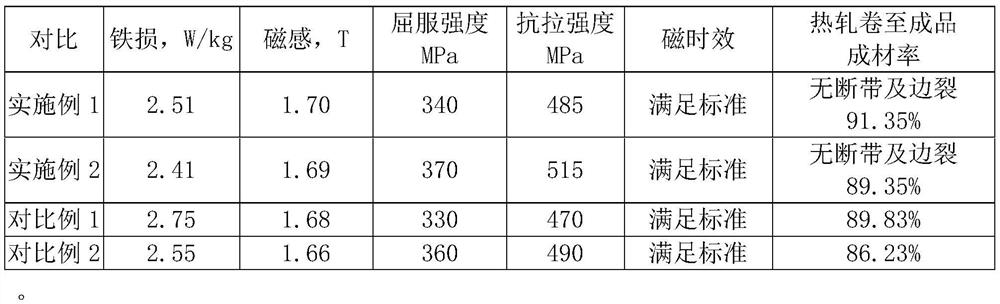

Examples

Embodiment 1

[0040] The method of producing non-oriented high-silicon steel by cold continuous rolling method, the steel chemical composition C: 0.0025%, Si: 2.61%, Als: 0.48%, Mn: 0.28%, O: 0.0056%, P: 0.010%, S: 0.0012% , N: 0.0017%, Ti: 0.0020%, V: 0.0015%, Nb: 0.0013%, B: 0.0045%, Sn: 0.065%, the rest is Fe and unavoidable residual elements; process route: hot metal desulfurization-converter smelting- RH refining - continuous casting - hot rolling - normalization - pickling - cold rolling - continuous furnace annealing - coating - performance inspection - packaging, the specific steps include:

[0041] 1) After RH vacuum decarburization treatment, aluminum deoxidation and partial aluminum alloying, 1 / 3 of the estimated amount of aluminum alloy is added; then the whole silicon steel is alloyed, boron alloying is added, the remaining aluminum alloy is added, and tin alloying is added;

[0042] 2) After alloying, the molten steel in the large tank is circulated for 6 minutes; the standing...

Embodiment 2

[0048] The method of producing non-oriented high-silicon steel by cold continuous rolling method, the steel chemical composition C: 0.0022%, Si: 2.88%, Als: 0.55%, Mn: 0.31%, O: 0.0060%, P: 0.011%, S: 0.0017% , N: 0.0019%, Ti: 0.0018%, V: 0.0014%, Nb: 0.0015%, B: 0.0049%, Sn: 0.105%, the rest is Fe and unavoidable residual elements; process route: hot metal desulfurization-converter smelting- RH refining - continuous casting - hot rolling - normalization - pickling - cold rolling - continuous furnace annealing - coating - performance inspection - packaging, the specific steps include:

[0049] After RH vacuum decarburization treatment, aluminum deoxidation and partial aluminum alloying, 1 / 3 of the calculated aluminum alloy content is added; then the whole silicon steel is alloyed, boron alloyed is added, the remaining aluminum alloy is added, other components are fine-tuned, and tin alloyed join in;

[0050] After alloying, the molten steel in the large tank is circulated 4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com