Self-propagating aluminum solder and welding rod

An aluminum flux, self-propagating technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of inability to use aluminum and aluminum alloy self-propagating welding, brittle failure of welds, poor mechanical properties, etc. , to achieve the effect of expanding the range of solid-liquid transition temperature, refining grains, and improving protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

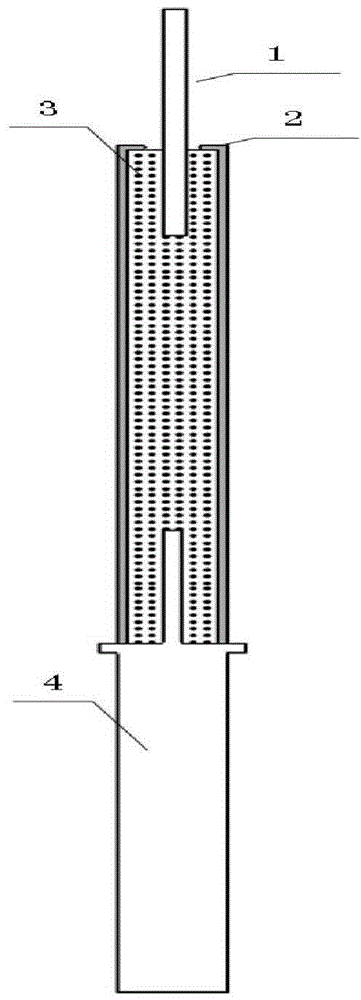

[0038] The preparation process of the self-propagating aluminum electrode of the present invention mainly includes: removing free water and bound water from the main components of the powder column, mixing them uniformly in proportion, then mixing them evenly with rosin powder and paraffin powder, and stirring at 90°C to form a slurry , assemble the ignition wire and the handle, and squeeze it repeatedly to make it densely formed into an attached figure 1 column shown. Finally, let it cool and shape at room temperature, wrap it in a thin aluminum tube, and vacuum pack it one by one.

[0039] The specific steps of using the self-spreading aluminum welding rod of the present invention include: taking out the welding rod from the vacuum package, holding the handle tightly so that the beginning of the welding rod is aligned with the weld to be welded, and then igniting the ignition line, tilting the welding rod according to specific needs for welding, and waiting for the welding r...

Embodiment 1

[0042] The selected mass ratio is gypsum powder 31.9%; aluminum powder 53%; calcium fluoride powder 2.5%; sodium fluorosilicate powder 1.5%; copper powder 4.5%; tin powder 2%; zinc powder 1.3%; silicon powder 2%; Powder 0.1%; 200-mesh powder medicament of yttrium powder 0.2% and silver powder 1%, prepare welding rod according to the above preparation process. Hold it backwards, the specific inclination angle is 65°, the distance between the burning end of the electrode and the surface of the base metal to be welded is 5mm, and the moving speed of the electrode is 9mm / s. Weld according to the above steps to achieve a butt joint aluminum plate with a thickness of 6mm welding.

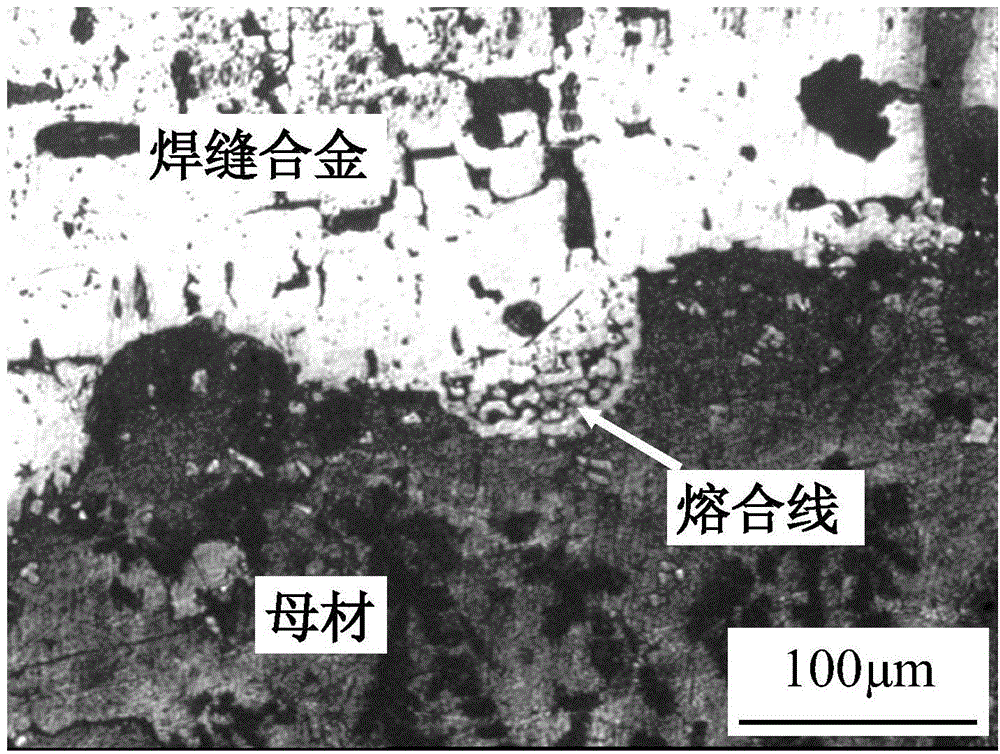

[0043] After the welded seam joint is sampled, it is observed under a metallographic microscope. The microstructure is as follows: figure 2 shown. In the figure, the weld alloy and the base metal are closely connected and infiltrated with each other, the fusion line is bent and the layers are clear, fo...

Embodiment 2

[0045] The selected mass ratio is 26% gypsum powder; 45% aluminum powder; 2.3% calcium fluoride powder; 1.2% sodium fluorosilicate powder; 7% copper powder; 13% tin powder; 2% zinc powder; 2% silicon powder; Powder 0.05%; 200-mesh powder medicament of yttrium powder 0.05% and silver powder 1.4%, prepare welding rod according to the above preparation process. Hold it backwards, the specific inclination angle is 70°, the distance between the burning end of the electrode and the surface of the base metal to be welded is 5mm, and the moving speed of the electrode is 8mm / s. Weld according to the above steps to achieve a butt joint aluminum plate with a thickness of 8mm welding.

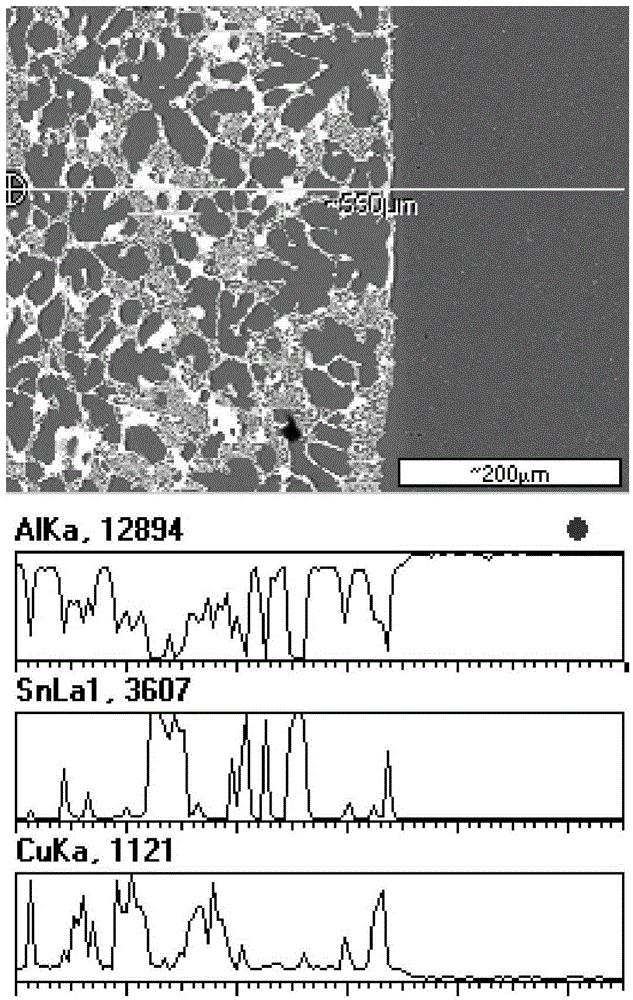

[0046] The welded joints were sampled and observed under a field emission scanning electron microscope, and line-scanned by an energy dispersive spectrometer. The results are as follows: image 3 shown. There are obvious differences in the microstructures on both sides of the fusion line. The structure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com