Preparation method of Mg-Zn-Ca series biomedical magnesium alloy

A biomedical and magnesium alloy technology is applied in the field of Mg-Zn-Ca series biomedical deformed magnesium alloy, Mg-Zn-Ca series biomedical magnesium alloy preparation, low-cost preparation, and can solve the problem of increasing the deformation degree of alloy blanks, It is not applicable to the problems of cost industrial production, hindering the growth of recrystallized grains, etc., to achieve the effect of increasing the degree of deformation, reducing the amount of solidification shrinkage, and increasing the nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

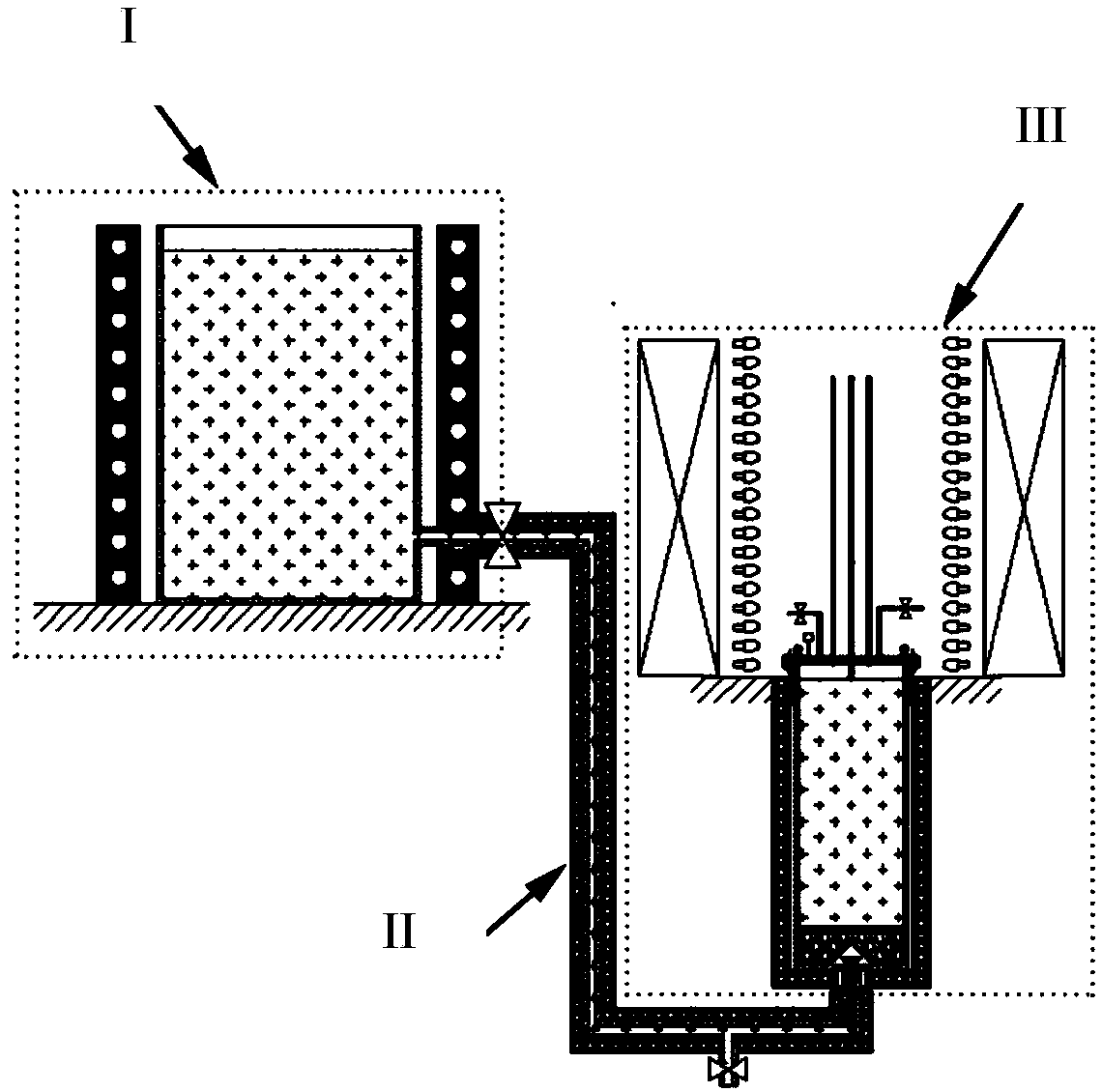

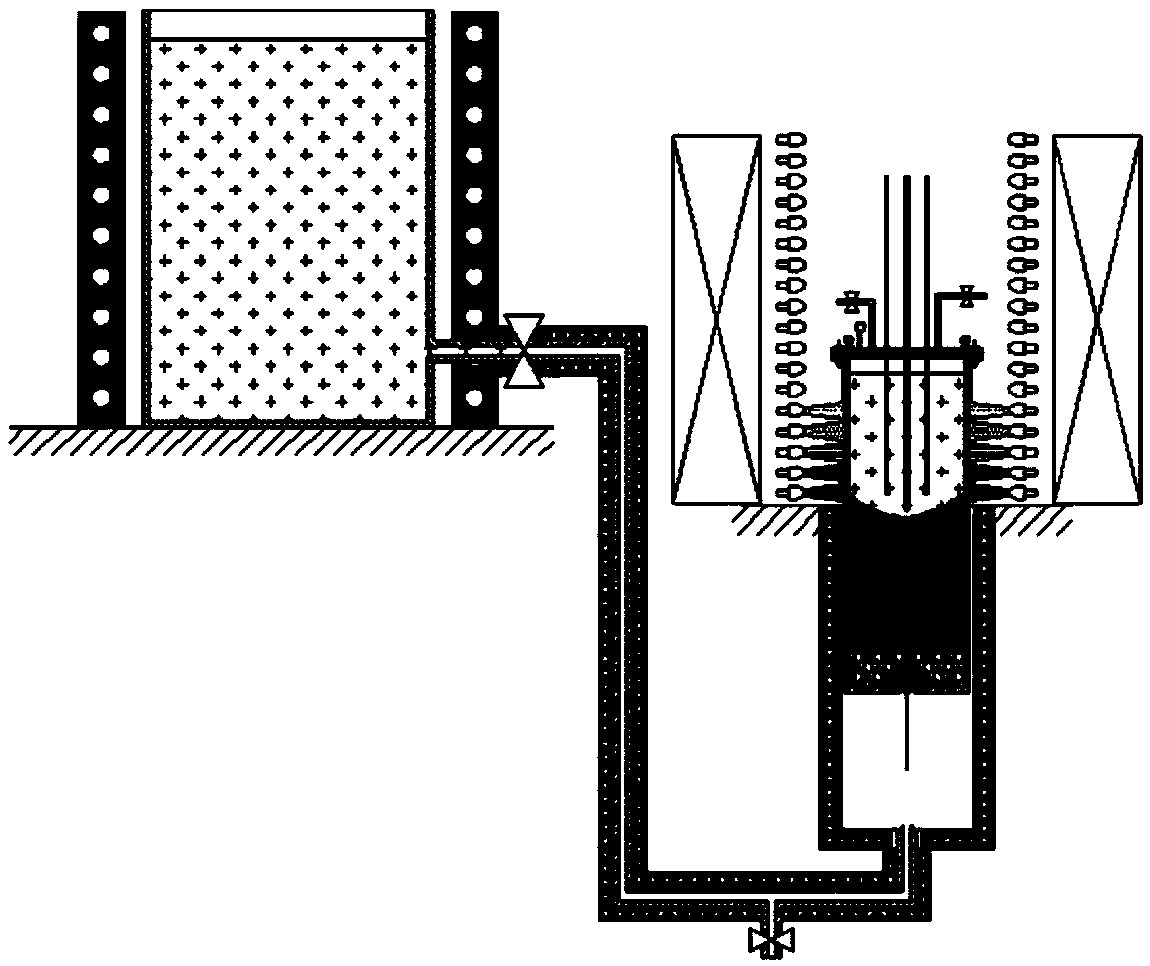

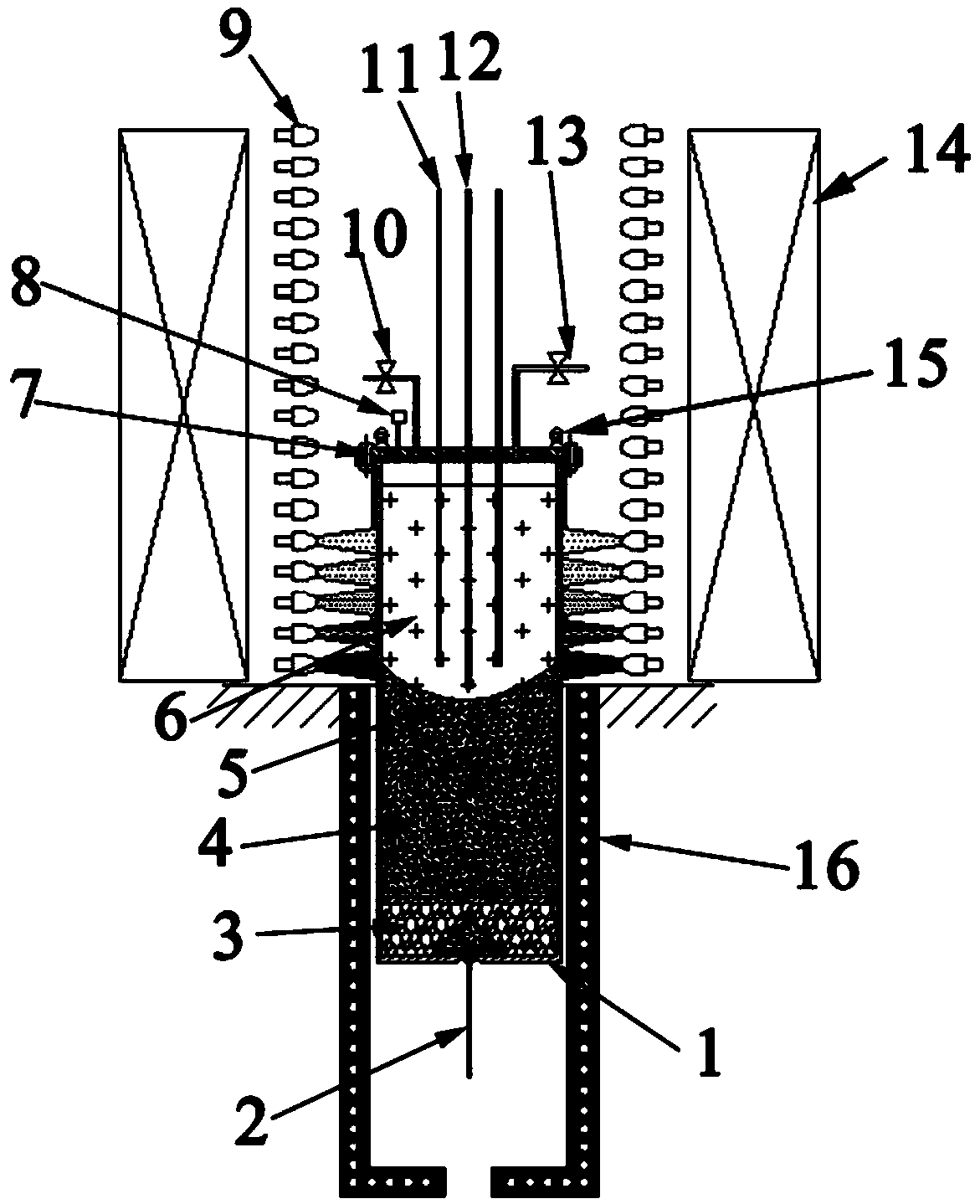

[0055] The present invention provides a low-cost preparation method of a Mg-Zn-Ca series biomedical magnesium alloy. The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0056] The preparation method of the Mg-Zn-Ca series biomedical magnesium alloy of the present invention comprises the following steps:

[0057] (1) Batching, melting and solidification system preparation

[0058] Determine the chemical composition of the alloy according to the required mechanical and degradation properties, use magnesium ingots with a purity greater than or equal to 99.9%, zinc ingots with a purity greater than or equal to 99.9%, Mg-Ca and Mg-Sr master alloys, and clean and dry the raw materials before smelting Grinding to remove the oxide layer.

[0059] The invention adopts submerged flow die-casting equipment for smelting and transfer, and adopts an integrated equipment for precisely controlling solidification and residual hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com