Method for manufacturing aluminum magnesium alloy structural parts through hammering reinforced arc added materials

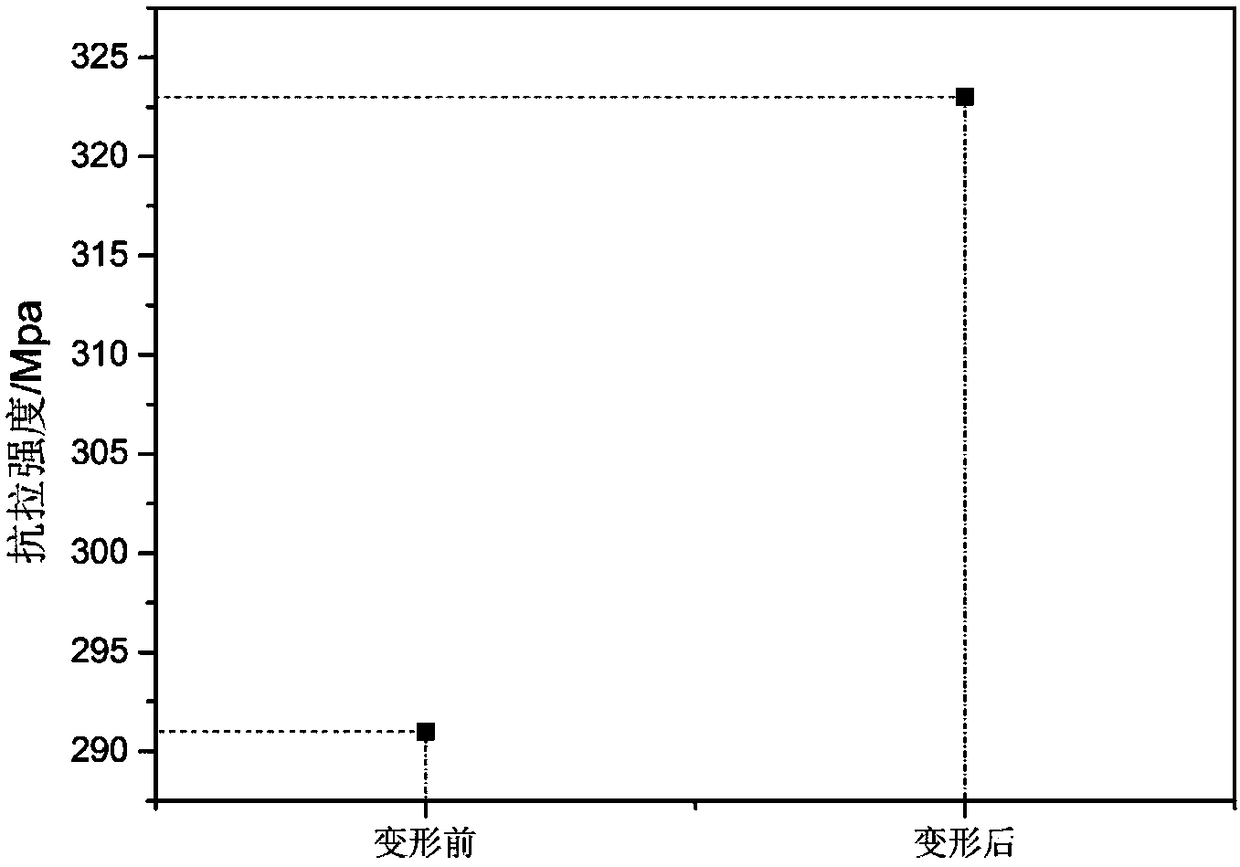

An aluminum-magnesium alloy and additive manufacturing technology, which is applied in the field of additive manufacturing, can solve the problems that mechanical properties cannot meet the requirements of use, cannot completely eliminate pores, and have pore defects, so as to improve the collapse phenomenon, reduce crack sources, and improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using aluminum-magnesium alloy 5183 welding wire as raw material, use the forming system to print layer by layer, and use the hammering system to hammer layer by layer. The specific steps are:

[0034] 1) Polish the 5083 aluminum alloy substrate with similar composition to the 5183 aluminum alloy welding wire with a steel brush and sandpaper, then clean the surface of the substrate with acetone and alcohol, and fix it on the turntable with a clamping device.

[0035] 2), import the three-dimensional model of the circular molded part into the slice software, the slice layer thickness is 1mm, and import the generated slice file into the control software, to be executed;

[0036] 3) Set the wire feeding speed (WFS) on the CMT welding machine to 5m / min, the moving speed of the welding torch to 0.3m / min, and the gas flow to 30L / min. Execute the program and form the component.

[0037] 4) The gas flow rate of the air hammer is set to 370L / min, the hammering speed is 10mm / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com