Pretreatment process for reducing defects of surface of ultrasonic impact test piece

An ultrasonic impact and pretreatment technology, which is applied in the field of improving the fatigue performance of welded joints and surface pretreatment, and can solve problems such as reduced surface quality, increased roughness, and complex shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

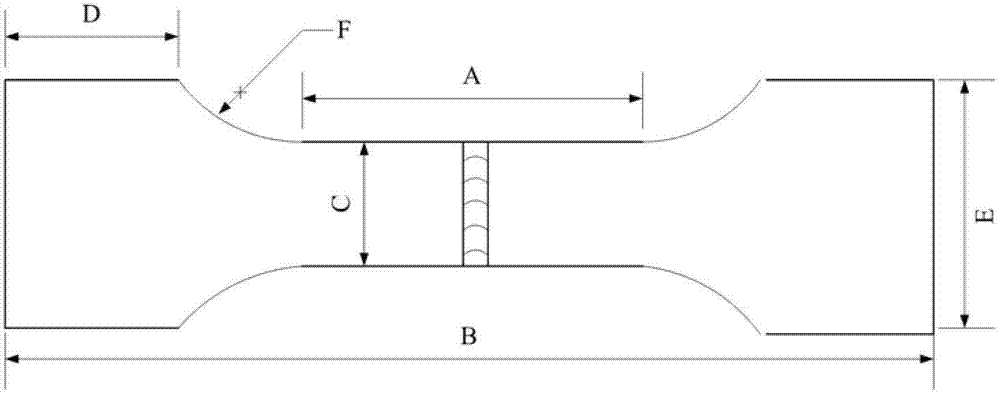

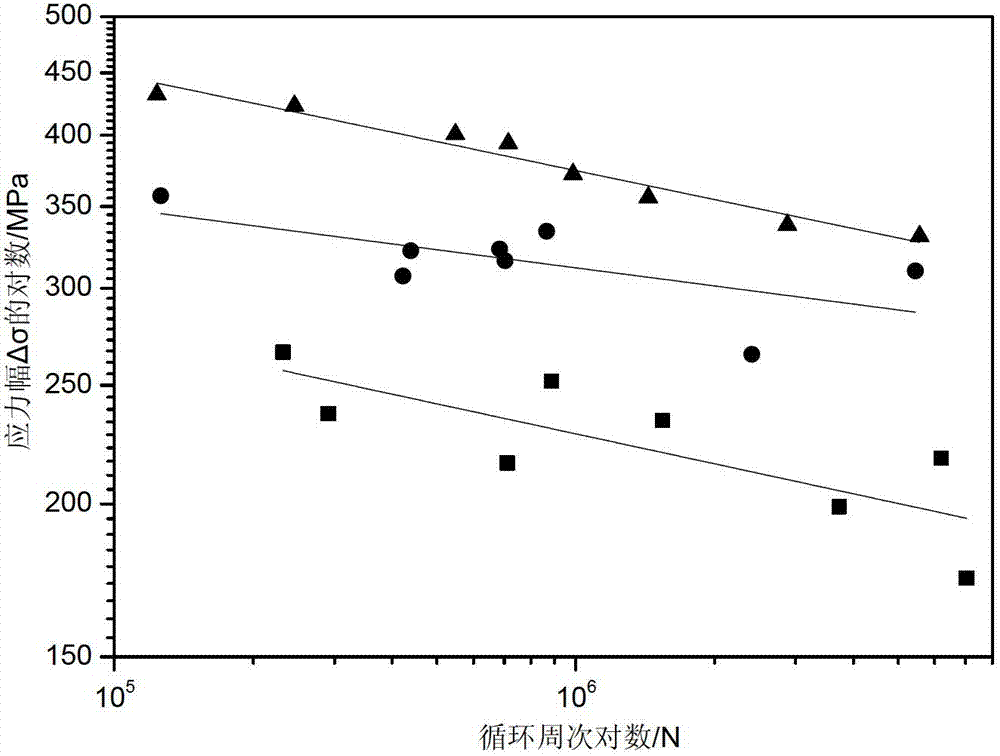

[0010] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. Analyze the specific implementation steps and superiority of the process of the present invention by comparing the fatigue test results of three groups of test pieces: (A) 8 original welded test pieces do not carry out surface treatment and ultrasonic impact treatment; (B) 8 test pieces In the original state, no surface treatment was performed, and ultrasonic impact was directly performed; (C) 8 specimens were first treated on the upper surface, followed by ultrasonic impact treatment with the same process as Group A (B). The material used in the test is Q345 steel, and the dimensions of the fatigue specimens are as follows: figure 1 shown. The specific implementation process includes the following steps:

[0011] First, the surface cleaning process. The surface pretreatment process mentioned in the technical plan is only applied to the C group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com