Aluminum alloy, induction plate for magnetic levitation rail transit and preparation method of induction plate

A technology for rail transit and aluminum alloys, which is applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, and analysis materials to achieve the effects of increasing strength, reducing resistivity, and strengthening alloy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

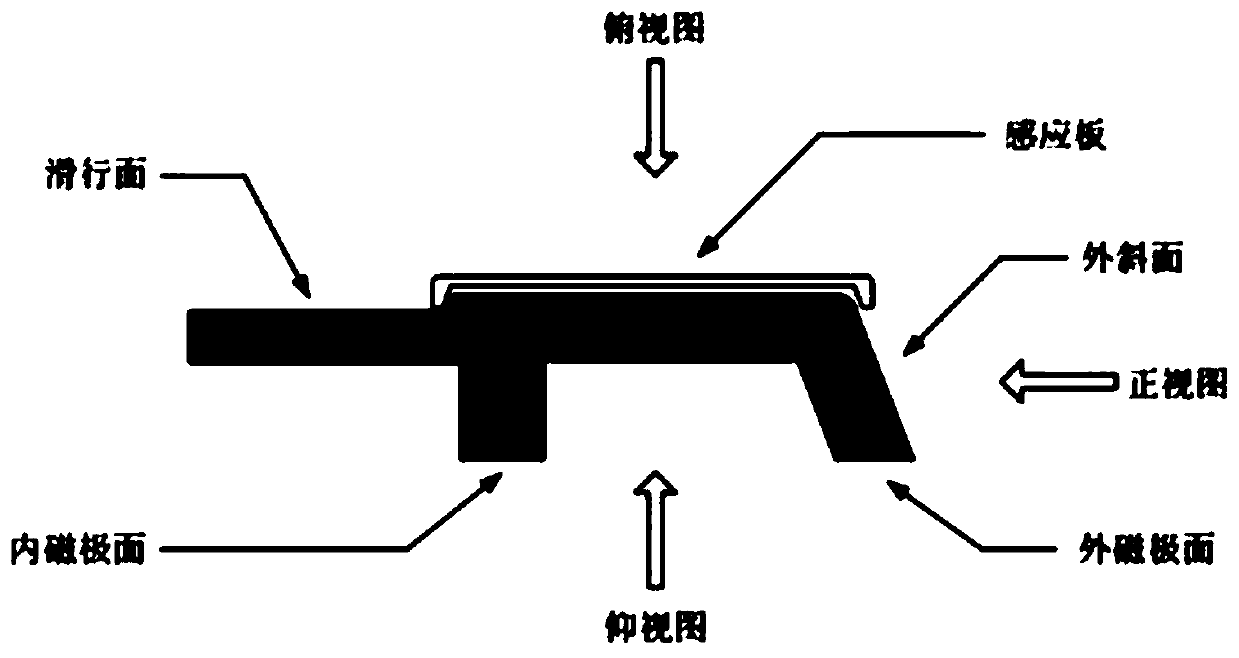

Image

Examples

preparation example Construction

[0037] In the third aspect, the embodiment of the present invention also provides a method for preparing an induction plate for a magnetic levitation rail transit. The method comprises the steps of:

[0038] S01. According to the elemental composition of aluminum alloy, after providing aluminum metal source for melting treatment, mixing Fe alloy, Cu alloy, Re alloy and B source to obtain the first aluminum melt;

[0039] S02. Performing refining treatment and online degassing treatment on the first molten aluminum to obtain the first molten aluminum;

[0040] S03. Casting the first molten aluminum to obtain an alloy ingot;

[0041] S04. Provide a mold, and squeeze the alloy ingot in the mold to obtain the rough product of the induction plate for magnetic levitation rail transit;

[0042] S05. Quenching and post-processing the rough product of the induction plate for the magnetic levitation rail transit to obtain the induction plate for the magnetic levitation rail transit. ...

Embodiment 1

[0072] A kind of induction plate for magnetic levitation rail transit and preparation method thereof

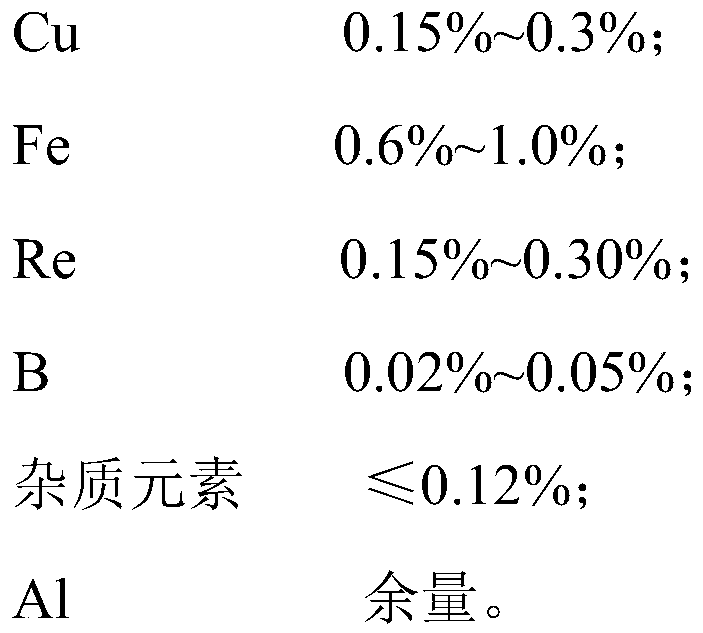

[0073] The induction plate for maglev rail transit uses the following aluminum alloys as raw materials, and the total weight of the aluminum alloys is 100%, as shown in Table 1 below, including the following elements in the following weight percentages:

[0074] Table 1

[0075]

[0076]

[0077] The induction plate for maglev rail transit is prepared by the method for preparing the induction plate for maglev rail transit, and the preparation method includes the following steps:

[0078] Provide an aluminum ingot with an aluminum content above 99.85%, and melt the aluminum-containing ingot at 754°C to obtain an aluminum-containing melt, mix Cu alloy and Fe alloy according to the content of each component of the aluminum alloy in Table 1, and fully stir Finally, carry out pre-stove analysis; then mix B agent, rare earth Re(La+Ce) master alloy, after fully stirring, carr...

Embodiment 2

[0085] A kind of induction plate for magnetic levitation rail transit and preparation method thereof

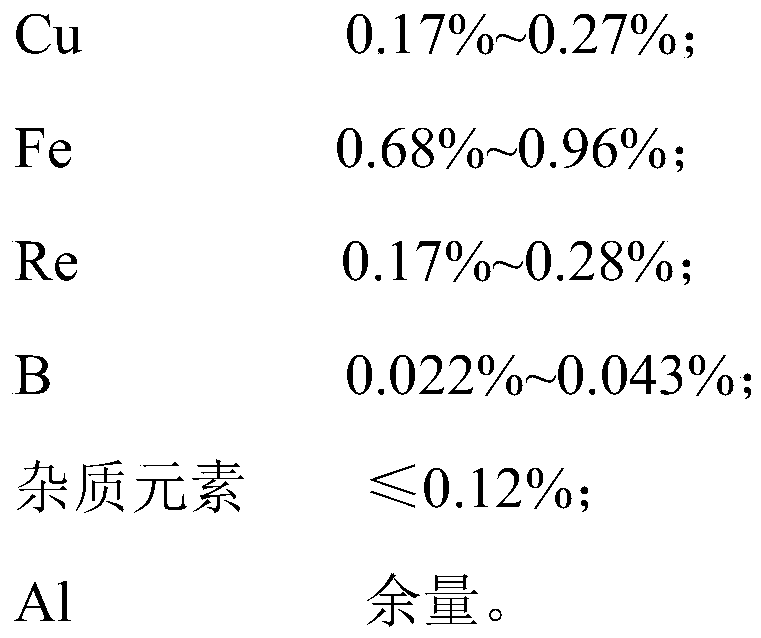

[0086] The induction plate for maglev rail transit uses the following aluminum alloys as raw materials, and the total weight of the aluminum alloys is 100%, as shown in Table 2 below, including the following elements in the following weight percentages:

[0087] Table 2

[0088]

[0089] The induction plate for maglev rail transit is prepared by the method for preparing the induction plate for maglev rail transit, and the preparation method includes the following steps:

[0090]Provide an aluminum ingot with an aluminum content above 99.85%, and melt the aluminum-containing ingot at 751°C to obtain an aluminum-containing melt, mix Cu alloy and Fe alloy according to the content of each component of the aluminum alloy in Table 1, and fully stir Finally, carry out pre-stove analysis; then mix B agent, rare earth Re(La+Ce) master alloy, after fully stirring, carry out pre-sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com