Heat-treatment-free high-toughness die-casting aluminum alloy and preparation method thereof

A technology of heat-free treatment and casting of aluminum alloy, which is applied in the field of metal materials, can solve the problems of alloy thermal stability, achieve good thermal stability, avoid strontium poisoning, and improve the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

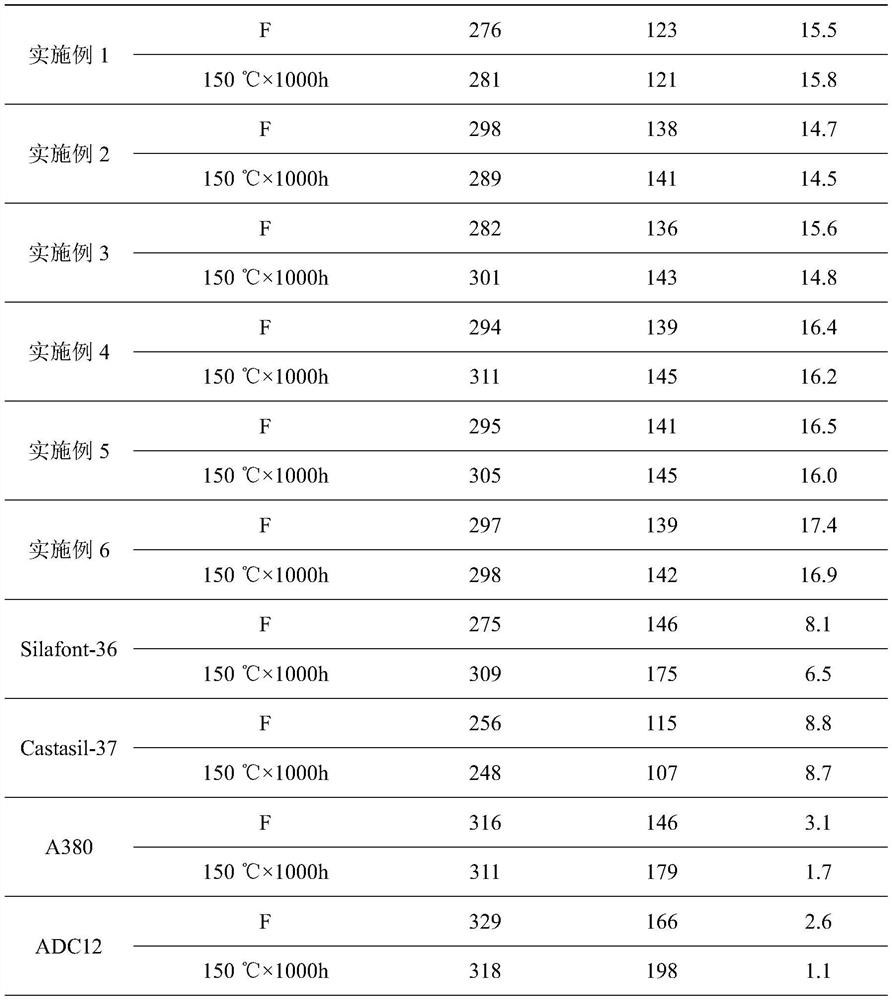

Embodiment 1

[0039] A heat-free high-strength and toughness die-casting aluminum alloy belongs to Al-Si-Mn-Mg-X alloy, and comprises the following components by mass percentage: Si 7.56wt.%, Ni 1.5wt.%, Mn 0.59wt.%, Mg 0.05wt.%, Cr 0.1wt.%, Zr 0.05wt.%, Ti 0.1wt.%, Sr 0.011wt.%, the rest are aluminum and inevitable impurities, of which Fe 0.13wt.% among the inevitable impurities, others The content of a single impurity element is less than or equal to 0.003wt.%, and the total amount of other impurities is less than or equal to 0.01wt.%. The size of the second phase is less than 20 μm.

[0040] (1) First, preheat pure aluminum, aluminum-silicon master alloy, aluminum-nickel master alloy, manganese agent, aluminum-chromium master alloy, aluminum-zirconium master alloy, aluminum-titanium master alloy, Al-10Sr master alloy and pure magnesium to 200°C.

[0041] (2) Calculate the weight of each raw material required according to the expected alloy composition, first put the pure aluminum proces...

Embodiment 2

[0047] A heat-free high-strength and toughness die-casting aluminum alloy belongs to Al-Si-Mn-Mg-X alloy, and comprises the following components by mass percentage: Si 8.01wt.%, Ni 1.25wt.%, Mn 0.63wt.%, Mg 0.1wt.%, Cr 0.12wt.%, Zr 0.15wt.%, Ti 0.07wt.%, Sr 0.015wt.%, the rest are aluminum and inevitable trace impurities, of which Fe 0.11wt in the inevitable trace impurities .%, the content of other single impurity elements is ≤0.003wt.%, and the total amount of other impurities is ≤0.01wt.%. Make sure that the second phase size is less than 20 μm.

[0048] (1) First, preheat electrolytic aluminum, instant silicon, pure nickel, aluminum-manganese master alloy, pure magnesium, pure chromium, pure zirconium, pure titanium and Al-10Sr master alloy to 185°C.

[0049] (2) Calculate the weight of each raw material required according to the expected alloy composition, first put the electrolytic aluminum processed in step (1) into an industrial melting furnace, heat it to 770 ° C ~ 7...

Embodiment 3

[0055] A high-strength and toughness die-casting aluminum alloy without heat treatment, the alloy belongs to Al-Si-Mn-Mg-X alloy, and comprises the following components by mass percentage: Si 8.94wt.%, Ni 0.78wt.%, Mn 0.47wt.%, Mg 0.15wt.%, Cr0.17wt.%, Zr 0.08wt.%, Ti 0.09wt.%, Sr 0.025wt.%, the rest are aluminum and inevitable trace impurities, among which Fe 0.10wt.% .%, the content of other single impurity elements is ≤0.01wt.%, and the total amount of other impurities is ≤0.1wt.%. Make sure that the second phase size is less than 20 μm.

[0056] (1) First, preheat pure aluminum, aluminum-silicon master alloy, aluminum-nickel master alloy, manganese agent, aluminum-chromium master alloy, aluminum-zirconium master alloy, aluminum-titanium master alloy, pure magnesium and Al-10Sr master alloy to 175°C.

[0057] (2) Calculate the weight of each raw material required according to the expected alloy composition, first put the pure aluminum processed in step (1) into an industri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com