Patents

Literature

69results about How to "Fine and uniform grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

InactiveCN1757775AGood mechanical propertiesImprove room temperature fracture toughnessRare earthMuffle furnace

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

A kind of preparation method of nano rare earth oxide doped molybdenum alloy electrode material

The invention relates to a preparation method of a molybdenum alloy electrode material doped with nano rare oxides. According to the preparation method, molybdenum powder is used as a raw material, the molybdenum powder and nano rare oxide powder are uniformly mixed by adopting a solid-solid doping method, wherein the nano rare oxides are lanthana oxide, cerium oxide or mixed rare earth oxide; and then the molybdenum alloy electrode material doped with different kinds and contents of nano rare earth oxides is prepared through adopting the processes of sieving, pressing and forming, sintering,forging and vacuum annealing heat treatment under certain temperature. The preparation method disclosed by the invention and the heat treatment process are simple and feasible; and the molybdenum alloy electrode material doped with the nano rare earth oxides, which is prepared by using the method disclosed by the invention, has the characteristics of uniform tissues, high compactness, high strength, high recrystallization temperature, high elongation rate, favorable deep processing performance, and the like.

Owner:XIAN FULAI ELECTRICAL ALLOY

Process for making double peak grain size distributed superfine grain structure from hyposteel

The invention discloses a process method for obtaining a bimodal grain size distribution ultra-fine grain structure of hypoeutectoid steel. The method obtains an ultra-fine grain structure through a control process method. The ultra-fine grain structure is characterized by: The distribution of medium grain size has bimodal characteristics, that is, there are relatively large grains with a fractional size of 1-3 μm in the ultra-fine grain matrix with a diameter of 0.4 μm or less; the composition characteristics of this type of engineering steel are containing Hypoeutectoid steel with carbon mass fraction less than 0.4%. The invention can be combined with the controlled warm rolling technology to economically produce ultra-fine grain steel plates and strips with high ductility.

Owner:YANSHAN UNIV

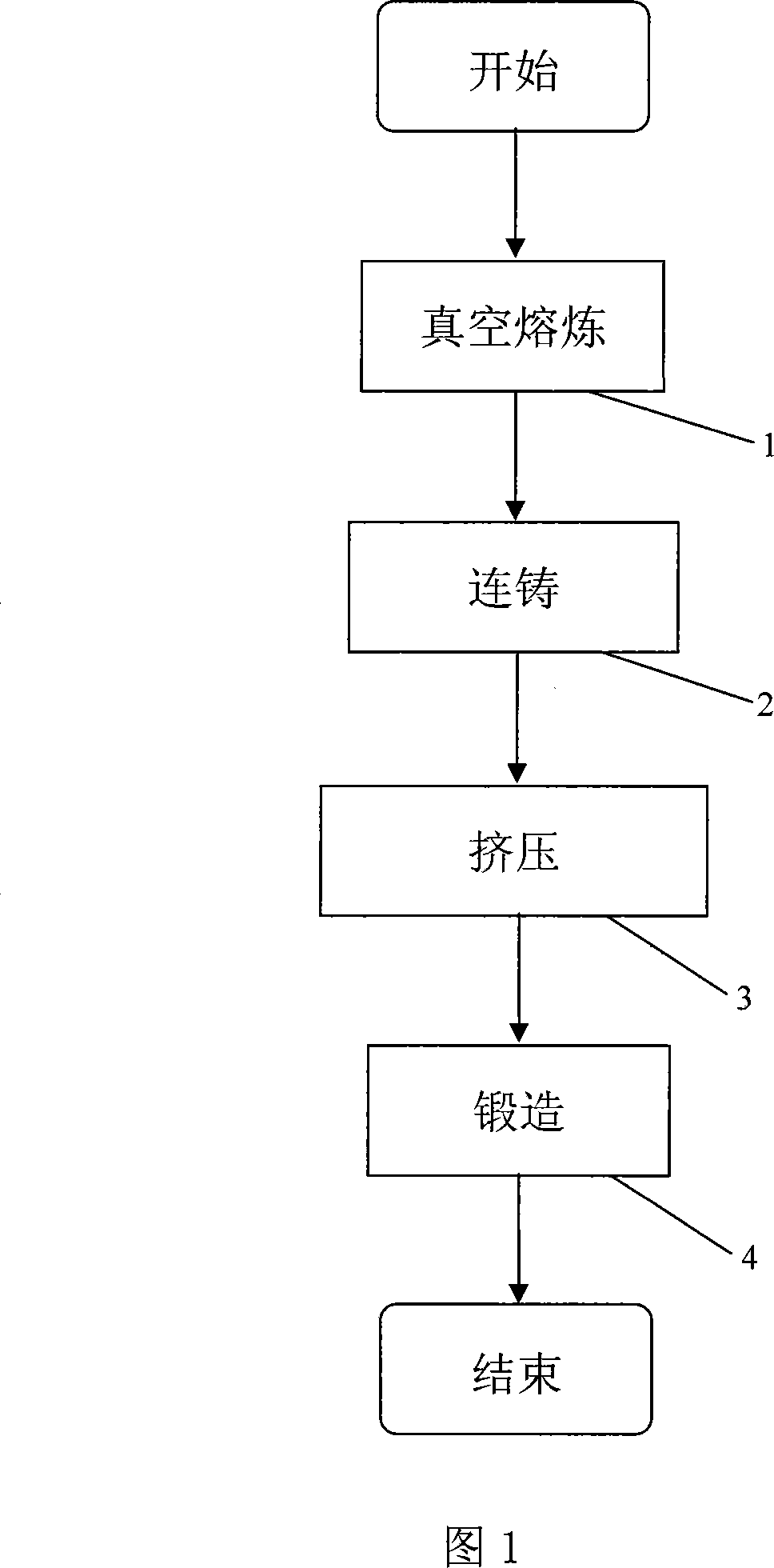

Technique for processing high-strength high-tractility magnesium alloy member

InactiveCN101121980AAvoid secondary oxidationGuarantee casting safetyExtrusion control devicesSteering controlElectromagnetic pump

The invention discloses a technology of processing a magnesium alloy with high intensity and flexibility, which subsequently includes vacuum melting, continuous casting, extrusion, forging and such procedures. The invention reasonably matches the solution body composition and the metamorphism liquid during casting process, and the grains are refined through the chilling action of a crystallizer at first; the magnesium alloy liquid is transmitted by an electromagnetic pump so as to prevent secondary oxidation and ensure safety in casting of the magnesium alloy; and then further refining the grains through electromagnetic mixing power, large ratio extrusion and heat treatment secondary crystallization, which effectively ensures tiny enough isometric crystals can be obtained from the alloy microstructure. The magnesium alloy elements of the automotive steering control arms, support elements of motorcycles and bicycles, can be obtained for the first time by the improvement, which are fully filled, good in surface quality, fine and even in grain size, reasonable in streamline distribution and without disordered streamline, vortexing and draining phenomena. The invention combines a plurality of technological processes into a production cycle, which reduces the turnover links, saves energy and reduces cost.

Owner:王仁辉

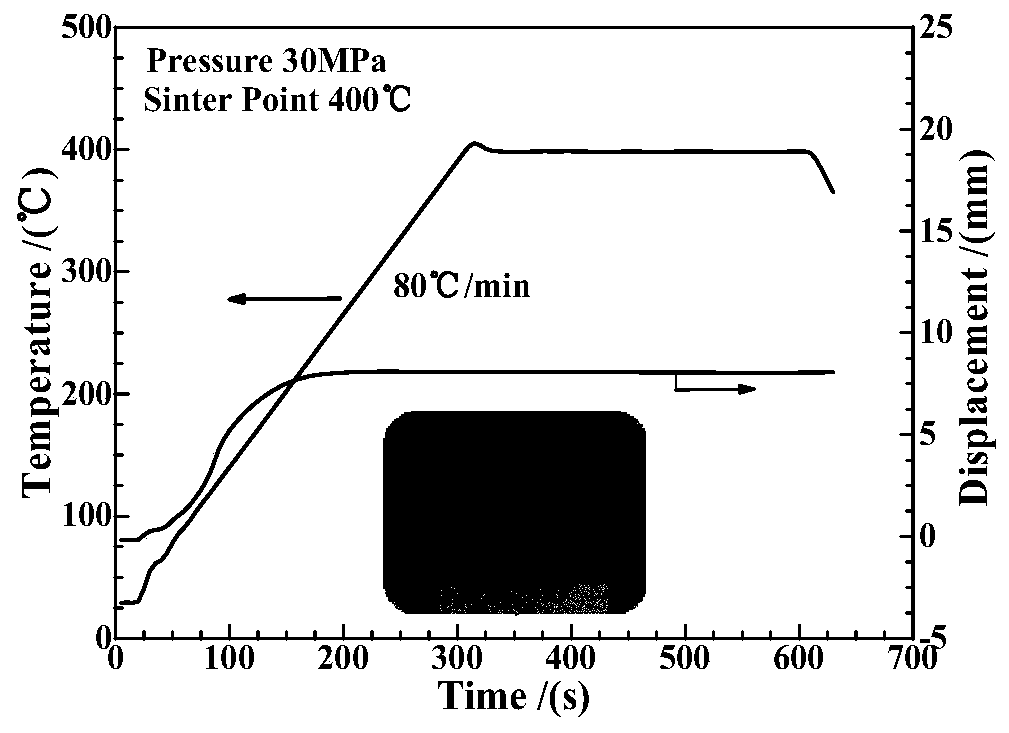

Method of preparing high pruity block titanium aluminium carbon material using discharge plasma sintering

A process for preparing high-purity Ti-Al-C block by discharge plasma sintering includes such steps as proportionally mixing Ti3AlC2 powder or Ti powder, Al4C3 powder and active carbon powder, ball grinding, baking sieving, loading in graphite mould, discharging plasma sinter under protection of inertial gas, holding the temp for a certain time and cooling. Its advantages are high purity (90% or more) and high mechanical performance.

Owner:TSINGHUA UNIV

Preparation method of high performance nanometer lanthanide oxide doped molybdenum-silicon-boron alloy

The invention provides a preparation method of a high performance nanometer lanthanide oxide doped molybdenum-silicon-boron alloy. The preparation method comprises the following steps: molybdenum powder, silicon powder and boron powder are used as raw materials, different contents of nanometer lanthanide oxide are doped, the materials are mixed evenly through ball milling, prepressing and presintering are performed, the obtained sintered body is smelted in a vacuum arc furnace, the smelting working current is 800-1000A, the obtained alloy ingots are ground and subjected to ball milling to prepare powder, the alloy powder is sieved with a 200-300 mesh Tyler sieve, the obtained alloy powder is sintered in a vacuum hot-pressing sintering furnace at 1500-1700 DEG C and 30-50MPa for 1-3 hours,and the product is cooled to the room temperature along with the furnace after sintering. By adopting the method, the defects such as high sintering temperature, long time, inadequate reaction and more macro-defects, of the traditional powder metallurgy technology for preparing the molybdenum-silicon-boron alloy can be overcome; and the prepared nanometer lanthanide oxide doped molybdenum-silicon-boron alloy is characterized by uniform structure, high density and high strength.

Owner:临沂明华管业有限公司

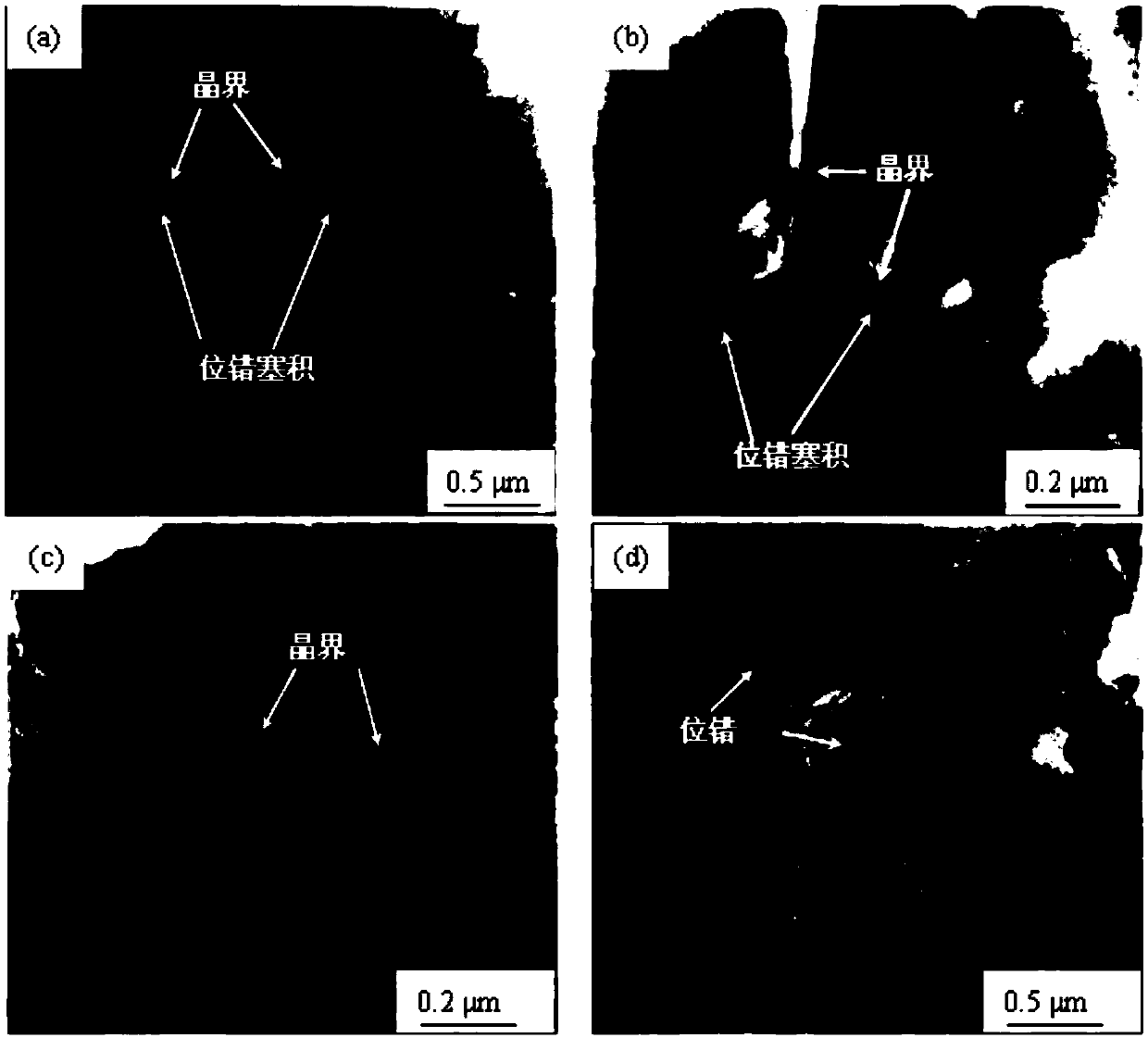

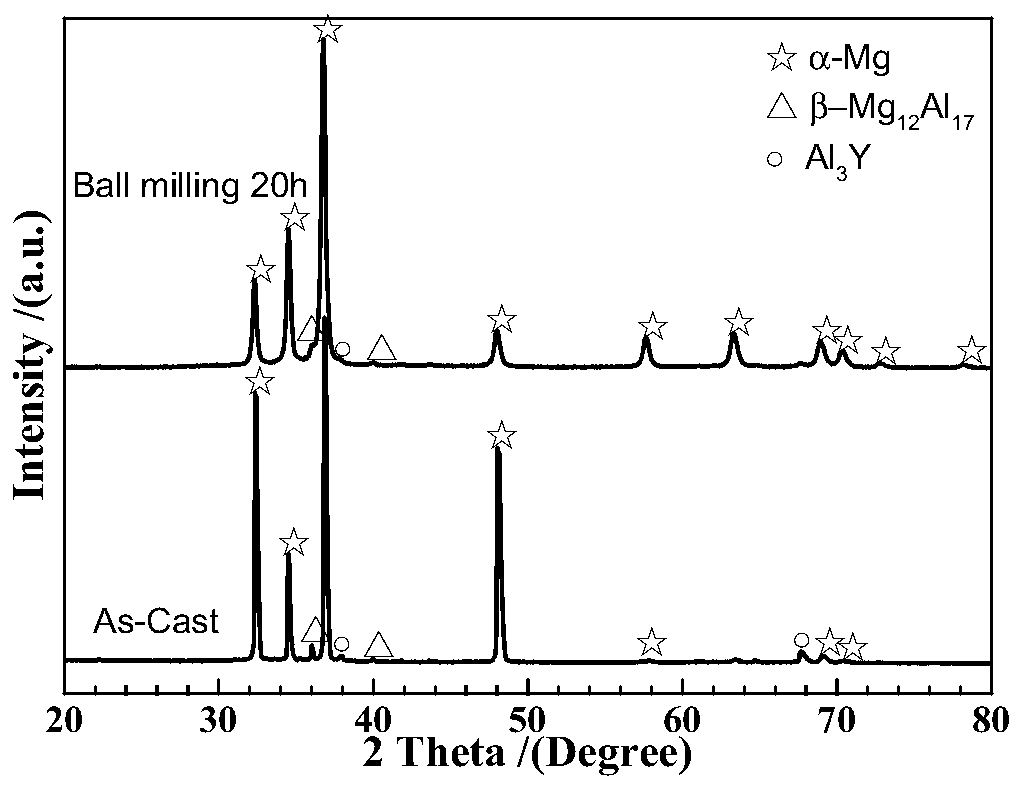

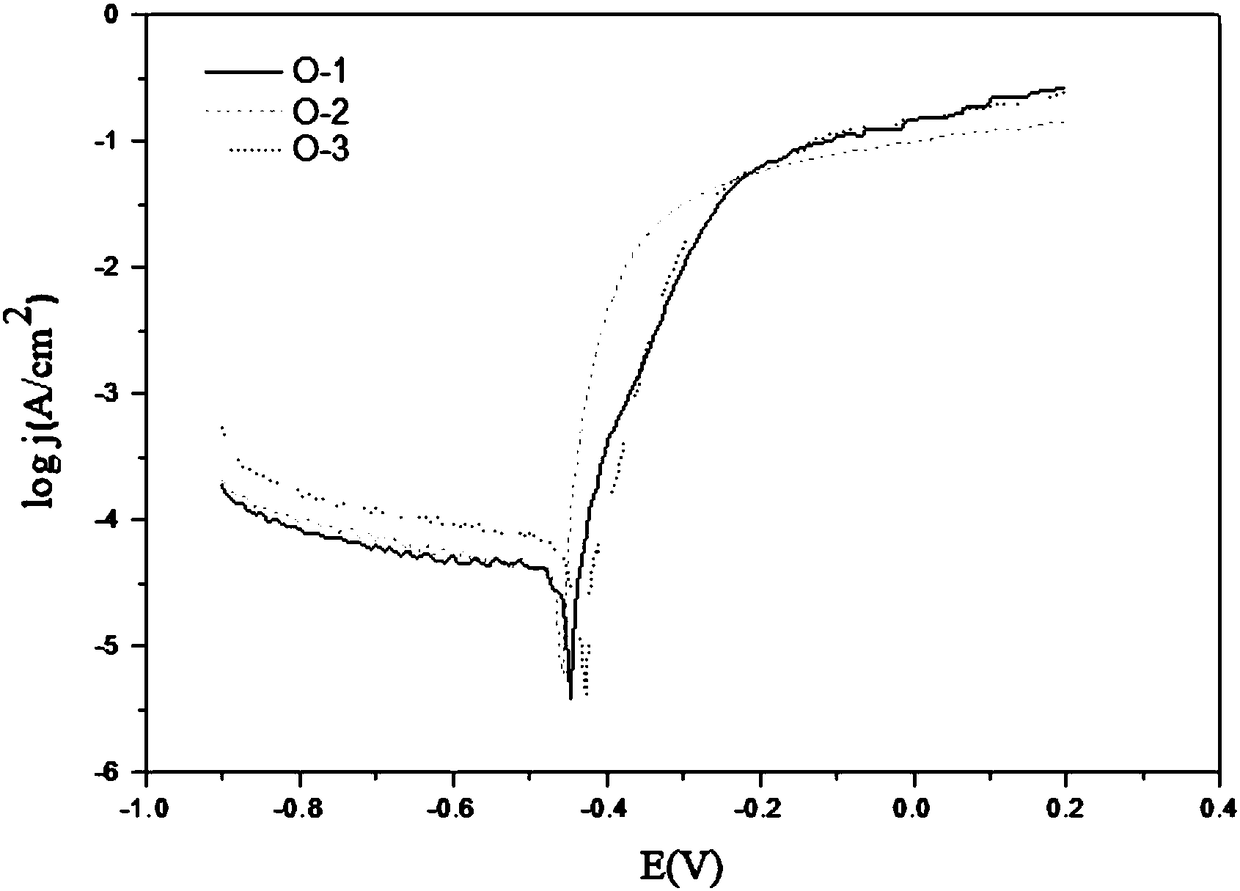

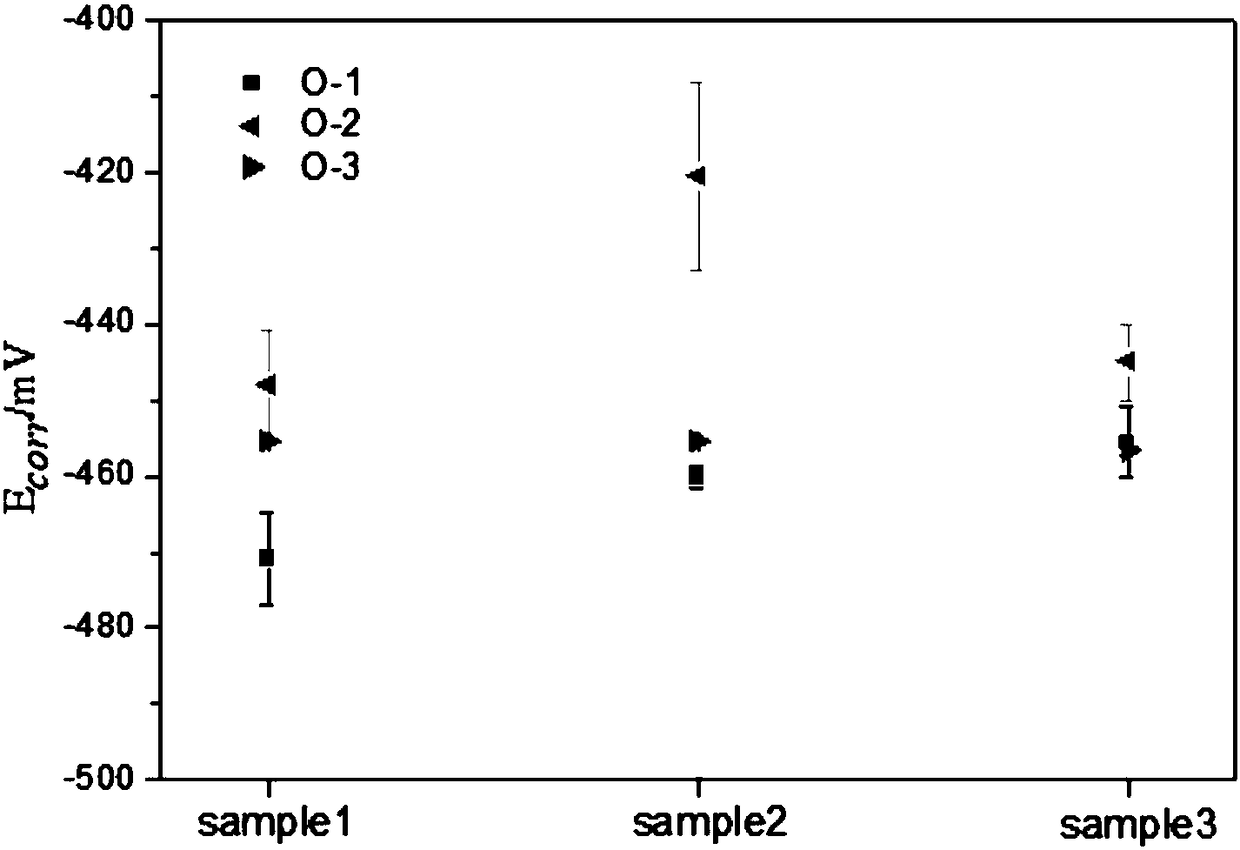

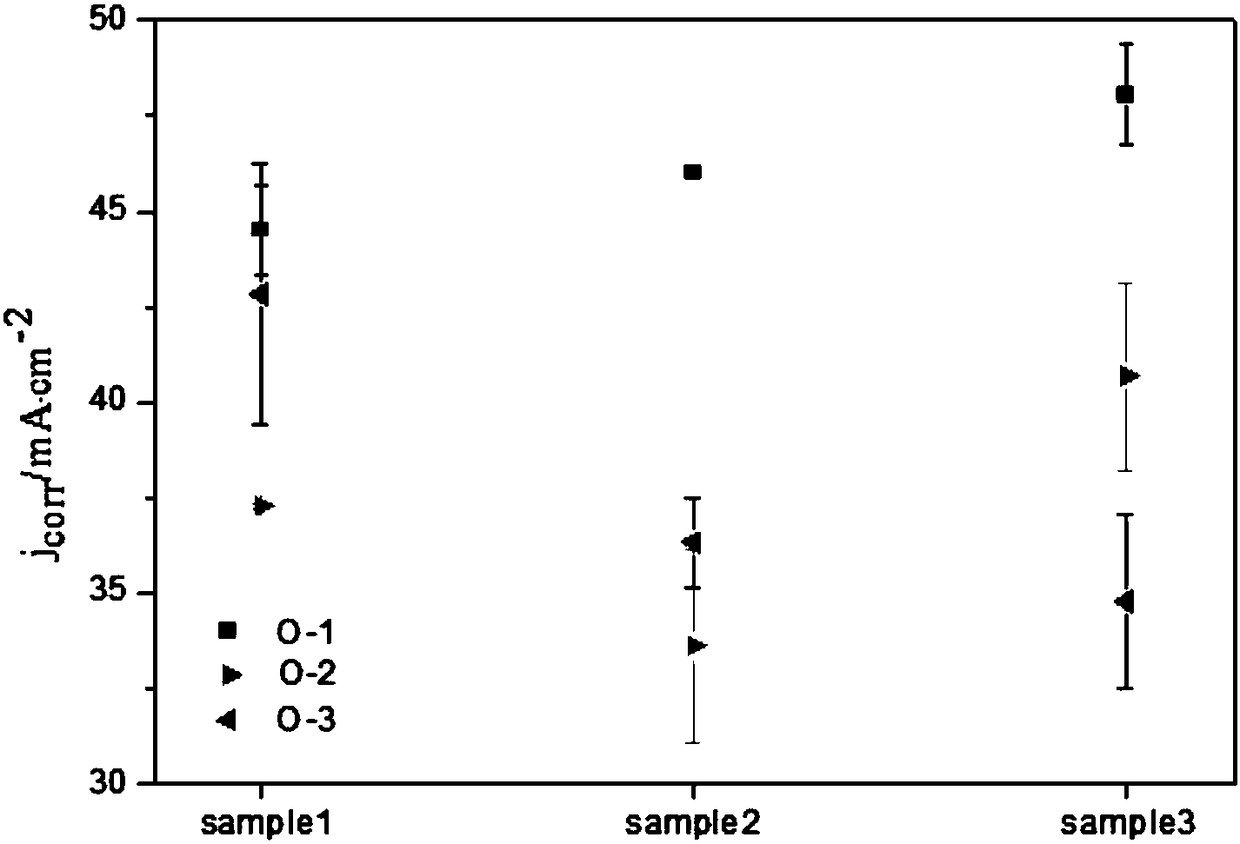

Anode strip material for magnesium-air battery and preparation method and application thereof

InactiveCN108682867AReduce dislocation densityImprove overall electrochemical performanceFuel and primary cellsCell electrodesYttriumAluminium

The invention belongs to the field of chemical power electrode materials, and discloses an anode strip material for a magnesium-air battery and a preparation method and application thereof. The preparation method comprises the steps of: placing magnesium, aluminum, lead and a magnesium-rare earth intermediate alloy into a graphite crucible, filling with argon gas, and casting a stirred melt into astainless steel crucible in a furnace to obtain a cerium and yttrium-modified casting state AP65 magnesium alloy; under an argon protection atmosphere, homogenizing and annealing the magnesium alloyand quenching with water; after preheating, performing hot extrusion, and controlling the amount of extrusion deformation to obtain a series of magnesium alloy strips with different thicknesses. The microstructure of the AP65 magnesium alloy can be regulated by alloying and extrusion deformation, so that the AP65 magnesium alloy has good corrosion resistance under an open circuit potential, can discharge, uniformly dissolve and inhibit hydrogen evolution under certain current density, thereby having a high open circuit voltage, discharge voltage and high anode utilization rate, and is suitableas anode materials for magnesium-air batteries.

Owner:GUANGDONG UNIV OF TECH

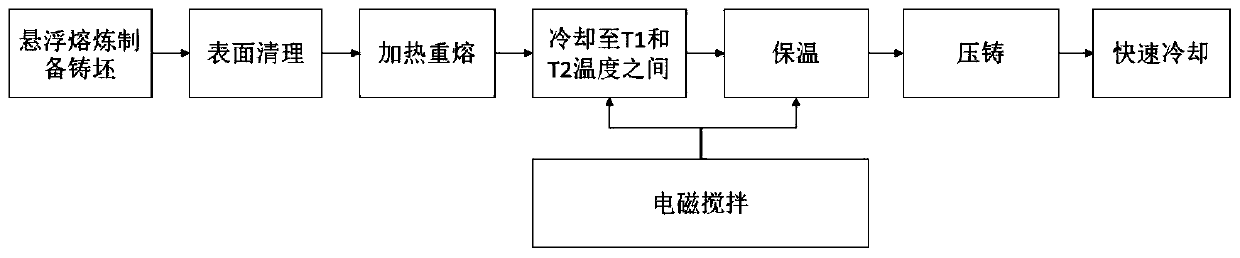

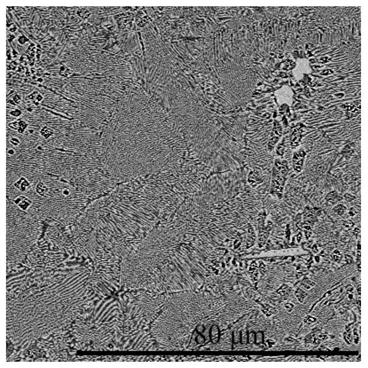

Refractory high-entropy alloy and forming method thereof

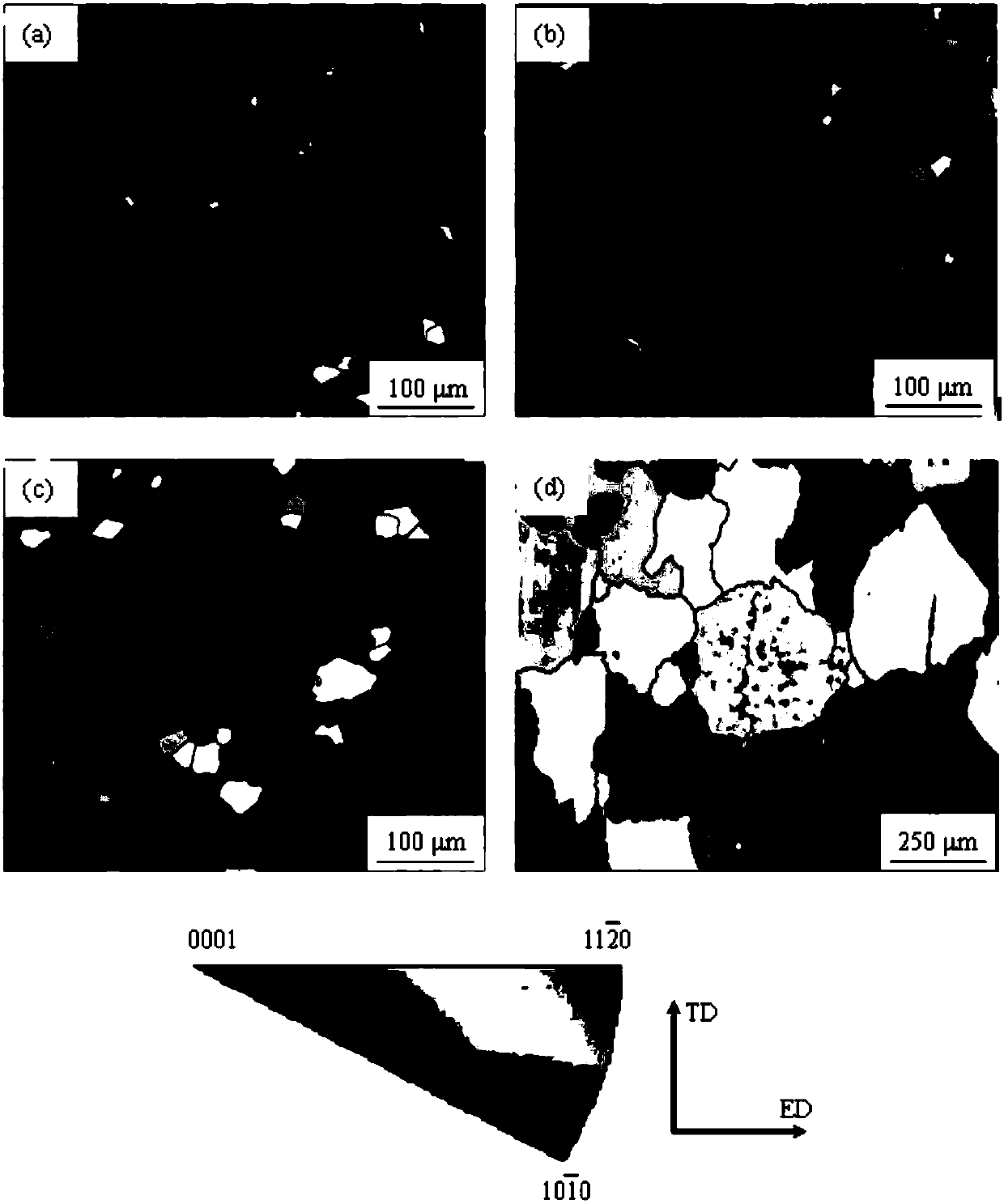

The invention relates to a refractory high-entropy alloy and a forming method thereof. The forming method comprises the steps of preparation of a refractory high-entropy alloy raw material, electromagnetic induction suspension smelting, high-frequency electromagnetic stirring of semi-solid slurry and die-casting forming. According to the method, suspension smelting, electromagnetic stirring and semi-solid forming are combined, the problem of serious component segregation commonly existing in high-entropy alloy is avoided, and a product with a fine and uniform microstructure and high density can be obtained.

Owner:苏州天峰动立合金科技有限公司

Method for preparing molybdenum-silicium-boron alloy

The invention discloses a method for preparing molybdenum-silicon-boron alloy, which comprises the steps that: molybdenum powder, silicon powder and boron powder are taken as raw materials; after even mixed treatment, the alloy powder is subjected to smelting in an arc-melting furnace, a smelting operating current is 700A to 800A; a lump after smelting is subjected to crushing and annealing treatment, the annealing temperature is 1200 DEG C to 1300 DEG C, the time is 0.5 hour to 1.5 hours; and then the alloy powder after the annealing treatment is put in an electricity-discharging plasma sintering furnace for sintering, the sintering temperature is 1400 DEG C to 1600 DEG C, the sintering time is 2min to 5min and the sintering pressure is 10MPa to 30MPa. The molybdenum-silicon-boron alloy prepared by the method has the advantages of simple method and fast speed, and has high organization compaction, strength and extensibility.

Owner:山东铭特金属材料科技有限公司

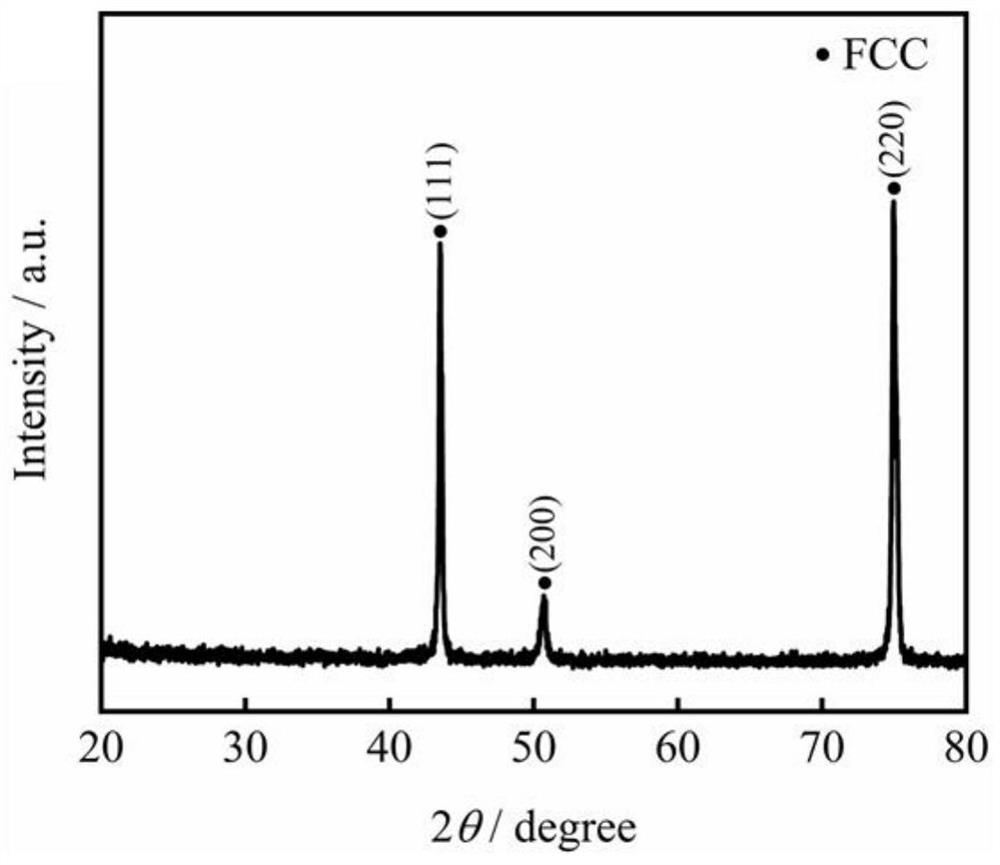

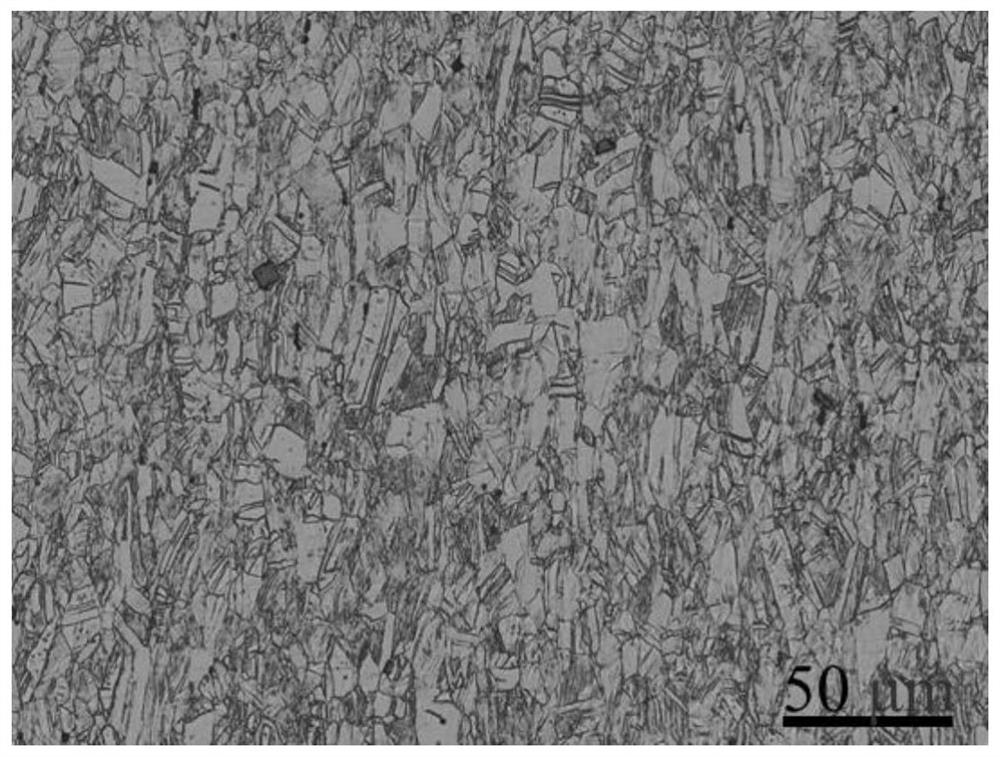

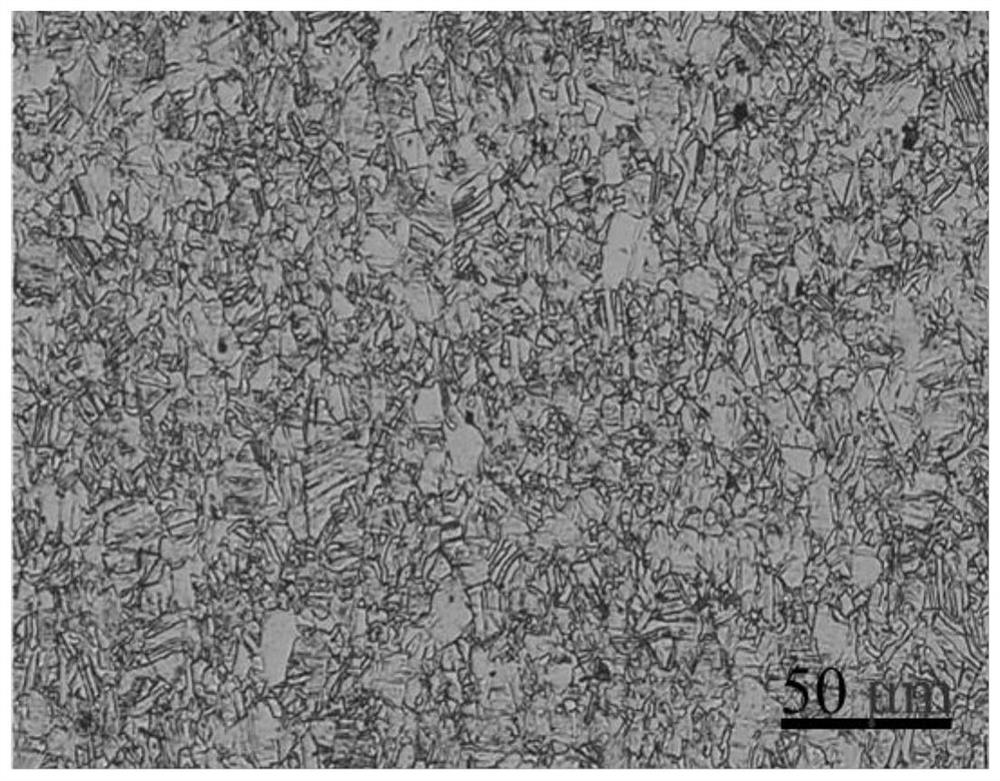

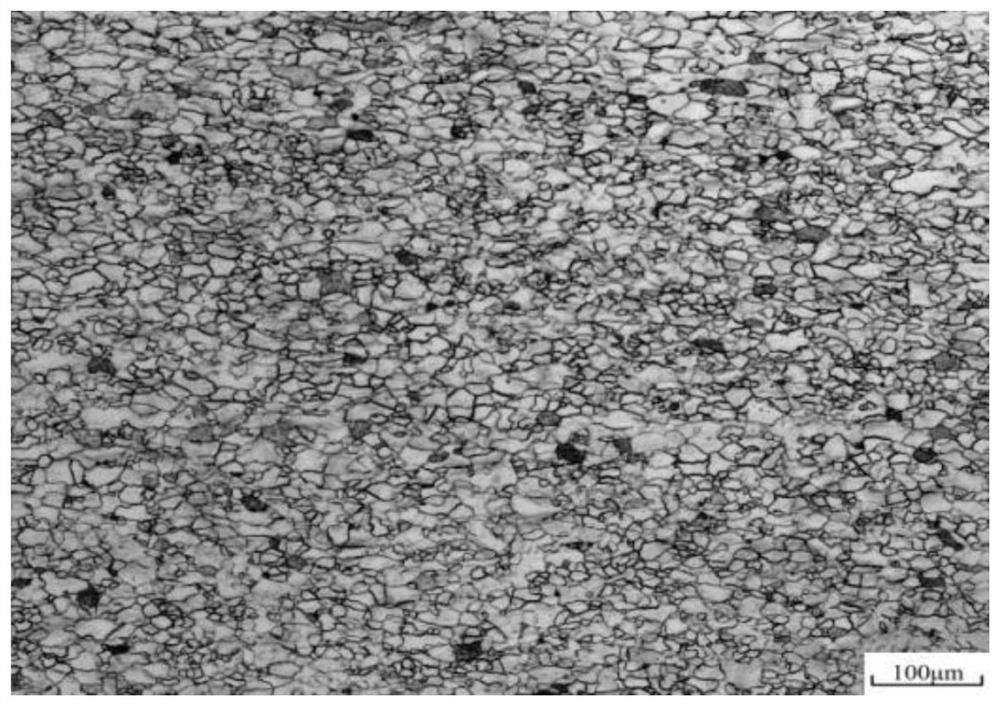

Preparation method of high-strength and high-toughness CrCoNi medium-entropy alloy homogeneous fine-grain thin plate

The invention belongs to the technical field of metal materials, and particularly relates to a preparation method of a high-strength and high-toughness CrCoNi medium-entropy alloy homogeneous fine-grain thin plate. The preparation method comprises the five steps of vacuum smelting, alloy ingot annealing, hammer cogging and drawing-out and high-temperature back-and-forth rolling forming. Accordingto hammer cogging and drawing-out, upsetting and drawing-out forging treatment is carried out on an annealed alloy cast ingot to prepare a plate blank; and the upsetting rate is 50-200 mm / s, and the drawing-out forging ratio is 2-10. According to the method, hammer cogging and drawing-out treatment is carried out after annealing, a large number of dendrites in an as-cast structure can be completely broken through severe plastic deformation in a short time, a fine and uniform grain structure is obtained, and metallurgical defects such as pores and looseness are reduced; and a high-temperature back-and-forth rolling process method is adopted, the grain size and the structure are refined, the strength, plasticity and toughness of materials are improved, and the anisotropy problem of an CrCoNimedium-entropy alloy is obviously reduced.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

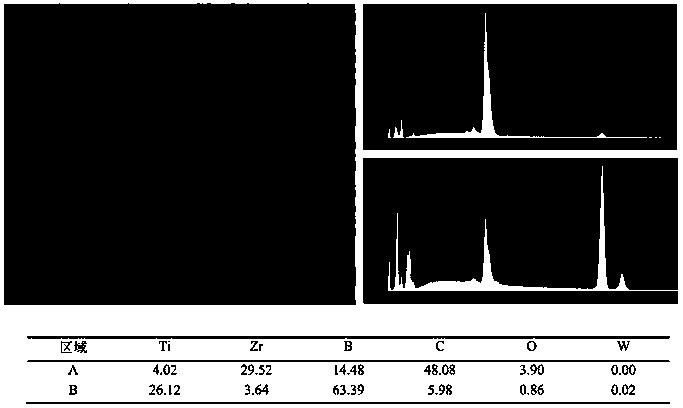

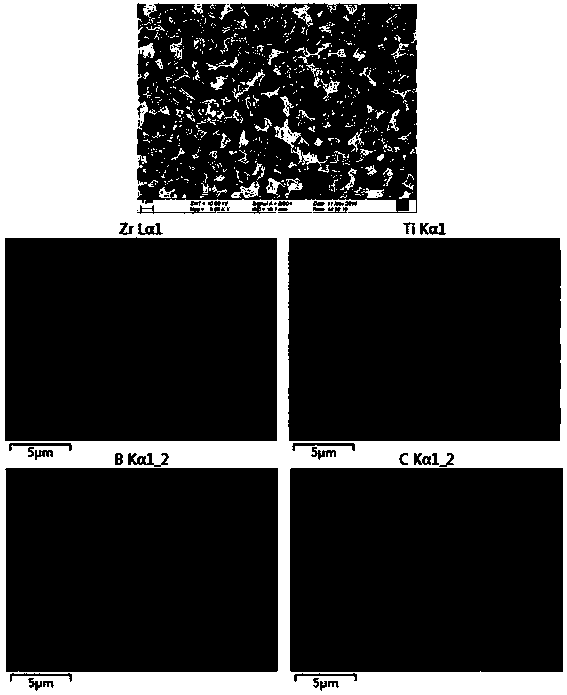

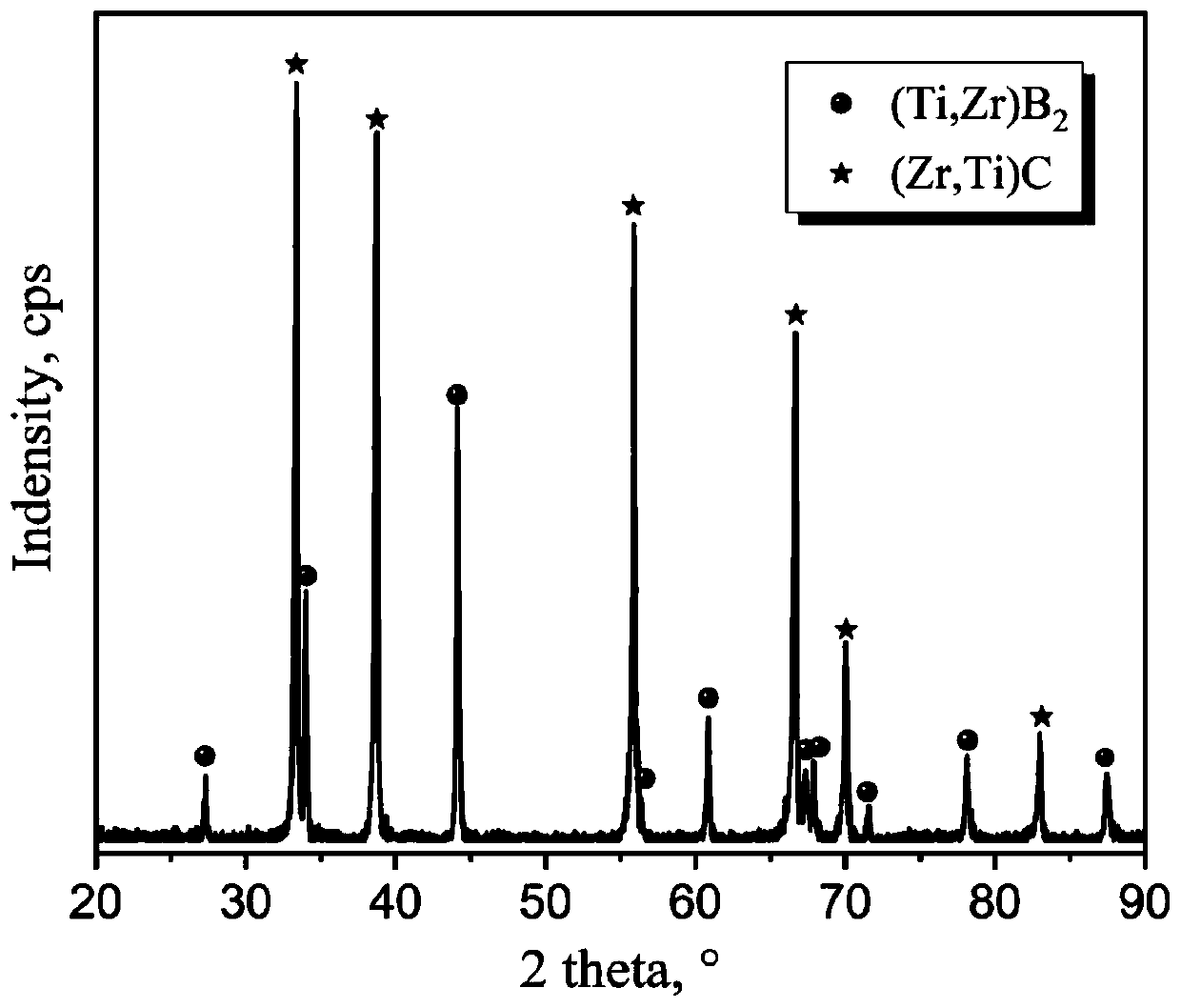

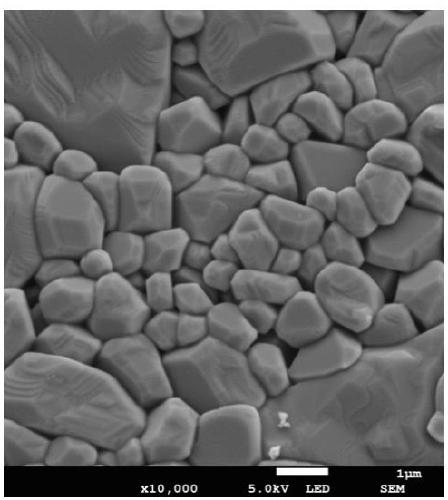

Method for low temperature preparation of diboride-carbide solid solution multiphase ceramic by reaction hot press sintering method

The invention relates to a method for low temperature preparation of a diboride-carbide solid solution multiphase ceramic by a reaction hot press sintering method, and belongs to the technical field of multiphase ceramic materials. The problem of high sintering temperature of an existing diboride-carbide multiphase ceramic is solved. According to the method for the low temperature preparation of the diboride-carbide solid solution multiphase ceramic by the reaction hot press sintering method, transition metal diboride and carbide which can produce solid phase exchange are selected, a compositepowder body is prepared by a high energy ball milling process, under the protection of vacuum or inert atmosphere, and the reaction hot press sintering is carried out to prepare the dense diboride-carbide solid solution multiphase ceramic. The solid-phase reaction and solid solution coupled synergistic process in the sintering process is fully used, compared with traditional hotpress sintering process for the preparation of multiphase ceramic materials directly using target diboronized and carbide powder bodies, the sintering temperature of the materials can be reduced by 250 DEG C to 400 DEGC, it is ensured that the material grain size is uniform and small by low temperature sintering, and the strength and toughness of the multiphase ceramic obtained are significantly improved.

Owner:HARBIN INST OF TECH

Nanocrystal ceramic corundum abrasive material and preparation method thereof

ActiveCN109231970ALower sintering temperaturePromote migrationOther chemical processesCompressive strengthNanometre

The invention relates to a nanocrystal ceramic corundum abrasive material and a preparation method thereof, and belongs to the field of ceramic corundum abrasive materials. The nanocrystal ceramic corundum abrasive material is prepared from the following components of Al2(SO3)3.18H2O and additives, wherein the additives comprise a dispersant, a liquid composite sintering additive and an Al2O3 (aluminum oxide) sol crystal seed. The preparation method of the nanocrystal ceramic corundum abrasive material comprises the following steps of adding the liquid composite sintering additive and the Al2O3 sol crystal seed into an Al2(OH)3 gel precursor; performing uniform ball milling, and drying by stages, so as to obtain a dry gel; crushing the dry gel, granulating, and screening, so as to obtain gel particles meeting the particle size requirement; calcining the gel particles by sections, cooling along with a furnace, and screening, so as to obtain the ceramic corundum abrasive material with different particle sizes. The invention also discloses a preparation method of the Al2O3 sol seed crystal and the prepared ceramic corundum abrasive material. The nanocrystal nanocrystal ceramic corundum abrasive material has the advantages that by introducing the Al2O3 sol crystal seed, the defects of difficulty in introducing of solid-state nanocrystal seeds and nonuniform mixing are overcome, andthe uniform mixing of the raw materials and additives is guaranteed; the microtopography with fine and uniform crystal seed size is realized, and the compressive strength and grinding property are improved.

Owner:YICHUAN DONGFENG ABRASIVES

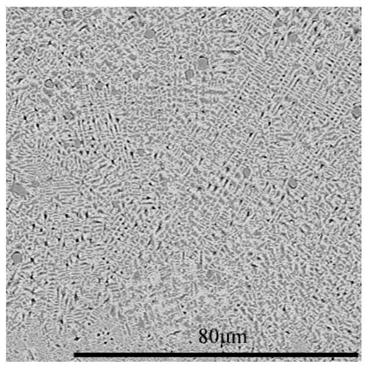

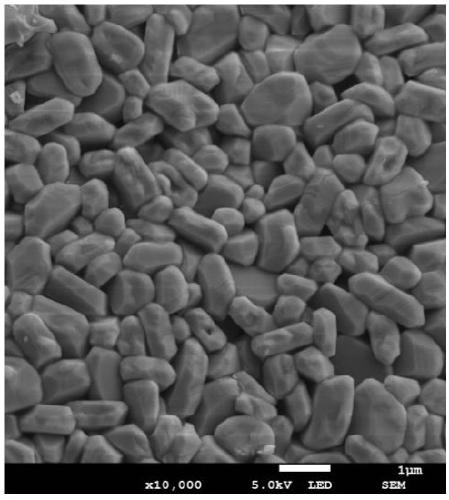

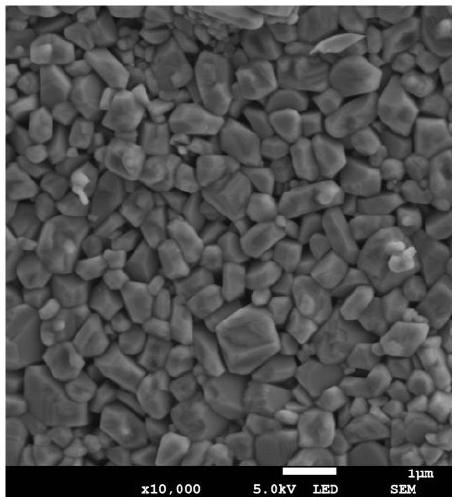

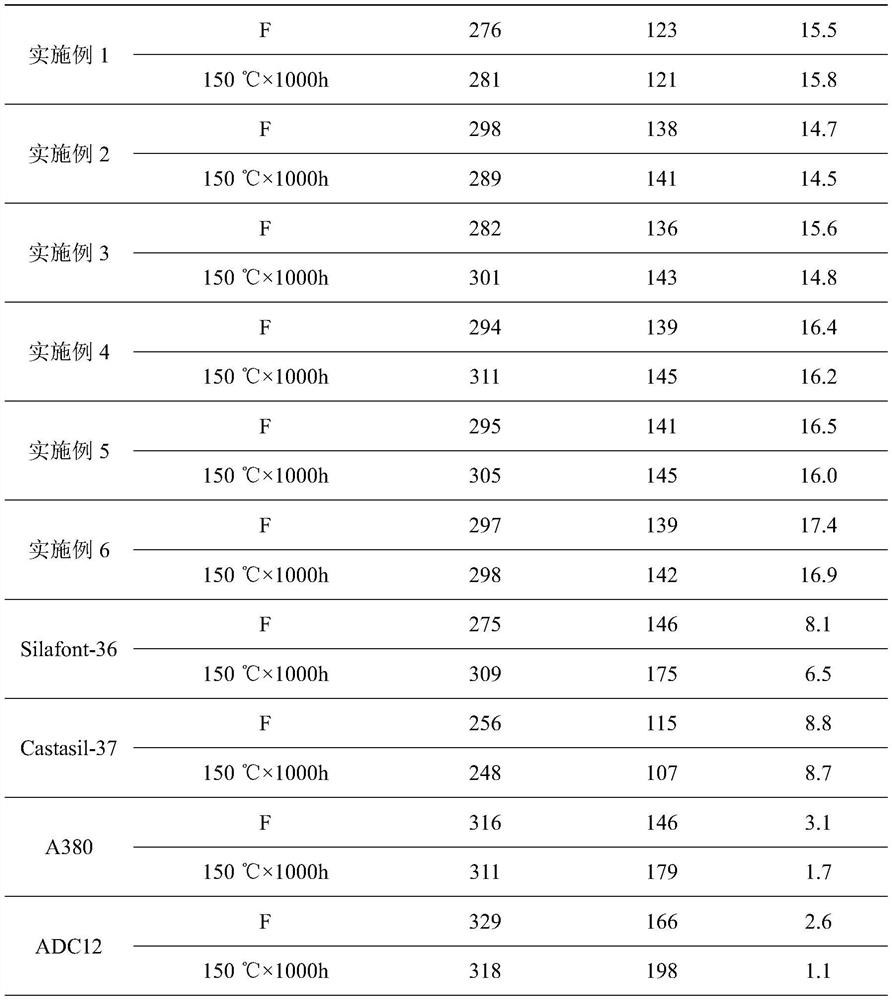

Heat-treatment-free high-toughness die-casting aluminum alloy and preparation method thereof

ActiveCN114717455AImprove thermal stabilityFine and uniform grain sizeMotor vehicle partHeat stability

The invention discloses a heat-treatment-free high-toughness die-casting aluminum alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 7.5 to 9.5 percent of Si, 0 to 1.5 percent of Ni, 0.4 to 0.8 percent of Mn, 0 to 0.4 percent of Mg, 0.08 to 0.3 percent of Cr, 0.01 to 0.15 percent of Zr, 0.03 to 0.1 percent of Ti, 0.005 to 0.025 percent of Sr and the balance of aluminum and inevitable impurity elements. The die-casting aluminum alloy is good in thermal stability, the mechanical property change does not exceed 10% after the die-casting aluminum alloy is kept at the temperature not higher than 150 DEG C for 1000 h, the die-casting state yield strength is larger than 120 MPa, the elongation is larger than 14%, the performance requirement of a car body die-casting structural part can be met without subsequent heat treatment, and the die-casting aluminum alloy is suitable for large-scale production. And the percent of pass of thin-wall die-casting structural part products can be greatly increased, and the use cost of automobile parts is reduced.

Owner:BEIJING CHEHEJIA AUTOMOBILE TECH CO LTD +1

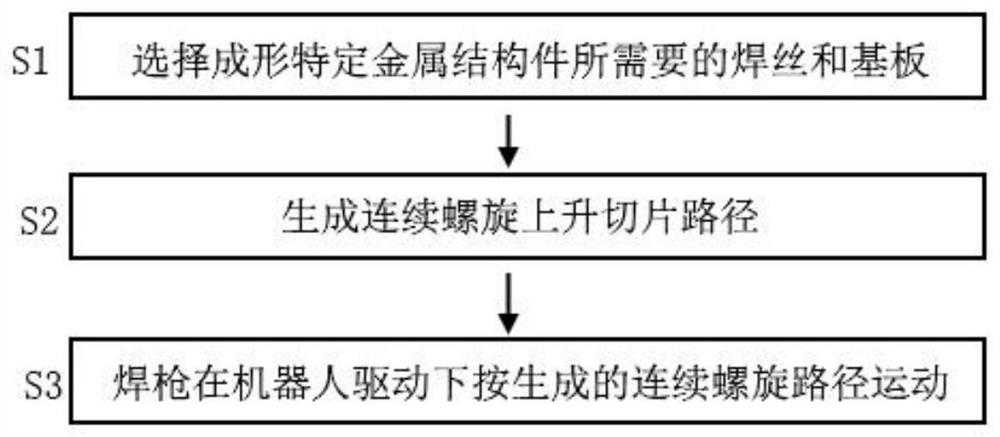

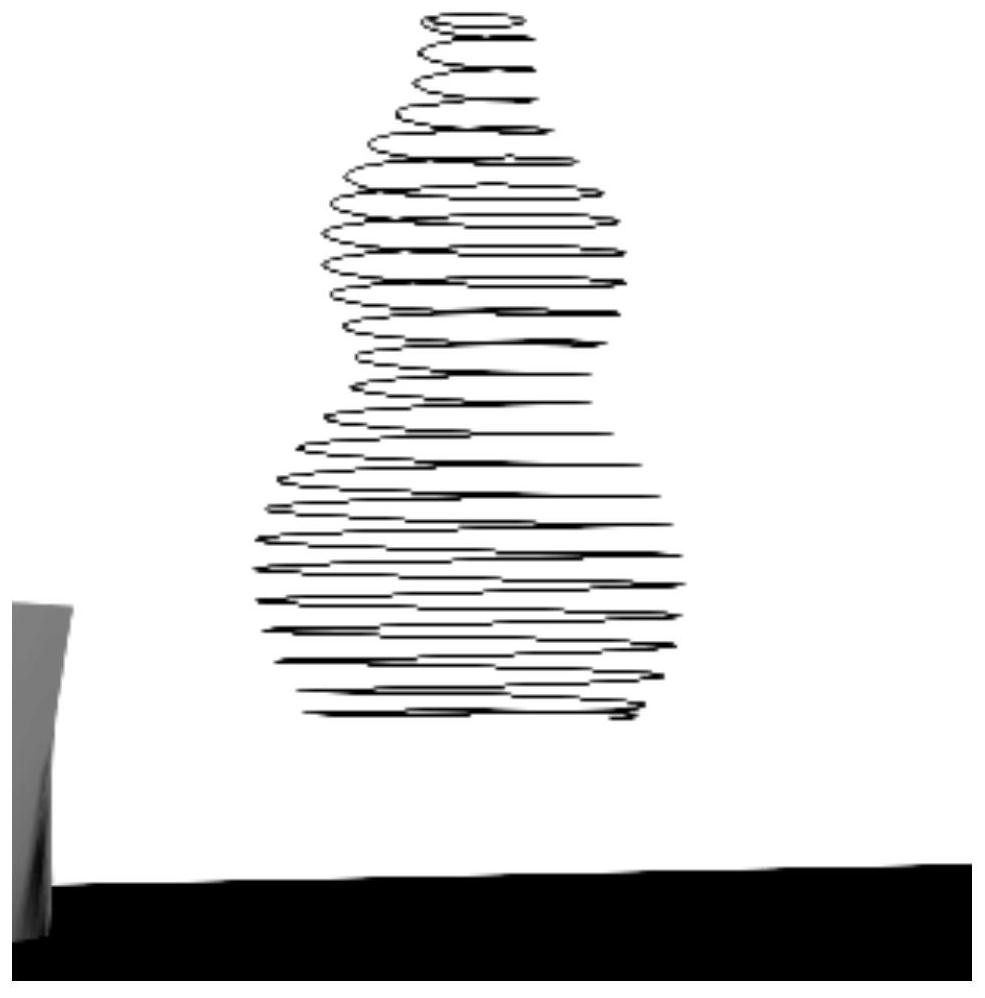

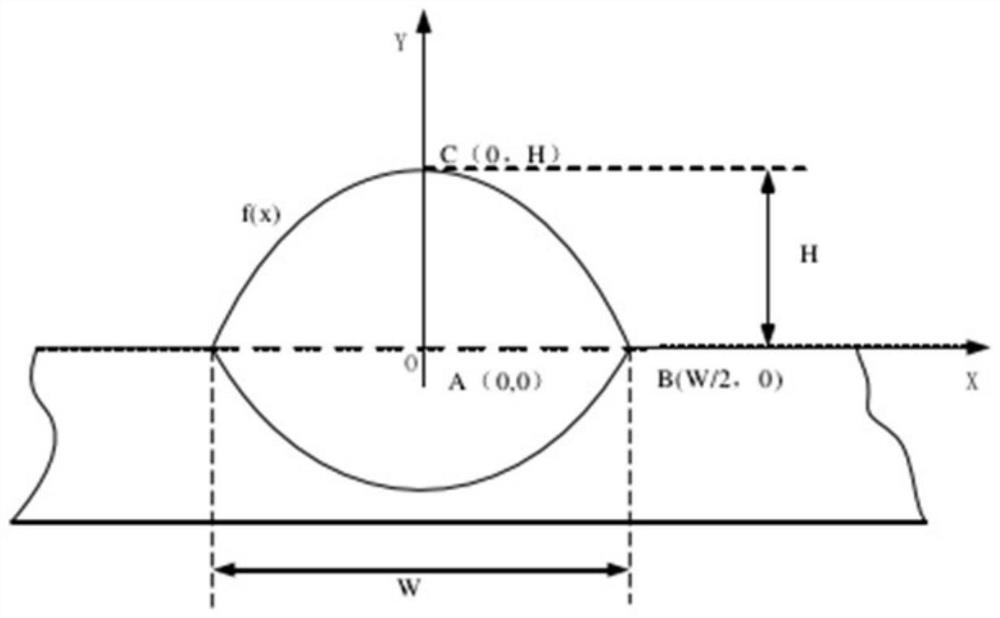

Metal structural part multi-layer single-pass continuous electric arc additive manufacturing method and system

ActiveCN111702292AGo digitalRealize intelligenceArc welding apparatusMaterials scienceIndustrial engineering

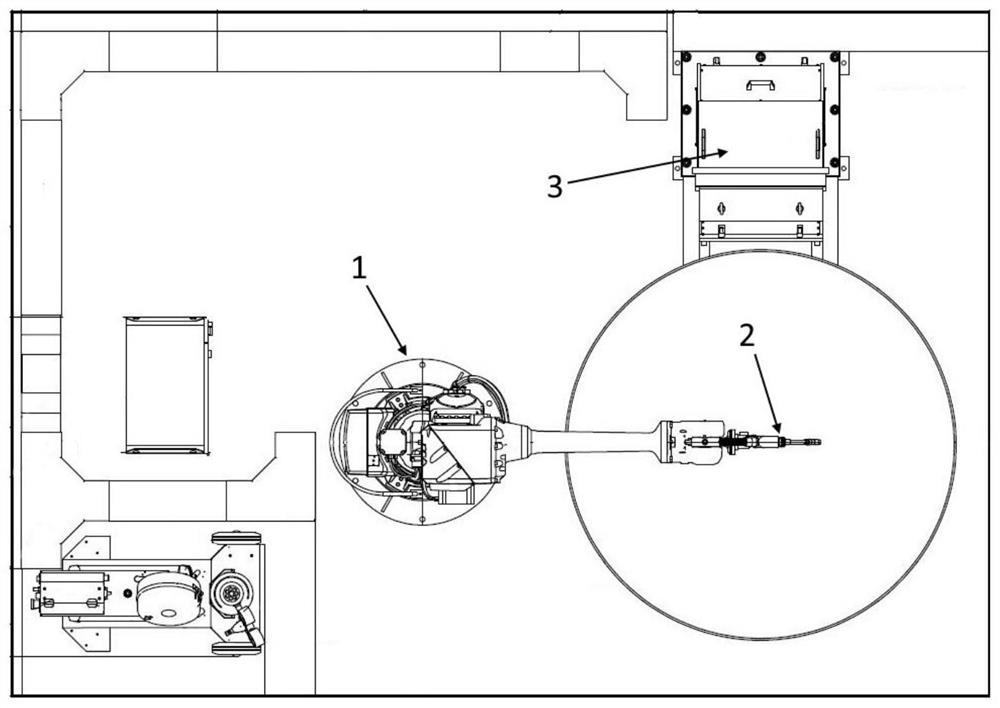

The invention discloses a metal structural part multi-layer single-pass continuous electric arc additive manufacturing method and system. The metal structural part multi-layer single-pass continuous electric arc additive manufacturing method adopts a welding machine as a heat source and a metal wire material as a molding material; and under the driving of a robot, a welding device moves on a substrate according to a planned continuous spiral rising slicing path to carry out electric arc additive manufacturing. Firstly, a welding wire and the substrate needed by molding a specific metal structural part are selected; secondly, the continuous spiral rising slicing path is generated; and thirdly, a welding gun moves according to the generated continuous spiral path under the driving of the robot, a servo system drives a welding gun mechanical arm according to a calculated spiral path, the welding gun mechanical arm drives the welding gun to print a single-pass welding seam along a desiredtrajectory, and the height of the welding gun from the substrate in the printing process is gradually increased according to the spiral path. The continuous spiral rising path enables the height of the welding gun from the substrate to be gradually increased in the whole 3D printing process; but the dry extension is kept invariable; arc quenching cannot be caused in the whole printing process; andfinally, the metal structural part with excellent performance is molded.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Sol-gel preparation method of barium titanate PTC ceramics

The invention discloses a sol-gel preparation method of barium titanate PTC ceramics, which comprises the following steps that: (1) the materials are measured according to the formula (Ba1-xYx)TiO3, and x is equal to 6 to 20 permillage, barium acetate water solution with the concentration of 1.3 to 1.6 mol / L is prepared, and tetrabutyl titanate solution with the concentration of 1.0 to 1.3 mol / L is prepared; (2) Y(NO3)3.6H2O is incorporated into the Ba(CH3COO)2 water solution, and then the mixed solution is dropped into the Ti(OC4H9)4 solution to obtain the mixed solution; (3) the mixed solution is held at the room temperature to obtain the sol, and the sol is dried to obtain the gel; (4) the gel is smashed, ground and sieved to be pre-burned to synthesize the BaTiO3 powder containing yttrium; (5) the BaTiO3 powder containing the yttrium, the BaCO3 and the BN are measured according to the mol ratio of 1: (0.02 to 0.03) : (0.04 to 0.06) and are mixed and ball milled after being added with deionized water; (6) the BaTiO3 powder containing glass-phase raw material is ball milled with solvent and dispersant, and then the obtained mixture is ball milled with bond and plasticizer to obtain sizing agent for curtain containing; (7) the sizing agent is formed in a curtain coating way; and (8) and flakes are sliced and sintered to obtain the ceramic piece. The prepared PTC ceramic has the advantages of small crystal grains, small room-temperature resistivity and large PTC effect.

Owner:HUAZHONG UNIV OF SCI & TECH

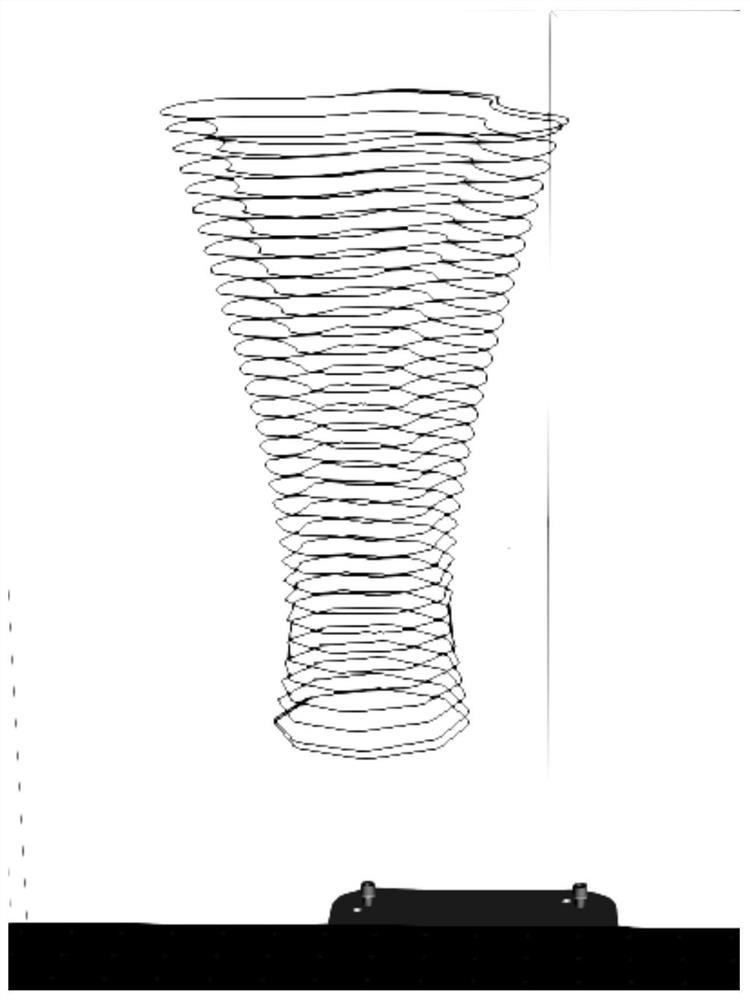

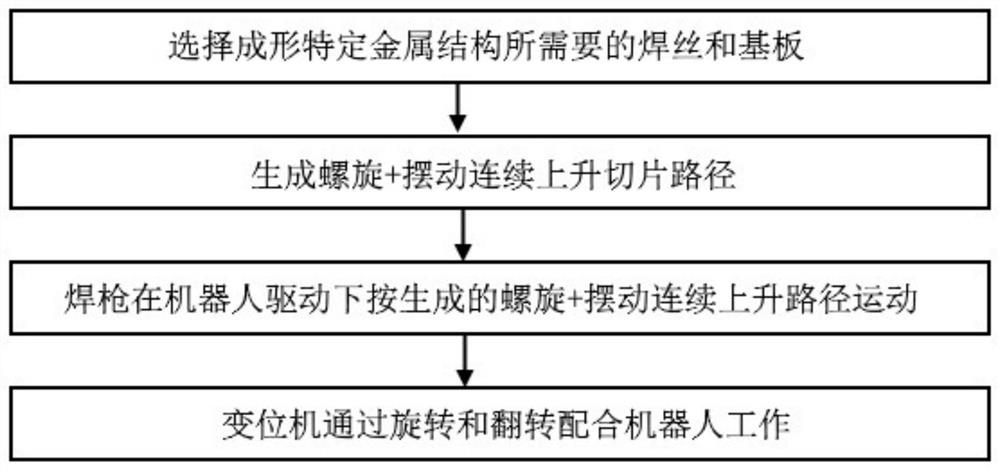

Wire arc additive manufacturing method, device and equipment for continuous growth of curved surface metal structure and computer storage medium

ActiveCN112846446ASolving the bottleneck of difficult continuous arc additive manufacturingContinuous ascending print pathAdditive manufacturing apparatusArc welding apparatusPath generationMechanical engineering

The invention provides a wire arc additive manufacturing method and system for continuous growth of a curved surface metal structure. The method comprises the following steps: selecting a welding wire and a base plate needed for forming a specific metal structure; generating a spiral and swinging continuous rising slice path; driving a welding gun by a robot to move according to the generated spiral and swinging continuous rising path; and enabling a positioner to cooperate with the robot to work through rotation and overturning. The system comprises a base assembly, a path generation module, an eight-axis linkage mechanism and a visual sensing module, wherein the base assembly is used for placing a specific metal structural member; the path generation module is used for generating the spiral and swinging continuous rising slice path; the eight-axis linkage mechanism (comprising a six-axis robot and a double-axis positioner) is used for tracking and printing according to the spiral and swinging continuous rising slice path generated by the path generation module; and the visual sensing module is used for monitoring a printed workpiece in real time. According to the method and system, the bottleneck that continuous wire arc additive manufacturing of an existing curved surface metal structural part is difficult is solved, the product development period is shortened, and the efficiency is improved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

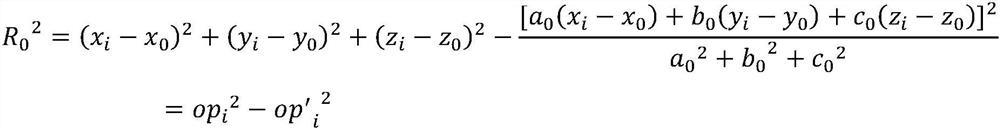

Normal-temperature plastic deformation-rapid solidification magnesium alloy anode material as well as preparation method and application thereof

ActiveCN110492094ADissolve fastIncrease discharge voltageFuel and secondary cellsCell electrodesHigh energyElectrochemistry

The invention relates to a normal-temperature plastic deformation-rapid solidification magnesium alloy anode material as well as a preparation method and application thereof. The preparation method comprises the following steps that S101, as-cast AP65 magnesium alloy is treated into magnesium chips, grains are refined through high-energy ball milling, and powder is obtained and ground; S102, in avacuum environment, spark plasma sintering is carried out after pretreatment, and the material is obtained, or S201, the as-cast AP65 magnesium alloy is treated into magnesium chips, grains are refined through high-energy ball milling, powder is obtained and ground; and S202, after spark plasma sintering is conducted, heat treatment is conducted under the vacuum condition, and the material is obtained. According to the invention, high-energy ball milling, spark plasma sintering and consolidation technology and the like are adopted, the magnesium alloy anode material is promoted to be rapidly and uniformly dissolved under low current density, and peeling off of a corrosion product is accelerated, so that the discharge voltage of the magnesium alloy is improved, the voltage fluctuation is reduced, stable work of an electric appliance is facilitated, and the comprehensive electrochemical performance of the magnesium alloy anode material is further improved.

Owner:GUANGDONG UNIV OF TECH

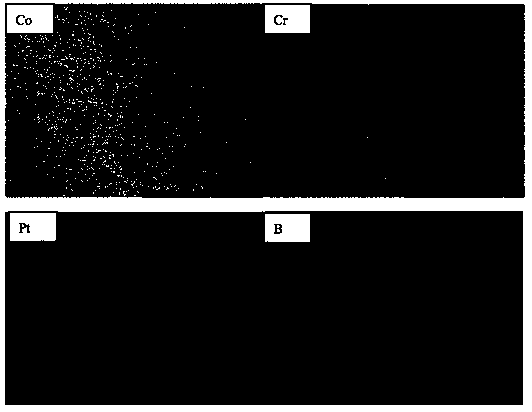

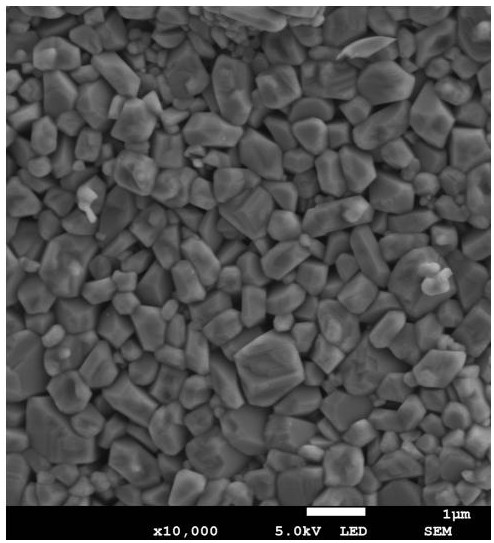

CoCrPt series alloy sputtering target and film and preparation method thereof

ActiveCN104032274ALow content of harmful impurity elementsFine and uniform grainMagnetic field orientationVacuum evaporation coatingRecording layerMachining

The invention discloses a CoCrPt series alloy sputtering target and film and a preparation method thereof. The CoCrPt series alloy sputtering target comprises an element B, wherein the content of the element B is 0-20 atomic percent; the alloy target comprises a Co-enriched phase and a B-enriched phase; the B-enriched phase is uniformly distributed in the Co-enriched phase; the average grain size of the Co-enriched phase is 20-50mu m; and the average grain size of the B-enriched phase is 0-20mu m. The method for preparing the CoCrPt series alloy sputtering target comprises the following steps: (1) performing vacuum melting; (2) performing hot isostatic pressure; (3) performing thermal machining; and (4) performing cold machining. The invention also discloses a magnetic recording medium prepared by using the CoCrPt series alloy sputtering target. The magnetic recording medium comprises a substrate layer, an adhesive layer, a soft magnetic layer, an intermediate layer and a magnetic recording layer, wherein the coercive force of the magnetic recording medium is 3000-5000Oe; and the squareness is 0.80-0.95. The CoCrPt series alloy sputtering target is uniform in chemical components and small in deviated nominal composition, and the technical problems in a conventional preparation process that rolling cracking is caused, the yield is low, the mount of deviated nominal composition of the chemical components of the alloy target is large, the content of harmful impurities is extremely high are solved.

Owner:YUNNAN PRECIOUS METALS LAB CO LTD

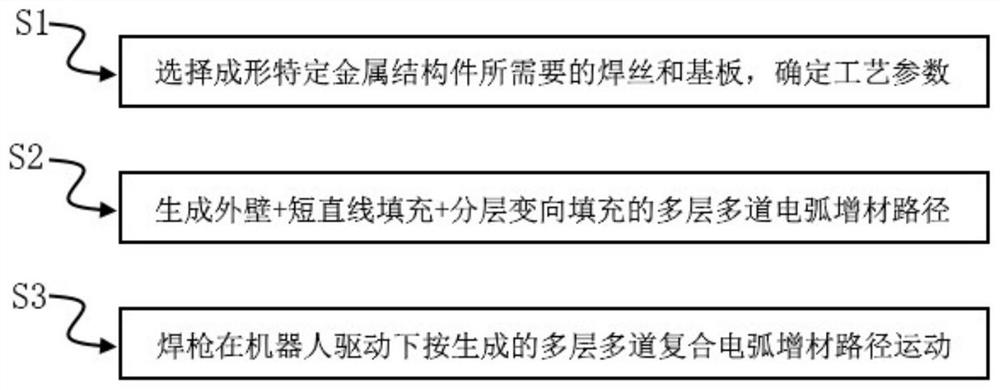

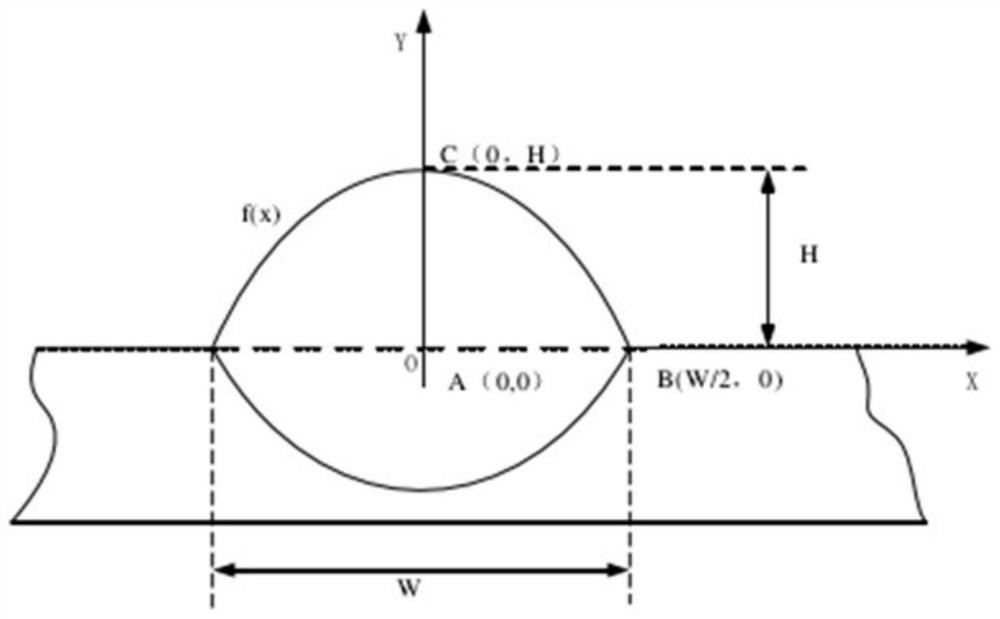

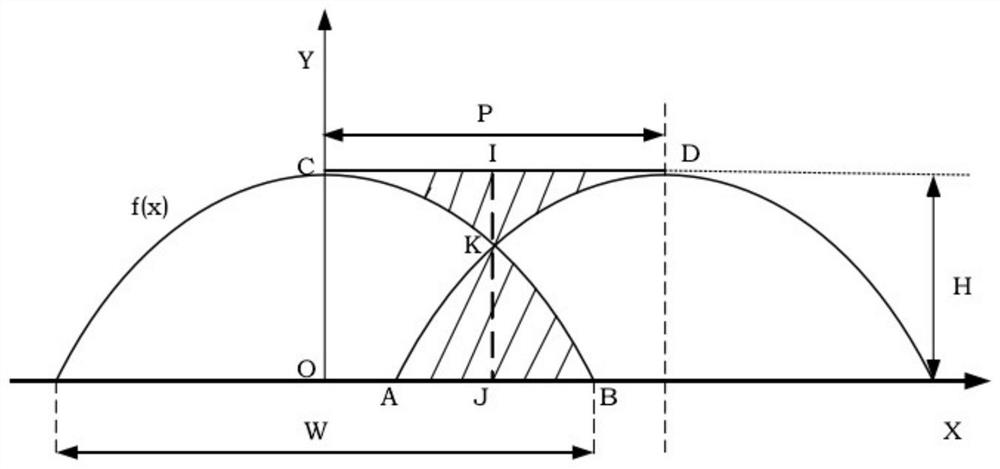

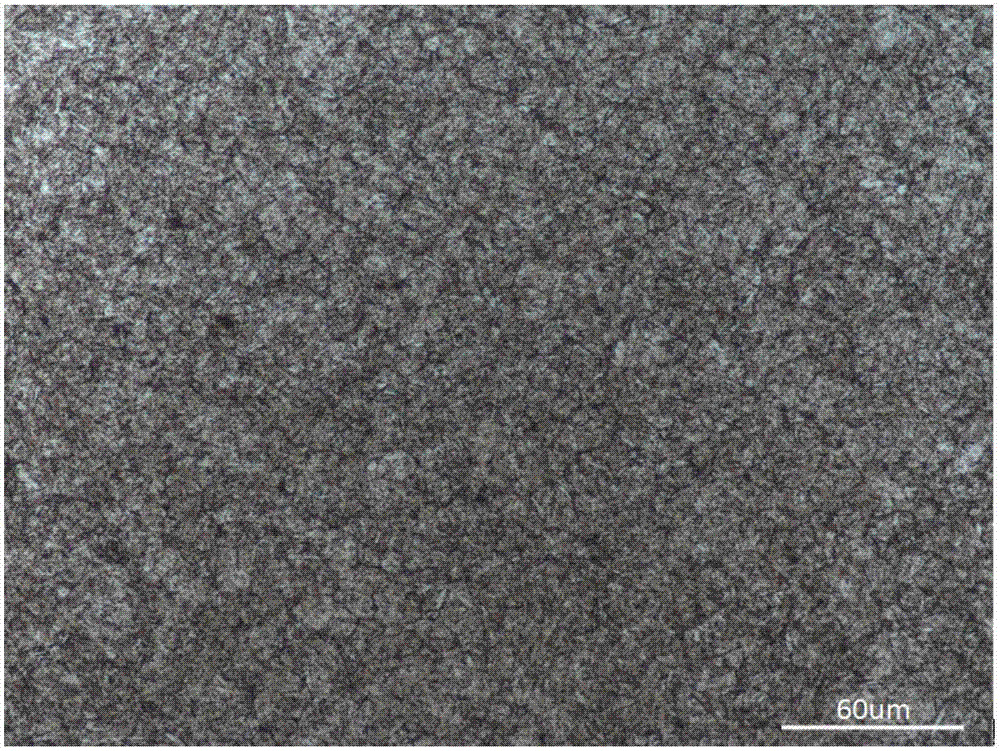

Multi-layer multi-pass composite wire arc additive manufacturing method and system for metal structure

ActiveCN112846445AHigh dimensional accuracyImprove mechanical propertiesAdditive manufacturing apparatusArc welding apparatusEngineeringMechanical property

The invention provides a multi-layer and multi-pass composite wire arc additive manufacturing method and system for a metal structure. The multi-layer and multi-pass composite wire arc additive manufacturing method for the metal structure comprises the following steps of: 1, selecting a welding wire and a substrate required for forming a specific metal structural part, and determining technological parameters; 2, generating a multi-layer and multi-pass wire arc additive path of outer wall, short straight line filling and layered turning filling; and 3, enabling a welding gun to move according to the generated multi-layer and multi-pass wire arc additive path under the driving of a robot. The welding gun is driven by the robot to conduct 3D printing according to the generated outer wall, short straight line filling and layered turning filling composite path; the outer wall path improves the size precision of a formed workpiece; the short straight line filling path solves the problem that the heights of complex structural parts are inconsistent in the printing process, and obvious macro buckling deformation is not prone to being formed; and through layered turning filling, interlayer defects are greatly reduced through, and the mechanical property of the workpiece is improved. Digitization, intellectualization and parallelization of part manufacturing are achieved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Heat treatment process for high-performance disc cutter of TBM

ActiveCN107345267AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesCarbideRoom temperature

The invention belongs to the field of heat treatment, and particularly relates to a heat treatment process for a high-performance disc cutter of a TBM. The heat treatment process comprises the following steps: 1, carrying out annealing treatment after steel forging; 2, carrying out double-refining heat treatment process before tempering, specifically, heating a forge piece to 1030 deg C-1060 deg C, keeping the temperature for 2 hours-3 hours, repeating the process, heating to 850 deg C-870 deg C and keeping the temperature for 2 hours-3 hours, cooling to 730 deg C-740 deg C and keeping the temperature for 4 hours-5 hours, and carrying out furnace cooling; and 3, carrying out quenching treatment, specifically, heating the workpiece to 1030 deg C-1060 deg C, keeping the temperature for 2 hours-3 hours, and carrying out oil quenching, then carrying out tempering treatment, specifically, heating the workpiece to 540 deg C-560 deg C, keeping the temperature for 1.5 hours-2.5 hours, carrying out air cooling to the room temperature, and repeating the tempering treatment for one time. According to the disc cutter of the TBM obtained through the process, carbide is fine and is distributed on a substrate in a dispersed mode, a grain size is uniform and fine, and the carbide and the grain size are subjected to the double-refining; and the disc cutter has high hardness, and good wear resistance and impact resistance, and the service life of the disc cutter is effectively prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

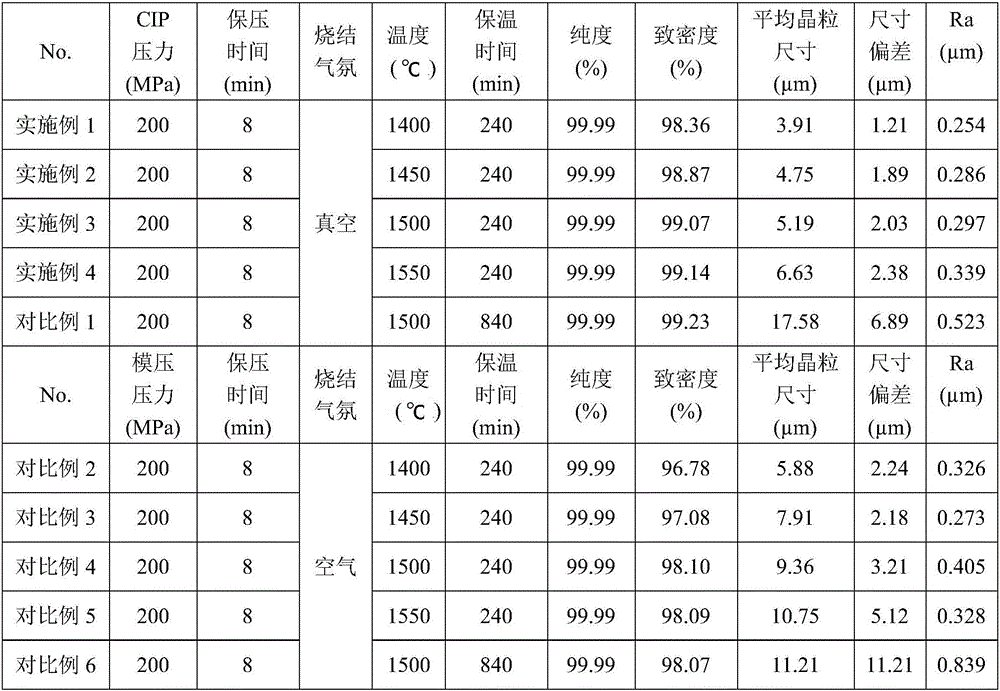

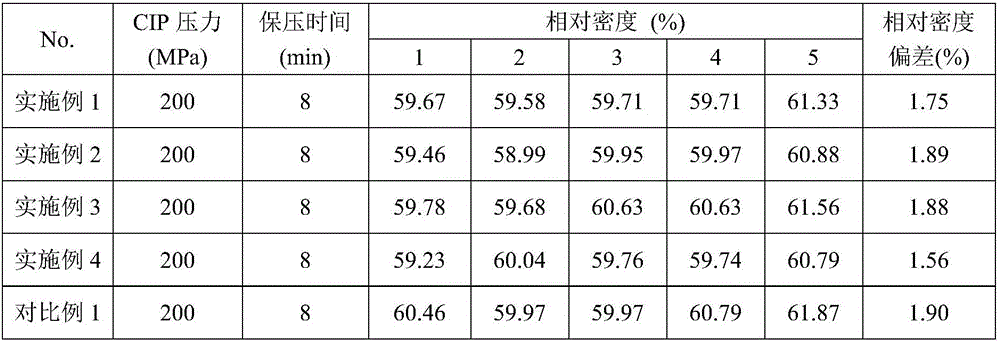

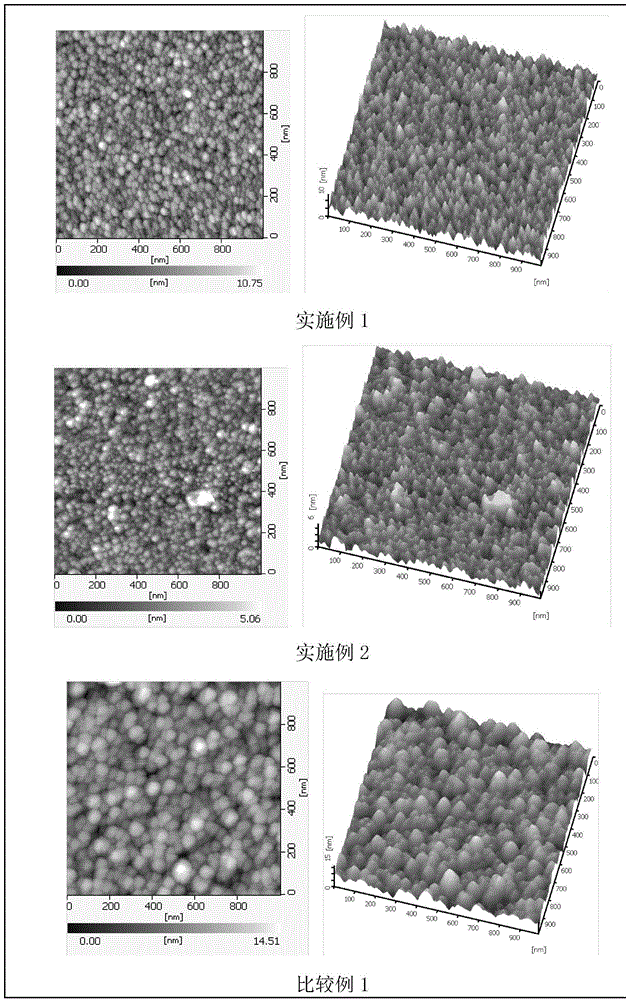

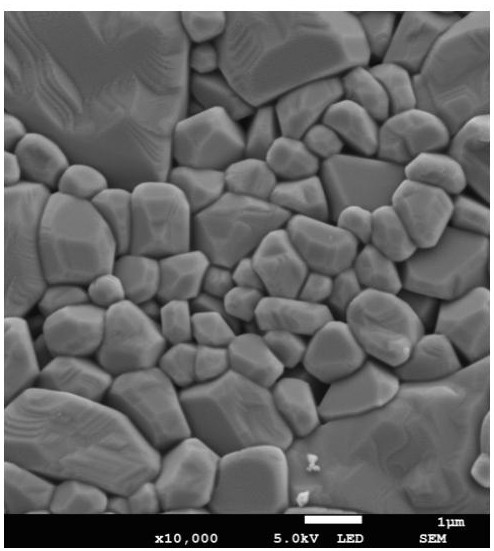

High-purity compact magnesium oxide target material and preparation method thereof

ActiveCN106587940AImprove particle size distributionGood particle dispersionVacuum evaporation coatingSputtering coatingSurface roughnessImpurity

The invention belongs to the technical field of novel material manufacturing and application and particularly relates to a high-purity compact magnesium oxide target material and a preparation method thereof. Magnesium oxide powder subjected to planetary ball milling are further subjected to isostatic cool pressing and vacuum sintering to obtain the near-net formed high-purity compact magnesium oxide target material, wherein a vacuum sintering temperature is 1400-1550 DEG C, heat preservation time is 2-10h, and a vacuum degree is 0.1-1.0Pa. The high-purity compact magnesium oxide target material prepared according to the method is 98.36% or above in compactness, 100ppm or below in total impurity element content, 7micron or blow in average grain size, 3.0micron or below in size deviation and 0.4micron or below in surface roughness Ra. The magnesium oxide target material prepared according to the method is high in purity and compactness and fine and uniform in grain size. The preparation method has advantages of short production cycle, low production cost, high production efficiency and availability for batch production.

Owner:GRIKIN ADVANCED MATERIALS

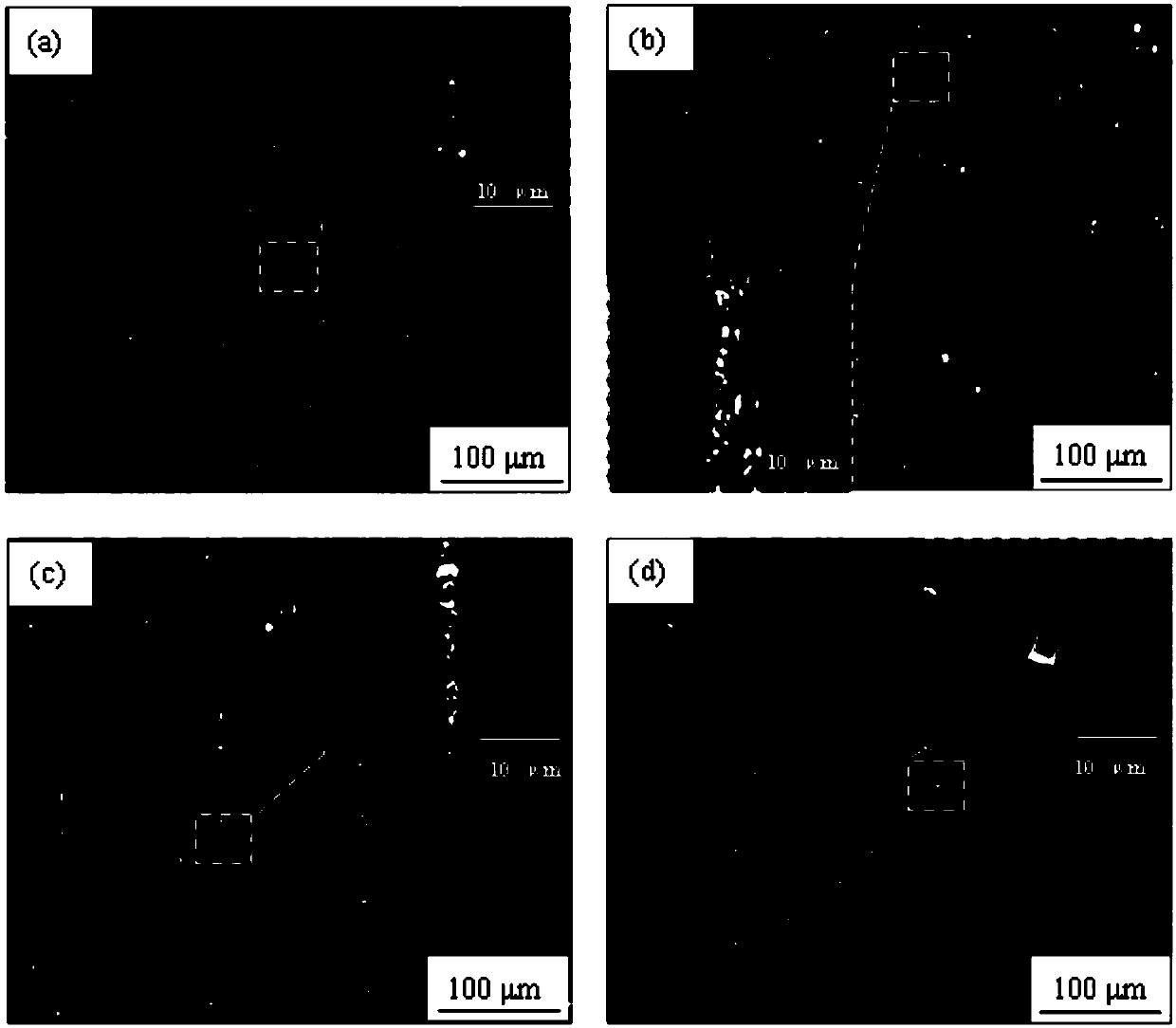

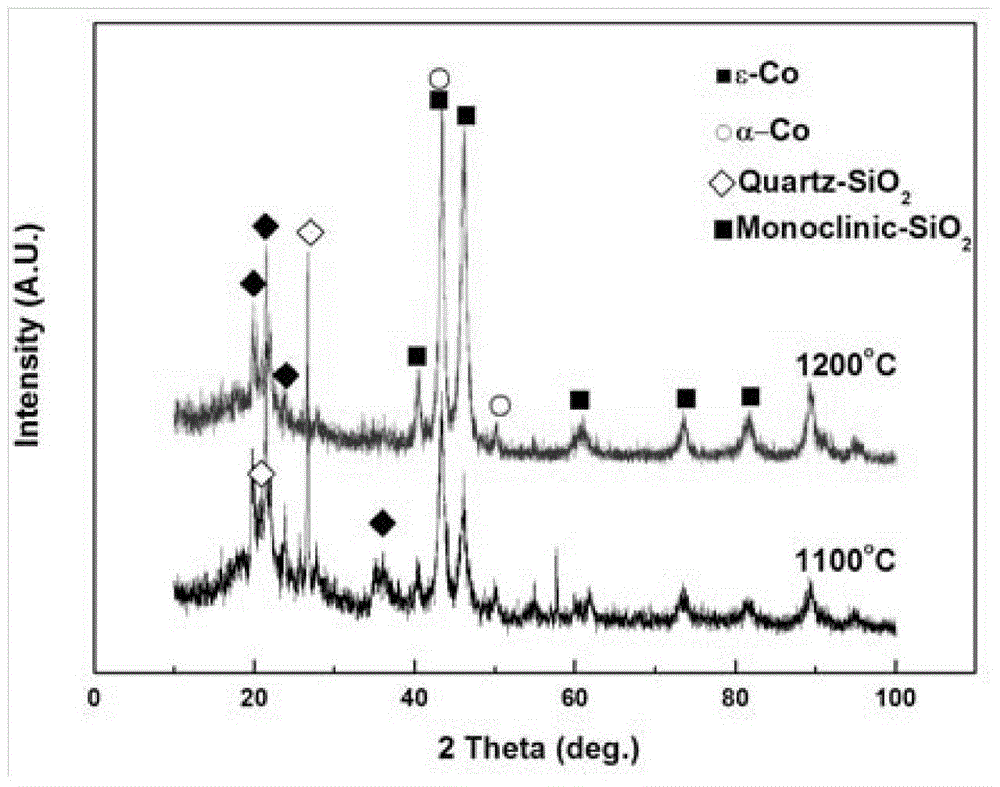

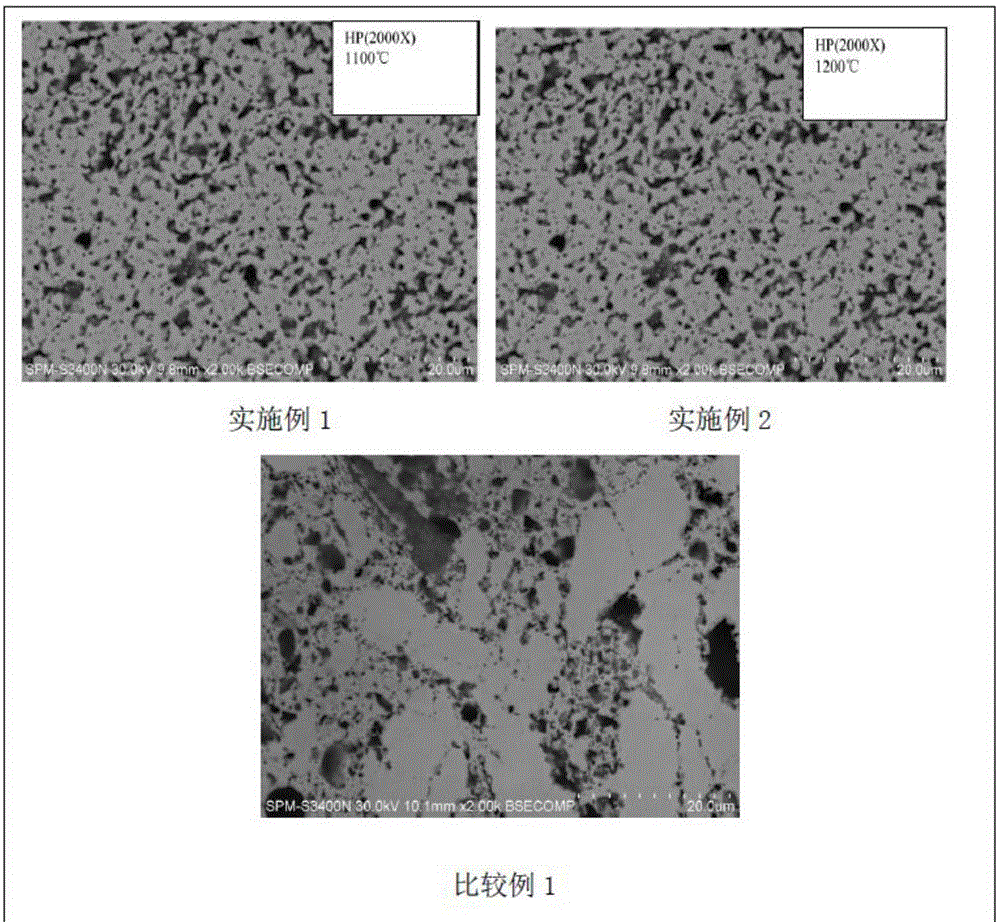

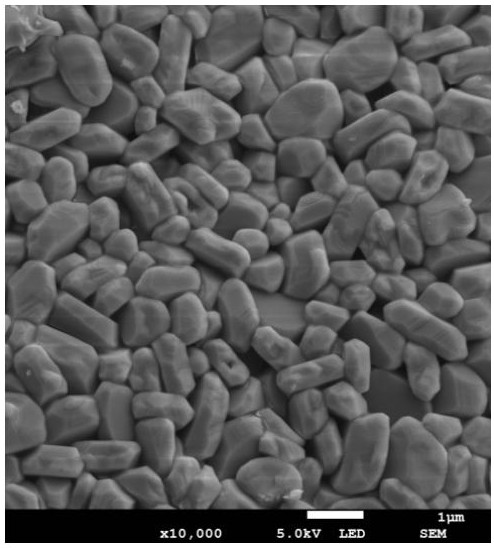

CoCrPt-oxide magnetic recording target, film and preparation method thereof

InactiveCN104060229ALow elemental contentFine and uniform grain sizeVacuum evaporation coatingSputtering coatingMagnetic susceptibilityOxide

The invention discloses a CoCrPt-oxide magnetic recording target, film and a preparation method thereof. The CoCrPt-oxide target includes one or several oxides selected from SiO2, TiO2, CrO, Cr2O3, Ta2O3, W2O3, Al2O3 and Y2O3, wherein the average grain size of the oxides is in the range of 3-20 mum. In the Alloy target, Co, Cr and Pt form an alpha-Co and epsilon Co two-phase Co based solid solution, which mainly comprises low temperature phase hexagonal epsilon-Co solid solution; the target has a thickness in the range of 2-6 mm, and magnetic susceptibility (PTF) value of 40%-60%. A magnetic recording layer of a magnetic recording medium prepared from the alloy target material is in preferred orientation growth of (002) crystal face, and in the X diffraction analysis, the X ray diffraction peak intensity ratio of the (002) crystal plane represented by the formula (1) is 70%-90%. The sputtering target provided by the invention has low content of harmful impurity elements, fine and uniform grain size, homogeneous chemical composition with small deviation from the nominal composition. The magnetic recording medium prepared from the above sputtering target material has uniform and fine grains, clear nonmagnetic grain boundaries, and excellent magnetic properties.

Owner:SINO PLATINUM METALS CO LTD

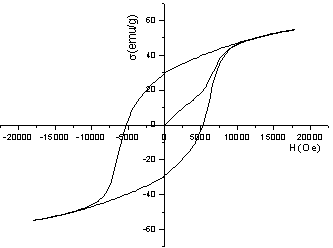

Nanocrystal M-shaped ferrite powder and synthesis method thereof

InactiveCN103342552AFine and uniform grain sizeIncrease the speed of calcination heatingMetallurgyNanoparticle

The invention discloses a nanocrystal M-shaped ferrite powder and a synthesis method thereof. The nanocrystal M-shaped ferrite powder is a single M-shaped ferrite powder with the particle size of 65-100nm; in the contained nanocrystal M-shaped ferrite powder, M:Fe:O=1:12:19 and M is Pb, Ba or Sr. The synthesis method of the nanocrystal M-shaped ferrite powder comprises the following steps of: firstly, dissolving citric acid into distilled water; then, adding Fe salt and M metal salt, and sufficiently stirring the mixture until the mixture is dissolved, and adjusting the pH value of the solution to 5-7.5 by using ammonium hydroxide; next, stirring the solution at the temperature of 75-100 DEG C to form a complex solution, and then, controlling the temperature at 60-120 DEG C to form a precursor; and finally, calcining the precursor at the temperature of 850-900 DEG C for 60-120min to obtain the nanocrystal M-shaped ferrite powder. The synthesis method has the characteristics of short synthesis period, high efficiency, low synthesis cost, suitability for mass production and the like; and the synthesized powder nanoparticles are fine and uniform.

Owner:SHANGHAI INST OF TECH

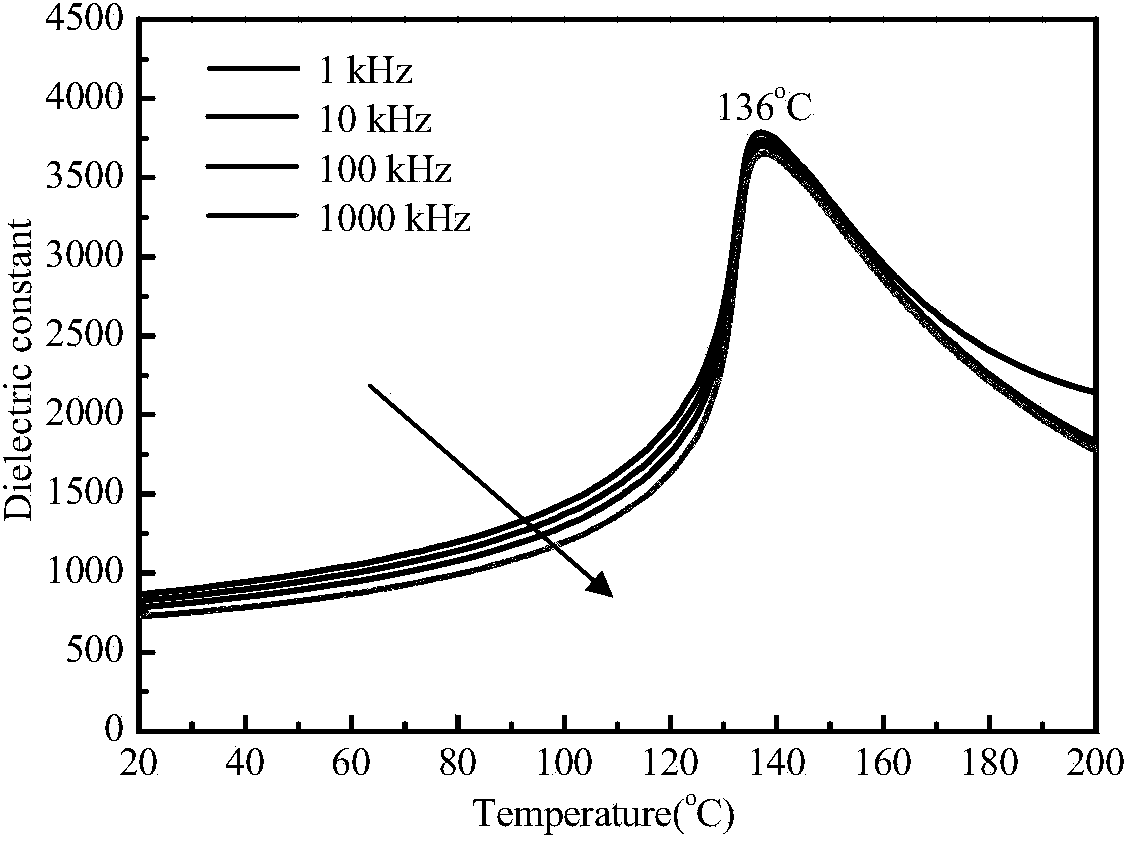

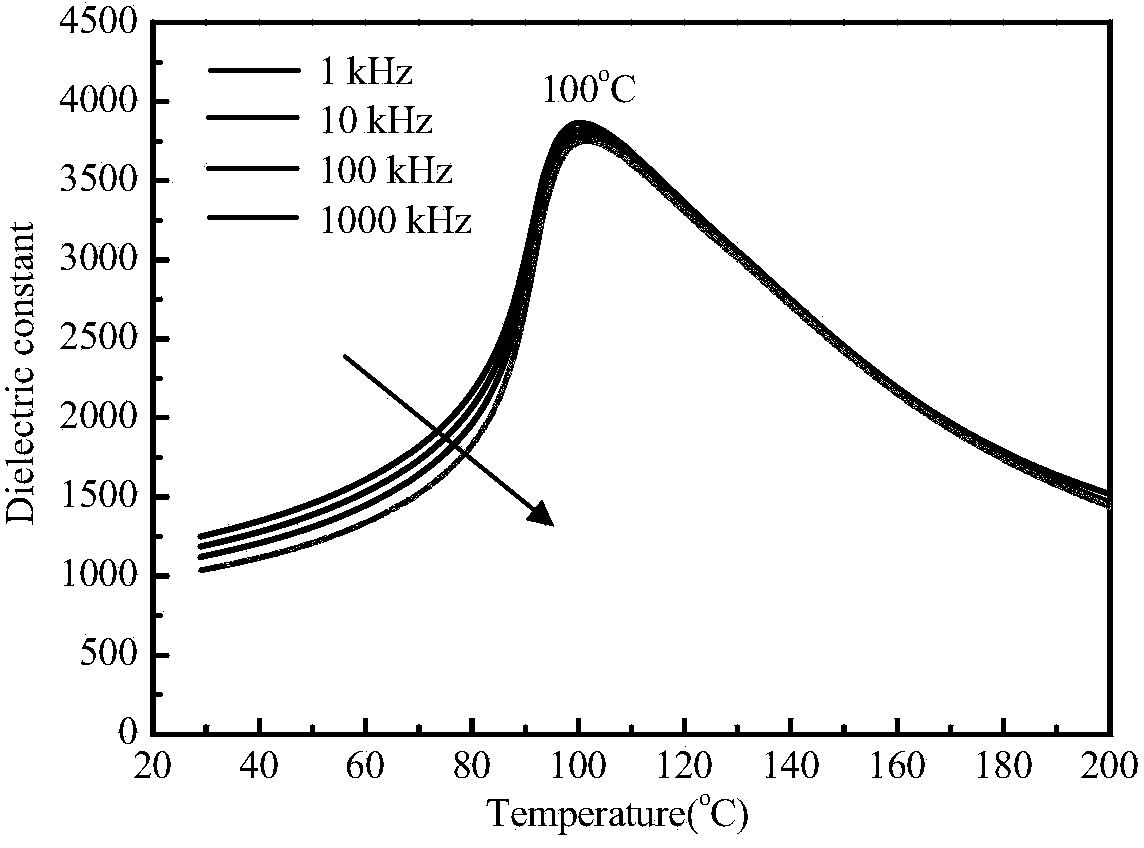

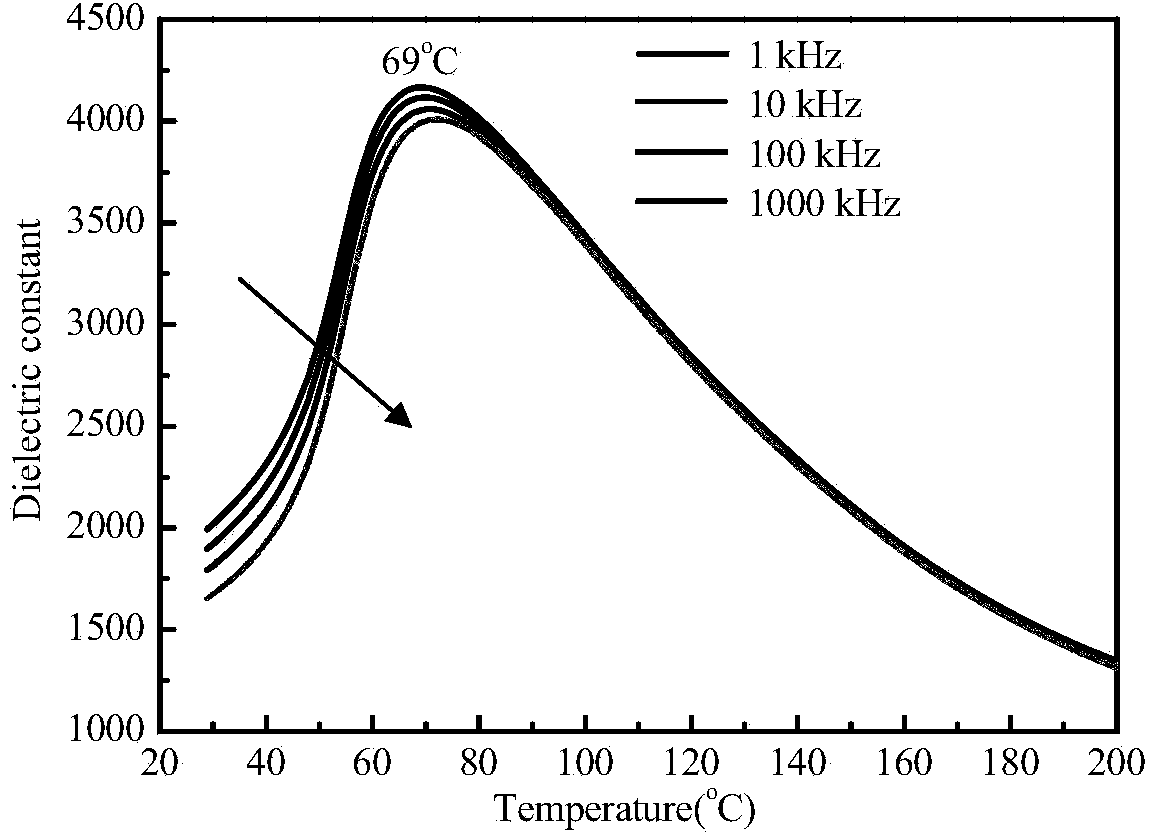

Preparation method of submicron-level relaxor ferroelectric

The invention relates to a preparation method of a submicron-level relaxor ferroelectric. The preparation method comprises the following steps of: firstly preparing water-soluble barium source, calcium source, zirconium source, bismuth source and titanium source into a mixed solution according to the stoichiometric ratio of the relaxor ferroelectric to be prepared; regulating the mixed solution to alkality to prepare a powdery precursor of the relaxor ferroelectric; then carrying out hydrothermal reaction on the powdery precursor to prepare powder of the relaxor ferroelectric; and carrying out blank forming and sintering to the powder to obtain the submicron-level relaxor ferroelectric. According to the preparation method, the submicron-level relaxor ferroelectric which is high in purity, high in compactness and small and uniform in grain size can be obtained within a short time through the combination of a hydrothermal method and a microwave sintering technology; the electric property and microstructure of ceramic are changed within a wide range by changing the quantity of doped elements, and the behavior of the relaxor ferroelectric of the ceramic is optimized, and therefore the submicron-level relaxor ferroelectric can be widely applied to the field of electronic ceramics.

Owner:SHAANXI UNIV OF SCI & TECH

Same-level multi-strand continuous casting device and method for magnesium alloy

ActiveCN105344958AReduce wrappingPrevent liquid level fluctuationsCarbon Dioxide / HeliumShielding gas

The invention provides a same-level multi-strand continuous casting device and method for magnesium alloy. The device comprises a flow guide pipe, a flow diversion box, hot top crystallizers, a flow diversion pipe, a shield gas pipe, a water tank and dummy ingots. The flow guide pipe is inserted in the flow diversion box. The flow diversion box and the hot top crystallizers are fixed to the water tank. The flow diversion box and the hot top crystallizers are connected through the flow diversion pipe. The shield gas pipe is connected with the flow diversion box and the hot top crystallizers. The dummy ingots are arranged under the top hot crystallizers. The method includes the technical steps that firstly, the dummy ingots stretch into the hot top crystallizers to be aligned, a heating sleeve is electrified, cooling water is led into the water tank, and shield gas is led into the shield gas pipe; secondly, a magnesium alloy melt is introduced into the device, a casting machine is started at a preset speed, and casting is conducted; and thirdly, when the preset cast ingot length is nearly reached, casting is stopped. Magnesium cast ingots manufactured through the same-level multi-strand continuous casting device and method for the magnesium alloy are smooth in surface, free of cracks, even in internal texture and even and fine in grain size.

Owner:NORTHEASTERN UNIV

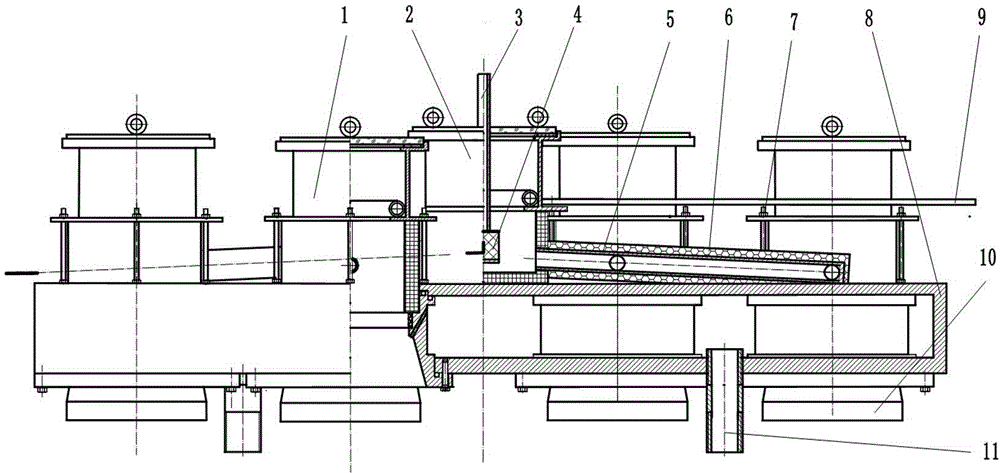

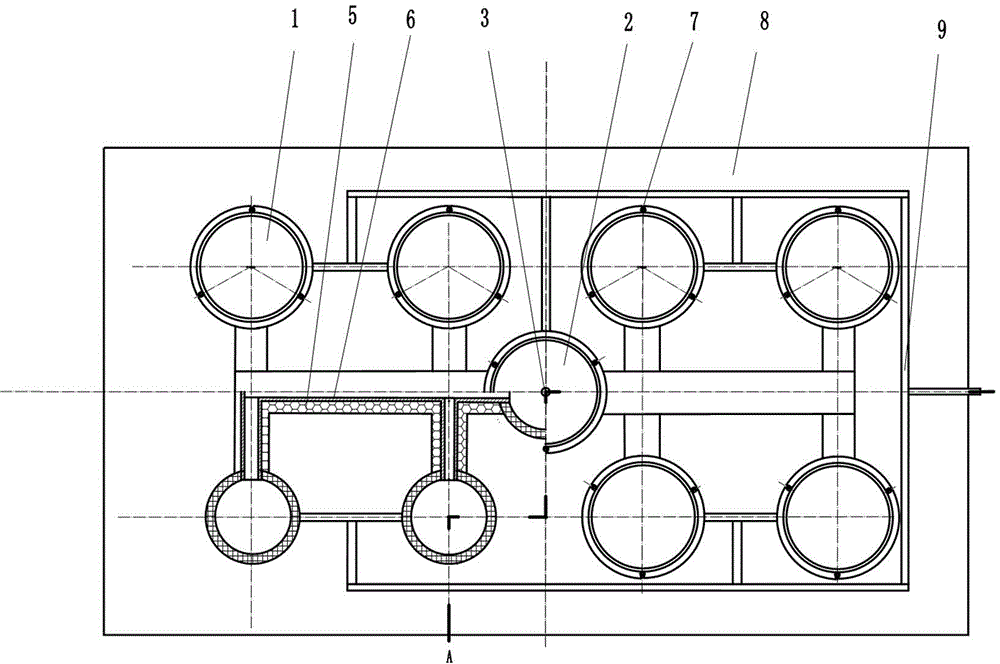

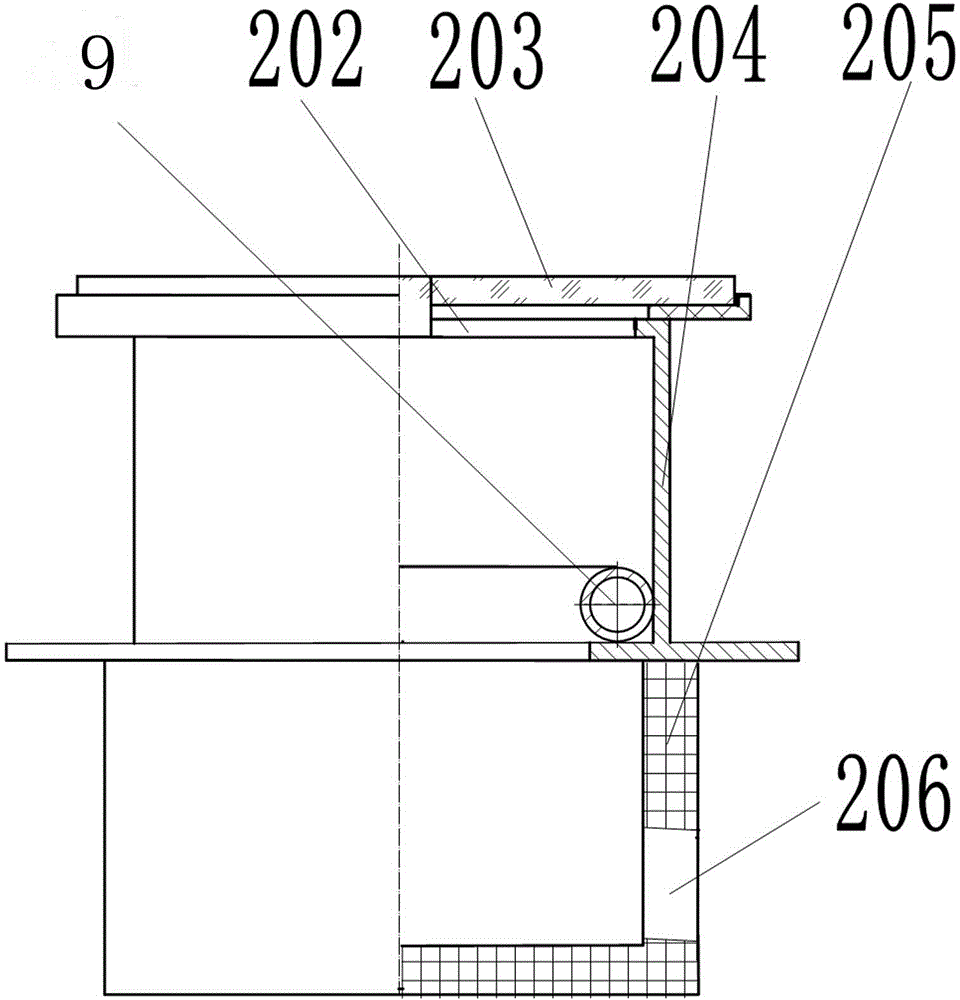

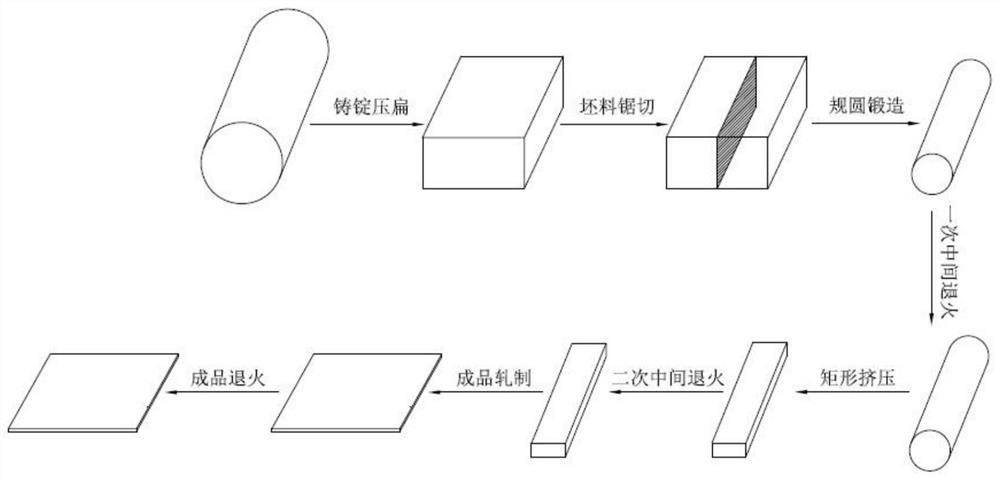

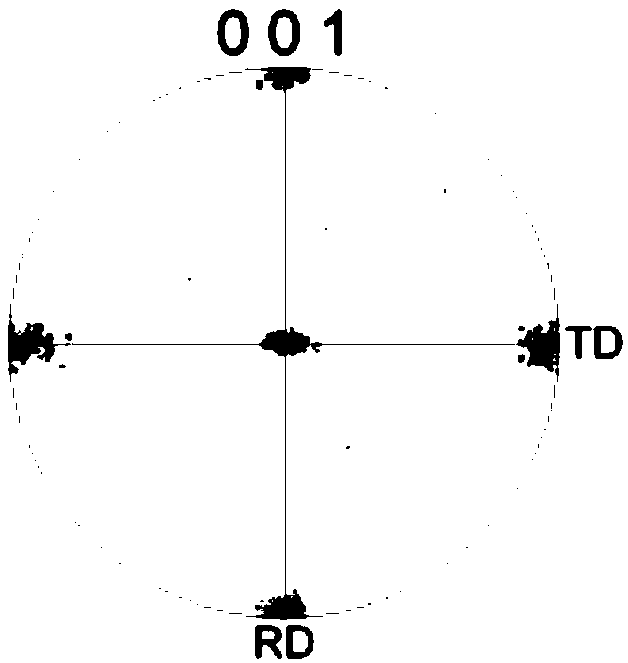

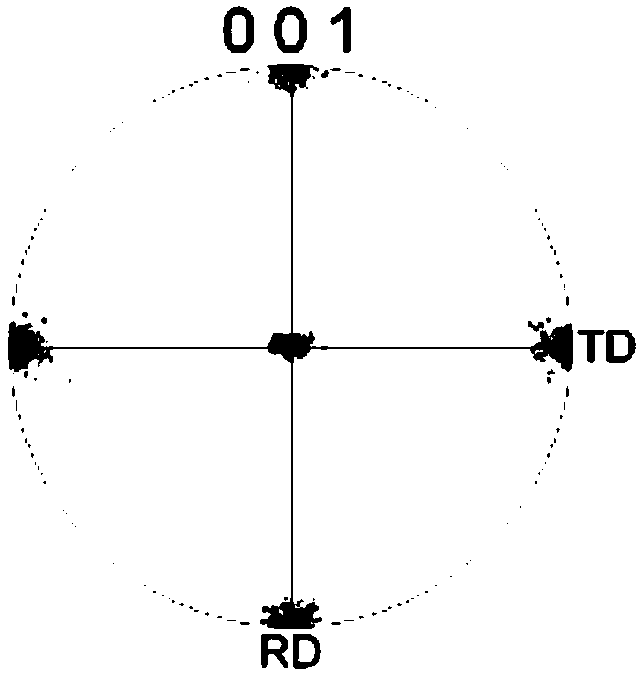

Method for optimizing grain size and uniformity of tantalum plate

ActiveCN112410699AUniform grain sizeIncreased degree of grain fragmentationCircular sectionSquare Shape

The invention discloses a method for optimizing grain size and uniformity of a tantalum plate. The method comprises the following steps: 1, a tantalum cast ingot with a circular section shape is flattened by using a rapid forging machine in a room-temperature environment to obtain a tantalum blank with a rectangular section shape; 2, saw cutting is conducted, and a tantalum blank with the square cross section is obtained; 3, forging and rounding are conducted after heat preservation, and a bar blank with a circular cross section is obtained; 4, primary annealing treatment is performed to obtain an annealed bar billet; 5, the bar billet is extruded after heat preservation to obtain a plate blank with a rectangular section; 6, secondary annealing treatment is conducted, and an annealed plateblank is obtained; 7, rolling is performed to obtain a plate; and 8, third-time annealing treatment is conducted, and a finished tantalum plate is obtained. By the method, preparation of the medium-thickness tantalum plate with the thickness ranging from 5 mm to 20 mm can be achieved, the grain size is superior to 6.5 levels, the maximum grain size is less than or equal to 38 [mu]m, the grain size of the plate in the thickness direction is uniform, and the grain size level difference between a surface layer and the core portion is within 0.5 level.

Owner:西安诺博尔稀贵金属材料股份有限公司

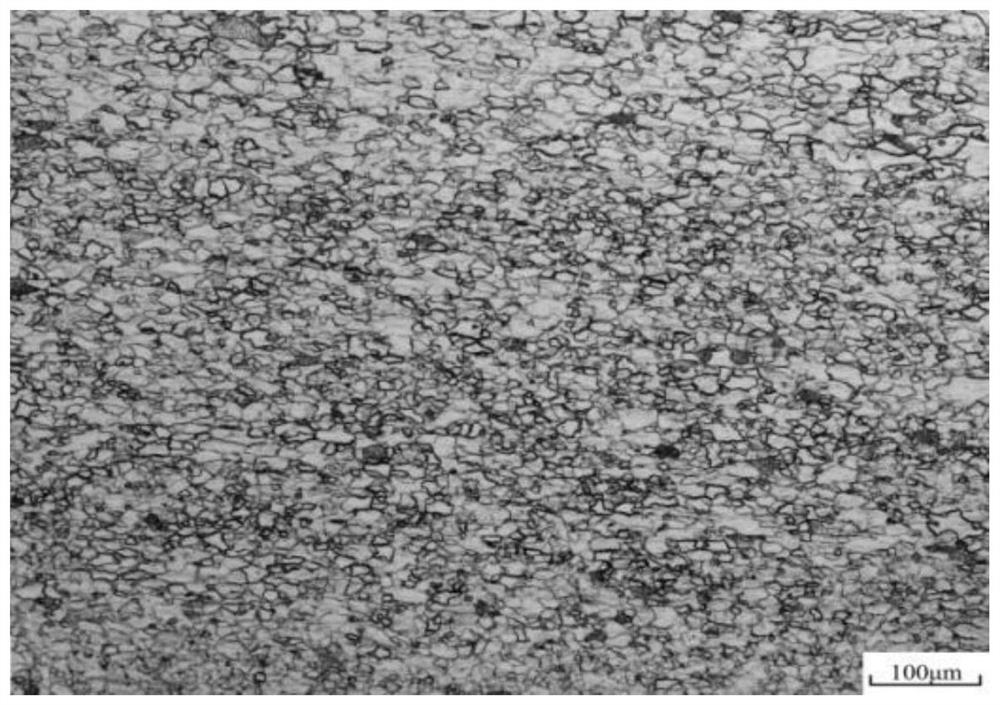

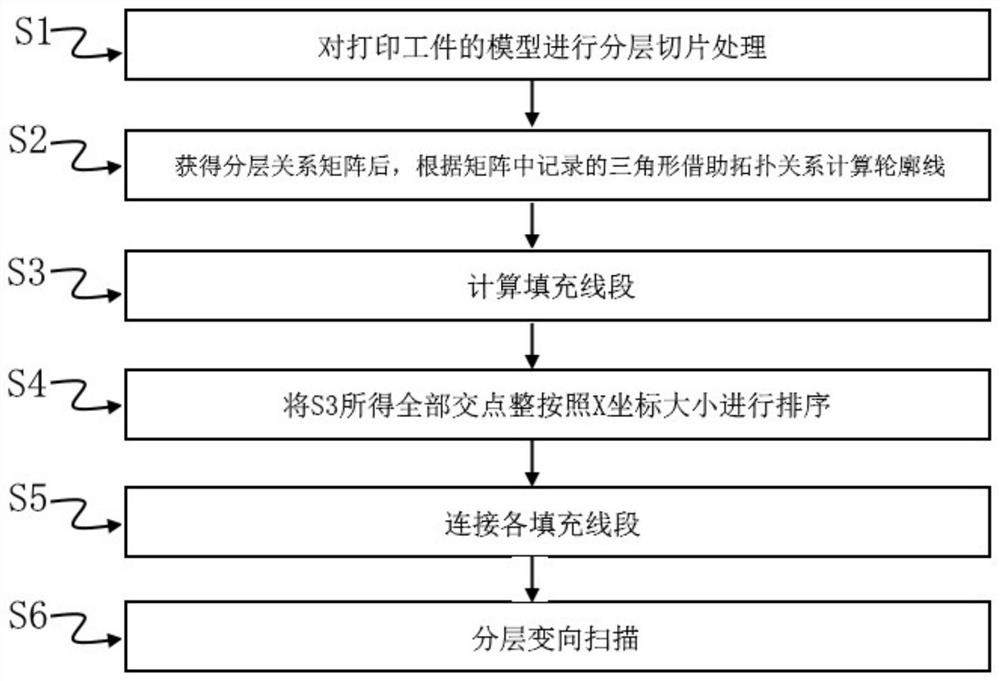

Automatic trajectory planning method and system for multi-layer and multi-channel wire arc additives of metal structure

ActiveCN112846232AHigh dimensional accuracyUniform grain sizeAdditive manufacturing apparatusIncreasing energy efficiencyTrajectory planningLine segment

The invention provides an automatic trajectory planning method and system for multi-layer and multi-channel wire arc additives of a metal structure. The automatic trajectory planning method comprises the following steps: Step 1, conducting layered slicing treatment on a model of a printed workpiece; Step 2, after obtaining a layered relation matrix, calculating a contour line according to triangles recorded in the matrix by means of a topological relation; Step 3, calculating filling line segments; Step 4, sorting all the intersection points obtained in the Step 3 according to the size of the X coordinate; Step 5, connecting the filling line segments; and Step 6, carrying out layered direction-changing scanning. Multi-layer and multi-channel 3D printing of a metal structural part is carried out according to the composite printing path of outer wall + short straight line filling + layered direction-changing filling, chemical components of a formed workpiece are uniform, the purity is high, and the structure is almost free of anisotropy. Multi-layer and multi-channel 3D printing of the metal structural part is carried out according to the composite printing path of outer wall + short straight line filling + layered direction-changing filling, the grain size of the formed workpiece is small and uniform, the mechanical performance is high, and the level of the formed workpiece can exceed that of a casting with the same component.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Method for improving corrosion resistance of 5083 aluminum alloy plate

The invention discloses a cast ingot uniformizing method for improving the corrosion resistance of a 5083 aluminum alloy plate. The cast ingot uniformizing method for improving the corrosion resistance of the 5083 aluminum alloy plate comprises the steps that a cast ingot is cut to be in a block shape; then the cast ingot is subjected to heat preservation at the temperature of 500-560 DEG C for 4-8 h for homogenizing treatment; the cast ingot is hot-rolled to 8-10 mm; low-deformation cold rolling is conducted for five passes till the thickness of the aluminum plate reaches 4 mm; and after coldrolling, the aluminum plate is annealed, and thus, an O-state 5083 aluminum alloy plate with high corrosion resistance is obtained. By the adoption of the cast ingot uniformizing method for improvingthe corrosion resistance of the 5083 aluminum alloy plate, the problems that during existing industrial production, energy consumption for uniformizing the 5083 aluminum alloy plate is high, the timefor uniformizing the 5083 aluminum alloy plate is long, and the metal oxidization loss is large are solved; and the corrosion resistance of the 5083 aluminum alloy plate treated through the cast ingot uniformizing method is very good.

Owner:CENT SOUTH UNIV

A kind of nanocrystalline ceramic corundum abrasive and preparation method thereof

ActiveCN109231970BLow priceImprove performanceOther chemical processesCompressive resistancePhysical chemistry

The invention relates to nanocrystalline ceramic corundum abrasives and a preparation method thereof, belonging to the field of ceramic corundum abrasives. The abrasives are made of Al 2 (SO 4 ) 3 •18H 2 Composition of O and additives, additives include dispersant, liquid composite sintering aid and Al 2 o 3 Sol crystal seeds, the method for preparing ceramic corundum abrasives includes adding Al 2 (OH) 3 Gel precursor added liquid composite sintering aid and Al 2 o 3 The sol crystal seeds are uniformly ball-milled and then dried step by step to obtain dry gel. The dry gel is crushed, granulated, and sieved to obtain gel particles that meet the particle size requirements. The gel particles are calcined in sections and then cooled in the furnace , Vitrified corundum abrasive particles of different particle sizes are obtained by sieving. Also published Al 2 o 3 The preparation method of the sol seed crystal and the prepared ceramic corundum abrasive. By introducing Al 2 o 3 Sol crystal seeds overcome the difficulty of introducing solid nano crystal seeds and uneven mixing, and ensure the uniform mixing of raw materials and additives, so that the prepared ceramic abrasive has a microscopic morphology with fine and uniform grain size, which improves its compressive strength and grinding performance. performance.

Owner:YICHUAN DONGFENG ABRASIVES

Strong-strength strong cubic texture layered composite base strip and preparing method thereof

ActiveCN109536907AHigh strengthInhibited DiffusionVacuum evaporation coatingSputtering coatingHydrogen annealingQuenching

The invention discloses a preparing method of a strong-strength strong cubic texture layered composite base strip. The preparing method comprises the steps that (1) alloy smelting and hot rolling arecarried out, wherein continuous casting is carried out to obtain a nickel tungsten alloy ingot with the tungsten atomic percentage composition being 12% to 14%, the thickness is 500 mm to 700 mm, rough rolling is carried out until the thickness is 50 mm to 70 mm, according to the process, heat preservation at 1290 DEG C is carried out for 20 minutes, 5-gate machining is carried out, heat preservation is carried out at 1250 DEG C for 20 min, finishing rolling is carried out until the thickness is 12 mm, 3-gate machining is carried out, and water quenching is immediately carried out after the first-gate machining; (2) cold rolling is carried out on a hot rolled sheet, wherein the surface is polished and descaled to be subjected to cold rolling until the thickness is 90 microns to 100 microns; (3) deposition of an alloy film is carried out, wherein magnetron sputtering is carried out on the strip surface for deposition of a Ti-V-Cr-Zr alloy film with the thickness being 30 n, the atomic percentage composition of each element is 25%, the purity is more than 99.9%, magnetron sputtering is carried out on the surface of the film for deposition of a Cu-Ni-W alloy film, the atomic percentage composition of Ni is 35%, the atomic percentage composition of W is 1%-3%, the thickness is 10 nm to 30 nm, and the two films are both subjected to single-face deposition; and (4) heat treatment ofthe alloy film is carried out, wherein according to the heat treatment process of a composite strip, the temperature-reaching furnace-entering annealing manner is adopted, heat preservation is carriedout at 1200 DEG C for 1 min to 3 min, and pure hydrogen annealing is carried out. By means of the preparing method, a high strength layered composite base strip is obtained.

Owner:HENAN UNIV OF URBAN CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com