Nanocrystal ceramic corundum abrasive material and preparation method thereof

A technology of ceramic corundum and nanocrystals, which is applied in the field of ceramic corundum abrasives, can solve problems such as uneven grain size and low grinding performance, and achieve the effects of reducing abnormal growth, inhibiting grain growth, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

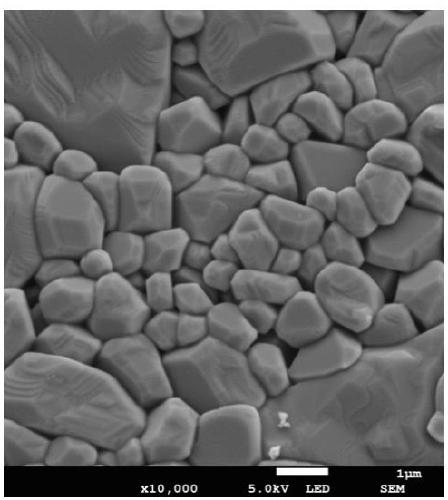

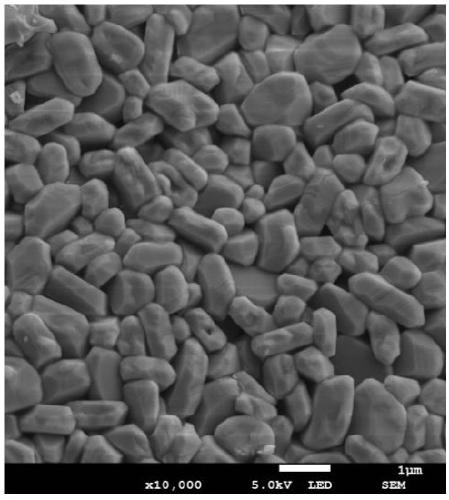

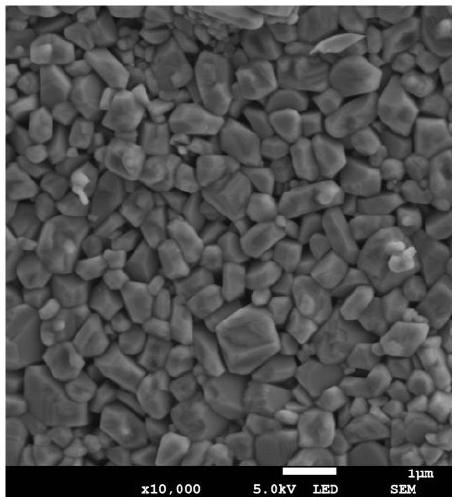

Image

Examples

Embodiment 1

[0044] First prepare Al 2 o 3 Sol crystal seed, its preparation method is: take by weighing 42g analysis grade Al (NO 3 ) 3 9H 2 Dissolve O in deionized water, add dispersant PEG1000, and make Al 3+ A solution with a concentration of 2.0mol / L; then heat 560ml of an ammonia solution with a concentration of 1.5mol / L to 85~90°C, add the above solution dropwise to the ammonia solution, stir while adding, and control the pH value at 9~10 In between, aged for 2 hours, obtained the precipitate after suction filtration, made the precipitate into a suspension with deionized water; heated the obtained suspension to 80~95°C, and added dropwise to the suspension with a concentration of 1.5mol / L of nitric acid solution 28ml, make Al 3+ / H + The ratio is 1 / 40~1 / 3, add and stir to get Al 2 o 3 Sol seed.

[0045] Carry out the preparation of ceramic corundum abrasive secondly, the preparation method of ceramic corundum abrasive is: take by weighing 55g Al 2 (SO 4 ) 3 18H 2 O, 0....

Embodiment 2

[0048] First prepare Al 2 o 3 Sol crystal seed, its preparation method is: take by weighing 42g analysis grade Al (NO 3 ) 3 9H 2 Dissolve O in deionized water, add dispersant PEG1000, and make Al 3+ A solution with a concentration of 1.5mol / L; then heat 560ml of an ammonia solution with a concentration of 1mol / L to 85~90°C, add the above solution to the ammonia solution dropwise, stir while adding, and control the pH value between 9~10 After aging for 2 hours and suction filtration, the precipitate was obtained, and the precipitate was made into a suspension with deionized water; the resulting suspension was heated to 80~95°C, and the concentration of 1mol / L was added dropwise to the suspension. 28ml of nitric acid solution to make Al 3+ / H + The ratio is 1 / 40~1 / 3, add and stir to get Al 2 o 3 Sol seed.

[0049] Carry out the preparation of ceramic corundum abrasive secondly, the preparation method of ceramic corundum abrasive is: take by weighing 55g Al 2 (SO 4 ) ...

Embodiment 3

[0052] Weigh 55g Al 2 (SO 4 ) 3 18H 2 O, 0.55g PEG1000 dissolved in deionized water, dubbed Al 3+ A solution with a concentration of 0.70mol / L. Slowly add 1.0mol / L ammonia solution dropwise to the above solution, and add the ammonia solution in 4 times, and the amount of the first addition should ensure that the NH 4+ / Al 3+ =1.0~2.5, the addition amount of the remaining 3 times guarantees NH 4+ / Al 3+ =0.005~0.015, stirring while adding dropwise, keeping the pH value at 9.4, stirring for 3 hours, aging for 2 hours, to obtain a uniform and transparent gel, which was obtained by suction filtration and washing 3 times to obtain Al(OH) 3 Gel precursor. Add 5.5wt% (3.025g) liquid composite sintering aid to the above precursor, the composition and mass percentage of the added liquid composite sintering aid are: 34.5% Si(OC 2 h 5 ) 4 , 50.5% Mg(NO 3 ) 2 ·6H 2 O, 14.0% Ca(NO 3 ) 2 4H 2 O, 1.0% H 3 BO 3 , then add Al 2 o 3 Sol Seed, Al 2 o 3 The content of sol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com