A kind of nanocrystalline ceramic corundum abrasive and preparation method thereof

A technology of ceramic corundum and nanocrystals, applied in the field of ceramic corundum abrasives, can solve problems such as low grinding performance and uneven grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

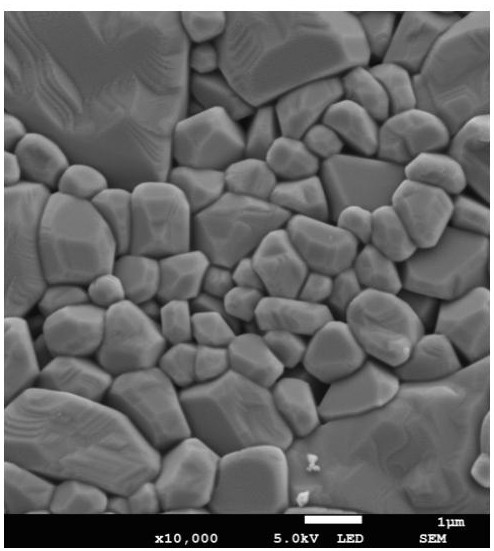

Image

Examples

Embodiment 1

[0044] First prepare Al 2 o 3 Sol crystal seed, its preparation method is: take by weighing 42g analysis grade Al (NO 3 ) 3 9H 2 Dissolve O in deionized water, add dispersant PEG1000, and make Al 3+ A solution with a concentration of 2.0mol / L; then heat 560ml of an ammonia solution with a concentration of 1.5mol / L to 85~90°C, add the above solution dropwise to the ammonia solution, stir while adding, and control the pH value at 9~10 In between, aged for 2 hours, obtained the precipitate after suction filtration, made the precipitate into a suspension with deionized water; heated the obtained suspension to 80~95°C, and added dropwise to the suspension with a concentration of 1.5mol / L of nitric acid solution 28ml, make Al 3+ / H + The ratio is 1 / 40~1 / 3, add and stir to get Al 2 o 3 Sol seed.

[0045] Carry out the preparation of ceramic corundum abrasive secondly, the preparation method of ceramic corundum abrasive is: take by weighing 55g Al 2 (SO 4 ) 3 18H 2 O, 0....

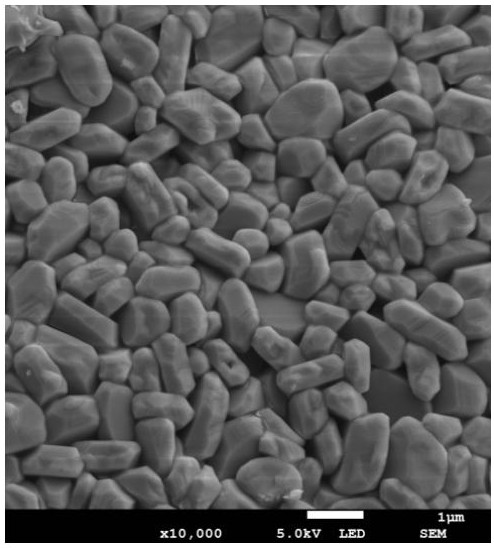

Embodiment 2

[0048] First prepare Al 2 o 3 Sol crystal seed, its preparation method is: take by weighing 42g analysis grade Al (NO 3 ) 3 9H 2 Dissolve O in deionized water, add dispersant PEG1000, and make Al 3+ A solution with a concentration of 1.5mol / L; then heat 560ml of an ammonia solution with a concentration of 1mol / L to 85~90°C, add the above solution to the ammonia solution dropwise, stir while adding, and control the pH value between 9~10 After aging for 2 hours and suction filtration, the precipitate was obtained, and the precipitate was made into a suspension with deionized water; the resulting suspension was heated to 80~95°C, and the concentration of 1mol / L was added dropwise to the suspension. 28ml of nitric acid solution to make Al 3+ / H + The ratio is 1 / 40~1 / 3, add and stir to get Al 2 o 3 Sol seed.

[0049] Carry out the preparation of ceramic corundum abrasive secondly, the preparation method of ceramic corundum abrasive is: take by weighing 55g Al 2 (SO 4 ) ...

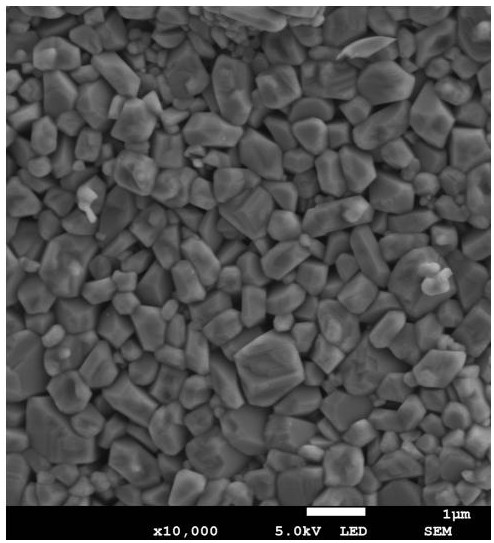

Embodiment 3

[0052] Weigh 55g Al 2 (SO 4 ) 3 18H 2 O, 0.55g PEG1000 dissolved in deionized water, dubbed Al 3+ A solution with a concentration of 0.70mol / L. Slowly add 1.0mol / L ammonia solution dropwise to the above solution, and add the ammonia solution in 4 times, and the amount of the first addition should ensure that the NH 4+ / Al 3+ =1.0~2.5, the addition amount of the remaining 3 times guarantees NH 4+ / Al 3+ =0.005~0.015, stirring while adding dropwise, keeping the pH value at 9.4, stirring for 3 hours, aging for 2 hours, to obtain a uniform and transparent gel, which was obtained by suction filtration and washing 3 times to obtain Al(OH) 3 Gel precursor. Add 5.5wt% (3.025g) liquid composite sintering aid to the above precursor, the composition and mass percentage of the added liquid composite sintering aid are: 34.5% Si(OC 2 h 5 ) 4 , 50.5% Mg(NO 3 ) 2 ·6H 2 O, 14.0% Ca(NO 3 ) 2 4H 2 O, 1.0% H 3 BO 3 , then add Al 2 o 3 Sol Seed, Al 2 o 3 The content of sol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com