Wire arc additive manufacturing method, device and equipment for continuous growth of curved surface metal structure and computer storage medium

A metal structure and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems that one-time printing is difficult to achieve, affect the structure and performance of the workpiece, and the surface roughness of the workpiece is high, so as to shorten the development cycle, improve efficiency, and process technical procedures. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

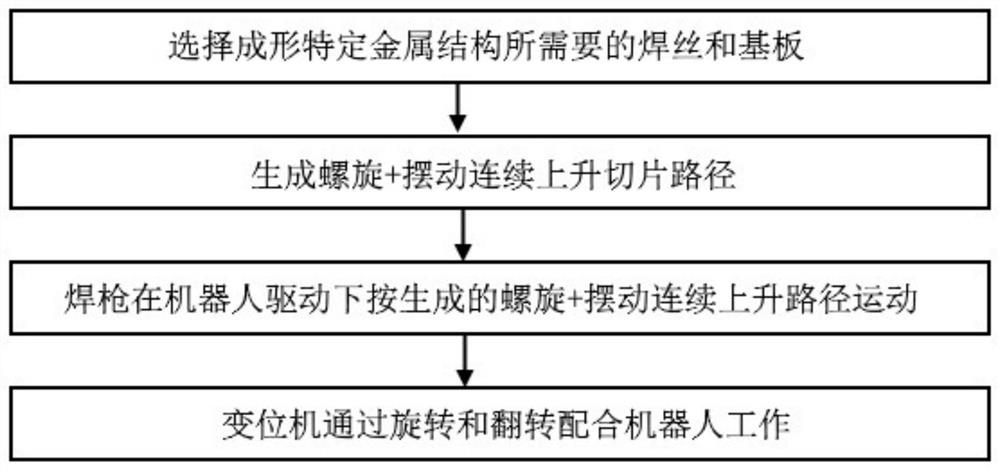

[0070] This embodiment proposes an arc additive manufacturing method for continuous growth of curved metal structures, the steps are as follows:

[0071] Step 1. Select the welding wire and substrate required to form a specific metal structure;

[0072] The process of selecting the wire and base plate required to form a particular metal structure is further:

[0073] Step 1-1. Determine the process parameters required to form a specific metal structure, including welding procedures, wire feeding speed, printing speed, slice layer height, type of shielding gas and flow rate. The relationship between each parameter is as follows:

[0074] V×F=v×f

[0075] In the formula, V represents the welding speed, F represents the cross-sectional area of the weld, v represents the wire feeding speed, and f represents the cross-sectional area of the welding wire; step 1-2, the weld cross-section of the workpiece is equivalent to a rectangle, and the following relationship is satisfied a...

Embodiment 2

[0089] On the basis of Embodiment 1, the process of generating the spiral + swing continuous ascending slice path is as follows: perform slice processing on the model of the workpiece to be printed, take any direction perpendicular to its rotary axis as the normal direction, and establish a tangent plane passing through the rotary axis . Rotate the tangent plane around the rotary axis, set the rotation angle θ each time, and intersect the tangent plane with the workpiece to obtain the slice profile of the model. When the cutting plane is rotated 360° around the rotation axis, all slice contour data of the model are obtained. Divide the extracted surface profile into several small straight line segments, and use cylinder fitting method to extract the central axis for each segmented area. Find the central axis of the slice contour data, divide the obtained surface contour data into small areas, perform least square cylindrical surface fitting on the next small area, and use the...

Embodiment 3

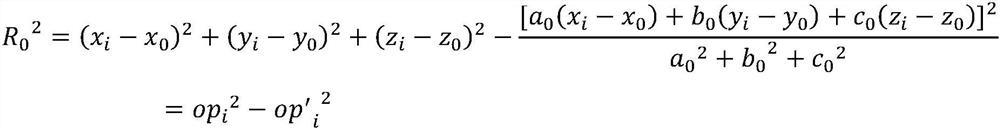

[0091] Ideally, the distances from the surface points to the axis of rotation should be equal in the small area of the surface contour, but in fact there is a small deviation (d 1 ≠ d 2 ≠ d 3 ≠ d 4 ), so the position of the central axis in the straight line segment is adjusted to meet the minimum distance deviation from each point in the small area of the surface contour to the central axis.

[0092] The cylindrical surface can be considered as a collection of points at a certain distance R from the central axis, which can be represented by 7 parameters, which are the central axis positioning point O(x 0 ,y 0 ,z 0 ), the central axis direction vector n 0 (a 0 ,b 0 ,c 0 ) and cylinder radius R; define the measuring point as p i (x i ,y i ,z i ), p′ i for p i Projection on the central axis, the connection line between the projection of the measuring point to the central axis and the measuring point is R 0 , the cylindrical surface expression is:

[0093]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com