Normal-temperature plastic deformation-rapid solidification magnesium alloy anode material as well as preparation method and application thereof

A technology of plastic deformation and anode materials, which is applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, structural parts, etc., and can solve the problems of poor stability of the discharge platform, difficulty in shedding of corrosion products, and low discharge voltage. and other problems, to achieve the effect of removing stress, improving comprehensive electrochemical performance and reducing alloy defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a magnesium alloy anode material, the preparation method of which is as follows.

[0042] 1. The composition of the cerium of the present embodiment, yttrium modified AP65 magnesium alloy is 6.1wt.% Al, 5.1wt.% Pb, 0.13wt.% Ce, 0.13wt.% Y, 88.54wt.% Mg. Among them, magnesium and aluminum are pure metals with a purity of 99.99wt.%, and cerium and yttrium are added in the form of magnesium-rare earth master alloy.

[0043] 2. Put the magnesium, aluminum, lead, magnesium-cerium and magnesium-yttrium intermediate alloys into the high-purity graphite crucible at one time, pump the air pressure in the furnace to 1.5Pa and then fill it with argon until the air pressure reaches 0.05MPa, Then the fully stirred melt is cast in a stainless steel crucible in the furnace to obtain a cast AP65 magnesium alloy ingot with a size of 400mm×200mm×(30-50)mm.

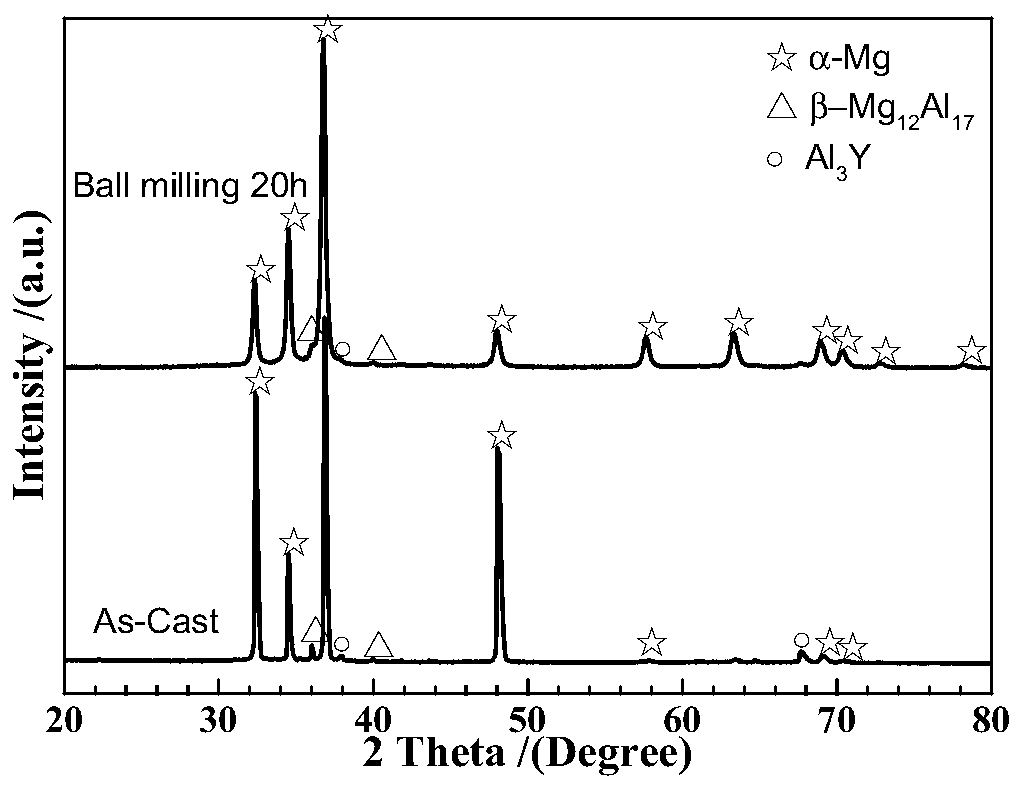

[0044] 3. Place the as-cast AP65 magnesium alloy ingot in a glove box filled with high-purity argon, use...

Embodiment 2

[0051] This embodiment provides a magnesium alloy anode material, the preparation method of which is as follows.

[0052] 1. The composition of the cerium of the present embodiment, yttrium modified AP65 magnesium alloy is 6.1wt.% Al, 5.1wt.% Pb, 0.13wt.% Ce, 0.13wt.% Y, 88.54wt.% Mg. Among them, magnesium and aluminum are pure metals with a purity of 99.99wt.%, and cerium and yttrium are added in the form of magnesium-rare earth master alloy.

[0053] 2. Put the magnesium, aluminum, lead, magnesium-cerium and magnesium-yttrium intermediate alloys into the high-purity graphite crucible at one time, pump the air pressure in the furnace to 1.5Pa and then fill it with argon until the air pressure reaches 0.05MPa, Then the fully stirred melt is cast in a stainless steel crucible in the furnace to obtain a cast AP65 magnesium alloy ingot with a size of 400mm×200mm×(30-50)mm.

[0054] 3. Place the as-cast AP65 magnesium alloy ingot in a glove box filled with high-purity argon, use...

Embodiment 3

[0061] This embodiment provides a magnesium alloy anode material, the preparation method of which is as follows.

[0062] 1. The composition of the cerium of the present embodiment, yttrium modified AP65 magnesium alloy is 6.2wt.% Al, 4.8wt.% Pb, 0.05wt.% Ce, 0.15wt.% Y, 88.8wt.% Mg. Among them, magnesium and aluminum are pure metals with a purity of 99.99wt.%, and cerium and yttrium are added in the form of magnesium-rare earth master alloy.

[0063] 2. Put the magnesium, aluminum, lead, magnesium-cerium and magnesium-yttrium intermediate alloys into the high-purity graphite crucible at one time, pump the air pressure in the furnace to 1.5Pa and then fill it with argon until the air pressure reaches 0.05MPa, Then the fully stirred melt is cast in a stainless steel crucible in the furnace to obtain a cast AP65 magnesium alloy ingot with a size of 400mm×200mm×(30-50)mm.

[0064] 3. Place the as-cast AP65 magnesium alloy ingot in a glove box filled with high-purity argon, use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com