Patents

Literature

152results about How to "Promote exfoliation" patented technology

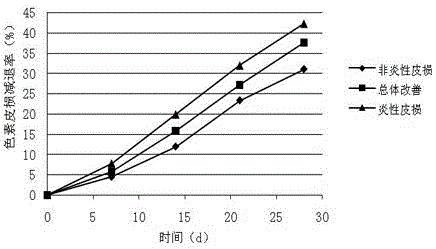

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

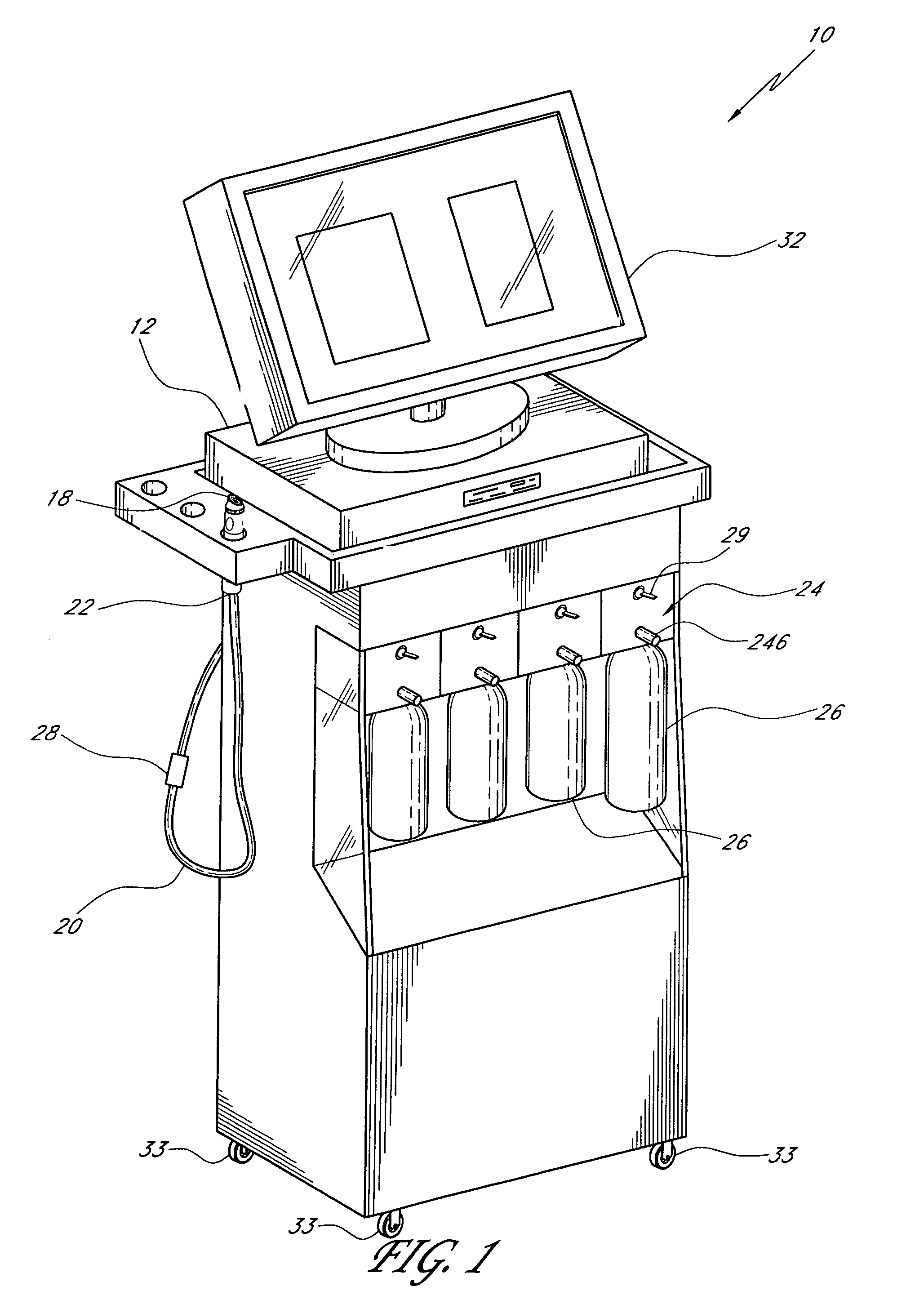

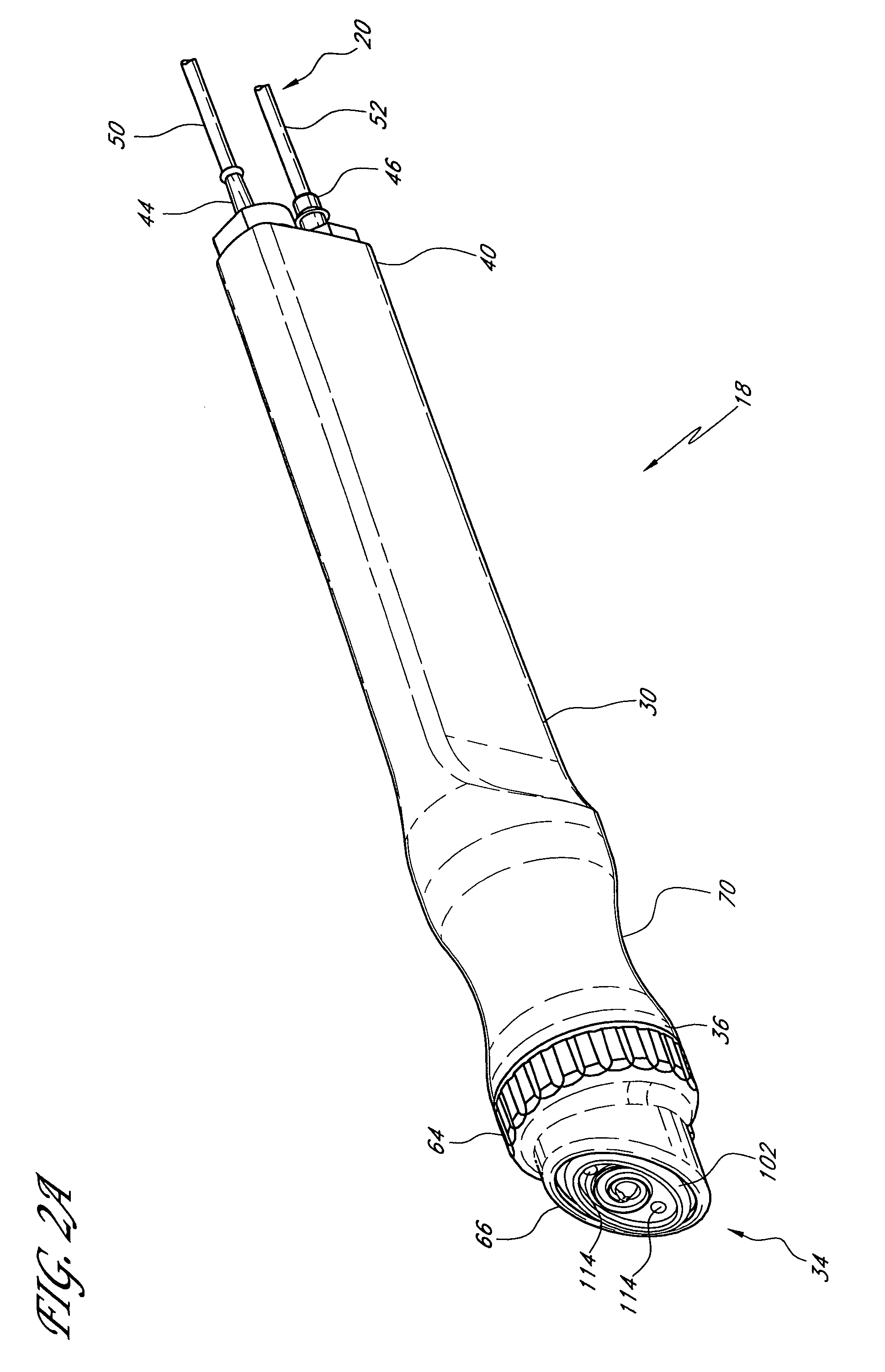

Apparatus and methods for treating the skin

ActiveUS20070156124A1Promote exfoliationIncrease chanceSurgical furnitureDiagnosticsUser inputEngineering

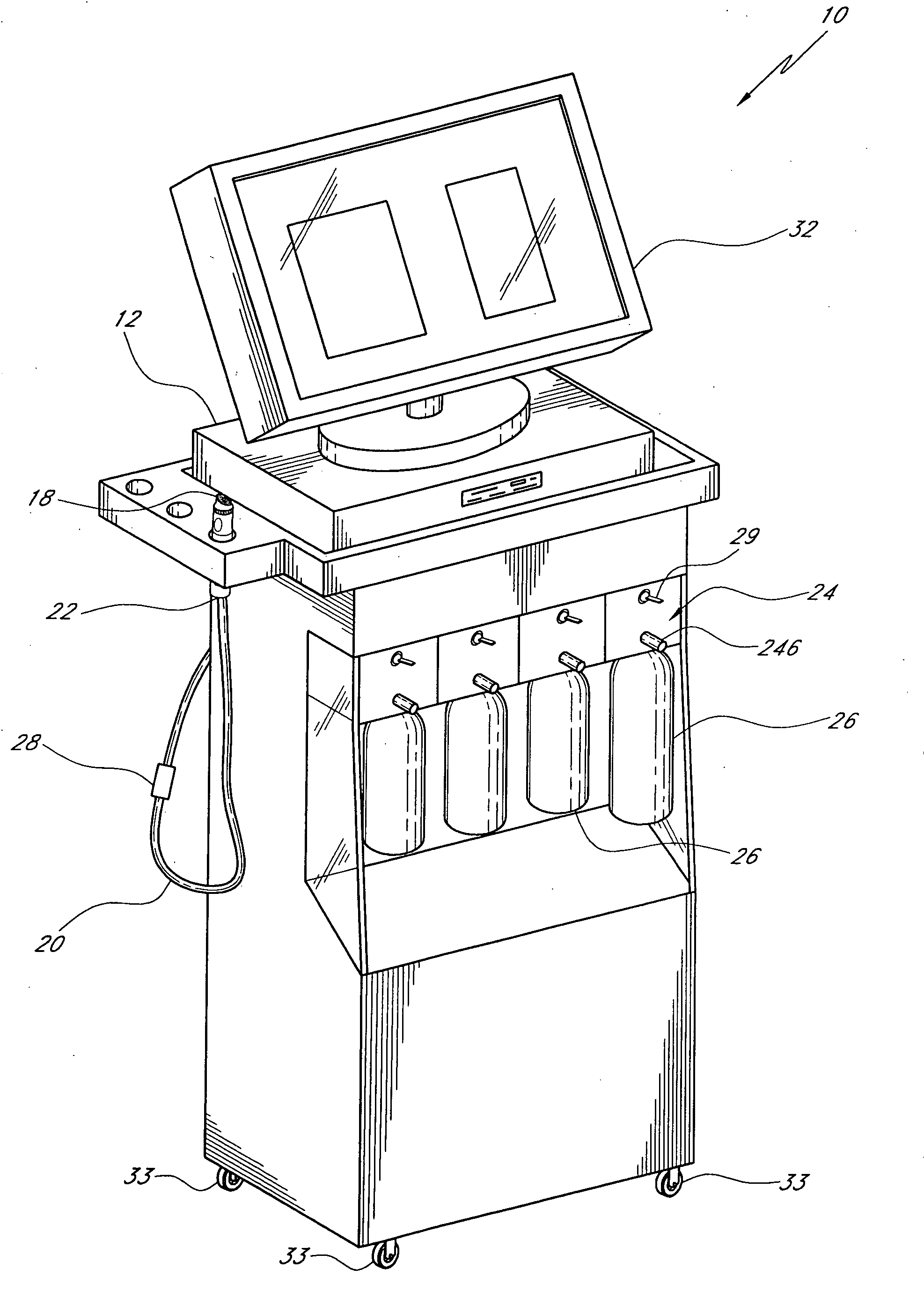

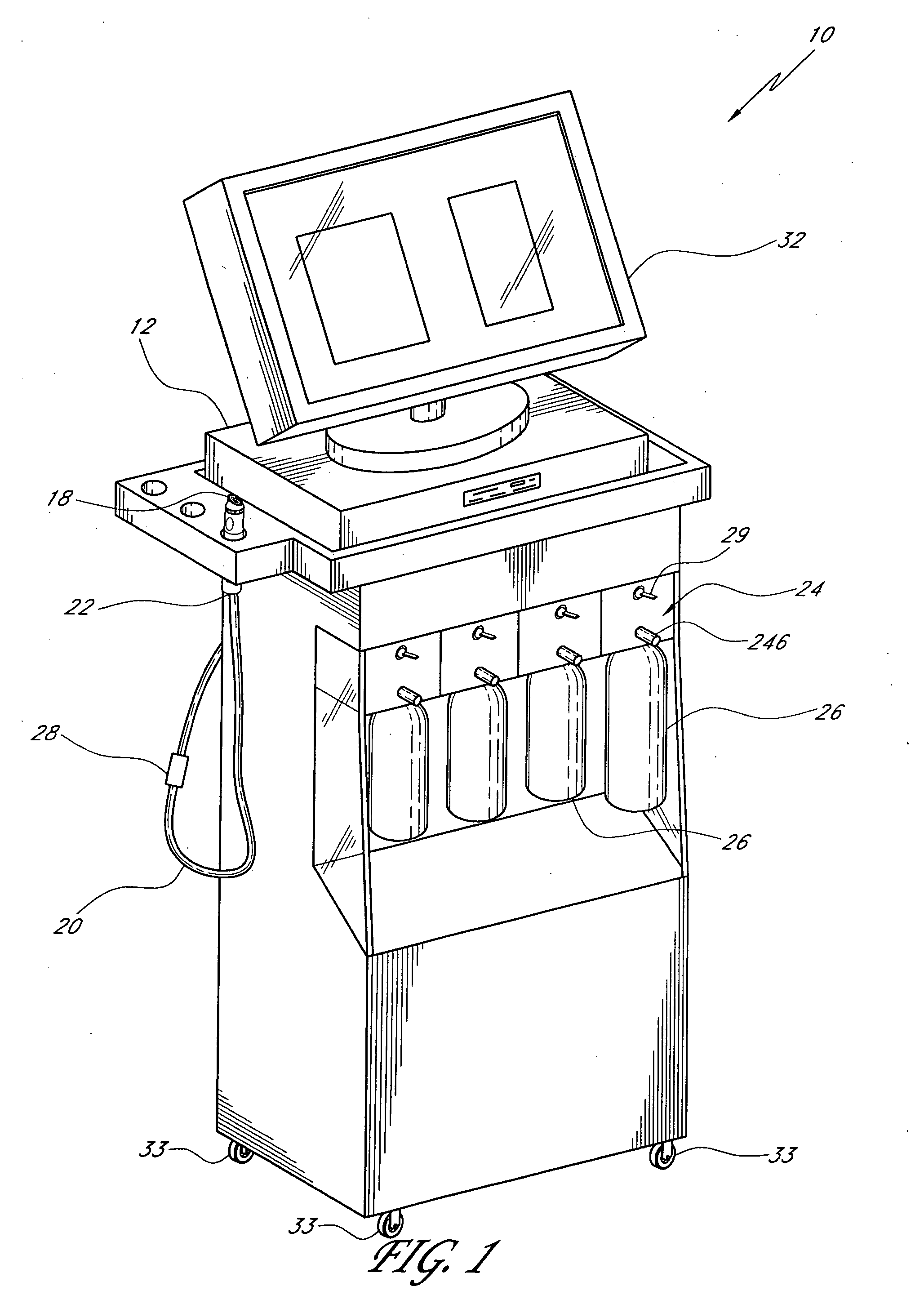

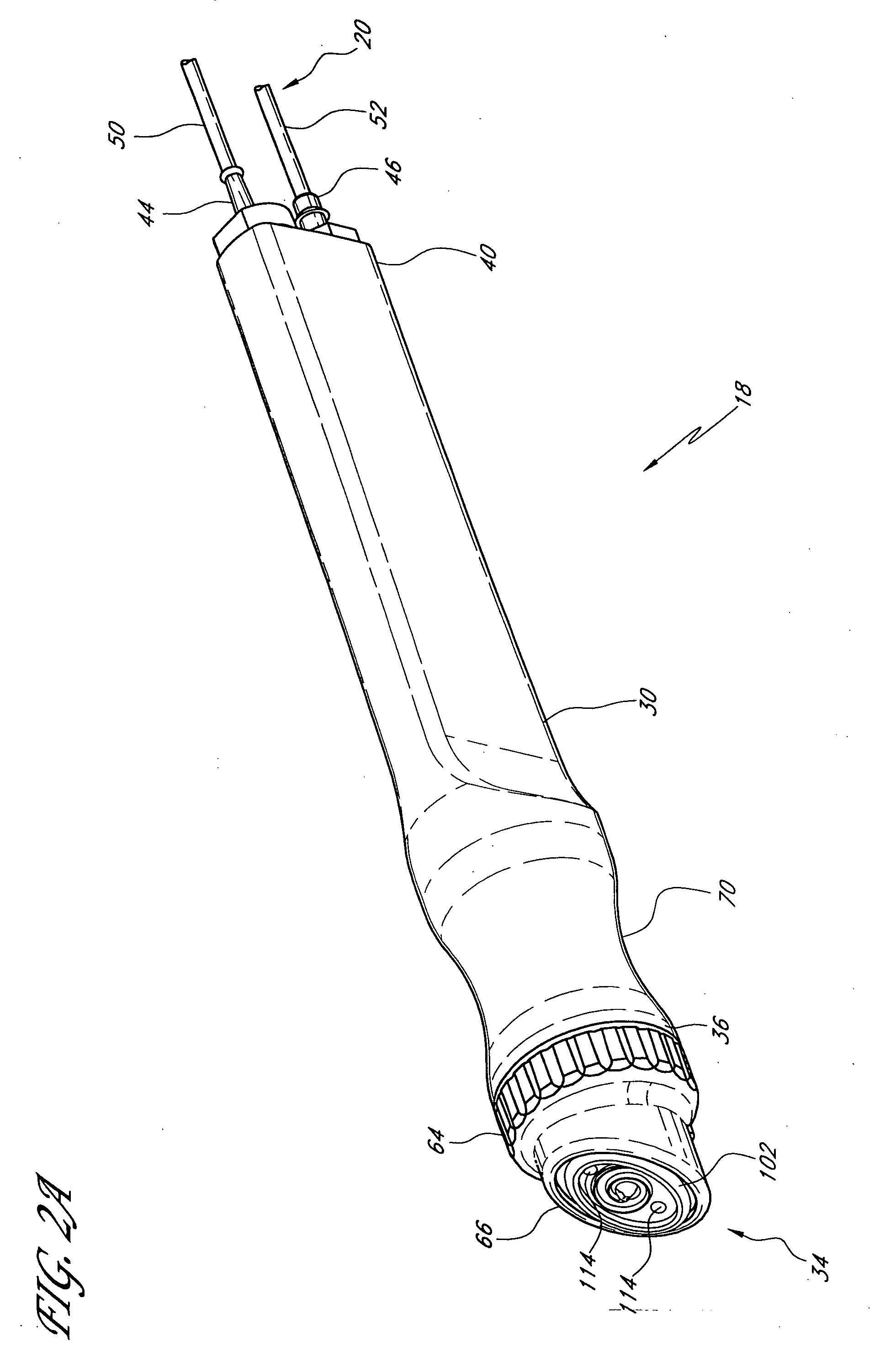

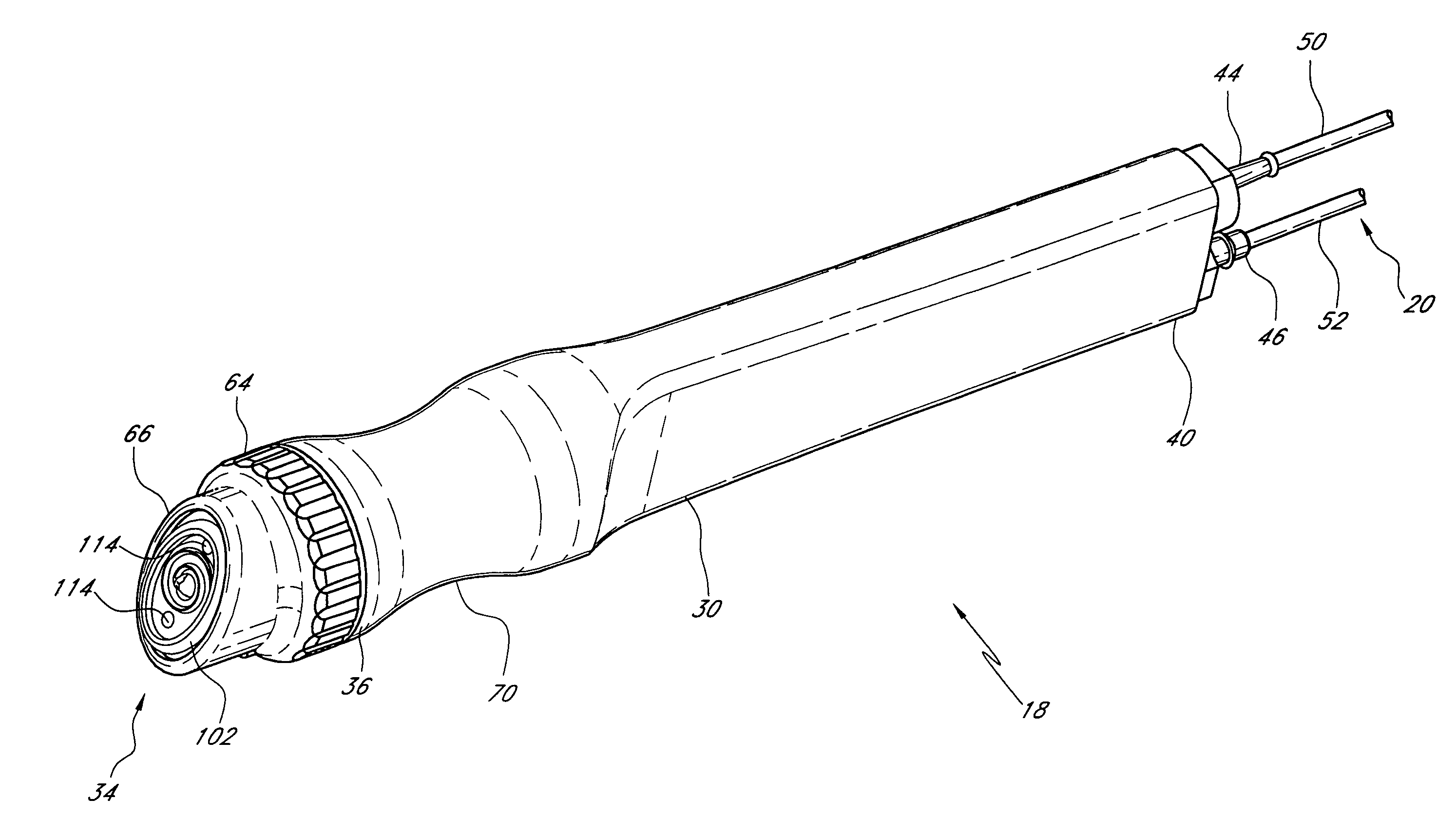

An apparatus for treating skin has a console with a user input device and a handpiece assembly. The handpiece assembly is configured to treat skin. A fluid line provides fluid communication between the console and the handpiece assembly. A manifold system is coupled to the console and controlled by the user input device. The manifold system is configured to hold releasably a plurality of fluid sources and deliver fluid from at least one of the plurality of fluid sources to the handpiece assembly.

Owner:HYDRAFACIAL LLC

Apparatus and methods for treating the skin

ActiveUS8048089B2Promote exfoliationIncrease chanceSurgical furnitureDiagnosticsUser inputBiomedical engineering

An apparatus for treating skin has a console with a user input device and a handpiece assembly. The handpiece assembly is configured to treat skin. A fluid line provides fluid communication between the console and the handpiece assembly. A manifold system is coupled to the console and controlled by the user input device. The manifold system is configured to hold releasably a plurality of fluid sources and deliver fluid from at least one of the plurality of fluid sources to the handpiece assembly.

Owner:HYDRAFACIAL LLC

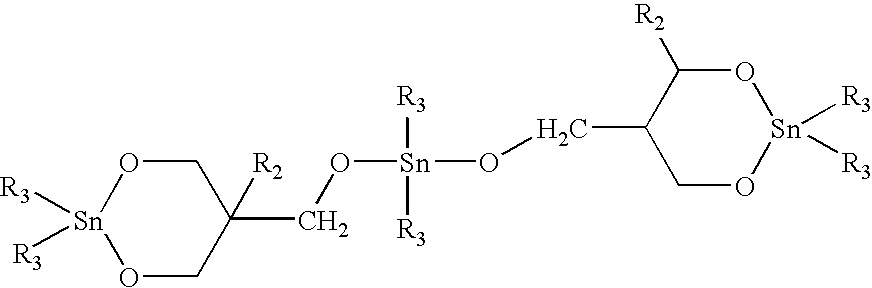

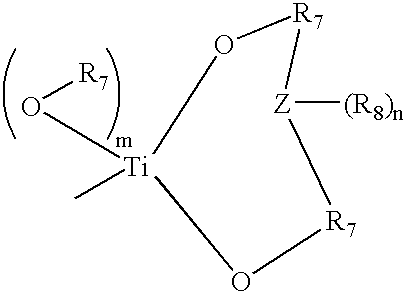

Polymerizable macrocyclic oligomer masterbatches containing dispersed fillers

Composites of macrocyclic oligomers and a filler material are made in a masterbatch process. The masterbatch contains at least 15% by weight of the filler material. The filler material is preferably a submicron sized material and is especially a clay or other layered material that can become at least partially exfoliated. The masterbatch can be let down into more of the macrocyclic oligomer, another polymer, another polymerizable material and subjected to polymerization conditions to form a nanocomposite material. Alternatively, the masterbatch can be polymerized to a high or intermediate molecular weight, and then blended with additional oligomer, polymer or other polymerizable material.

Owner:PAQUETTE MICHAEL STEVEN +5

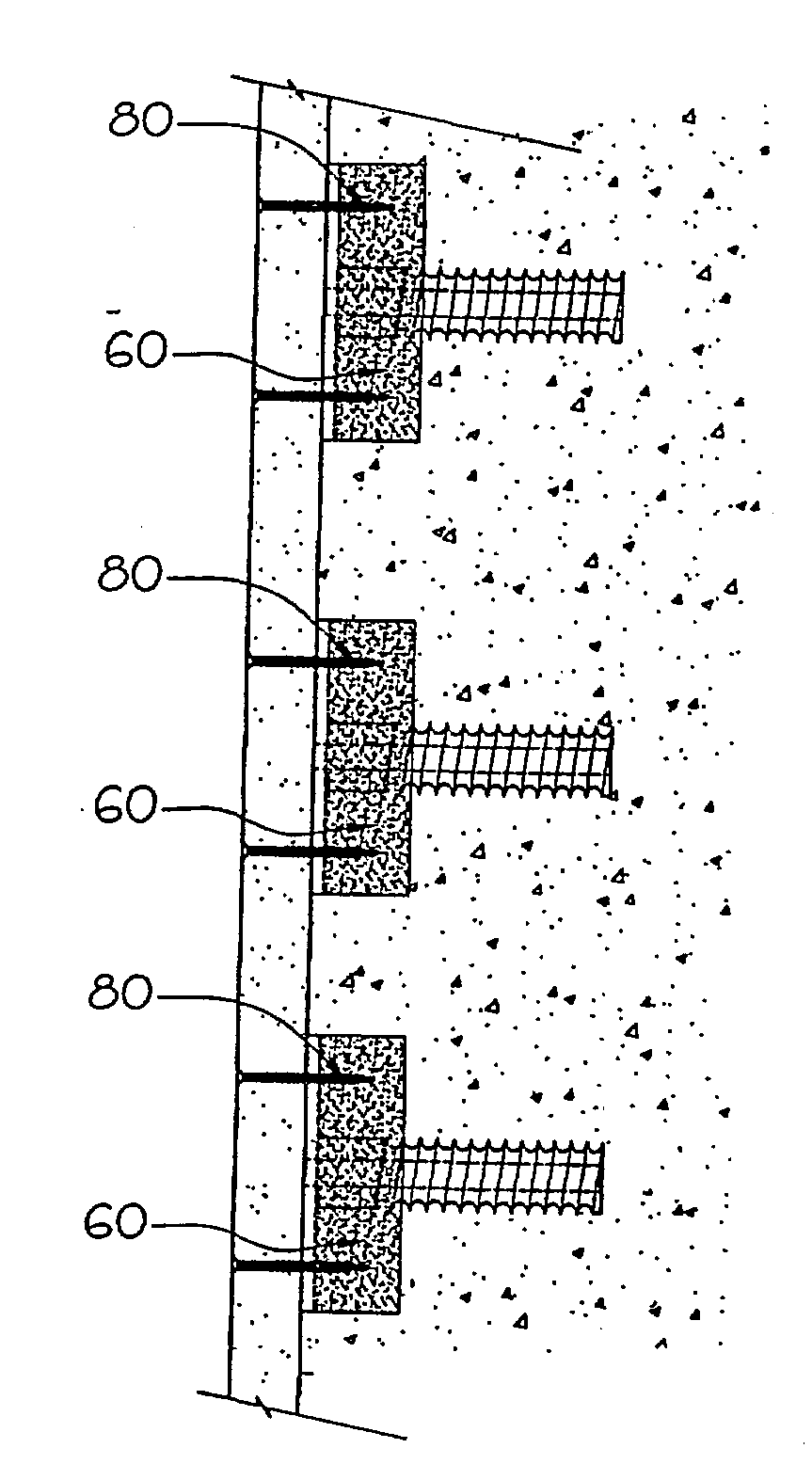

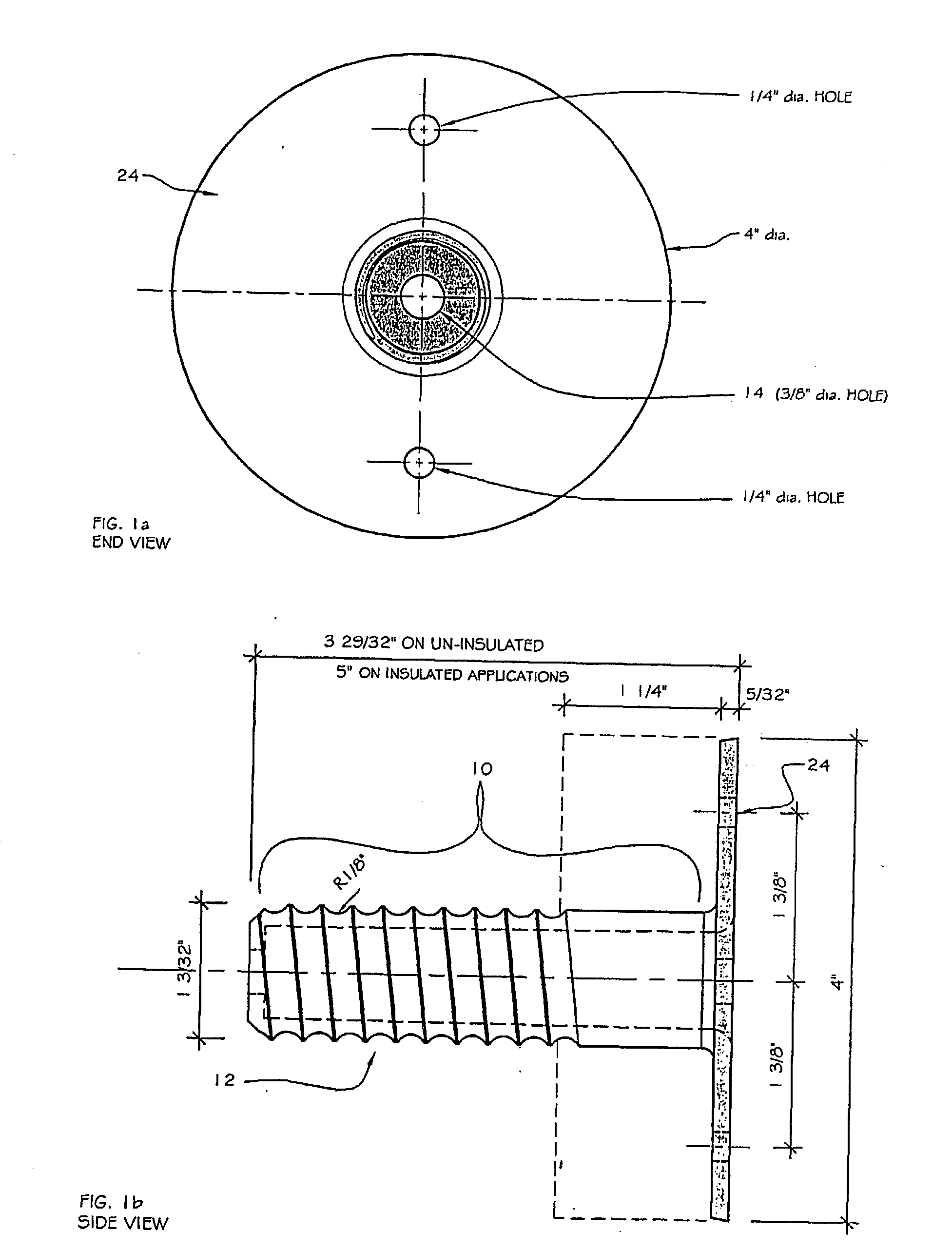

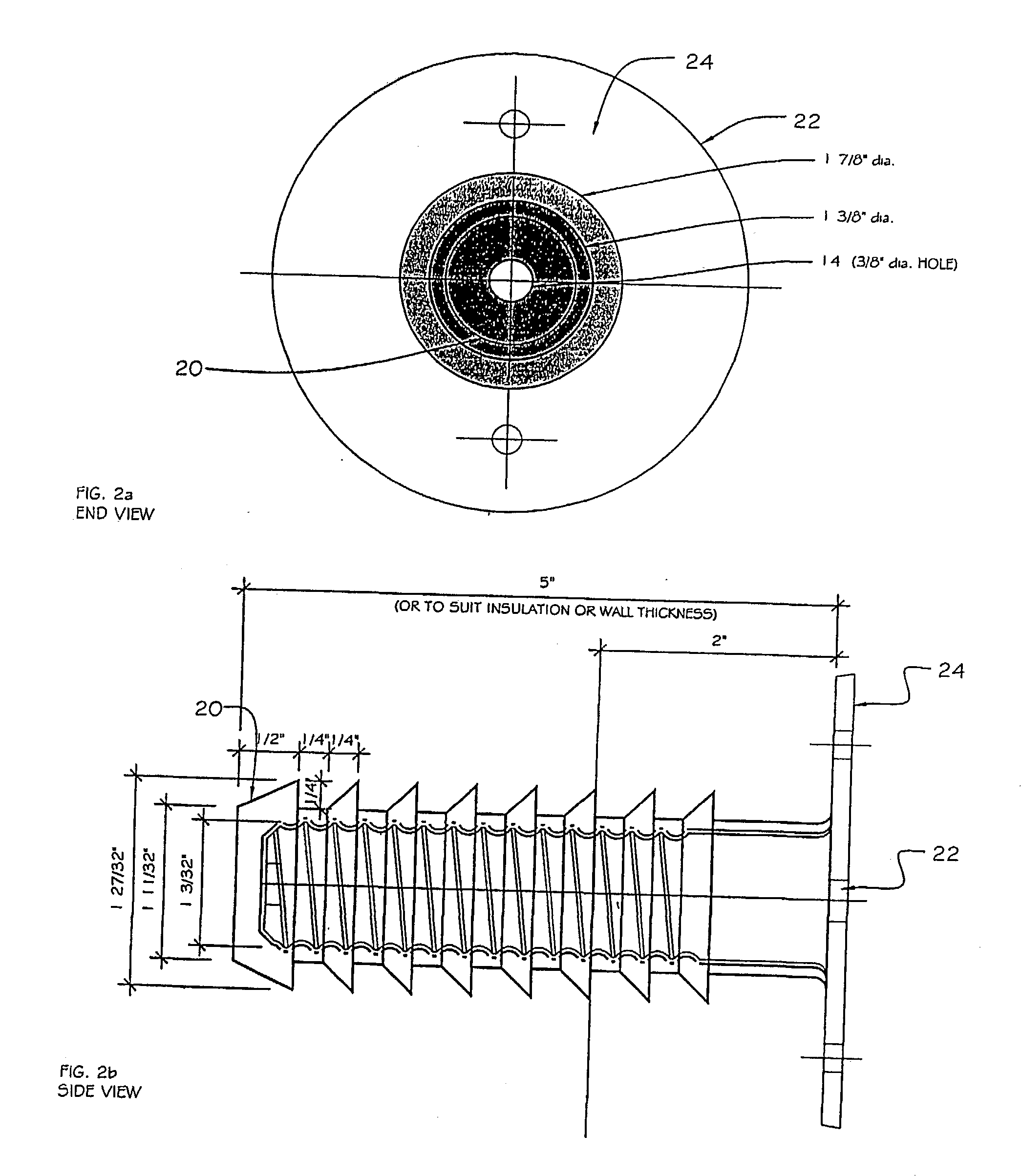

Fastening device with adjustable fastening surface embedded in cast panel or other products

A component (20, 22) and method for a casting process, typically for cold-process casting of concrete wall, floor, ceiling or other panels or element in situ in building construction, leaving embedded in the cast panel a fastening surface (24) which can be adjustable to allow correction of non-uniform cast surfaces. The component may be integrated to conventional form-tie systems which use ties to space removable / reusable forms, holding forms a set distance apart, and can also hold a barrier material (typically expanded foam insulation) against the inner surface of a form(s) while casting is underway; when the forms are removed, leaving a component embedded providing an adjustable surface suitable for attaching material such finishing sheet material. The component can allow adjustment of its mounting surface with respect to the cast surface and to other like components in the cast panel to provide for (substantially) uniform surface for mounting finishing materials and / or fixtures.

Owner:JANEWAY DAVID

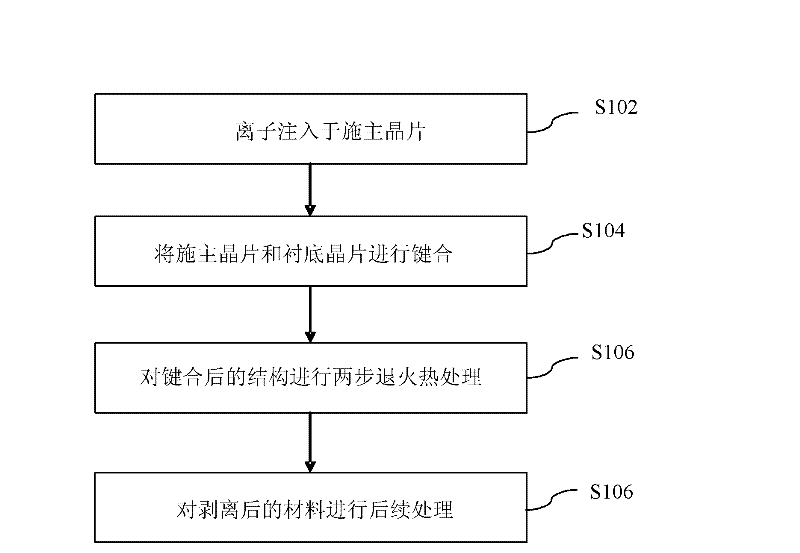

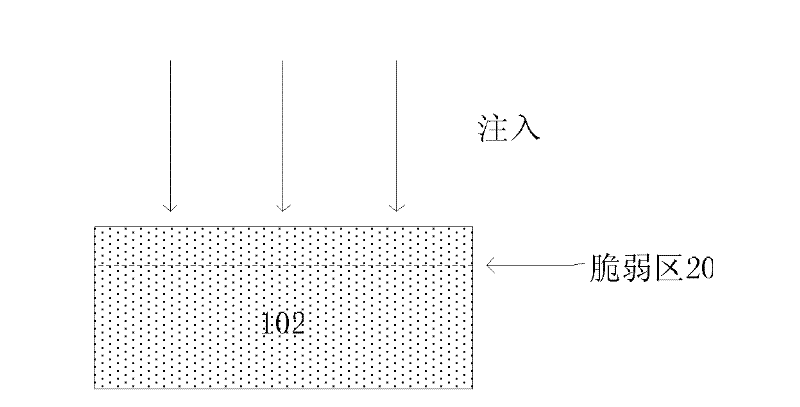

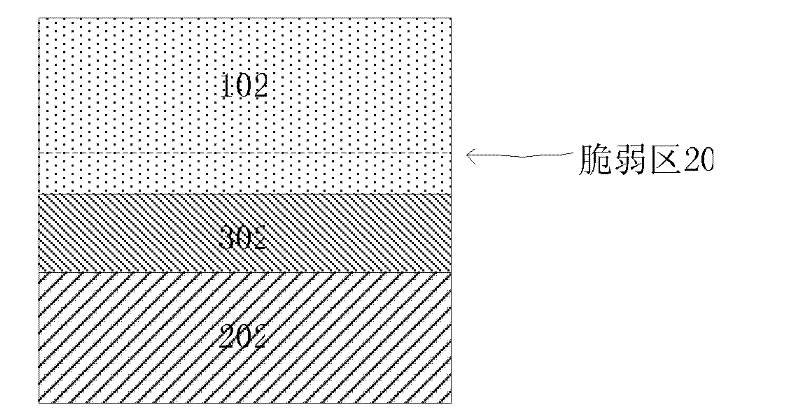

Method for forming composite functional material structure

InactiveCN102347219APromote exfoliationQuality improvementSemiconductor/solid-state device manufacturingSurface layerHigh energy

The invention discloses a method for forming a composite functional material structure. The method comprises the steps of: A. injecting high energy ions in a donor wafer surface layer, and forming a fragile zone at the projecting gunshot of ion injection, wherein the energy of the ion injection ranges from 60 KeV to 500 KeV; B. bonding a donor wafer with an underlay wafer, and forming a composite structure comprising the donor wafer and the underlay wafer; and C. annealing the composite structure formed by bonding, peeling off the donor wafer in the fragile zone, attaching the donor wafer thin-layer structure to the surface of the underlay wafer, and forming the composite functional material structure. A better transfer thin layer can also be obtained even in the presence of a small number of bonding defects by employing high energy ion injection, controlling the position of the projecting gunshot in a farther distance away from the surface and utilizing the peeling of the wafer surface layer, so that the quality and the performance of the transfer layer and the peeling efficiency are increased.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

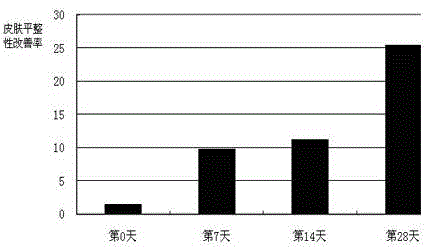

Beautifying and nursing essence and preparation method thereof

InactiveCN103908424AAvoid allergic reactionsNo side effectsCosmetic preparationsToilet preparationsCuticleUmbilical cord tissue

The invention discloses a beautifying and nursing essence and a preparation method thereof. The essence is prepared from an epidermis cell nutrient solution and contains a plurality of cell growth factors, amino acids and vitamins. The essence mainly comprises an epidermal growth factor, a fibroblast growth factor, collagen type I, a stem cell growth factor, a horn cell growth factor and amino acids and vitamins including gamma-aminobutyric acid, coenzyme Q, medical vitamin C, medical vitamin B5 and medical vitamin E. The preparation method for the essence comprises the following steps: acquisition of epidermis of umbilical cord tissue of a newborn; cell culture; collection of a cell nutrient solution; filtration sterilization; condensation of a volume; addition of active components; addition of glycerin and hyaluronic acid; etc. The beautifying and nursing essence provides a plurality of endogenous nutritional ingredients with physiological activity for the skin, can promote metabolism of epidermis cells and repair damaged cells, has a moisture retention effect and is applicable to skin beautifying and nursing.

Owner:奥思达干细胞有限公司

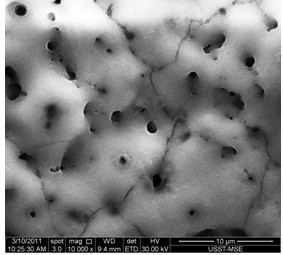

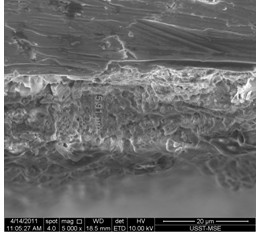

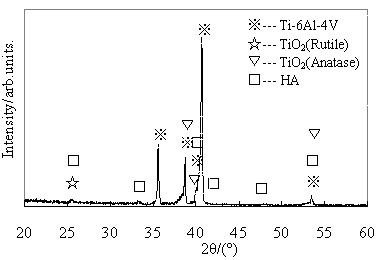

Titanium dioxide-hydroxyapatite gradient coating of medical titanium or titanium alloy surface and preparation method

InactiveCN102330086AImprove the problem of coating peelingPromote exfoliationSuperimposed coating processProsthesisMicro arc oxidationHydroxyapatite coating

The invention discloses a titanium dioxide-hydroxyapatite gradient coating of a medical titanium or titanium alloy surface and a preparation method. The inner layer of the titanium dioxide-hydroxyapatite gradient coating is a composite layer of the titanium dioxide and the hydroxyapatite while the outer layer of the titanium dioxide-hydroxyapatite gradient coating is a hydroxyapatite coating. The preparation method comprises the following steps of: using titanium or titanium alloy as anode and metal stainless steel as cathode; carrying out microarc oxidation on the titanium or titanium alloy by using a direct current pulse power supply; after forming a porous structure containing titanium dioxide and amorphous calcium and phosphorus on the surface of the titanium or titanium alloy, coating the hydroxyapatite on the surface; and finally obtaining the titanium dioxide-hydroxyapatite gradient coating. The porous structure formed after the microarc oxidation is beneficial for improving the bonding strength of a titanium or titanium alloy substrate and the costing; the titanium dioxide layer formed by the microarc oxidation has a transitional effect on the performance so that the residual stress between the substrate and a hydroxyapatite bioactive coating can be reduced. The preparation method has the advantages of simplicity and convenience in operation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

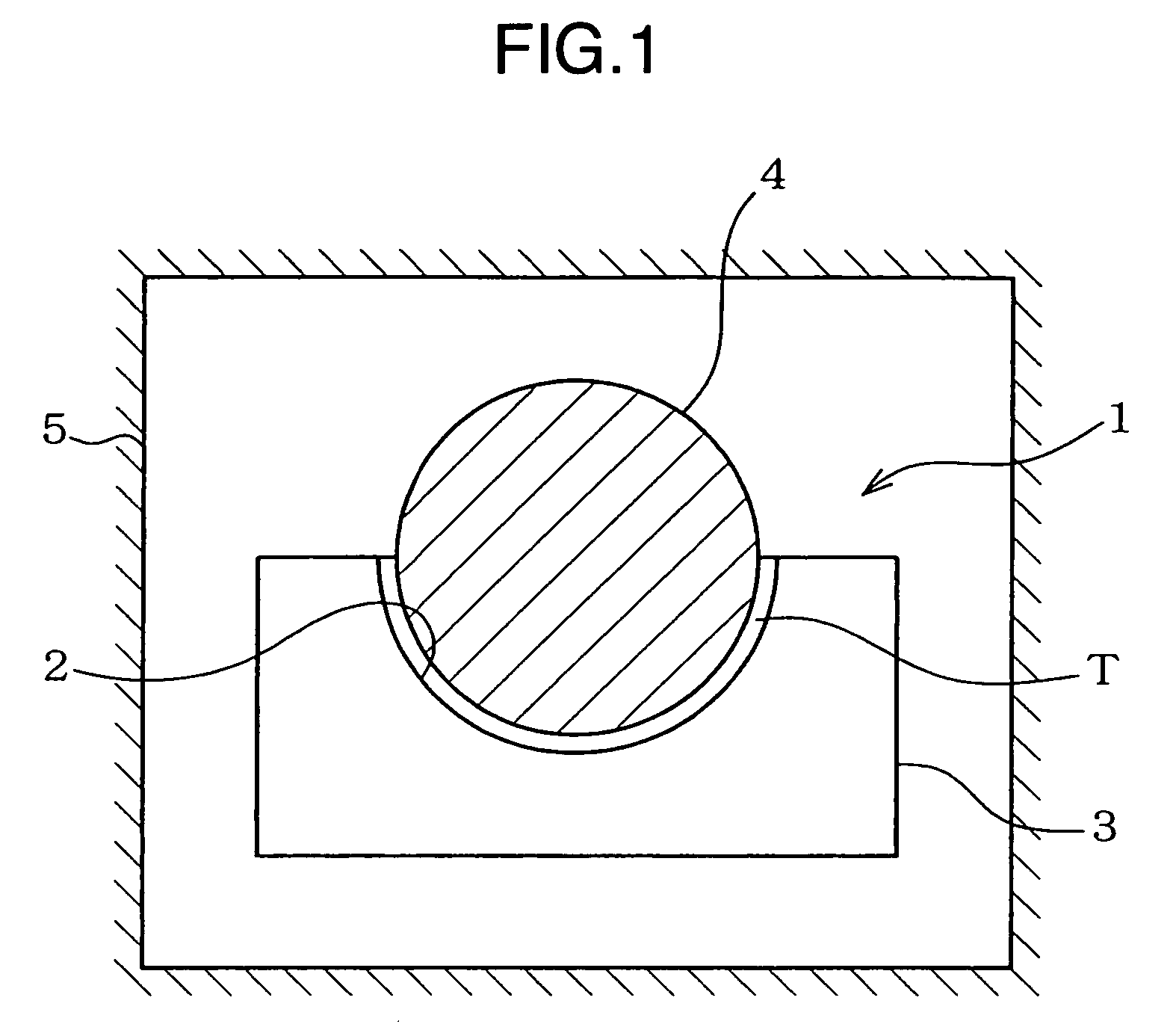

Plain bearing

InactiveUS20070082825A1Improve cavitation resistanceHigh bonding strengthShaftsBearing componentsResin coatingPlain bearing

Disclosed is a plain bearing having a back metal layer and a bearing alloy layer of an Al alloy. The bearing alloy layer is formed on the back metal layer. The Al alloy contains not more than 2 mass % Sn. There is provided a resin-coating layer on the bearing alloy layer. The resin-coating layer consists of a solid lubricant and a resin binder.

Owner:DAIDO METAL CO LTD

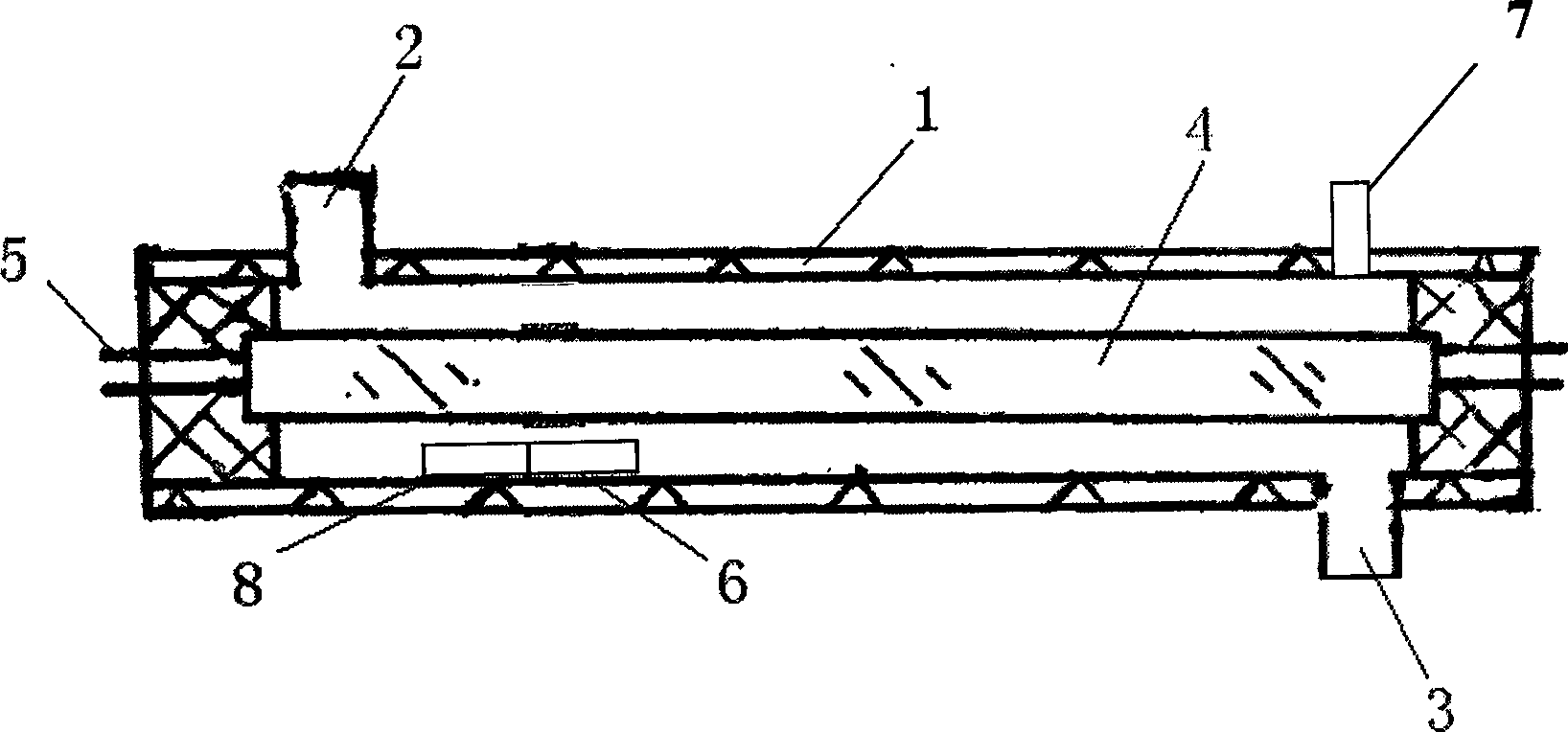

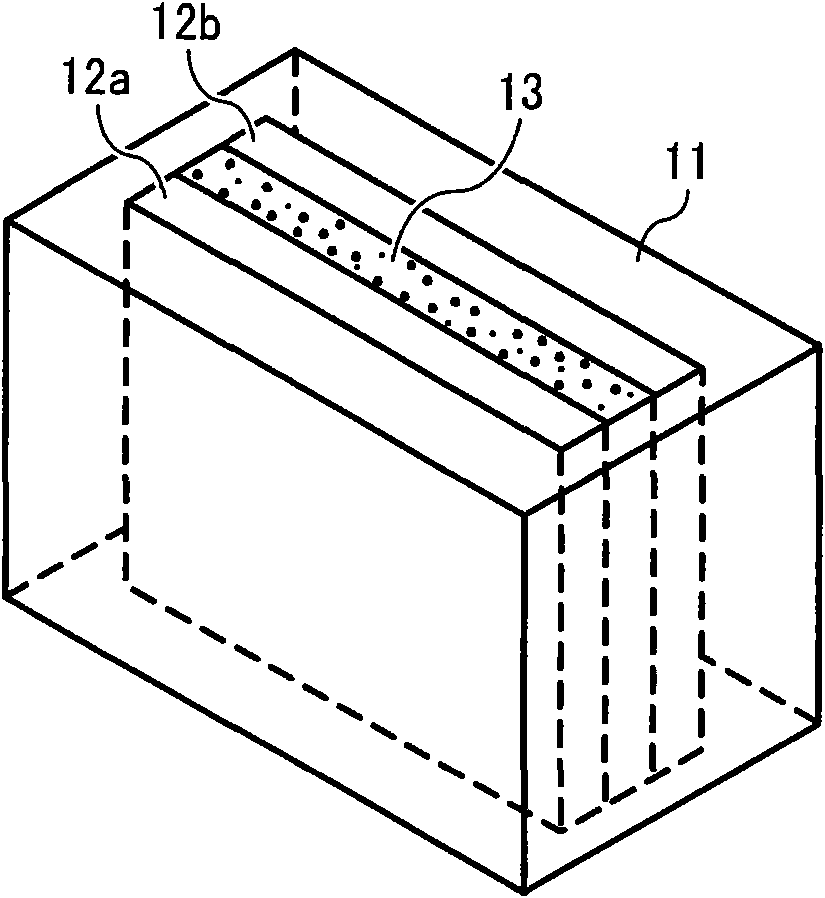

Sterilizing unit of ultraviolet radiation for water body cleaned by ultrasonic

InactiveCN1872710AImprove the bactericidal effectGood removal effectWater/sewage treatment by irradiationCleaning using liquidsEngineeringUltraviolet germicidal light

This invention discloses a water UV sterilizer using ultrasonic wave for cleaning. The UV sterilizer comprises an outer shell and a UV lamp. A water inlet and a water outlet are set on the outer shell. The spiral UV lamp is sealed at the center of the shell. Two electrodes are set on both sides of the UV lamp, and extend out of the shell. An ultrasonic wave energy converter is fixed at the inner wall of the shell. The ultrasonic wave energy converter is connected with an ultrasonic wave signal generator, which is connected with a power. When the UV lamp needs to be cleaned, water is introduced into the shell, and the ultrasonic wave signal generator is started, which generates high frequency vibrational signal. The high frequency signal is converted into mechanical vibration by the energy converter. Microbubbles are generated and break continuously in the water, and impact the UV lamp, thus cleaning the UV lamp. The invention can conveniently clean the UV lamp, and raise the sterilization efficiency.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

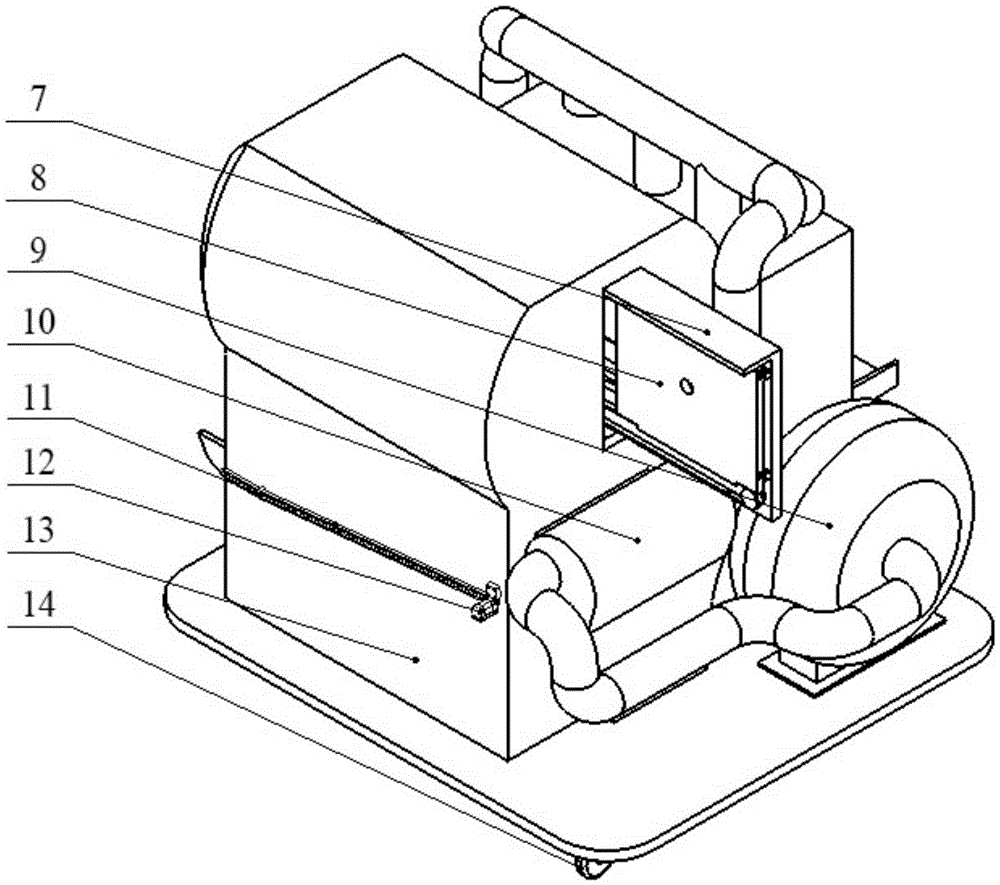

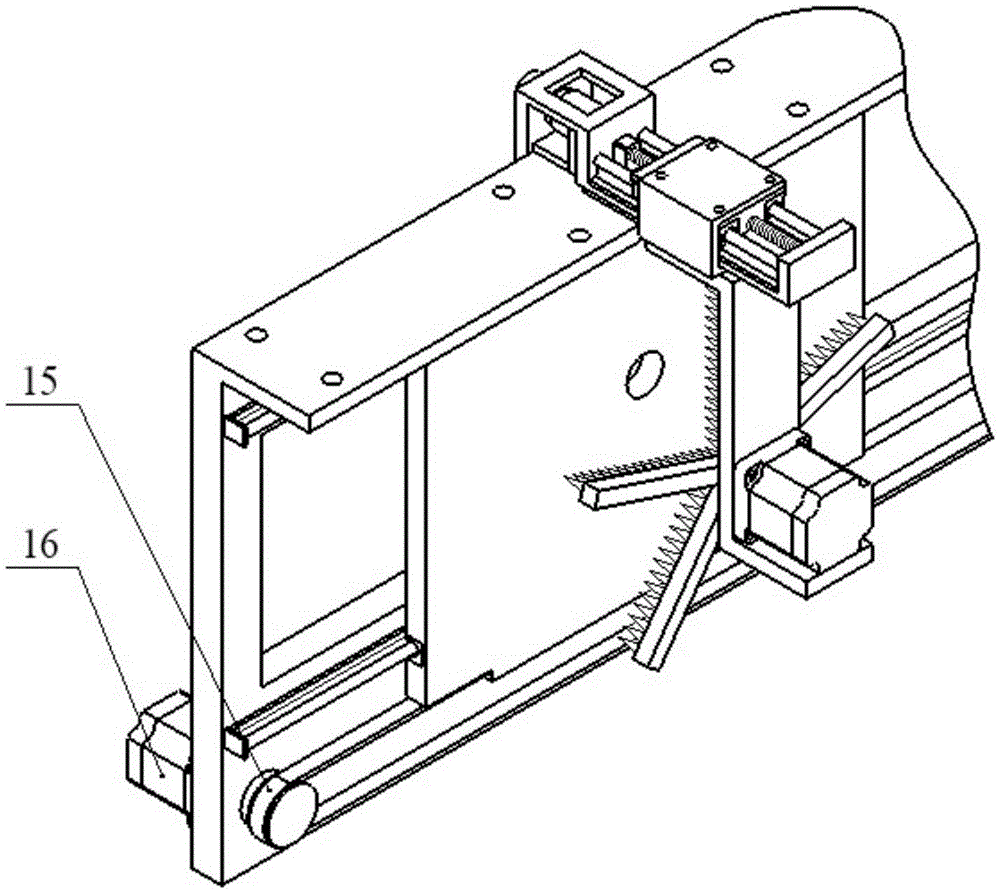

Production device of fiber color points and spinning method of color point yarns

The invention provides a production device of fiber color points and a spinning method of color point yarns, and improves the common cotton spinning machinery, i.e. adding a cotton feeding system on various carding machines, simultaneously being dispensed with a cotton stripping device, installing a stripping and conveying device, configuring all the technological parameters (e.g. transmission rate, cutting die, doffer space and the like) of the carding machines, and being reformed into a device capable of producing various fiber color points. The spinning method utilizes the production device, selects the kind and the dosage of an adhesive suitable for the fiber to produce color points with different size specifications, different tightness and extensive color change according to different fiber types during the production process of the color points.

Owner:广东广纺检测技术股份有限公司

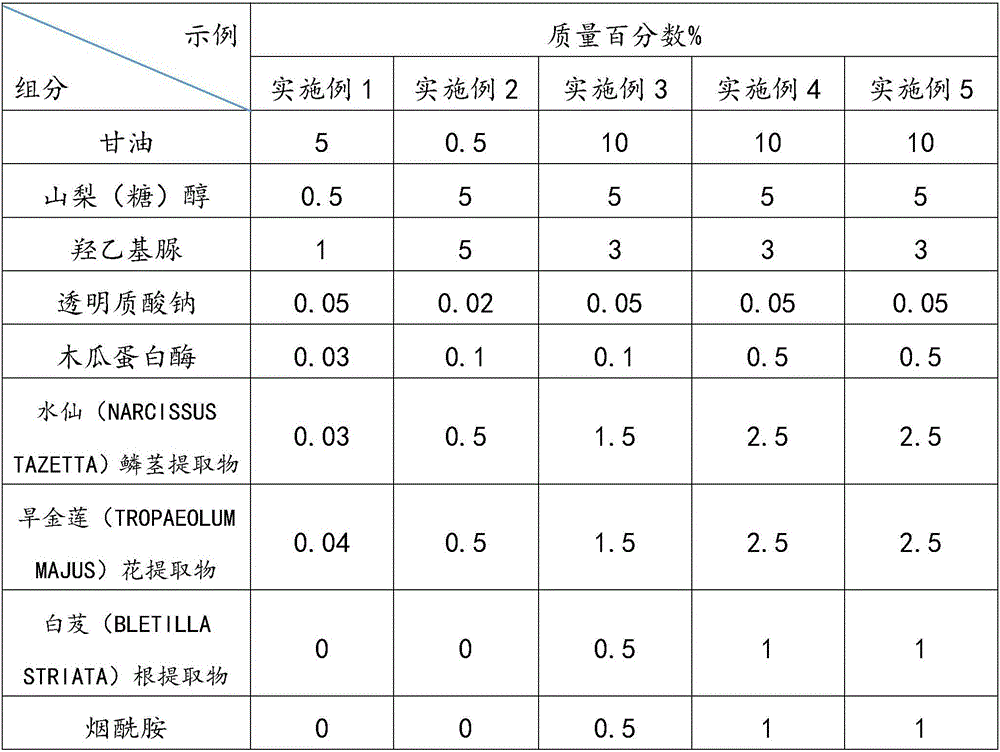

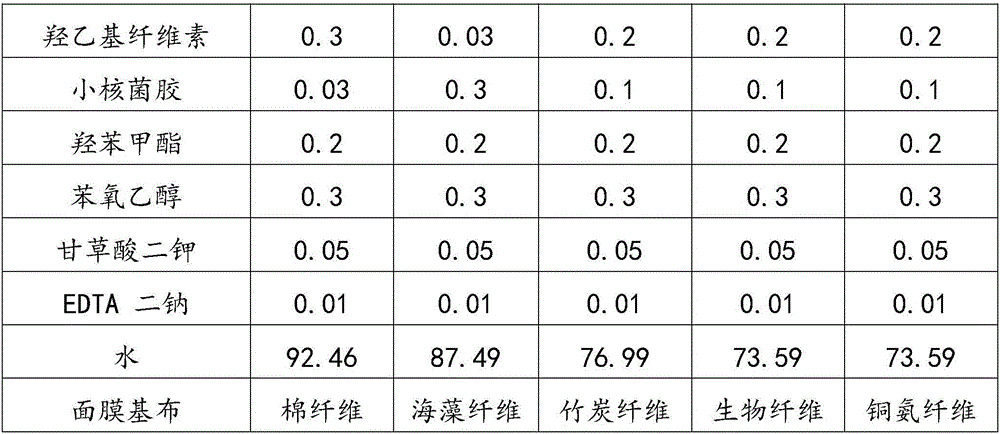

Whitening and moisture supplementing mask

InactiveCN106580837AImprove skin radianceAccelerate exfoliationCosmetic preparationsToilet preparationsSodium hyaluronateChemistry

The present invention discloses a whitening and moisture supplementing mask, which contains (1) a mask base cloth, and (2) a mask essence, wherein the mask essence comprises (a) a water-soluble thickener, (b) a humectant, (c) a whitening composition and (d) a water-containing carrier, wherein the humectant comprises a polyol, sodium hyaluronate and hydroxyethylurea, and the whitening composition comprises papain, a narcissus bulb extract and a tropaeolum majus extract. According to the present invention, the whitening and moisture supplementing mask can accelerate the peeling of old and waste skin cutin, promote the skin surface layer regeneration, inhibit the tyrosinase activity, inhibit the melanocyte division, reduce the melanogenesis, and achieve the good whitening effect from multiple angles.

Owner:江西登云健康美业互联有限公司 +1

Quenchant for medium carbon alloy steel abrasion-resistant material

The invention relates to the technical field of heat treatment quenching, and discloses a quenchant for medium carbon alloy steel abrasion-resistant material. The quenchant comprises, by weight, 6% to 8% of sodium hydroxide, 6% to 8% of zinc chloride, 1% to 5% of sodium chloride, 0.01% to 0.03% of sulfonated castor oil, 0.01% to 0.05% of antifoaming agents, 0.1% to 0.5% of soap, 0.1% to 0.4% of preservative, 0.1% to 0.5% of antirust agents, 0.1% to 0.5% of lubricants, 0.1% to 0.5% of sterilizing agents and the balance water. The quenchant is reasonable in formula, and a quenched piece can have high hardness and is even in hardness. Sodium hydroxide and oxide skin on the surface of the quenched piece can interact with each other to generate hydrogen, so that the oxide skin can be rapidly peeled off, and the surface of the quenched piece can be in a shining silver color. Zinc chloride and sodium hydroxide react to generate strong zinc oxide, and the cooling speed of a high temperature area is higher than the cooling speed of water while the cooling speed of a low temperature area is lower than the cooling speed of water, so that deformation of the quenched piece is small, the quenched piece is not prone to cracking, and the surface of the quenched piece is shining.

Owner:响水源达轴承座制造有限公司

Gynecological sugar-free gynaecopathia treating particle and preparation method thereof

The invention relates to a Chinese medicinal sugar-free gynaecopathia treating particle for treating gynaecopathia and a preparation method thereof. The particle is prepared from the following raw and auxiliary materials in parts by weight: 115 parts of prepared rehmannia root, 46 parts of szechuan lovage rhizome, 93 parts of white paeony root, 46 parts of Chinese mugwort leaf, 69 parts of Chinese angelica, 46 parts of liquoric root, 69 parts of donkey-hide gelatin, and non-cane-sugar auxiliary materials consisting of 100-800 parts of a diluent, 0-100 parts of a wetting agent, 0-50 parts of a bonding agent and 0-10 parts of a flavoring agent. The preparation method comprises the following steps of: extracting volatile oil from Chinese angelica, Chinese mugwort leaf and szechuan lovage rhizome, adding water into decoction dregs, white paeony root, prepared rehmannia root and liquoric root for decocting twice for 3 hours in a first time and 2 hours in a second time, combining decoctions, standing for 18-24 hours, and filtering to obtain an extract; and smashing the donkey-hide gelatin, adding donkey-hide gelatin powder and non-cane-sugar auxiliary material powder into the extract, preparing into particles, drying and spraying volatile oil. The particle is a sugar-free preparation, and is suitable for people suffering from diabetes and other people with no sugar requirements; and the using amount of the auxiliary materials is lowered remarkably.

Owner:武汉哈瑞医药有限公司

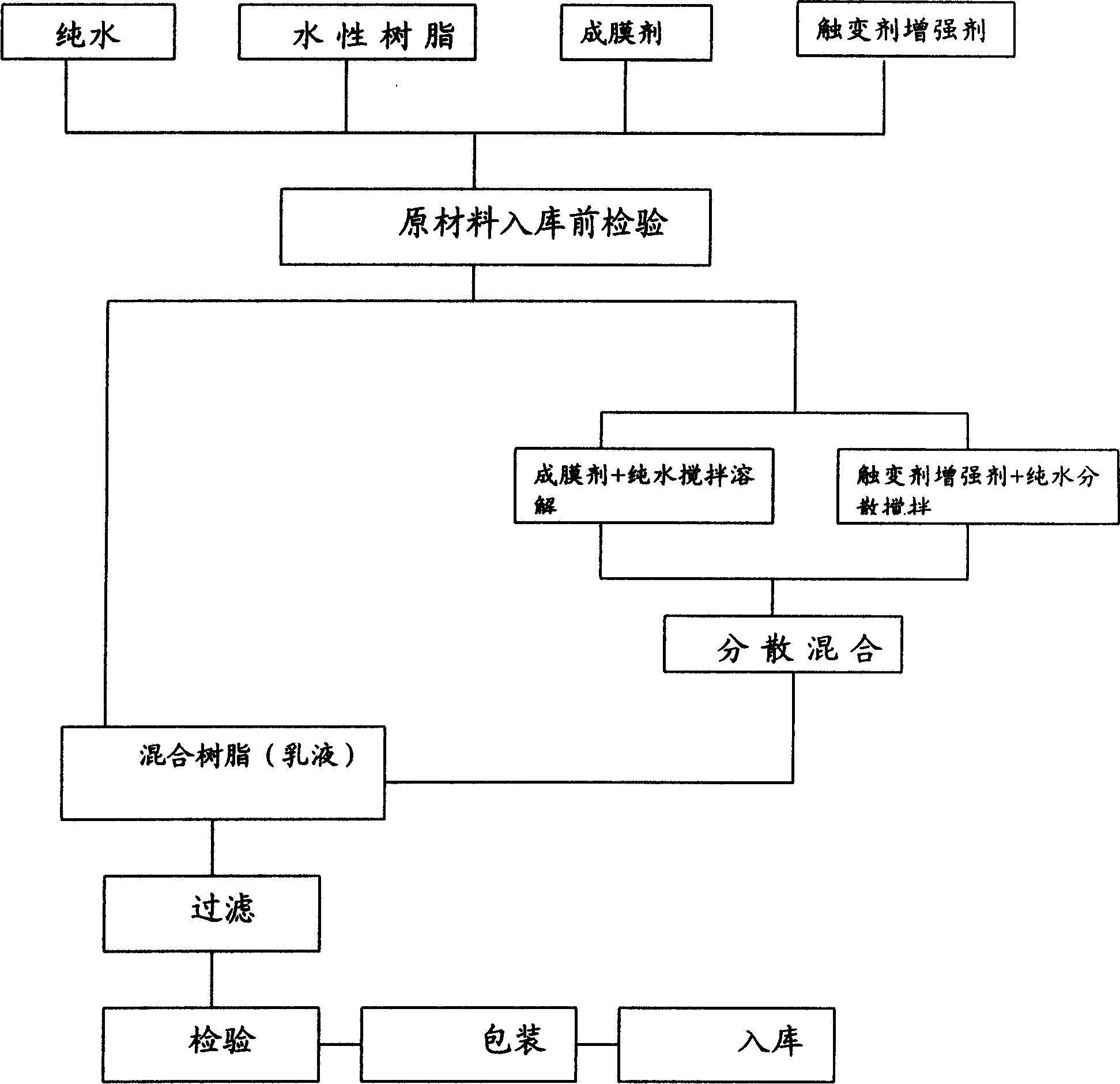

Water paint for protecting surface of car and household electrical apparats

The invention relates to a water protective paint for automobile and domestic surfaces, and its weight proportions: a water resin latex composed of acrylic resin 70-85 shares, modified acrylic resin 10-25 shares and epoxy resin 5-10 shares, reinforcing agent 1-3.5 shares, thixotropic agent 1-3 shares and film-forming agent 1-4 shares; where the reinforcing agent is silicon dioxide with particle size below 15 mum, the thixotropic agent is fibrin compound with molecular weight 1500-6000, and the film forming agent is one or two of the glycol and propylene alcohol. It has proper strength, hardness, flexibility and elongation. It has no bad effect on original paint coated surfaces of automobiles, home appliances, etc and can play a good role in protecting.

Owner:徐厚训

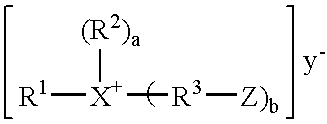

Clay dispersant and preparation method thereof

InactiveCN109628073AStrong dispersion abilityIncrease surface tensionDrilling compositionShield machineDecomposition

The invention belongs to the technical field of material science, in particular to a clay dispersant and a preparation method thereof. The clay dispersant comprises, by weight, the following raw materials: 15-35 parts of a surfactant; 5-10 parts of a diffusion agent; 8-12 parts of a penetrant; 4-8 parts of a reinforcing agent; 20-30 parts of a stripping agent; wherein the surfactant is a mixture of arachidonic acid amidopropyl hydroxysulfobetaine, trihalogenated N-carbonyl aniline, C14H29(OCOCH(CH3))2OSO3K, stearic acid and sodium hexametaphosphate according to a mass ratio of 3:5:5-10:10:15;the clay dispersant has strong dispersing capability on soil, the surface tension of the soil can be greatly improved, and the clay dispersant can play an emulsifying role in a wide pH value range; the clay dispersant can quickly react with the soil within 5 seconds, so that the viscous soil can be quickly peeled off under the strong decomposition effect, the loss of a shield machine is reduced,and the working efficiency is improved.

Owner:南京军盾化工科技有限公司

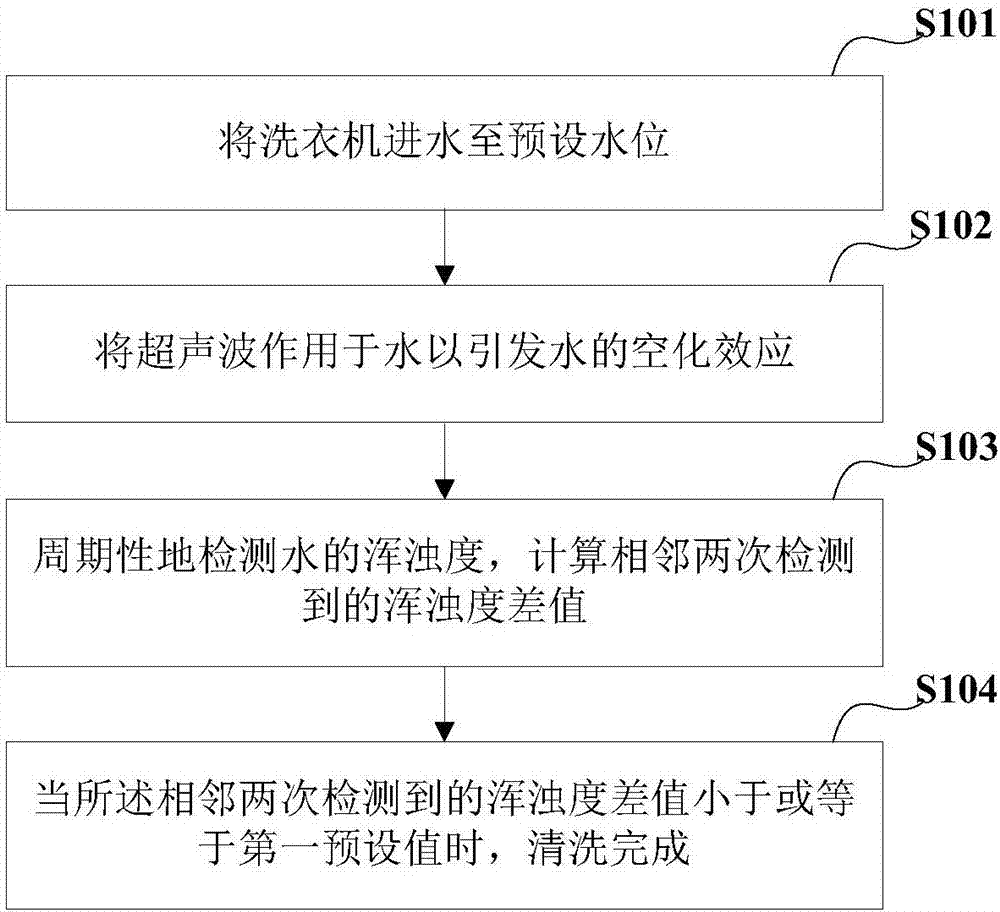

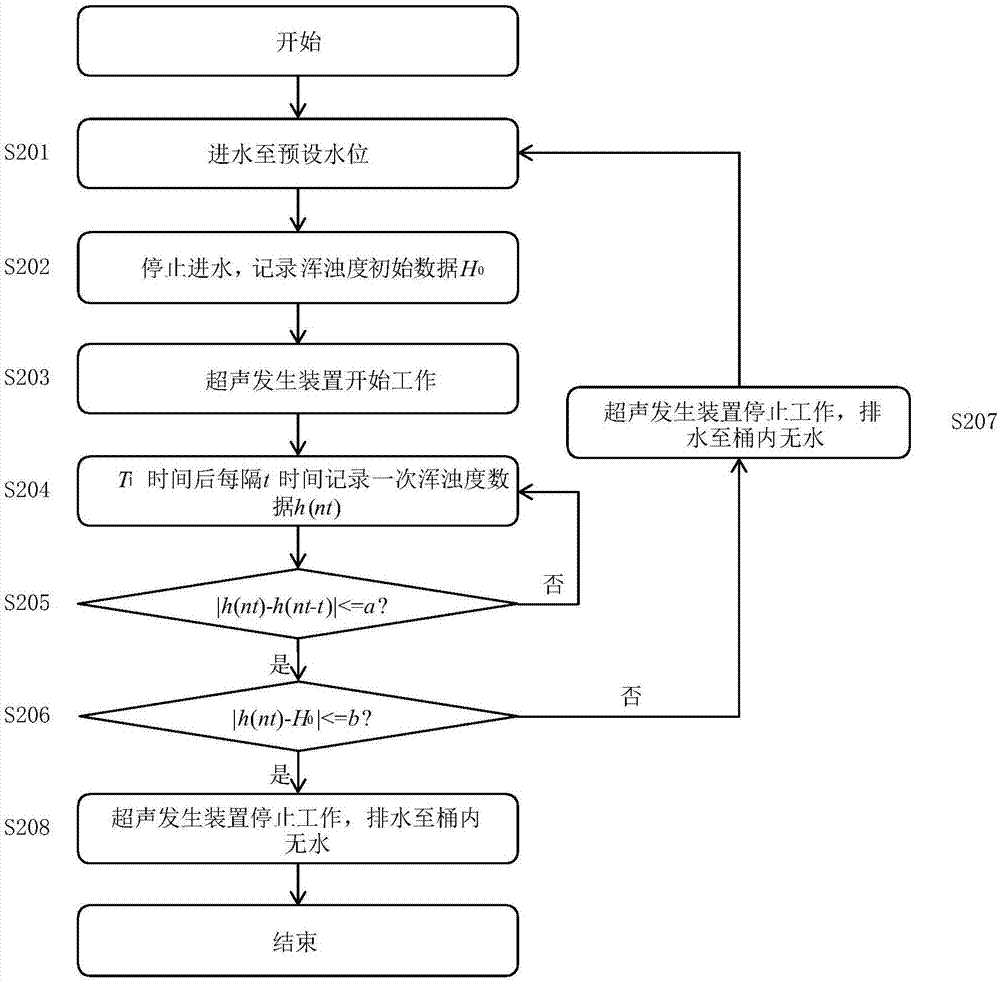

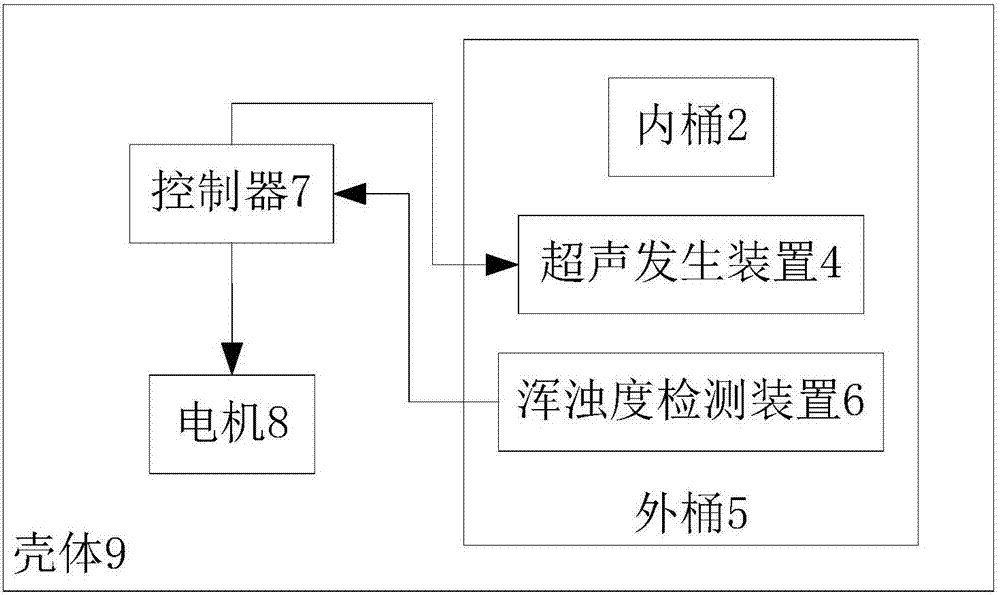

Washing machine cleaning method, washing machine and machine-readable storage medium

ActiveCN106958116APromote exfoliationOther washing machinesControl devices for washing apparatusUltrasound - actionCavitation

The embodiment of the invention provides a washing machine cleaning method, a washing machine and a machine-readable storage medium, and belongs to the field of home appliances. The washing machine cleaning method comprises the following steps: feeding water into the washing machine till a preset water level; exerting ultrasonic on the water to cause a cavitation effect of the water; periodically detecting water turbidity, and calculating a difference value between the water turbidity obtained in two adjacent detections; when the difference value between the water turbidity obtained in the two adjacent detections is smaller than or equal to a first preset value, completing cleaning. Through the technical scheme, the ultrasonic is exerted on the water to cause the cavitation effect of the water, so that dirt on the surface of a barrel wall and in gaps can be quickly peeled off so as to achieve the effects of cleaning pollutants inside the washing machine and purifying an internal space of the washing machine.

Owner:广德市旗锋咨询有限公司

Aerated concrete block with high thermal insulation property

The invention discloses an aerated concrete block with high thermal insulation property. The aerated concrete block with high thermal insulation property is prepared by the following raw materials by weight: 0.04-0.06 part of nekal BX, 0.003-0.01 part of magnesium powder, 0.04-0.05 part of triethanolamine oleate, 4-5 parts of cement, 0.1-0.3 part of oxidized starch, 0.002-0.006 part of glycerin triacetate, 0.01-0.03 part of ethylene glycol monomethyl ether, 0.1-0.5 part of wood fiber, 10-20 parts of expanded perlite powder, 7-9 parts of slag powder, 17-19 parts of kaolin, 1-2 parts of alum and 0.2-0.4 part of chitosan.

Owner:安徽中龙建材科技有限公司

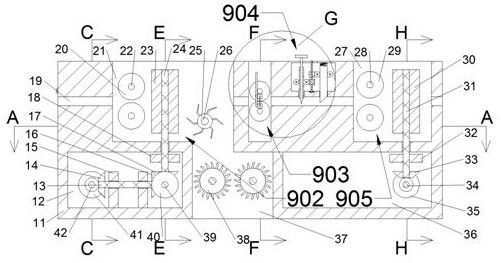

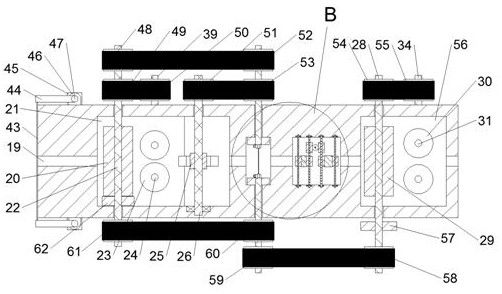

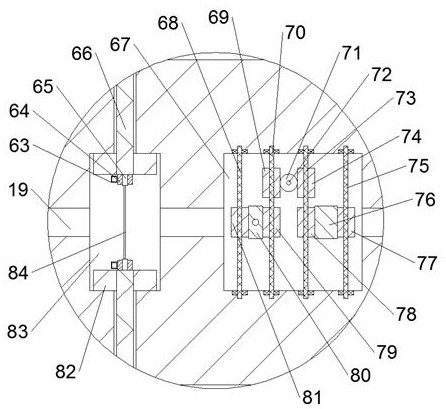

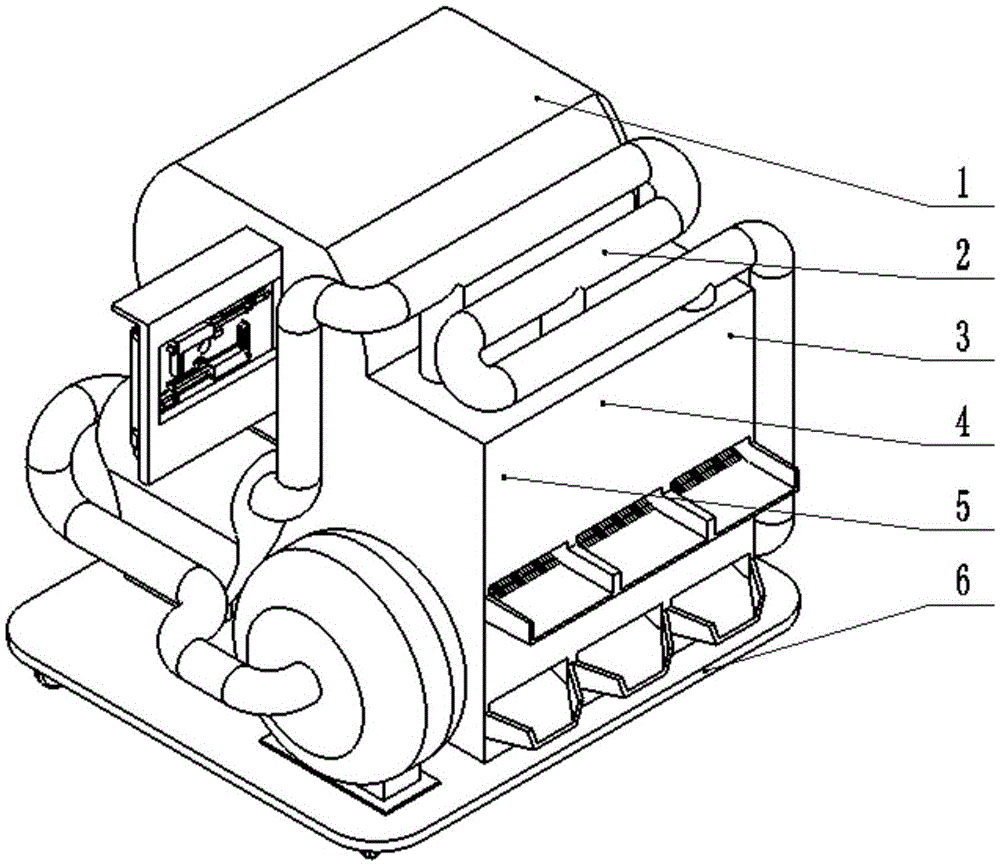

Automatic peeling, cutting and recycling device adapting to cable and wire deformation

InactiveCN111696734AImprove adaptabilityAchieve reductionBasic electric elementsElectronic waste recyclingStructural engineeringElectric cables

The invention discloses an automatic peeling, cutting and recycling device adapting to deformation of cables and wires. The automatic peeling, cutting and recycling device comprises a box body, wherein a wire conveying hole is formed in the box body in a left-right penetrating mode, and a transmission cavity is formed in the box body. According to the invention, the height of the cable wire is determined by pre-positioning the cable wire, so that the height of the cutting device is adjusted, adaptation and cutting of deformed cables and wires are realized, and cutting depth is ensured; the annular cutting device is used for cutting the cable wire skin into sections, so that stripping of the cable and wire skin is facilitated; the cable wire skin is pushed into the crushing device through the pushing claw, and the wire core is cut into sections through the cutting device, so that the post-treatment of cable wire recovery is facilitated; and the device does not need to perform traction pretreatment on the cable wire, the short cable wire is conveniently treated, and the recovery efficiency is improved.

Owner:NINGBO ZHENHAI TENGYUAN ELECTRONICS

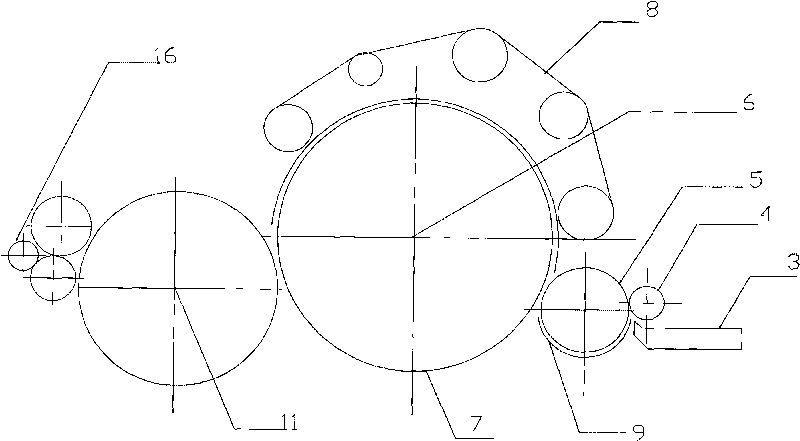

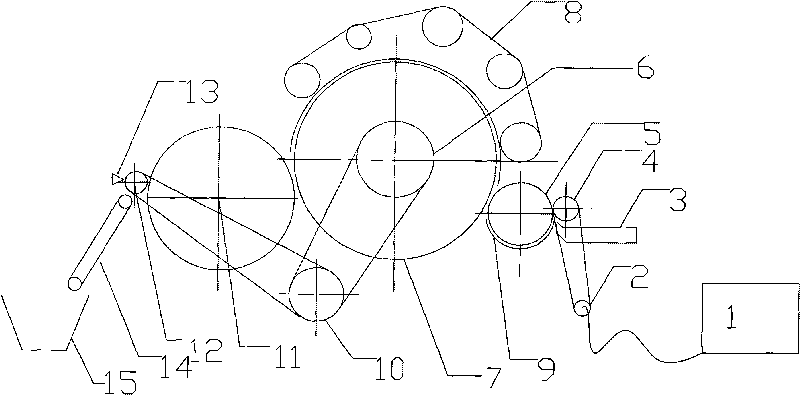

Sunflower seed sorting machine

ActiveCN105532193APromote exfoliationWon't pop outSievingGas current separationSunflower seedEngineering

The invention discloses a sunflower seed sorting machine, and belongs to the field of agricultural machines. The sunflower seed sorting machine is composed of a sunflower seed peeling mechanism, a sunflower seed sorting mechanism and a machine base. The sunflower seed peeling mechanism is provided with a sunflower disc fixing device and a peeler and peels off sunflower seeds from the sunflower disc. The sunflower seed sorting mechanism is provided with an air suction pipeline, an induced draft fan, an impurity removal box, a filter sieve and a weight sorting box structure, weight sorting of sunflower seeds is completed, and universal wheels are arranged on the machine base, so that movement of the sunflower seed sorting machine is facilitated. The sunflower seed sorting machine can effectively replace a large amount of labor force, meanwhile, efficiency and quality of the sunflower seed peeling and sorting stage are ensured, and practical problems in the sunflower seed peeling and sorting process are solved.

Owner:巴彦淖尔市晨泰工贸有限公司

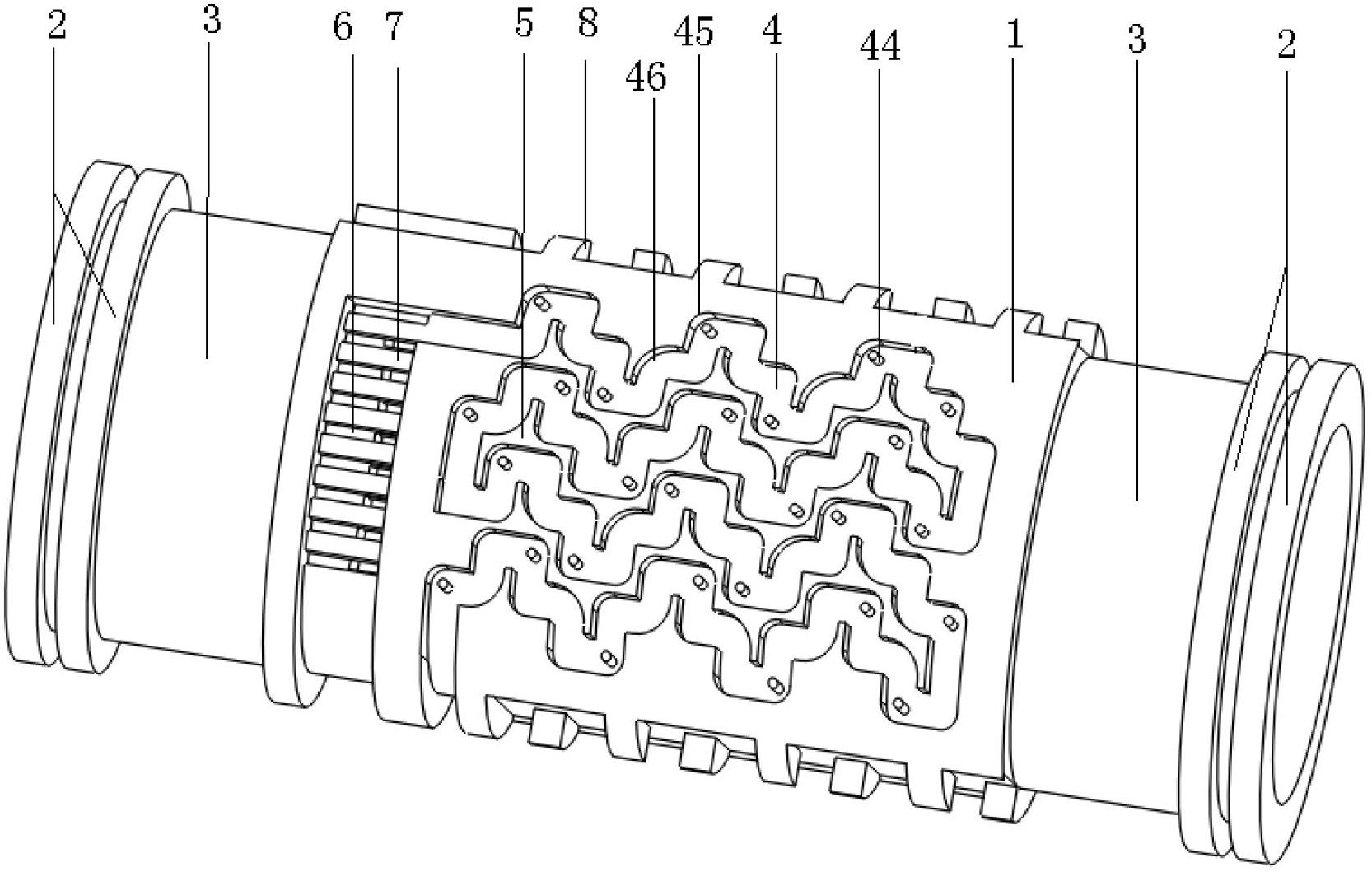

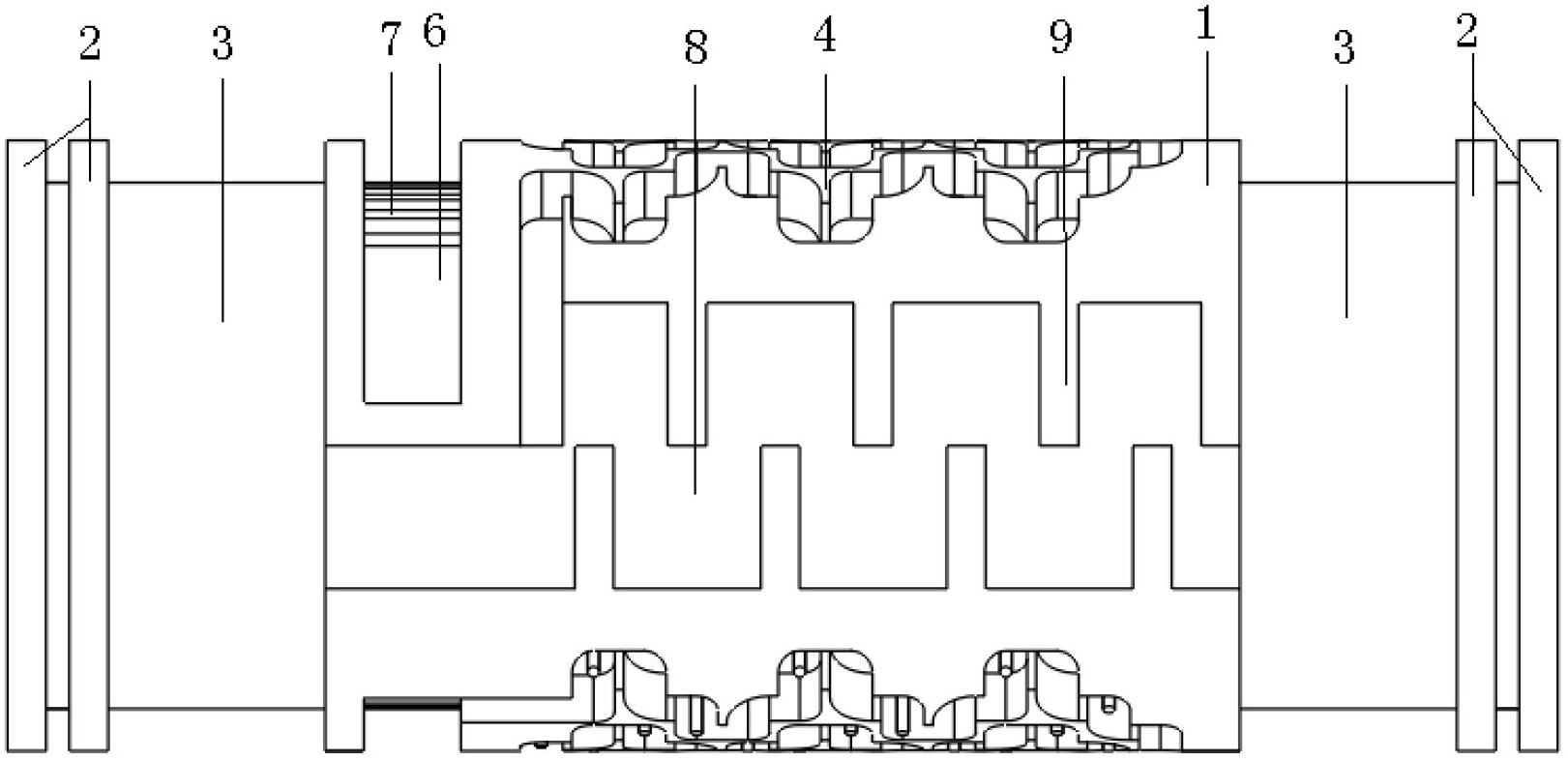

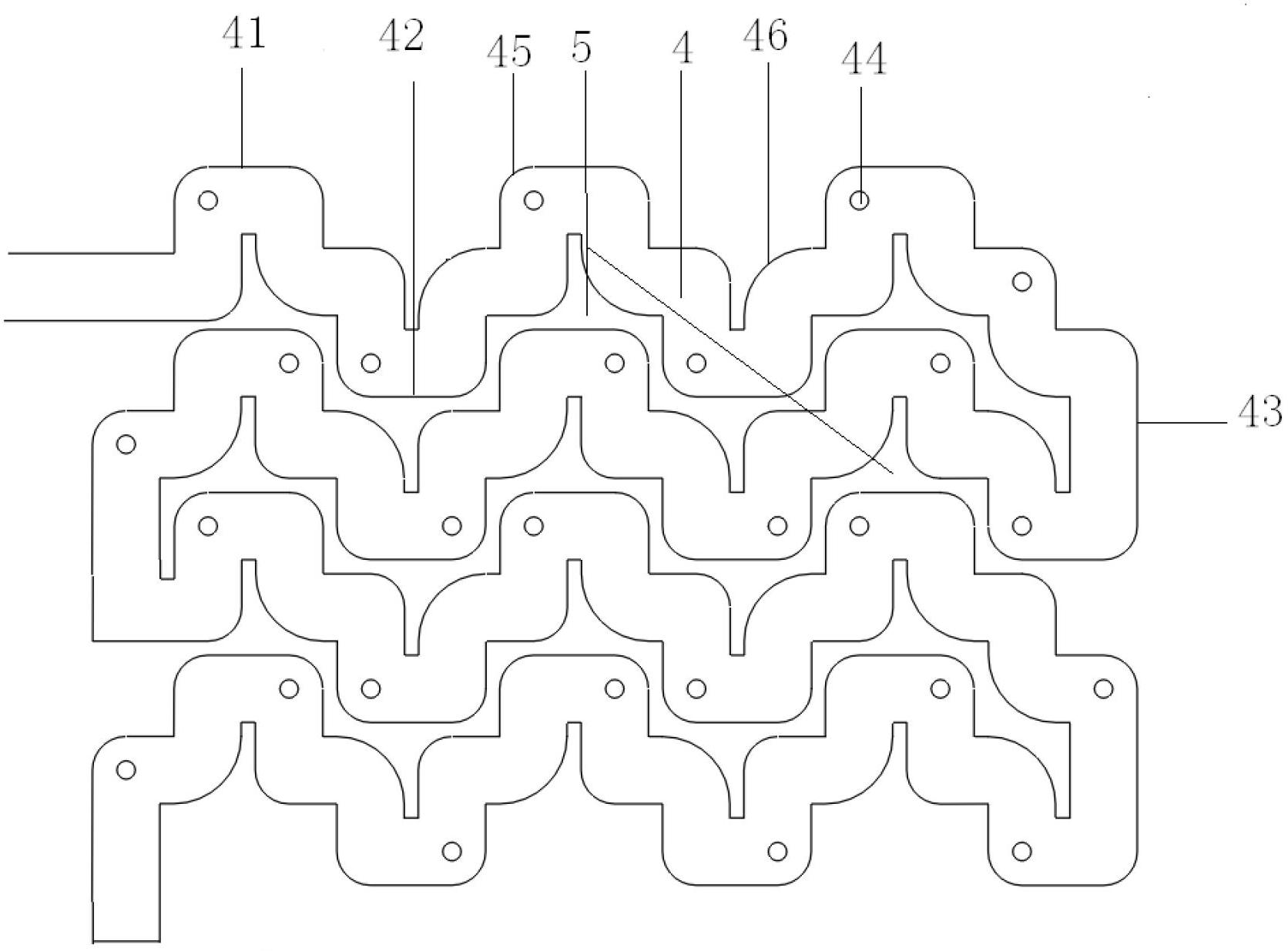

Special surface drip irrigation emitter capable of automatically cleaning blocking antibiotic membranes

ActiveCN102658246AIncreased turbulenceIncrease carrying capacitySpray nozzlesDrip irrigationEngineering

The invention relates to a special surface drip irrigation emitter capable of automatically cleaning blocking antibiotic membranes. The special surface drip irrigation emitter is characterized by comprising a dripper body disposed in a drip irrigation tube, two end adhesion surfaces are disposed at the outermost ends of two axial sides of the dripper body, two water outlets are arranged on the dripper body and positioned on inner sides of the two end adhesion surfaces, two groups of flow channels are radially arranged on the dripper main body at intervals and positioned between the two water outlets, each group of flow channels consists of a plurality of flow channels axially disposed and communicated with each other, two water inlets are arranged at one end of the dripper body and positioned among the two groups of flow channels and the corresponding water outlet at intervals, a trash rack is arranged on each water inlet, each group of flow channels is connected with the corresponding water inlet, two flow buffering areas are axially arranged on the surface of the dripper body and between the two groups of flow channels, a plurality of water retaining components are arranged inside each flow buffering area in a staggered manner, a radial side of each flow buffering area is correspondingly communicated with one group of flow channels, and two axial ends of the two flow buffering areas are correspondingly communicated with the water outlets at the corresponding ends.

Owner:CHINA AGRI UNIV

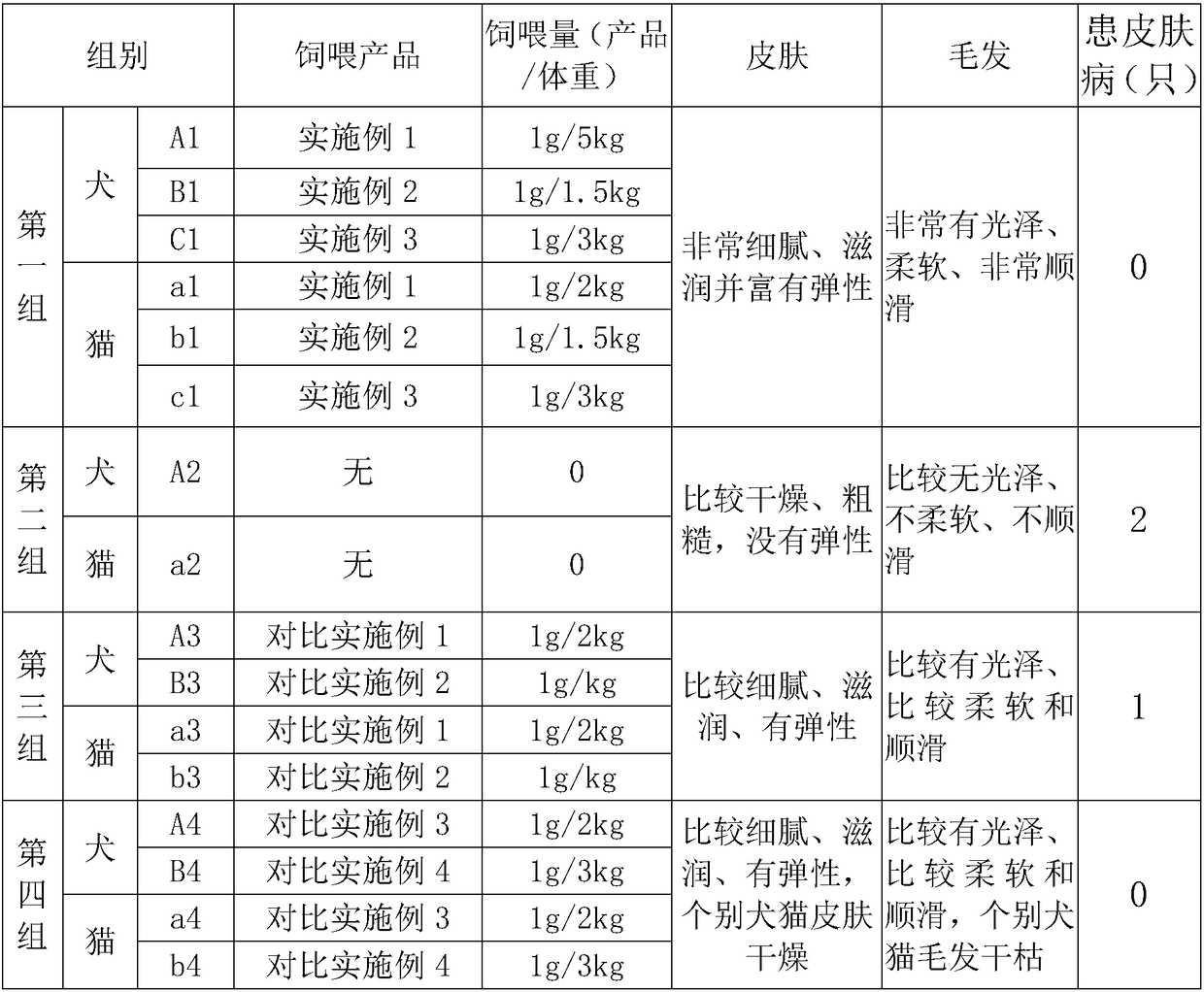

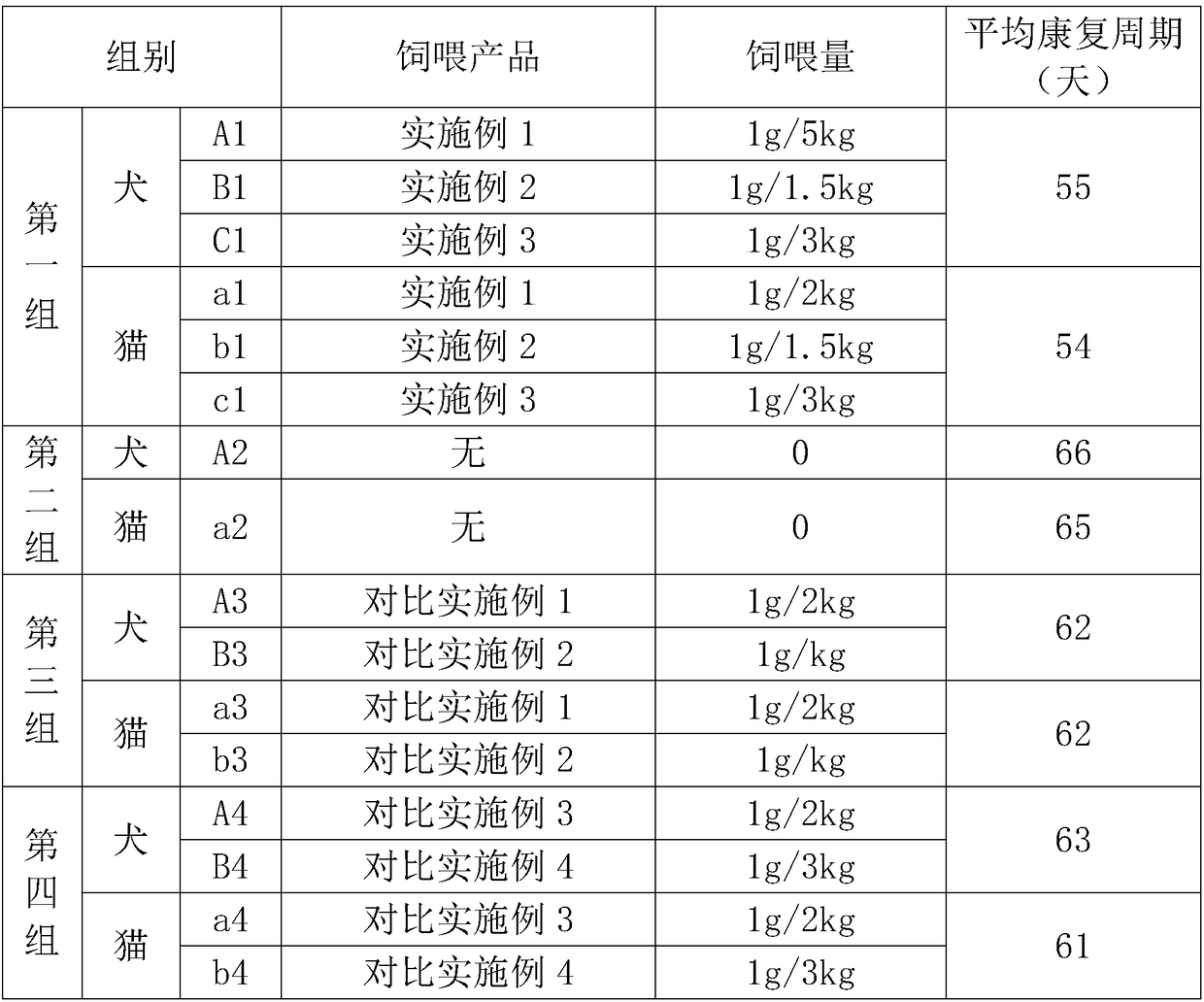

Functional food for skin nursing of pet dogs and cats and making method of functional food

PendingCN108125048AImprove skin damage and drynessEasy to peel offAnimal feeding stuffAccessory food factorsCanis lupus familiarisLecithin

The invention relates to the technical field of animal feeds, in particular to a functional food for skin nursing of pet dogs and cats. The functional food is made from the following raw materials inparts by weight: 6-10 parts of group B complex vitamins, 2.7-6.5 parts of vitamin A, 1-3 parts of vitamin E, 6-11 parts of lecithin, 6-15 parts of methionine, 5-10 parts of L-cystine, 2.5-5 parts of zinc methionine, 7-10 parts of fish oil, 4-7 parts of chicken liver powder, 0.3-0.7 part of magnesium stearate and 55-80 parts of auxiliary materials. The invention further relates to a making method of the functional food for skin nursing of pet dogs and cats including powder, granules and tablets. The functional food contributes to improvement on the condition that the skin of the dogs and the cats is damaged and dried, and easy to peel off, and seborrhagia and epilation are easy to cause, the functional food has health-care effect on skin, can promote growth of clothing hair development andgrowth cells and body cells and is good in palatability, and the making method is simple.

Owner:上海宠幸宠物用品有限公司

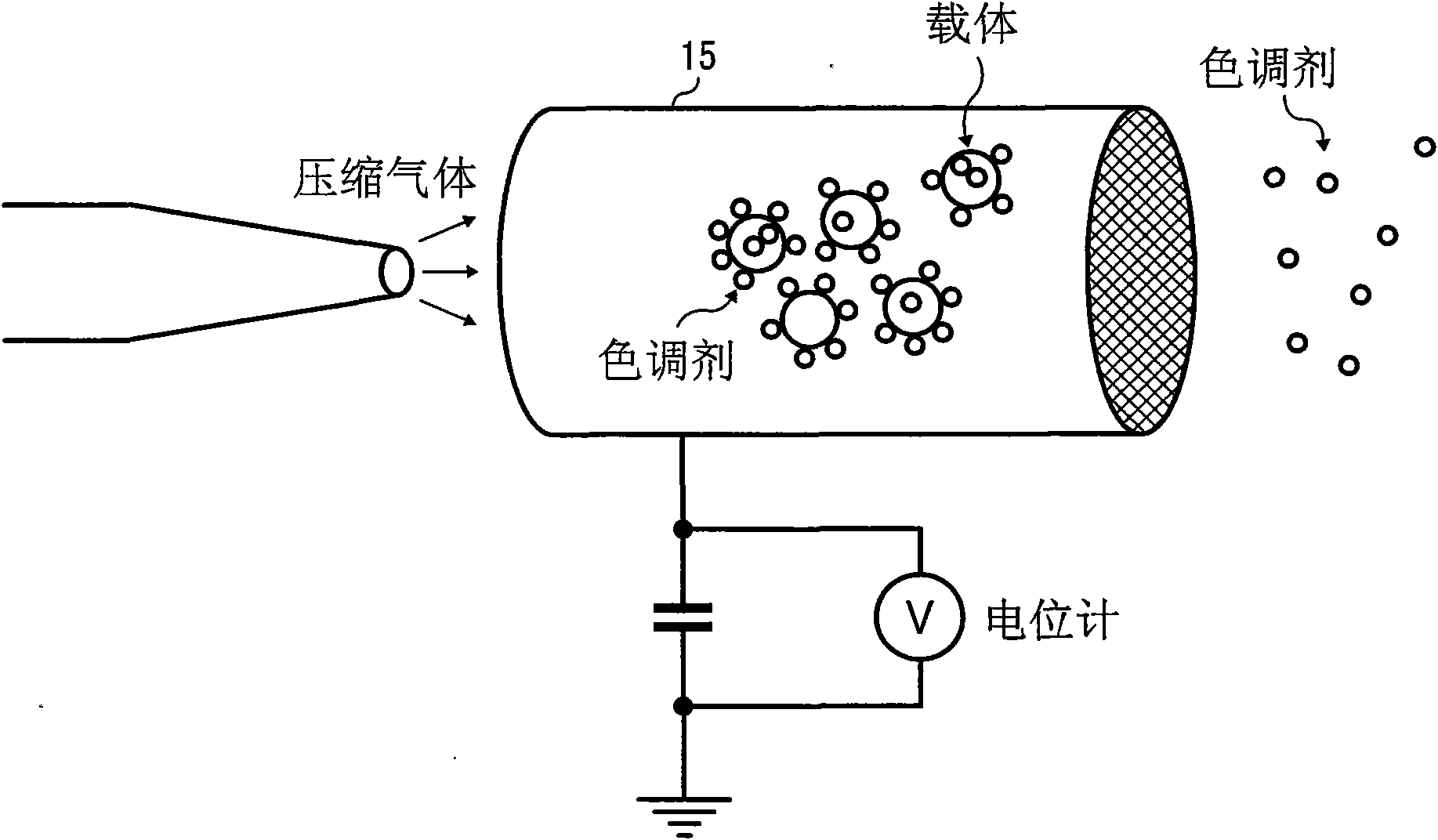

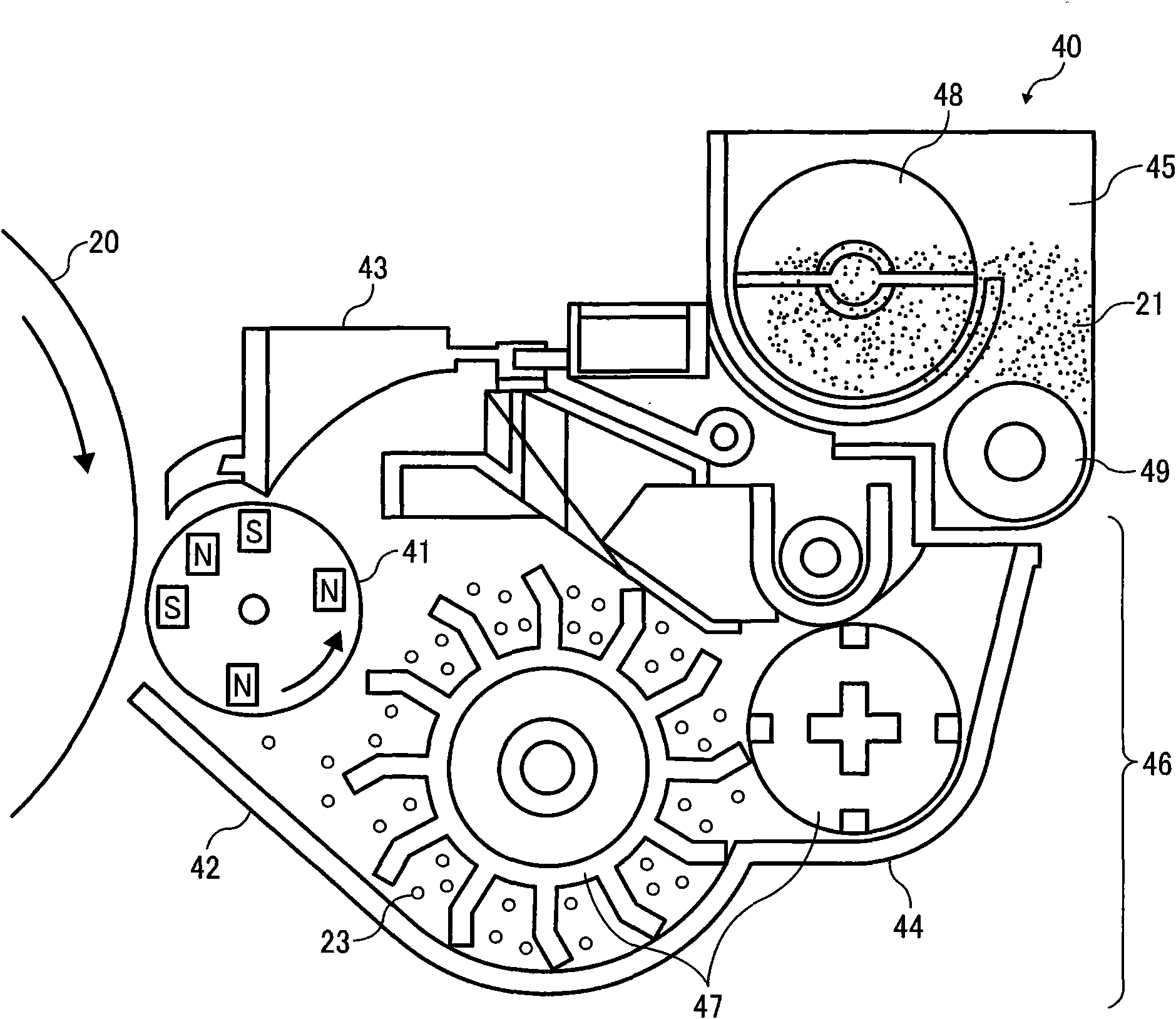

Carrier for use in developer developing electrostatic image and developer using the carrier

InactiveCN101840171AExcellent abrasion resistanceLess void tonerDevelopersElectrographic process apparatusParticulatesEngineering

The carrier includes a particulate core material having magnetism; and a resin layer located on the surface of the particulate core material. The resin layer is prepared by forming a layer including a copolymer, which includes a unit (A) having a specific acrylic siloxane structure, a unit (B) having a specific acrylic silicone structure having a crosslinking ability, and a unit (C) having a specific acrylic structure in a specific ratio, on the particulate core material, and then subjecting the layer to a heat treatment to crosslink the layer.

Owner:RICOH KK

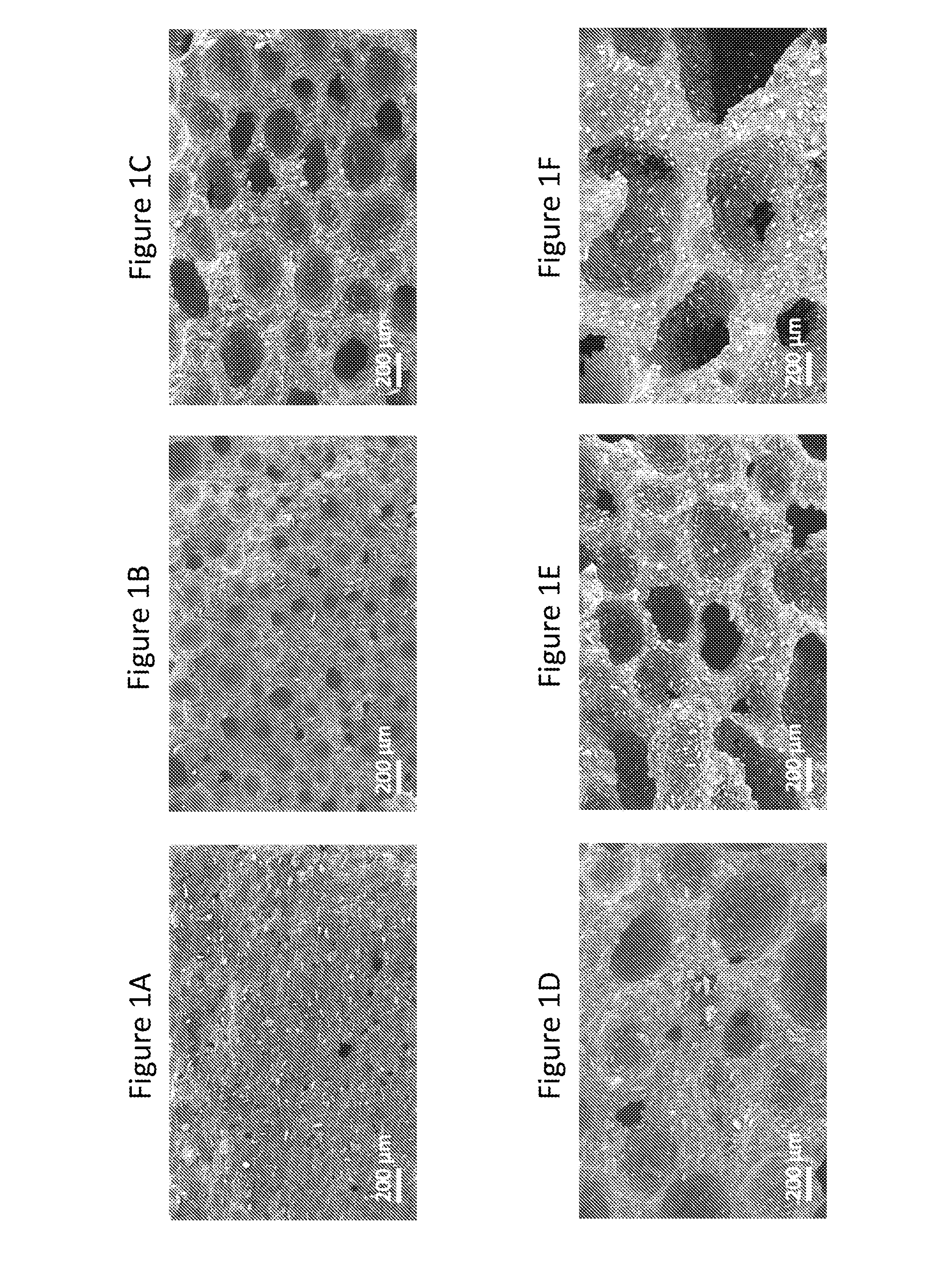

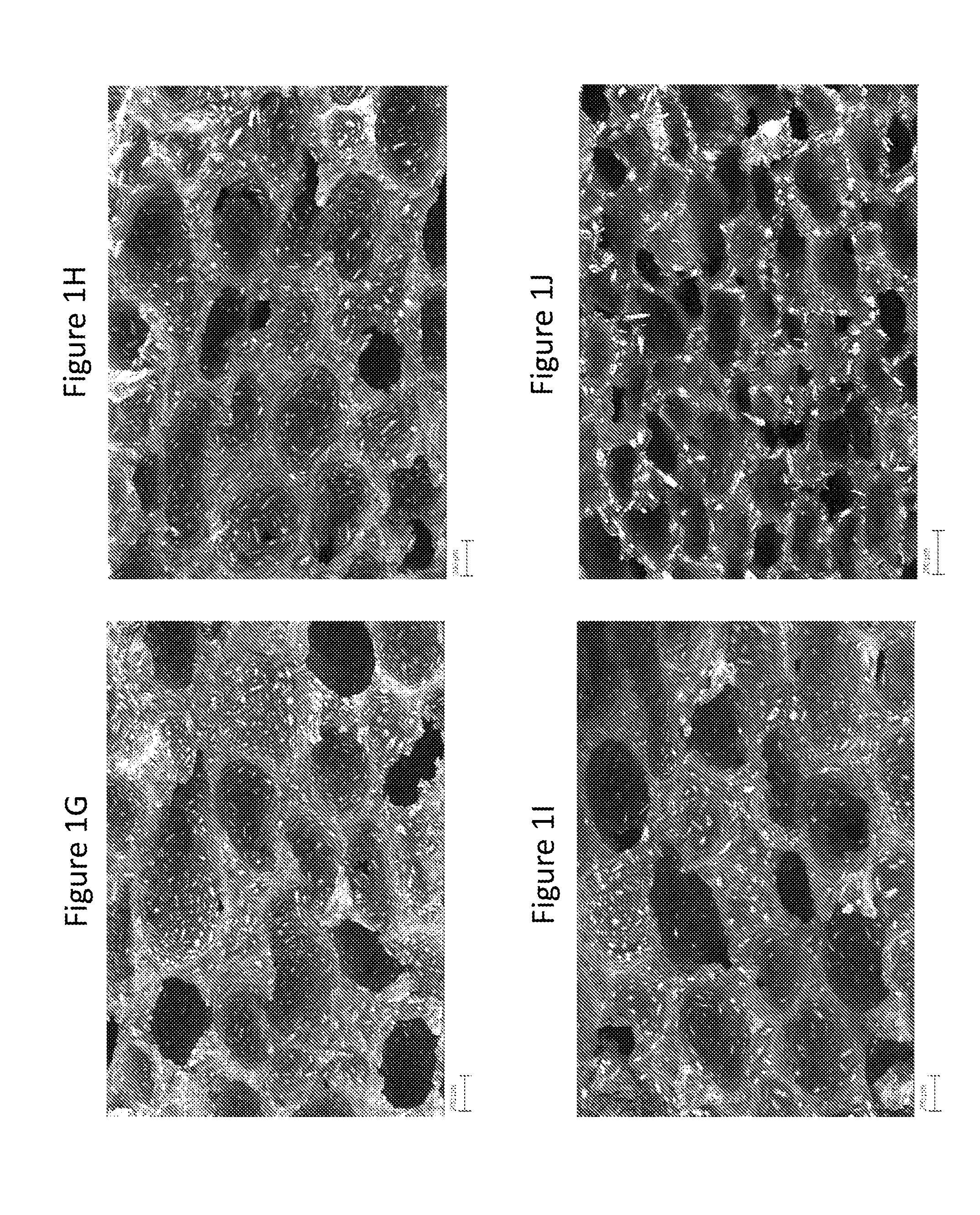

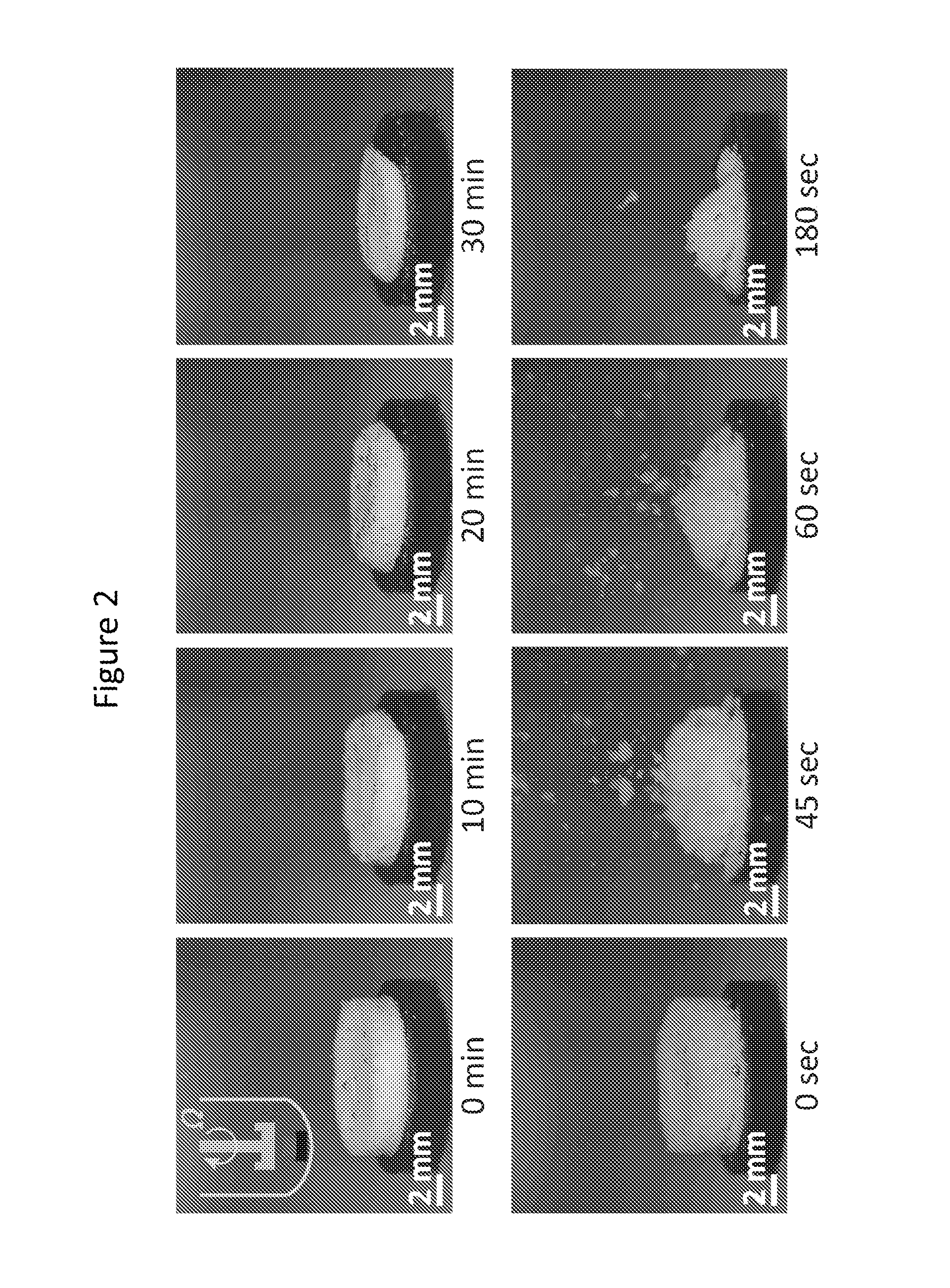

Melt-processed polymeric cellular dosage form

InactiveUS20160184230A1Promotes quick releaseImprove uniformityPowder deliveryBiocideImmediate releaseSolid Dose Form

Presented herein are polymeric cellular dosage forms exhibiting improved immediate release properties, while maintaining high uniformity and satisfactory mechanical properties (e.g., to permit necessary handling). An exfoliating polymeric cellular dosage form is described herein that can be cost-effectively manufactured via batch or even non-batch (continuous or semi-continuous) melt processing. The solid dosage forms have a unique cellular microstructure featuring a number of open, interconnected cells. The cell walls contain the active ingredient(s) as well as an excipient that swells in the presence of a physiological fluid such as gastrointestinal fluid and / or saliva under physiological conditions.

Owner:BLAESI ARON H

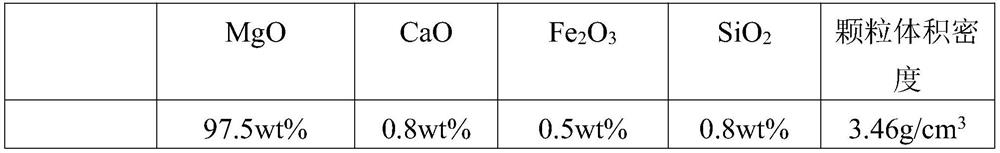

Magnesia carbon brick for vicinity of furnace door of electric arc furnace and preparation method of magnesia carbon brick

PendingCN112125650AImprove thermal conductivityImprove toughnessThermal dilatationElectric arc furnace

The invention relates to a magnesia carbon brick for the vicinity of the furnace door of an electric arc furnace and a preparation method of the magnesia carbon brick. The prepared magnesia carbon brick is prepared from the following raw materials in parts by weight: 20-30 parts of fused magnesia of which the granularity is more than or equal to 3mm and less than 5mm, 20-40 parts of fused magnesiaof which the granularity is more than or equal to 1mm and less than 3mm, 10-20 parts of fused magnesia of which the granularity is more than or equal to 0.1 mm, 5-20 parts of fused magnesia powder ofwhich the granularity is smaller than 0.088 mm, and 12-16 parts of flake graphite, 1-3 parts of phenolic resin binder, and 1-6 parts of additive; the content of magnesium oxide in the fused magnesiteis greater than or equal to 97.5 wt%, and the volume density of the fused magnesite is greater than 3.45 g / cm <3>. According to the magnesia carbon brick for the vicinity of the furnace door of an electric arc furnace and a preparation method of the magnesia carbon brick of the invention, the phenolic resin binder is used; the phenolic resin binder is utilized to prepare the fused magnesite and flake graphite with different particle sizes under the action of the additive, so that the magnesia carbon brick has the advantages of good heat-conducting property, low thermal expansion coefficient,high tensile strength, good toughness, oxidation resistance and scour resistance.

Owner:北京利尔高温材料股份有限公司

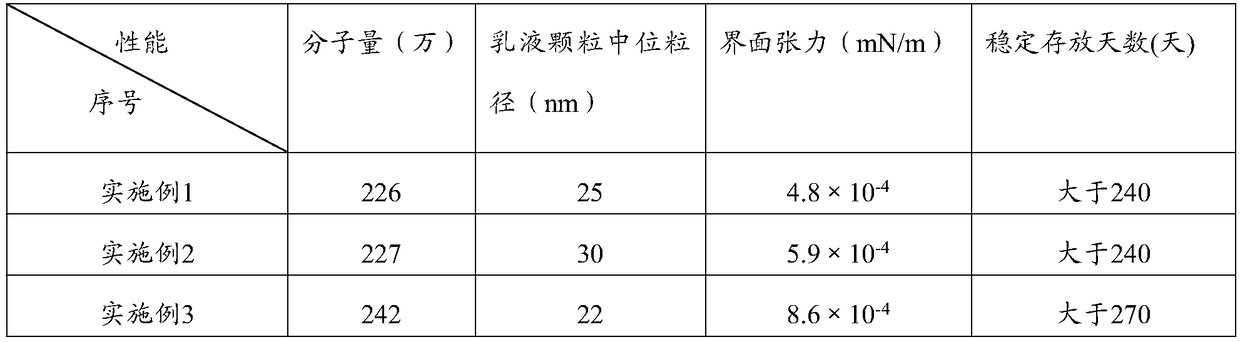

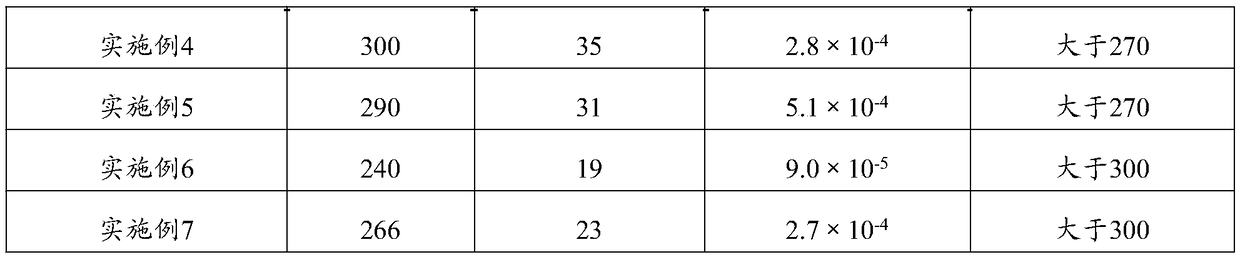

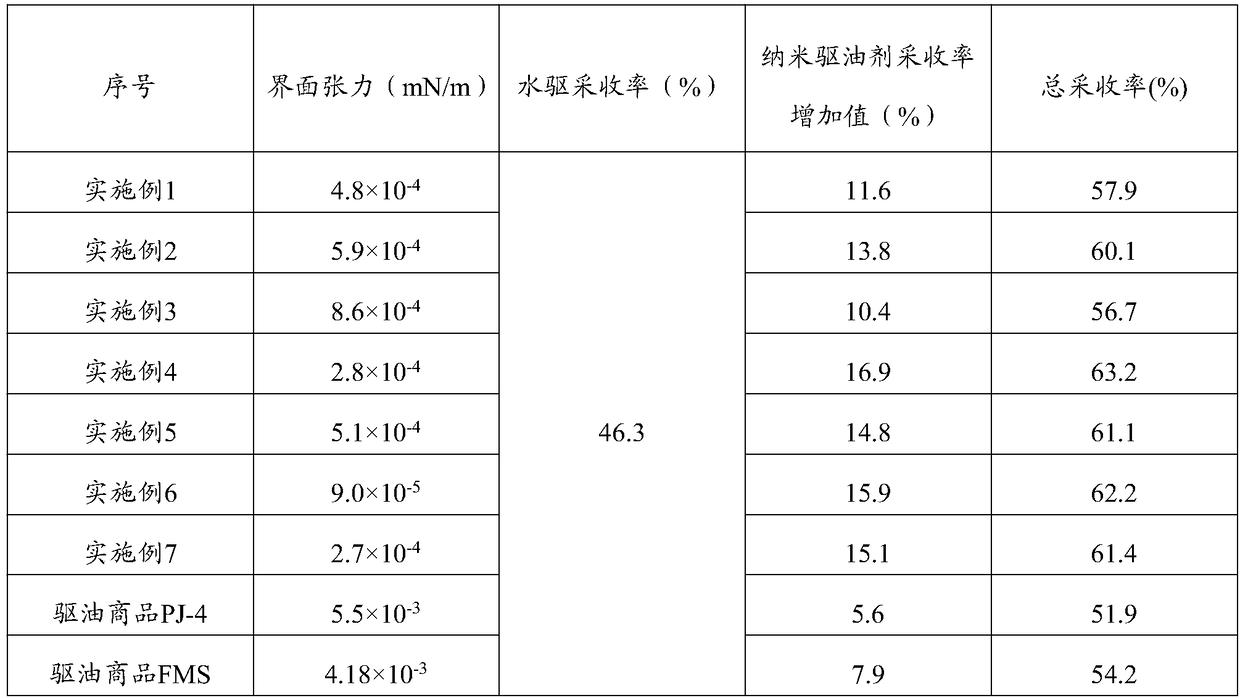

Nanometer emulsion oil-displacing agent and preparation method thereof

ActiveCN109233780ASimple componentsImprove surface activityDrilling compositionOxidizing agentMineral oil

The invention provides a nanometer emulsion oil-displacing agent and a preparation method thereof. The nanometer emulsion oil-displacing agent provided by the invention comprises the following ingredients in parts by weight: 30-45 parts of mineral oil, 3-8 parts of an emulsifier, 30-50 parts of monomer alkaline and water mixed liquor, 0.01-0.5 part of a cross-linking agent, 0.05-0.5 part of an oxidizing agent and 0.04-0.7 part of a reductant. According to the nanometer emulsion oil-displacing agent, raw materials are mixed and stirred orderly to form the emulsion of a water in oil system. Themolecular weight of the prepared nanometer emulsion oil-displacing agent is greater than 2000 thousands, a grain size in a particle is less than 40nm, interfacial tension is 9.0*10<-5>-8.6*10<-4> / m, astable storage period is greater than 240 days, and layering is unlikely to happen. The nanometer emulsion oil-displacing agent can reach any corner communicated with an oil deposit, rock surface wettability is changed, and swept volume is improved so as to be favorable for peeling and harvesting crude oil.

Owner:GUANGHAN HUAXING NEW TECH DEV INST GENERAL PARTNERSHIP +1

Hand sanitizer and preparation method

InactiveCN108078889AEffective decontaminationImprove decontamination effectCosmetic preparationsToilet preparationsGlycerolHand sanitizer

The invention discloses a hand sanitizer and a preparation method, and belongs to the technical field of daily chemical products. The hand sanitizer is prepared from the following raw material components in parts by mass: 45 to 50 parts of lanolin glycerol, 8 to 15 parts of surfactant, 5 to 10 parts of ethanol, 3 to 8 parts of vitamins, 5 to 8 parts of essential oil, and 3 to 5 parts of pearl powder, the balance of deionized water, citric acid, a co-surfactant and an emulsifier. The preparation method comprises the steps that: the lanolin glycerol, the surfactant, the co-surfactant, vitamins,pearl powder, deionized water and emulsifier are weighed, after stirring, mixing and heating, ethanol and essential oil are added, and the mixture is stirred until the mixture is evenly mixed, finally, the pH is adjusted to weak acidity, and package is sealed to obtain a final product. The product can not only achieve a purpose of effective decontamination, but also is easy to wash in a short time, maintains the hand's skin in a comfortable, fresh state, and has an excellent skin care effect.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

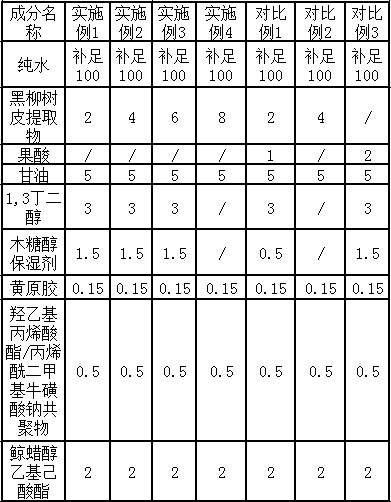

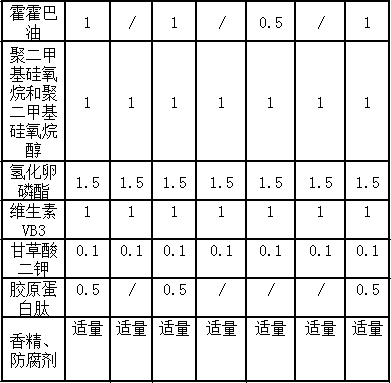

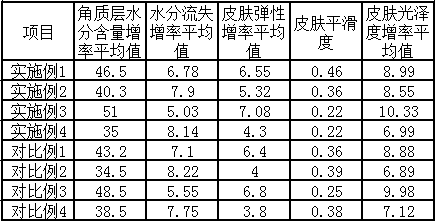

Skin care composition containing black willow bark extract

InactiveCN109528582ADestroy active ingredientsEffective active preservationCosmetic preparationsToilet preparationsMedicineSkin repair

The invention relates to the field of cosmetics, and discloses a skin care composition containing a black willow bark extract. The composition comprises the following components in percentage by mass:0.1-30% of black willow bark extract, 0.1-20% of a humectant, 0.01-3% of a thickening agent, 0.1-20% of grease, 0.1-5% of an emulsifier, 0.01-10% of functional additives and the balance of purified water. The composition can effectively soften cutin, help the aged cutin fall off, clean skins, effectively help skins repair rough pores, and make the skins more moisturized, younger and healthier.

Owner:OPAL COSMETICS HUIZHOU

Skin repairing composition as well as preparation method thereof and application in cosmetics

InactiveCN110279602APlay a role in water retentionRebuild adhesionCosmetic preparationsToilet preparationsCentella asiatica extractCuticle

The invention relates to a skin repairing composition as well as a preparation method thereof and application in cosmetics. The skin repairing composition comprises the following raw materials in parts by weight: 1-10 parts of ceramide 3, 5-15 parts of hydrogenated lecithin, 5-15 parts of a hydrogenated olive oil unsaponifiable matter, 5-15 parts of a strigose oat extract, 10-20 parts of tetrahydromethyl pyrimidine carboxylic acid, 5-15 parts of a centella asiatica extract and 0.5-2 parts of ethoxy piperazine ethanesulfonic acid. By adopting the skin repairing composition provided by the invention, components take a synergetic effect into play, the self repairing capability of cells and the skin immunity can be improved inside, and the epidermal thickness can be increased and skin barriers can be repaired outside, that is, the skin repairing composition takes a skin repairing effect into play from both inside and outside, so that a remarkable skin repairing effect can be achieved, and the skin repairing composition is safe and non-irritant, and can be easily used in formula systems of various dosage forms of cosmetics.

Owner:SHANGHAI YAOJIAN BIO TECH

Essence lotion composition containing lipidosome with skin brightening and whitening effects and a preparation method of the essence lotion composition

ActiveCN113712872APromote exfoliationEasy to updateCosmetic preparationsToilet preparationsWhite willow bark extractCodium fragile extract

The invention discloses an essence lotion composition containing lipidosome with skin brightening and whitening effects and a preparation method of the essence lotion composition. The essence lotion composition contains the following raw material components: 1.0%-45.0% of lipidosome with skin brightening and whitening effects, 5.0%-40.0% of emollient, 0.5%-30.0% of emulsifier, 0.5%-20.0% of filler, 0.1%-10.0% of thickener, 0.3%-5.0% of preservative, 0.01%-5% of pH regulator, 0.01%-1.0% of daily essence and the balance deionized water. The lipidosome with the skin brightening and whitening effects comprises the following main functional components: a white willow bark extract, undecylenoyl phenylalanine, nicotinamide and a codium fragile extract. The multiple different functional components are subjected to transdermal co-delivery through the lipidosome, and multi-effect and multi-target whitening synergistic interaction can be realized in the aspects of inhibiting generation, transportation, metabolism and the like of melanin.

Owner:湖北省麦诗特生物科技有限公司

Preparation method of high-purity quartz sand

The invention discloses a preparation method of high-purity quartz sand, and belongs to the technical field of mineral refining, and the preparation method comprises the following steps: crushing: crushing quartz sand crude ore into quartz sand particles; ultrasonic scrubbing: performing ultrasonic scrubbing on quartz sand particles; magnetic separation: selecting high gradient magnetic separatorfor three times magnetic separation of quartz sand fine sand; acid leaching: performing microwave heating quartz sand after flotation, then stirring and soaking with a 10% oxalic acid solution; flotation: mixing the quartz sand after acid leaching with water and putting into a flotation machine, adjusting the pH value in three steps, and using different collectors for flotation at the same time; drying and bagging: drying in a vacuum drying oven, and vacuum bagging after cooling. The preparation process is simple, reasonable and efficient in design; iron impurities in the quartz sand can be removed by ultrasonic scrubbing, multiple magnetic separation, microwave heating and acid leaching and flotation; the iron impurities in the prepared high-purity quartz sand are reduced to below 0.35 mg / kg; and the product has stable quality and high efficiency, and is suitable for large-scale popularization and application.

Owner:SICHUAN QINGCHUAN HONGYUAN STONE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com