Nanometer emulsion oil-displacing agent and preparation method thereof

A nano-emulsion and oil-displacing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that oil displacement sweep volume and oil displacement efficiency cannot be optimized, and it is difficult to maximize oil displacement and reduce viscosity. Insufficient capacity and other problems, to achieve the effect of strong surface activity, increased sweep volume, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides the preparation method of the nanoemulsion oil displacement agent described in above-mentioned scheme, comprises the steps:

[0035] (1) under the condition of nitrogen protection, the cross-linking agent and the monomer alkali-water mixture are mixed to obtain the monomer aqueous phase solution;

[0036] (2) Mineral oil is mixed with an emulsifier to obtain an oil phase;

[0037] (3) adding the oil phase obtained in the step (2) to the aqueous monomer solution obtained in the step (1) for emulsification to obtain an emulsion;

[0038] (4) under the condition of nitrogen protection, the oxidant, reducing agent and the emulsion obtained in the step (3) are mixed and polymerized to obtain a nanoemulsion oil displacement agent;

[0039] There is no limitation on the order of the steps (1) and (2).

[0040] In the invention, the cross-linking agent is mixed with the monomer alkali-water mixed liquid under the nitrogen protection condition to...

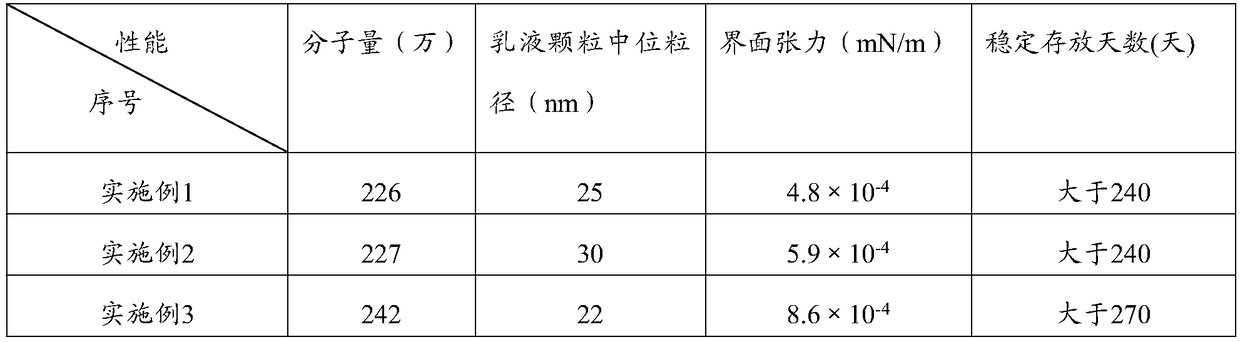

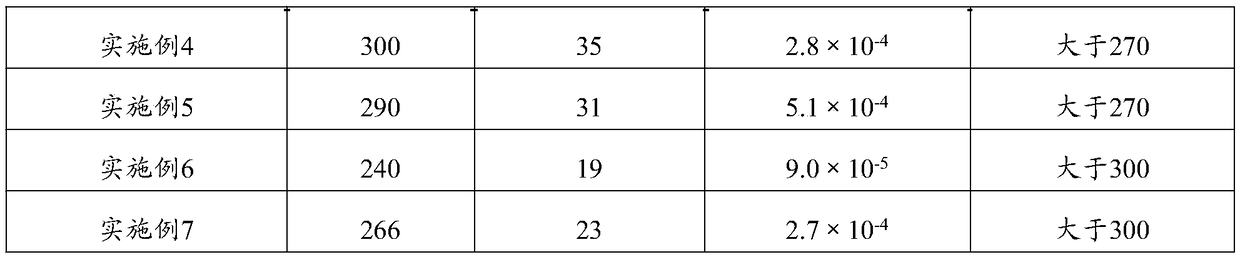

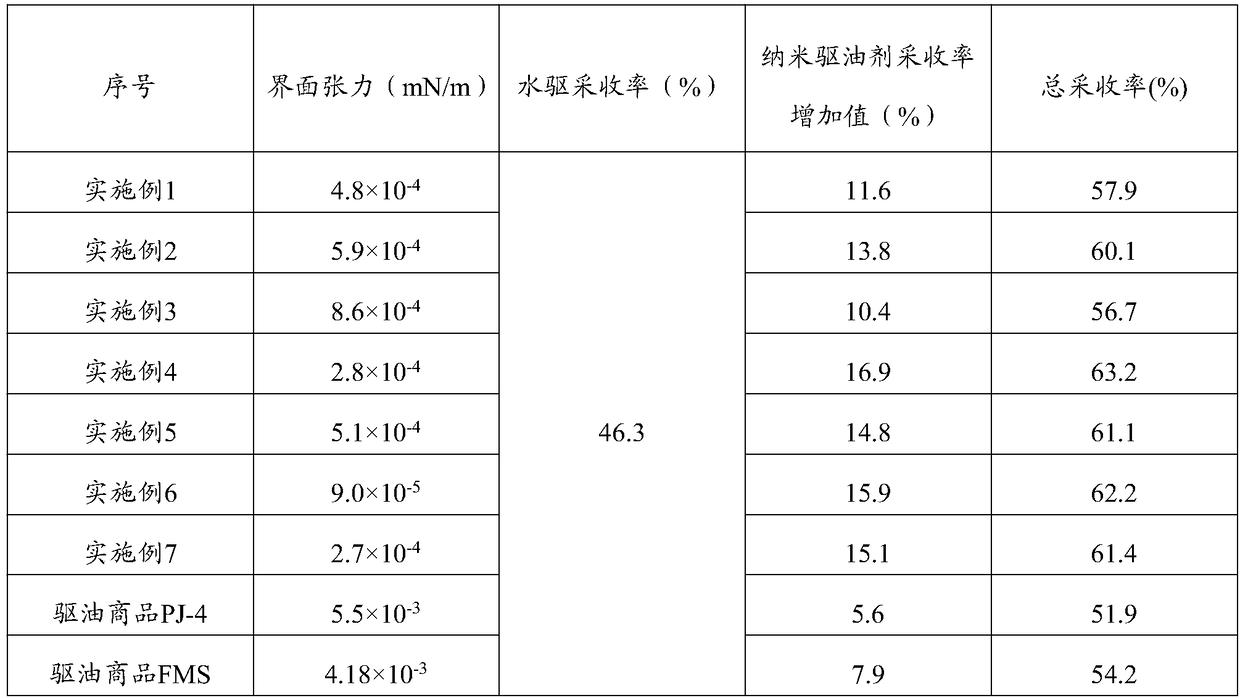

Embodiment 1

[0052] A nanoemulsion oil displacement agent, prepared from raw materials comprising the following parts by weight: 45 parts of mineral oil, 6 parts of emulsifier, 48 parts of monomer alkali-water mixture, 0.2 part of crosslinking agent, 0.3 part of oxidizing agent, reducing agent 0.5 copies;

[0053] The preparation method of above-mentioned nanoemulsion oil displacement agent, comprises the steps:

[0054] Weigh each raw material according to the stated weight, put the sodium acrylate aqueous solution with a mass concentration of 60% in the reaction kettle, and pass through nitrogen to remove the air, add N,N-methylenebisacrylamide and stir evenly to obtain the sodium acrylate aqueous phase solution; add the mixture of Span 80 and Tween 60 to industrial white oil and stir evenly to obtain an oil phase; add the oil phase to the reaction kettle and mix it with the sodium acrylate aqueous phase solution, and stir at a rate of 1600 rpm to form a milky white emulsion; Raise the ...

Embodiment 2

[0056] A nanoemulsion oil displacement agent, prepared from the following raw materials by weight: 37 parts of mineral oil, 4 parts of emulsifier, 30 parts of monomer alkali-water mixture, 0.5 part of crosslinking agent, 0.05 part of oxidizing agent, reducing agent 0.04 part; Preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com