Patents

Literature

250results about How to "Improve cavitation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser cladding technological method and alloy material for laser cladding

ActiveCN102168210AUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusCavitationSlag

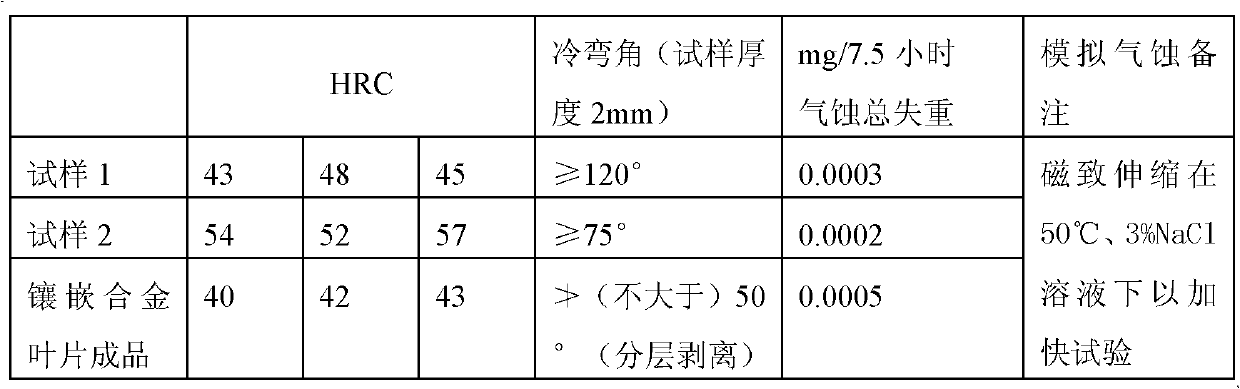

The invention discloses an alloy material for laser cladding. The alloy material is alloy powder and contains the following components in percent by weight: C: 0.85-0.98%, Cr: 35-45%, Fe: 3-5%, Si: 0.5-1.0%, W: 3.5-5.5%, Mo: 1 .0-1.5%, Ni: 6-8%, V: 1.5-2.0%, Ti: 1.0-2.0%, B: 0.5-1.5%, Nb: 0.10-0.50%, Re: 0.5-1.5%, and Co: the balance. The invention also discloses a laser cladding technological method adopting the alloy material. In the technical scheme, under the combined action of the added alloy elements, cladding layer tissue is uniform and tiny and has no pore, no inclusion and no included slag; and preheating is not needed when a blade is cladded and crack does not emerge. The alloy material has high rigidity and excellent cavitation resistance; without follow-up heating treatment, a cladded part can be directly fine machined to use; and the laser treatment technology has good adaptivity and is simple and feasible in operation.

Owner:HANGZHOU BOHUA LASER TECH

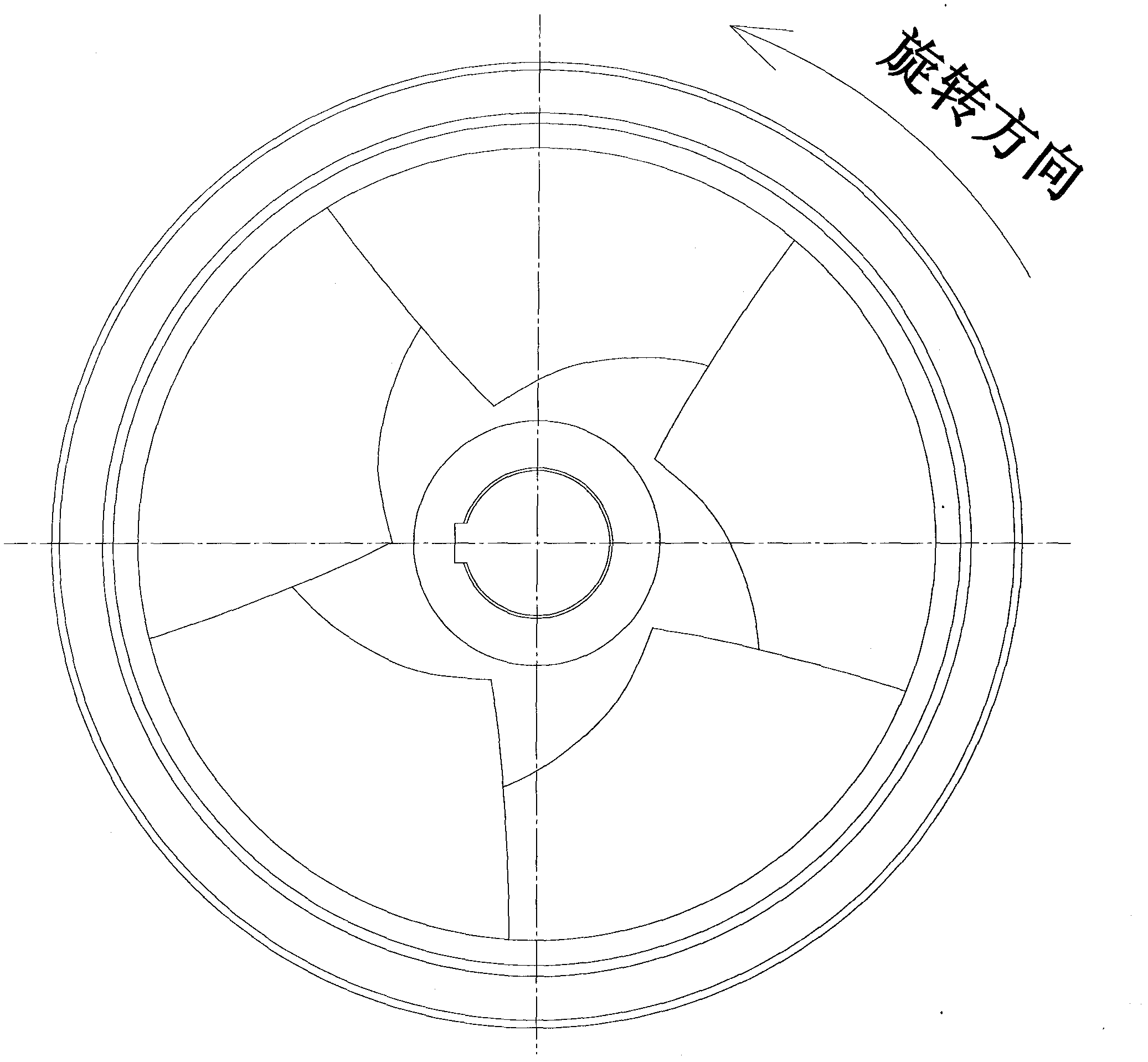

CFD (Computational Fluid Dynamics)-based modeling design method for nuclear main pump and designed million-kilowatt-grade nuclear main pump impeller

InactiveCN102207101AEasy to chooseImprove hydraulic performancePump componentsPumpsImpellerConversion coefficients

The invention discloses a CFD (Computational Fluid Dynamics)-based modeling design method for a nuclear main pump and a designed million-kilowatt-grade nuclear main pump impeller, belonging to the technical fields of design and manufacture of pumps. The CFD-based modeling design method for the nuclear main pump is characterized by comprising four steps of: 1, selecting a model pump impeller satisfying similar conditions with a pre-designed pump impeller according to the design parameters of a million-kilowatt-grade nuclear main pump; 2, calculating size conversion coefficients by utilizing a conventional modeling design formula, and selecting 3-4 different size coefficients within a certain range to convert the model pump impeller; 3, carrying out numerical simulation respectively on the 3-4 pump impellers obtained in the step 2, and carrying out logarithm fitting on a relation between the size coefficients and delivery lift to obtain the nuclear main pump impeller meeting requirements; and 4, optimizing the nuclear main pump impeller obtained in the step 3 to complete the design. The invention has the advantages that the design problem of the high-temperature and high-pressure large-flow million-kilowatt-grade nuclear main pump is solved, and a design process is concise, efficient and controllable.

Owner:DALIAN UNIV OF TECH

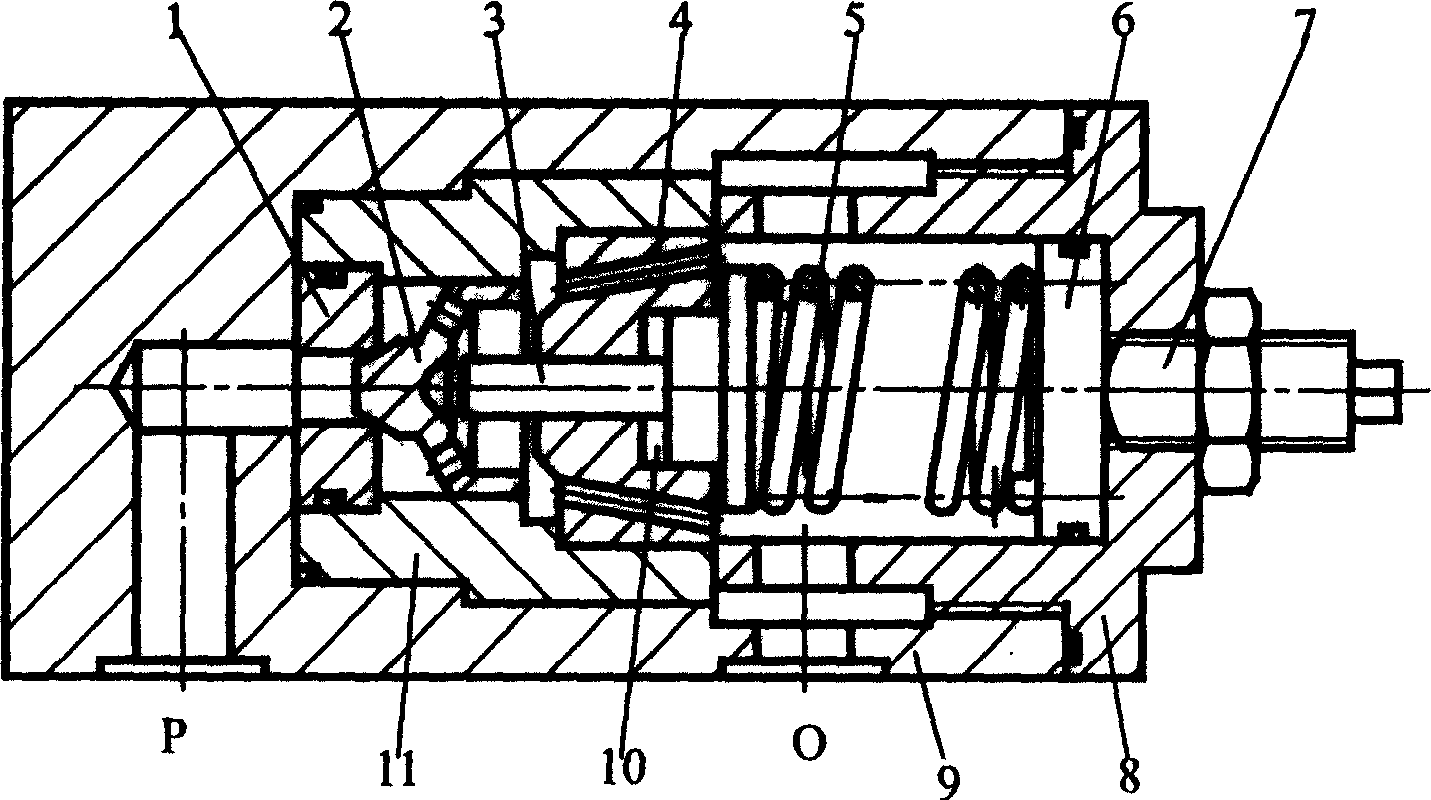

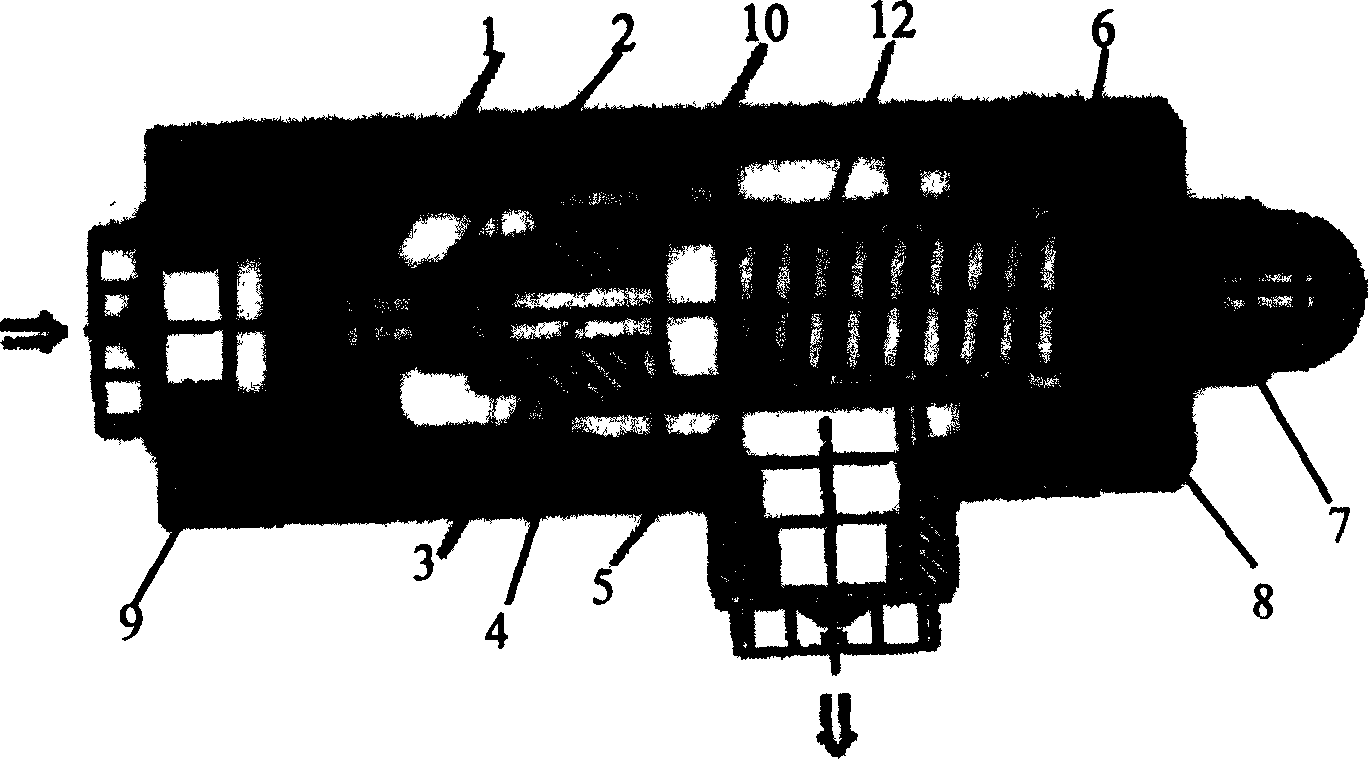

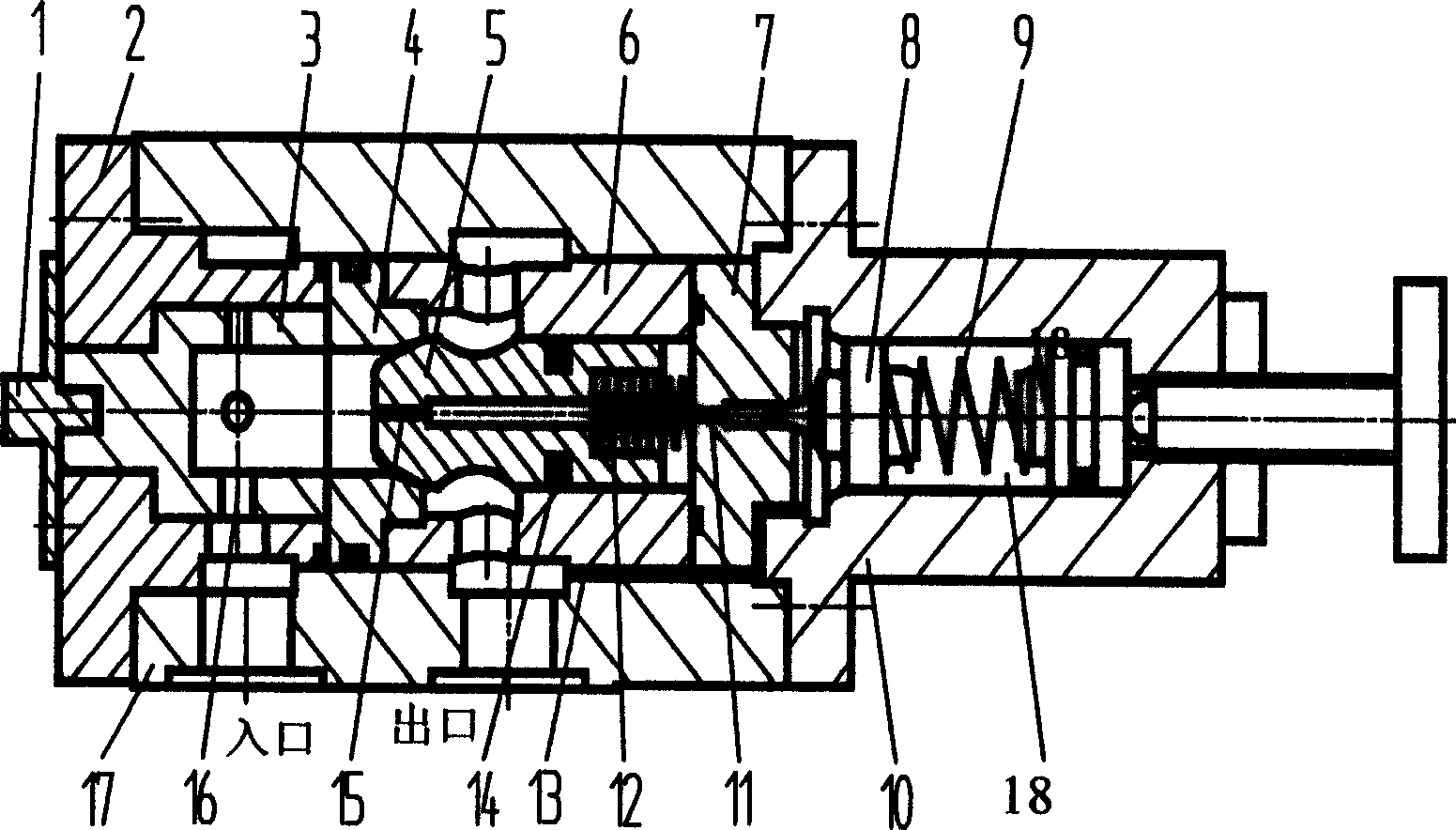

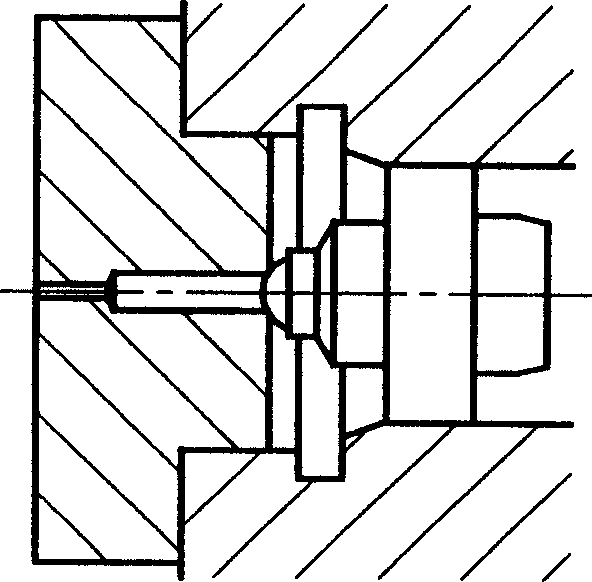

Middle high pressure directly-acting hydraulic overflow valve

ActiveCN1563764AReduce leakageImprove cavitation resistanceEqualizing valvesSafety valvesLow noiseWater based

The present invention relats to pressure control element in hydraulic system and belongs to the field of valve. The present invention includes valve seat, valve core, damping rod, damping sleeve, valve sleeve, pressure regulating spring, spring seat, end cap and regulating screw. The valve core is one cavity; the damping rod and the damping sleeve have their inner holes form fitting interval and damping cavity; the valve seat and the valve core form one conic valve structure; and the valve core has small holes in its shoulder and tail end forming guide surface to the inner hole of the valve sleeve. The present invention is suitable for use as pressure controlling valve in high and medium pressure hydraulic system with water-based work medium. Compared with similar overflow valves, the present invention has the advantages of less leakage, high cavitation erosion resistance, less vibration, low noise and stable work performance.

Owner:WUHAN MAJOR DAY DIGITAL MACHINERY MFG CO LTD

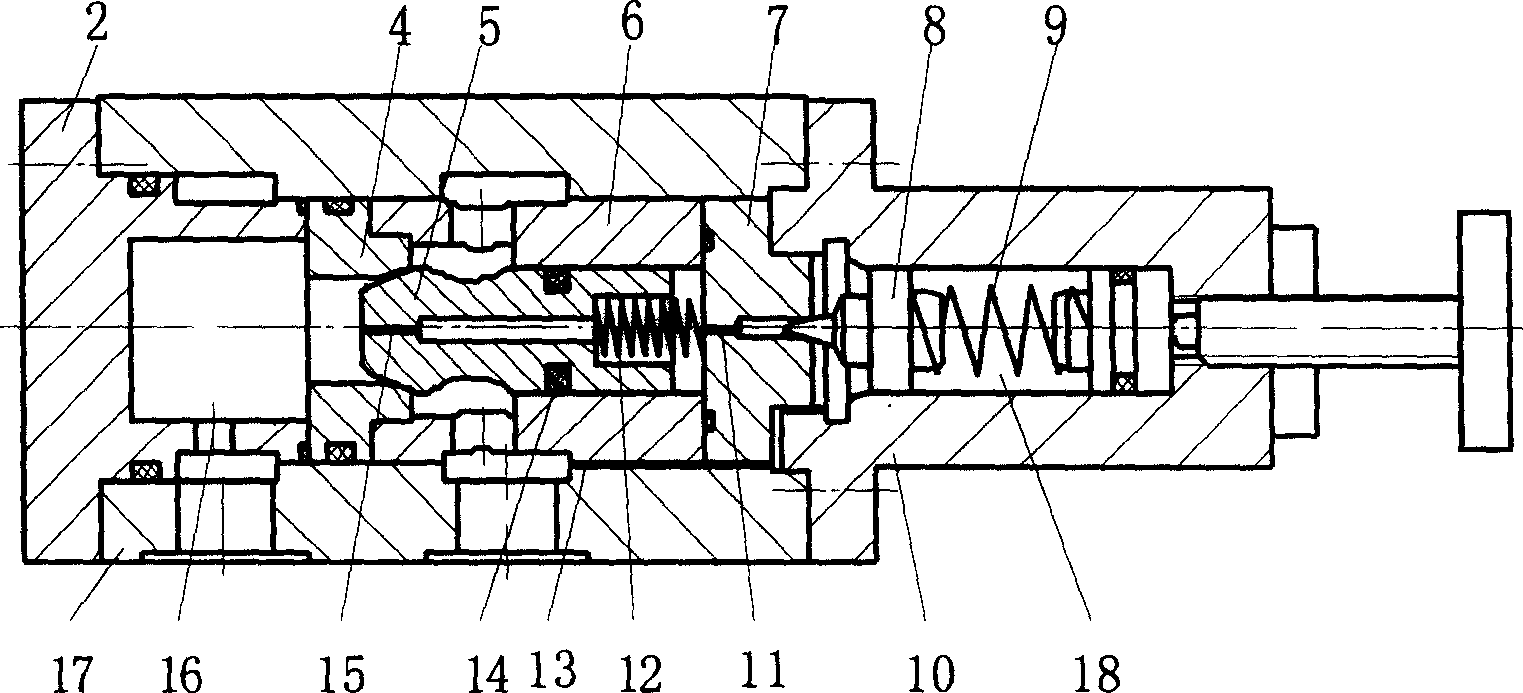

Leading type water pressure overflow valve

InactiveCN1619198AImprove job stabilityReduce working pressure differenceEqualizing valvesSafety valvesEngineeringValve seat

The present invention relates to a pilot type hydraulic overflow valve. Its main valve body has front end cover, in said main valve body a main valve seat, a main valve buckle, a main valve core and a main valve spring are set, and said pilot valve is formed from its valve seat, valve core and pressure-regulating spring, said pilot valve is connected with said main valve. Said invention also provides the structure of main valve and pilot valve, and provides the application range of said valve.

Owner:HUAZHONG UNIV OF SCI & TECH

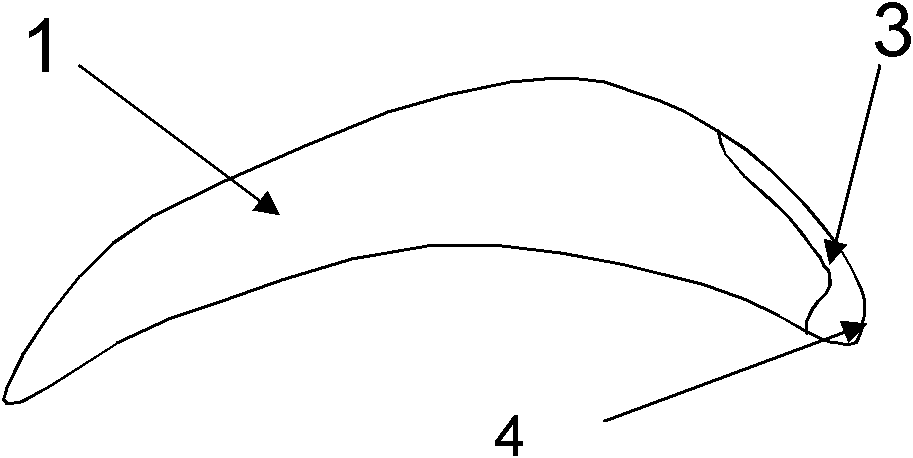

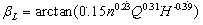

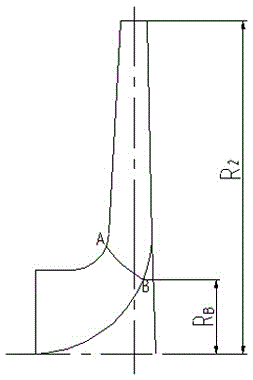

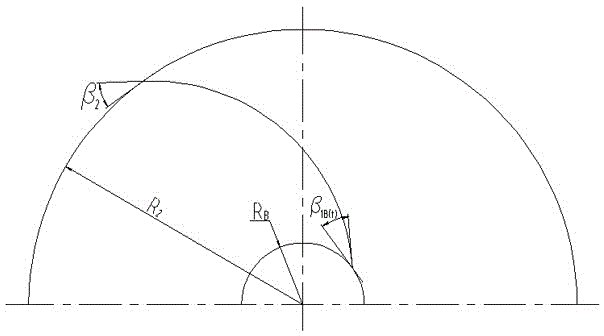

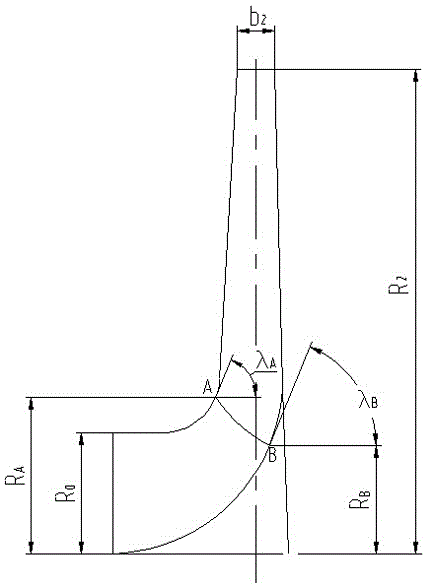

Method for optimally designing impellers of bidirectional axial flow pumps

The invention discloses a method for optimally designing impellers of bidirectional axial flow pumps. The method is characterized by comprising steps of designing hydraulic power on planar hydraulic power graphs of impellers in a central symmetry manner; completely modifying working faces of wing sections of the impellers into straight lines, enabling inlets and outlets of the backs of the wing sections of the impellers to be in circular arc transition, properly thickening the middles of the wing sections of the impellers and modifying the wing sections of the impellers into symmetrical structures; designing the impellers according to a plurality of main parameters including wrap angles phi of blades, diameters d<h> of hubs, diameters D of the impellers, setting angles beta<L> of lines, chord lengths I and radiuses R<1> of the lines. The method has the advantages that the performance of the impellers of the bidirectional axial flow pumps can be improved by means of optimizing the wing section and the planar graphs of the impellers on the basis of the traditional streamline method for designing impellers of axial flow pumps, and accordingly the purpose of improving the efficiency and the cavitation erosion resistance of the impellers of the bidirectional axial flow pumps can be achieved; high efficiency, a wide efficient range and the good cavitation erosion resistance of the bidirectional axial flow pumps can be guaranteed by the aid of the method, and the method is applicable to bidirectional axial flow pumps with the specific speeds ranging from 600 to 2000.

Owner:JIANGSU UNIV

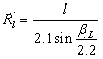

Plasma-sprayed ceramic layer on neodymium-iron-boron permanent magnet material surface and preparation method of plasma-sprayed ceramic layer

ActiveCN107254656AFirmly connectedFast preparationMolten spray coatingPermanent magnet manufactureComposite ceramicAlloy

The invention discloses a plasma-sprayed ceramic layer on a neodymium-iron-boron permanent magnet material surface capable of avoiding the failure phenomena, such as foaming in a protective layer of the neodymium-iron-boron permanent magnet material surface and peeling of the protective layer and a preparation method of the plasma-sprayed ceramic layer. The plasma-sprayed ceramic layer on the neodymium-iron-boron permanent magnet material surface comprises a neodymium-iron-boron machine body, an Al2O3-TiO2 composite ceramic layer and a Ni-Al alloy layer transition layer. The preparation method comprises the steps of (1) pretreating a neodymium-iron-boron matrix; (2) carrying out preheating treatment on the pretreated neodymium-iron-boron matrix in a vacuum environment; (3) preparing the Ni-Al alloy layer transition layer on the surface of the preheated neodymium-iron-boron matrix by adopting plasma spraying; and (4) preparing the Al2O3-TiO2 composite ceramic layer on the surface of the Ni-Al alloy layer transition layer by adopting plasma spraying. According to the plasma-sprayed ceramic layer of the neodymium-iron-boron permanent magnet material surface and the preparation method of the plasma-sprayed ceramic layer, rapid preparation of the high-quality protective layer on the neodymium-iron-boron permanent magnet material surface can be achieved, no by-product exists in the preparation process, and the plasma-sprayed ceramic layer is green, clean and free of pollution.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Double-stage variable-speed oppositely-rotating axial flow pump flow passage component for water spraying propelling

InactiveCN103291651AImprove lifting efficiencyImprove stabilityPump componentsPropulsive elementsImpellerAxial-flow pump

The invention discloses a double-stage variable-speed oppositely-rotating axial flow pump flow passage component for water spraying propelling. A primary-stage impeller is in an inducer mode. The rotating direction of the primary-stage impeller is opposite to the rotating direction of a secondary-stage impeller. The rotating speed of the primary-stage impeller and the rotating speed of the secondary-stage impeller are different so as to meet the cavitation performance requirement and the lift efficiency requirement respectively. The ratio of the rotating speed n1 of the primary-stage impeller to the rotating speed n2 of the secondary-stage impeller is between 1 and 2. The boss diameter ratio dh to D of the primary-stage impeller is between 0.25 and 0.6. According to the double-stage variable-speed oppositely-rotating axial flow pump flow passage component for water spraying propelling, a double-stage variable-speed oppositely-rotating axial flow pump is good in cavitation resistant performance, high in lift efficiency and compact in structure, expands the use range of a traditional axial flow pump, and is applicable to the water spraying propelling fields with the operating requirements of good cavitation resistant performance, high lift efficiency, compact structures and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Epoxy resin mortar and preparation method

In the invention, epoxy, meidum plain emergy, diluent and curing agent are used as raw material, their weight percentage are (wt%): epoxy 12-16, medium plain emergy 73-82, diluent 1.5-2.5, curing agent 4.5-8.5. epoxy is optimum selected A-type E44 epoxy, medium plain emery can be river sand or quartz sand, diluent can be epoxy propane butyl ether, curing agent is optimum selected modified M-phthalic amine curing agent. Modifying method of said M-phthalic amine curing agent is that M-phthalic amine curing agent and monocycle oxo-compound do chemical combining reaction to generate liquid amine compound, then to be modified by acylate.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Molybdenum-disulfide radical anti-corrosion wear-reduced coating

InactiveCN101070449AImprove wear resistanceImprove carrying capacityAnti-corrosive paintsEpoxy resin coatingsOxygenSolvent

The present invention belongs to chemical paint technique area, specifically, it is amolybdenum disulfide fire-resistant anticorrosion antifriction paint. It selects fire-resistant bisphenol. A oxygen resin as gelatinizing agent, dicyandiamide as curing agent, molybdenum disulfide as lubricant, carbon black as antiseptic agent, and then add the mixed solvent. Finally the molybdenum disulfide fire resistant anticorrosion antifriction paint is formed. In the middle or high temperature environment, the coat has not only good abrasive resistance, bearing capacity and lubricity, but also excellent anticorrosion, grease-proof and erosion resistance. The effect: surface-prevention, antifriction, sealing, lubrication and extension the use of components. The metal sealing gasket painted with this paint can be used for a long time in the high temperature condition. It can reach the requirement of working in difficult condition, such as car ventilating pipe sealing components.

Owner:FUDAN UNIV

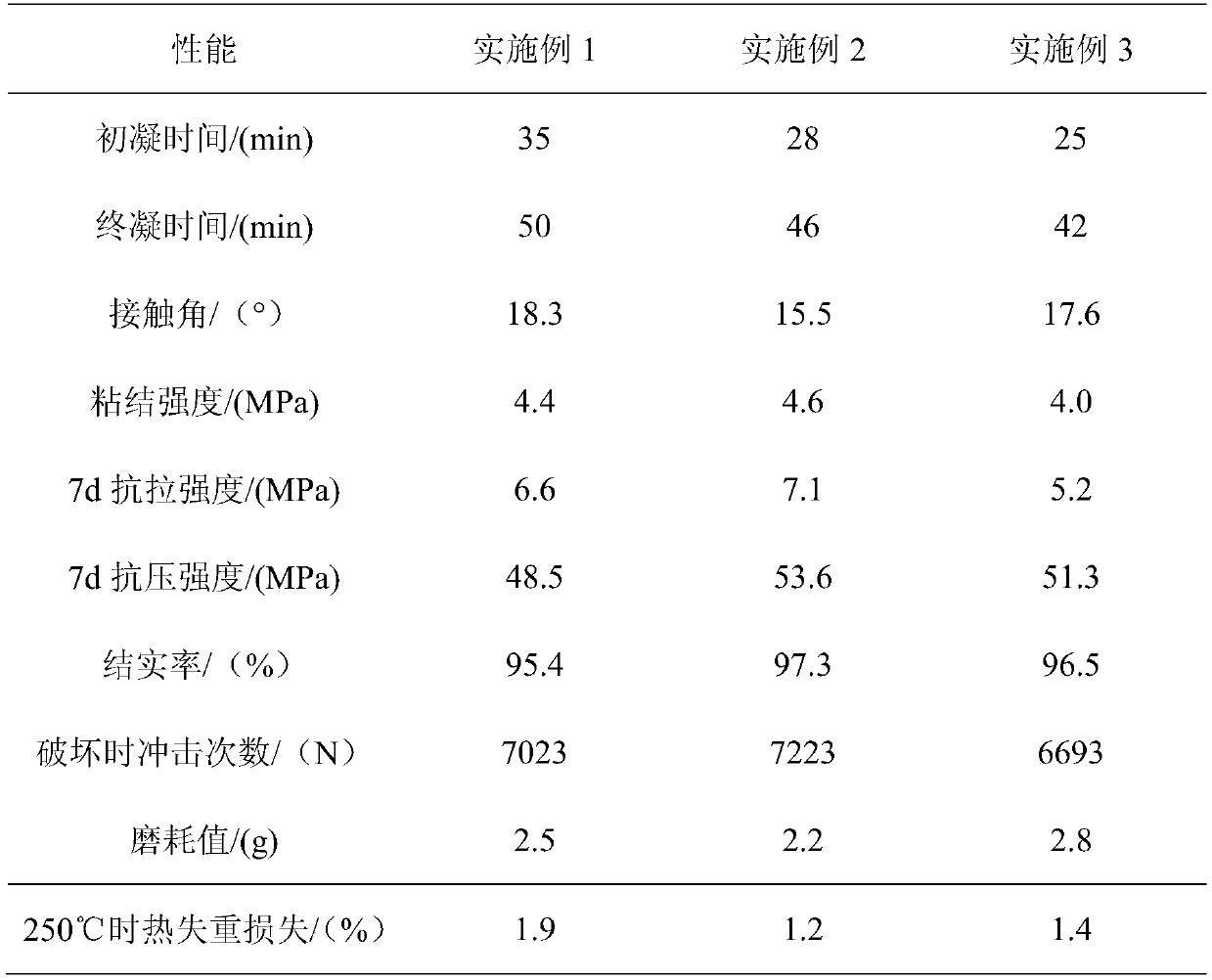

Double-doped grouting material for repairing pavement and preparation method of double-doped grouting material

The invention relates to a double-doped grouting material for repairing a pavement and a preparation method of the double-doped grouting material. The double-doped grouting material is prepared from the following components in parts by weight: 50 to 70 parts of silicate cement, 20 to 30 parts of aluminate cement, 5 to 8 parts of silica fume, 10 to 15 parts of coal ash, 8 to 12 parts of barite powder, 1 to 3 parts of retarding admixture, 10 to 15 parts of waterborne epoxy resin, 3 to 8 parts of polyurethane, 0.5 to 0.8 part of antioxidant, 0.1 to 0.3 part of defoaming stabilizer, 1 to 4 parts of coupling agent, 0.3 to 0.5 part of surfactant, 3 to 8 parts of waste rubber powder, 0.05 to 0.2 part of cement reinforcing agent, and 0.1 to 0.3 part of water retaining agent. The double-doped grouting material prepared by the invention has high permeability, impact and wear resistance, high strength, high toughness, high temperature resistance and good durability, can solidify loose particles,has good binding property with original pavement concrete and is suitable for repairing various pavements.

Owner:CHANGAN UNIV

Large submersible electric pump

InactiveCN1694335AReduce temperature riseHighlight substantiveMechanical energy handlingCooling/ventillation arrangementEngineeringHigh rise

This invention relates to a large diving pump to control the temperature rising of the stator and rotor effectively. An air-water cooling system formed by an air cooling circulation made up of centrifugal fans and a water cooler set at the shell is formed in the motor, which can effectively reduce the rising of the temperature of the stator windings. The plan for reducing the high rising temperature of the rotor is to form a surface trench of large pitch to play the role of a screw fan forcing the internal air to flow through the air space surface and bring away with the heat generated by the rotor to form an independent cooling system of rotor ventilation with the outer water cooler.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

Nano coating protective pipe and its coating manufacture process

InactiveCN101169215ASmall volume shrinkageSmooth rotationCorrosion preventionPipe protection against corrosion/incrustationSteel tubeParaffin oils

The invention discloses a nanometer coating protective pipe prepared by nanometer squama coating and production technique of coating, wherein, the nanometer coating protective pipe consists of three parts of a pipe body, a basal layer and a function layer. The basal layer is the substrate of the nanometer coating and coated on the surface of the pipe body when contacts with a metal base body. The function layer is the facial layer of the nanometer coating and coated on the surface of the basal layer when the function layer contacts with corrosive medium. The nanometer coating the protective pipe disclosed in the invention changes the surface characteristic of the steel pipe products, and acquires a novel characteristic completely different from the original steel pipe products and enables the products to satisfy the need of people towards hi-tech development. The nanometer coating can provide oil pipe products with good performance in resisting corrosion, paraffin, scale and abrasion, so as to greatly prolong the maintenance period of the pipeline products in oil extracting wells, water injecting wells and conveying pipelines of oil fields.

Owner:白日忠

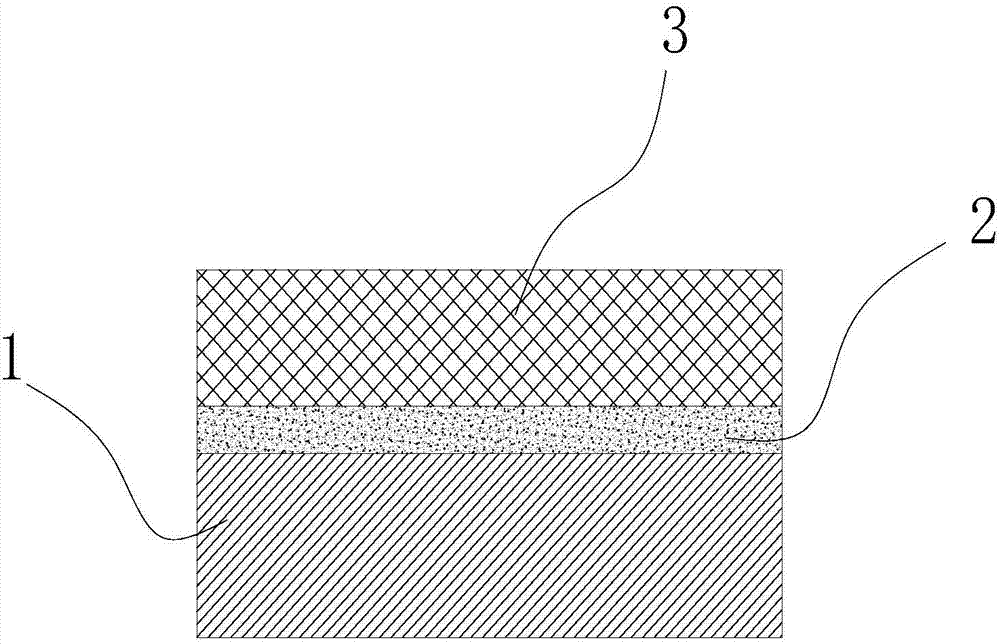

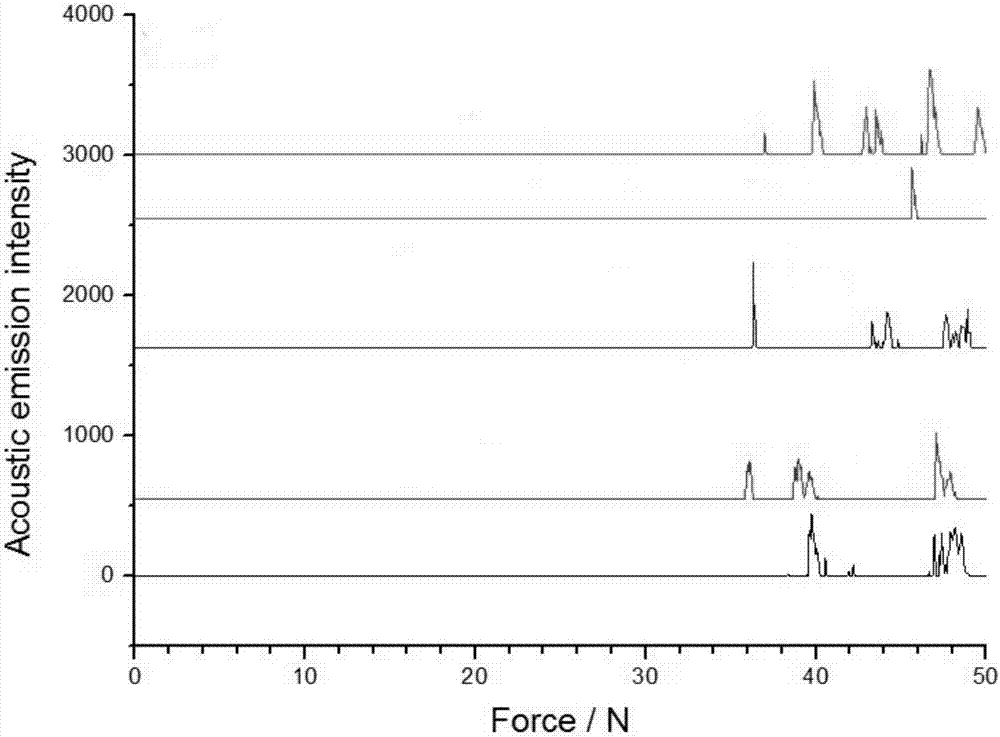

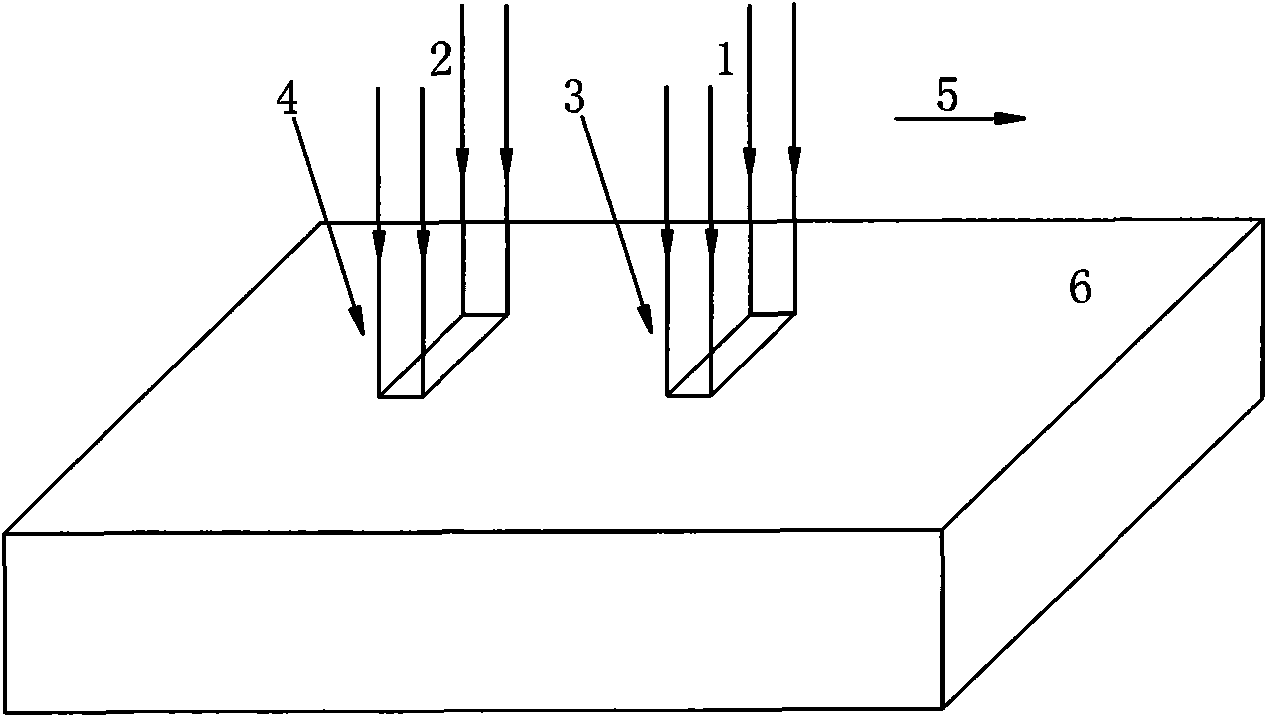

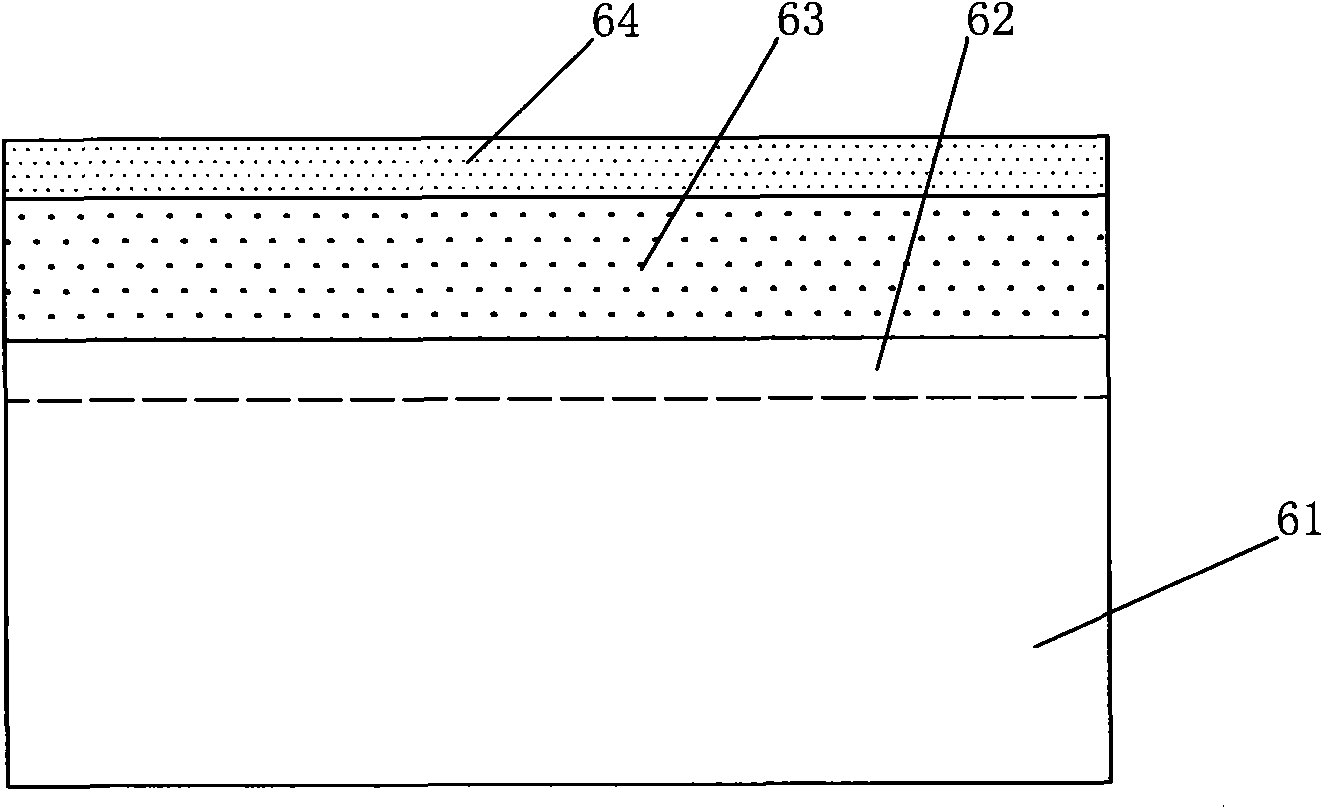

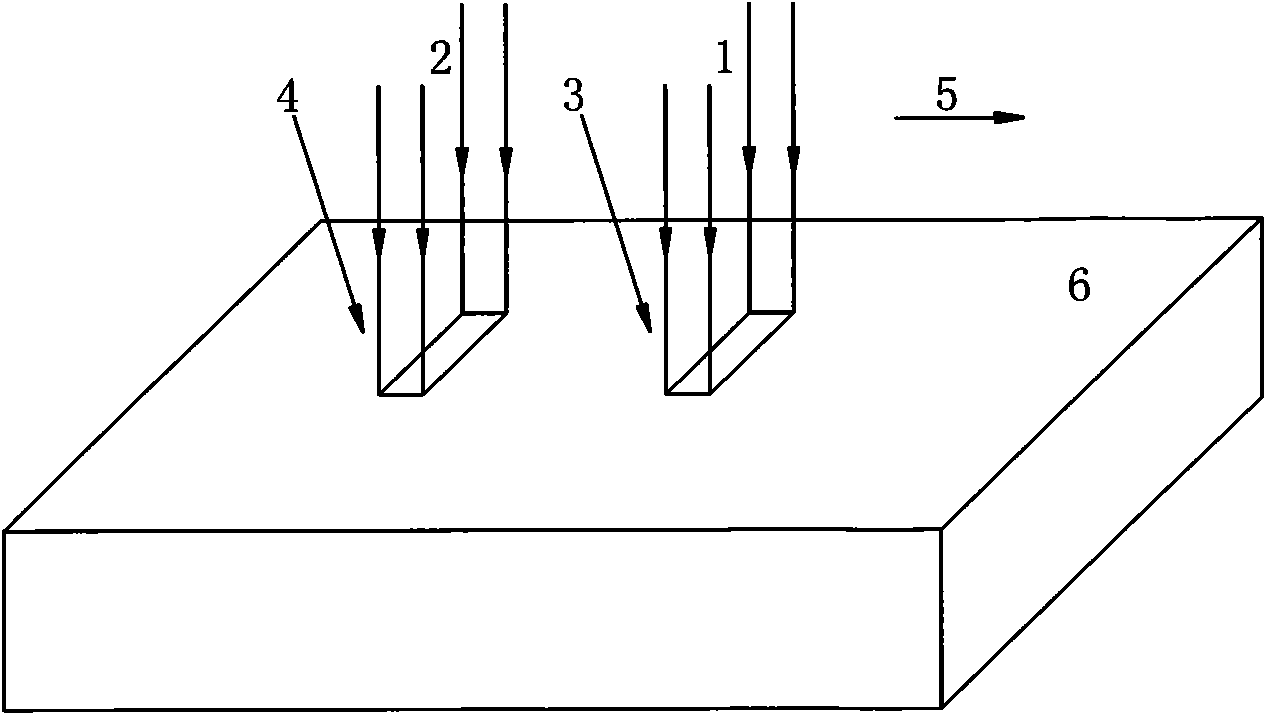

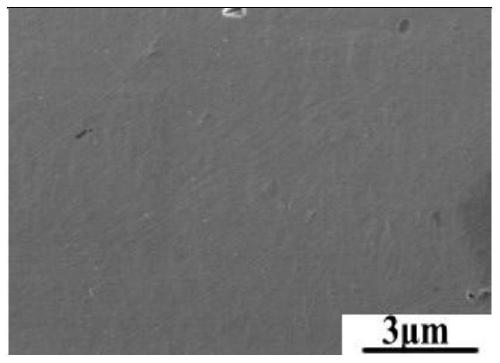

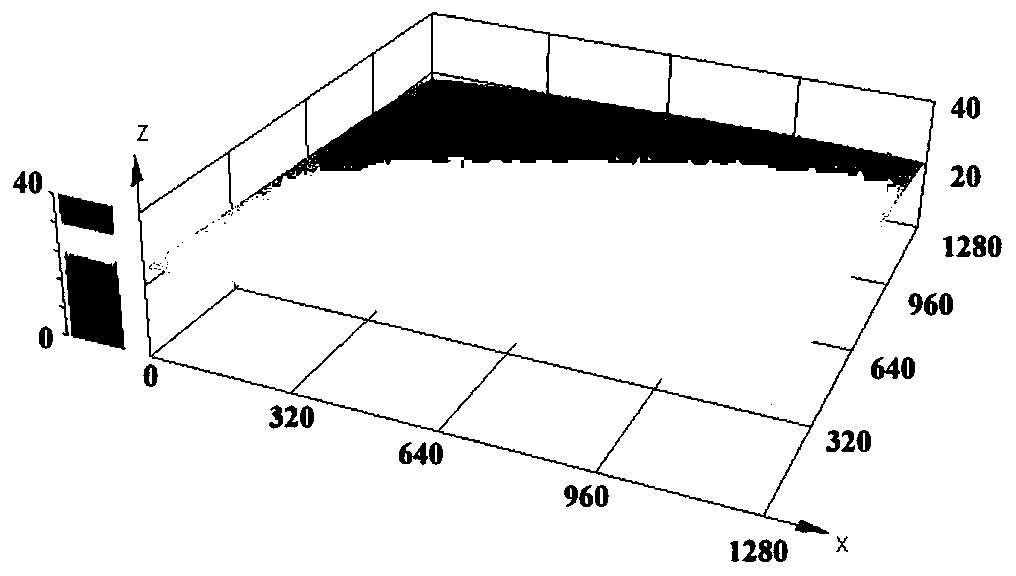

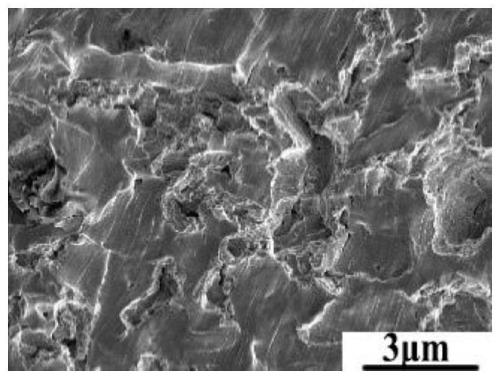

Cavitation-erosion-resistant laser re-melting method of metal ceramic coating through thermal spraying

InactiveCN110699626ASurface texture improvementRegular coating structureMolten spray coatingCeramic coatingCermet

The invention relates to the technical field of cavitation-erosion-resistant coatings, and discloses a method for preparing a cavitation-erosion-resistant coating through a thermal spraying and laserre-melting compound technology. The method comprises the following steps that (1) a metal ceramic composite coating is prepared on a matrix through thermal spraying; and (2), laser re-melting treatment is carried out on the metal ceramic composite coating obtained in the step (1), the surface of the metal ceramic coating is re-melted to form a new structure under high-density energy of lasers, thestructure property of the coating is enhanced after cooling, and the cavitation erosion resistance of the coating can be greatly improved. The method effectively eliminates the problem that ceramic powder deposits on the surface of the matrix through direct laser cladding, the obtained coating is low in porosity, the surface is compact and smooth, the cavitation erosion resistance is excellent, the coating can be widely applied to propellers, water turbine blades and other equipment prone to cavitation damage, the service life of the equipment can be prolonged, the frequency of maintaining the equipment due to cavitation damage is greatly reduced, and the using efficiency of the equipment is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Mixed fiber concrete pipe

The invention relates to a mixed fiber concrete pipe, wherein mixed fiber concrete for forming the pipe comprises the following components according to the parts by weight: 322-540 parts of cement, 140-220 parts of water, 475-828 parts of sand, 864-1,306 parts of cobbles, 0.2-20 parts of polymer fibers and 20-140 parts of steel fibers. The mixed fiber concrete pipe has low raw material cost, light weight, high tensile strength, flexural strength, shearing strength and torsional strength, better durability and fatigue resistance, stronger capacities of shock resistance, abrasion resistance and cavitation resistance and better crack resistance, conforms to an energy saving and emission reduction policy and is a renewal product of the existing concrete pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Surface composite strengthening technology for precipitation hardening stainless steel and precipitation hardening stainless steel material

The invention discloses a surface composite strengthening technology for precipitation hardening stainless steel and a precipitation hardening stainless steel material processed by the technology. In the technology, two laser beams are utilized to carry out controllable selection deep-layer solid solution and alloying composite strengthening treatment on a substrate synchronously, thus solving the problem existing when two techniques of solid solution and alloying are synchronously composited, and the invention also provides a laser treatment method which not only has high local fatigue resistance and high solid solution strengthening depth but also obtains higher surface hardness, wear resistance and anti-cavitation performance, so that the overall strengthening layer depth, performance and hardening gradient of the material at a processing area are controlled, and the application range of the precipitation stainless steel is enlarged.

Owner:姚建华

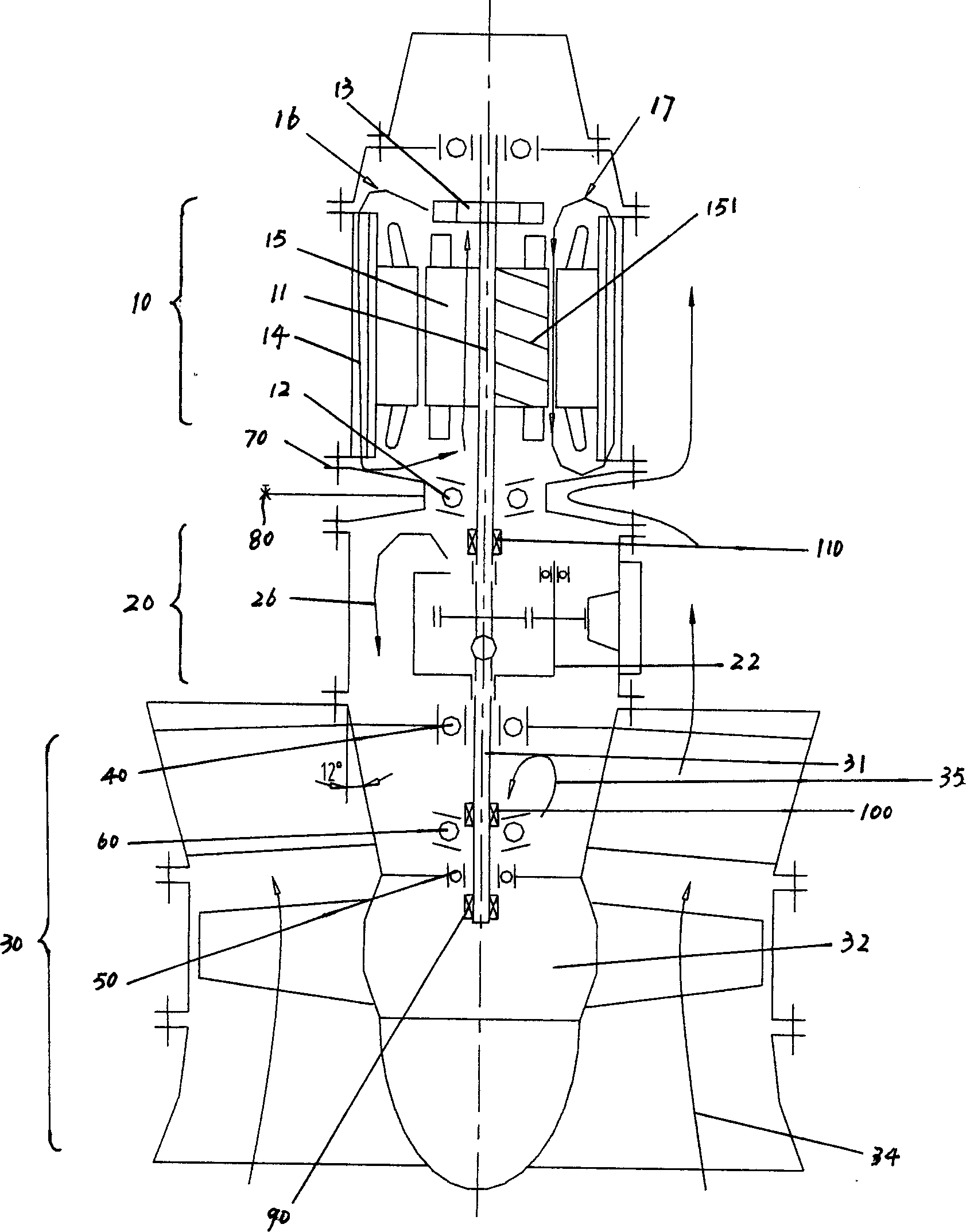

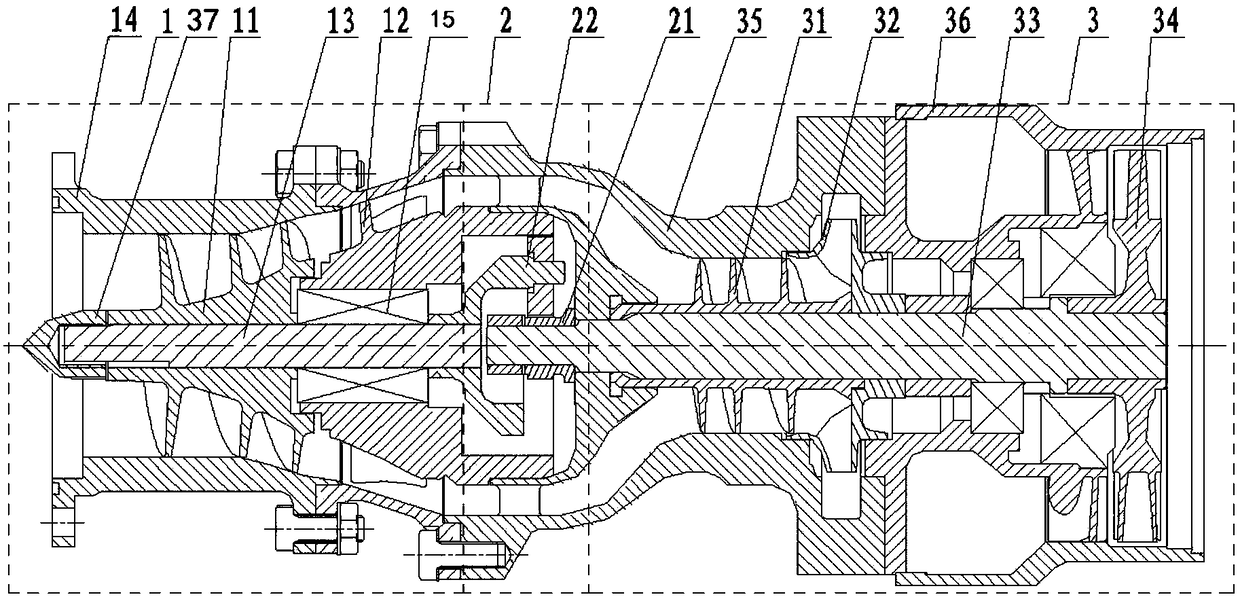

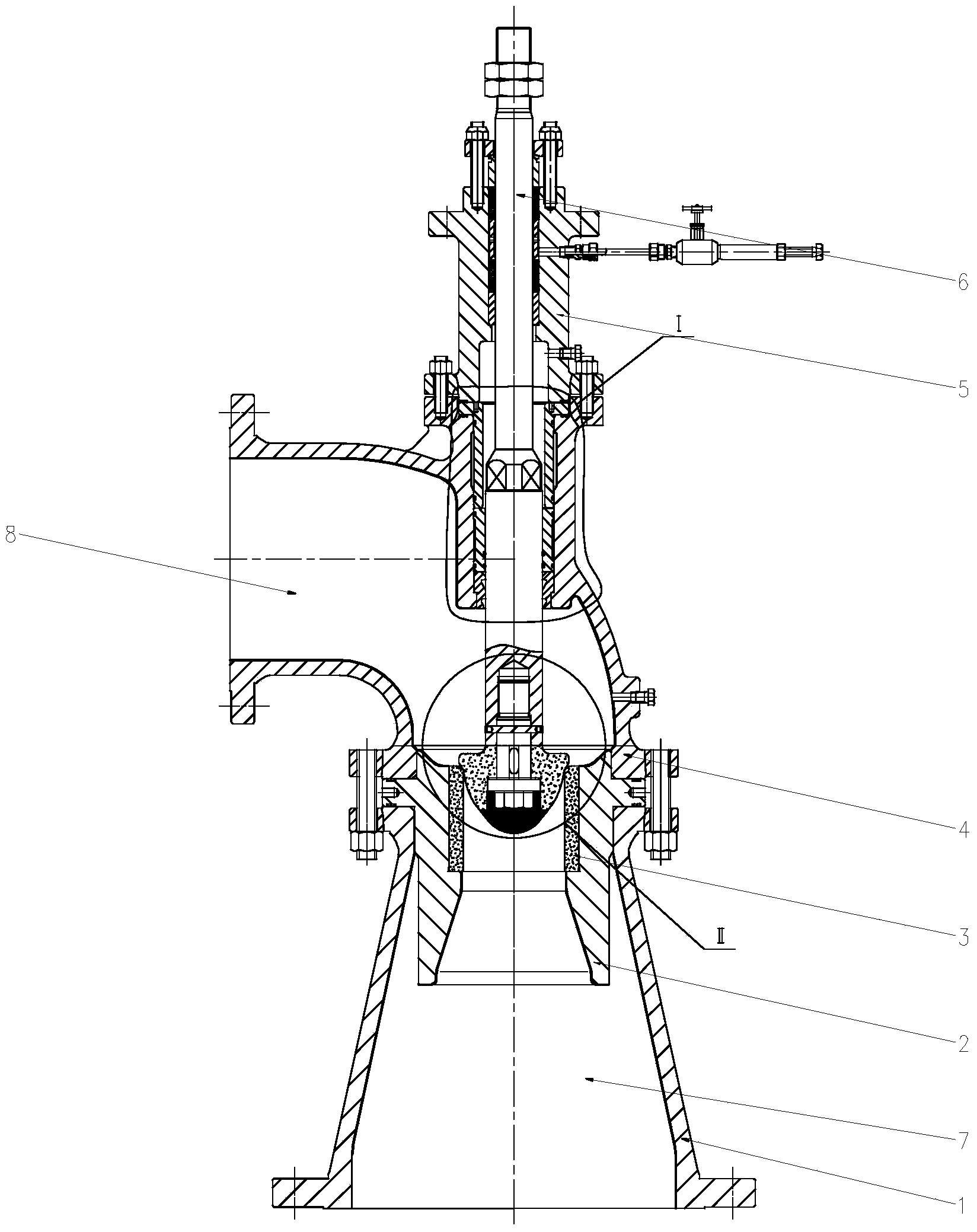

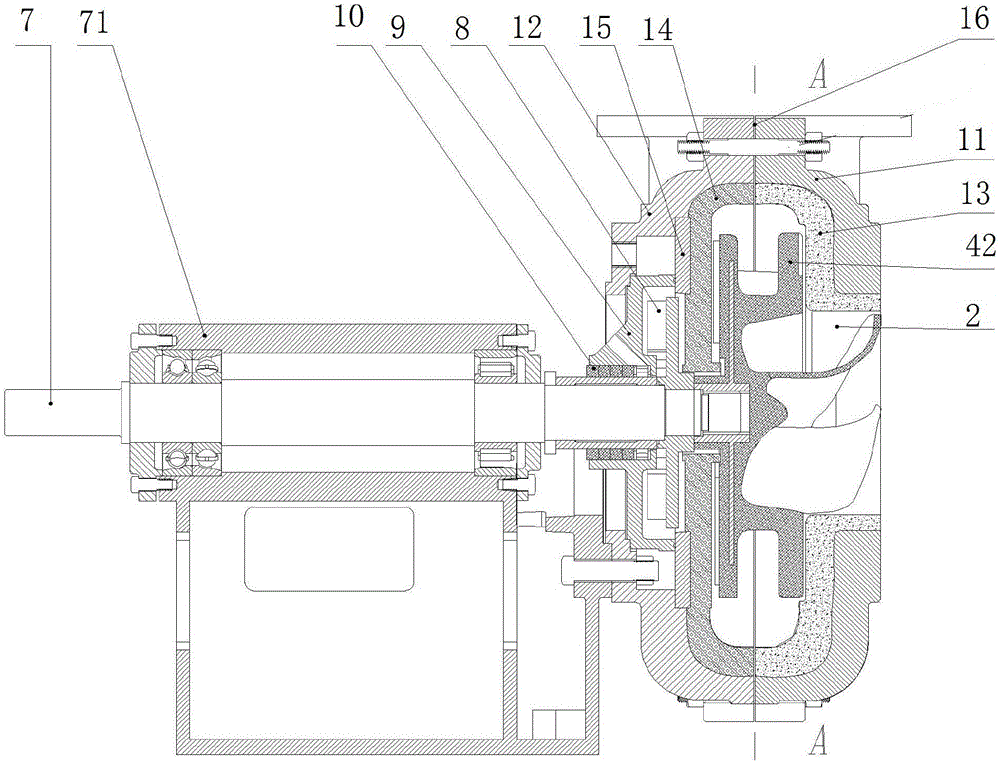

Air turbine pump with pre-pressing pump

InactiveCN108386366AImprove cavitation resistanceImprove anti-cavitation performancePump componentsPump installationsImpellerLow speed

The invention relates to an air turbine pump with a pre-pressing pump. The problems that an existing air turbine pump cannot work at low inlet pressure and is low in system efficiency, is complex in system structure, and is difficult to use in a small-size space are solved. The air turbine pump comprises the pre-pressing pump, a speed reducer and a main pump; the pre-pressing pump comprises a front shell, a pre-pressing impeller and a pre-pressing pump shaft, and the pre-pressing impeller is arranged on the pre-pressing pump shaft and is arranged in the front shell; the main pump comprises a middle shell, a rear shell, an induction wheel, a centrifugal wheel, a turbine and a main pump shaft, the induction wheel and the centrifugal wheel are both arranged in the middle shell, the turbine isarranged in the rear shell, the middle shell is correspondingly and fixedly connected with the front shell and the rear shell, the induction wheel and the turbine are arranged on the two sides of themain pump shaft correspondingly, the centrifugal wheel is arranged between the induction wheel and the turbine, the main pump shaft penetrates through the induction wheel and is connected with the speed reducer; and the speed reducer comprises a high-speed gear and a low-speed gear train, the main pump shaft is connected with the high-speed gear of the speed reducer, and the pre-pressing pump shaft is connected with the low-speed gear system of the speed reducer.

Owner:XIAN AEROSPACE PROPULSION INST

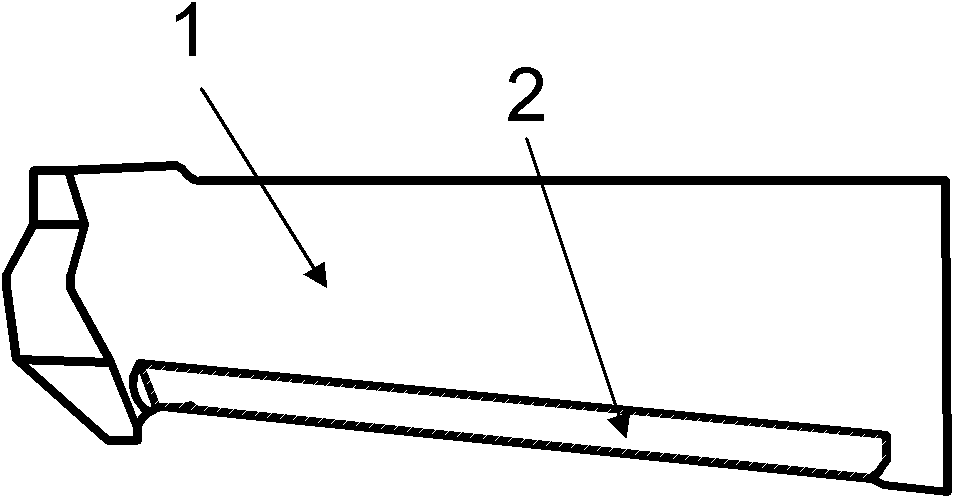

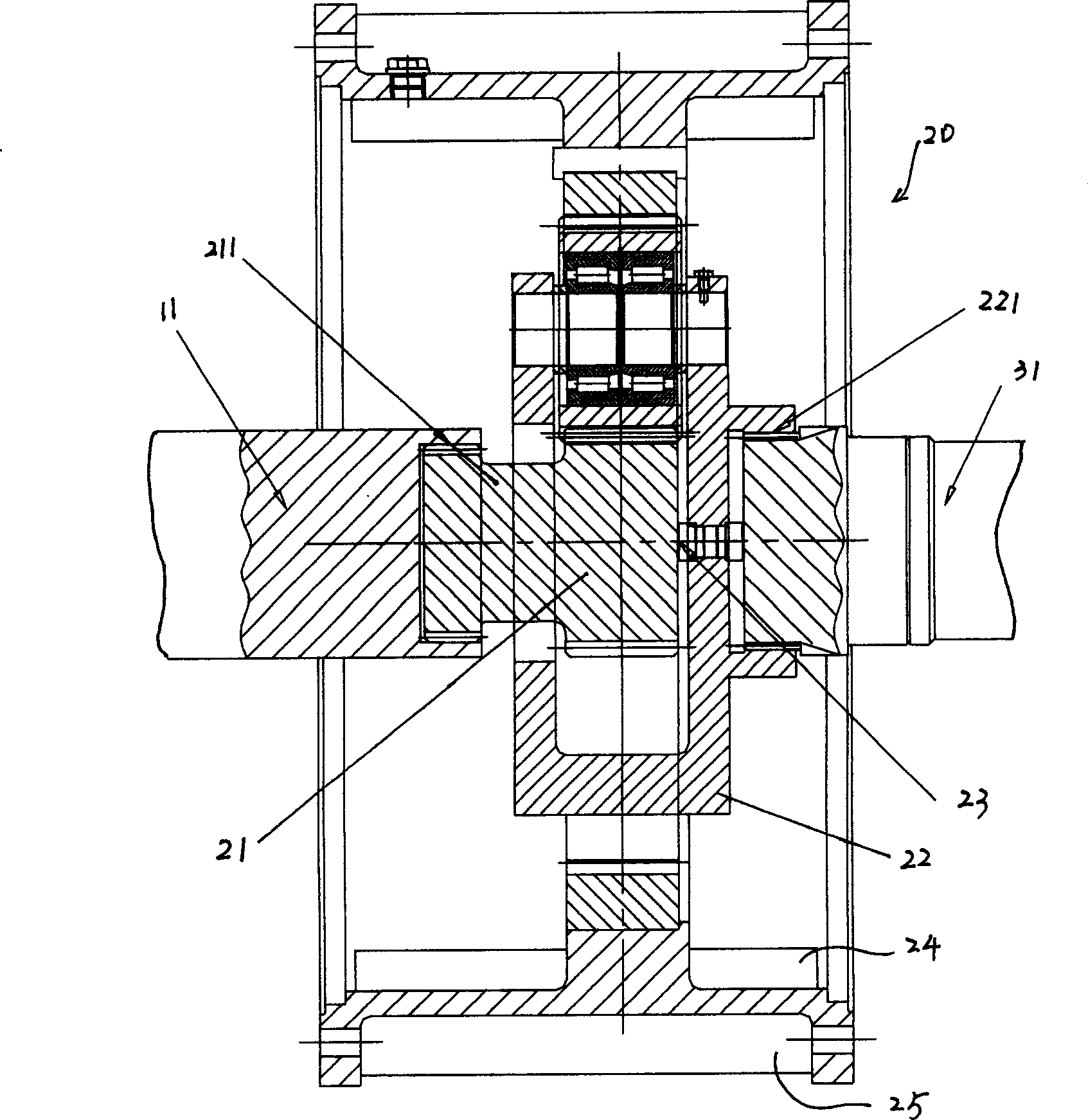

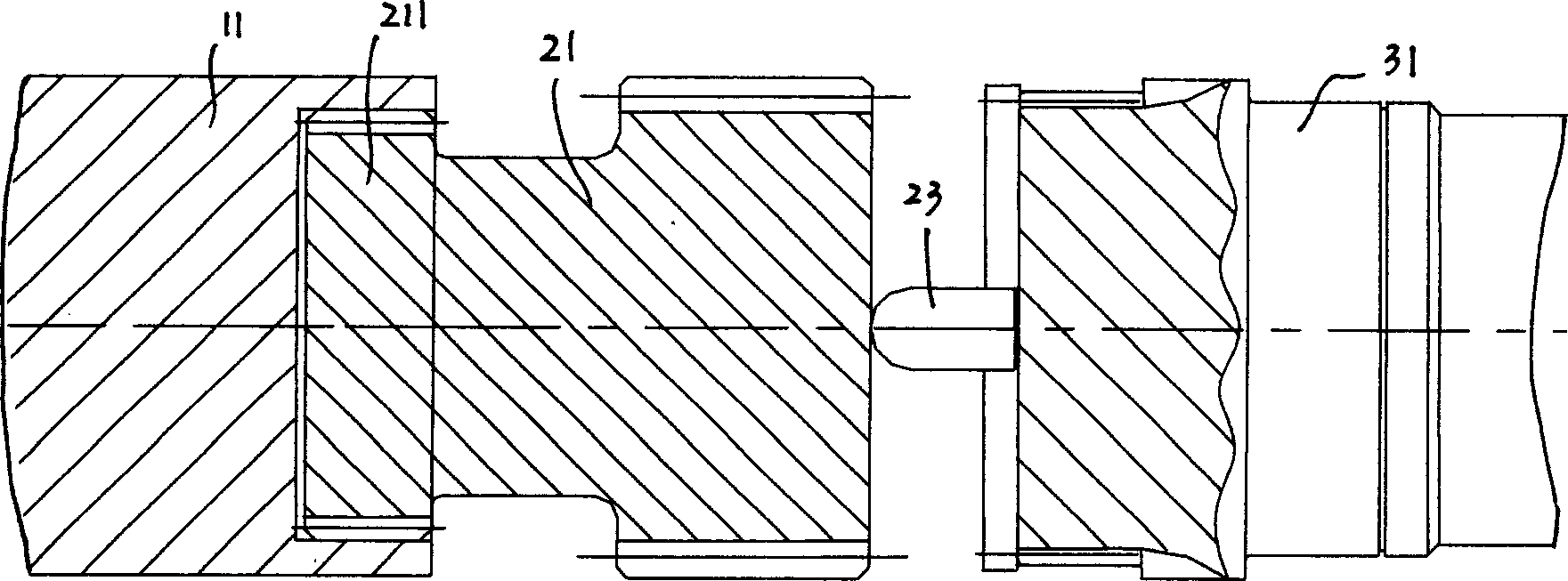

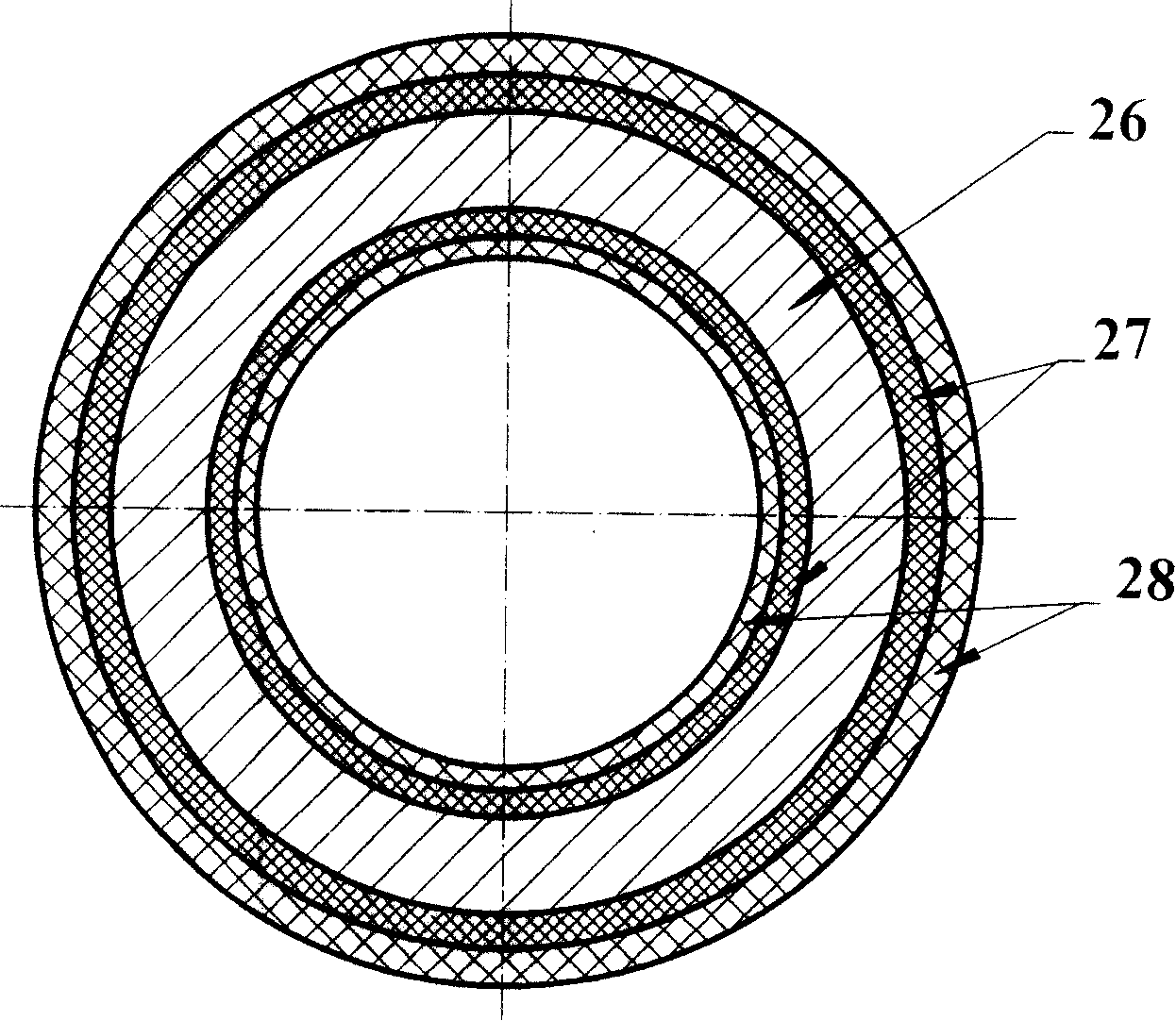

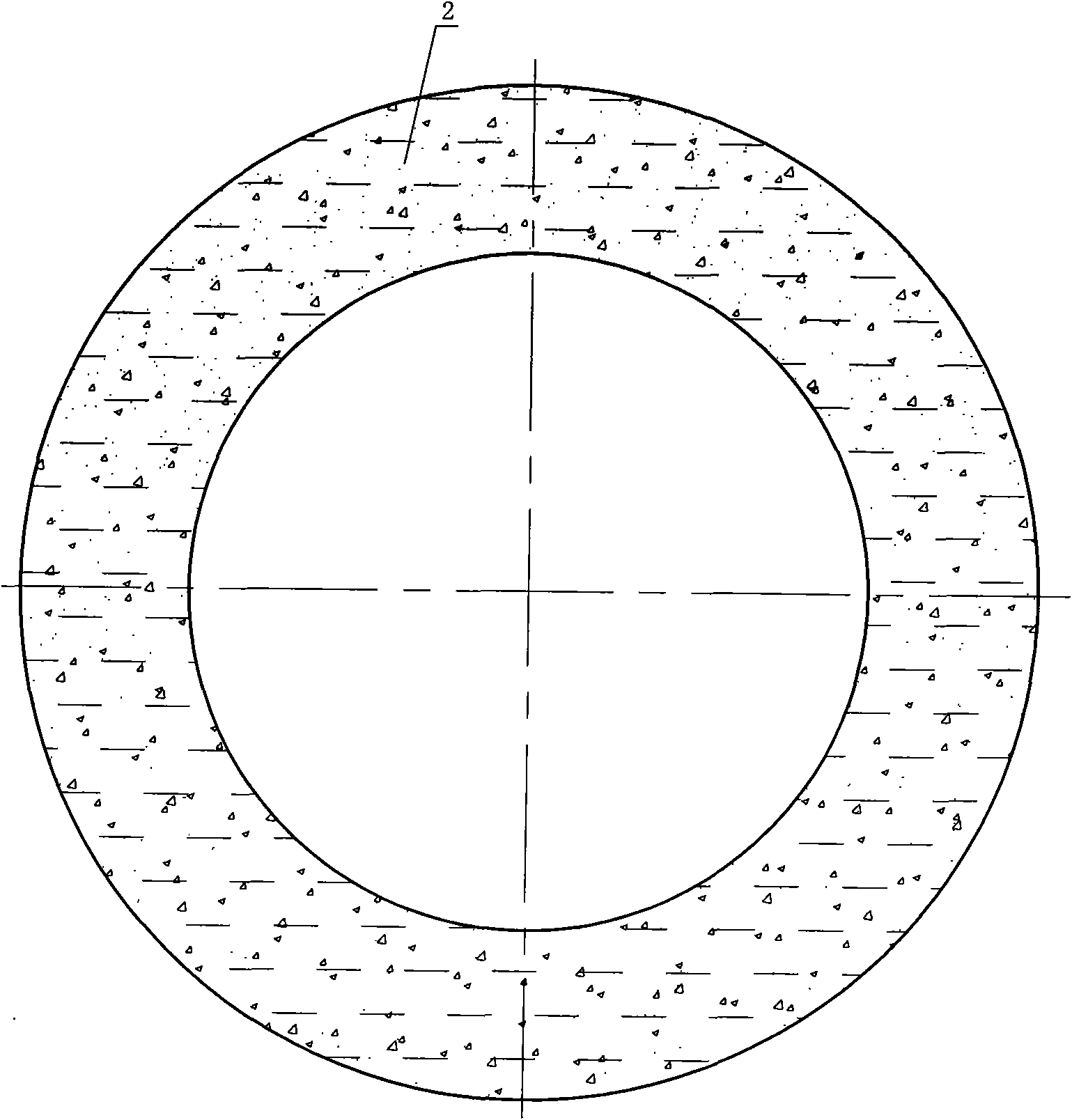

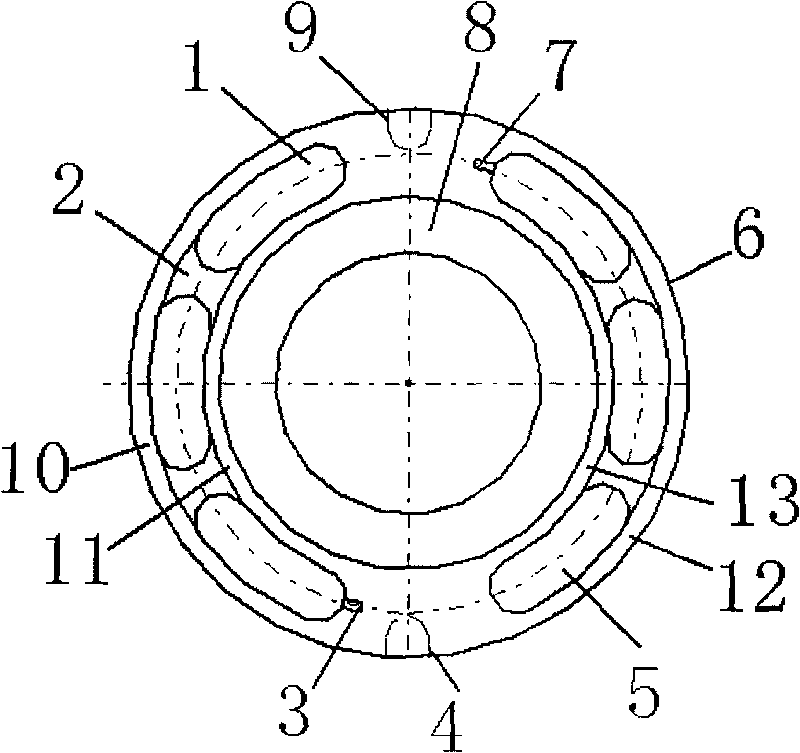

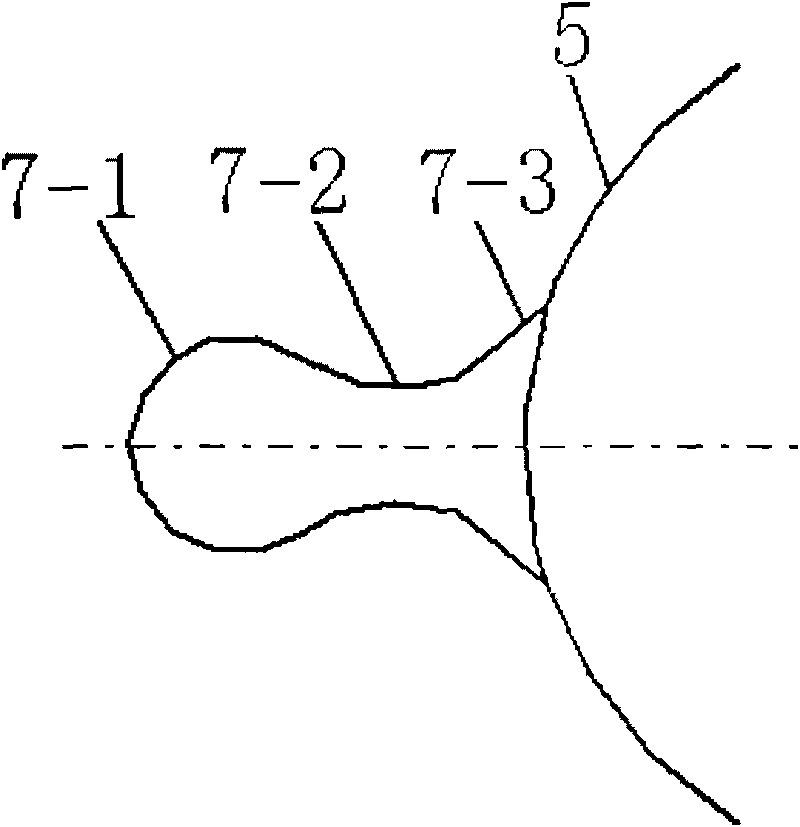

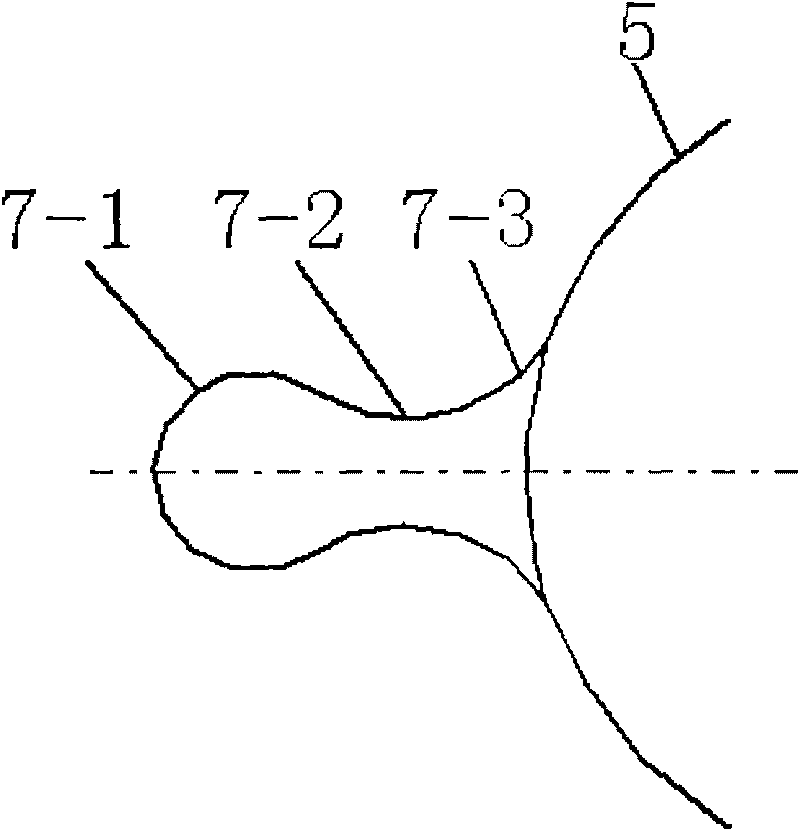

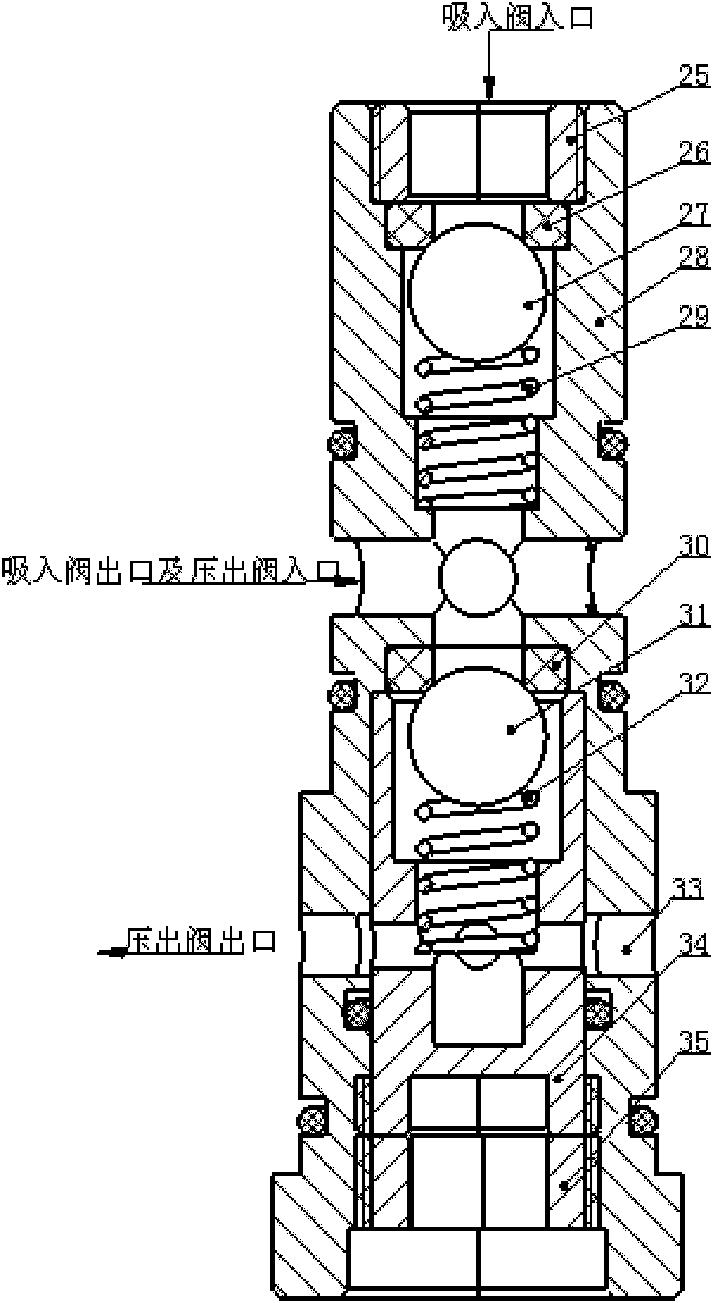

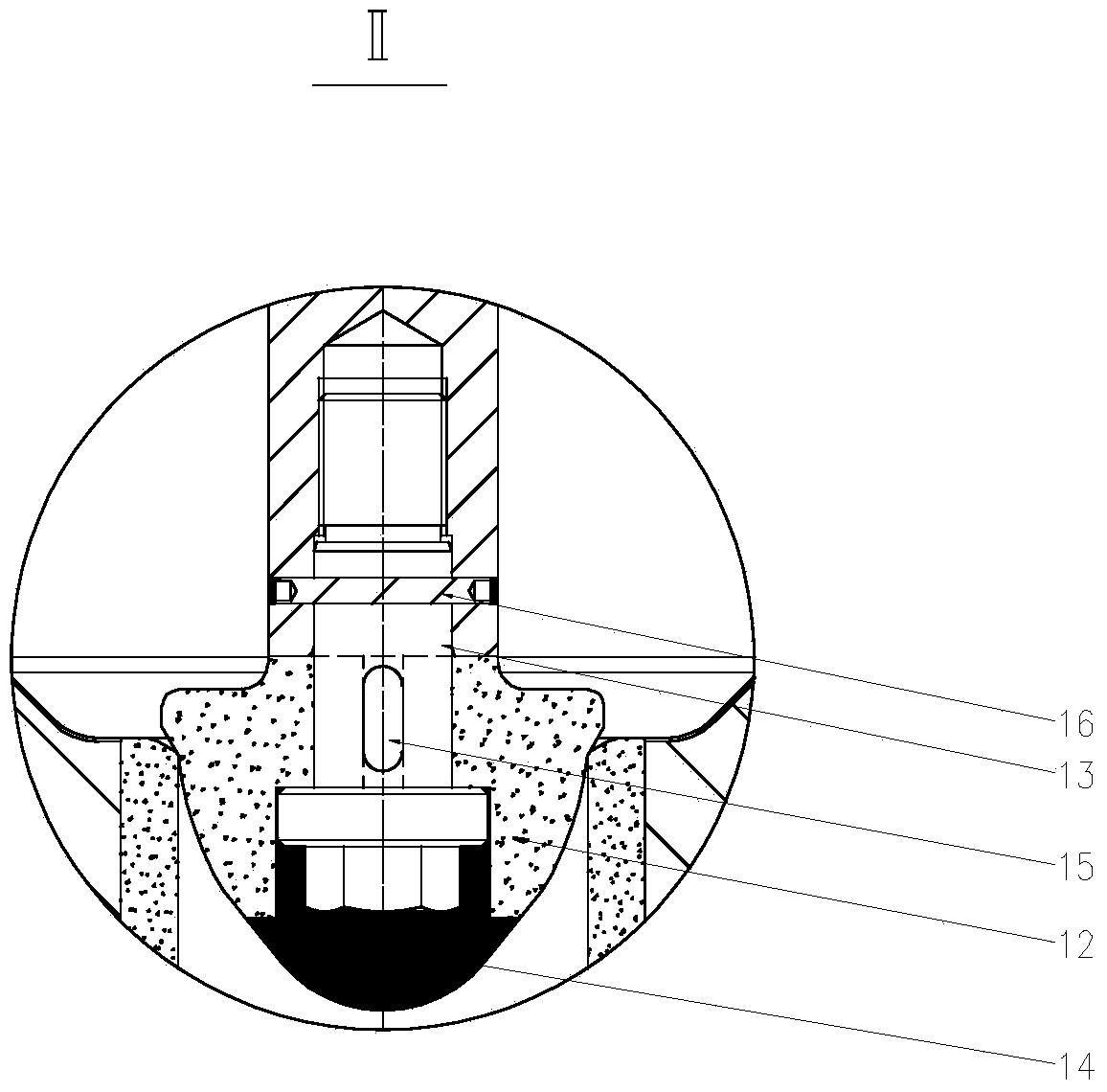

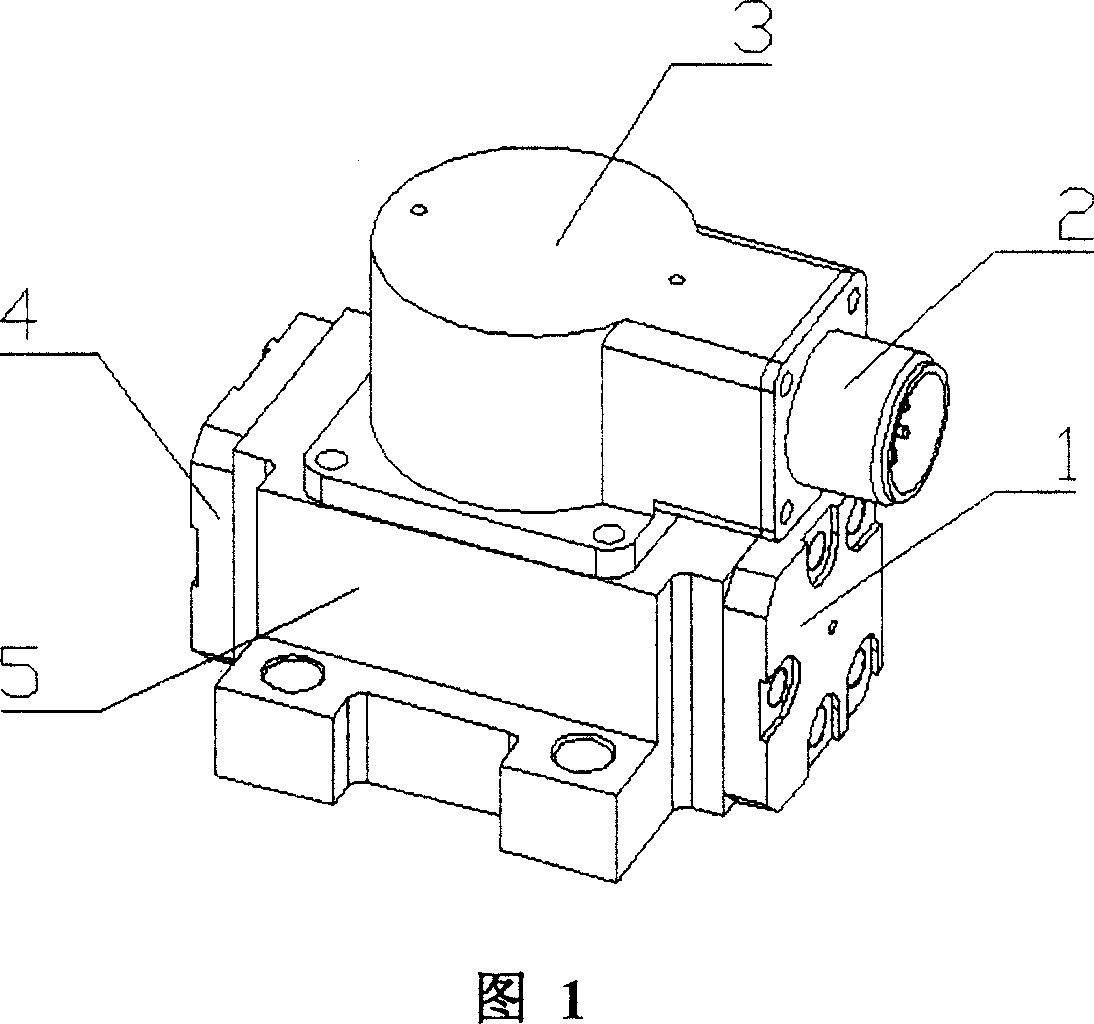

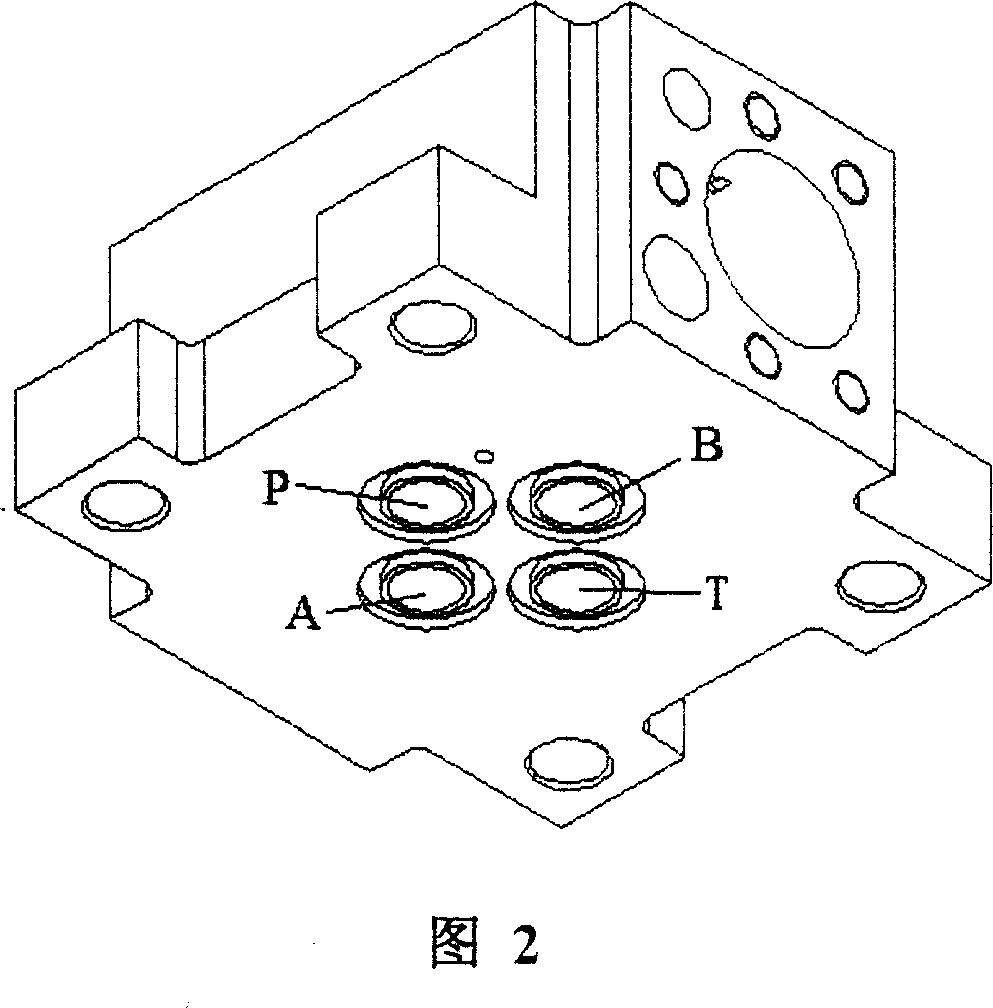

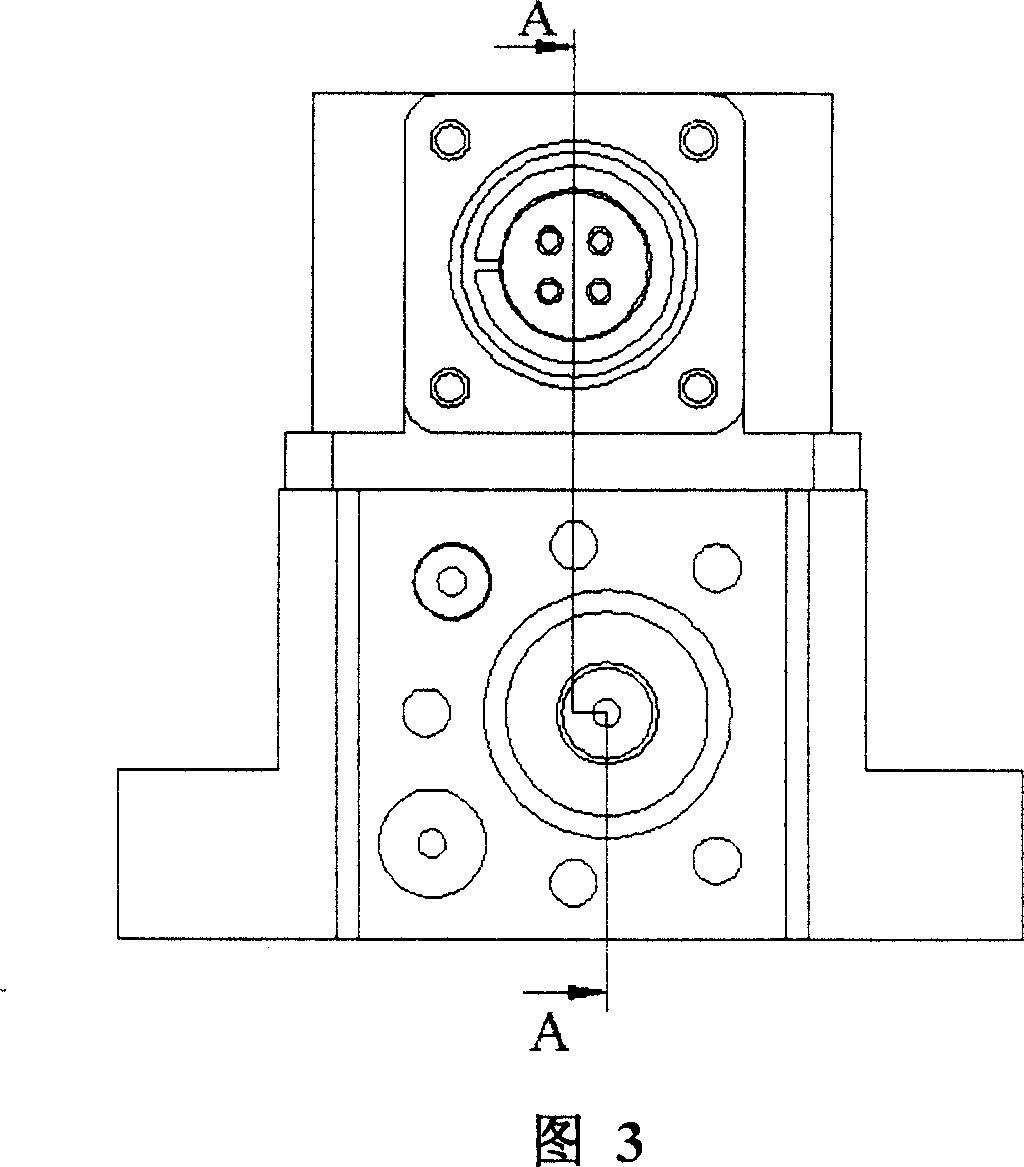

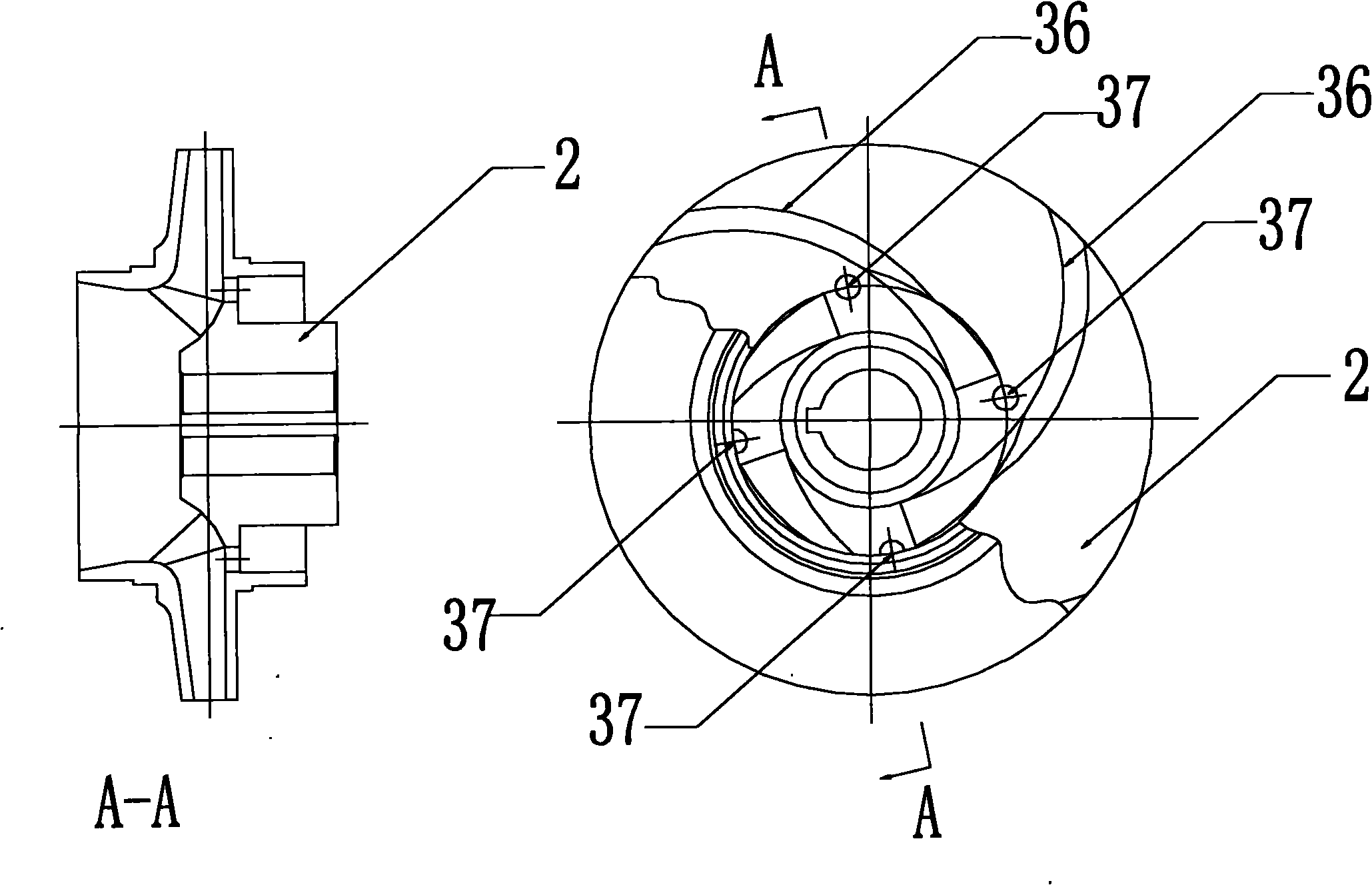

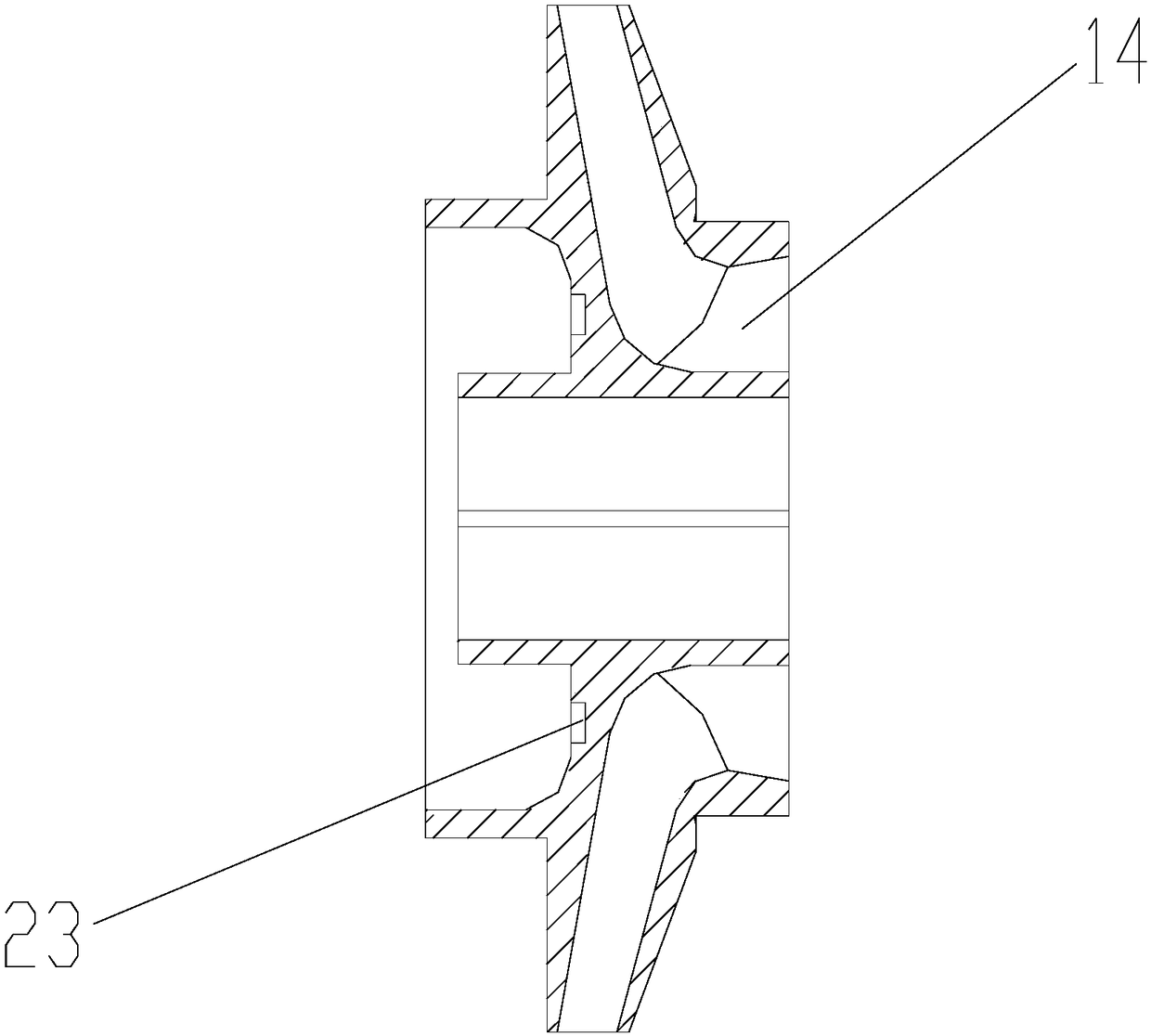

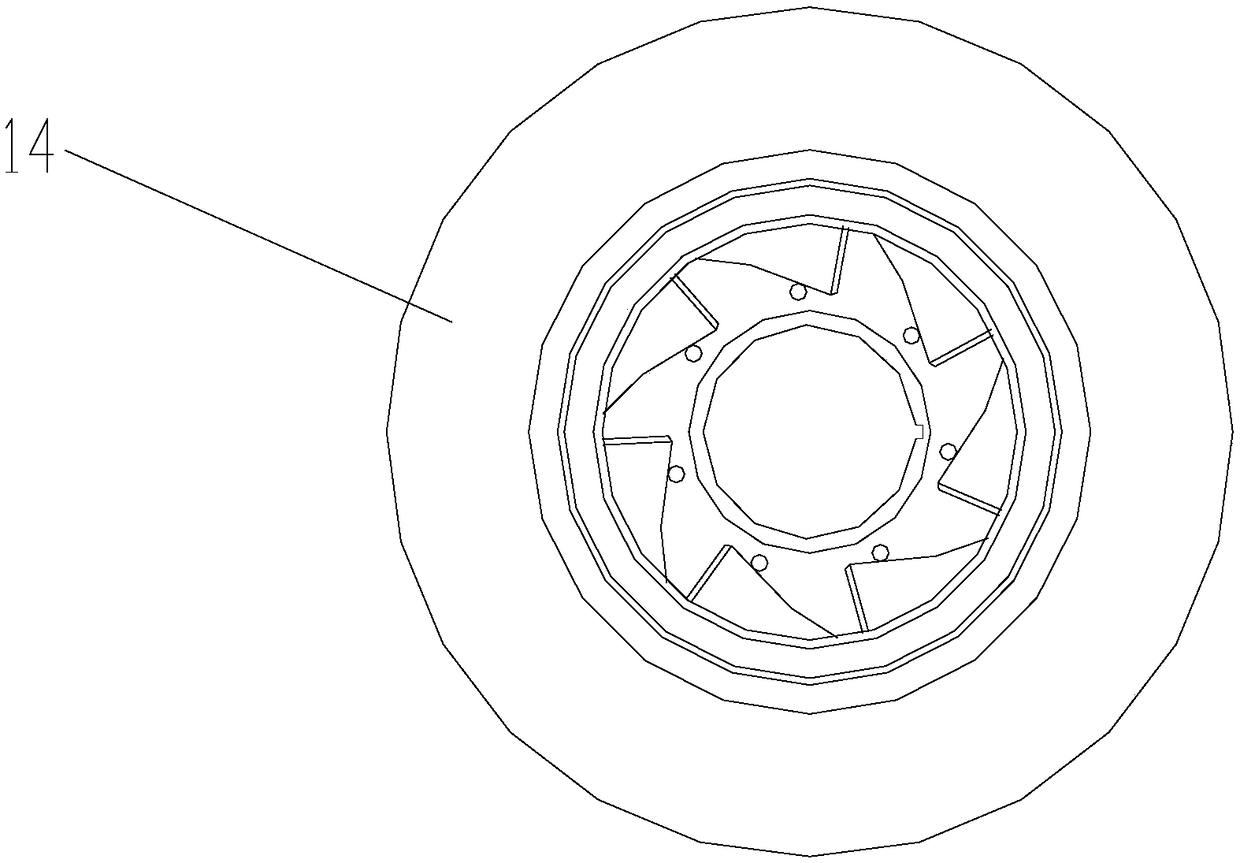

Port plate for plunger pump

InactiveCN101694211AReduce generationIncrease stiffnessPump controlPositive-displacement liquid enginesLow noiseWater based

A port plate for a plunger pump belongs to a port plate for a hydraulic plunger pump, and aims at reducing cavitation corrosion, vibration and noise of the plunger pump during the distribution process, and improving the work stability of a pump. The port plate is circular, wherein a low pressure zone kidney slot and a high pressure zone kidney slot which are symmetrical relative to a cross shaft and are mutually isolated are arranged in a circular ring, the low pressure zone kidney slot and the high pressure zone kidney slot are respectively formed by kidney-shaped through holes which are divided into N segments, the inlets of the low pressure zone kidney slot and the high pressure kidney slot are respectively provided with a low pressure zone vibration-damping groove and a high pressure zone vibration-damping groove, the front end of the high pressure zone vibration-damping groove or the high pressure zone vibration-damping groove is a circular structure, the tail end is a V shape or an arc-shaped gradually-opened structure, the middle portion is an arc transition structure provided with a reducing hole, and the depths of all portions are different. The port plate has excellent cavitation resistance, small vibration, low noise and excellent work stability, and is suitable for plunger pump sport plates which utilize seawater, fresh water, high water base, mineral oil and the like as work medium, and is simultaneously also suitable for oil-pressure plunger pumps which utilize mineral oil as work medium.

Owner:HUAZHONG UNIV OF SCI & TECH

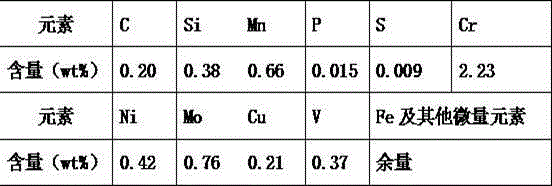

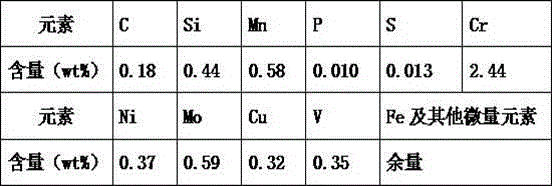

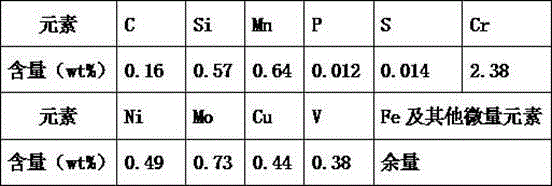

Cast steel part for ultra-supercritical thermal power generating unit and production process of cast steel part

ActiveCN104878311AHigh strengthImprove hardenabilityFoundry mouldsFoundry coresHeat resistanceWear resistance

The invention discloses a cast steel part for an ultra-supercritical thermal power generating unit. The cast steel part is characterized by being prepared from the following chemical components in percentage by weight: 0.15 to 0.20% of C, not greater than 0.60% of Si, 0.4 to 0.8% of Mn, not greater than 0.02% of P, not greater than 0.015% of S, 2.2 to 2.5% of Cr, not greater than 0.5% of Ni, 0.5 to 0.8% of Mo, not greater than 0.5% of Cu, 0.3 to 0.4% of V, and the balance of Fe and inevitable micro impurities. The invention further discloses a process for producing the cast steel part. The cast steel part is high in wear resistance, corrosion resistance and heat resistance, high in toughness, and applicable to the ultra-supercritical thermal power generating unit.

Owner:SANMING CITY YIJUN MACHINERY FOUNDRY

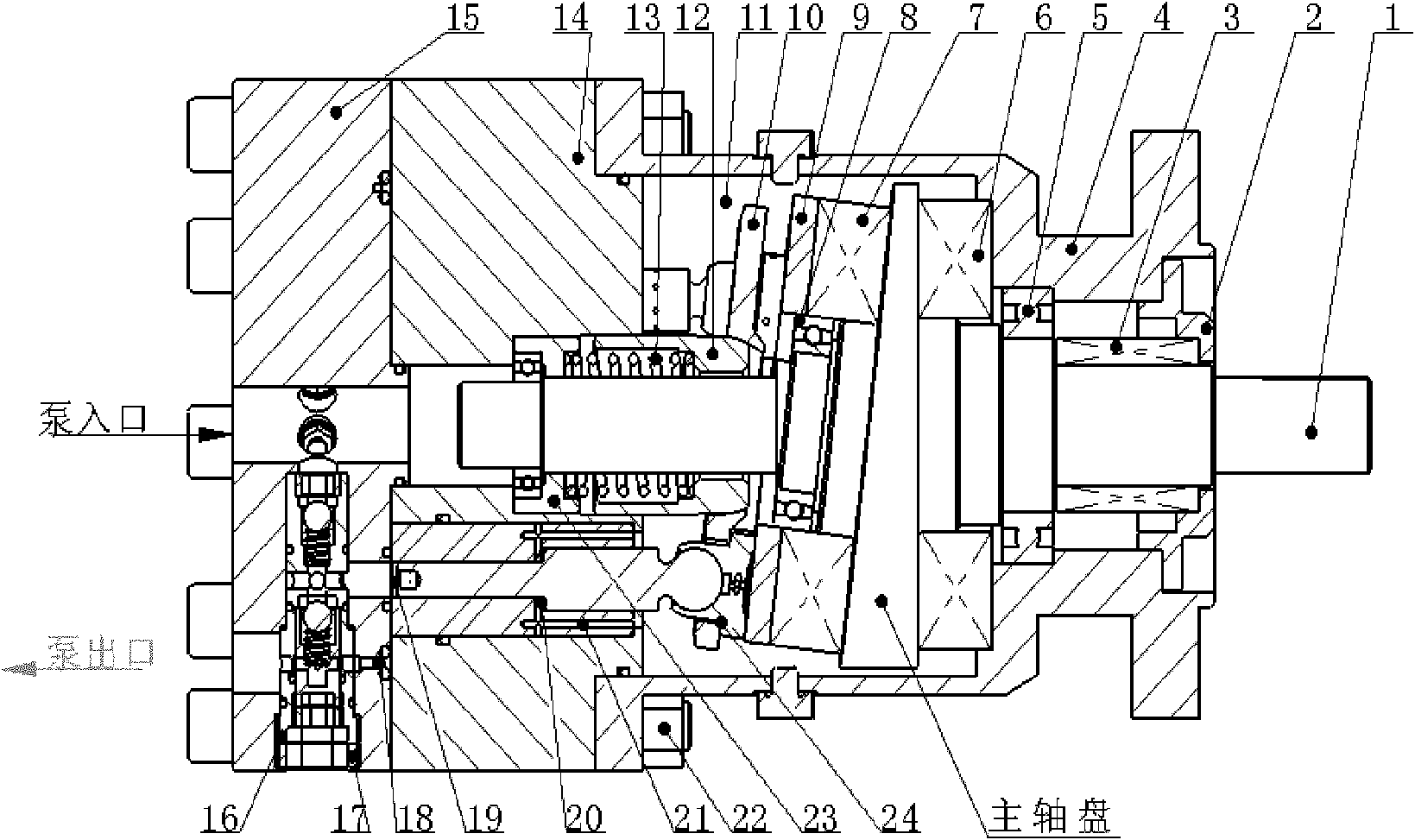

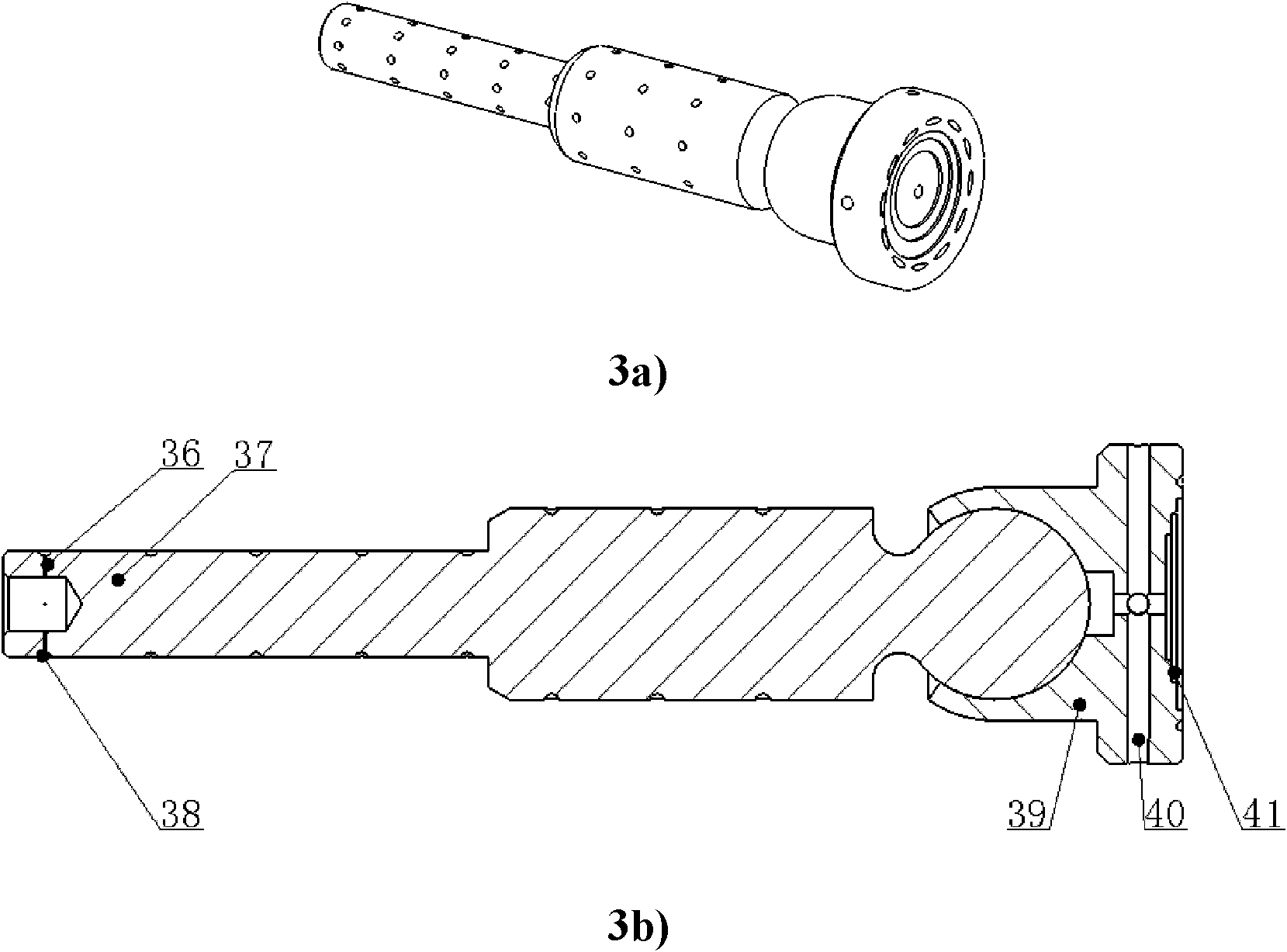

Fully water-lubricated super-pressure plunger water pump

InactiveCN101956685AReduce contact stressSolve friction and wear problemsPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionEngineering

The invention provides a fully water-lubricated super-pressure plunger water pump, mainly comprising a cavity, a live spindle and a plunger flow-distribution unit; the plunger flow-distribution unit comprises a flat valve assembly and a plunger slipper assembly; the plunger slipper assembly is used for dividing the cavity into a pressure cavity and a lubricating cavity which are independent from each other; the plunger slipper assembly carries out reciprocating motion by the driving of the live spindle so that the flat valve assembly sucks in water and discharges water through a water pump inlet and a water pump outlet, and water is simultaneously conveyed to the lubricating cavity through the water pump inlet so as to provide fluid to the rotating unit for lubricating and realizing full water lubrication. The flat valve assembly is designed integrally, and the assembly can be replaced quickly when maintenance so as to shorten maintenance time; the plunger is a stepped structure, the cylindrical surface thereof is provided with recesses, and the bottom of the slipper is provided with a stepped support cavity, thereby solving the wearing and friction problem of the plunger / plunger sleeve pair and slipper / sloping cam plate pair under high-speed heavy-duty condition, and prolonging the service life of the water pump.

Owner:HUAZHONG UNIV OF SCI & TECH

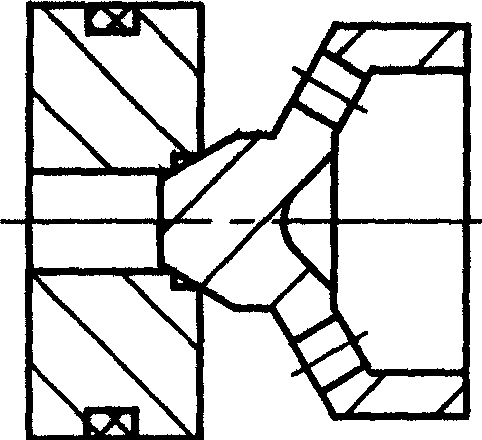

Black water coking-preventing impact-resistant shockproof regulating angle valve special for coal chemical industry

ActiveCN103591303AImprove anti-blocking performanceAvoid vortexLift valveValve housingsFluid controlControl valves

The invention relates to a regulating angle valve, in particular to a black water coking-preventing impact-resistant shockproof regulating angle valve special for the coal chemical industry, and belongs to the field of fluid control valves. The black water coking-preventing impact-resistant shockproof regulating angle valve comprises a diffusion tube and a valve body, wherein the lower end of the valve body is connected with the diffusion tube through a bolt. An inlet flowing channel is arranged in the valve body, an outlet flowing channel is arranged in the diffusion tube and is communicated with the inlet flowing channel, and the inlet flowing channel is perpendicular to the outlet flowing channel. A valve carrier base is arranged in the outlet flowing channel and is clamped through the diffusion tube and the valve body, and a valve carrier is arranged in the valve carrier base. The black water coking-preventing impact-resistant shockproof regulating angle valve is simple in structure and novel in design, can effectively solve the technical problems that a traditional black water regulating angle valve is easy to coke, poor in impact resistant performance, undesirable in shockproof effect and the like in a use process, is widely applied in sites of customers, and effectively lowers production operation cost of the customers.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Hydraulic pressure servo valve

InactiveCN1959130AHigh control precisionReduce frictionServomotor componentsCircuit elementsWorking pressureTorque motor

A servo valve of water pressure consists of permanent magnet torque motor, pre-amplification unit and sliding valve power unit. It is featured as arranging filter stopper at two ends of filtering screen end to form concentric circular seam between said stopper and valve body, opening valve body fixed damping hole at valve body between said stopper and valve bush, using water contained in gap between spool and valve bush to form fixed liquid resistance and spool static pressure support of pre -amplification unit.

Owner:HUAZHONG UNIV OF SCI & TECH

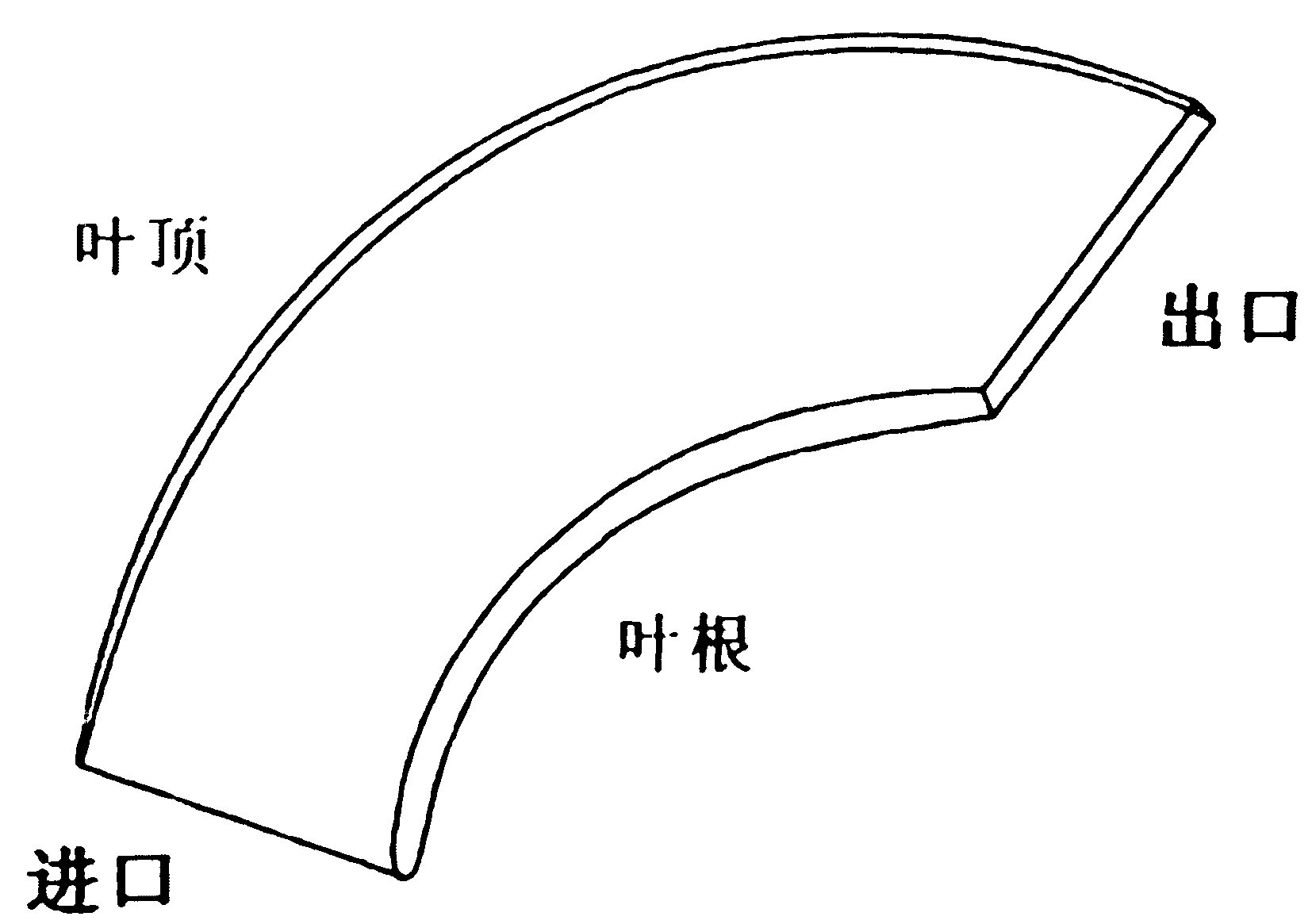

Wear-resisting corrosion-resistant composite coating for ship water-jet propeller impeller and preparation method thereof

ActiveCN103614682ASolving Powder Separation ProblemsImprove performanceMolten spray coatingPump-jetImpeller

The invention discloses a wear-resisting corrosion-resistant composite coating for a ship water-jet propeller impeller and a preparation method thereof, belonging to the technical field of corrosion-resistant wear-resisting coatings of a metal base body. The coating is obtained by a TiC in-situ reinforced NiTi intermetallic compound-based composite coating through solid-solution and aging treatment. The preparation method of the coating comprises the following steps: (1), preparing Ni-Ti-C composite powder by taking sucrose as a precursor of carbon and taking Ti powder and hydroxyl Ni powder as materials; (2), preparing a TiC in-situ reinforced NiTi intermetallic compound-based composite coating on the surface of a stainless steel impeller of a ship water-jet propeller by taking the Ni-Ti-C composite powder as the material through a plasma-beam cladding technology; and (3), carrying out solid-solution treatment and aging treatment on the coating obtained in the step (2) to obtain the coating. The coating disclosed by the invention can greatly improve cavitation erosion resistance, wearing resistance and corrosion resistance of the stainless steel impeller of the ship water-jet impeller.

Owner:中国人民解放军92537部队

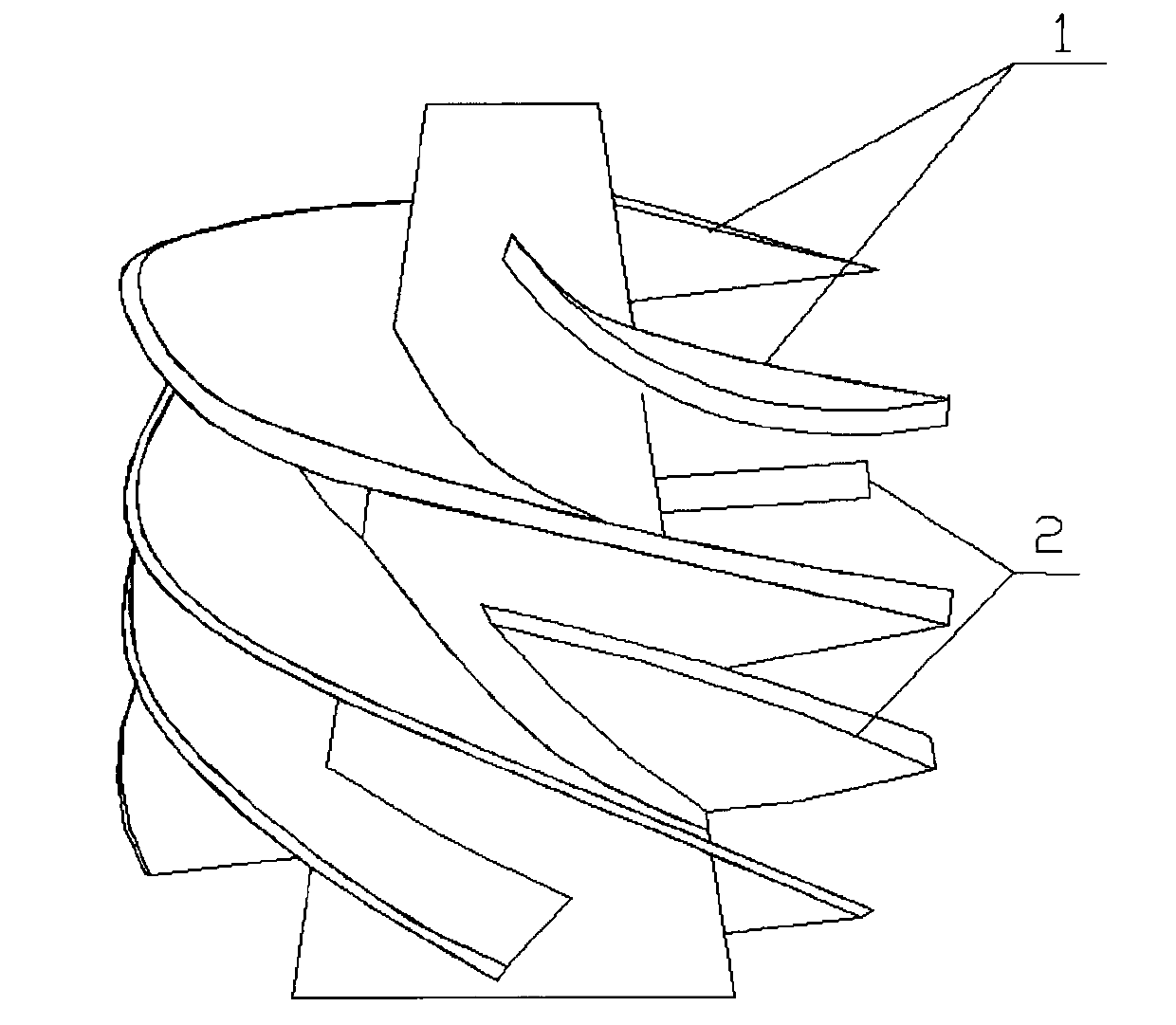

Pitch-varying design method of inducer with long and short blades

InactiveCN103104544AImprove efficiencyImprove cavitation resistancePump componentsPumpsCavitationEngineering

The invention relates to a pitch-varying design method of an inducer with long and short blades. On the basis of the design of a conical pitch-varying inducer, the long and short blades of the inducer are designed to be alternatively arranged, and the outlets of the long and short blades are positioned on one same radial surface. By virtue of the design method, flow separation and boundary layer separation near the outlets of the blades of the inducer are avoided, an outlet flow field is improved, and the efficiency and the cavitation resistance of the inducer are improved.

Owner:JIANGSU UNIV

Laser cladding anti-cavitation-erosion coating and preparation method thereof

InactiveCN111074265AEvenly distributedFine grainMetallic material coating processesMartensite transformationShape-memory alloy

The invention relates to a laser cladding anti-cavitation-erosion coating and a preparation method thereof, and belongs to the technical field of alloy coatings. The anti-cavitation-erosion coating isa shape memory alloy coating that is clad on the surface of a workpiece by a laser; and the shape memory alloy coating can absorb most of the energy and pulse stress generated by bubble-sweepdown based on cycling characteristics such as superelasticity and a shape memory effect of the shape memory alloy coating, and is subjected to superelastic deformation and martensite phase transformation, after external force is unloaded, the shape memory alloy coating is subjected to elastic recovery and martensite reverse phase transformation to be subjected to strain recovery, thus the most of the energy generated by the bubble-sweepdown can be buffered and dissipated, self-injury is avoided, and the purposes of prolonging the cavitation-erosion induction period and curbing initiation and propagation of cavitation-erosion cracks so as to improve anti-cavitation-erosion performance are realized. The technological process of laser cladding is simple, the coating can be prepared selectively at a local subtle position according to needs, and the cost is effectively reduced. The laser cladding titanium-nickel coating and the preparation method thereof can be used for preparation and repair of ship propellers, and have good economical efficiency and application prospects.

Owner:JIANGSU UNIV

Cavitation prevention slurry pump

InactiveCN105927595AExtend your lifeEasy to demouldSpecific fluid pumpsPump componentsHigh concentrationImpeller

The invention discloses a cavitation prevention slurry pump. The cavitation prevention slurry pump comprises a pump body. The pump body is provided with a suck-in opening and a discharge opening. An impeller is arranged in the pump body and provided with main blades and induction blades. The induction blades extend into the suck-in opening. The main blades and the induction blades are connected. The cross section area of the suck-in opening is 3 to 10 times of the cross section area of the discharge opening. The invention aims at providing the slurry pump which can prevent cavitation and can convey high-concentration two-phase flow or high-vapor-content three-phase flow.

Owner:GUANGZHOU TOTALL MATERIAL TECH CO LTD

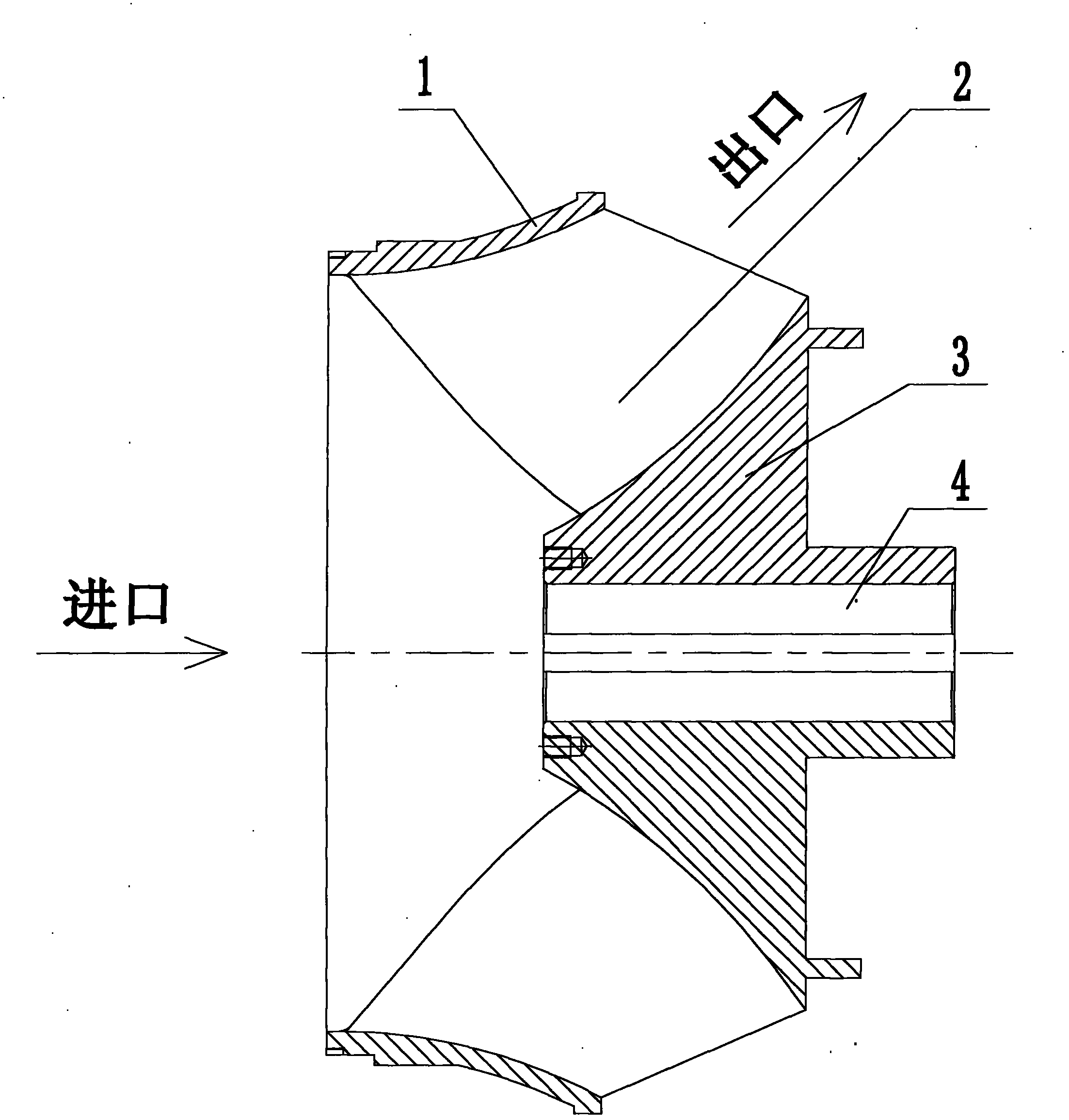

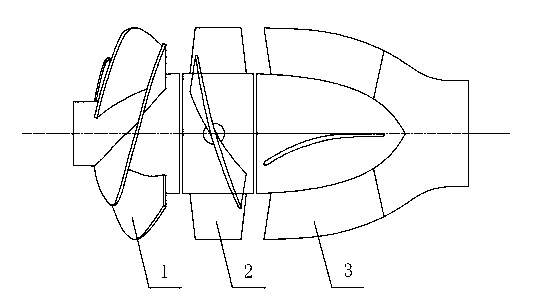

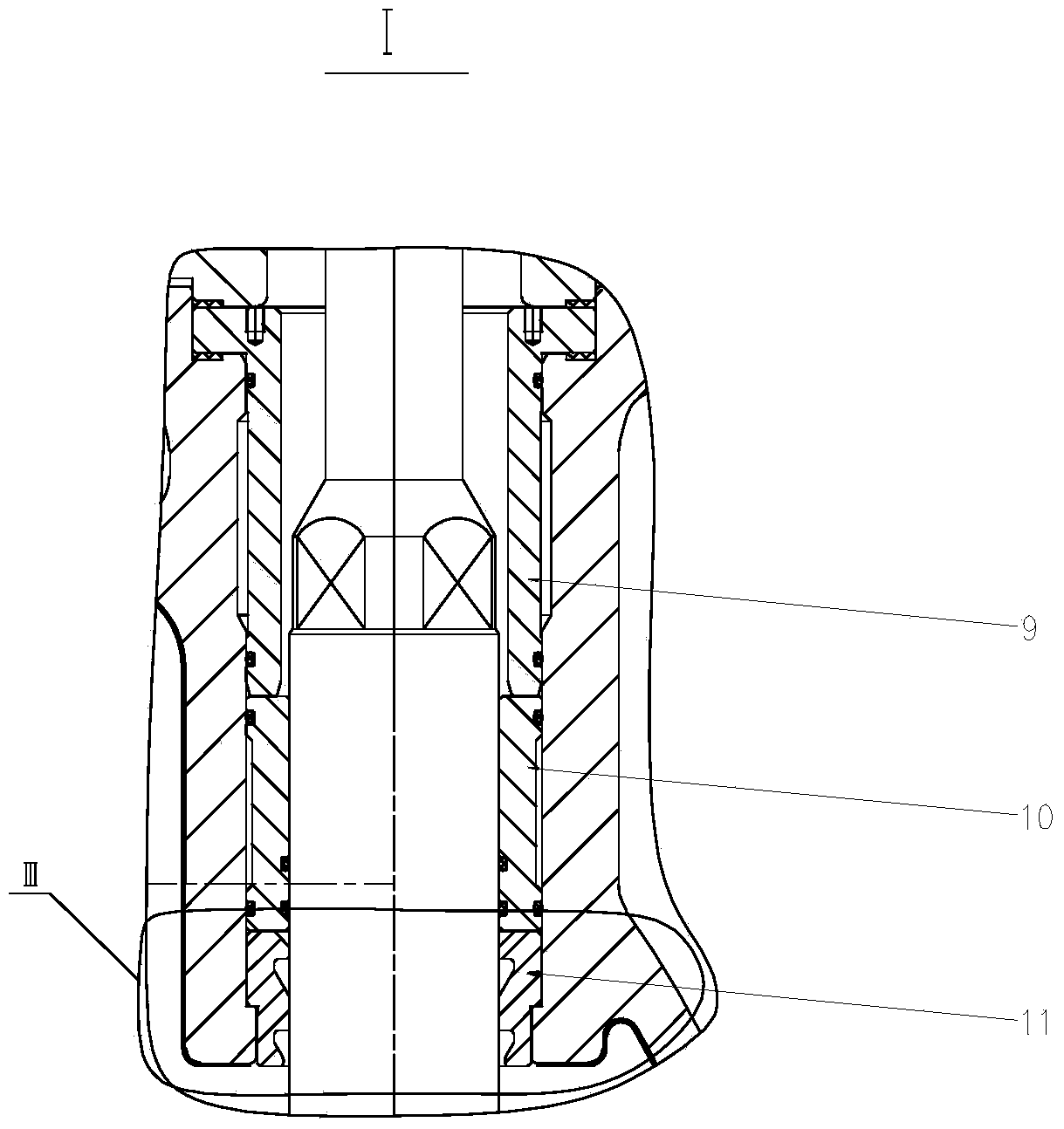

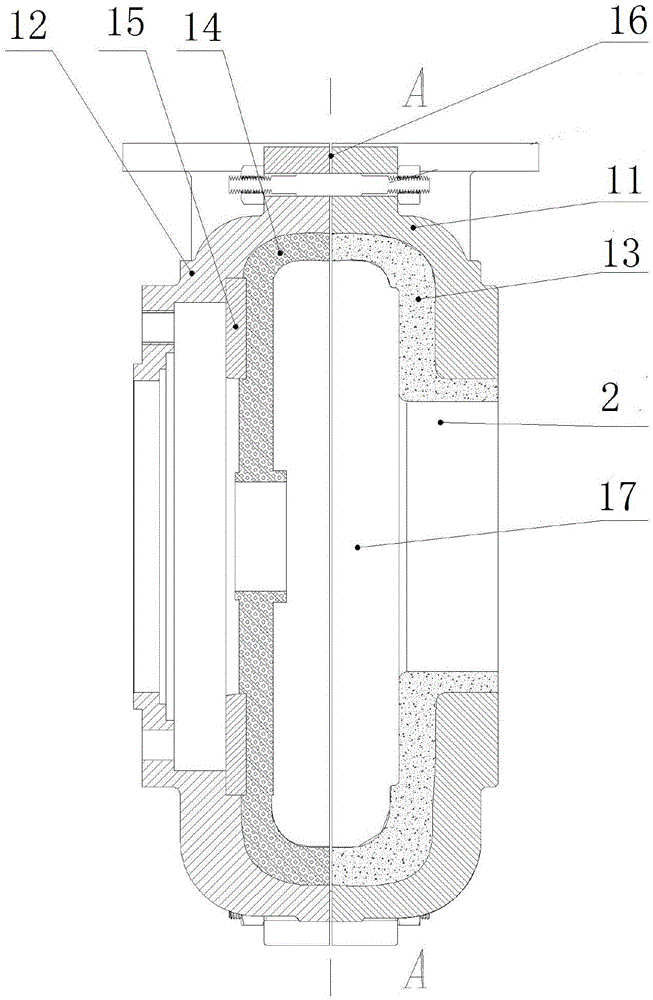

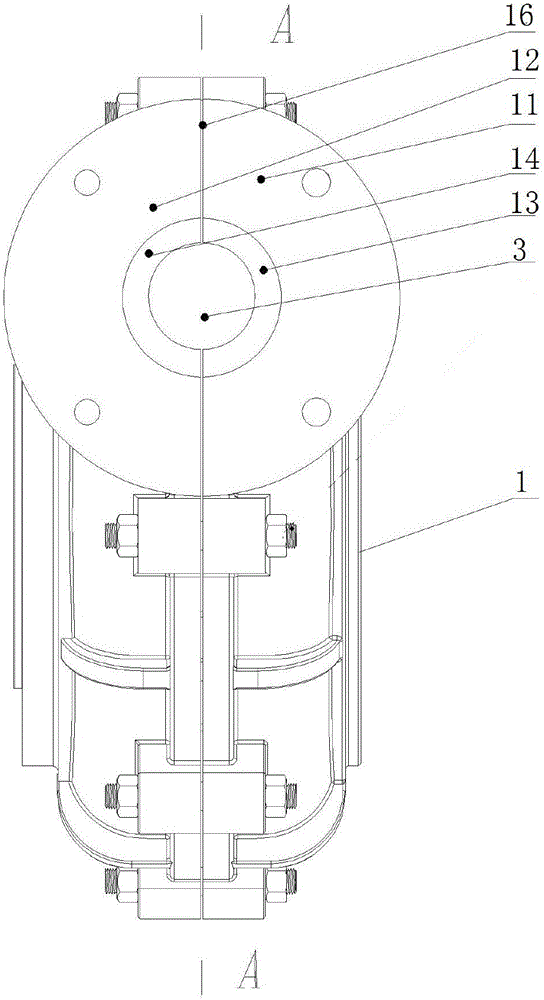

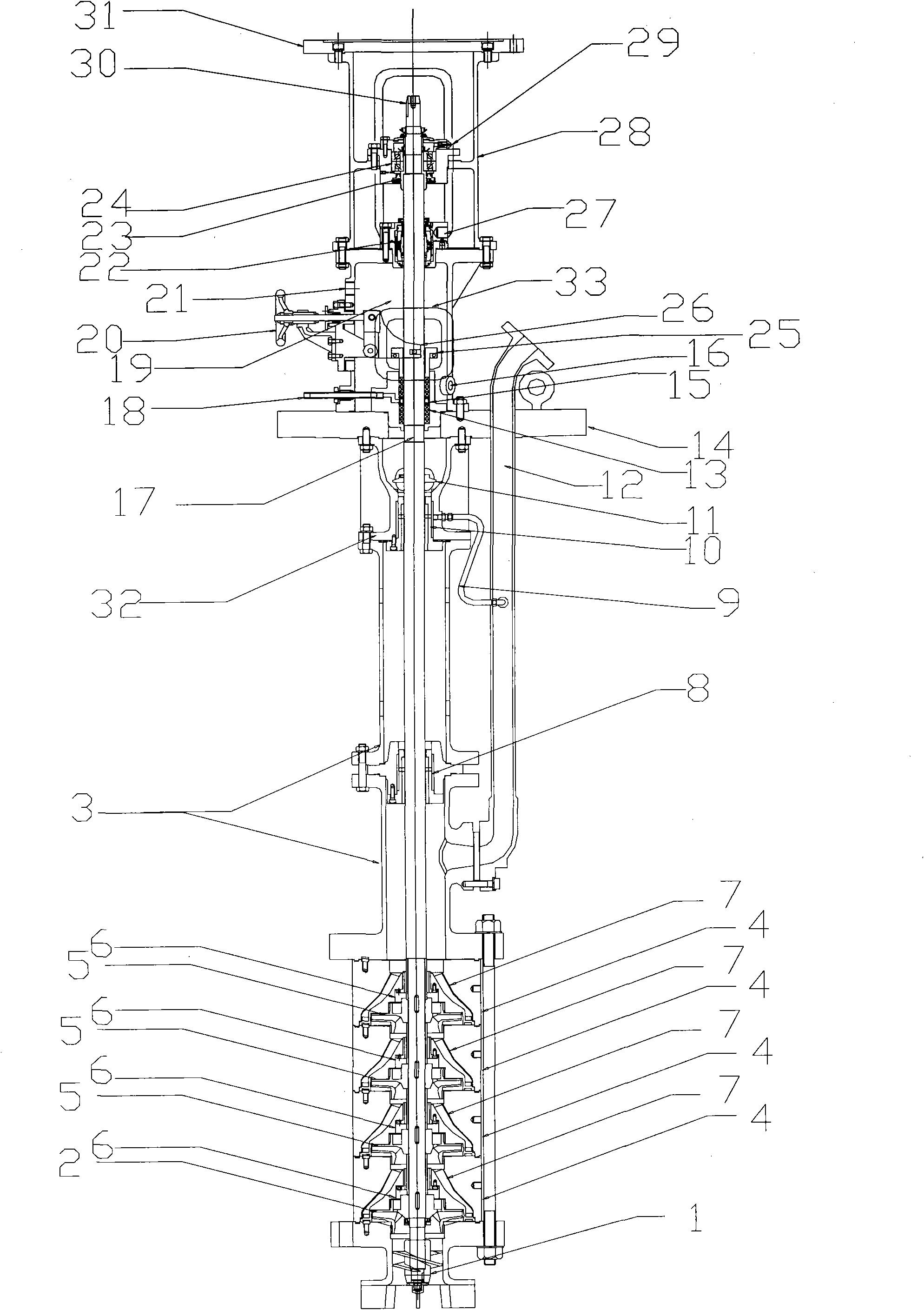

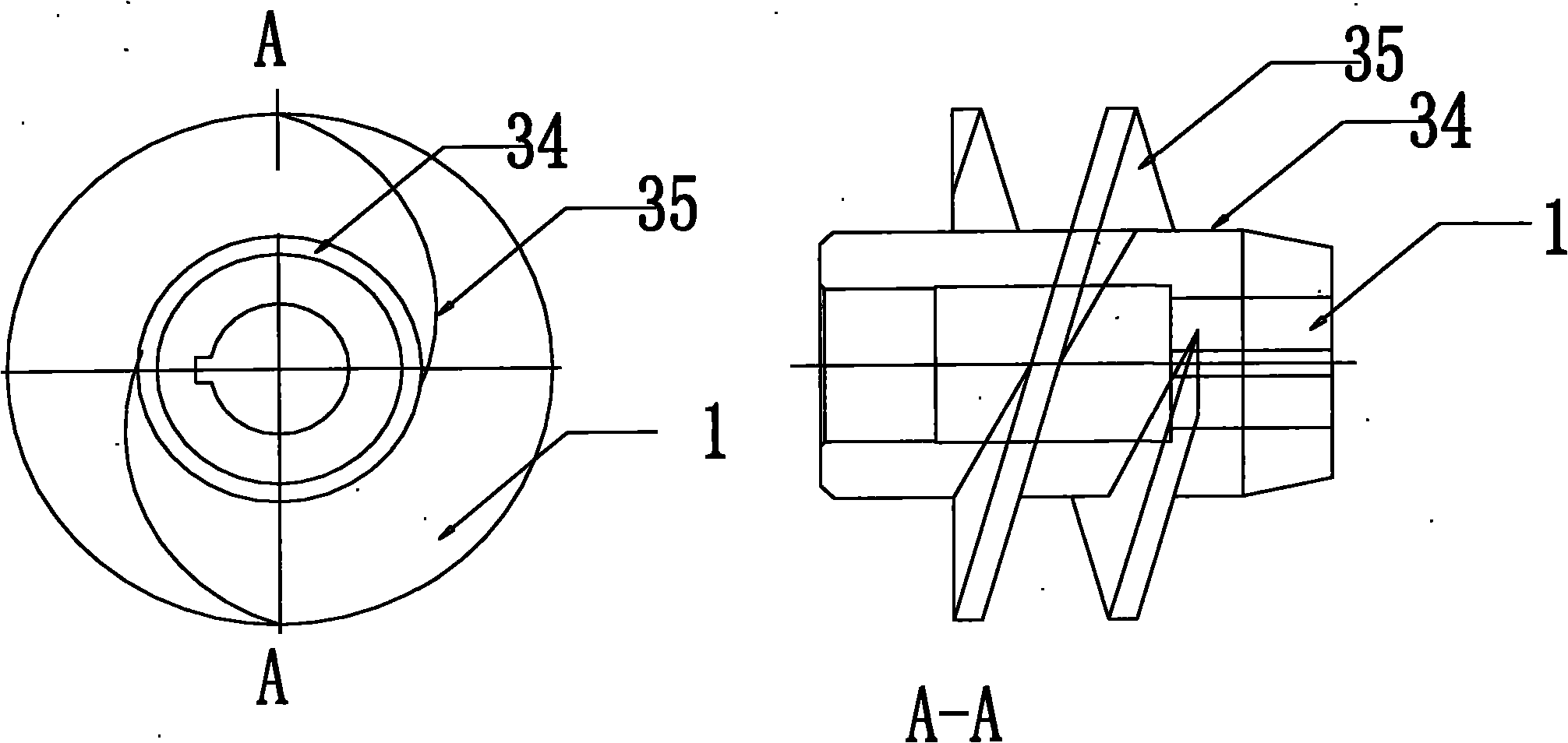

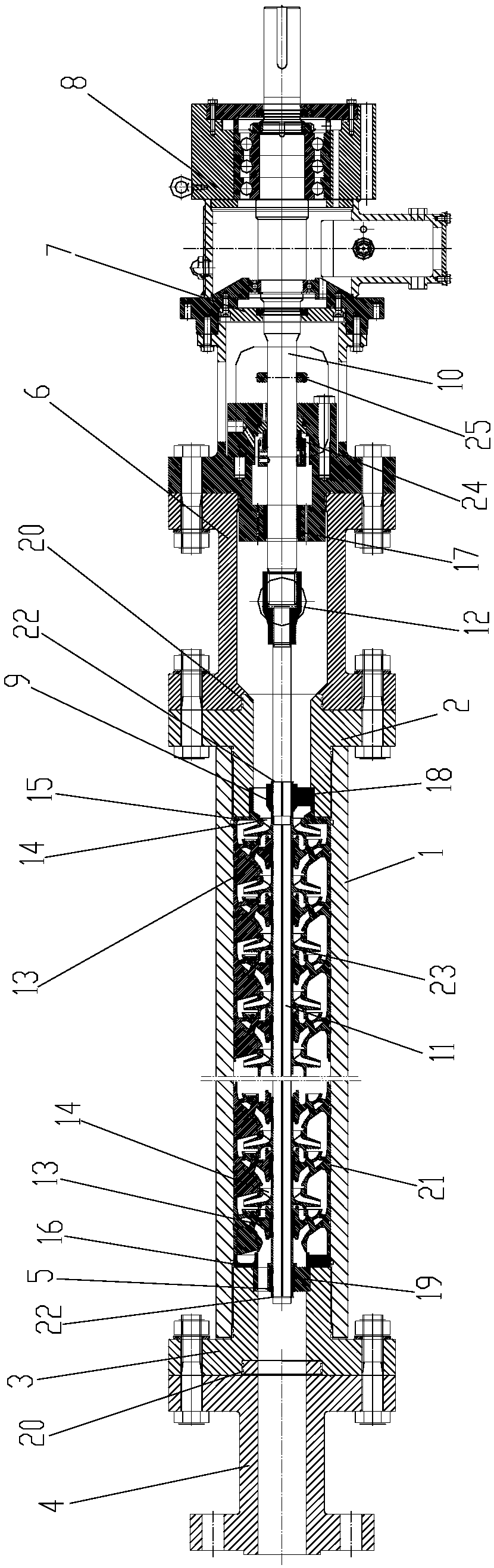

Multi-stage axial flow submerged pump with long shaft and method for conveying phosgene

InactiveCN102062107AExtended use timeExtended service lifeSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a multi-stage axial flow submerged pump with a long shaft and a method for conveying phosgene, which are mainly used for pressurizing and conveying the phosgene or chlorine gas. The submerged pump is provided with an inducer (1), a primary impeller (2), a secondary impeller (5), an auxiliary sliding bearing and shaft sleeve (6), a lower main sliding bearing and shaft sleeve (8), an upper main sliding bearing and shaft sleeve (10), a seal cavity (19) and a bearing bracket (28). The lower end of a packing box (13) is provided with an emergency seal rubber pneumatic bag (17); a double-end face mechanical seal (22) is sleeved on a pump shaft (30); a radial balancing hole (37) is arranged on the impeller; and the auxiliary sliding bearing and shaft sleeve (6) is made from silicon carbide. When both of the mechanical seal and the packing seal become invalid, high pressure nitrogen gas ensures that the emergency seal rubber pneumatic bag (17) is inflated to clasp the shaft so as to quickly block leakage of the conveyed phosgene.

Owner:甘肃银光聚银化工有限公司 +1

Multistage deep sea mixture pump with axial force transmission structure

ActiveCN108468645AImprove performance dropImprove cavitation resistanceSpecific fluid pumpsPump componentsImpellerAxial force

The invention discloses a multistage deep sea mixture pump with an axial force transmission structure. The pump comprises a pump case. Two ends of the pump case are fixedly provided with an inlet pumpcover and an outlet pump cover. The other end of the outlet pump cover is fixedly connected with an outlet connecting pipe. The outlet pump cover is coaxially provided with an outlet bearing pedestal. The other end of the inlet pump cover is fixedly connected with an inlet connecting pipe, a bearing box, and a motor. The inlet pump cover is coaxially provided with an inlet bearing pedestal. The bearing box is internally provided with a bearing box shaft. One end of the bearing box, far away from a motor, extends into the inlet connecting pipe. The pump case is internally provided with a pumpshaft. One end of the pump shaft extends into the inlet connecting pipe and is connected with the bearing box by a shaft, and the other end of the pump shaft is in the outlet bearing pedestal. A plurality of stages of static pressure expanders are uniformly sleeved on the pump shaft along an axial direction in sequence. Ends of the pressure expanders, close to the inlet pump cover, are provided with closed impellers which are fixedly coupled with the pump shaft in a cooperated manner. A thrust collar is arranged between a first stage impeller and the inlet bearing pedestal. The pump is high inoperation efficiency under a working condition of high gas content, and the pump is easy to process and install.

Owner:XIAN UNIV OF TECH

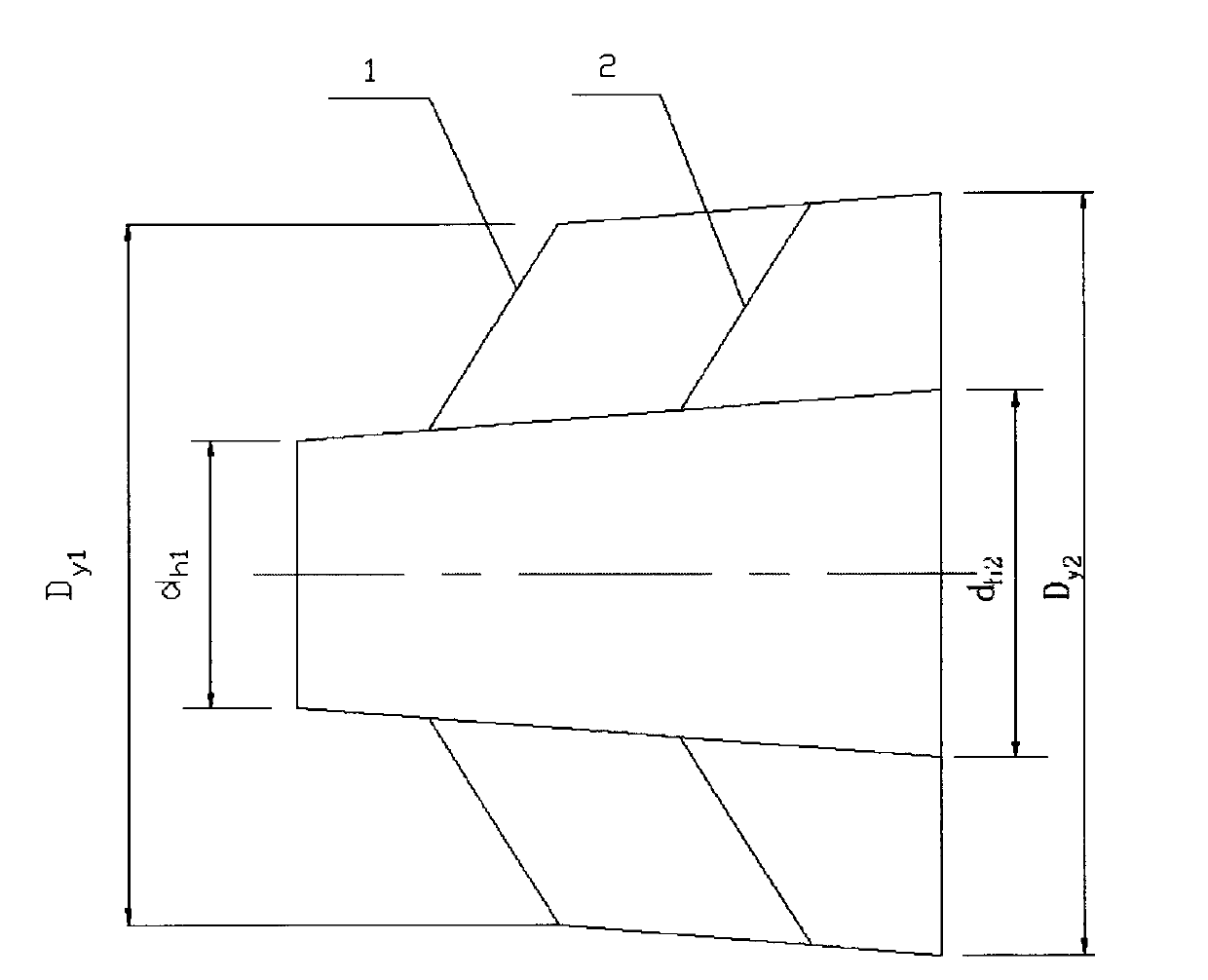

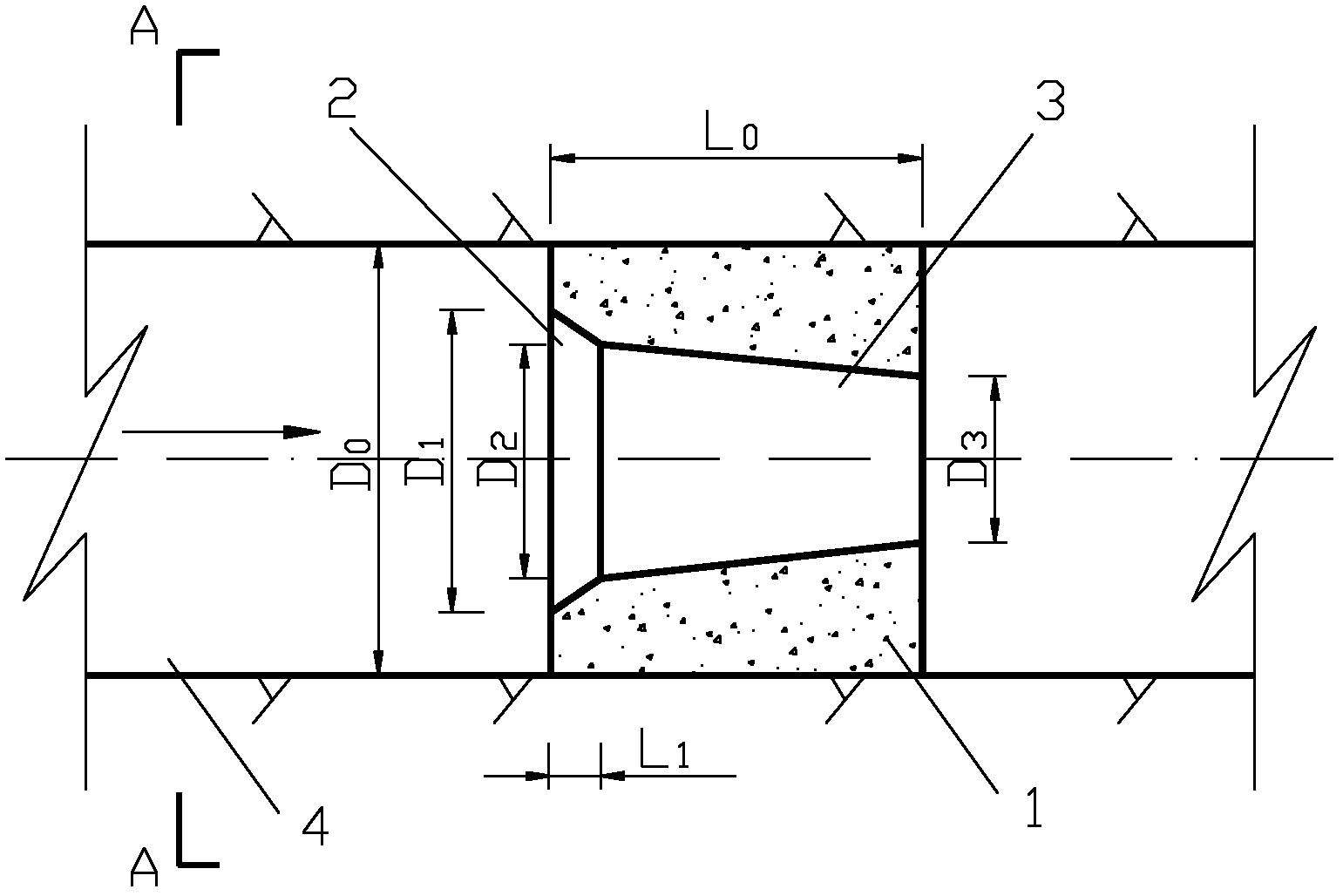

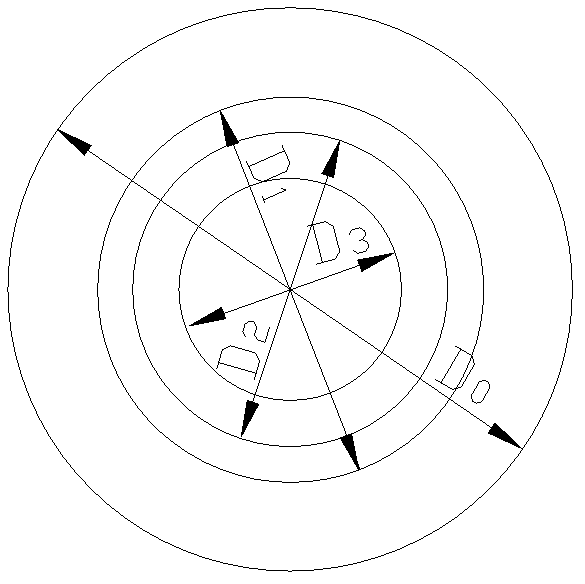

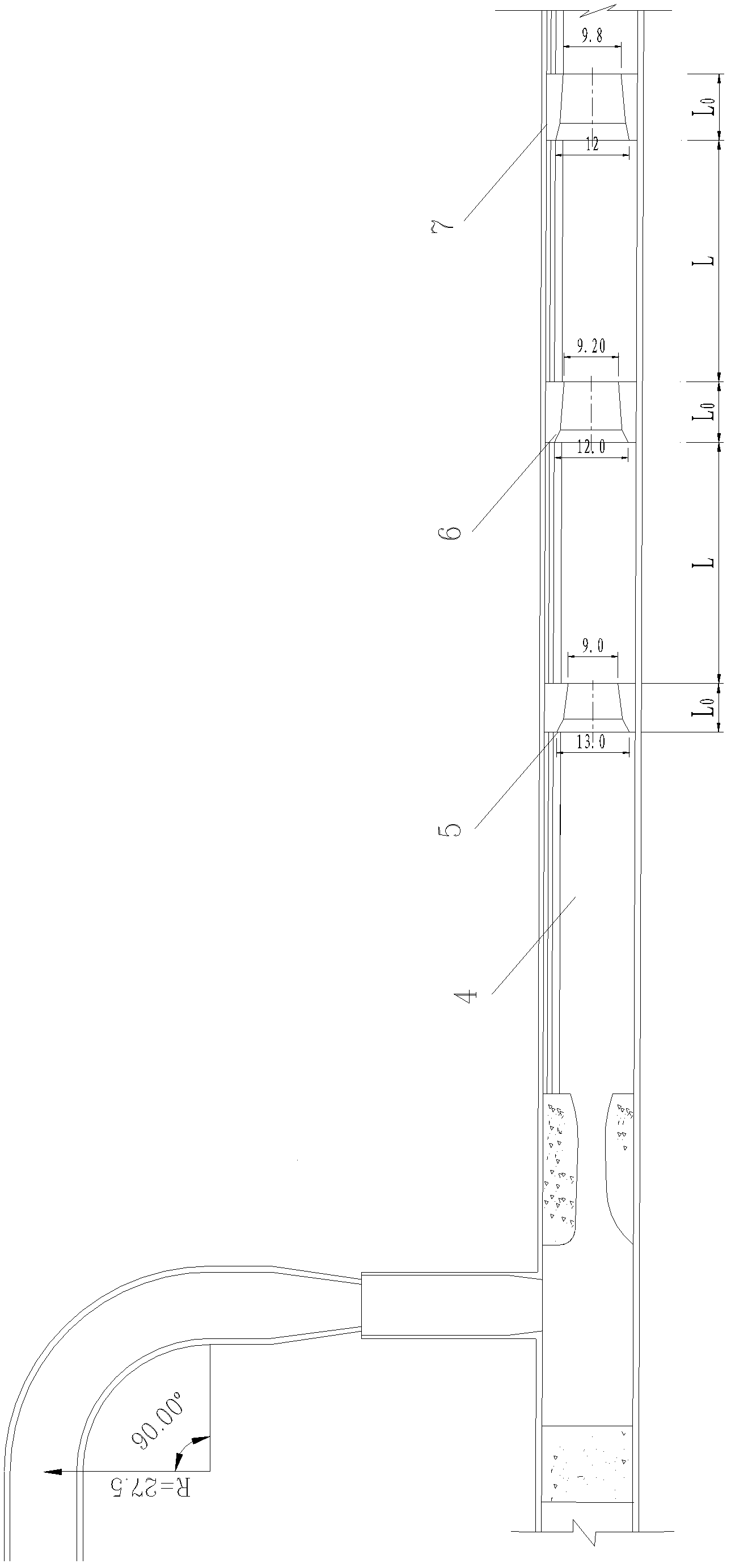

Broken line inlet type hole plug energy dissipater

InactiveCN102322047AImprove cavitation resistanceImprove energy dissipation effectBarrages/weirsWater-power plantsPolygonal lineSoftware engineering

The invention relates to a broken line inlet type hole plug energy dissipater used for a pressure spillway tunnel. The broken line inlet type hole plug energy dissipater comprises a hole plug base and an overflowing hole arranged in the hole plug base, the overflowing hole is formed by connecting two contract truncated cone-shaped holes which are provided with front ends larger than rear ends and are in different tapers, and the outlet of the front contract truncated cone-shaped hole is the inlet of the rear contract truncated cone-shaped hole. Total length L0 of a hole plug meets the following relation: L0=0.6 D0-2.5D0, the diameter D1 of the inlet of the front contract truncated cone-shaped hole meets the following relation: D1=0.6 D0-1.0D0, the ratio D1 / D2 of the diameter D1 of the inlet of the front contract truncated cone-shaped hole to the diameter D2 of the outlet of the front contract truncated cone-shaped hole is 1.05-1.3, the length L1 of the front contract truncated cone-shaped hole meets the following relation: L1 =0.1 L0-0.4L0, and the ratio D2 / D3 of the diameter D2 of the inlet of the rear contract truncated cone-shaped hole to the diameter D3 of the outlet of the rear contract truncated cone-shaped hole is 1.05-1.4, wherein D0 is the diameter of a spillway tunnel in the relations.

Owner:SICHUAN UNIV

Preparation method of water-based magneto rheological hydraulic transmission medium

InactiveCN102041154APrevent agglomeration and sedimentationImprove rust resistanceLubricant compositionEngineeringSoft water

The invention relates to a preparation method of a water-based magneto rheological hydraulic transmission medium, comprising: proportioning 55-70% of deionized soft water, 29-45% of magnetic particle and 1-10% of additive; successively adding; and mixing and stirring to obtain the water-based magneto rheological hydraulic transmission medium. The medium has good stability and inoxidizability and can greatly improve the abrasion resistance and the rust protection of a hydraulic system working medium.

Owner:KUNMING UNIV OF SCI & TECH

Designing method of cylindrical blade with controllable inlet setting angle

InactiveCN105134646AReduce impact hydraulic lossBoost Energy IndexPump componentsPumpsImpellerCavitation

The invention discloses a designing method of a cylindrical blade with the controllable inlet setting angle. A designing and shape drawing process of a novel cylindrical blade is given. The inlet edge of the novel blade and the blade inlet attack angle at the intersection of a front cover plate and a rear cover plate can both be given. The impact hydraulic loss at the positions of the blade inlet can be reduced through the controllable inlet setting angle, the major reason for the large hydraulic loss of a traditional cylindrical blade is eliminated, and the purpose of increasing the blade energy index is achieved. The anti-cavitation capability of the blade can be improved through the blade structure, and the application range of the cylindrical blade is enlarged. After the blade is used in an impeller with the specific speed reaching 120, a pump can still have high hydraulic efficiency.

Owner:XIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com