Laser cladding anti-cavitation-erosion coating and preparation method thereof

A laser cladding and coating technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of insufficient anti-cavitation corrosion ability of ship propellers, and achieve the effect of good hardness and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

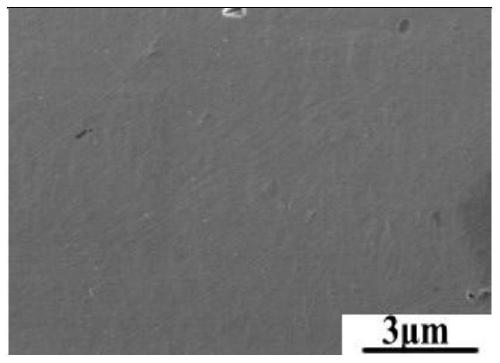

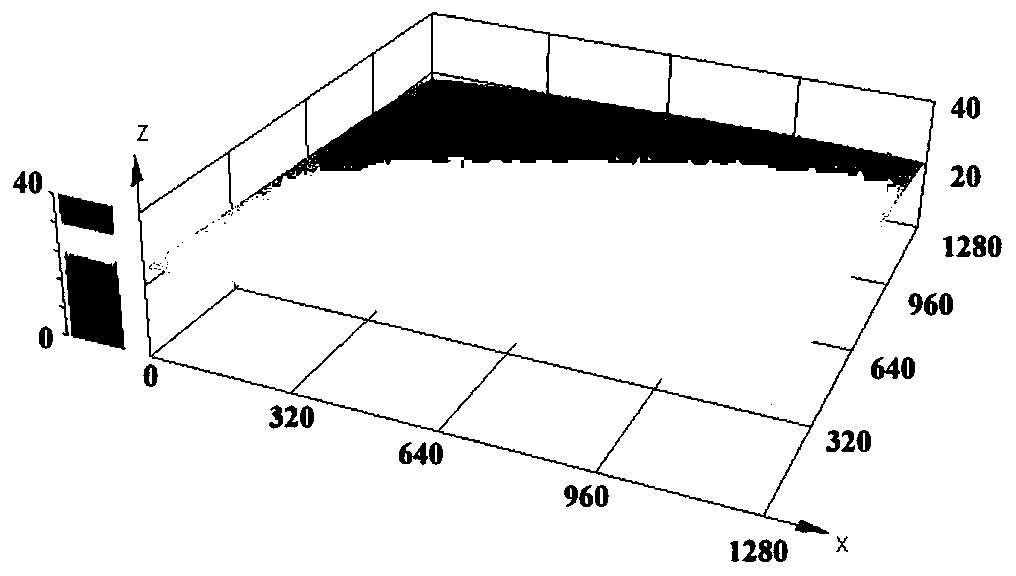

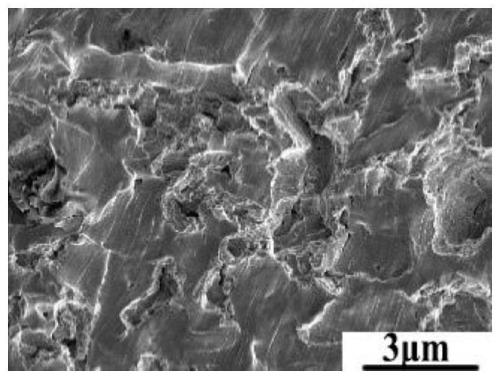

Embodiment 1

[0030] Titanium powder and nickel powder were weighed in the ratio of Ti:Ni=44%:56% by mass, put into a vacuum ball mill for grinding and mixing, and the grinding time was 20 minutes to make the powder particle size 300 mesh. Using a fiber laser, under an argon protective atmosphere, the argon gas flow rate is 15L / min, and the obtained powder is laser clad by coaxial powder feeding. The laser power is 1200W, the spot diameter is 3mm, the scanning speed is 6mm / s, the overlapping rate is 50%, and the powder feeding speed is 8g / min. A shape-memory alloy coating of Ti:Ni=44%:56% was obtained on the nickel-aluminum bronze surface.

Embodiment 2

[0032] Titanium powder and nickel powder are weighed in the ratio of Ti:Ni=44%:56% by mass percentage, put into a vacuum ball mill for grinding and mixing, the time is 20min, the powder particle size is 300 mesh, using a fiber laser, in argon Under the gas protection atmosphere, the flow rate of argon gas is 15L / min, and the obtained powder is carried out by laser cladding by means of coaxial powder feeding. The laser power is 1400W, the spot diameter is 4mm, the scanning speed is 8mm / s, the overlapping rate is 50%, and the powder feeding speed is 10g / min. A shape-memory alloy coating of Ti:Ni=44%:56% was obtained on the nickel-aluminum bronze surface.

Embodiment 3

[0034] Titanium powder and nickel powder are weighed in the ratio of Ti:Ni=44%:56% by mass percentage, put into a vacuum ball mill for grinding and mixing, the time is 20min, the powder particle size is 300 mesh, using a fiber laser, in argon Under the gas protection atmosphere, the flow rate of argon gas is 15L / min, and the obtained powder is carried out by laser cladding by means of coaxial powder feeding. The laser power is 1600W, the spot diameter is 5mm, the scanning speed is 10mm / s, the overlapping rate is 50%, and the powder feeding speed is 12g / min. A shape-memory alloy coating of Ti:Ni=44%:56% was obtained on the nickel-aluminum bronze surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com