Leading type water pressure overflow valve

A pilot valve, relief valve technology, applied in valve devices, safety valves, balance valves, etc., can solve the problems of pilot valve lateral vibration, noise and working stability are not well solved, and reduce leakage. and wire drawing erosion, small friction coefficient, and the effect of improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

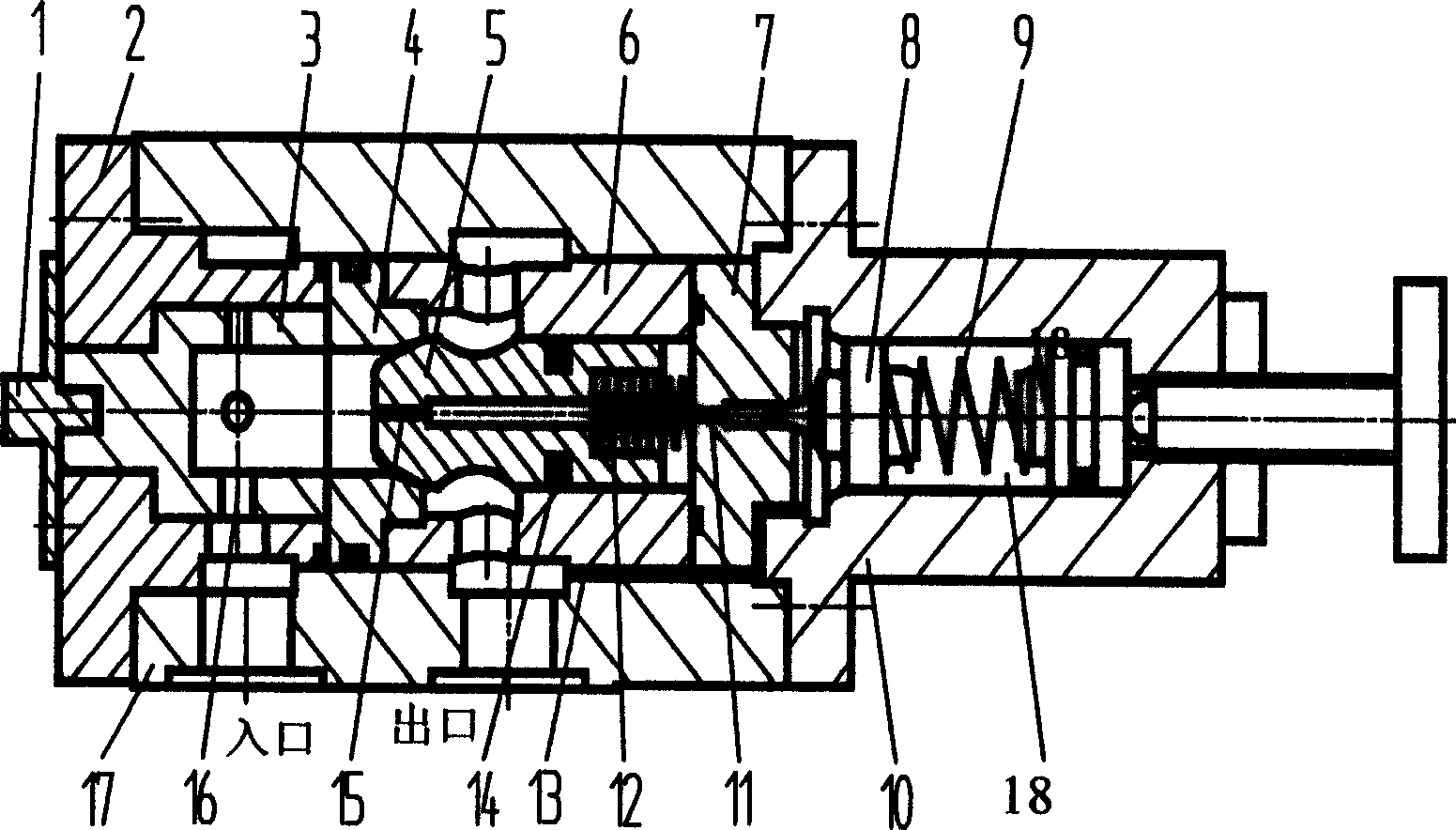

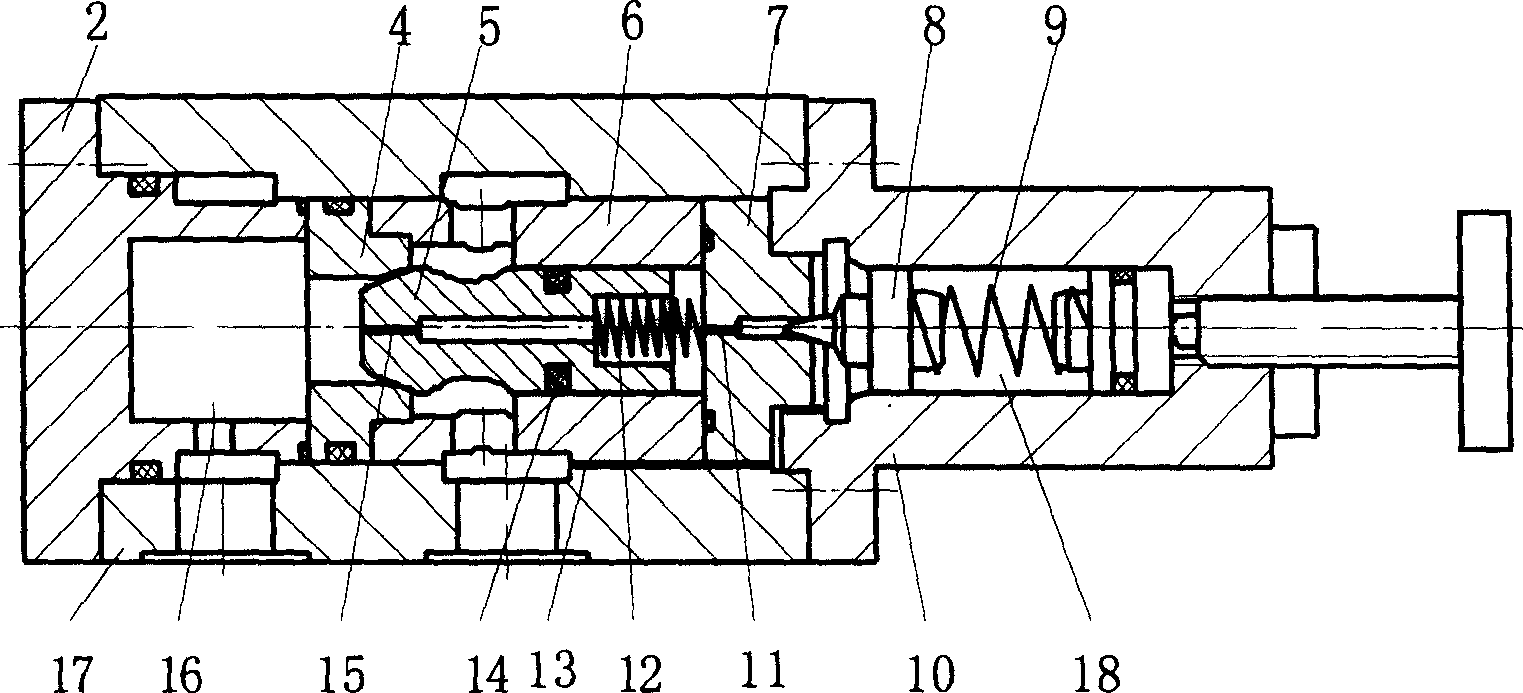

[0027] figure 1 As shown, an embodiment of the present invention includes: pressure adjustment knob 1, front end cover 2, throttle ring 3, throttle hole 16, main valve body 17, main valve seat 4, main valve core 5, rubber-plastic combination Seal 14, main valve damping hole 15, main valve sleeve 6, main valve spring 12, pilot valve seat 7, pilot valve damping hole 11, pilot valve core 8, pressure regulating spring 9, pilot valve body 10. The pilot valve and the main valve are fixed on the main valve body 17 through the pilot valve body 10 and connected coaxially, the pilot valve seat 7 presses the main valve spring 12, the main valve is a cone valve structure, and the pilot valve can adopt a cone valve or ball valve structure .

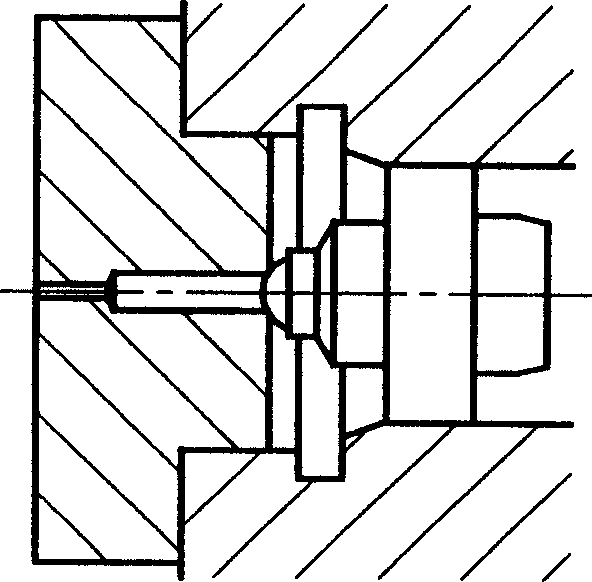

[0028] figure 2 Indicates an implementation state in which the pilot valve is a ball valve structure.

[0029] image 3 Represents another embodiment of the present invention. When there is only one throttle hole on the throttle ring, the thrott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com