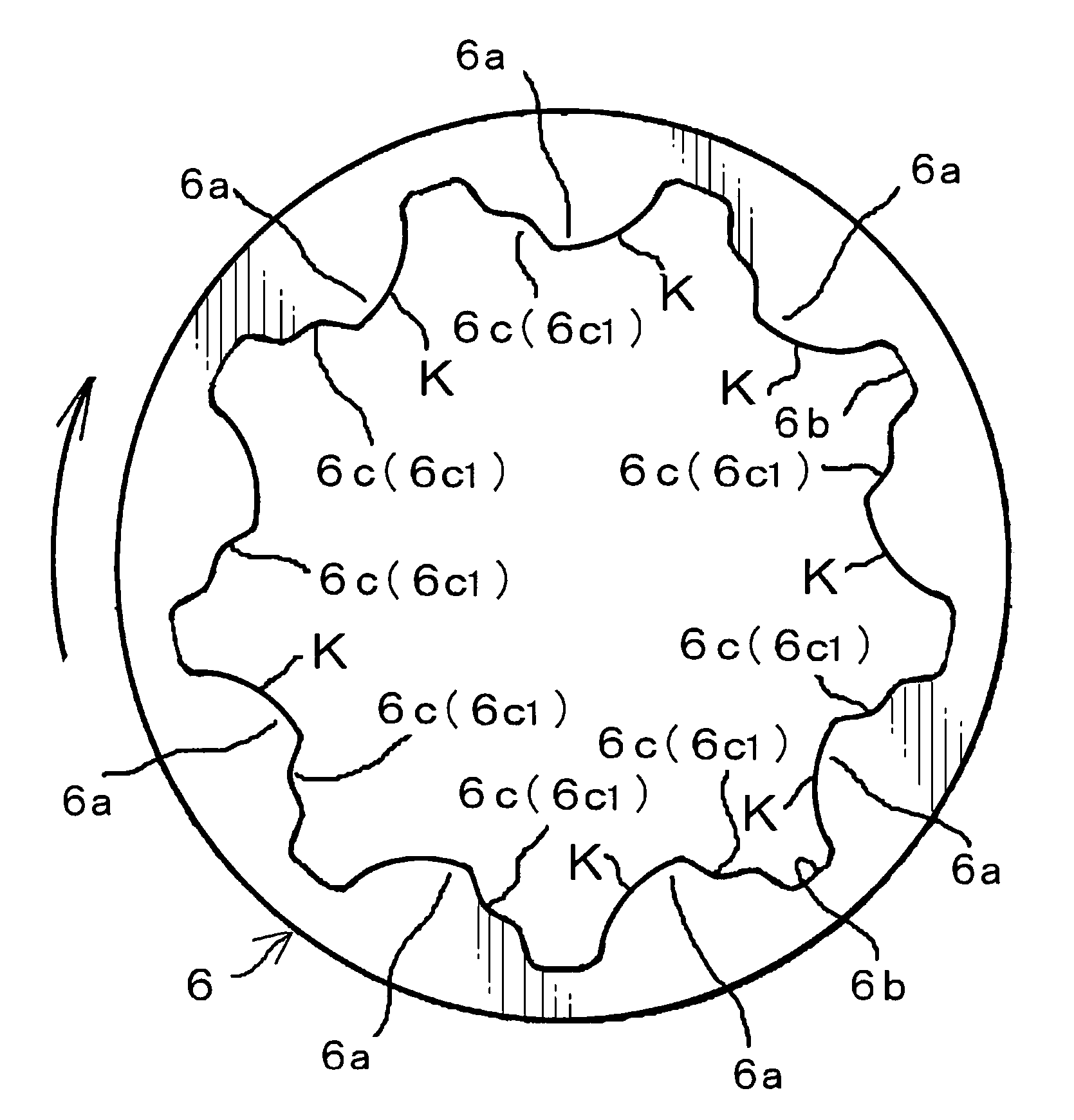

Patents

Literature

64results about How to "Suppress cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

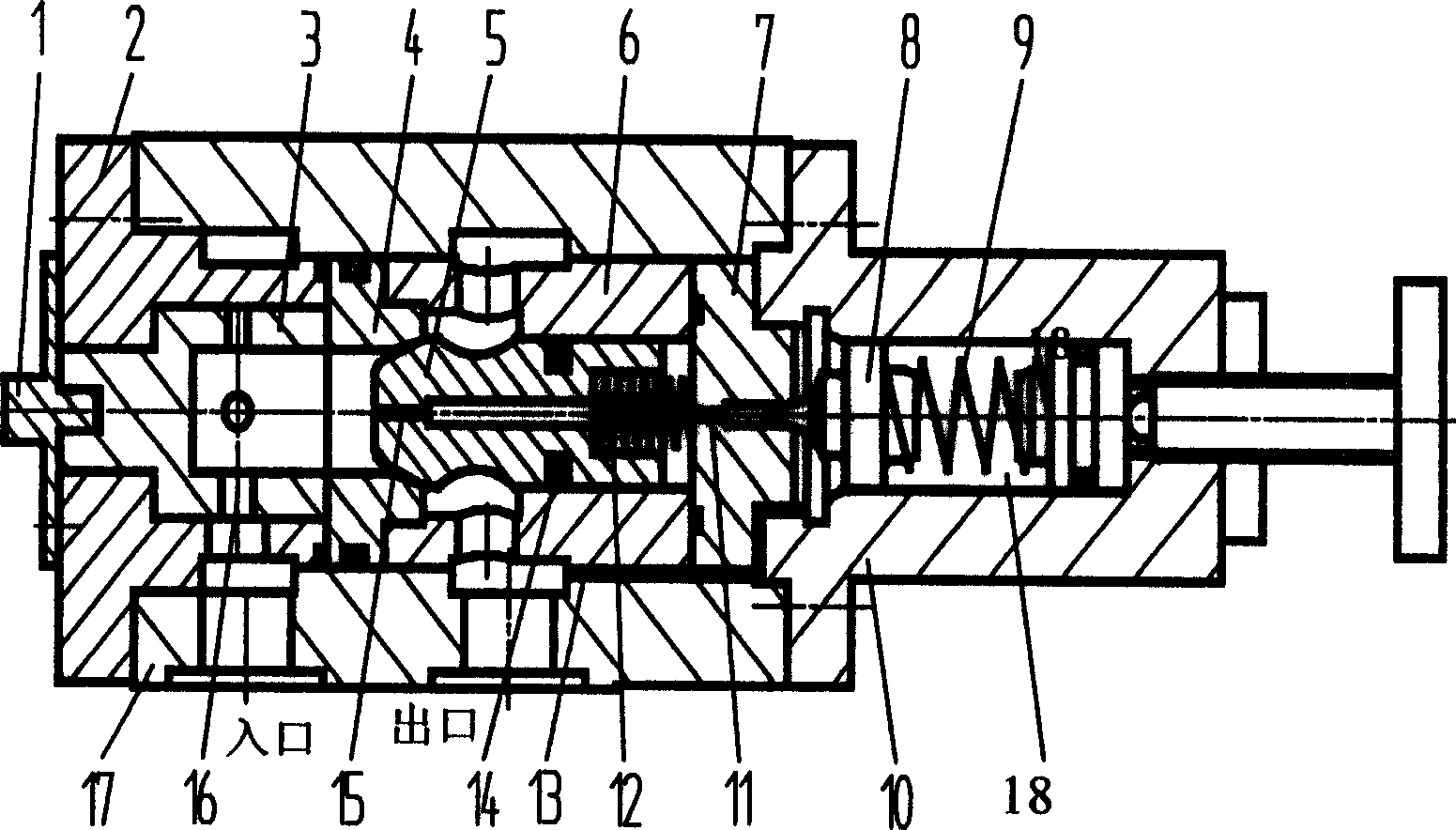

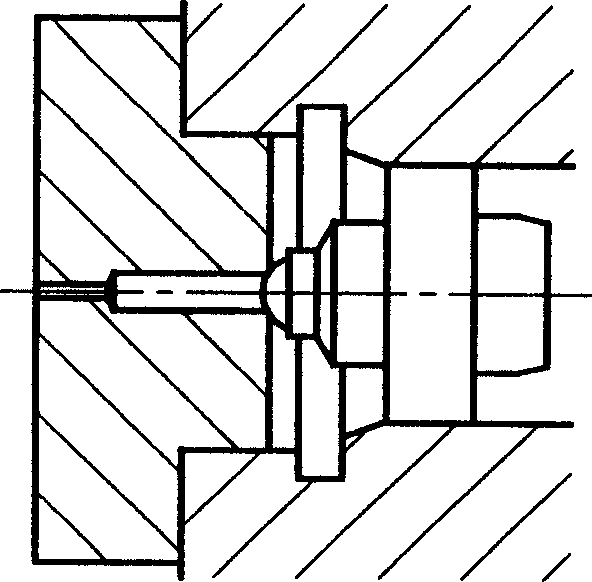

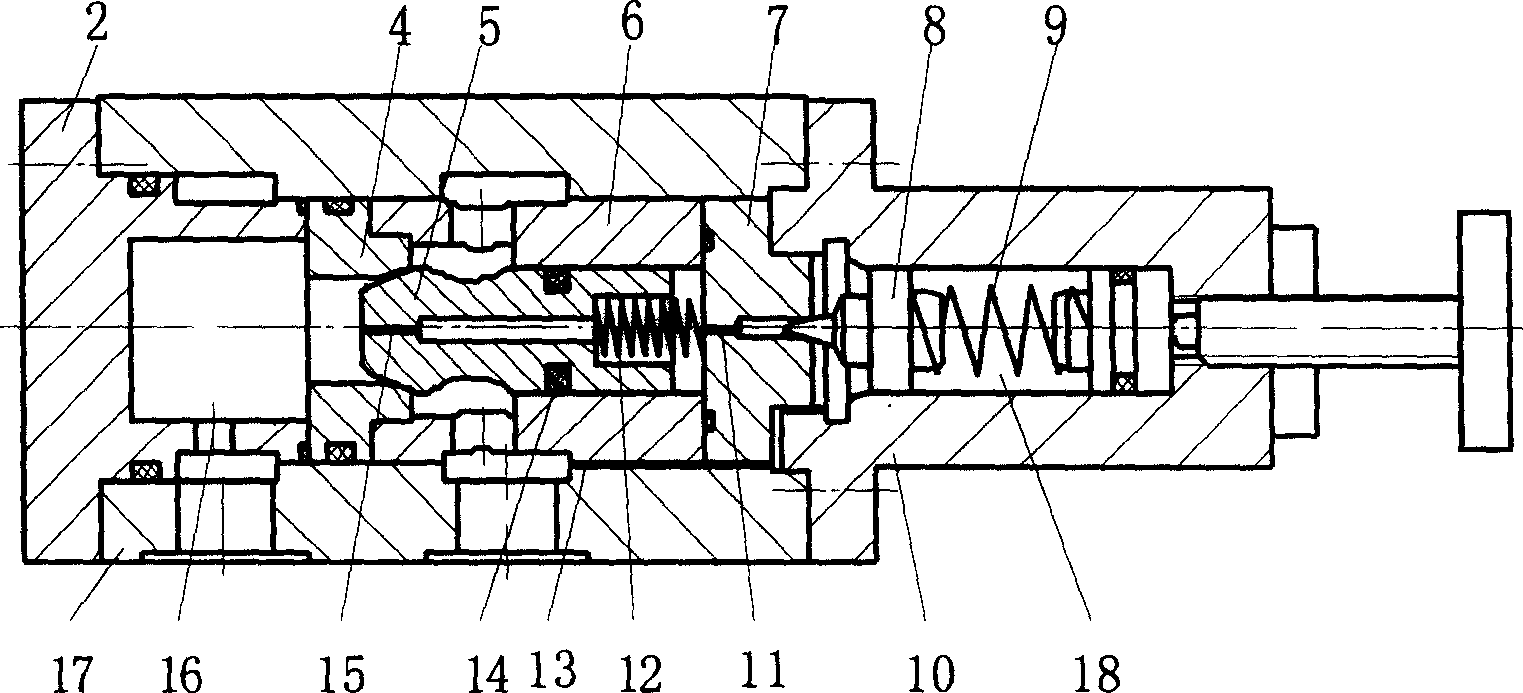

Leading type water pressure overflow valve

InactiveCN1619198AImprove job stabilityReduce working pressure differenceEqualizing valvesSafety valvesEngineeringValve seat

The present invention relates to a pilot type hydraulic overflow valve. Its main valve body has front end cover, in said main valve body a main valve seat, a main valve buckle, a main valve core and a main valve spring are set, and said pilot valve is formed from its valve seat, valve core and pressure-regulating spring, said pilot valve is connected with said main valve. Said invention also provides the structure of main valve and pilot valve, and provides the application range of said valve.

Owner:HUAZHONG UNIV OF SCI & TECH

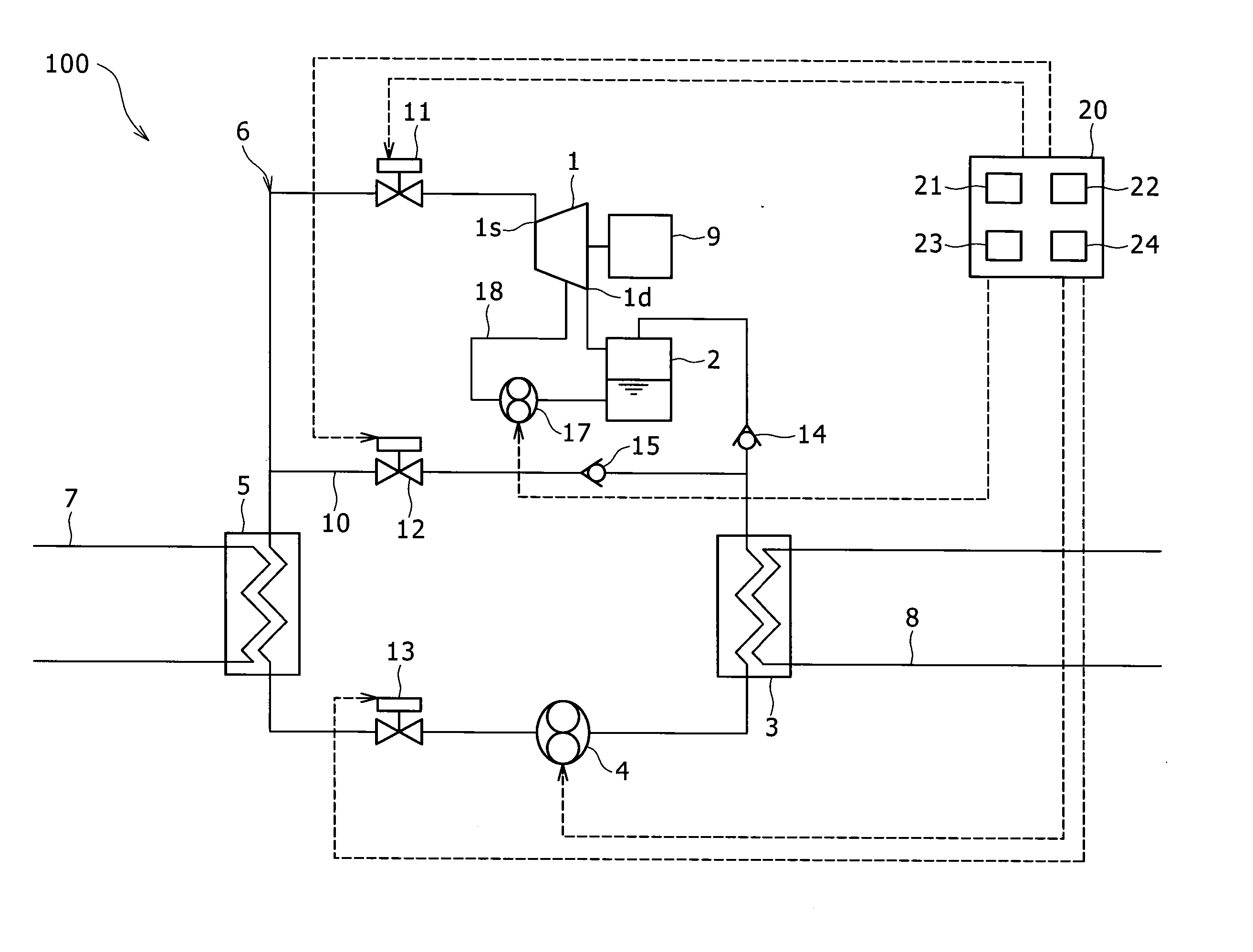

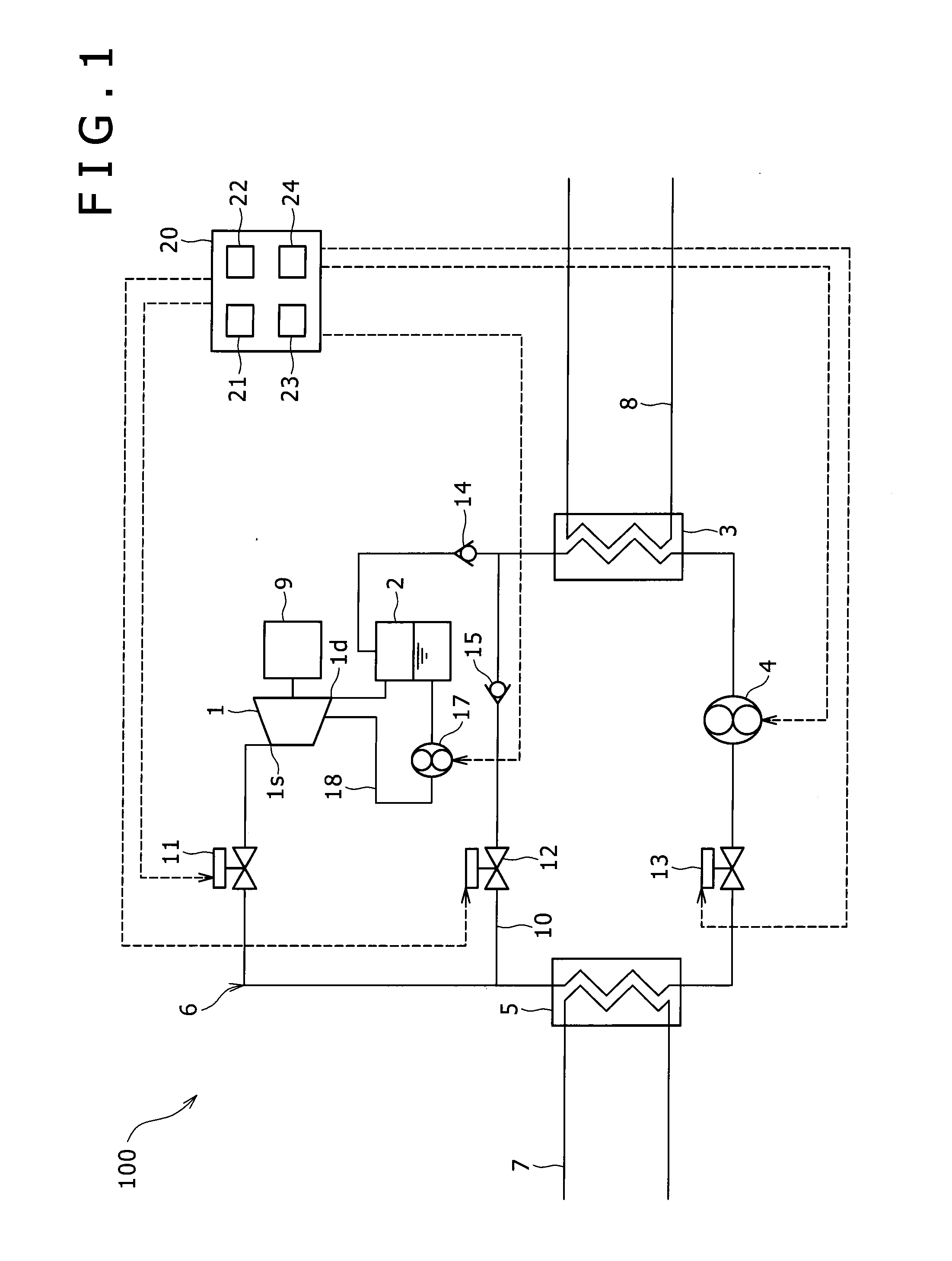

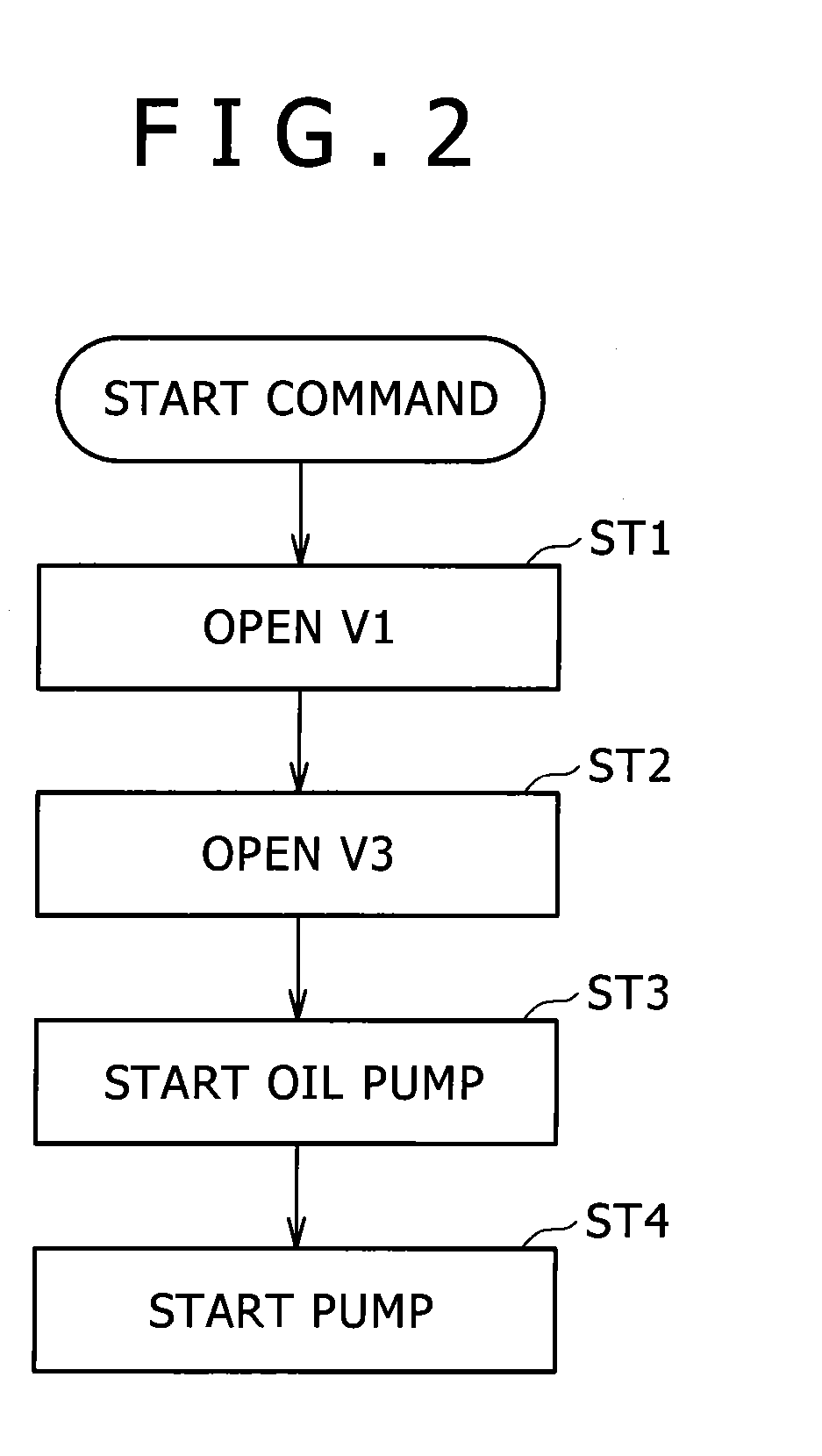

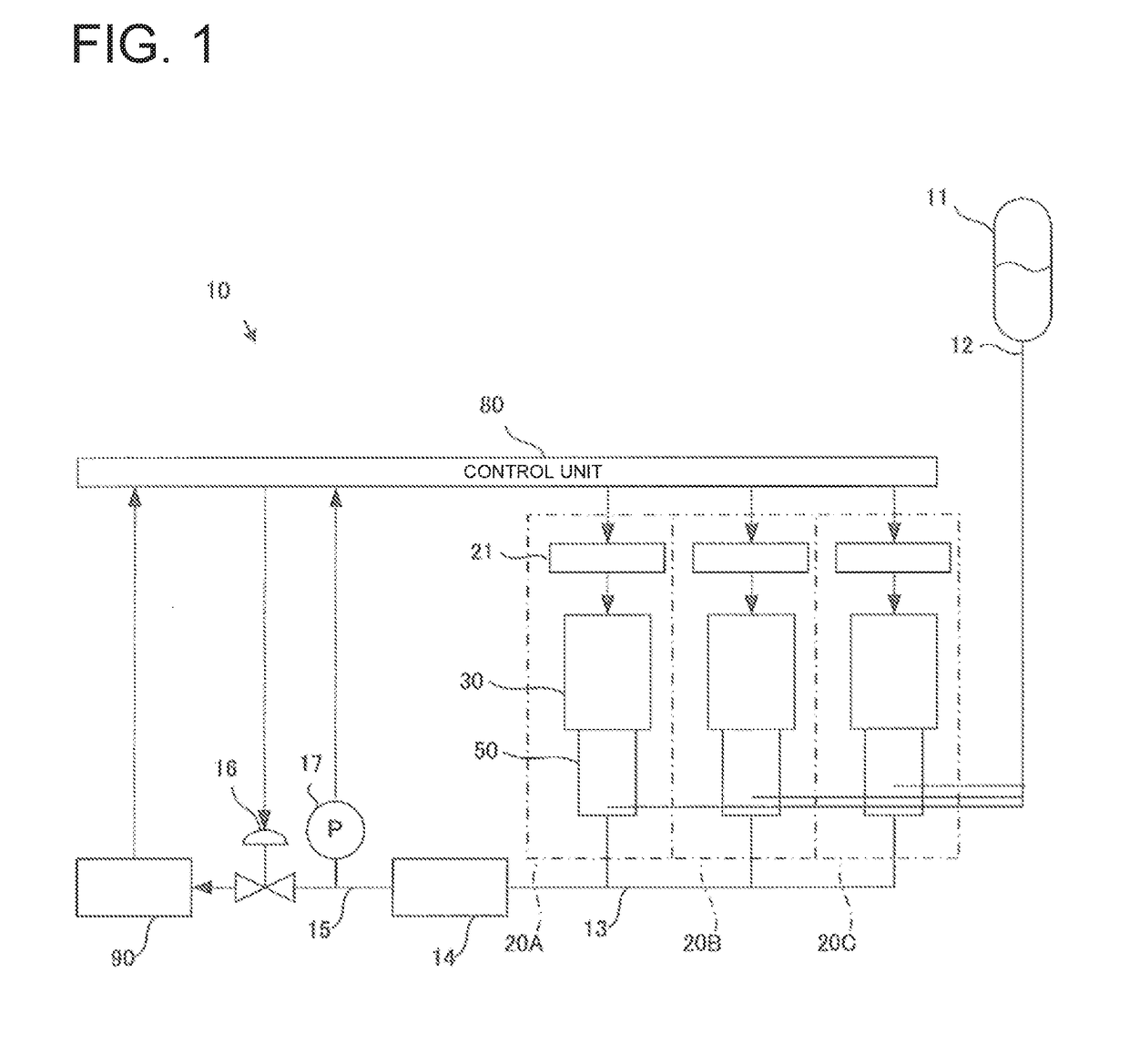

Power generation apparatus

InactiveUS20120312021A1Reduce riskReduce the amount of solutionFeed water supplySteam engine plantsCavitationControl signal

A power generation apparatus that suppress cavitation includes a first on / off valve provided between a steam generator and an expander in a circulating channel; a bypass channel connected between an area between the steam generator and the first on / off valve and an area between the expander and a condenser; a second on / off valve provided in the bypass channel; a third on / off valve provided between a pump and the steam generator; and a controller. When stopping the pump, the controller outputs a control signal that stops the pump, a control signal that closes the first on / off valve, a control signal that opens the second on / off valve, and a control signal that closes the third on / off valve. In the case where a predetermined condition has been met, the controller outputs a control signal that closes the second on / off valve.

Owner:KOBE STEEL LTD

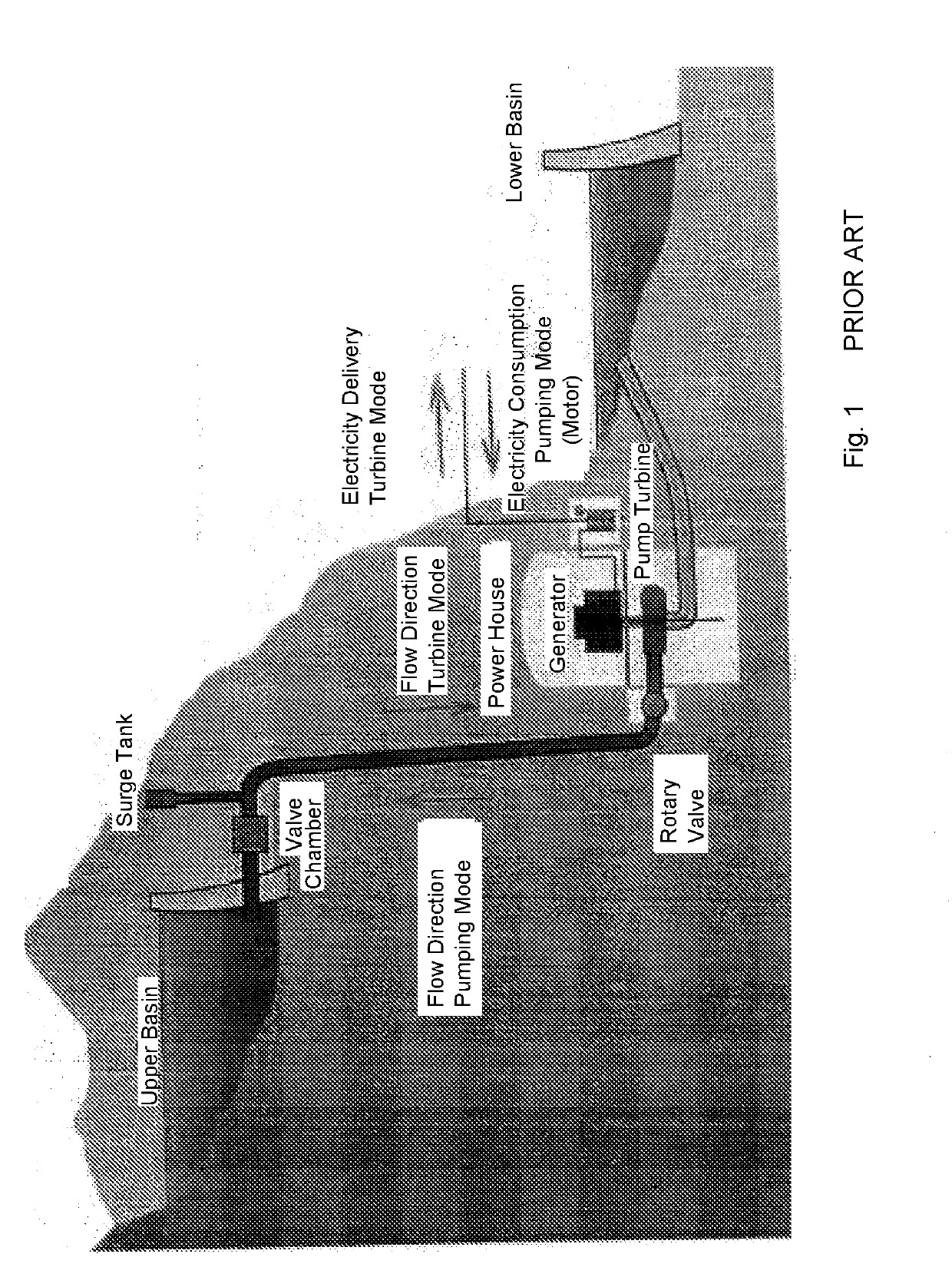

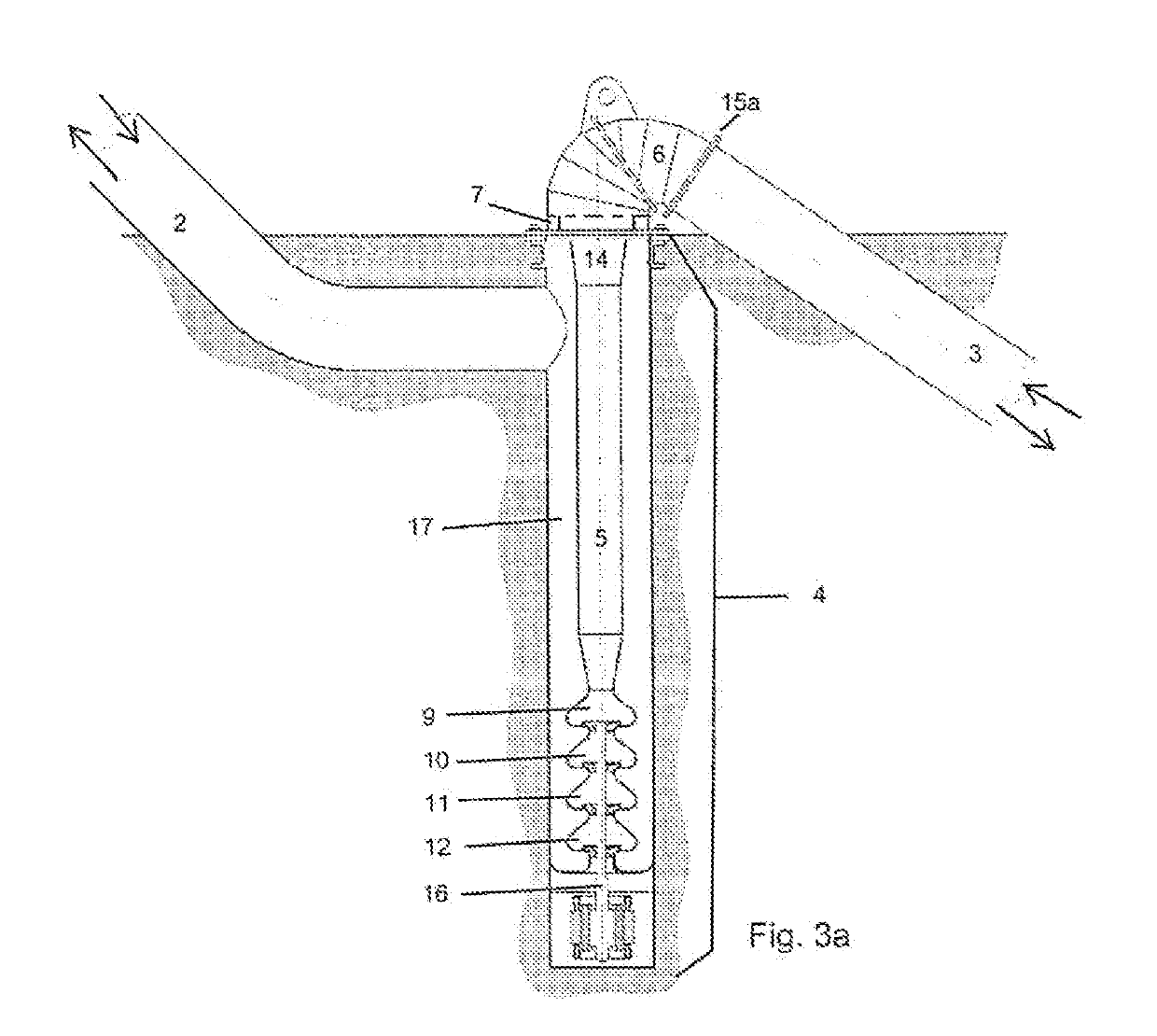

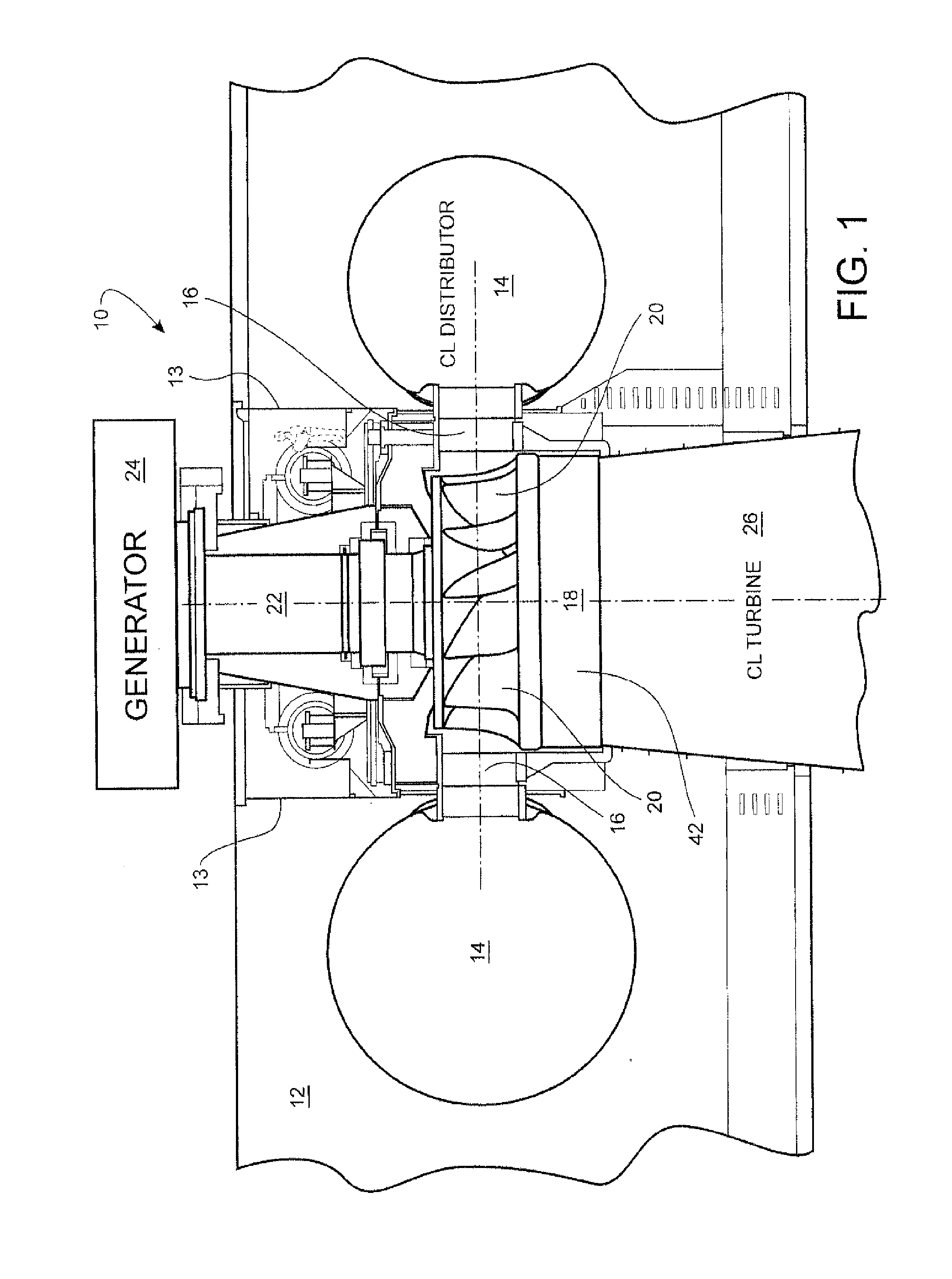

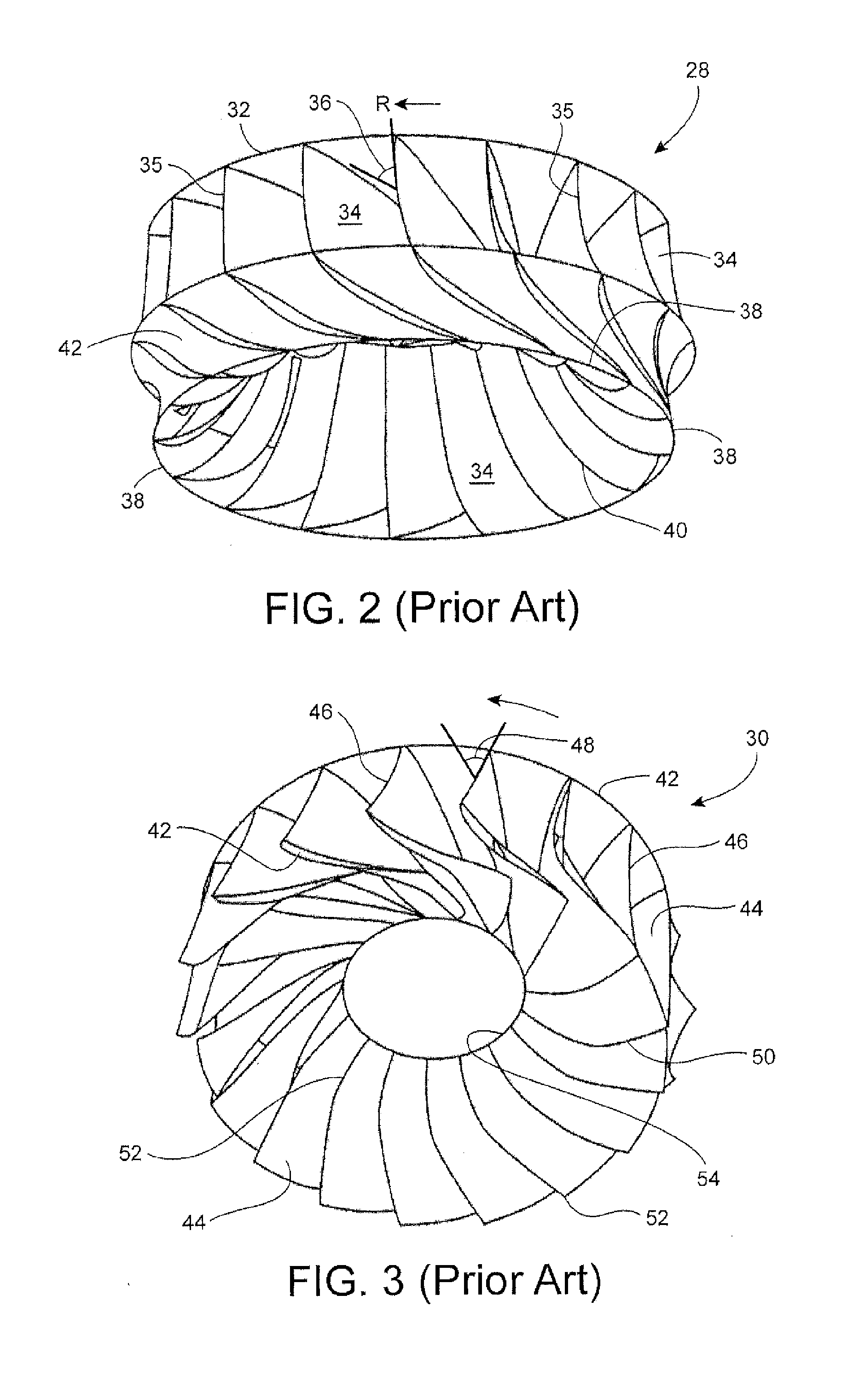

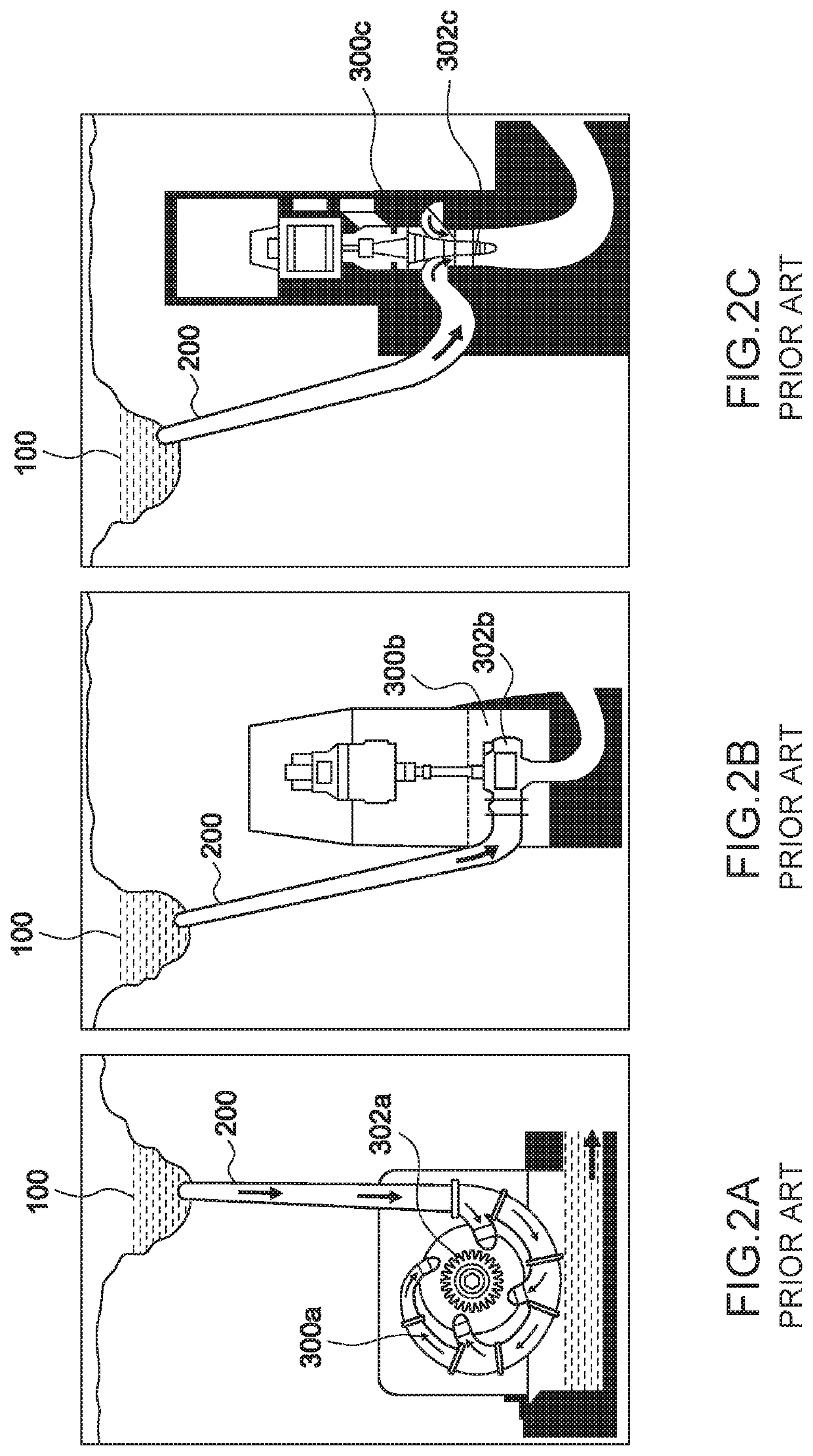

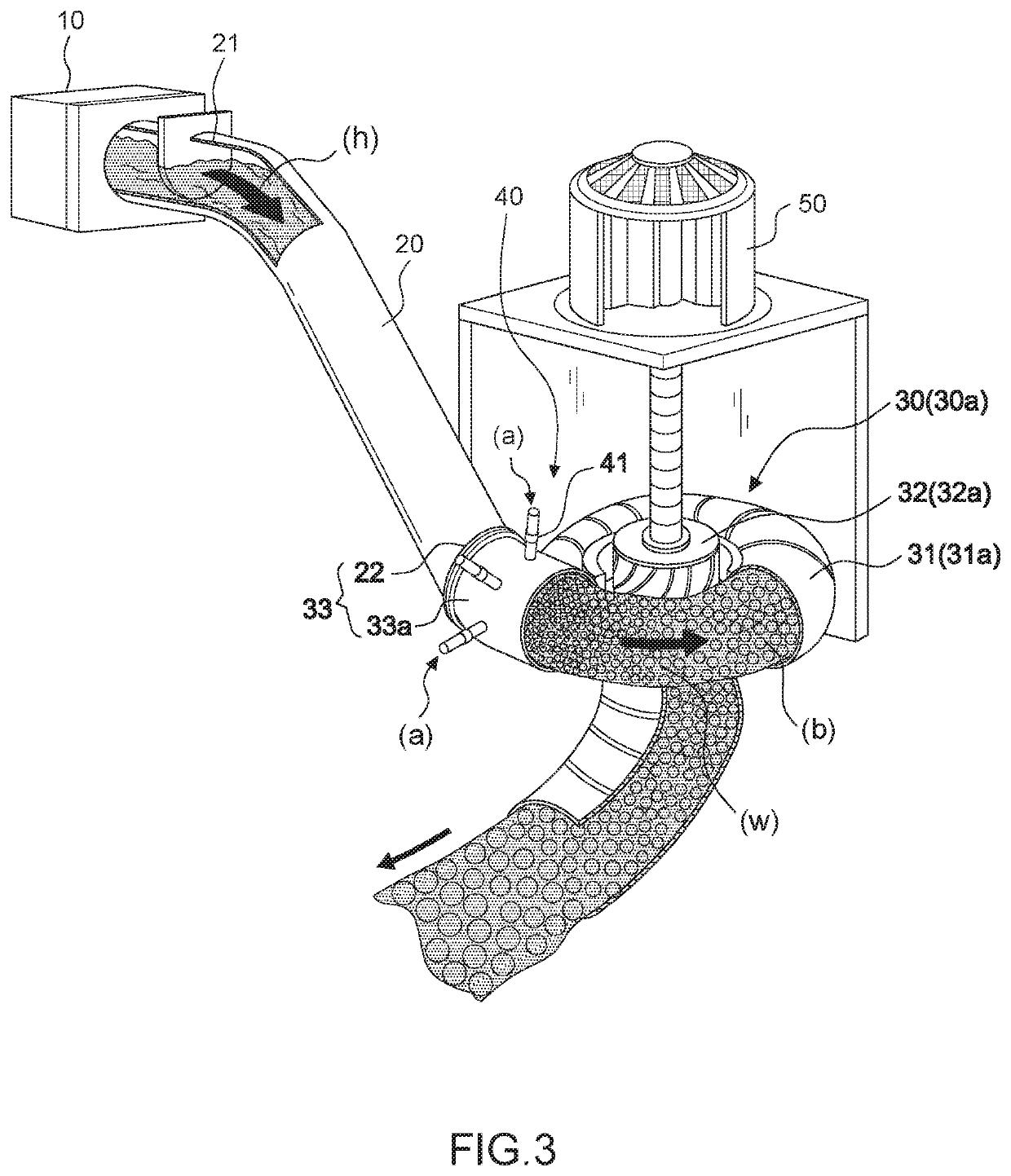

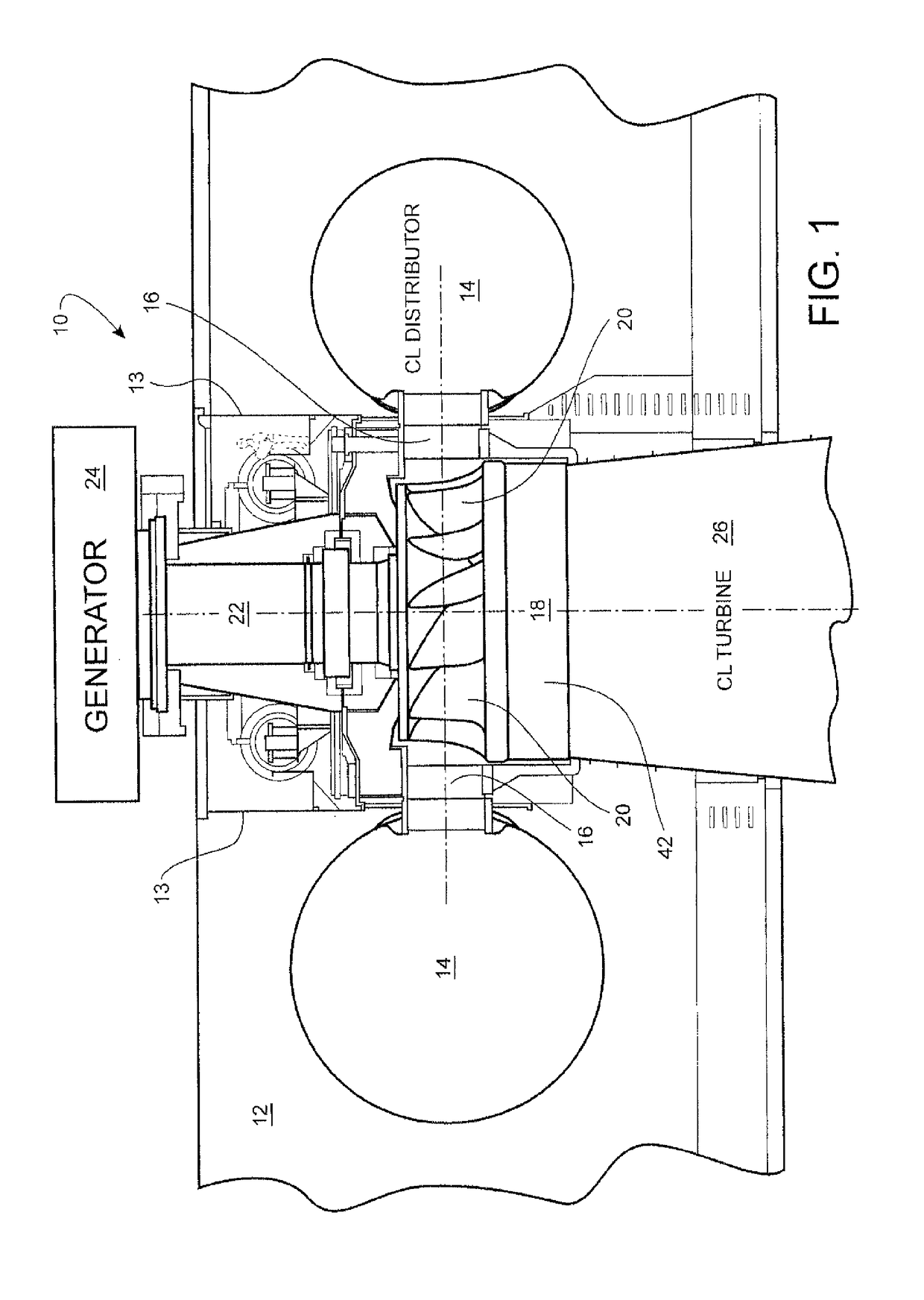

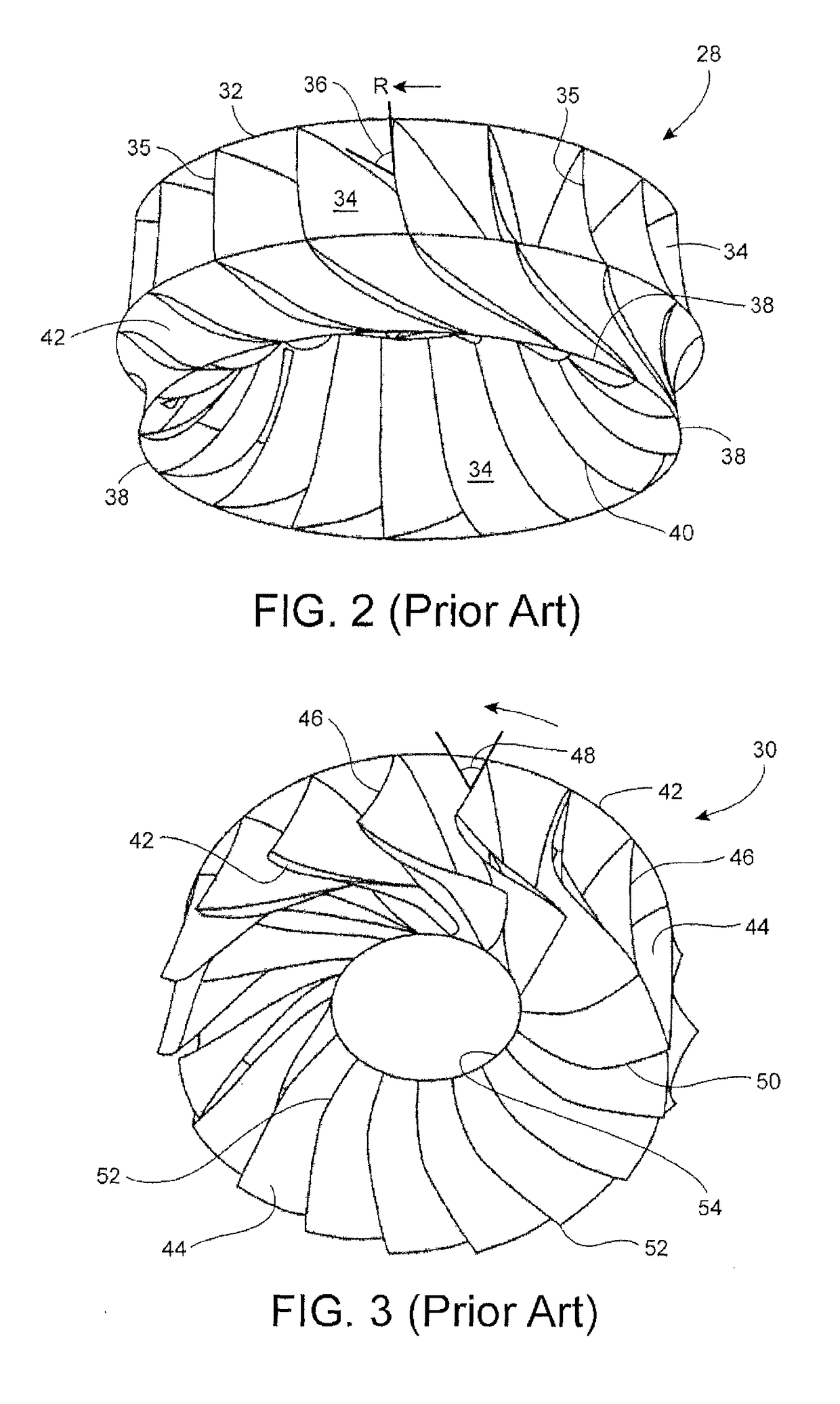

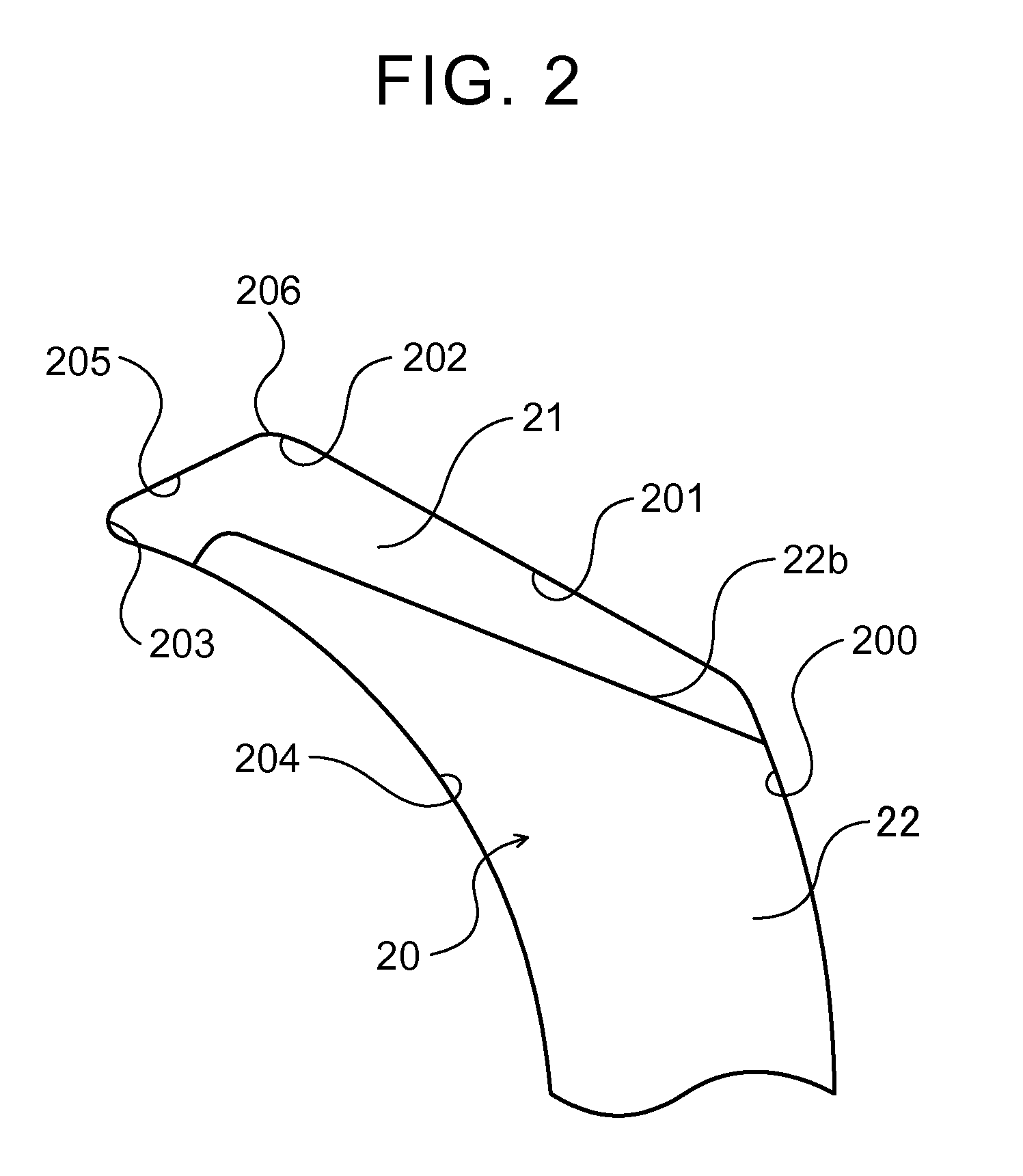

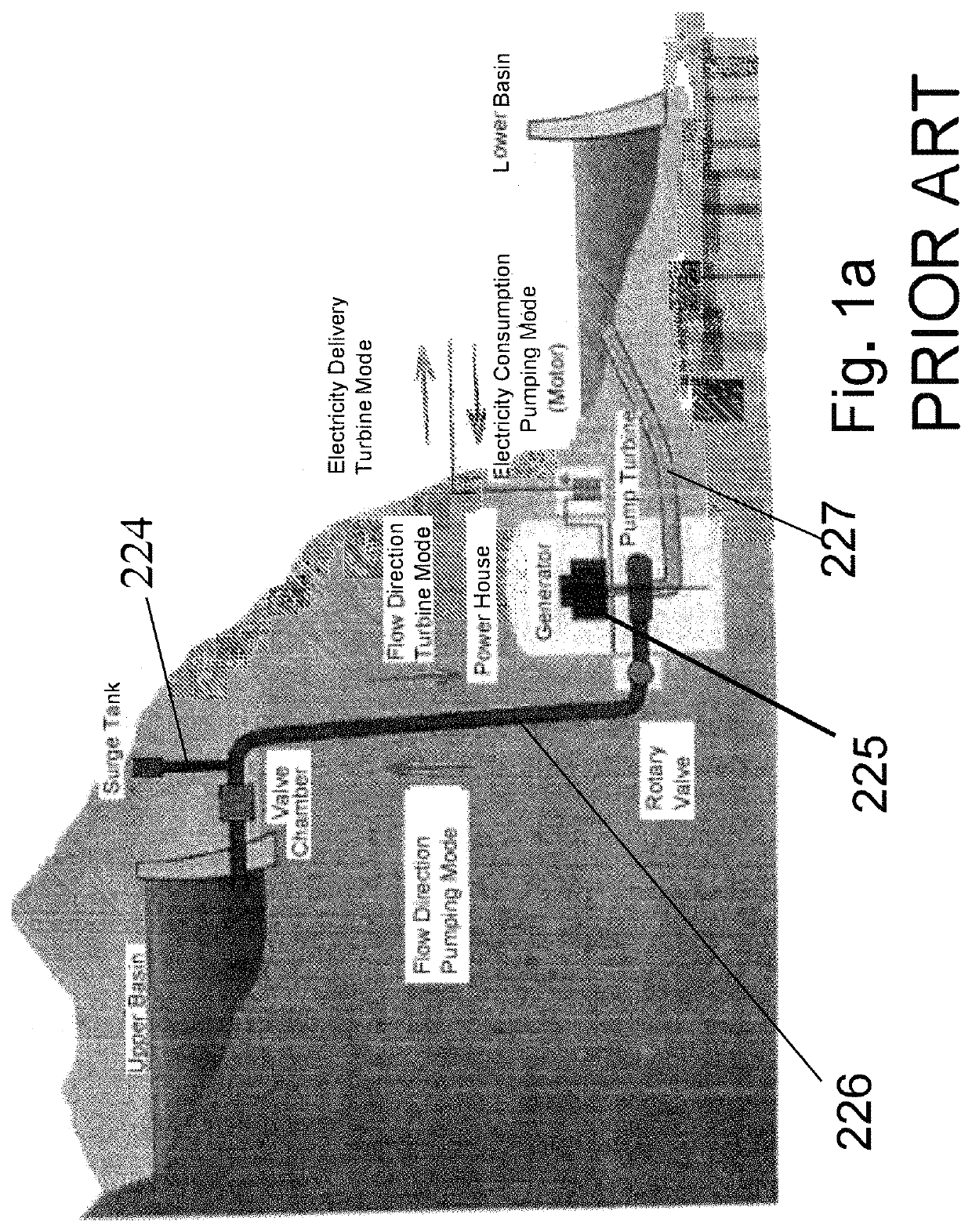

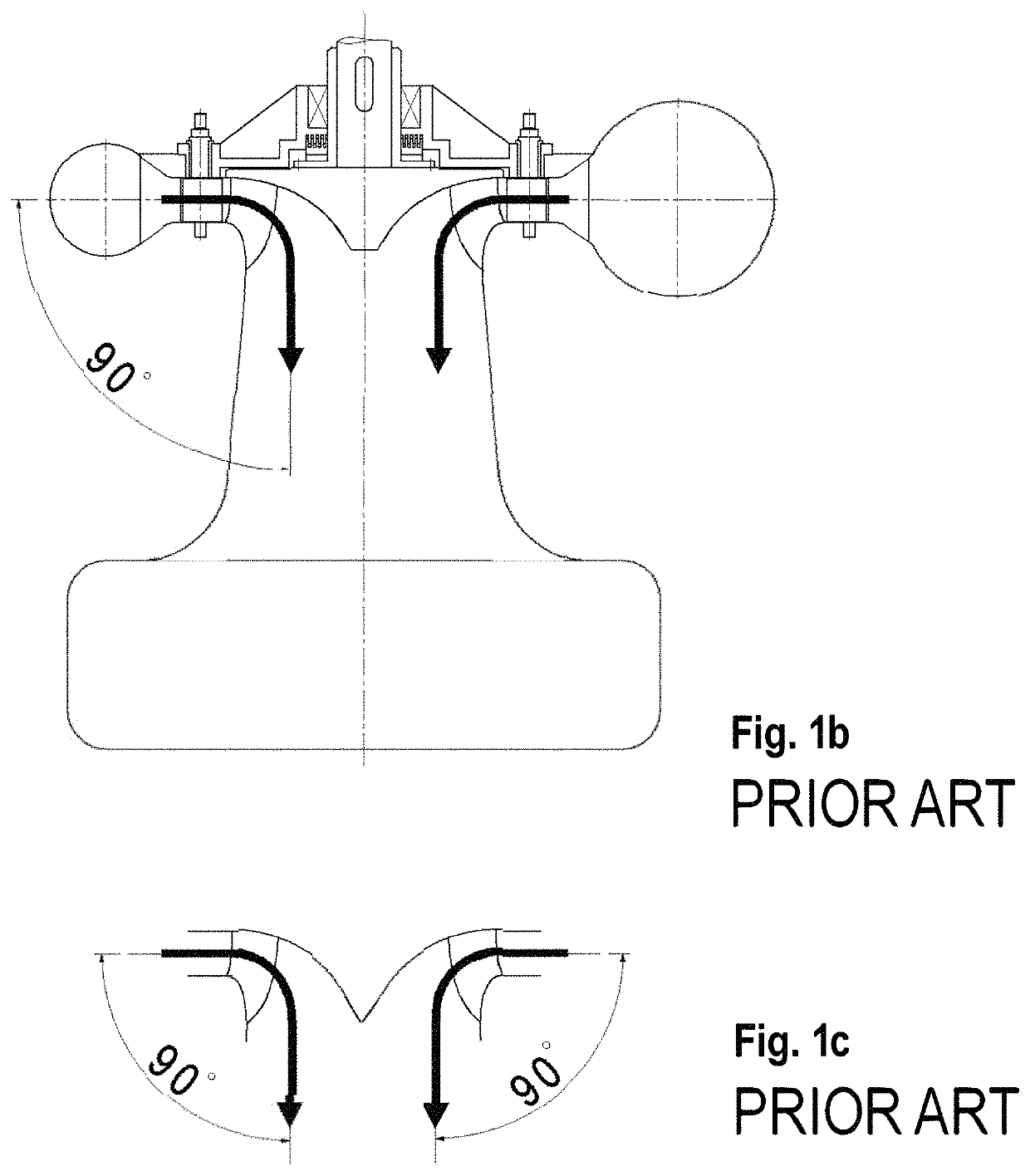

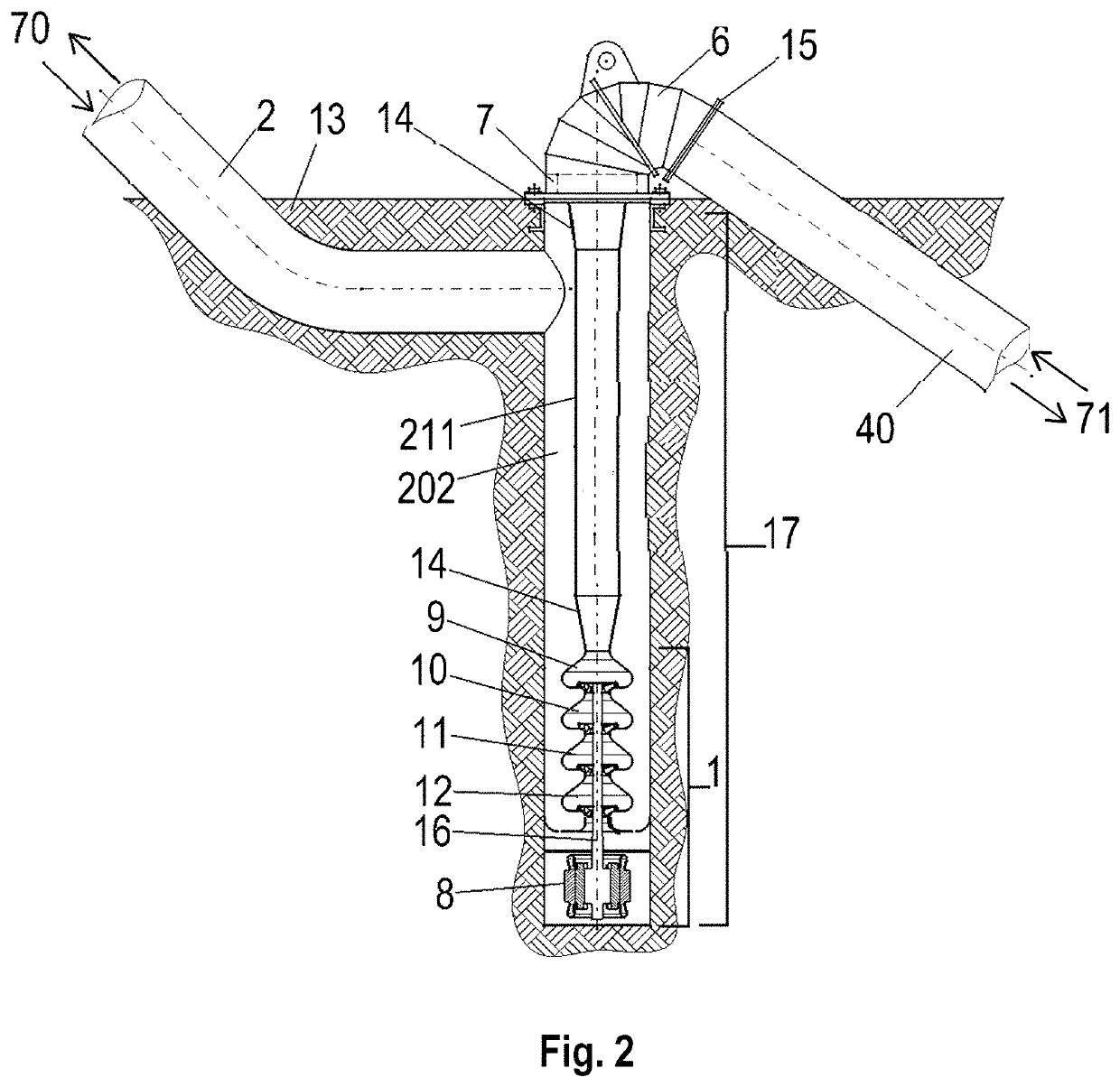

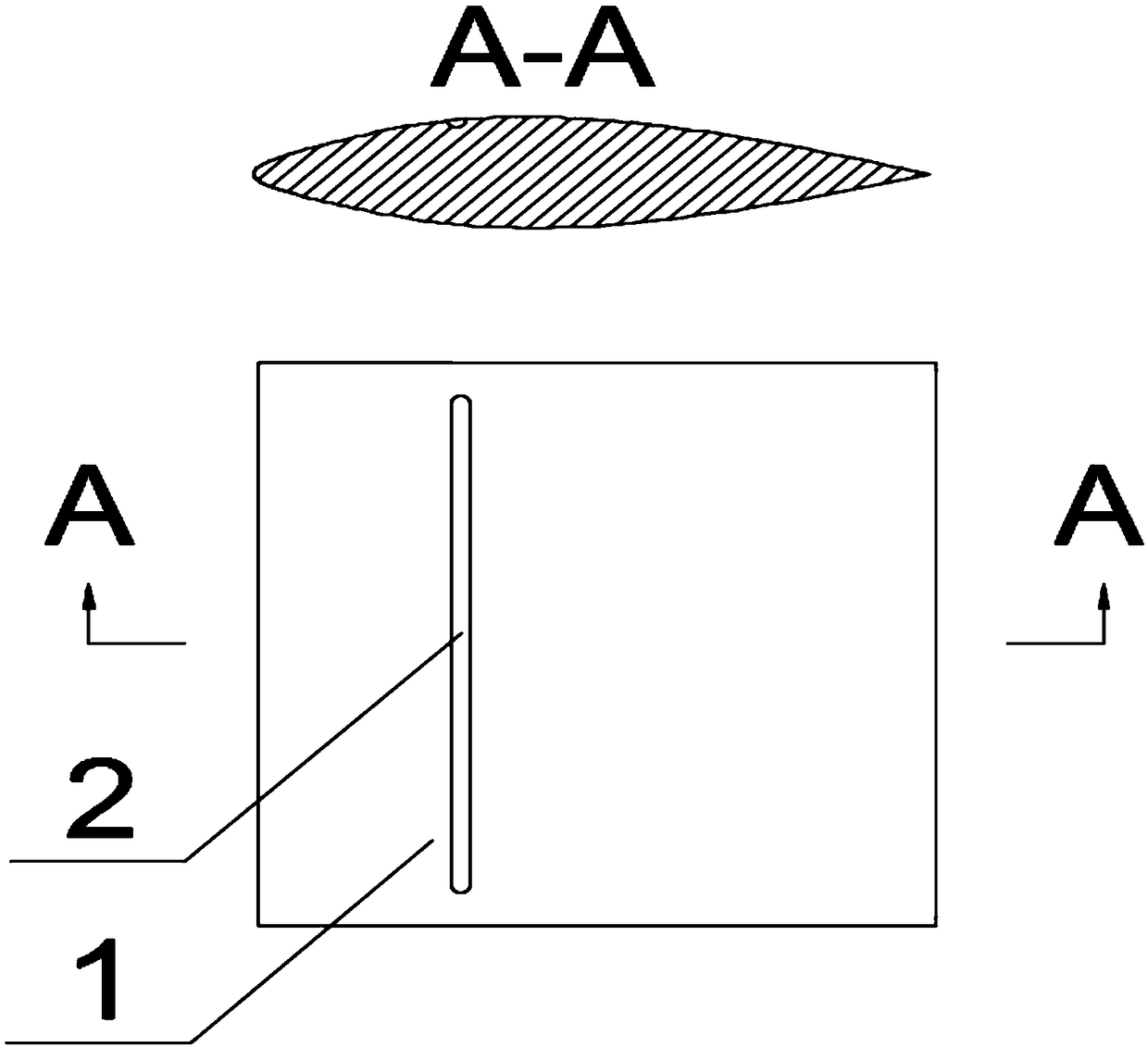

Improved Reversible Pump-Turbine Installation

ActiveUS20190186458A1Maximized ratioMaximizes headPump componentsWater-power plantsCavitationWater flow

The present invention is a reversible pump-turbine installation position in a vertical shaft instead of in a conventional underground powerhouse or deep concrete powerhouse. The required plant cavitation coefficient may be achieved by simply boring a vertical shaft to the required depth rather than routing the water flow to and from a deeply buried powerhouse. A pneumatically controlled pressure relief valve may be incorporated into this invention.

Owner:BHE TURBOMACHINERY LLC

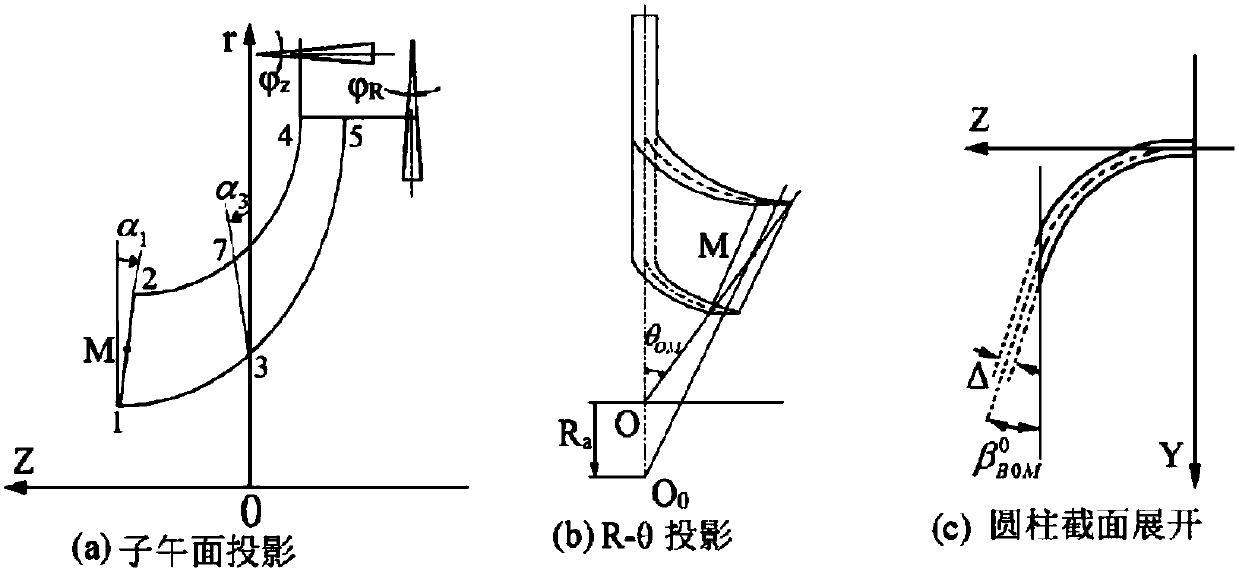

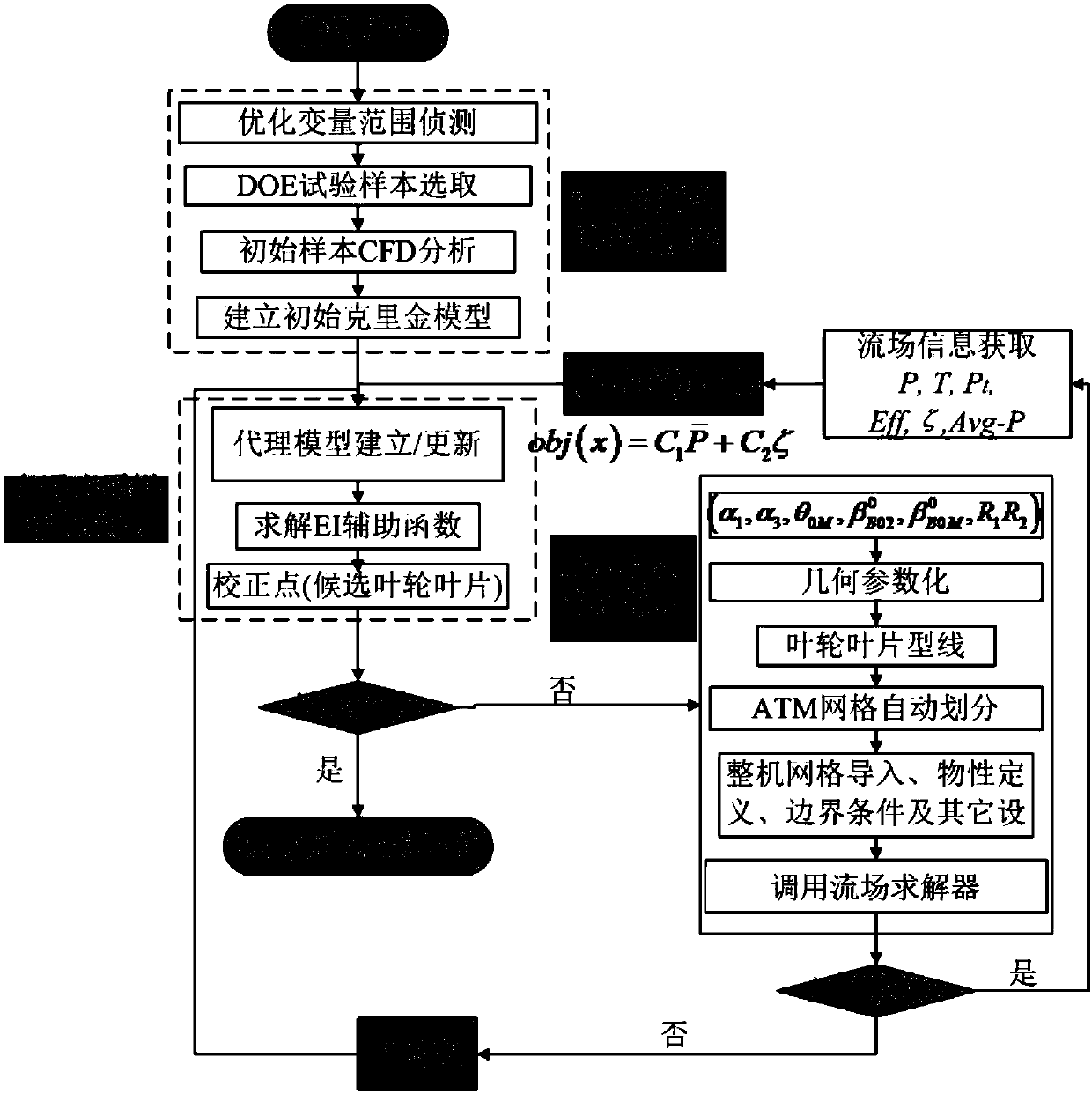

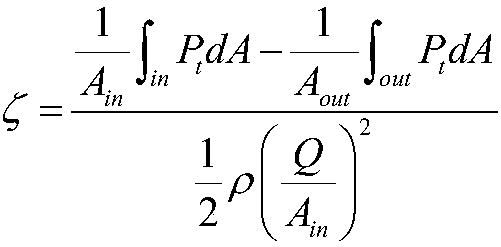

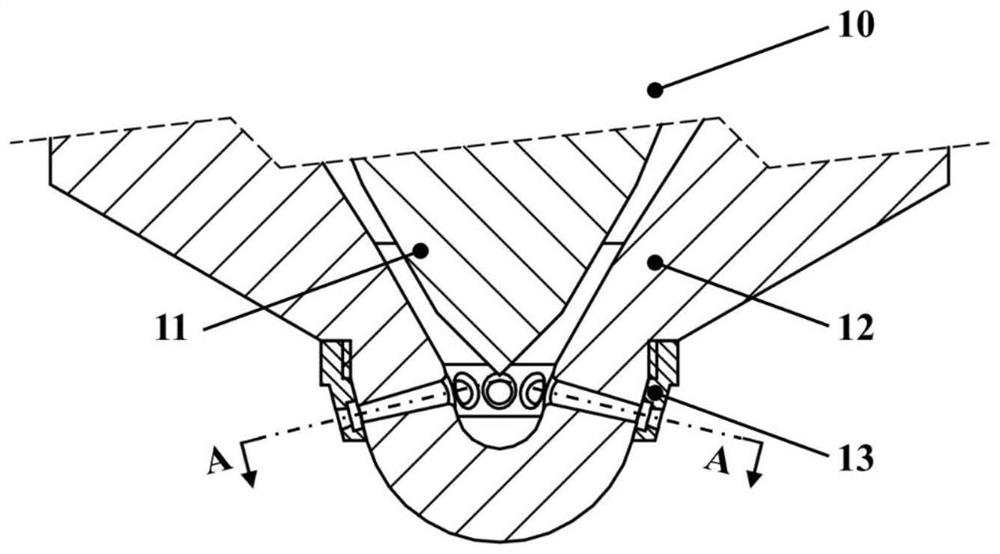

Effective control method for vortex cavitation flowing in low-temperature liquid expander

ActiveCN108561195AImprove performanceImprove operational reliabilityMachines/enginesSafety/regulatory devicesImpellerEngineering

The invention discloses an effective control method for vortex cavitation flowing in a low-temperature liquid expander. The effective control method comprises the steps of researching of the low-temperature liquid expander vortex cavitation mechanism considering the low-temperature fluid thermal-mechanical effect, impeller geometrical parameter sensitivity analysis for vortex cavitation flowing inthe low-temperature liquid expander, characterization presentation of complex vortex cavitation flowing in the low-temperature liquid expander, construction of a flow field optimizing objective function and flow field optimizing control variables with the purpose of controlling vortex cavitation flowing, and parallel solving of a vortex cavitation flowing optimizing control problem. According tothe effective control method, the performance and operation reliability of the low-temperature liquid expander can be effectively improved.

Owner:XI AN JIAOTONG UNIV

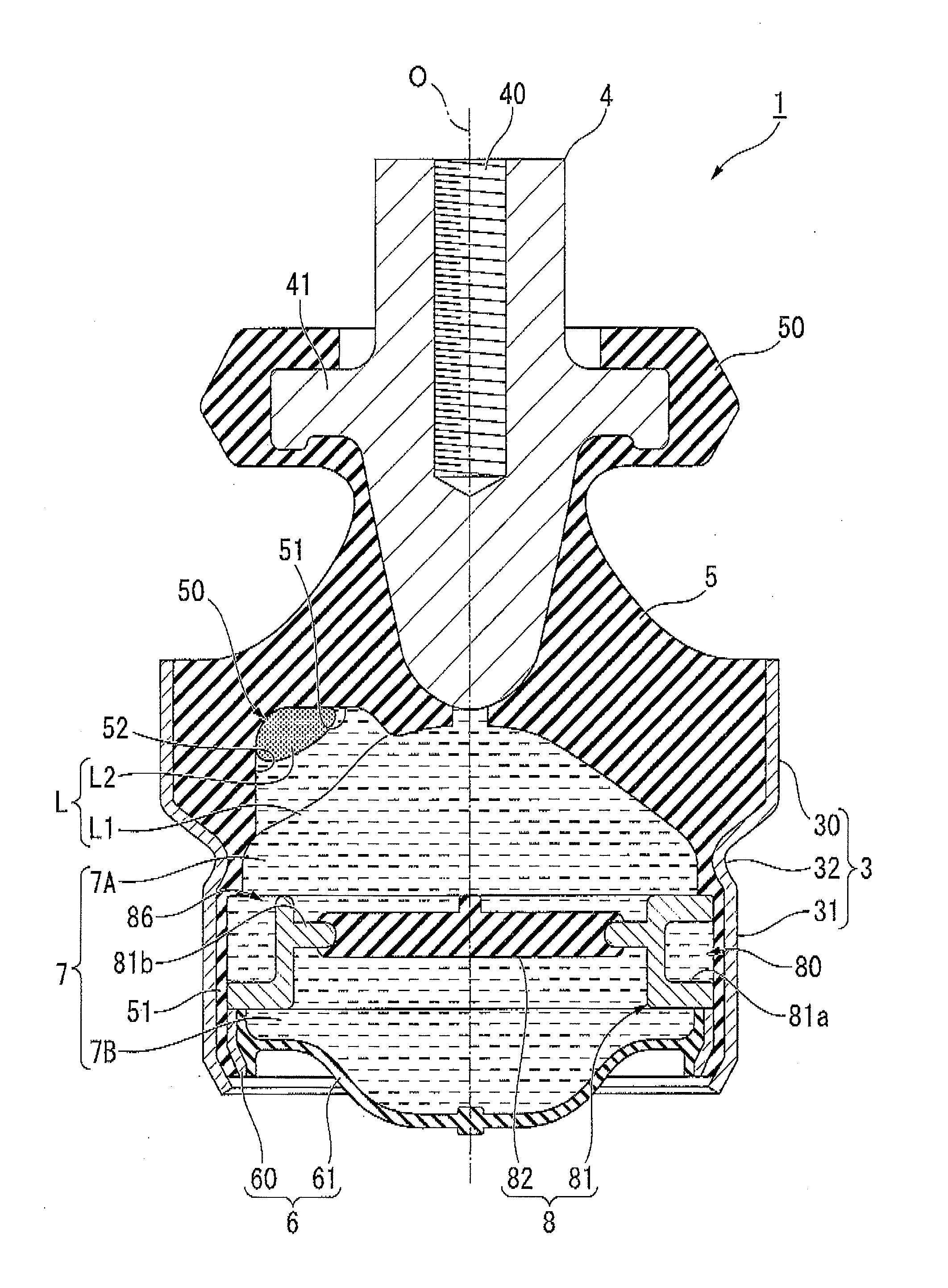

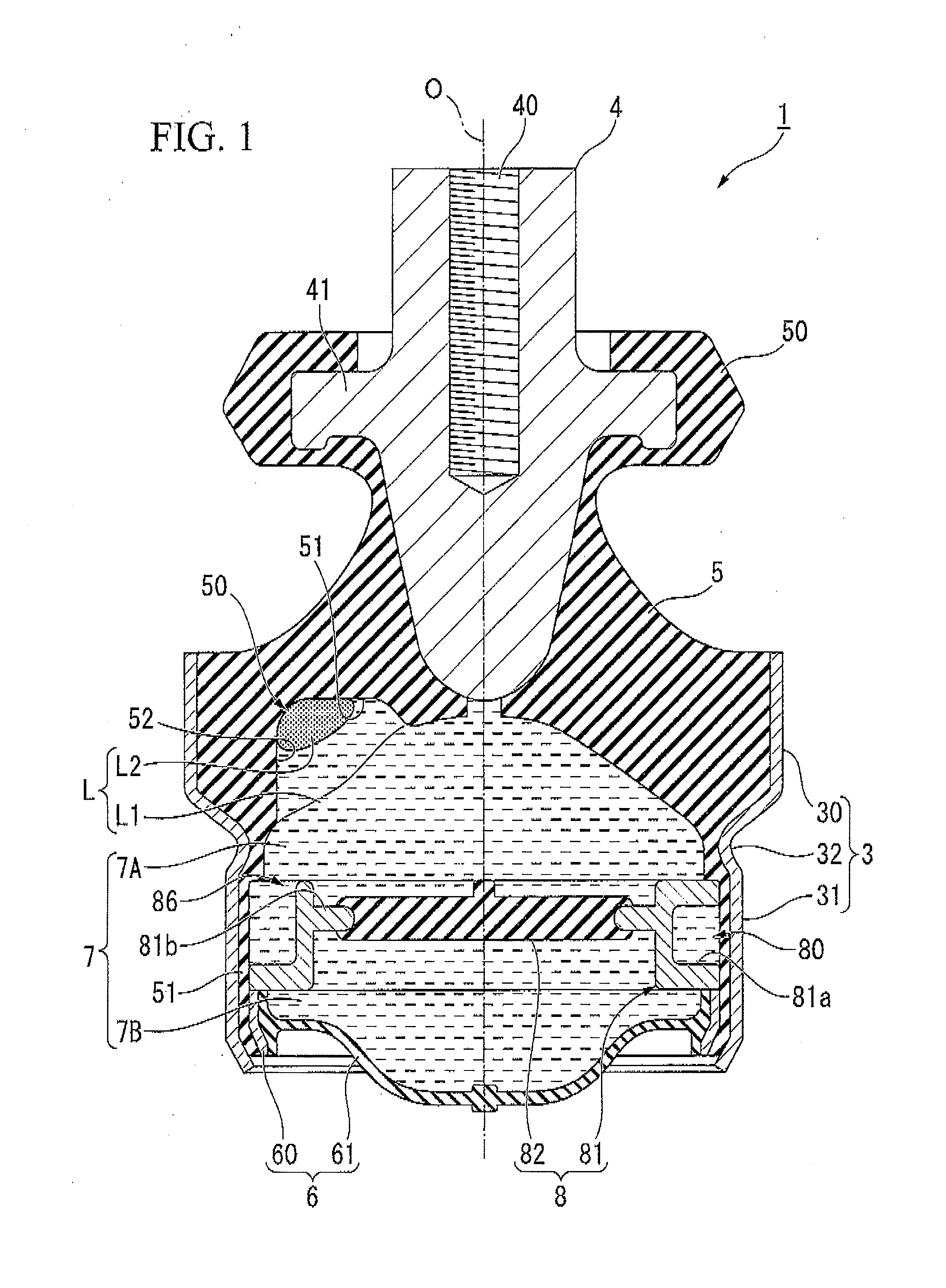

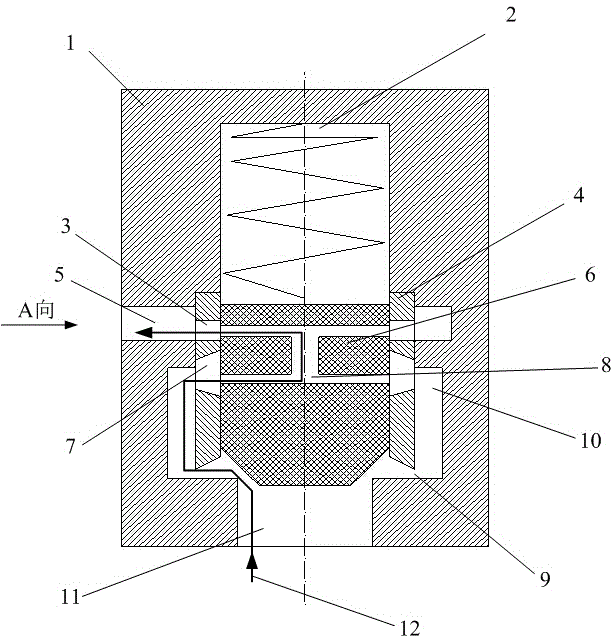

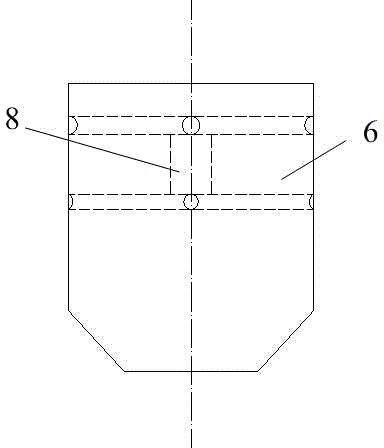

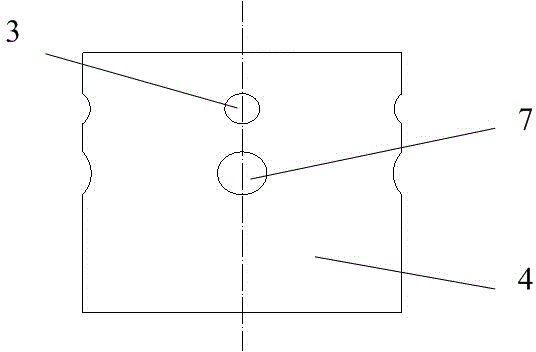

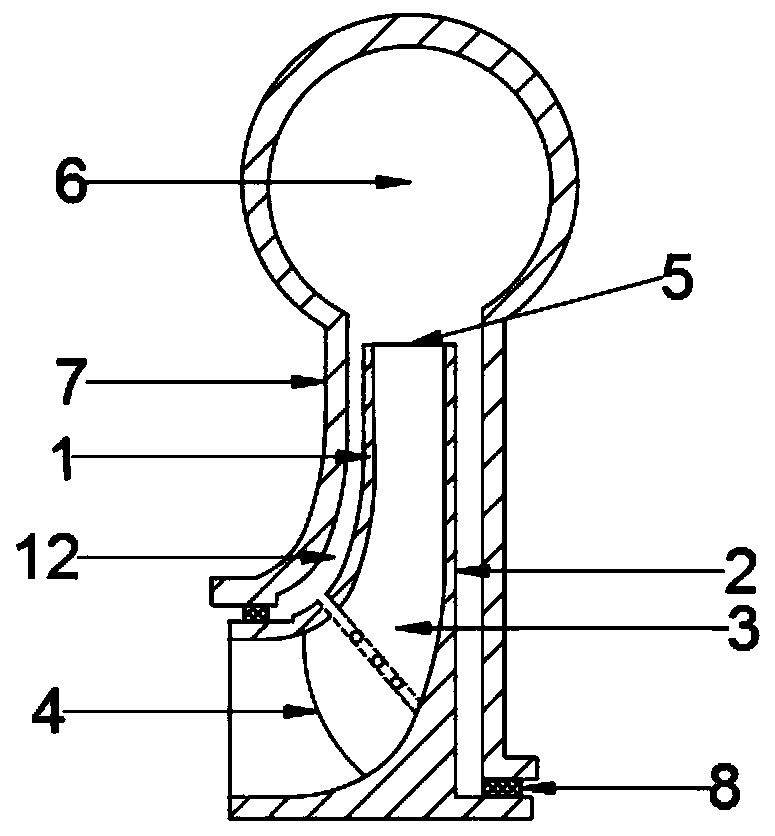

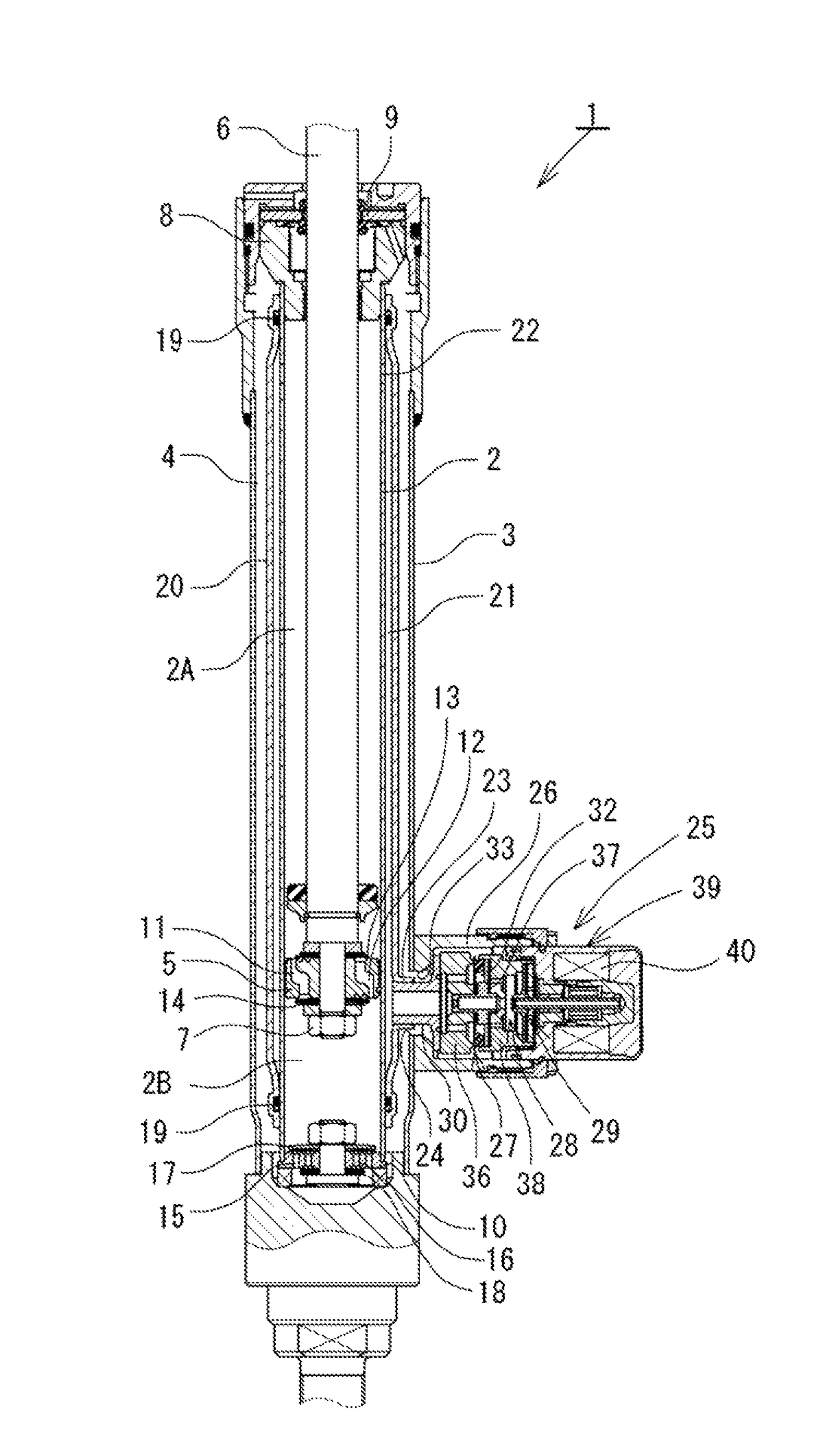

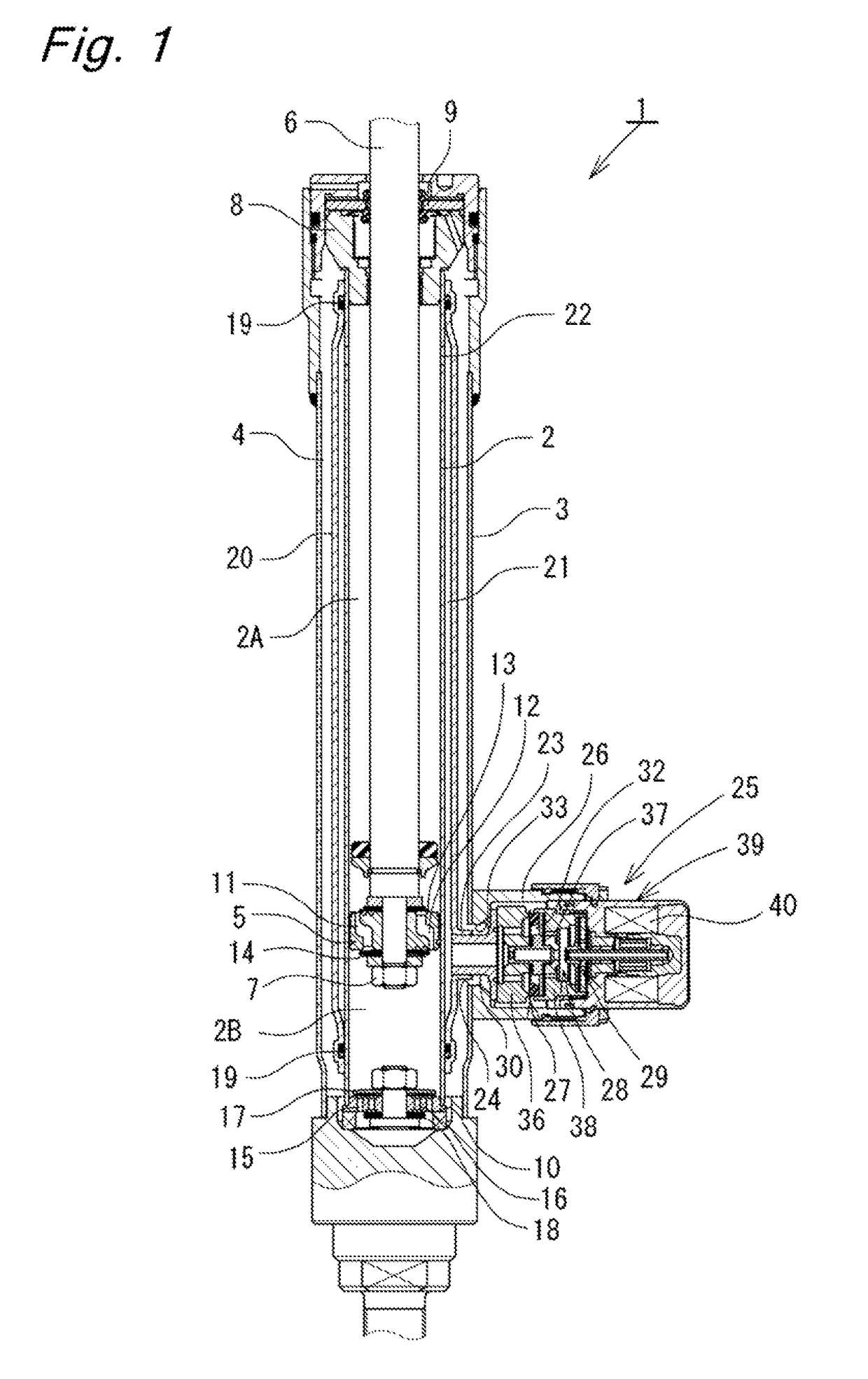

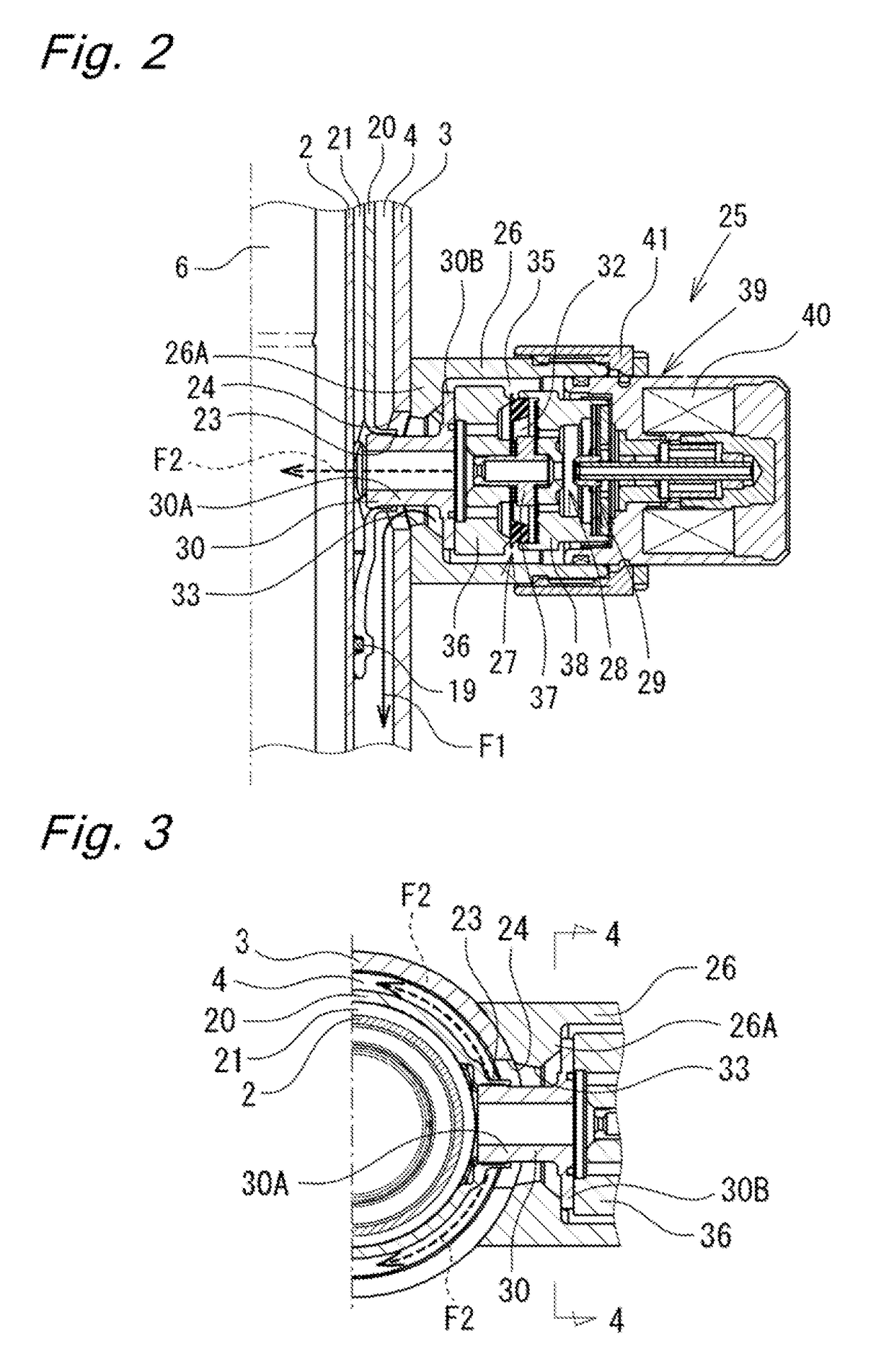

Vibrationproof device

ActiveUS20120139174A1Increase in sizeSuppress cavitationMachine framesLiquid springsElastomerEngineering

A vibrationproof device which is a liquid sealed vibrationproof device includes a tubular first mounting member (3) that is connected to either one of a vibration generating portion and a vibration receiving portion, a second mounting member (4) that is connected to other one, an elastic body (5) that elastically connects the first mounting member (3) and the second mounting member (4), and a partition member (8) that partitions a liquid chamber (7) of the inside of the first mounting member (3) into a main liquid chamber (7A) of an upper side having the elastic body as a portion of a wall surface and an auxiliary liquid chamber (7B) of a lower side, and a restricting passage (80) which communicates with the main liquid chamber (7A) and the auxiliary liquid chamber (7B). In addition, a first liquid (L1) is contained as a main liquid and a second liquid (L2) which is insoluble in the first liquid (L1) is contained as an added liquid in the sealed liquid (L), and the vapor pressure of the second liquid (L2) is higher than the vapor pressure of a main component of the first liquid (L1) in the same temperature and a specific gravity of the second liquid (L2) is lighter than a specific gravity of the first liquid (L1).

Owner:PROSPIRA CORP

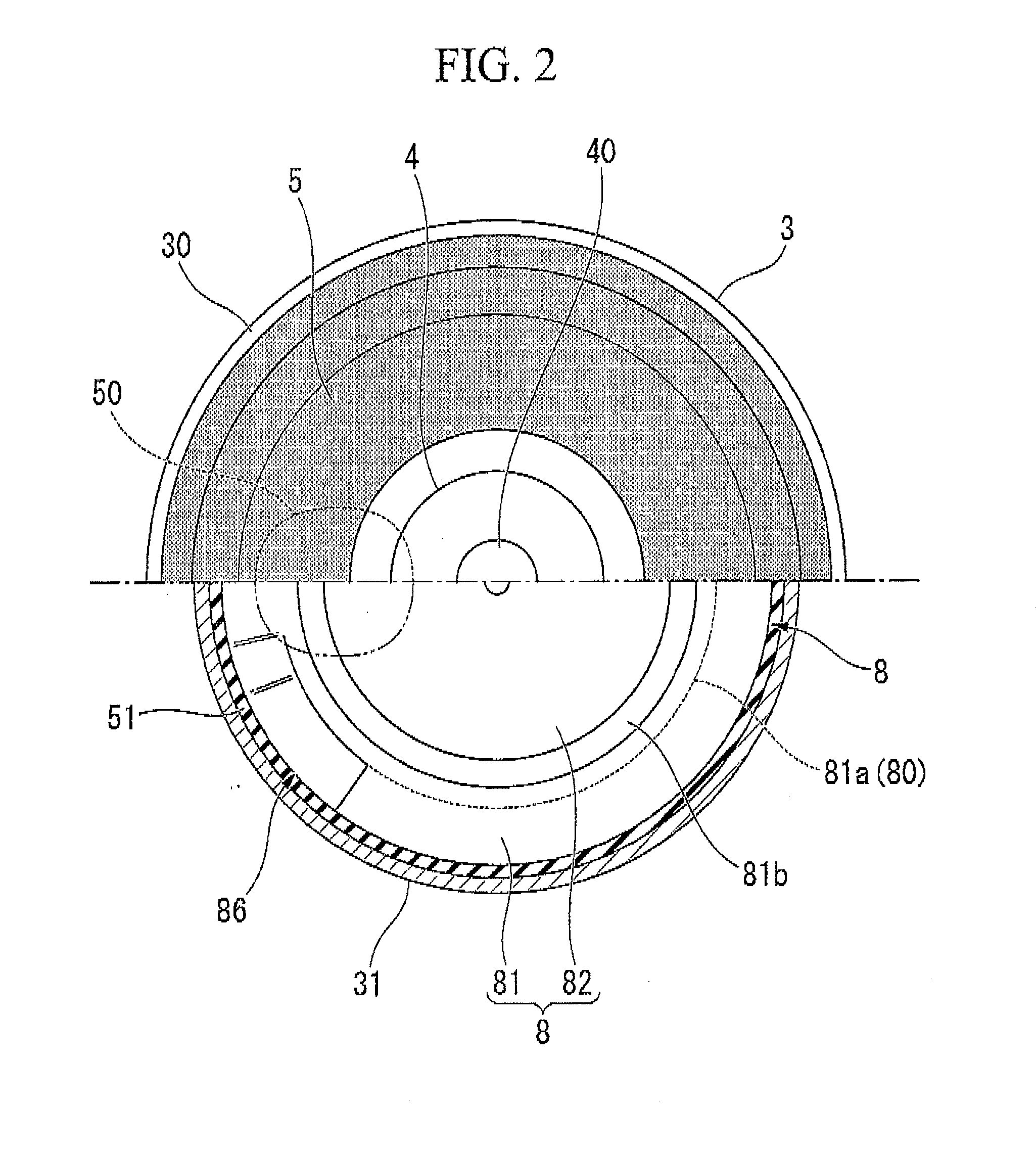

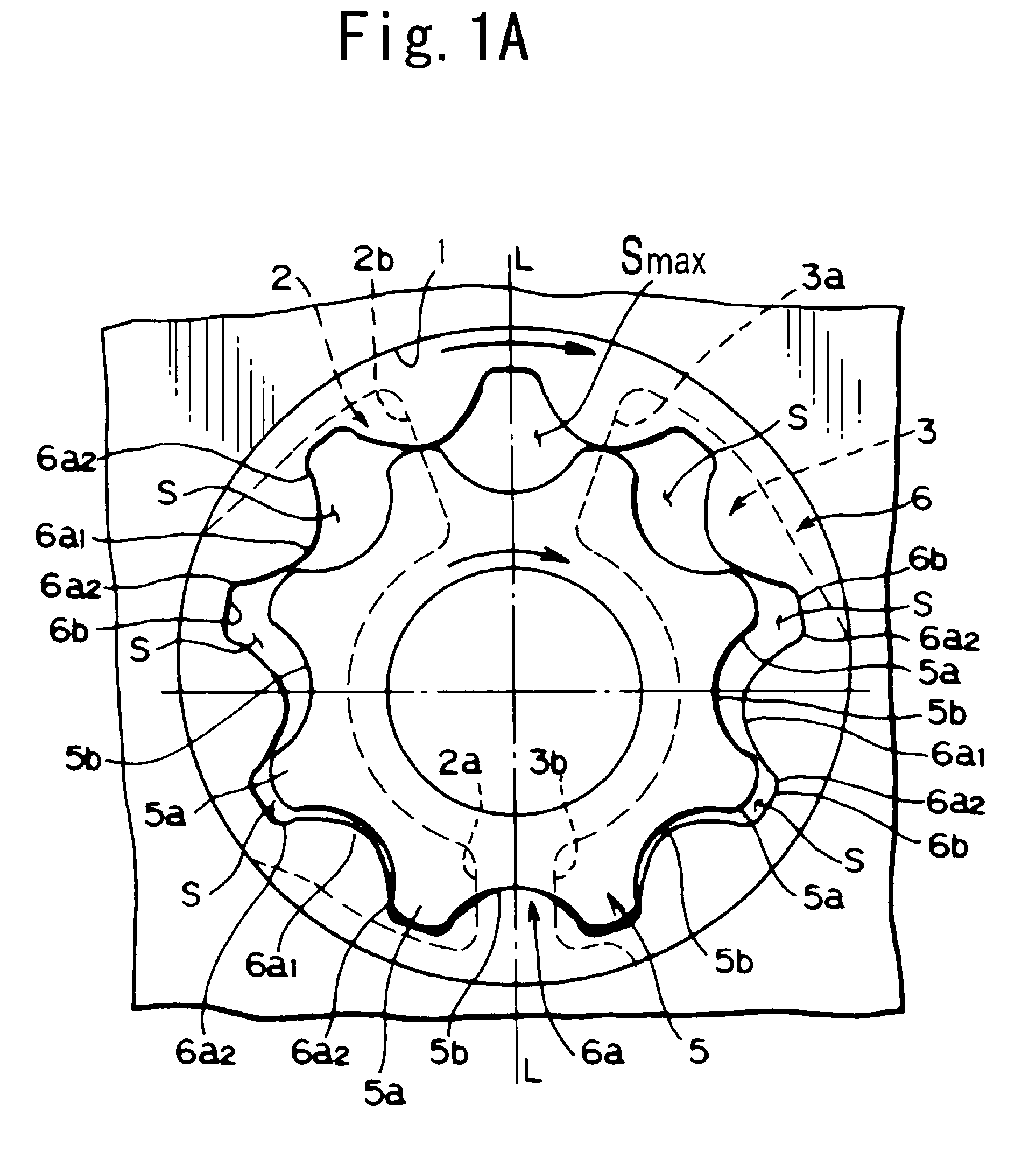

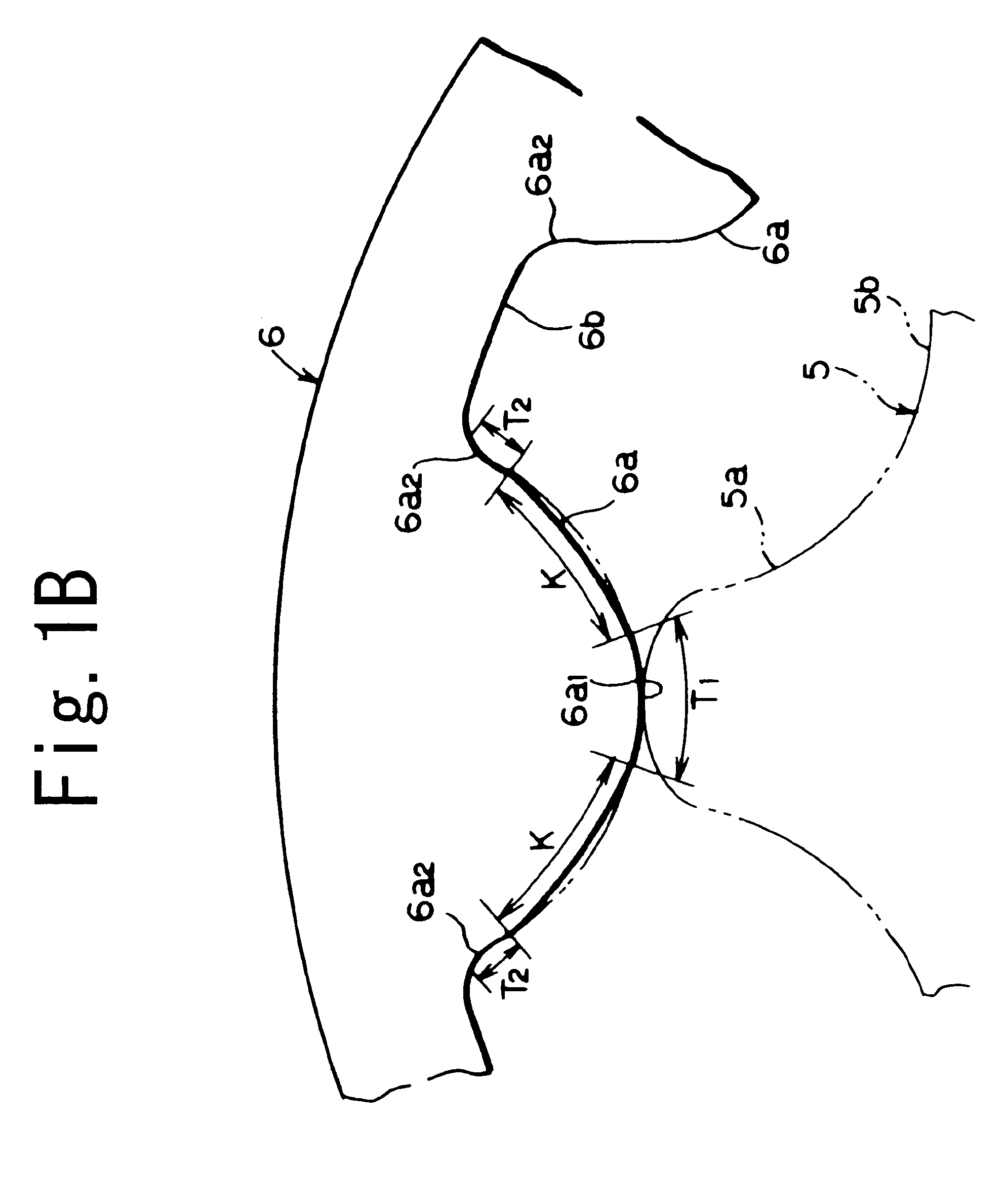

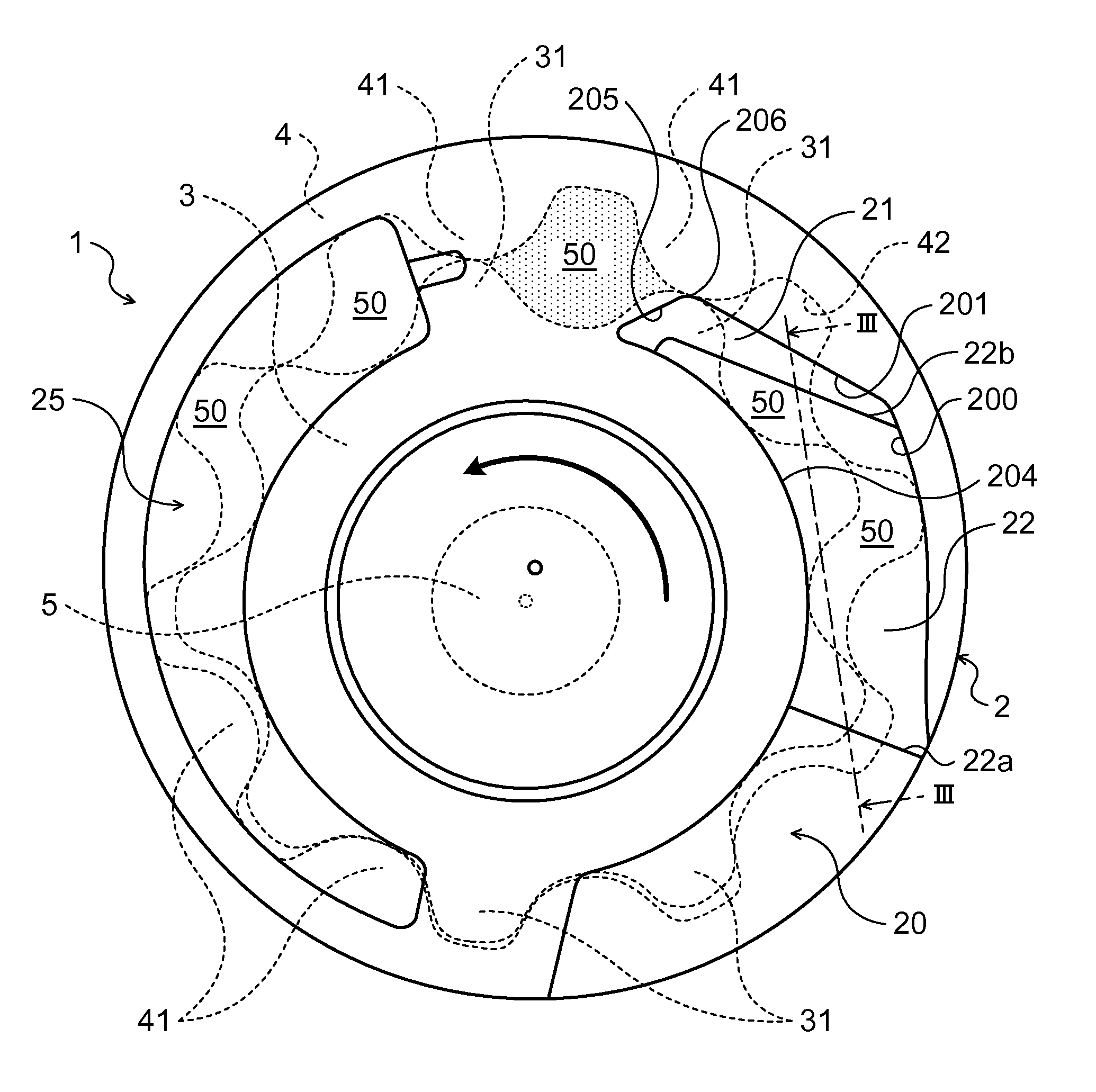

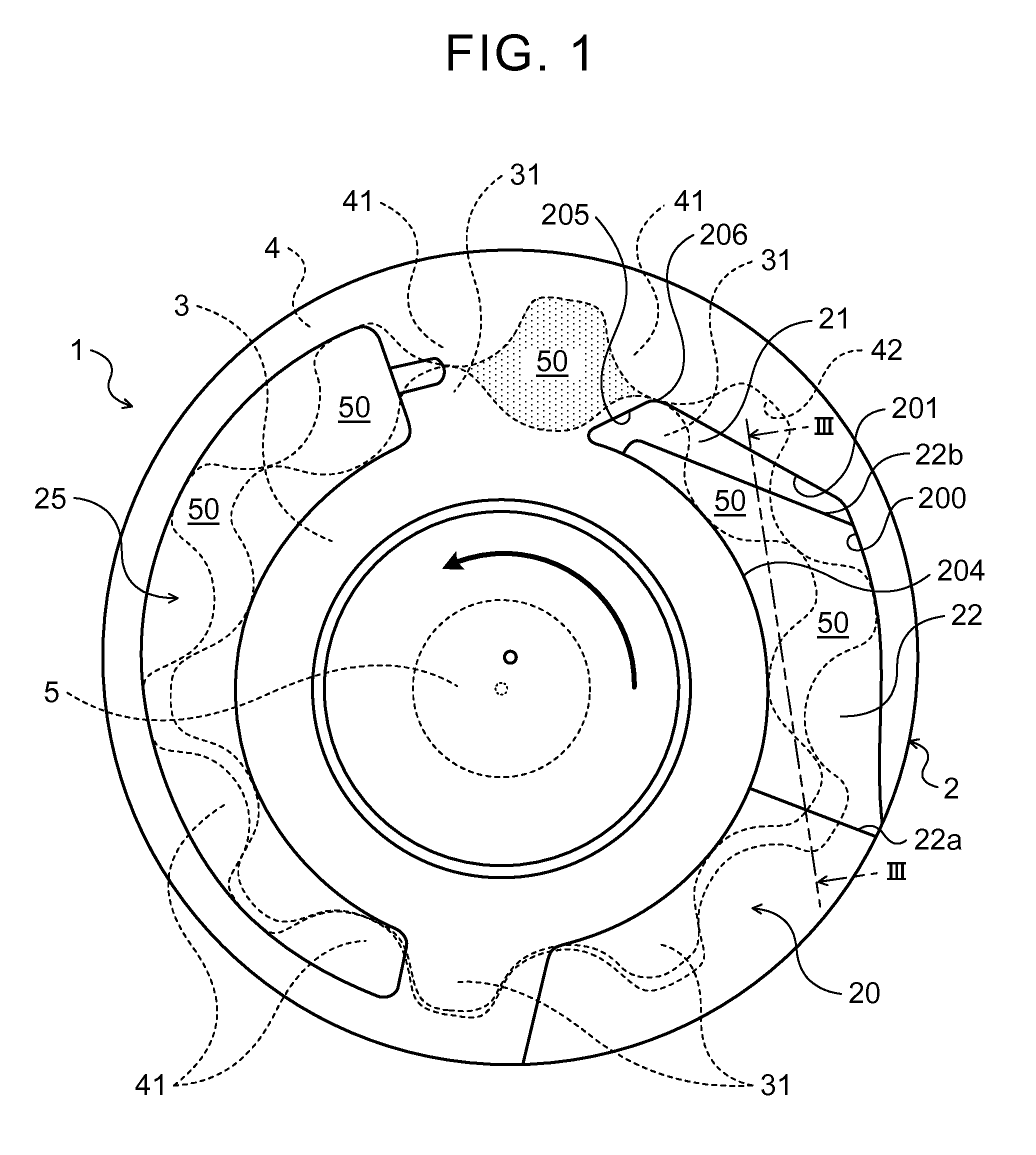

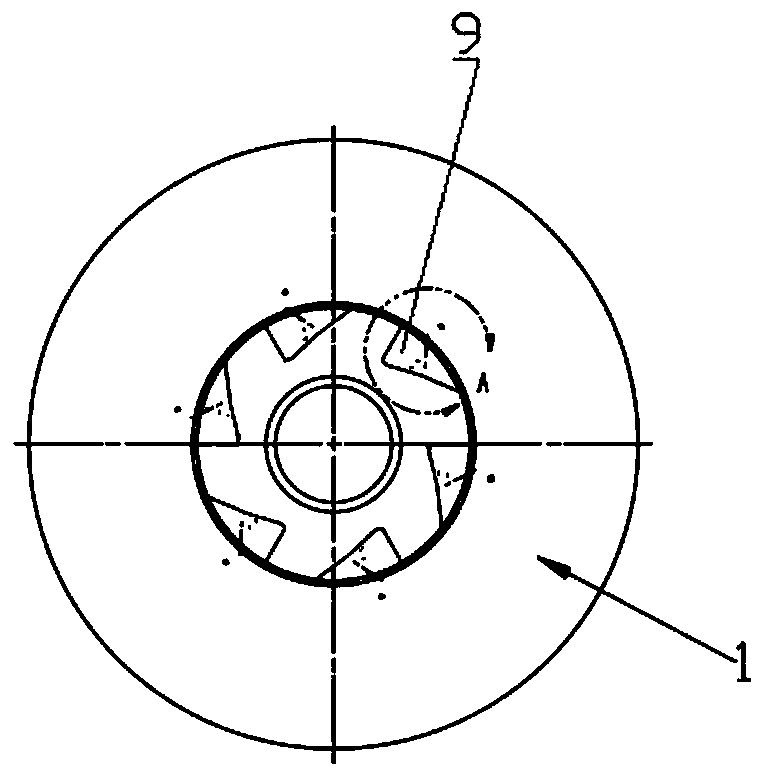

Trochoidal oil pump

ActiveUS7384251B2Stable rotation driveEasy dischargeEngine of arcuate-engagement typeOscillating piston enginesEngineering

A trochoidal oil pump which makes it possible to achieve an improved reduction in discharge pulsation and noise, and which makes it possible to realize such a reduction using an extremely simple structure. The trochoidal oil pump of the present invention comprises a rotor chamber 1 which has an intake port 2 and discharge port 3, an outer rotor 6 and an inner rotor 5. A plurality of inter-tooth spaces S, S, . . . that are formed by the tooth shapes 5a and 6a of the inner rotor 5 and outer rotor 6 comprise a maximum sealed space Smax that is positioned in the region of the partition part 4 between the intake port 2 and discharge port 3, a plurality of inter-tooth spaces S, S, . . . within the region of the intake port 2, and a plurality of inter-tooth spaces S, S, . . . within the region of the discharge port 3. The plurality of inter-tooth spaces S, S, . . . in the intake port 2 and discharge port 3 respectively communicate with each other

Owner:YAMADA SEISAKUSHO KK

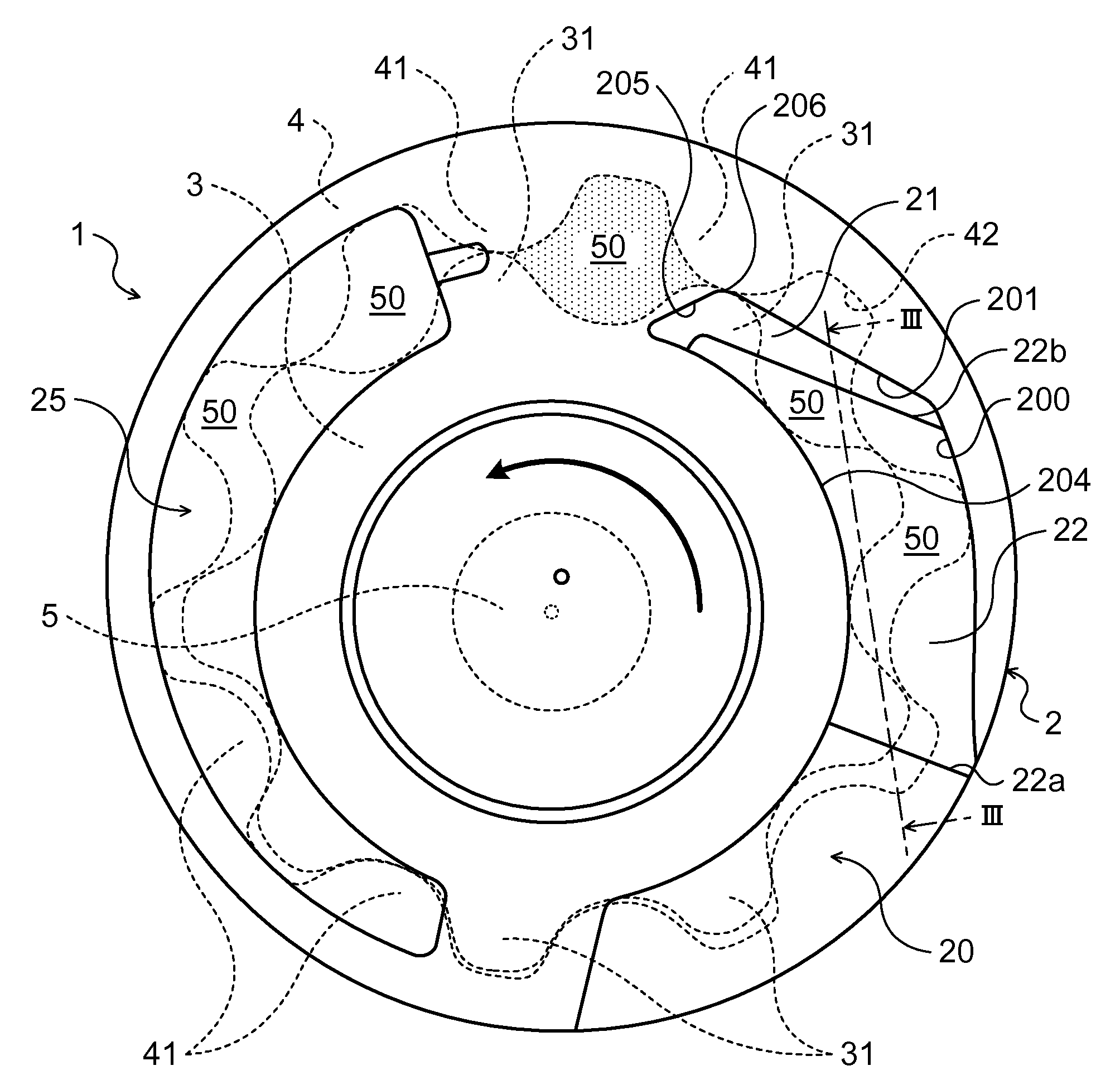

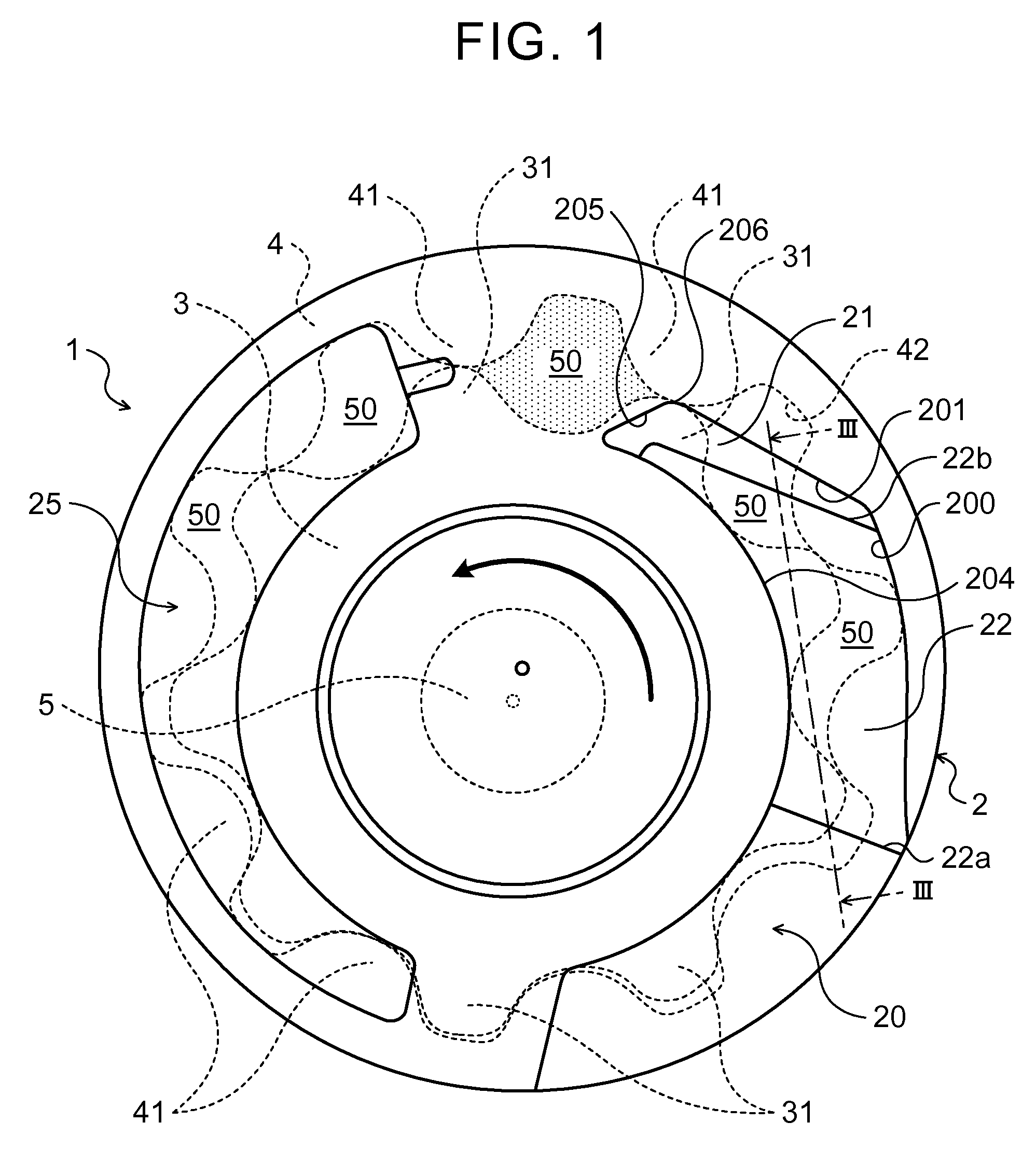

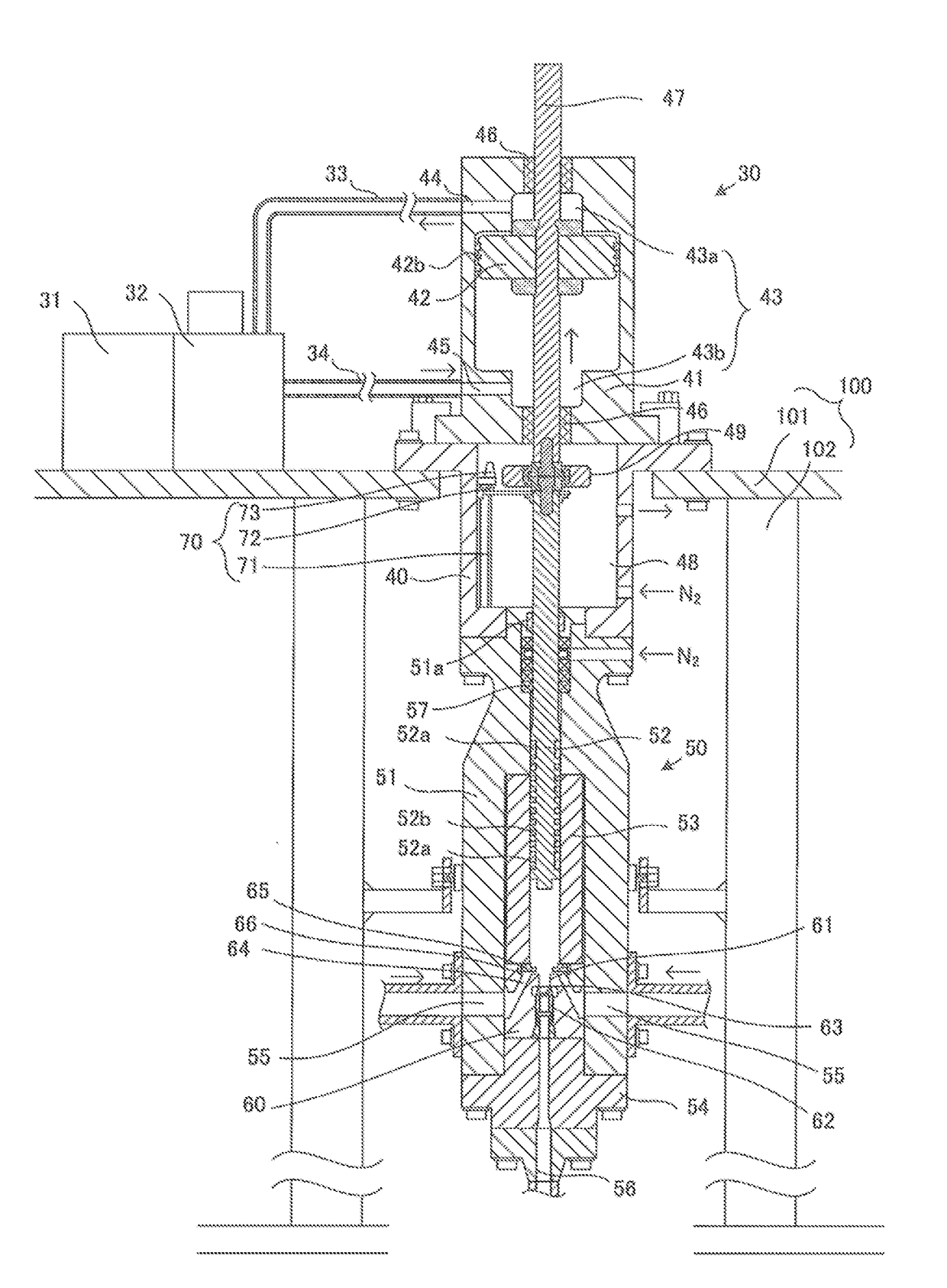

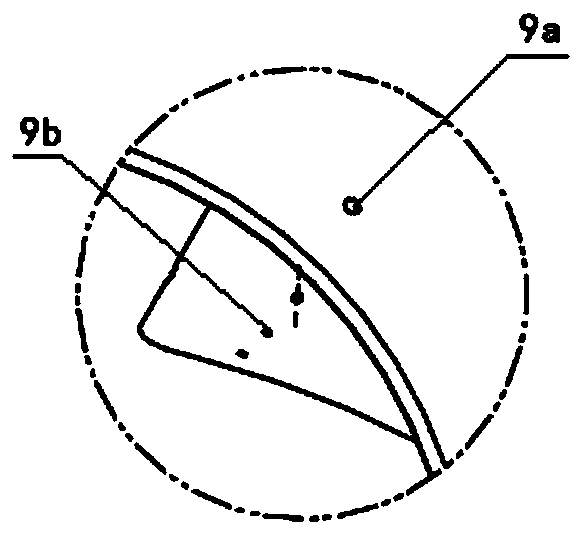

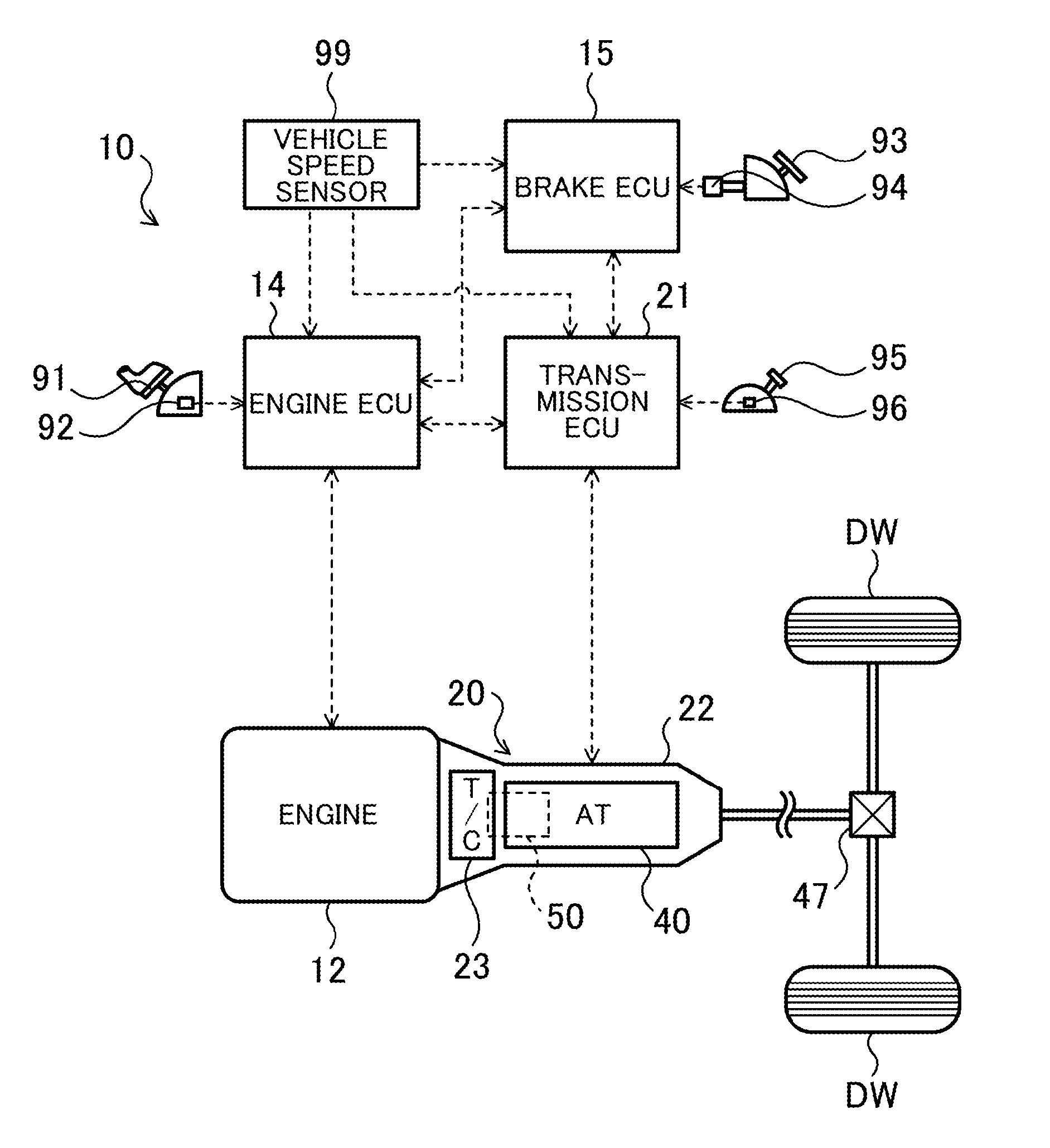

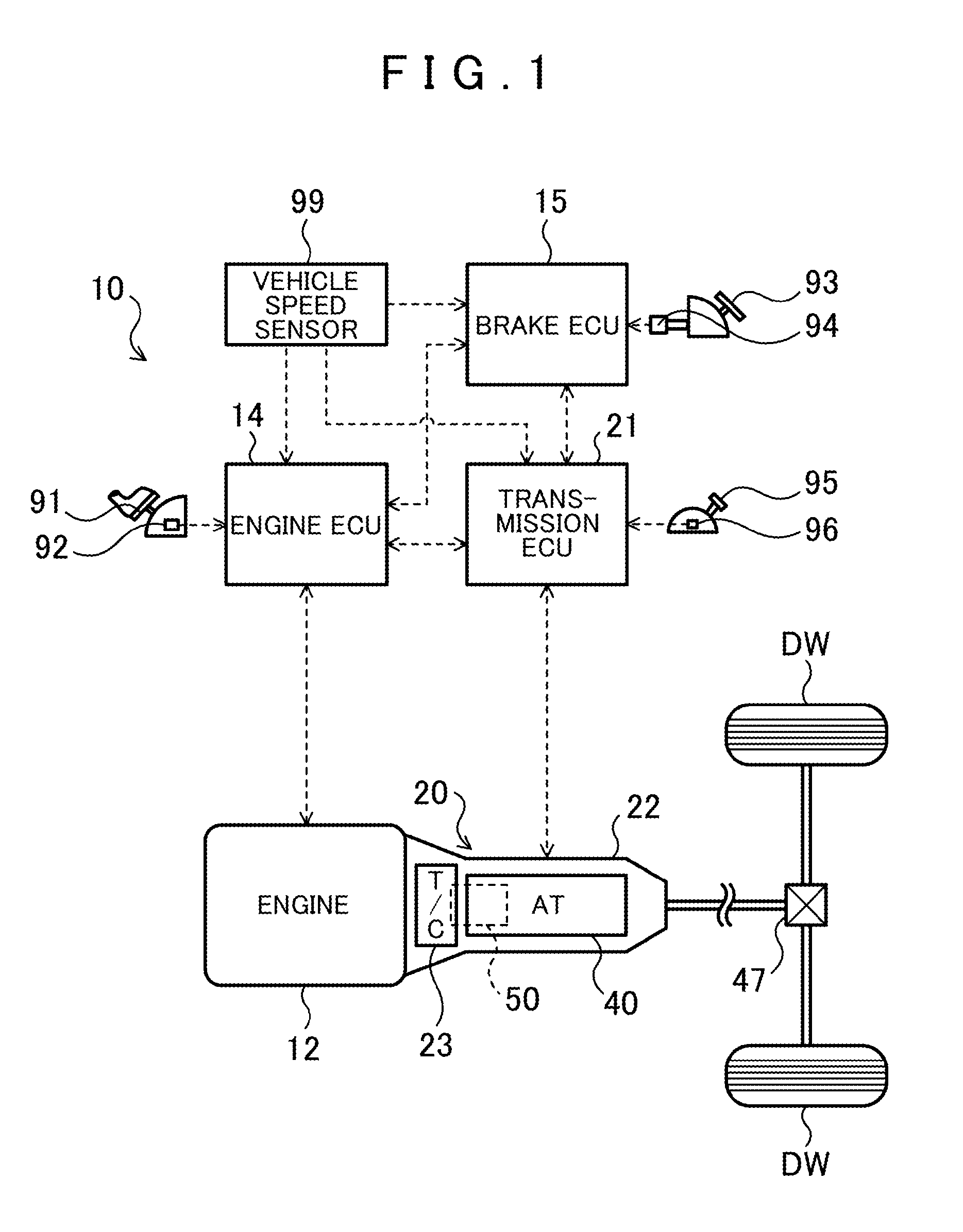

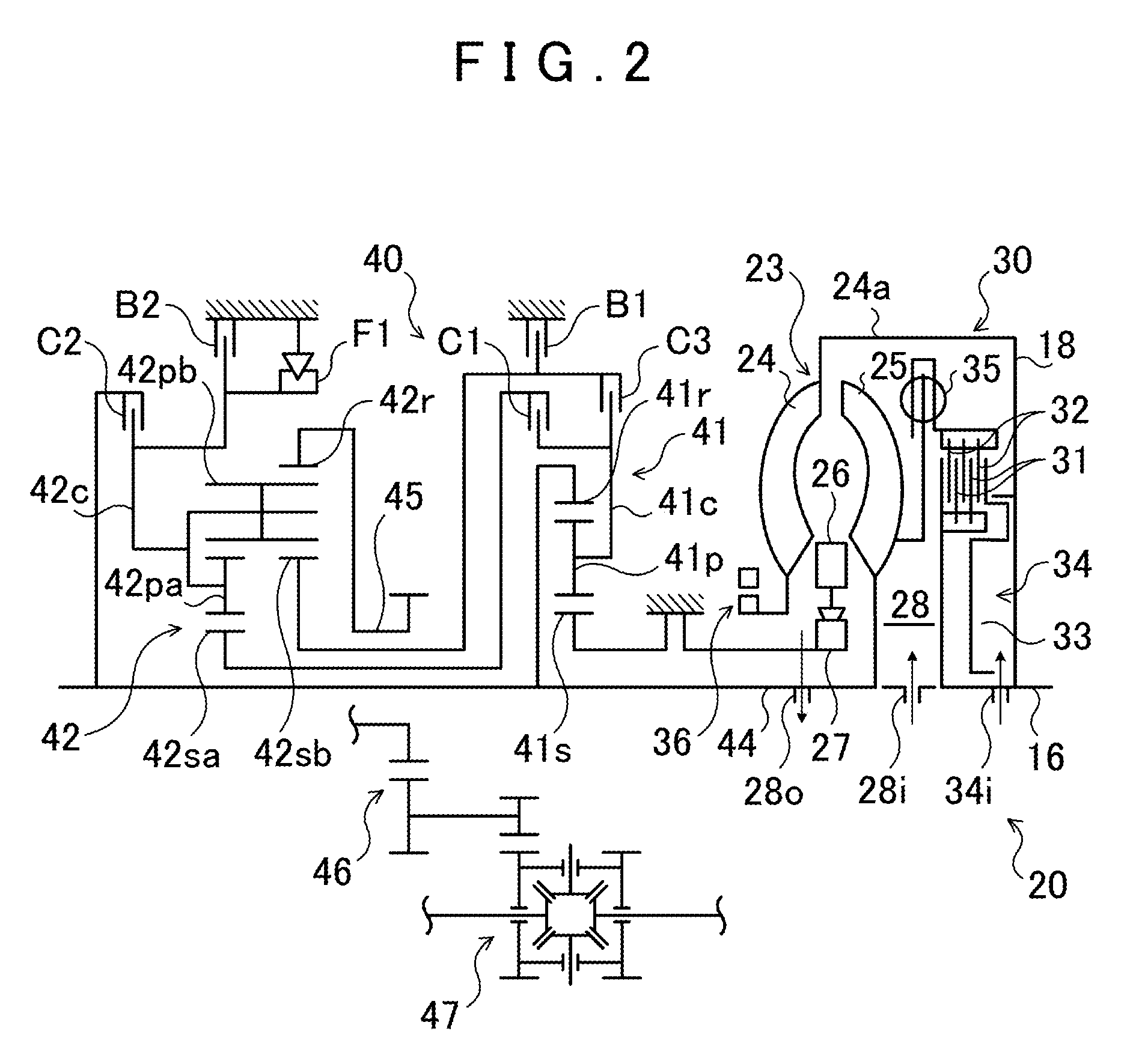

Gear pump

ActiveUS20150219097A1Suppress cavitationImprove suction efficiencyEngine of intermeshing engagement typeRotary piston pumpsGear pumpEngineering

In a gear pump, an outer inner wall surface of a suction port which is located on a downstream side in a rotor rotation direction, that is, a first inner wall surface, is located inward of a bottom land between internal teeth of an outer rotor, and the suction port has a shallow portion extended inward from the first inner wall surface on the downstream side in the rotor rotation direction, and a deep portion that is formed so as to be continuous with the shallow portion and that is deeper than the shallow portion. Communication between an inter-tooth chamber and the suction port is cut off with the inter-tooth chamber facing only the shallow portion.

Owner:AISIN AW CO LTD

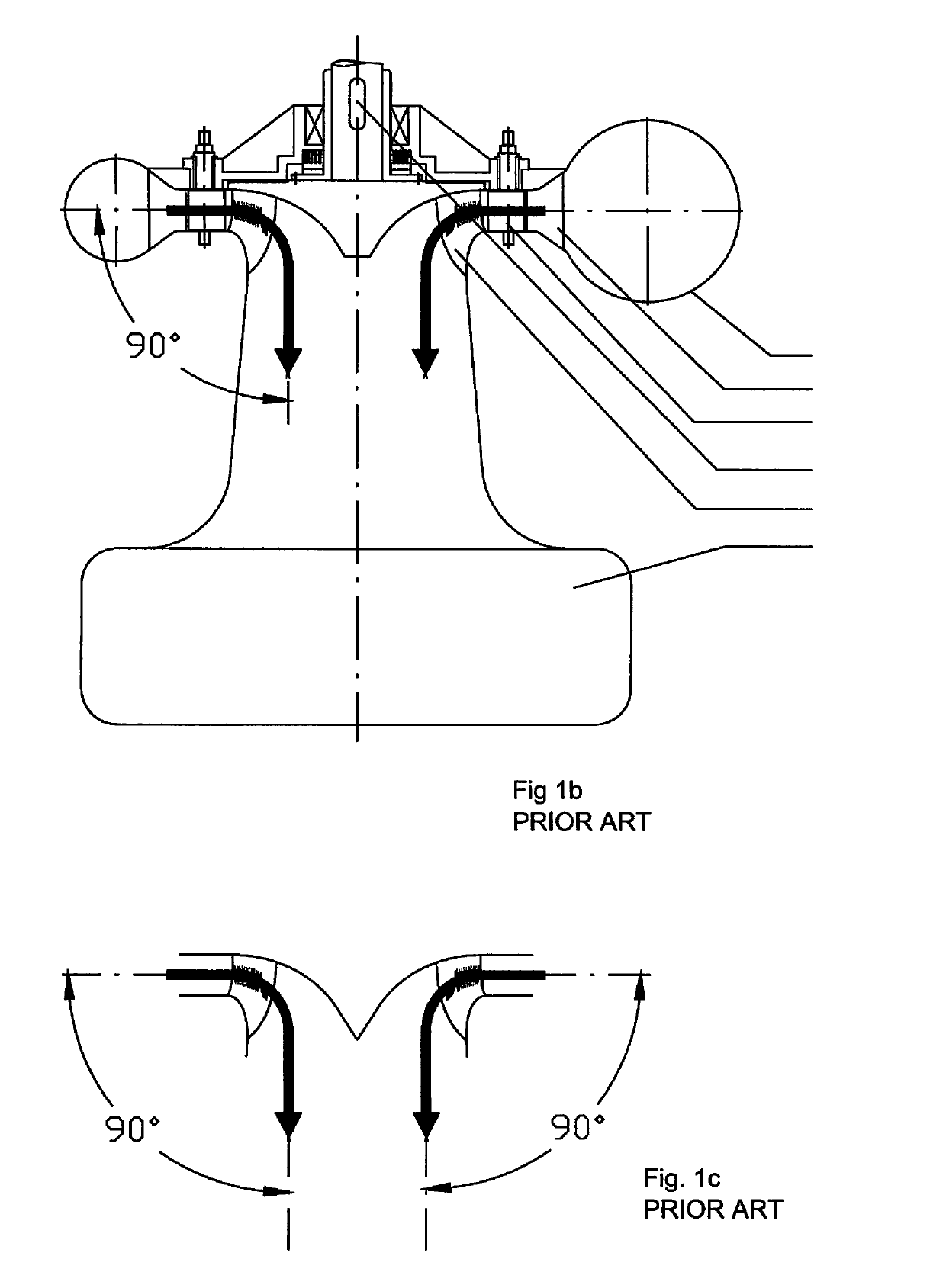

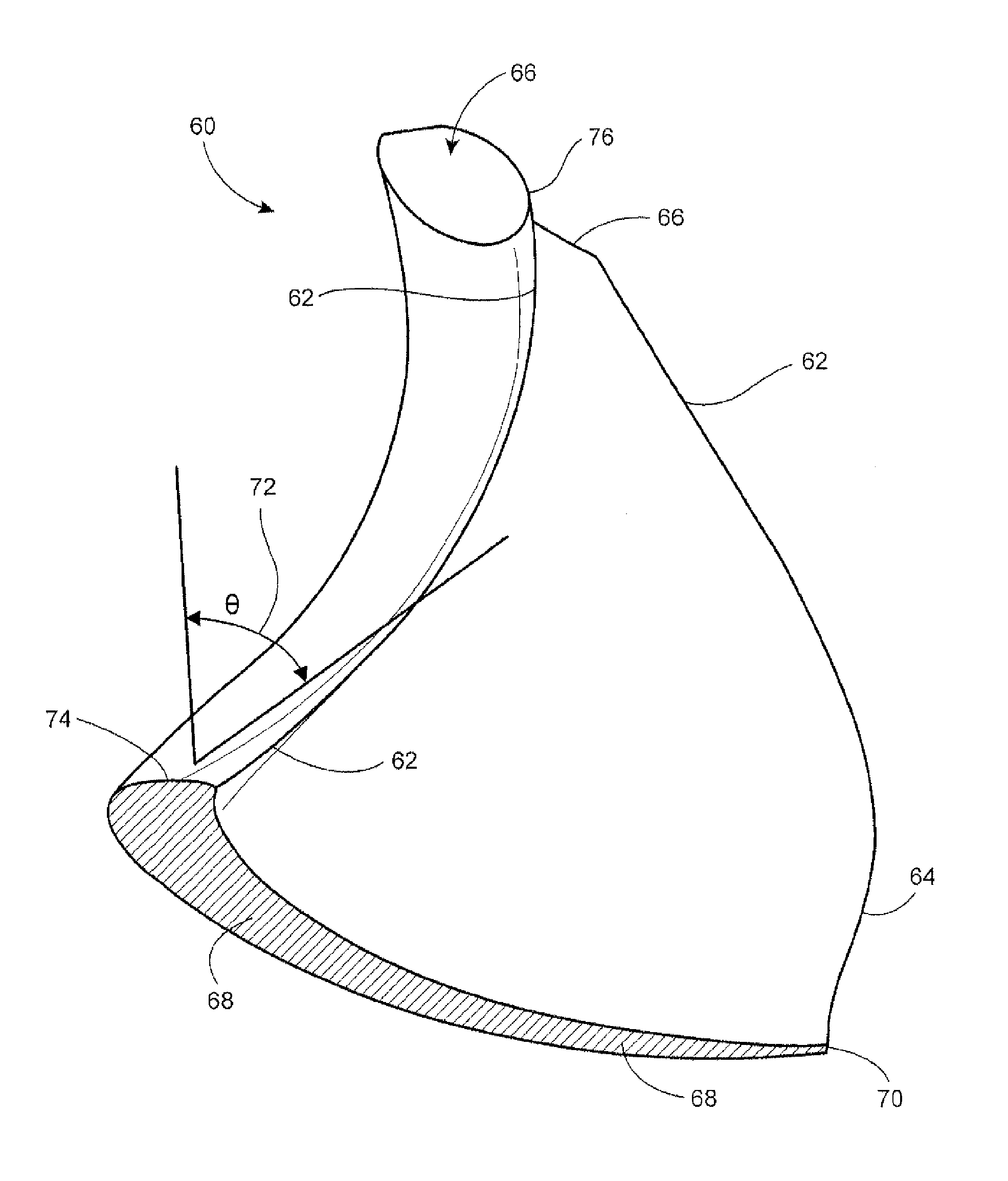

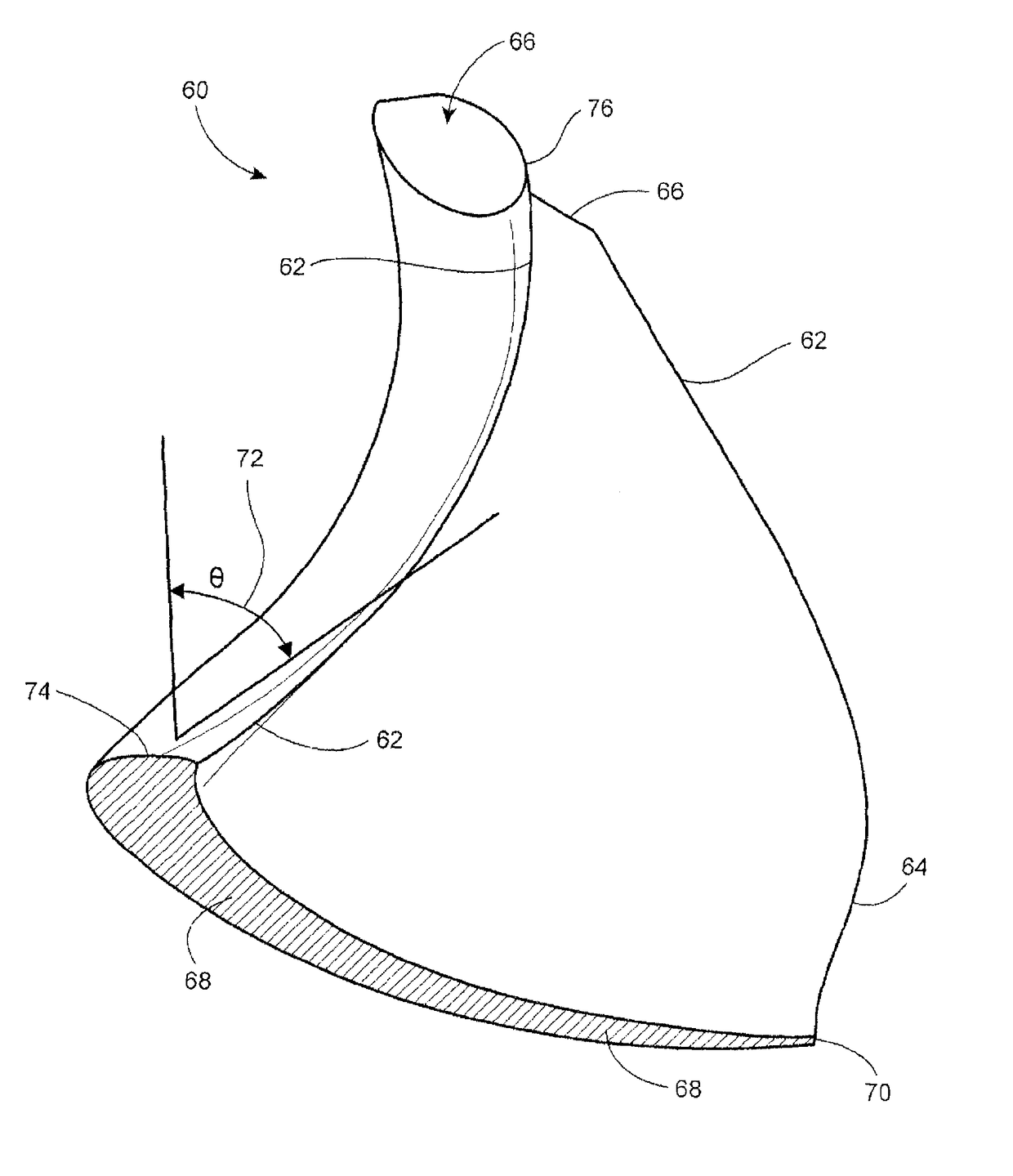

Compact blade for runner of francis turbine and method for configuring runner

ActiveUS20140294590A1Improve performanceEnergy efficiencyHydro energy generationReaction enginesLeading edgeFrancis turbine

A blade for a runner of a Francis turbine having a throat diameter (Dth), the blade including: a maximum thickness of no less than 0.03 Dth and a leading edge having a maximum lean angle of no less than 45 degrees, wherein the lean angle is defined by a vertical line and the leading edge.

Owner:ANDRITZ HYDRO LTD

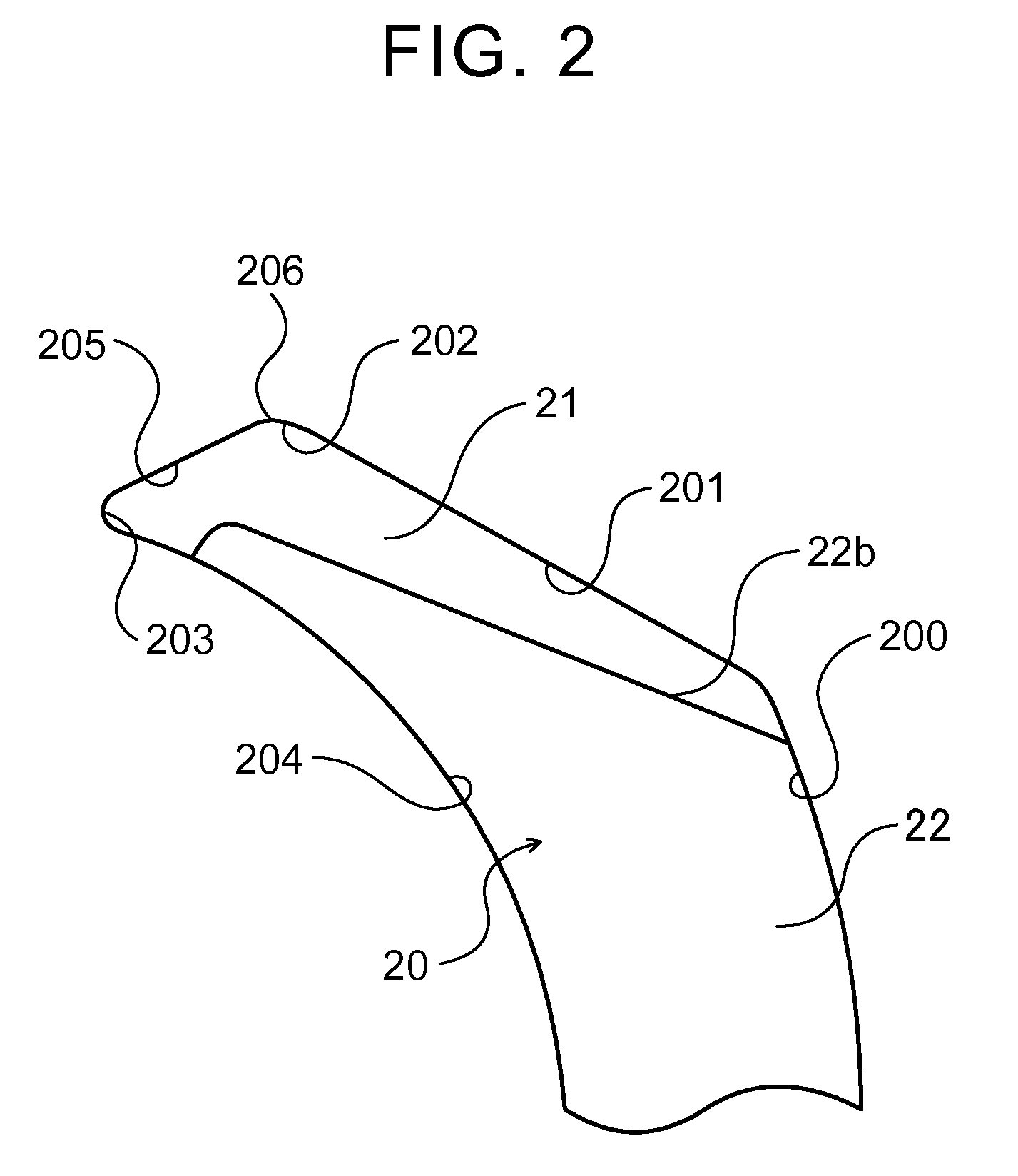

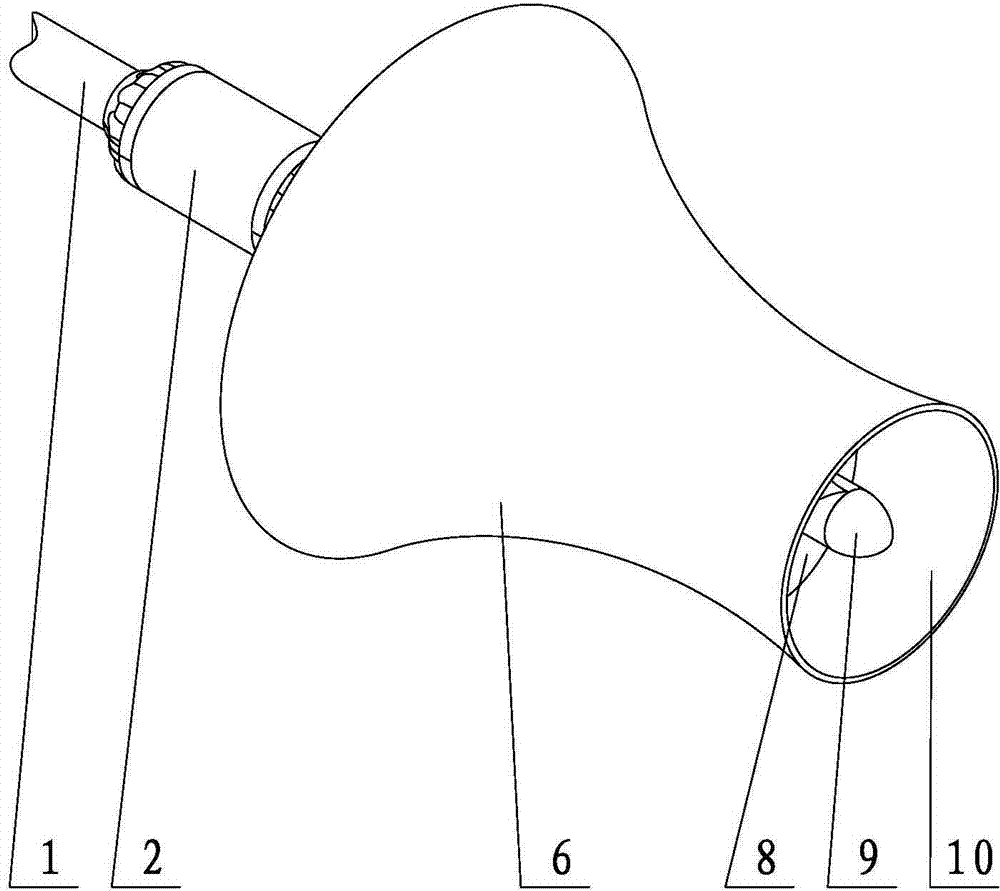

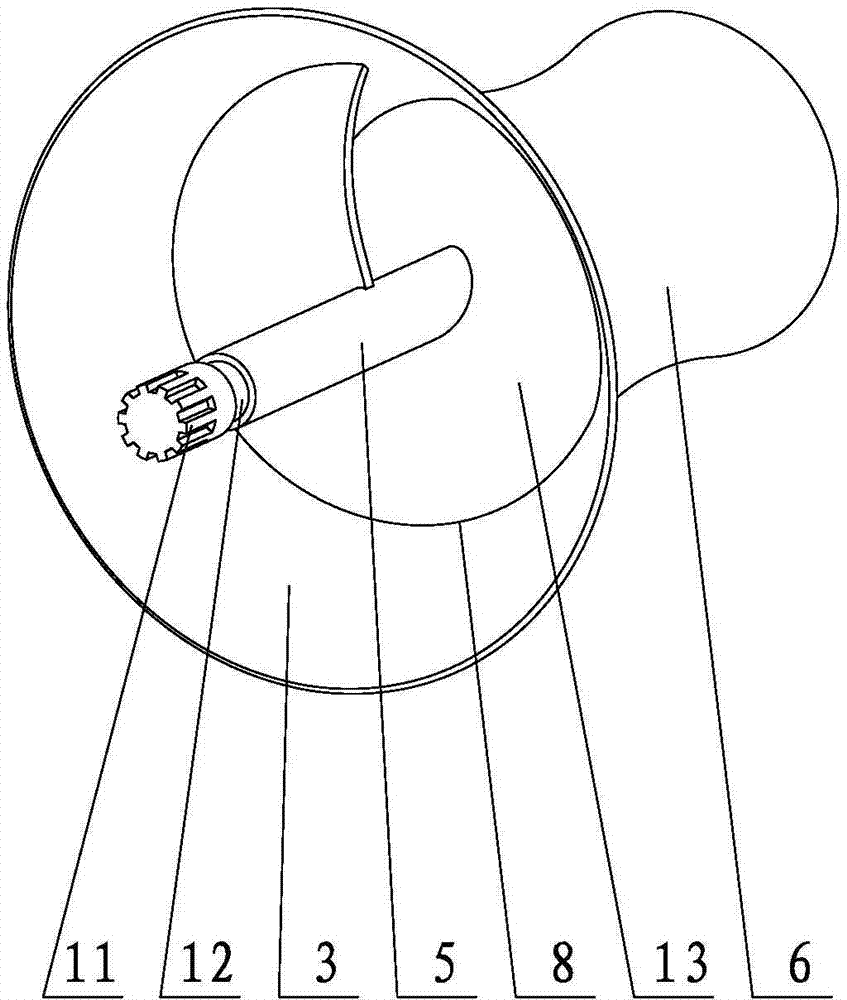

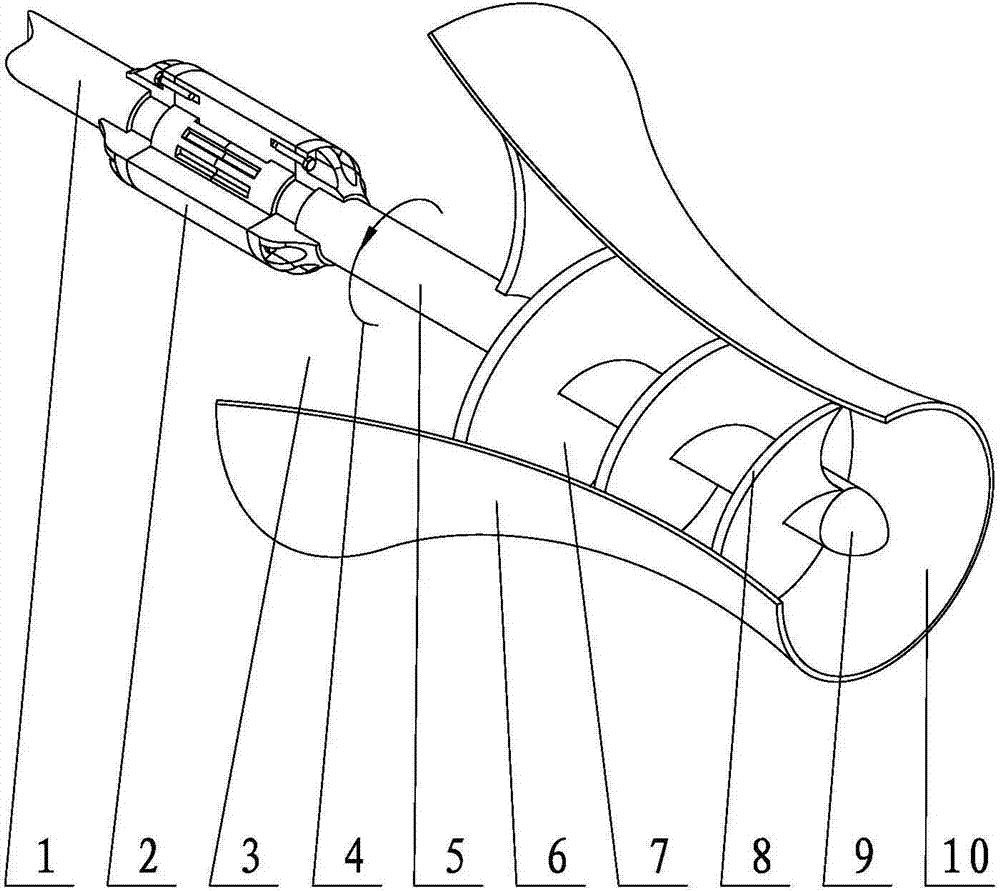

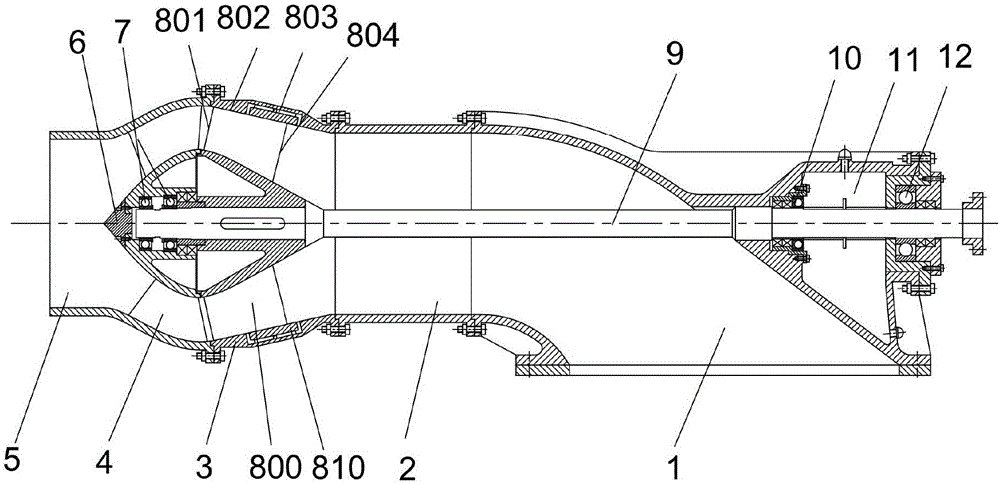

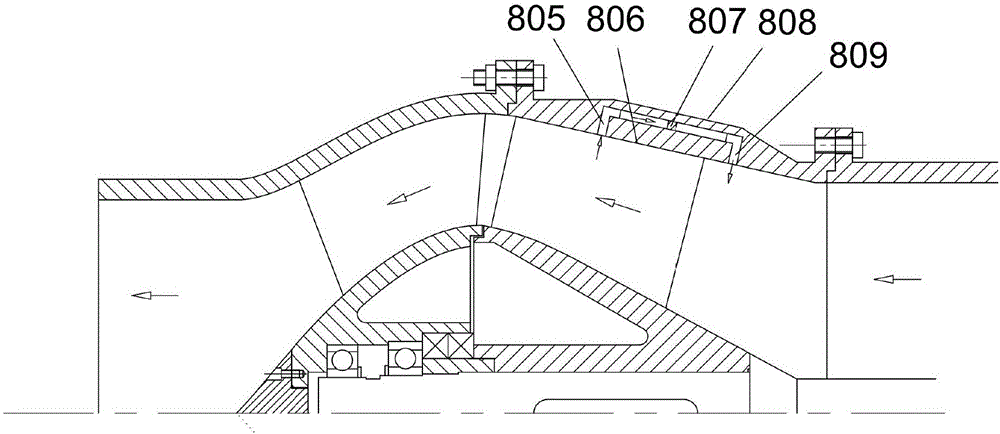

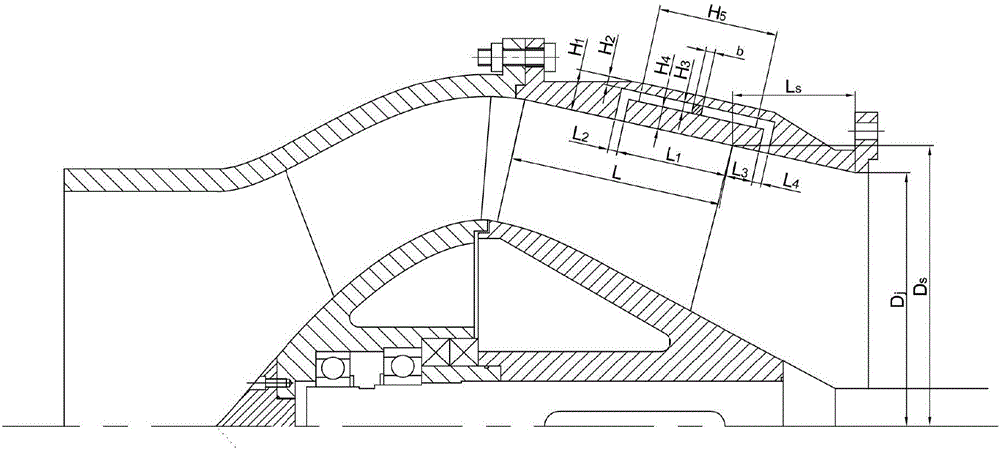

Curved culvert type marine propeller

The invention provides a curved culvert type marine propeller, relating to marine propellers. The curved culvert type marine propeller mainly comprises a coupling component, a propeller shaft, a curved culvert, propeller blades and a tail cone, wherein the curved culvert type marine propeller is driven to rotate according to a rotation direction by a ship shaft so as to drive a ship to travel forwards. When the ship travels forwards, the cross section diameter of the front edge of the culvert is far greater than that of a throat of the culvert, resistance is generated by the front edge of the culvert, then, the hydrostatic pressure of a water absorbing area in the front edge of the culvert is increased, thus, the air bubble limit of the propeller is delayed, and the degree of cavitation is lowered, so that noise and vibration are lowered, the cavitation is lowered, and the performance of the propeller is improved; blade tips of the propeller blades of the curved culvert type marine propeller are connected together with the internal surface of the curved culvert, so that the curved culvert type marine propeller can be high in structural strength and rigidity and is suitable for being made from composite materials which are represented by carbon fiber reinforced plastics.

Owner:中交四航局江门航通船业有限公司

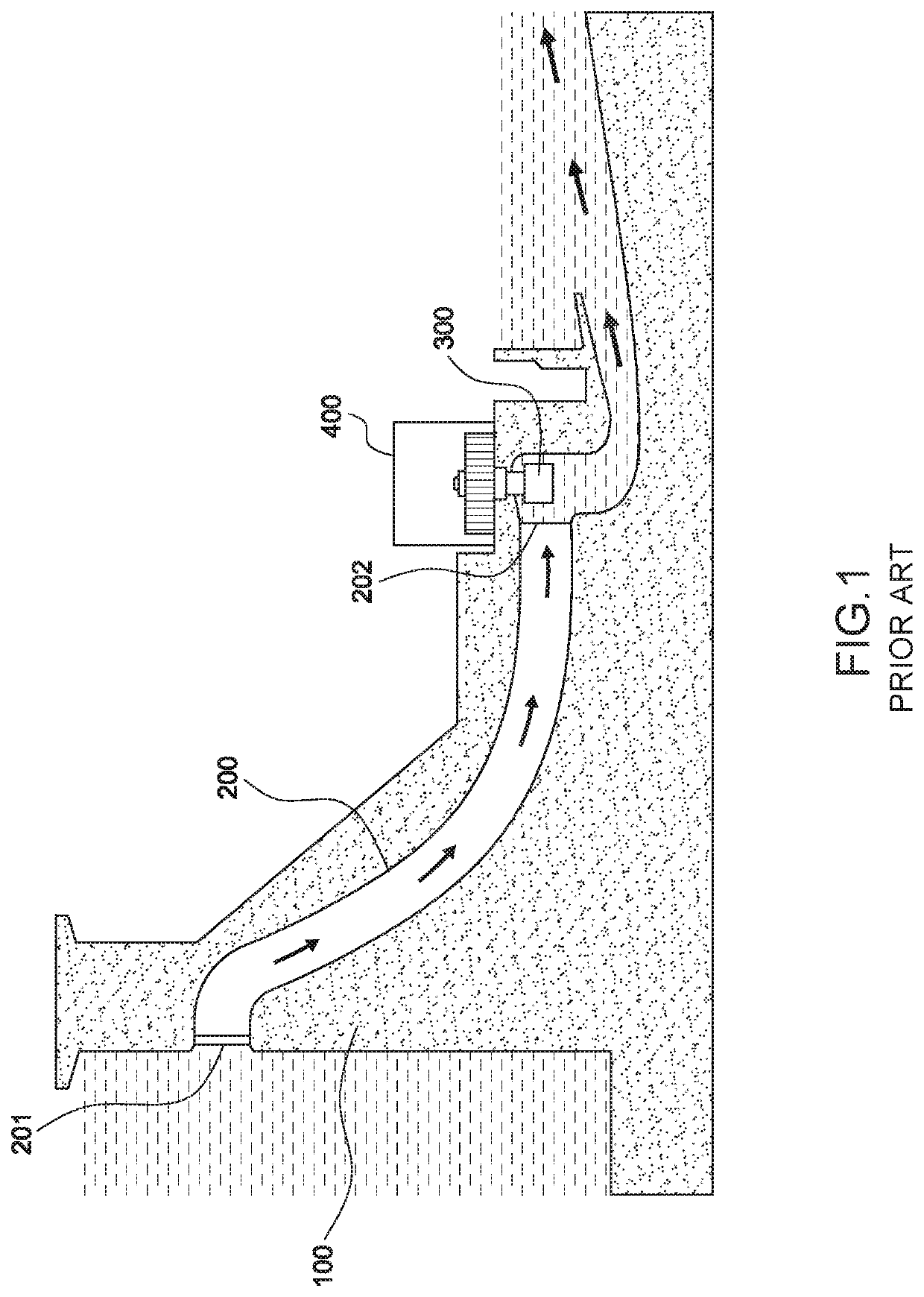

Method to enhance operation efficiency of water turbines and to reduce cavitation of components thereof

ActiveUS20200141380A1High strengthOperation efficiency can be improvedEngine fuctionsFinal product manufacturePenstockAir bubble

A method to dispose at least one air guiding tube between a penstock and a water turbine installed on a dam to form negative pressure at an outlet of the air guiding device by the water kinetic energy produced from high speed of water flow to take in external air for pressurizing, so as to produce a plurality of pressured air bubbles mixed into the water. The water with pressured air bubbles would be decompressed when flowing to an exit of the penstock and has their volumes increased, so as to enhance the water kinetic energy for driving the water turbine more efficiently; meanwhile the method can prevent from production of cavities and further avoid damages of the components of the water turbine from cavitation.

Owner:LIN ZUEI LING

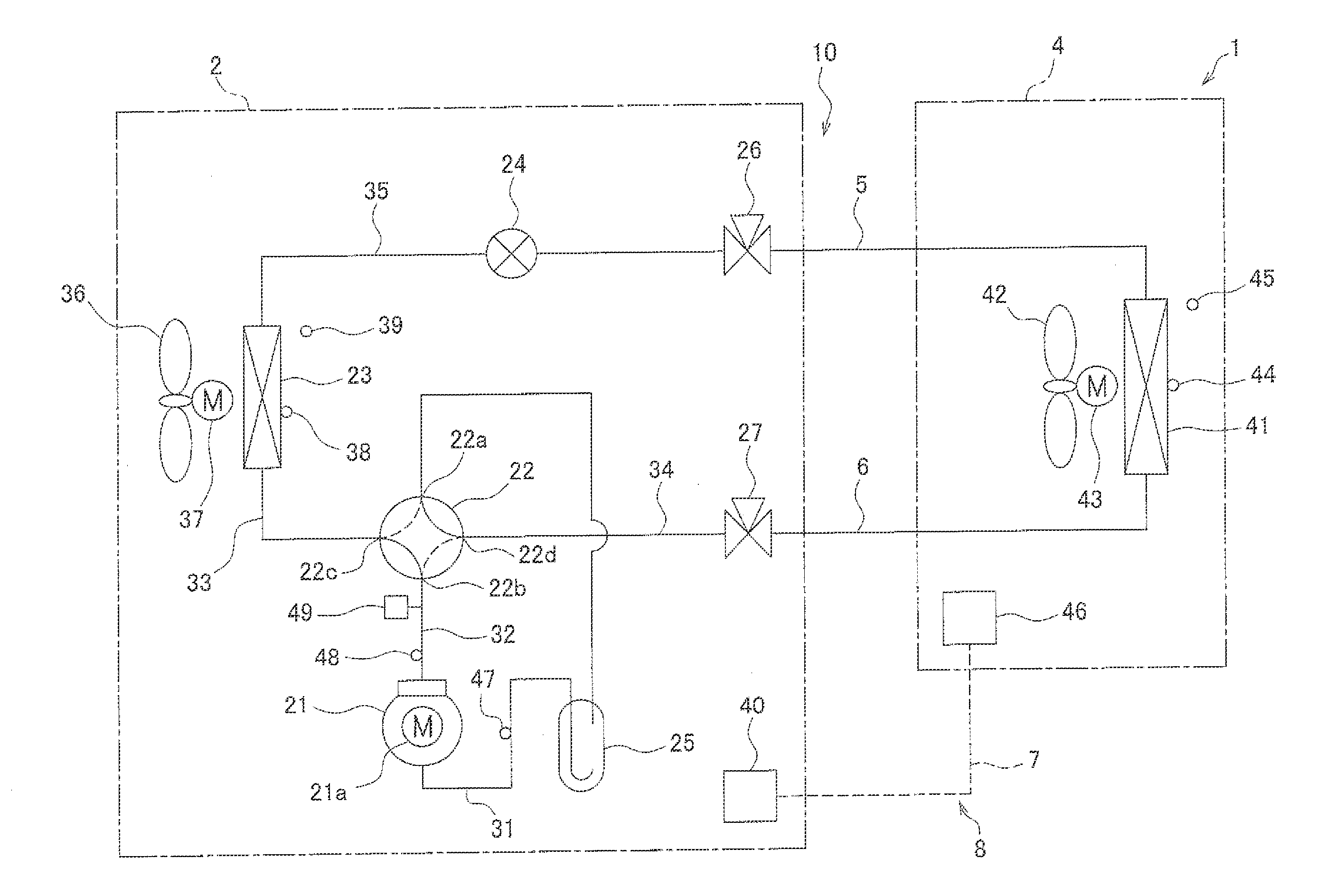

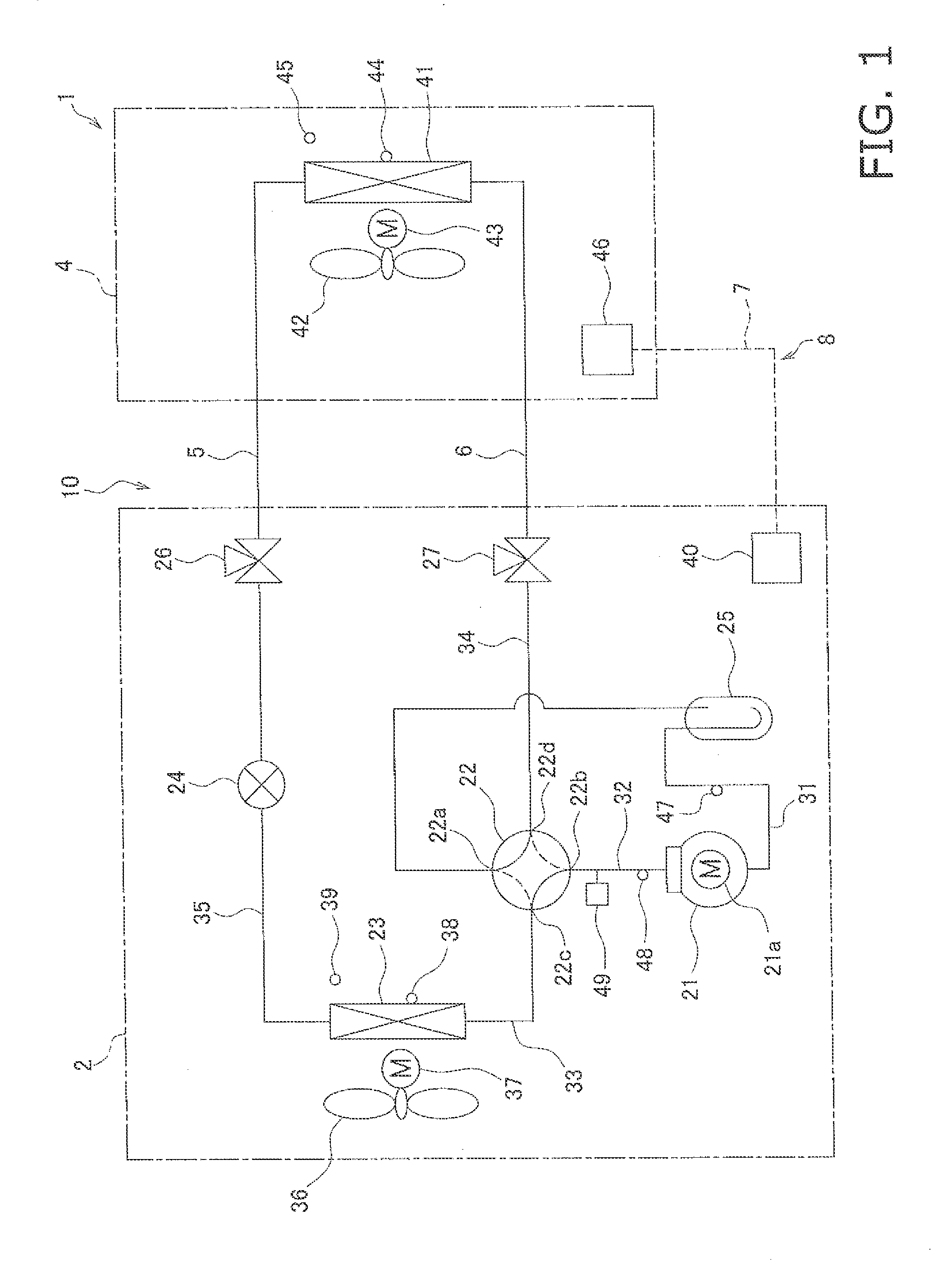

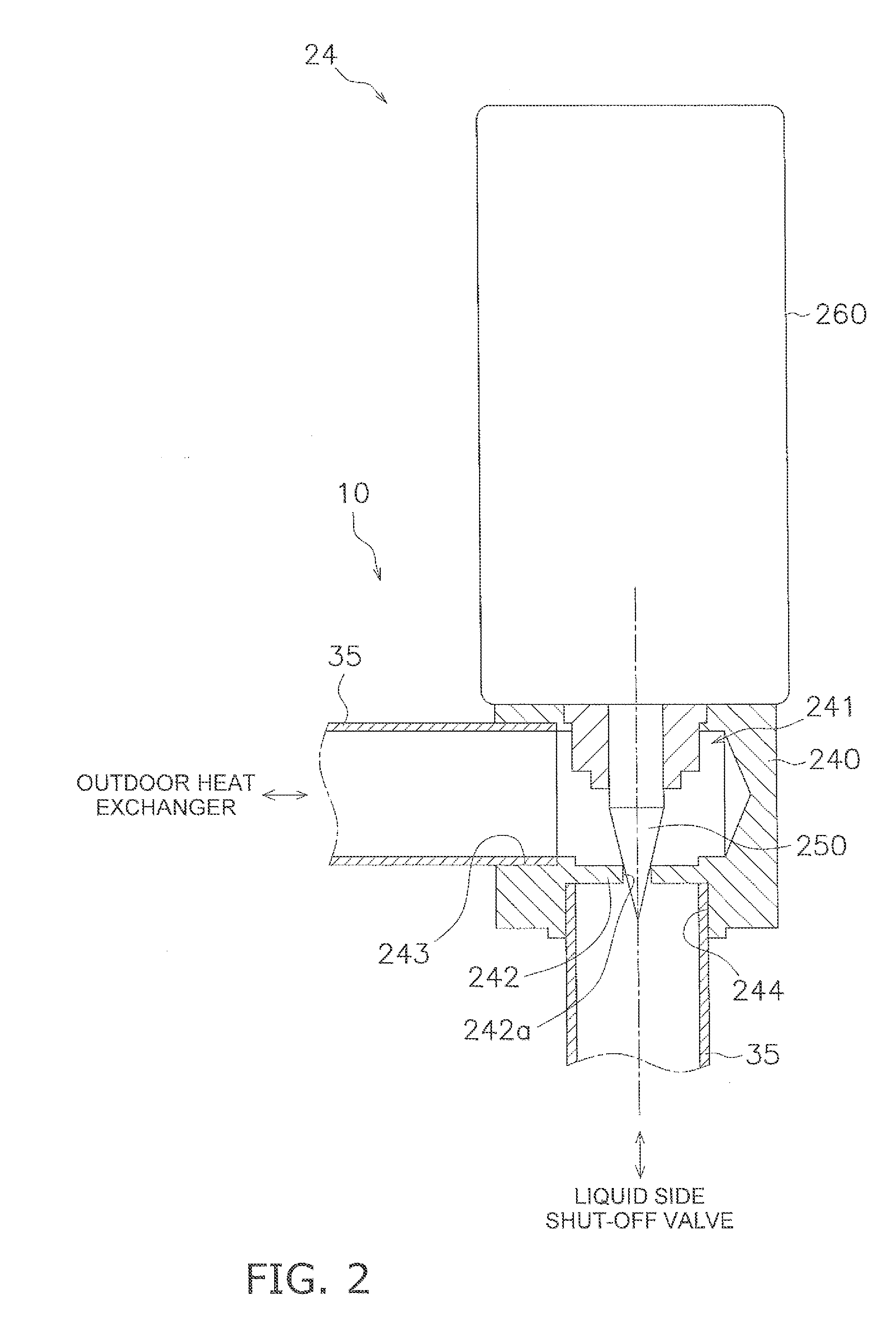

Air conditioner

InactiveUS20150052923A1Easy for cavitationSuppress cavitation noiseMechanical apparatusEvaporators/condensersRefrigerantEngineering

An air conditioner includes an outdoor fan and a refrigerant circuit having a compressor, an outdoor heat exchanger, an expansion valve, and an indoor heat exchanger connected to each other. An expansion valve refrigerant discharge control, in which the compressor is driven in a state where the outdoor fan is stopped and the expansion valve is open, is performed when a cooling start noise reduction condition that a state of refrigerant at inlet and outlet ports of the expansion valve is in a one-phase liquid state is satisfied when starting the cooling operation. An expansion valve normal switching control, in which an opening of the expansion valve is reduced and an operating frequency of the compressor is increased, is performed after the expansion valve refrigerant discharge control.

Owner:DAIKIN IND LTD

Low noise cone valve

ActiveCN104895857AReduce axial hydraulic forceReduce the pressure gradientServomotor componentsFluid-pressure actuator componentsLow noiseEngineering

The invention discloses a low noise cone valve. A center hole working as an oil inlet is formed in the bottom surface of a valve body; a valve sleeve is disposed in the center hole of the valve body; the valve sleeve is in a threaded connection with the valve body; a valve core is covered with the valve sleeve and in sliding cooperation with the valve sleeve; the valve core is connected to the bottom of the center hole of the valve body; a valve sleeve oil outlet and a valve sleeve oil inlet are respectively formed in the upper and lower side surfaces of the valve sleeve; an oil outlet communicated with the valve sleeve oil outlet is formed in the side wall of the valve body on the valve sleeve oil outlet; an annular gap channel communicated with the valve sleeve oil inlet is formed in the side wall of the valve body on the valve sleeve oil inlet; a gap forming a valve sleeve front throttling port is formed between the front end of the valve sleeve and the inner wall of the gap channel; and the oil inlet in the bottom surface of the valve body is connected with the gap channel via the valve sleeve throttling port. The low noise cone valve is advantaged by simple structure, great manufacturability and simple operation; and valve noise can be reduced.

Owner:ZHEJIANG UNIV

Compact blade for runner of Francis turbine and method for configuring runner

ActiveUS9605647B2Improve performanceSuppress cavitationRotary propellersHydro energy generationLeading edgeFrancis turbine

A blade for a runner of a Francis turbine having a throat diameter (Dth), the blade including: a maximum thickness of no less than 0.03 Dth and a leading edge having a maximum lean angle of no less than 45 degrees, wherein the lean angle is defined by a vertical line and the leading edge.

Owner:ANDRITZ HYDRO LTD

Sectional type oil nozzle and optimization design method thereof

PendingCN114060192AReduce energy lossGeometric cavitation suppressionFuel injection apparatusMachines/enginesOptimal designNeedle valve

The invention discloses a sectional type oil nozzle and an optimization design method thereof. The oil nozzle comprises a needle valve, a needle valve body and a turbulent flow ring sleeve, wherein the needle valve and the needle valve body are coaxially matched, and the needle valve is located in the needle valve body; oil injection holes which are evenly distributed in the circumferential direction are formed in the needle valve body, turbulent flow concave cavities and flare openings are formed in the turbulent flow ring sleeve, and the turbulent flow concave cavities, the flare openings and the oil injection holes are coaxially distributed and are the same in number; and the turbulent flow ring sleeve is in threaded connection with the needle valve body, adjacent boundaries are consistent in shape and are in close fit, and the structure can enhance the circulation performance and the atomization performance of the oil nozzle at the same time. Based on the sectional type oil nozzle, a transparent oil nozzle internal flow and spray visualization experiment table is established; factors, levels and indexes of sectional nozzle structure design are extracted, an experiment is carried out based on orthogonal experiment design, and sensitivity analysis is carried out on data; and a BP neural network model is established and trained based on MATLAB, an optimal solution combination and a multi-index weight coefficient are solved by using the model, the correctness of results is verified through carrying out a visual experiment, and the optimization of the oil nozzle design is completed.

Owner:JIANGSU UNIV

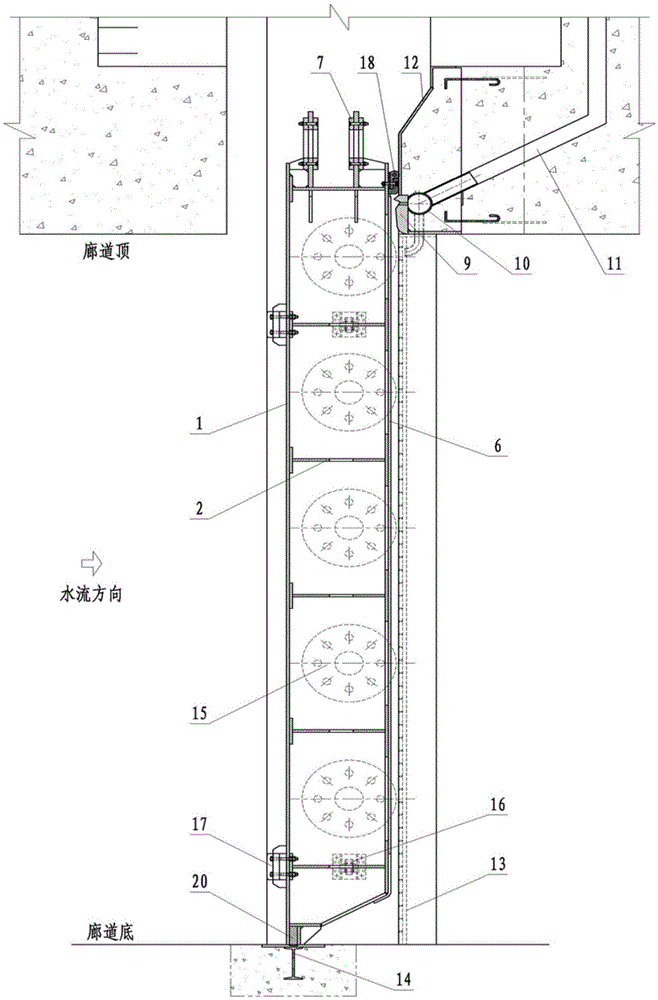

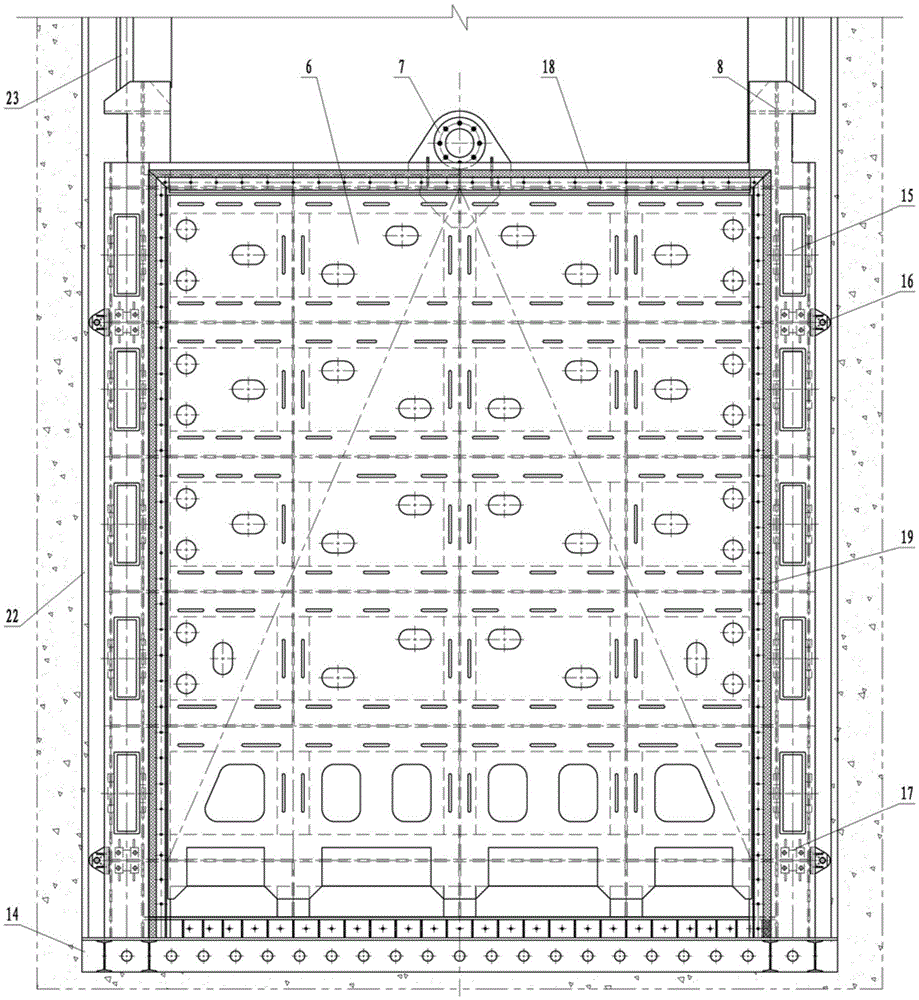

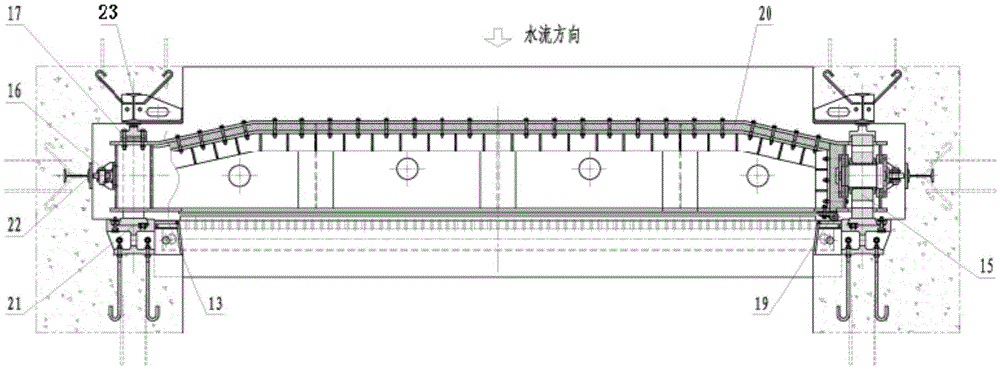

Planar valve capable of achieving natural ventilation of door lintel and reducing opening and closing force

ActiveCN105625289ANatural ventilation guaranteeSmall opening and closing forceDry-docksClimate change adaptationCavitationNatural ventilation

The invention discloses a planar valve capable of achieving natural ventilation of a door lintel and reducing opening and closing force. The planar valve capable of achieving natural ventilation of the door lintel and reducing the opening and closing force comprises a door body structure, a door lintel and embedded part system, a waterstop system, a supporting and limiting system and a track system. The door lintel and embedded part system comprises a ventilating device, a top waterstop embedded part, a lateral waterstop embedded part and a bottom waterstop embedded part. The ventilating device is arranged below a top waterstop behind a door, and a gap is formed between the ventilating device and a backboard of a door body, so that natural ventilation is achieved. The top waterstop is arranged on the rear flange of a top main beam. A lateral waterstop is arranged on the rear flanges of inner edge beams. A bottom watertop is arranged below a bottom beam arranged along a panel. Main rolling wheel devices are arranged in two edge beams between main beams. A lateral limiting device is arranged on a web of the outer edge beam at the ends of the main beams. A reverse limiting device is arranged on the panel between the edge beams at the ends of the main beams. The planar valve is suitable for a medium-waterhead or high-waterhead ship lock; air-etching cavitation of the door lintel and the bottom edge can be restrained, the valve opening and closing force is reduced, energy consumption is reduced, and the service life of the ship lock is prolonged.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

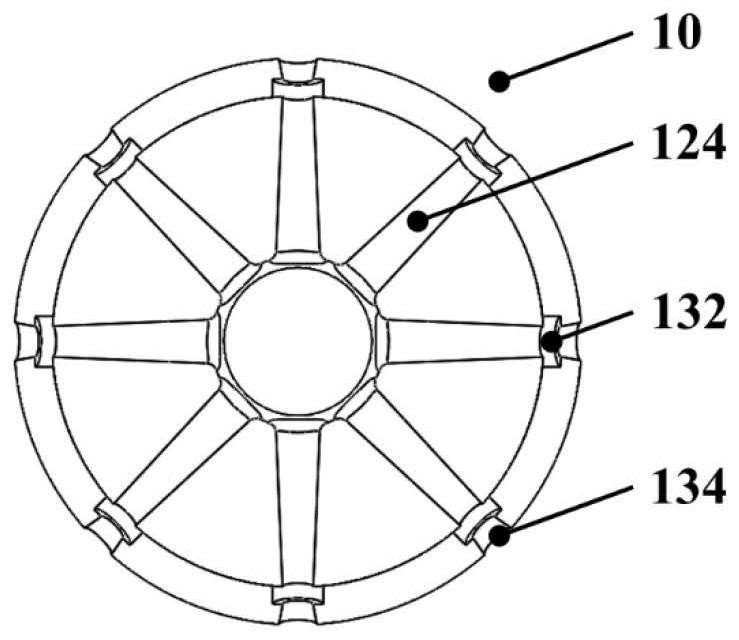

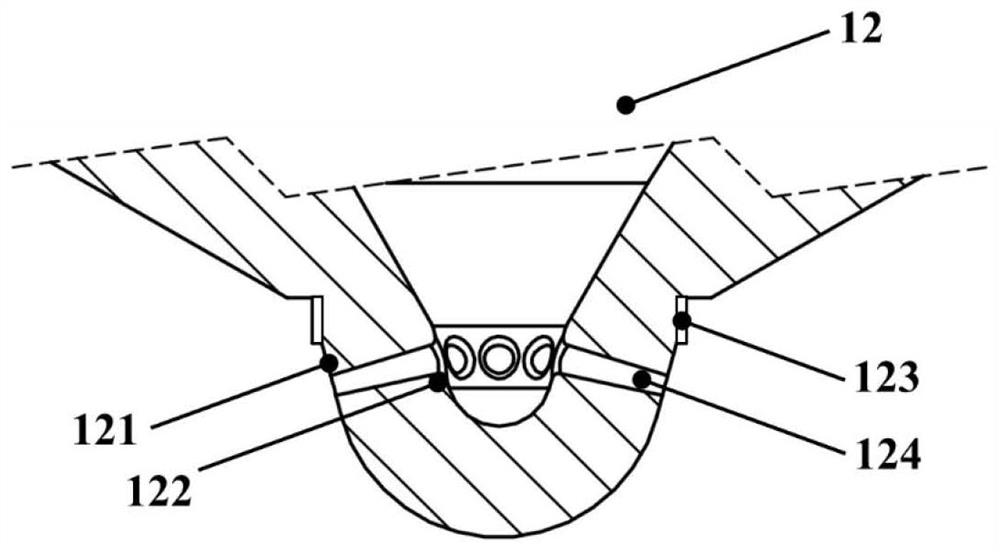

High cavitation-resistant water-spraying propelling pump perforated at rim of impeller

ActiveCN106762804ASolve the problem of high anti-cavitationIncrease pressurePump componentsPropulsive elementsImpellerCavitation

The invention discloses a high cavitation-resistant water-spraying propelling pump perforated at the rim of an impeller. The pump comprises a water-absorbing bend, a suction straight tube, the impeller, a guide vane, a nozzle, a guide vane caudal vertebra and a main shaft. The outlet of the water-absorbing bent is connected to the inlet of the suction straight tube, the outlet of the suction straight tube is connected to the inlet of the impeller, the outlet of the impeller is successively connected to the guide vane and the nozzle, the guide vane caudal vertebra is connected to the tail portion of the guide vane, and the impeller is fixed on the main shaft through a key; a hole in the rim of the impeller is formed in the outer wall of the impeller at the rim of an impeller blade of the impeller of the impeller blade, the hole in the rim of the impeller is a hole in the rim of the outer wall surface of the impeller at the rim of the impeller blade, and the hole in the rim of the impeller is in a shape of an annular runner which is formed by rotatable sweeping of a meridional flow channel according to a rotary shaft. According to the pump disclosed by the invention, a local high pressure fluid at the rim of the impeller is imported to the front edge, close to the rim, of the impeller blade through the hole at the rim, so that the pressure of an impeller blade inlet region is increased to inhibit cavitation, the high cavitation-resisting problem of the high-speed efficient water-spraying propelling pump is solved, and meanwhile, the structure meets the design space limitation of the spray pump.

Owner:SHANGHAI JIAO TONG UNIV +1

Gear pump including an inner rotor having a plurality of teeth

ActiveUS9581156B2Suppress cavitationImprove suction efficiencyOscillating piston enginesRotary piston pumpsTooth chamberEngineering

In a gear pump, an outer inner wall surface of a suction port which is located on a downstream side in a rotor rotation direction, that is, a first inner wall surface, is located inward of a bottom land between internal teeth of an outer rotor, and the suction port has a shallow portion extended inward from the first inner wall surface on the downstream side in the rotor rotation direction, and a deep portion that is formed so as to be continuous with the shallow portion and that is deeper than the shallow portion. Communication between an inter-tooth chamber and the suction port is cut off with the inter-tooth chamber facing only the shallow portion.

Owner:AISIN AW CO LTD

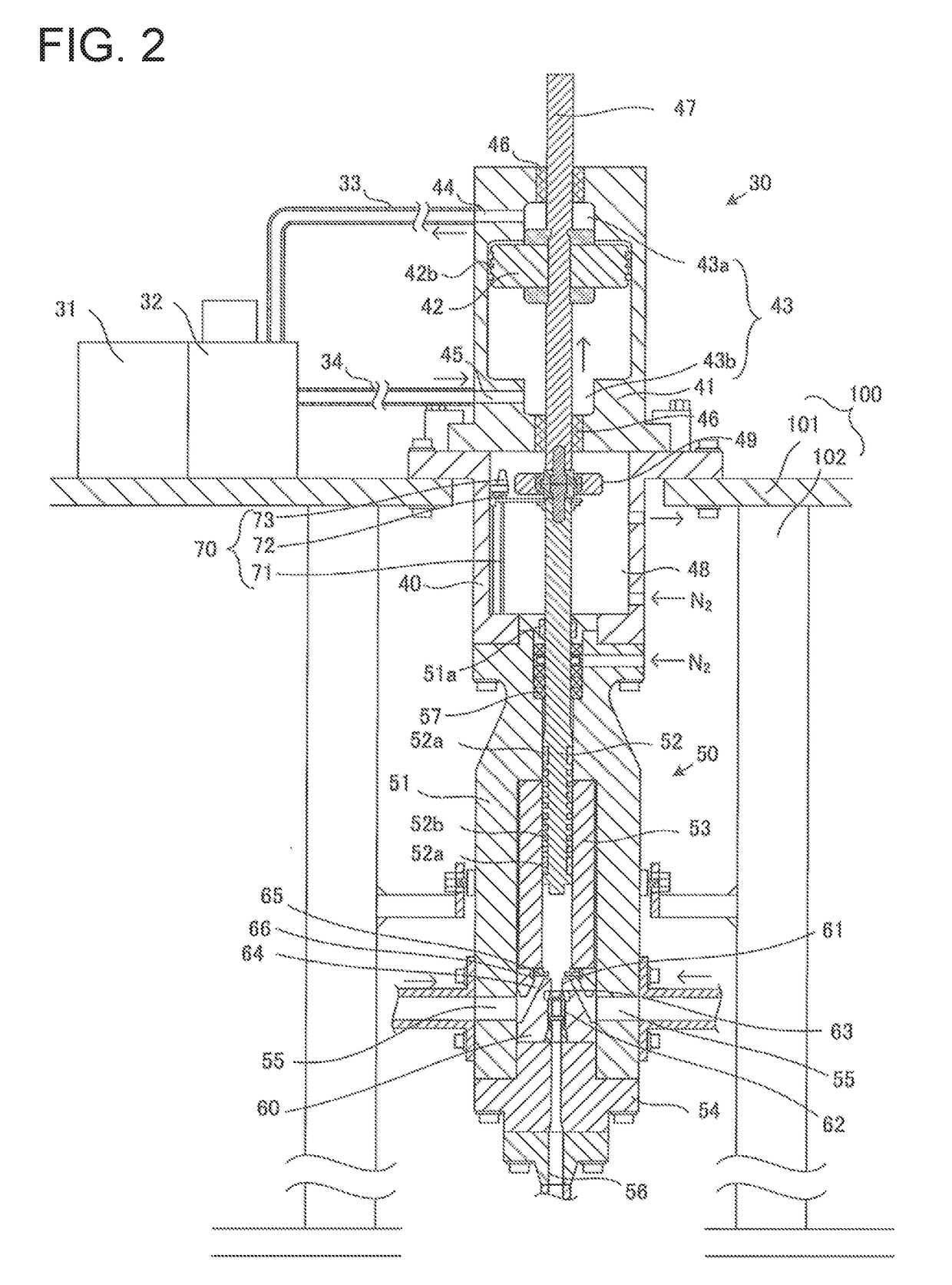

Fuel Supply Device and Fuel Supply Method

ActiveUS20180119658A1Suppress cavitationReduce pressureInternal combustion piston enginesFuel supply apparatusReciprocating motionCycle time

A fuel supply device includes: a linear actuator; a reciprocating pump having a boosting piston driven by the linear actuator, configured to axially reciprocate, and configured to alternately repeat suction of the fuel and ejection of the fuel more boosted than the fuel at a time of suction by reciprocation of the boosting piston; and a controller to control driving of the linear actuator. When reciprocation amplitude of the boosting piston is A (A>0) and a reciprocating cycle time is T, the controller controls the linear actuator so a maximum value of an absolute value of acceleration when the reciprocating pump sucks the fuel with an absolute value of speed of the boosting piston increasing is smaller than A·(2π / T)2, and so a maximum value of the absolute value of the acceleration of the boosting piston when the reciprocating pump ejects the fuel is larger than A·(2π / T)2.

Owner:MITSUI E&S MACHINERY CO LTD

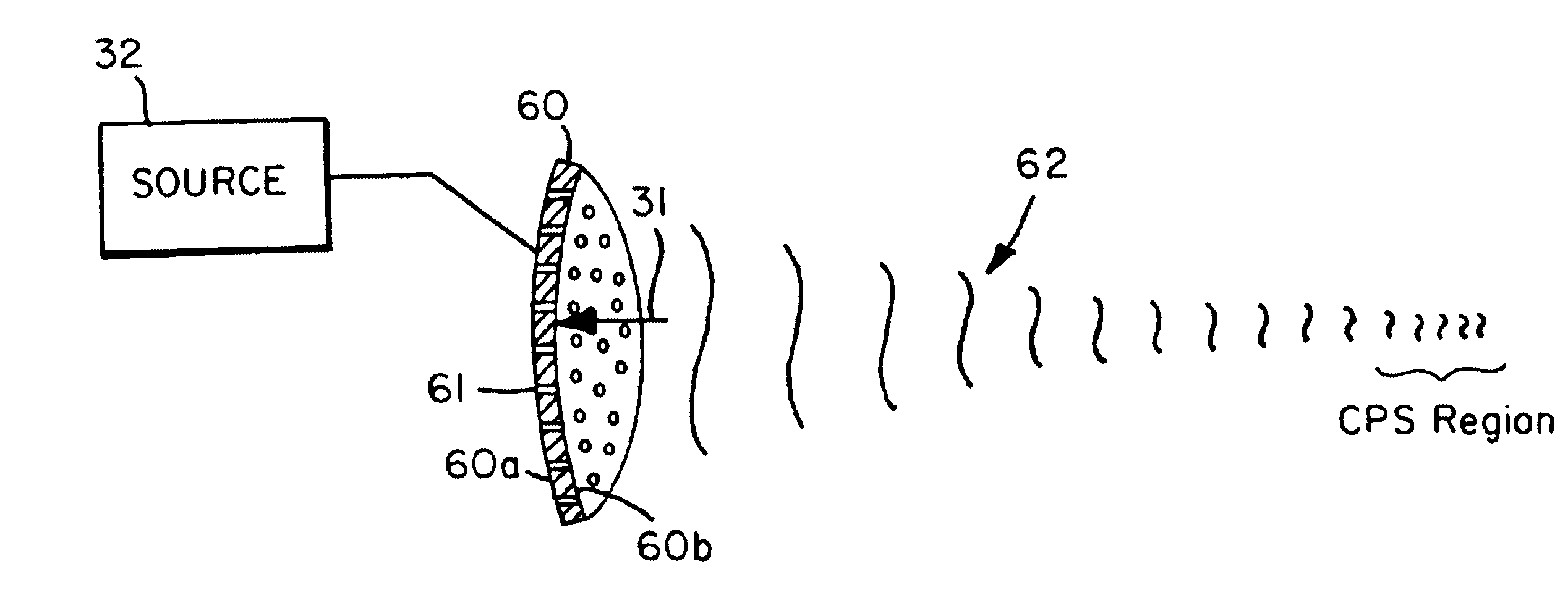

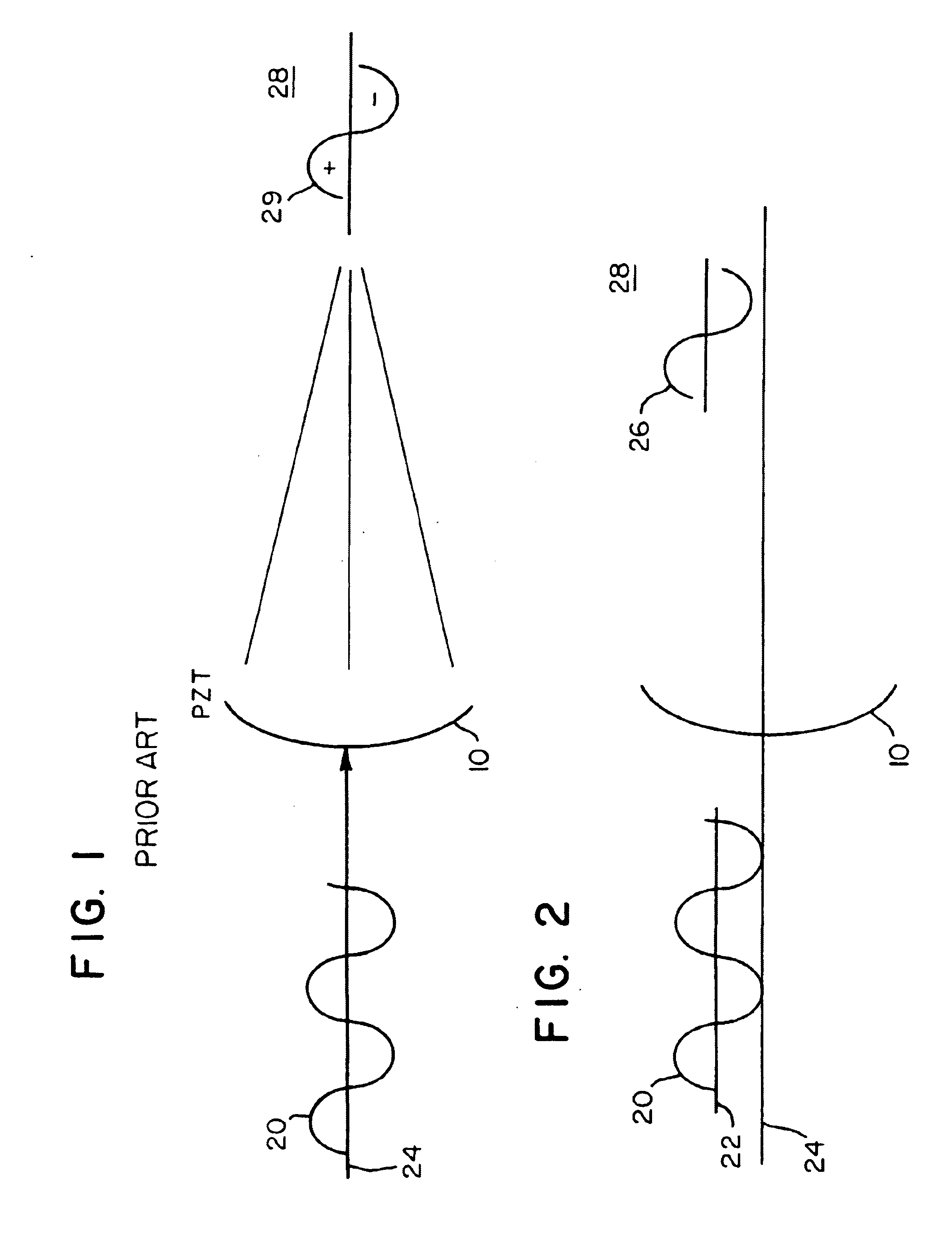

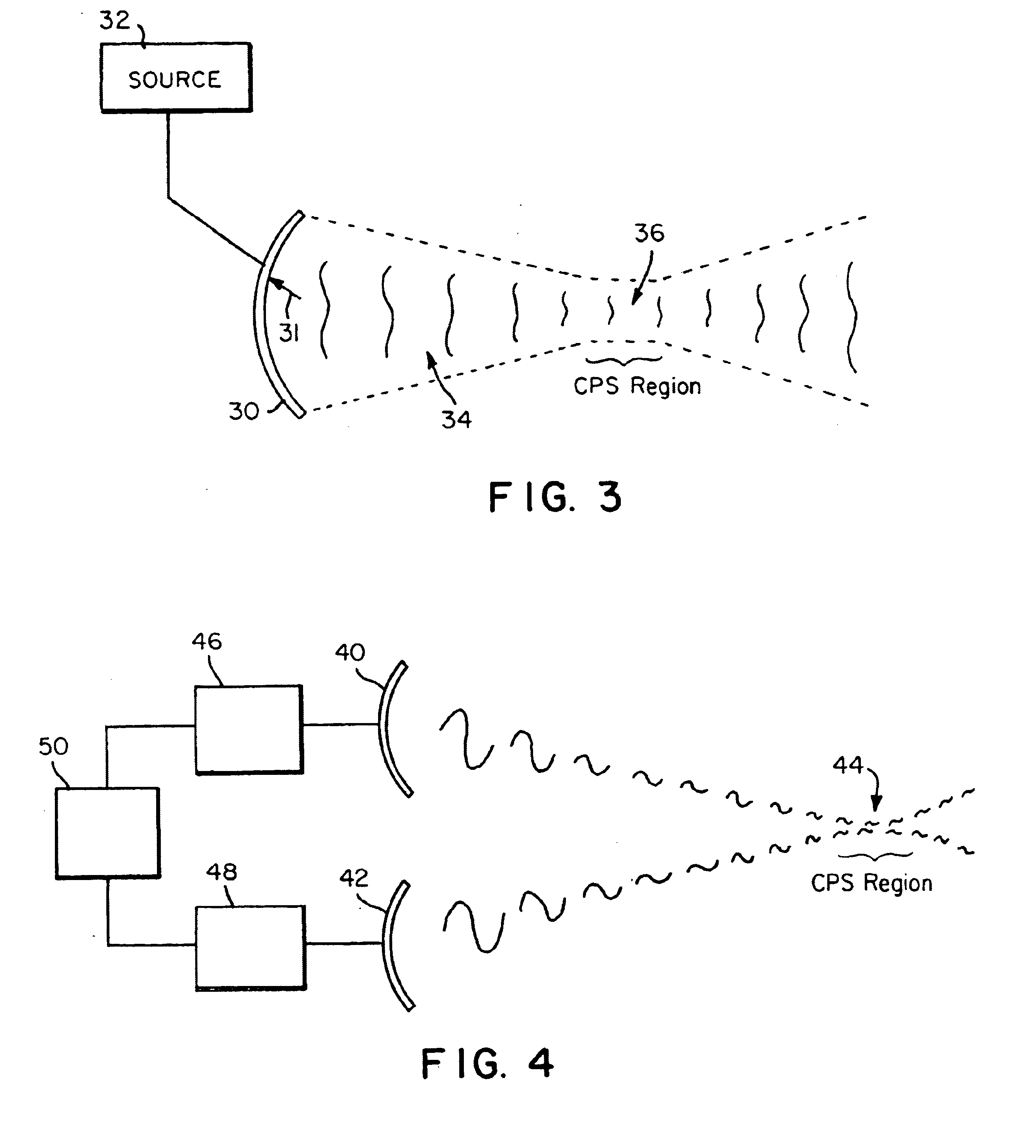

Method and apparatus for acoustic suppression of cavitation

The invention provides a method and apparatus for suppressing hydrodynamic cavitation through the use of high frequency (>500 kHz) and high amplitude (>1 atmospheres) acoustic energy. The method includes biasing a transducer driving signal to generate an acoustic field having a positive pressure halves. The resulting acoustic field is imposed on a region where cavitation is to be preempted. A cavitation preempting acoustic field in the liquid is similar in effect as using a hyperbaric confinement for imposing hydrostatic pressure, a known method for suppressing cavitation. In this regime, suppression of cavitation will be due to imposing a dominant high amplitude, high-frequency pressure field to ensure that the gaps between the compressive pulses are shorter than 10−7 to 10−6 seconds, which is less than that typically necessary to cause cavitation.

Owner:OVIVO SWITZERLAND AG

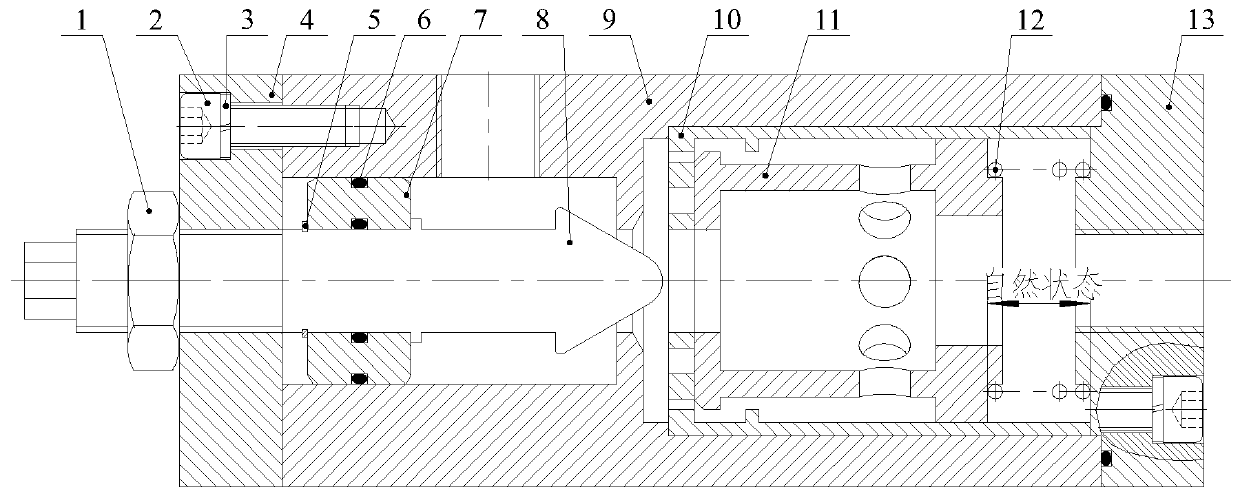

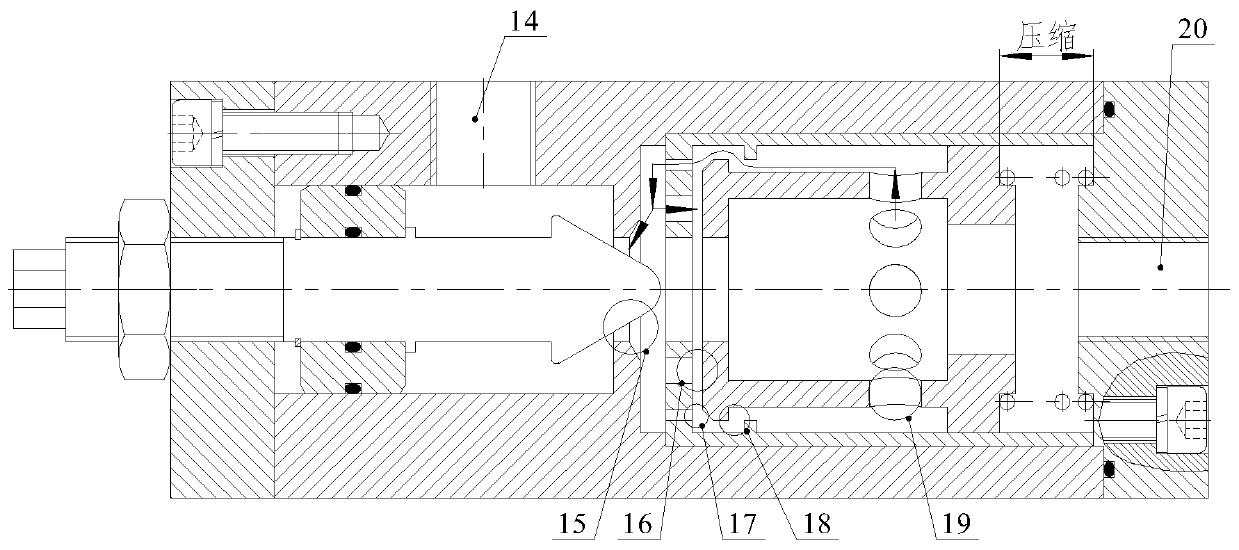

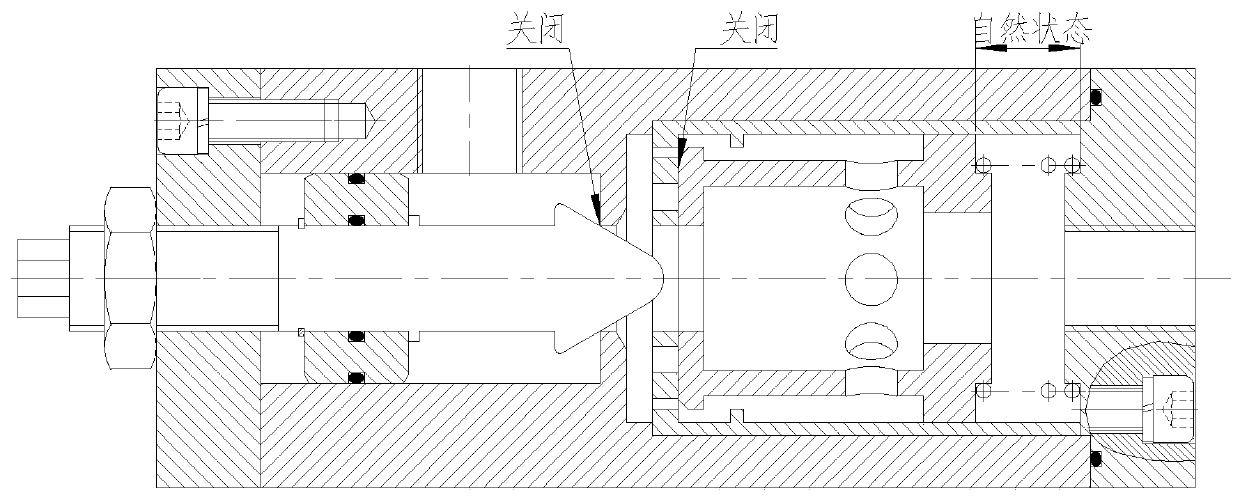

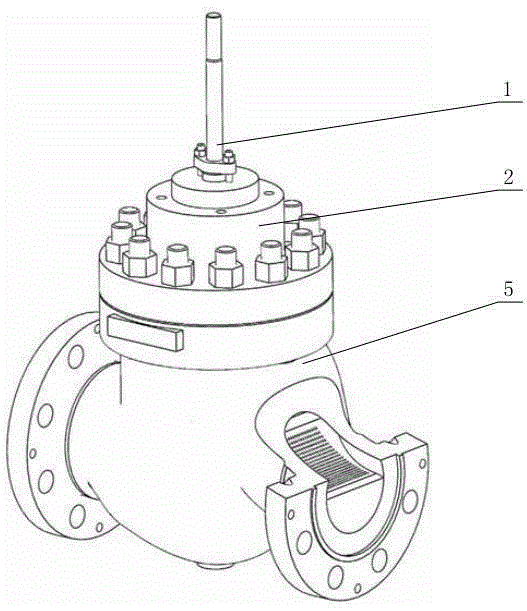

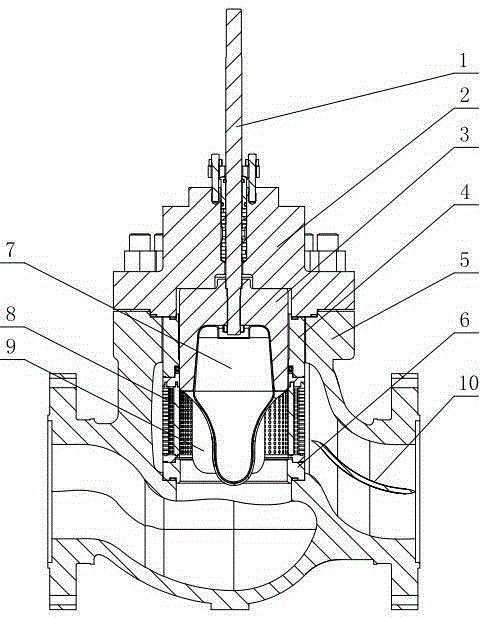

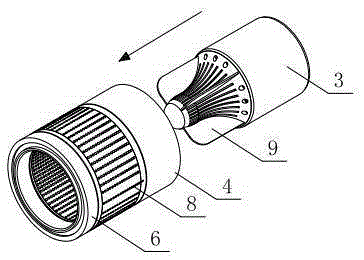

Throttle valve with built-in pressure reducing drainage device

PendingCN110107555AImproved valve port pressure distributionSuppress cavitationServomotor componentsShuttle valveEngineering

The invention discloses a throttle valve with a built-in pressure reducing drainage device. The throttle valve is characterized in that the throttle valve comprises a left end cover, a guide sleeve, athrottle valve core, a valve body, a pressure reducing valve sleeve, a drainage device, a pressure reducing spring, a right end cover and the like; a water inlet and a water outlet are respectively arranged on the valve body and the right end cover; the guide sleeve is arranged between the throttle valve core and the valve body; the pressure reducing valve sleeve is arranged in a valve body hole;the drainage device is arranged in an inner hole of the pressure reducing valve sleeve and is capable of sliding left and right; the pressure reducing spring is arranged between the drainage deviceand the right end cover and is used for adjusting the displacement of the drainage device; two groups of kidney-shaped holes with different diameters are formed in the left side of the pressure reducing valve sleeve; steps are arranged inside the drainage device; ladders are arranged at the end part of the pressure reducing valve sleeve; and a pressure reducing valve port is formed by the steps and the ladders. According to the throttling valve, water at the outlet can be led to a throttling valve port, and the pressure at the throttling valve port is basically constant no matter how high thepressure of the water outlet is, so that the cavitation inhibition effect is basically the same under different working condition pressures, and the throttling valve is applicable to various pressureapplication occasions.

Owner:QINGDAO UNIV OF SCI & TECH

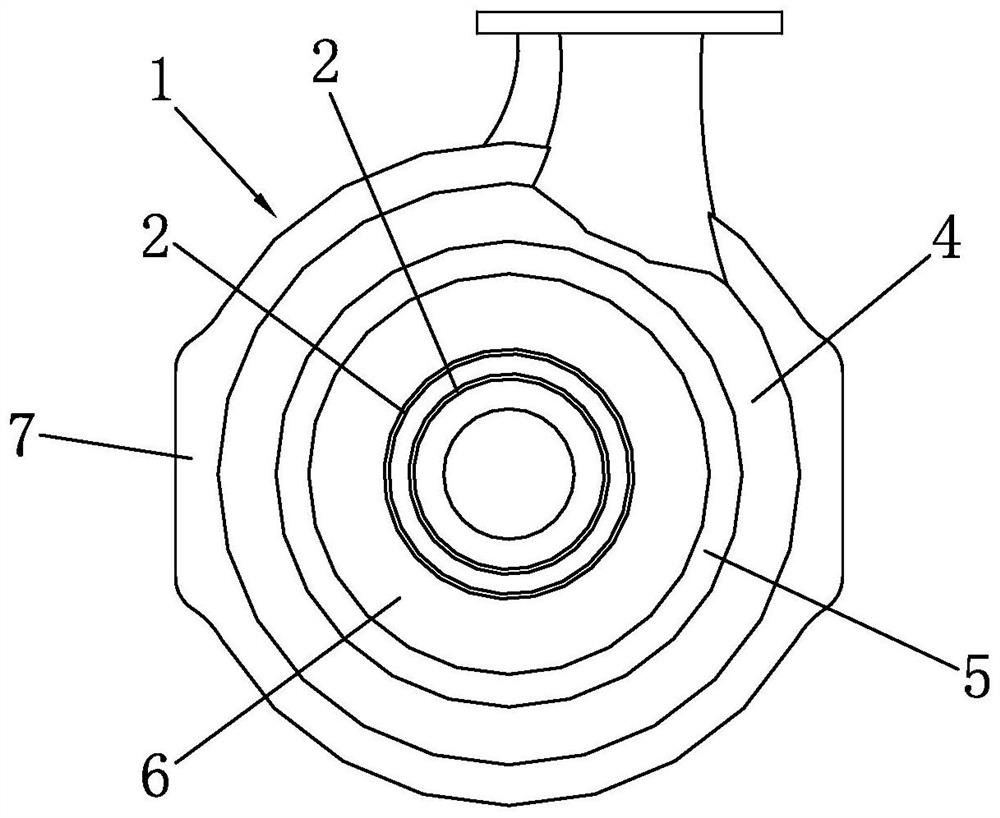

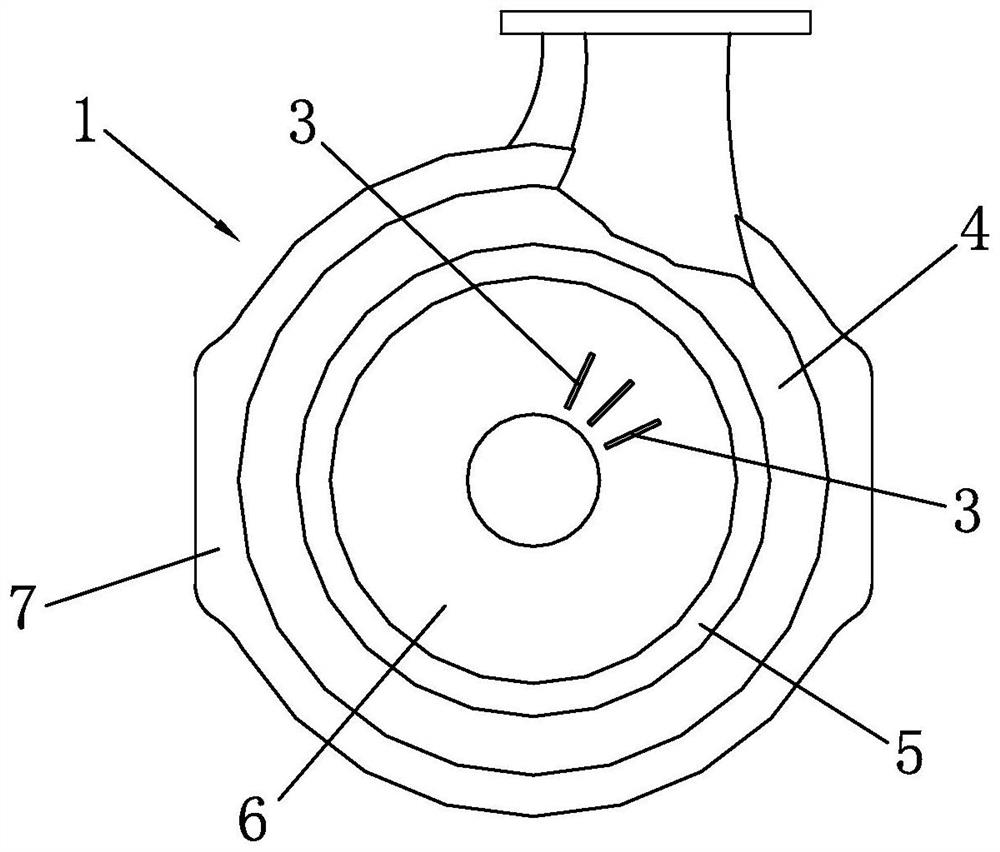

Impeller for restraining cavitation of back surface of pump impeller blades and design method thereof

PendingCN110750935ASuppress cavitationExpand the scope ofGeometric CADDesign optimisation/simulationImpellerFront cover

Owner:XIHUA UNIV

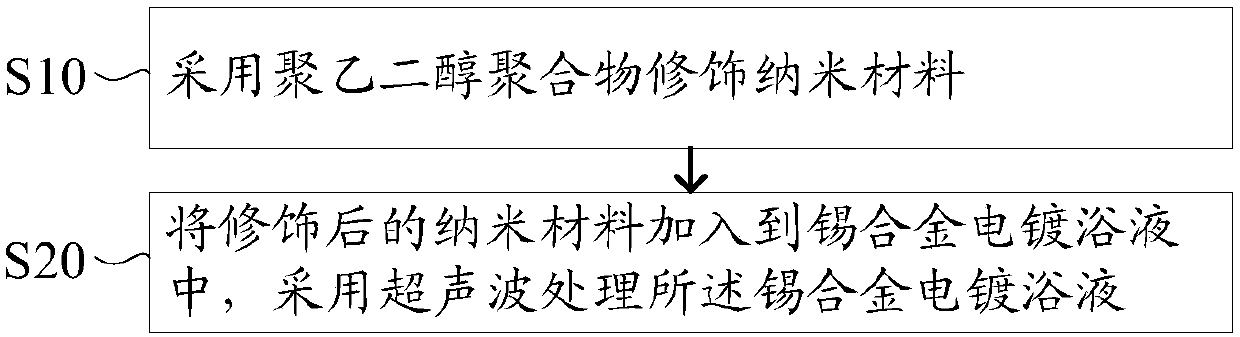

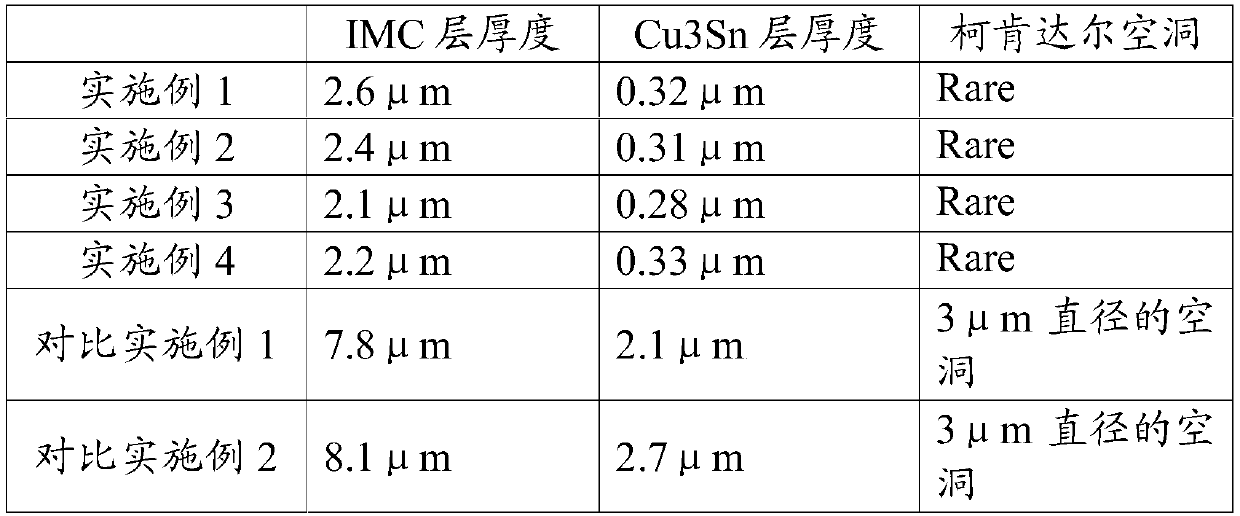

Forming method of tin alloy electroplating bath liquid and preparation method of soldering tin salient point plating

ActiveCN109594108AEvenly dispersedUniform depositionElectrolytic coatingsNanoparticlePolyethylene glycol

The invention provides a forming method of tin alloy electroplating bath liquid, a preparation method of a soldering tin salient point plating and the soldering tin salient point plating. The formingmethod of the tin alloy electroplating bath liquid includes the steps that a nanomaterial is modified with a polyethylene glycol polymer; and the modified nanomaterial is added into the tin alloy electroplating bath liquid, and the tin alloy electroplating bath liquid is treated through ultrasound. According to the forming method of the tin alloy electroplating bath liquid, the preparation methodof the soldering tin salient point plating and the soldering tin salient point plating, the nano-material is surface-modified through the polymer, the modified nanoparticles are evenly dispersed in the tin alloy electroplating bath liquid, the stability of the nanomaterial in the tin alloy electroplating bath liquid is improved, the ultrasound is used for dispersion treatment, the possibility of clustering of the nanoparticles is reduced, uniform deposition during electroplating of the nanoparticles can be effectively guaranteed, the nanoparticles can be effectively embedded into lattices of the formed soldering tin salient point plating, and the effect of inhibiting forming of intermetallic compounds is achieved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

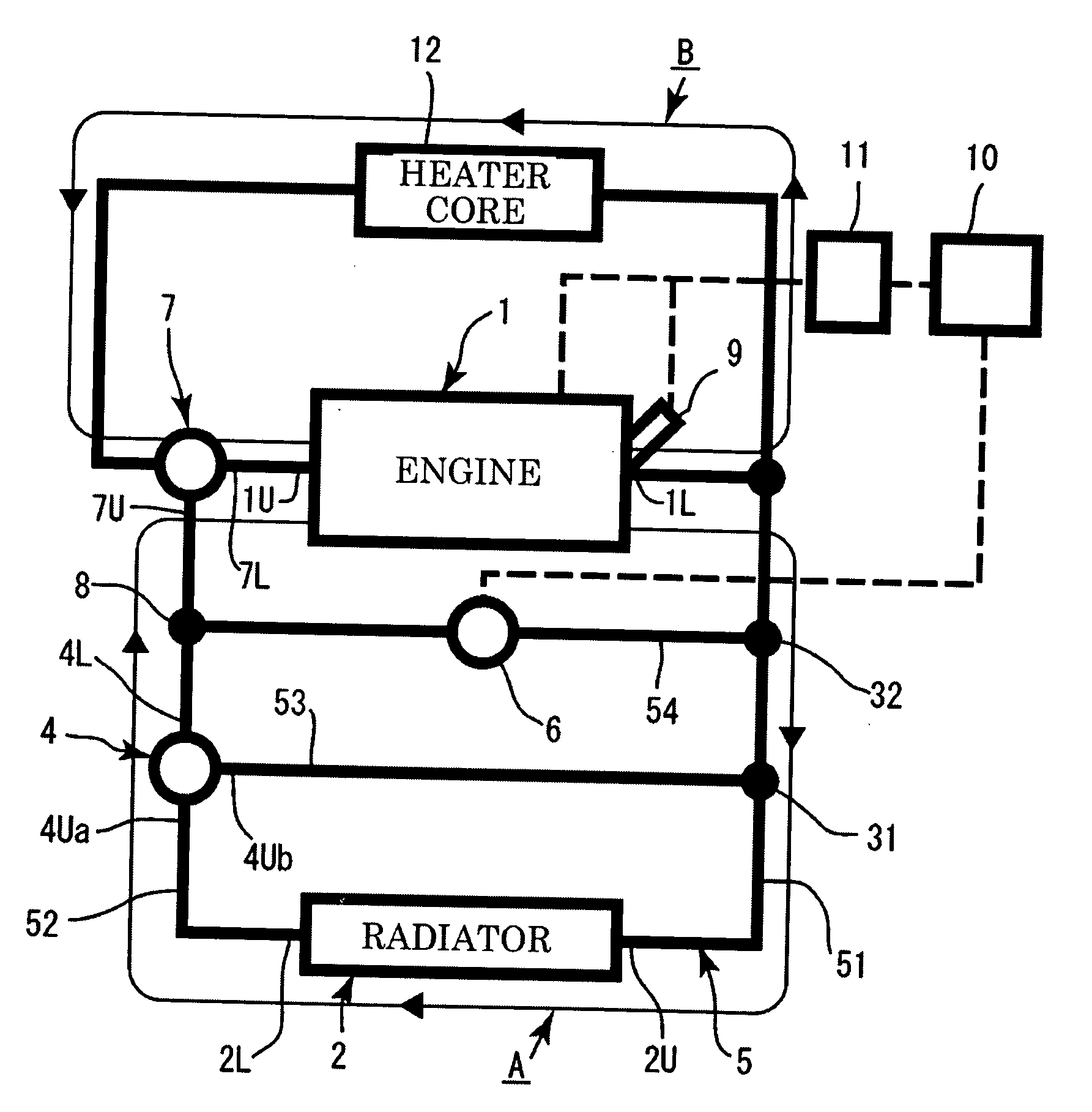

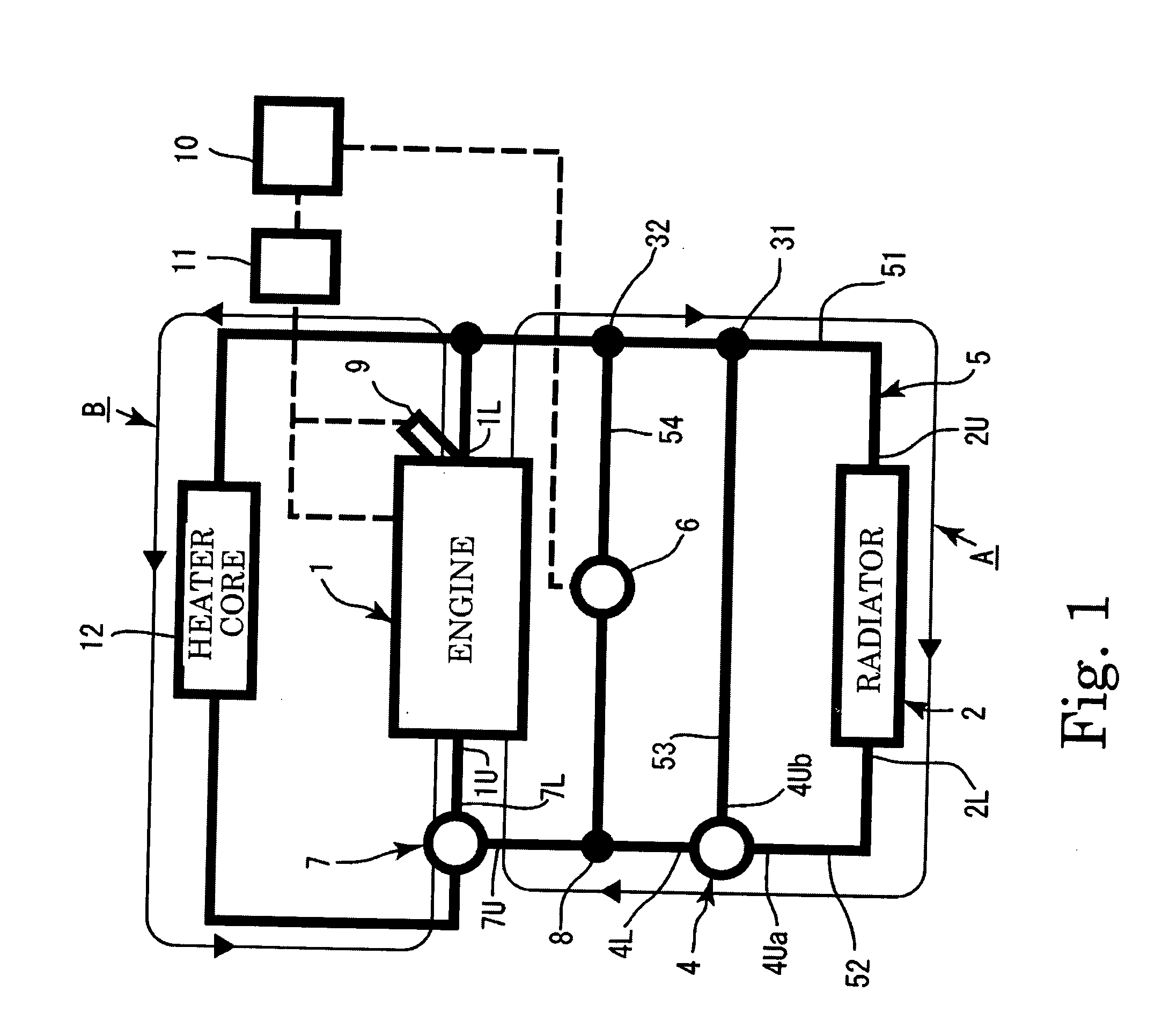

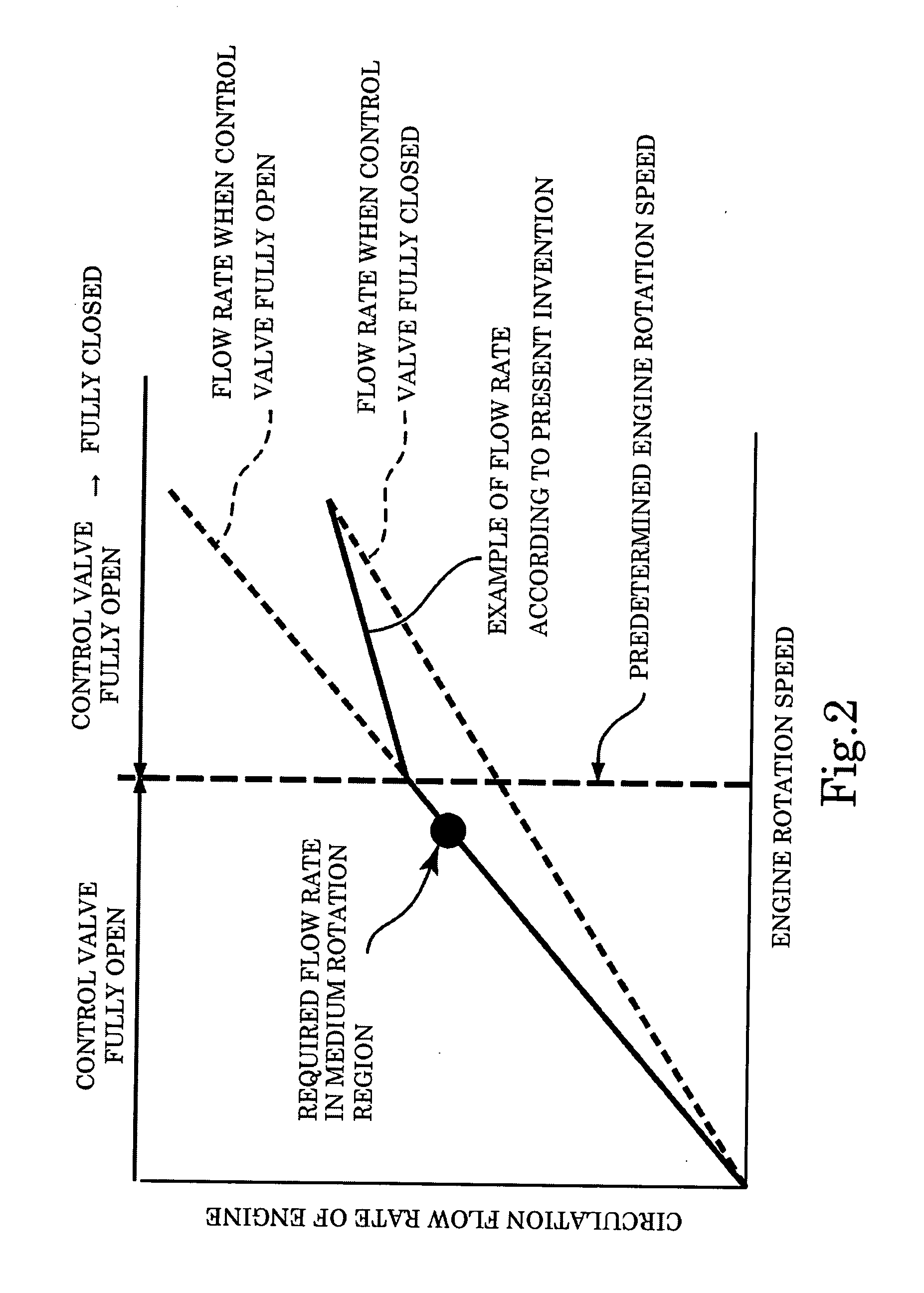

Engine cooling apparatus

InactiveUS20120024243A1Suppress cavitationHigh regionCoolant flow controlMeasurement deviceCavitationEngineering

The present invention provides an engine cooling apparatus that is capable of suppressing cavitation in a high rotation region while achieving an increase in a circulation flow rate of cooling water in a low / medium rotation region. The engine cooling apparatus includes: a main cooling water circuit that circulates the cooling water between an engine and a radiator; a branch portion provided between the engine and the radiator; a thermostat; temperature detecting means; a first bypass flow passage; a second bypass flow passage that connects the engine to the branch portion; a control valve; a bypass convergence portion; a water pump; valve opening control means; and engine rotation speed detecting means.

Owner:YAMADA SEISAKUSHO KK

low noise control valve

ActiveCN104048102BReduce pulsating pressureCompact structureValve members for absorbing fluid energyLow noiseCavitation

Owner:中国船舶重工集团公司第七〇二研究所

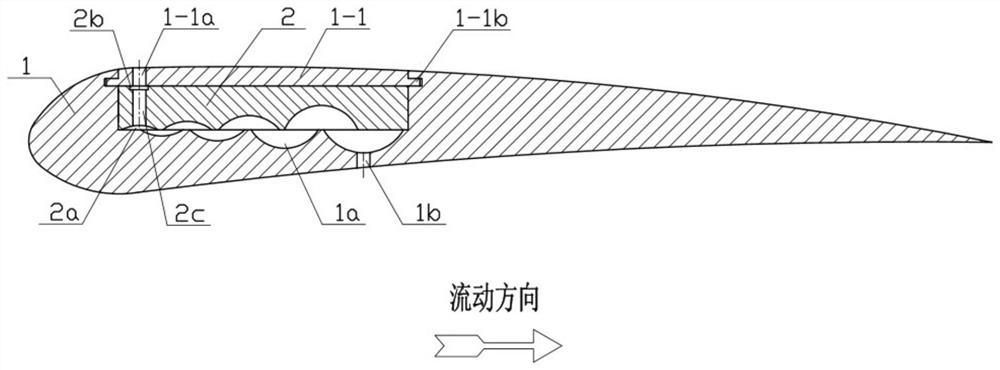

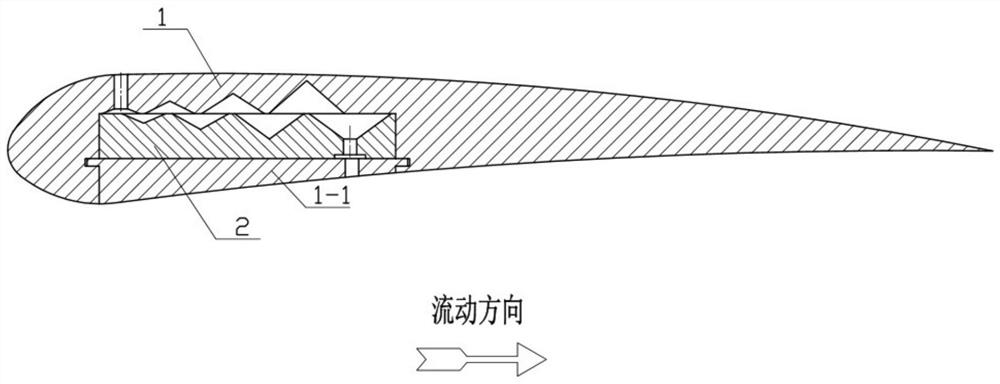

Cavitation suppressionwing section device

ActiveCN111852998AIncrease pressureSuppress cavitationFluid dynamicsEngineeringStructural engineering

The invention provides a cavitation suppression wing section device which comprises a wing section and a sliding block. The sliding block is movably mounted in the wing section. Multiple arranged grooves are arranged on any sliding face of the sliding block and the surface, in contact with the sliding face, of the wing section. Through moving of the sliding block, the grooves on any sliding face of the sliding block at least communicate with the adjacent grooves on the surface, in contact with the sliding face, of the wing section, and the grooves are used for forming at least one pressure reduction runner in the flowing direction. An inlet and outlet communicating with the pressure reduction runners is arranged on the wing section. Through moving of the sliding block, the passage cross sections between the grooves on the sliding block and the grooves on the wing section are changed to be used for adjusting the flowing capacity of the pressure reduction runners. According to the cavitation suppression wing section device, the structure is simple and compact, the adjustable pressure reduction runners can meet the specific anti-cavitation requirements of fluid machines running underdifferent work conditions, and the device has wide development space and application prospects.

Owner:JIANGSU UNIV

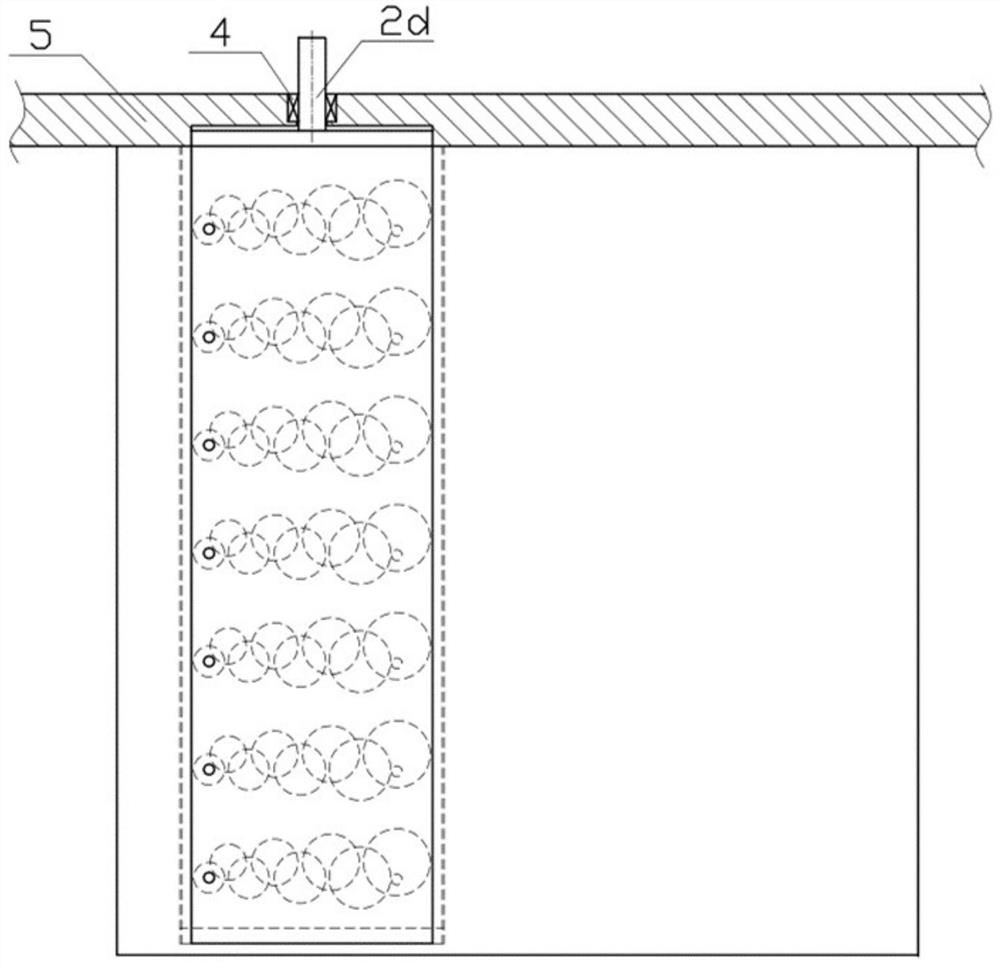

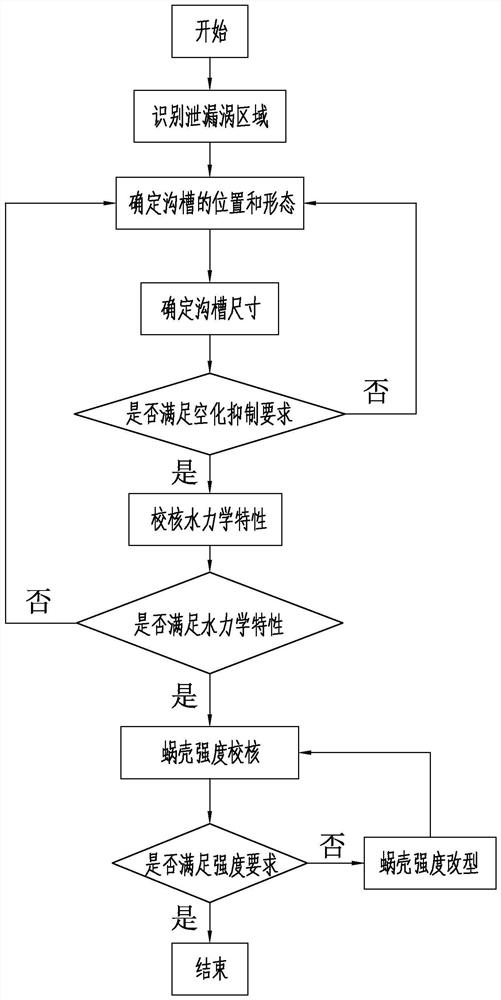

Centrifugal pump volute for cavitation suppression and design method and installation method thereof

PendingCN114017391AIncrease pressureReduce low pressure areaPump componentsDesign optimisation/simulationDecreased pressureEngineering

The invention discloses a centrifugal pump volute for cavitation suppression and a design method and an installation method thereof, wherein the centrifugal pump volute comprises a volute body, the volute body is provided with grooves, the grooves are annular grooves and radial grooves, and the annular grooves or the radial grooves are formed in the inner side of the volute body; and fluid is accumulated in the grooves, the pressure of the position where leakage vortexes are located is improved, a low-pressure area generated by the leakage vortexes is reduced, and cavitation is restrained on the premise that hydraulic characteristics such as lift efficiency are not reduced basically. According to the design method, the grooves are designed, and the positions, the shapes and the sizes of the grooves are determined. According to the installation method, a shell, a first side plate and a second side plate are mounted according to the design result, the manufacturing quality of the shell, the first side plate and the second side plate can be conveniently controlled, the annular grooves or the radial grooves can be conveniently formed in the second side plate, the positions and the shapes of the grooves can be conveniently controlled, and meanwhile it is ensured that the width and the depth of the grooves meet the design requirement.

Owner:ZHEJIANG HANYI ELECTROMECHANICAL CO LTD

Hydraulic pressure control device

InactiveUS20110302915A1Simple structureAppropriate settingFluid couplingsGearing controlEngineeringPiston

A hydraulic pressure control device including a valve for generating a circulating pressure to a hydraulic power transmission chamber in which power is transmitted between an input- and output side of a hydraulic power transmission element via hydraulic oil; and a valve for generating a lock-up pressure supplied to a lock-up chamber that faces the hydraulic power transmission chamber with a lock-up piston included in a lock-up clutch interposed therebetween. The hydraulic pressure control device controls the hydraulic pressures in the hydraulic power transmission chamber and in the lock-up chamber; and the circulating pressure valve has a spool to which the circulating pressure is applied as a feedback pressure and another hydraulic pressure is applied when the lock-up clutch is engaged / disengaged, and a spring urges the spool, and sets the circulating pressure to a constant first pressure when the lock-up clutch is disengaged and to a constant second different pressure when the lock-up clutch is engaged, depending on forces to the spool by the feedback pressure and on the spring.

Owner:AISIN AW CO LTD

Reversible pump-turbine installation

ActiveUS11300093B2Increase the number ofSuppress cavitationPump componentsWater-power plantsPower stationClassical mechanics

The present invention is a reversible pump-turbine installation positioned in a vertical borehole instead of in a conventional underground powerhouse or deep concrete powerhouse. The required plant cavitation coefficient may be achieved by simply boring a vertical borehole to the required depth rather than routing the water flow to and from a deeply buried powerhouse. A pneumatically controlled pressure relief valve may be incorporated into this invention.

Owner:BHE TURBOMACHINERY LLC

Special configuration blade for improving surface cavitation flow characteristics

ActiveCN108953217AReduce thicknessSuppress back jetPump componentsFinal product manufactureManufacturing technologySuction stress

The invention discloses a special configuration blade for improving surface cavitation flow characteristic, and belongs to the technical field of design and manufacturing of hydraulic machinery. According to the design, cavitation is inhibited through directly using a pit of a suction surface of the blade to influence jet flow and pressure distribution, so that a configuration which meets cavitation inhibition requirements and does not influence hydrodynamic performance of the blade is formed. According to the special configuration blade, the cavitation generation can be delayed, the jet flowcan be inhibited, so that the effect of reducing the influence of the cavitation on the hydraulic mechanical performance is achieved.

Owner:DALIAN UNIV OF TECH

Shock absorber

ActiveUS10012282B2Suppress cavitationSuppressing occurrenceSpringsLiquid based dampersEngineeringPiston rod

A flow of hydraulic oil induced by sliding movement of a piston in a cylinder is controlled by a damping force generating mechanism to generate a damping force. A flow of hydraulic oil from a casing of the damping force generating mechanism toward a reservoir is regulated by a passage groove formed on the bottom of the casing so as to be directed downward in the reservoir. Thus, the hydraulic oil is efficiently supplied to a base valve from the damping force generating mechanism even when the hydraulic oil is sucked from the reservoir into a cylinder lower chamber through a passage in the base valve during the extension stroke of a piston rod. Therefore, it is possible to suppress a sharp reduction in pressure in the lower part of the reservoir and hence possible to suppress the occurrence of aeration and to obtain stable damping force characteristics.

Owner:HITACHI ASTEMO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com