low noise control valve

A control valve, low-noise technology, applied in valve details, valve device, valve device for absorbing fluid energy, etc., can solve the problems of component or system damage and fracture, auditory fatigue of production personnel, poor working comfort, etc., to achieve attenuation of fluid Fluctuating pressure, compact structure, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

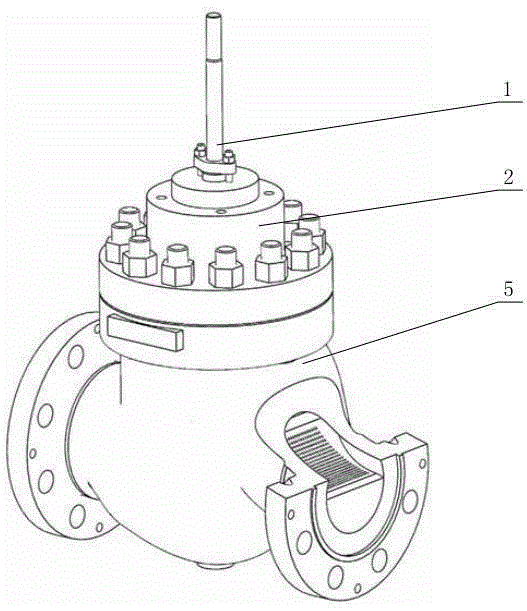

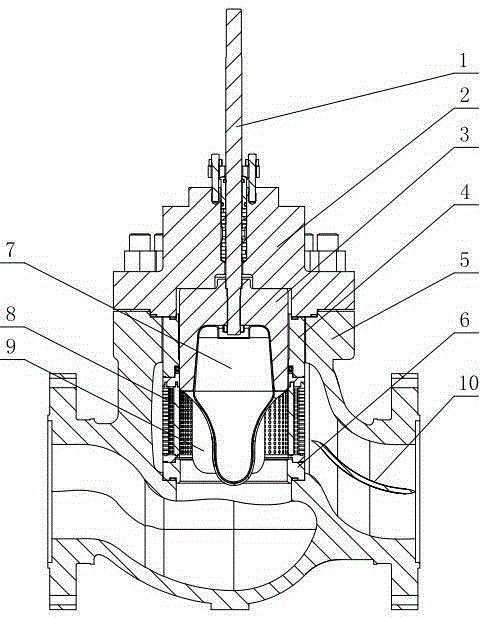

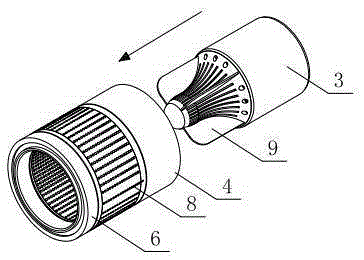

[0031] Such as figure 1 and figure 2 As shown, the low-noise control valve of this embodiment includes a valve body 5, the valve plug 3 is installed in the middle of the valve body 5 through the upper valve seat 4, and the valve cover 2 is installed on the top of the valve plug 3, which is located in the middle of the valve cover 2 and the valve plug 3 The valve stem 1 is installed at the opening; the upper part of the elastic airbag cavity 7 is clamped in the valve plug 3, and the lower part of the elastic airbag cavity 7 is installed in the inflow guide device 9, which is connected to the valve plug 3 through bolts 11, A valve sleeve 8 is installed on the outer end of the inflow diversion device 9, and the valve sleeve 8 is installed on the lower valve seat 6; a sandwich outlet rectification device 10 is welded on the outlet pipe wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com