A low frequency-oriented pulsation pressure attenuation device and its performance testing method

A technology of pulsating pressure and attenuation devices, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. It can solve the problems of large volume, poor adaptability, and single attenuation frequency band of resistive filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

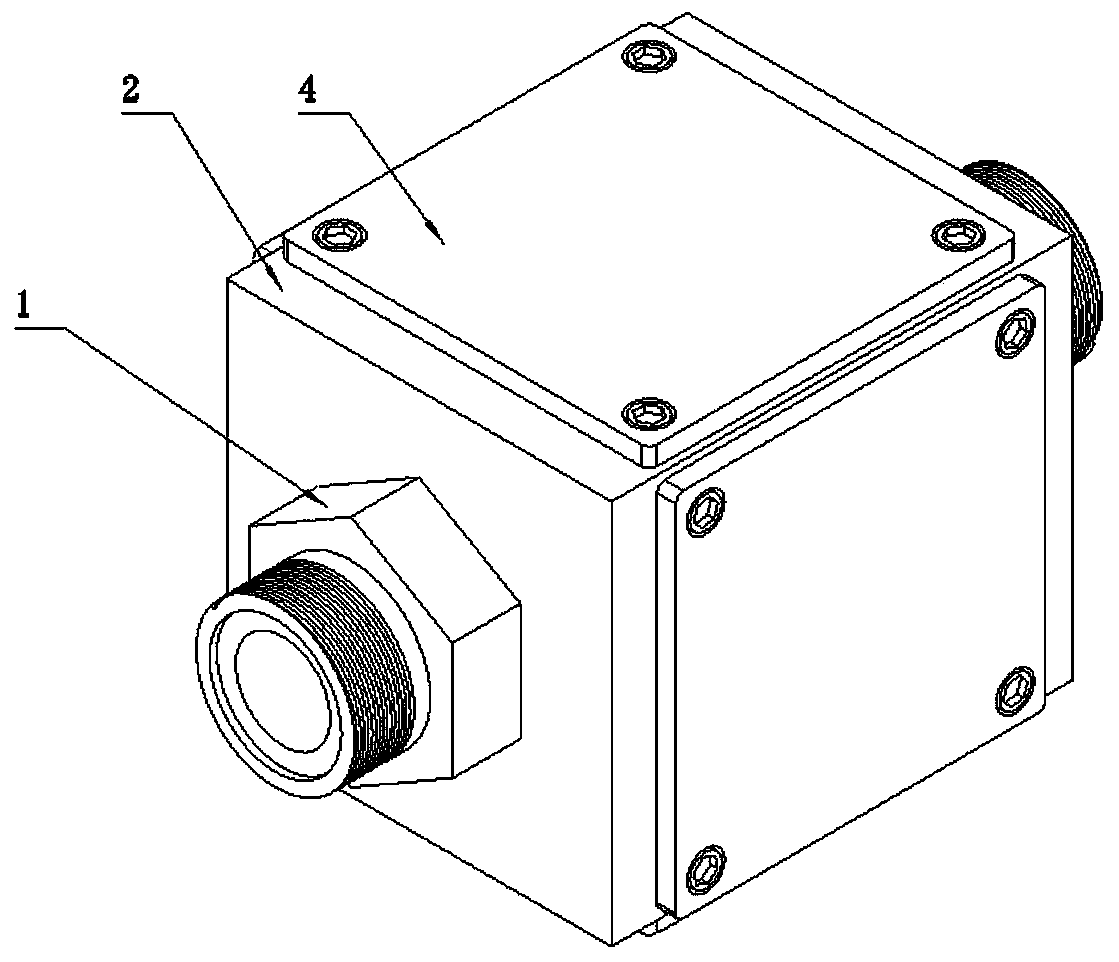

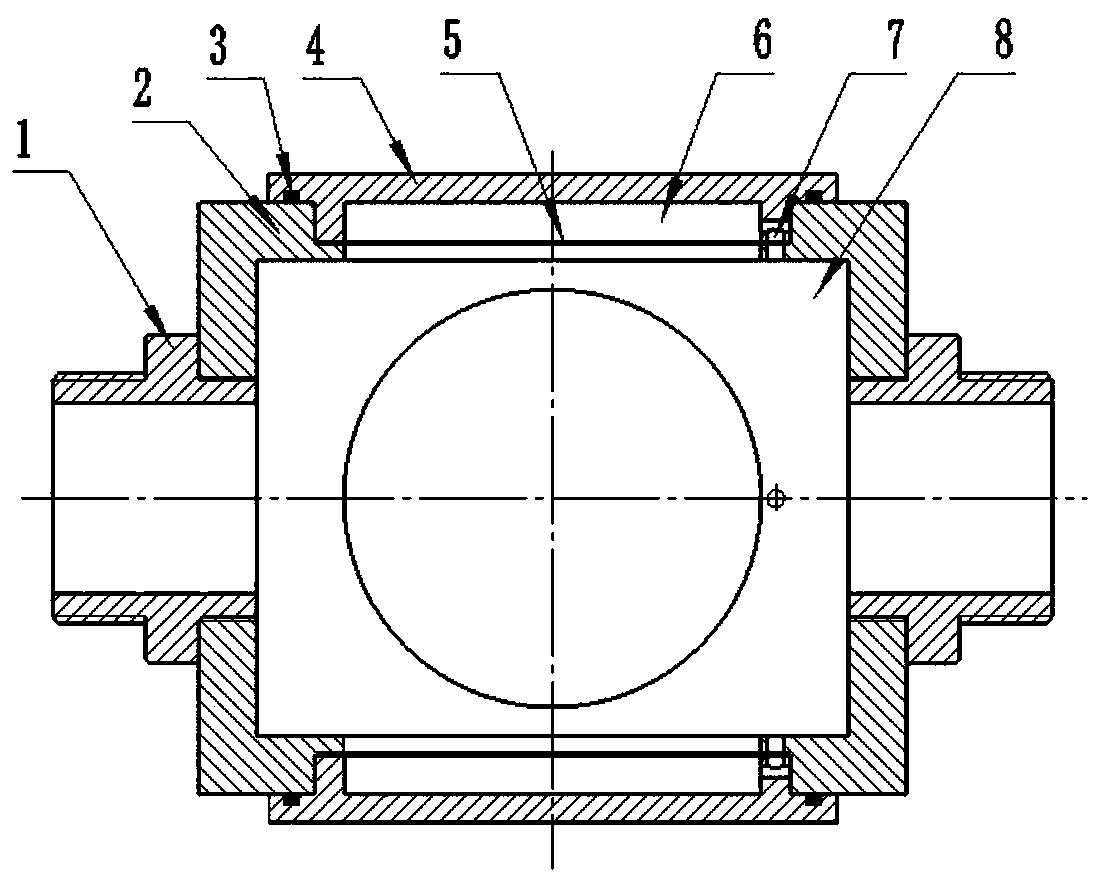

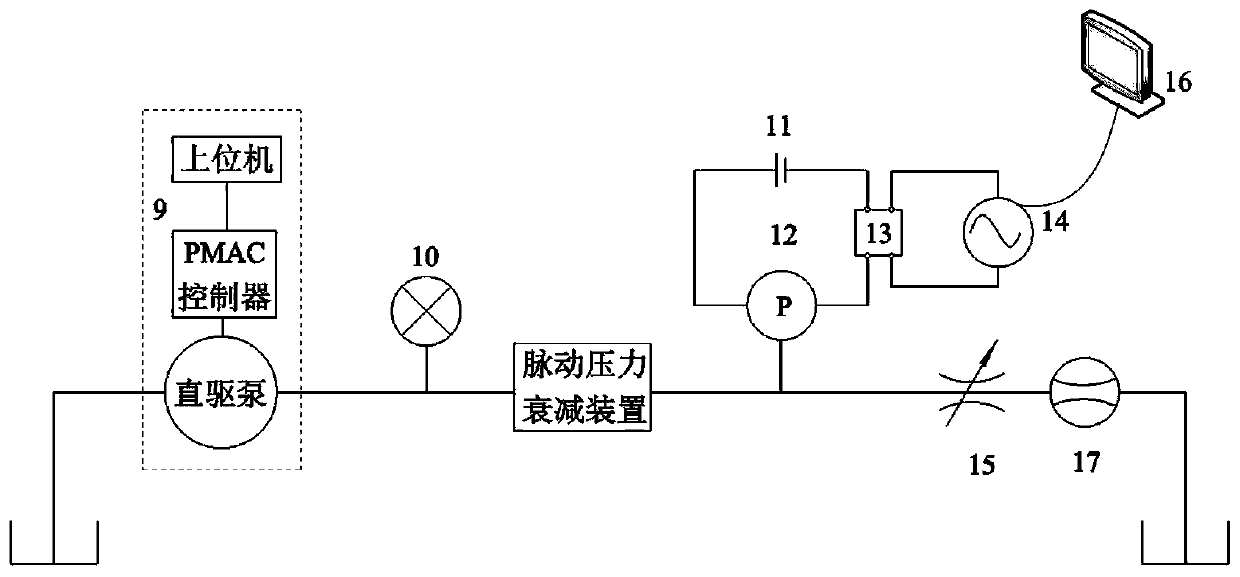

[0029] Such as figure 1 , 2 As shown, a pulsating pressure attenuation device for low frequency is mainly composed of pipe joint (1), shell (2), O-ring (3), gland (4), elastic sheet (5) and hexagon socket bolt and so on. The shell is welded by stainless steel sheets and encloses the main chamber (8); round recesses with different diameters are respectively processed around the shell (2), and the elastic thin plate is placed on the recesses, and the gland (4 ), the static pressure balance cavity (6) is formed between the two, and the diameters of the elastic thin plates (5) are different, and their first-order natural frequencies are respectively the fundamental frequency to the fourth harmonic of the direct-drive pump outlet pressure pulsation The wave frequency is equal; the gland (4) is tightly connected to the shell (2) through the inner hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com