Patents

Literature

42results about How to "Change flow pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

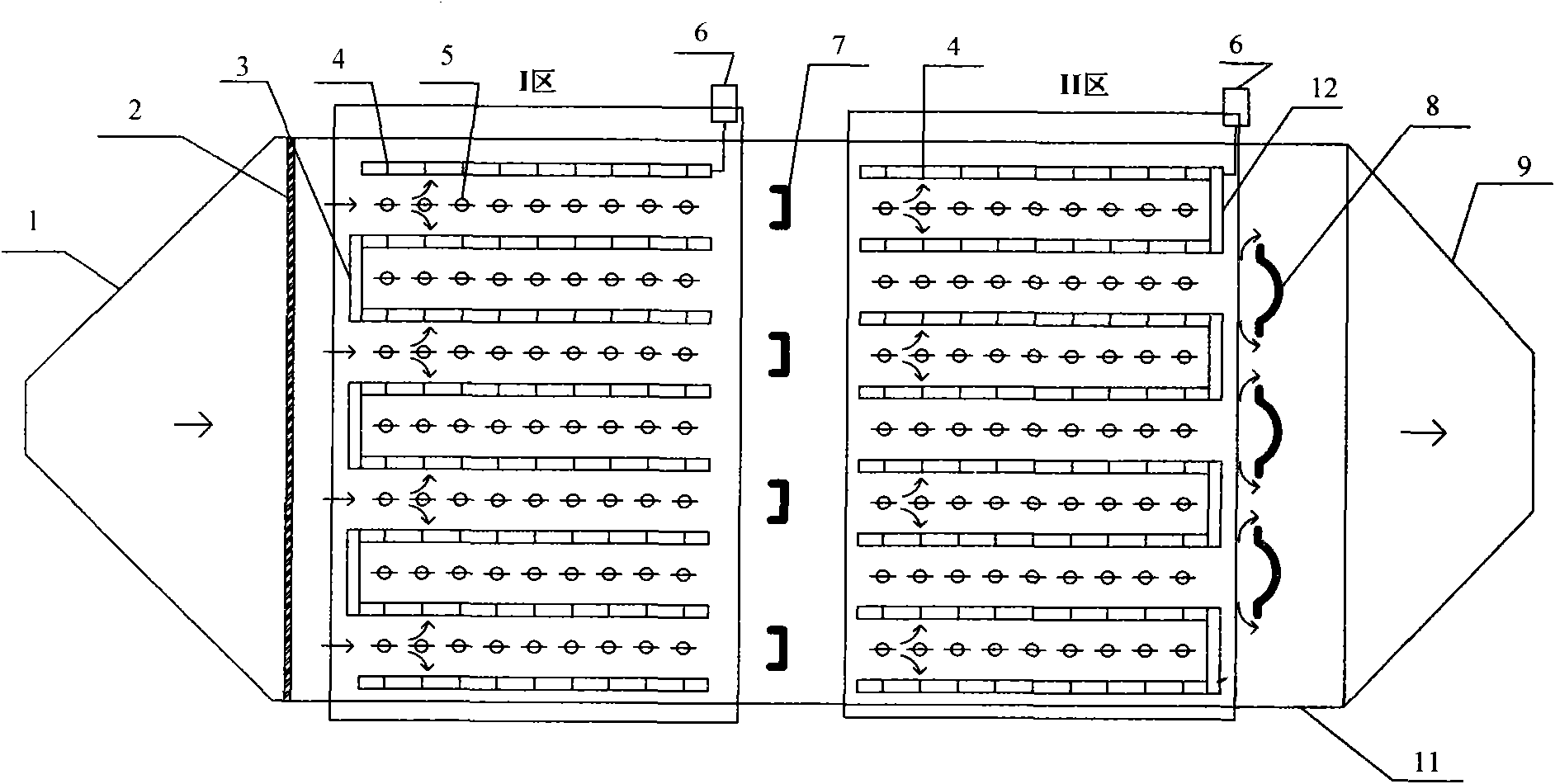

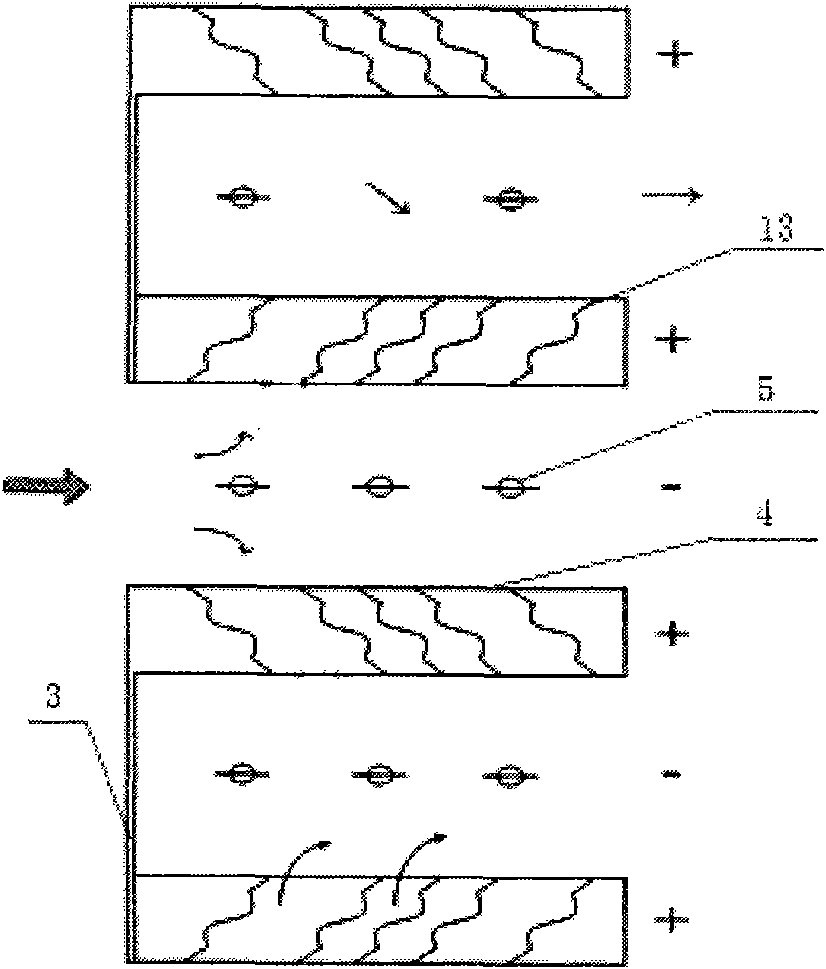

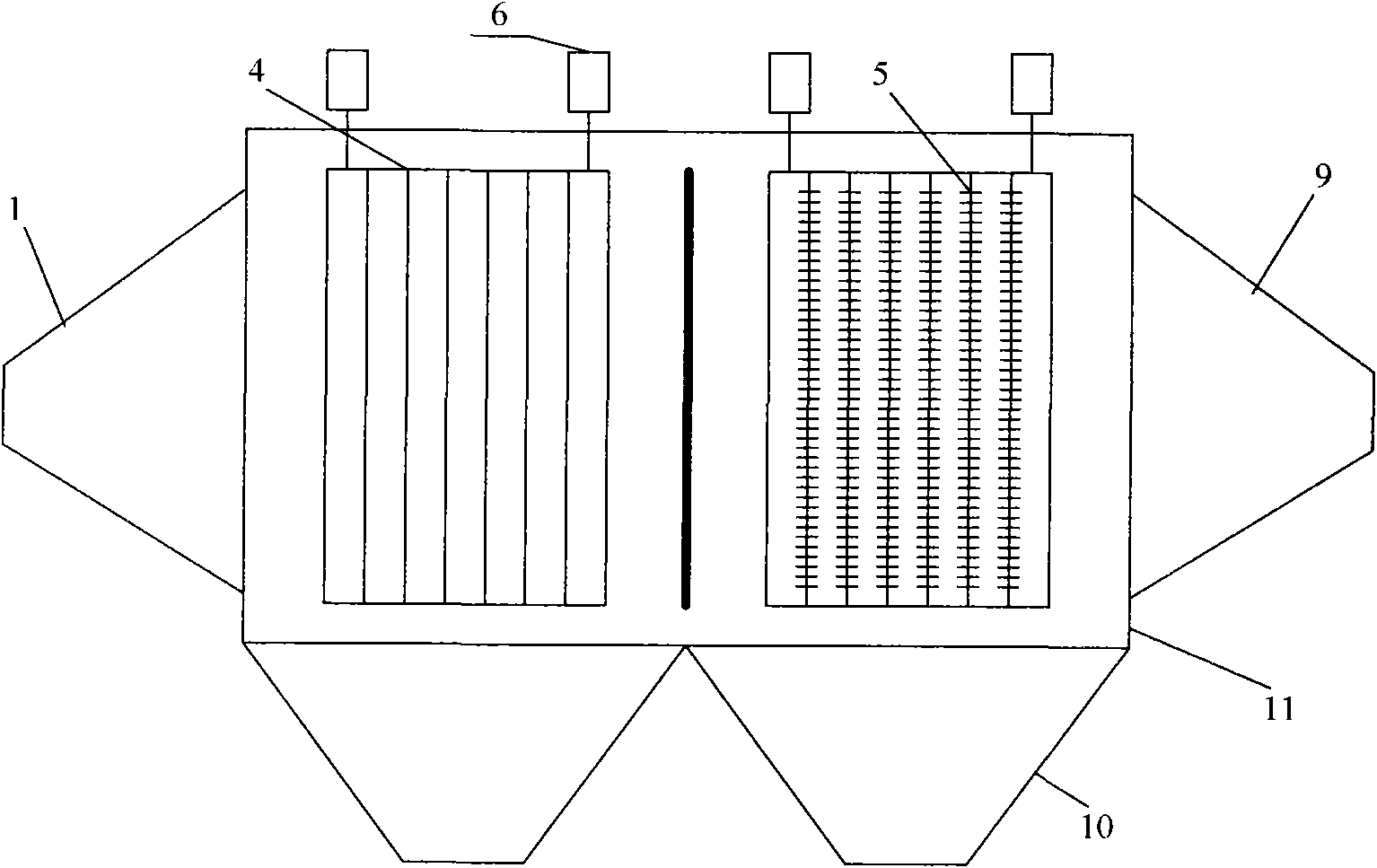

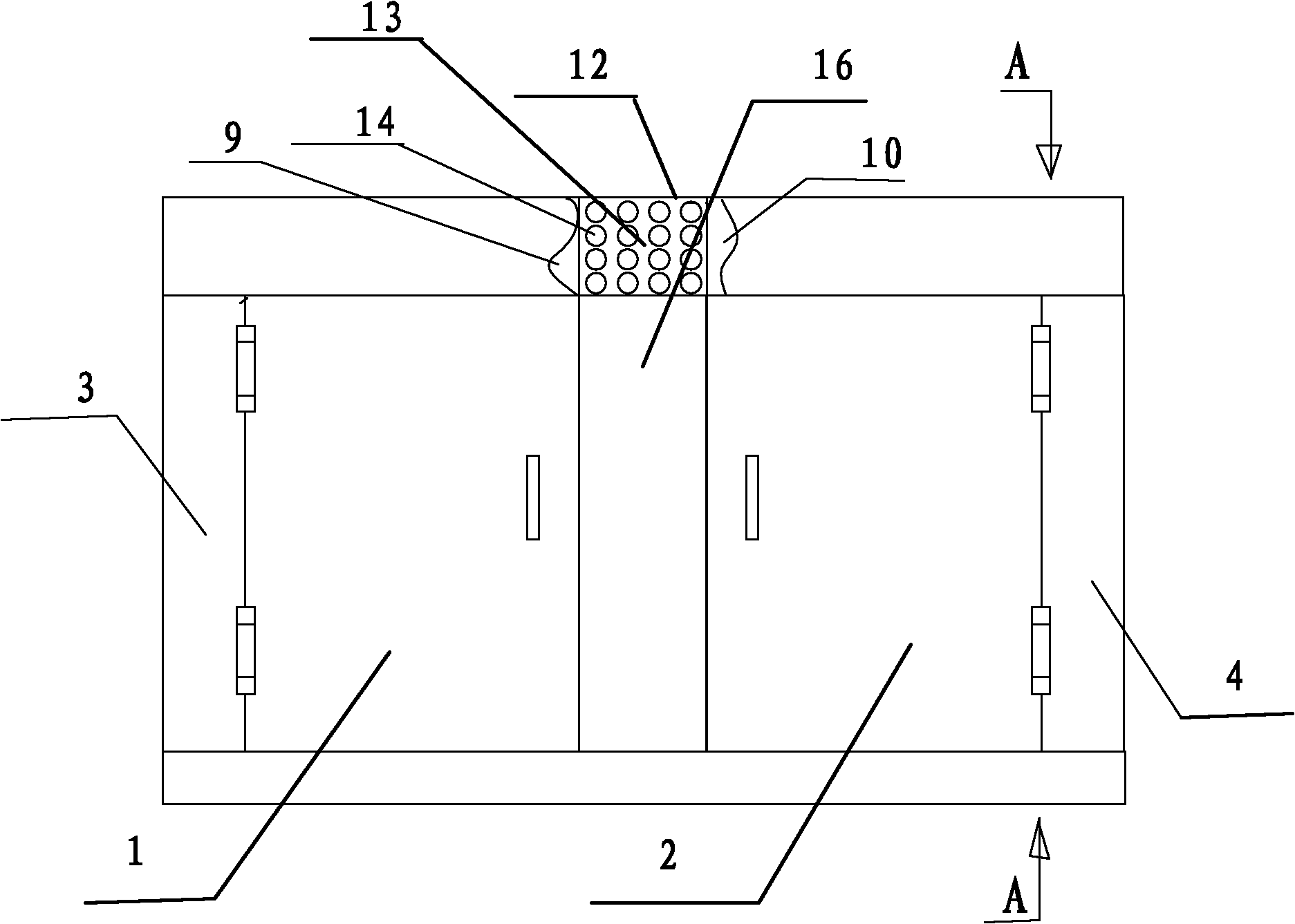

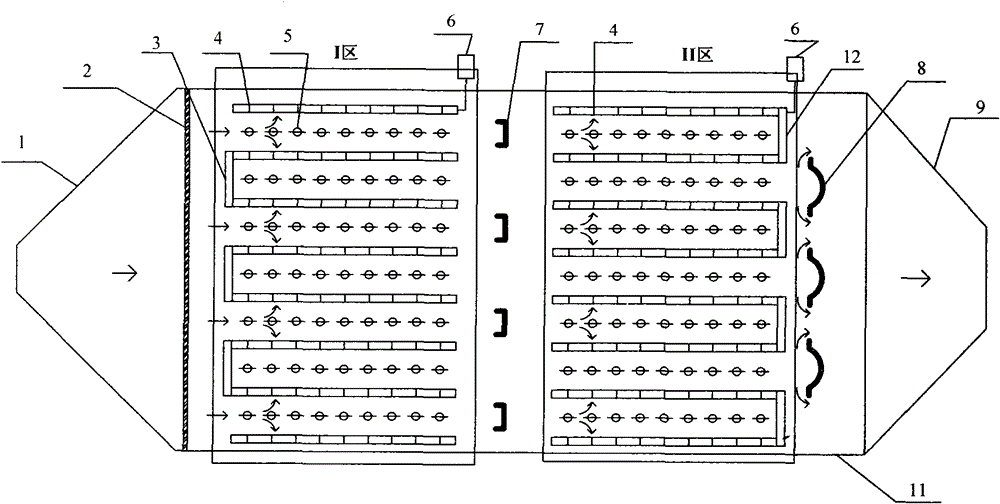

Mixed-flow electric dust collector

ActiveCN101862705AAvoid affecting the dust collection effectReduce volumeExternal electric electrostatic seperatorElectrode constructionsMixed flowEqualization

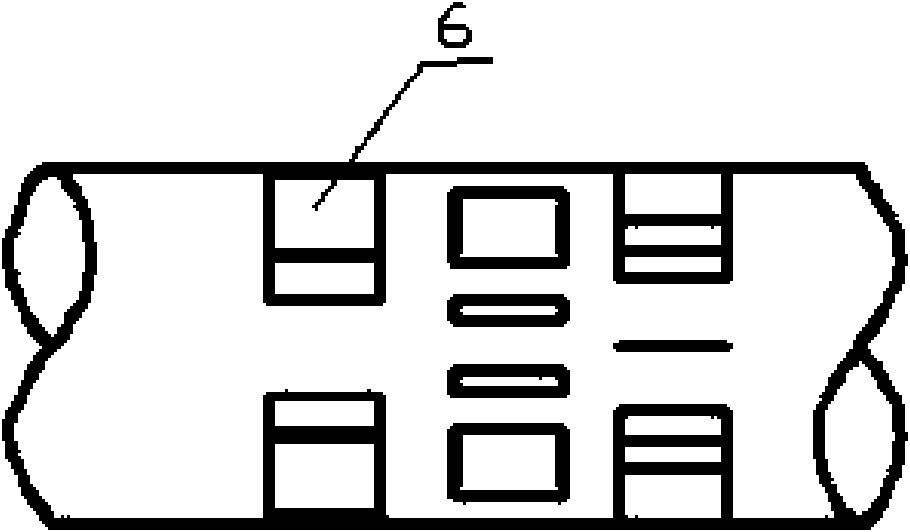

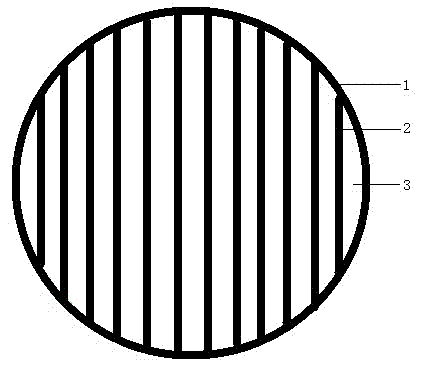

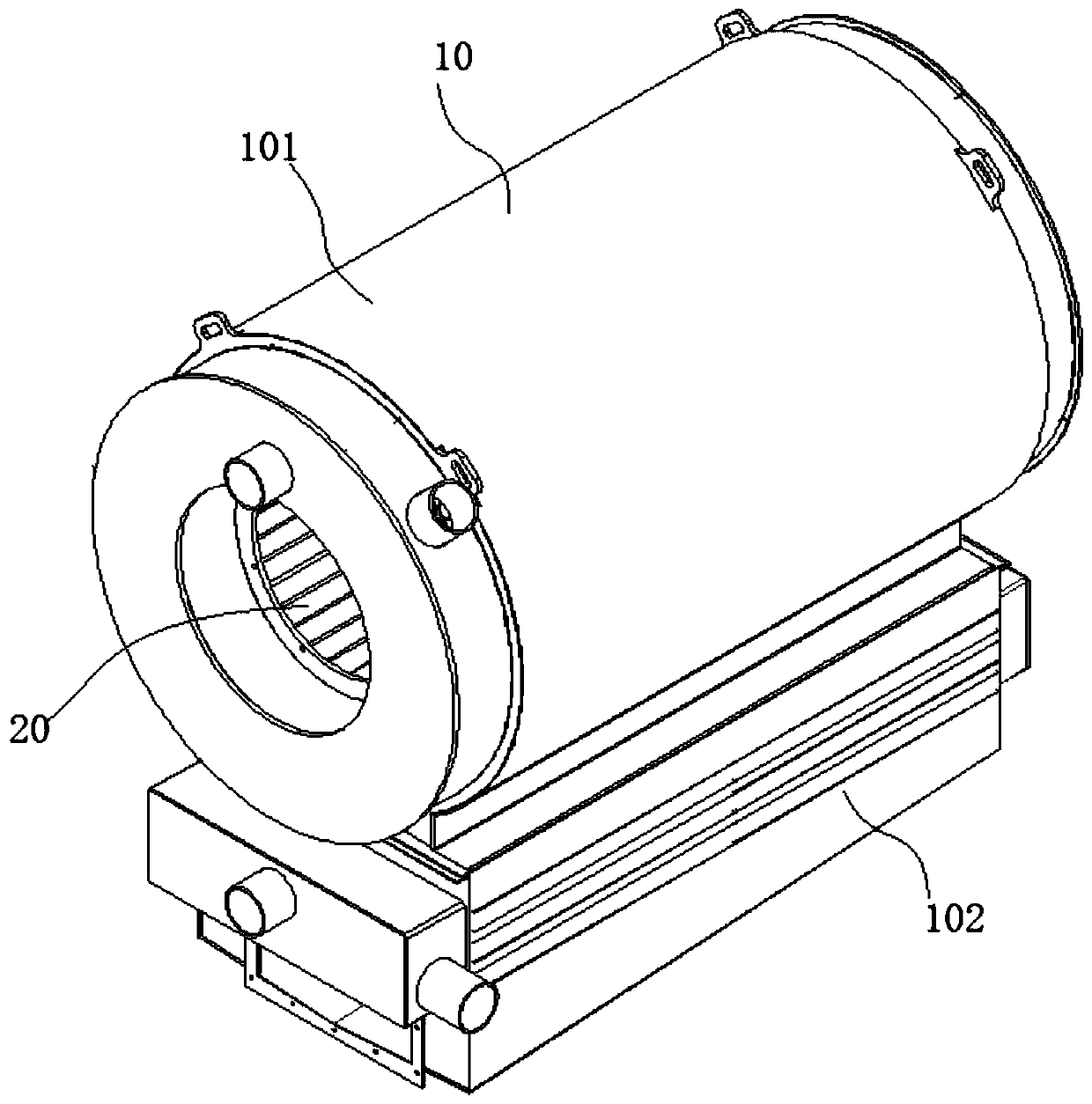

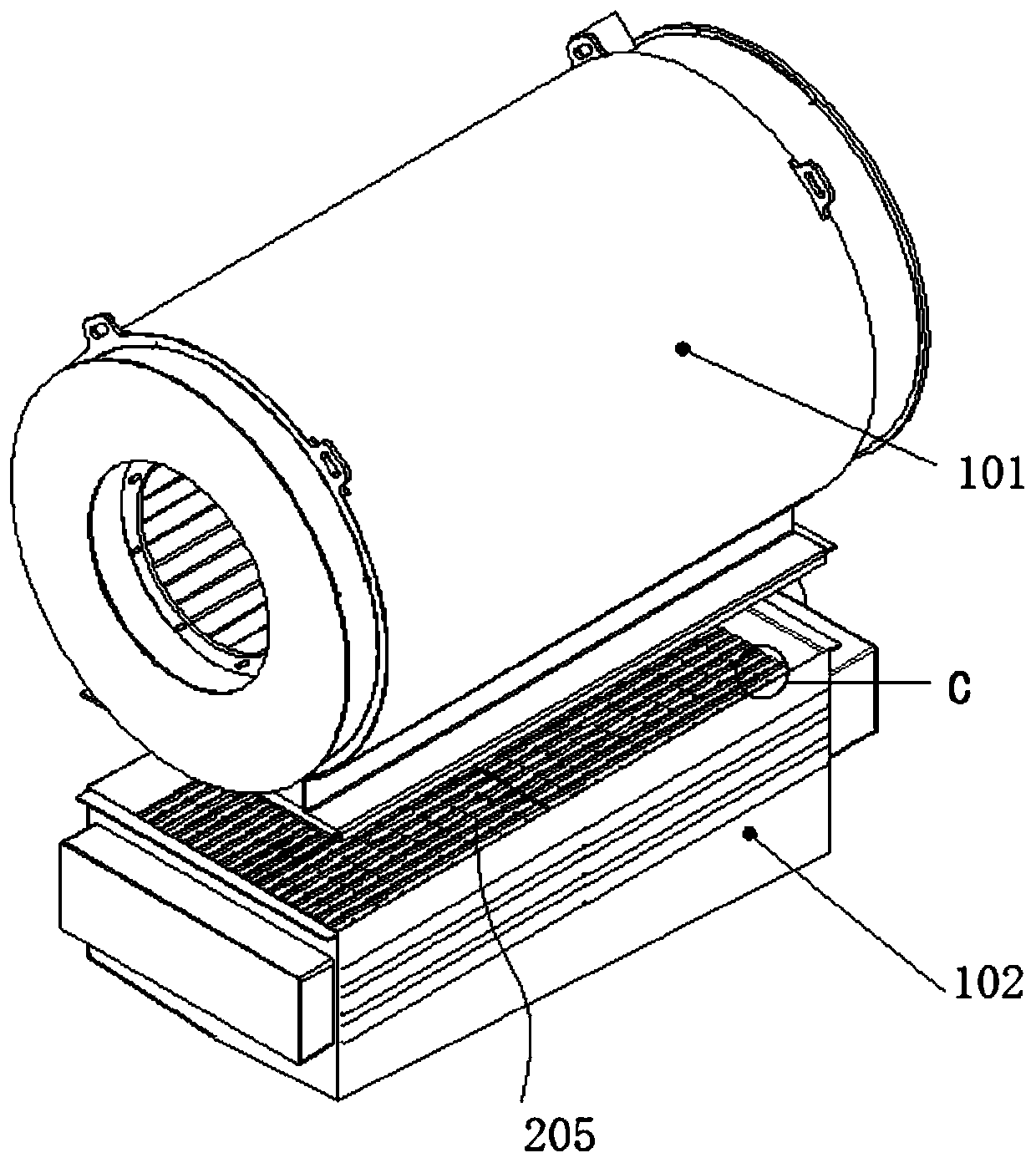

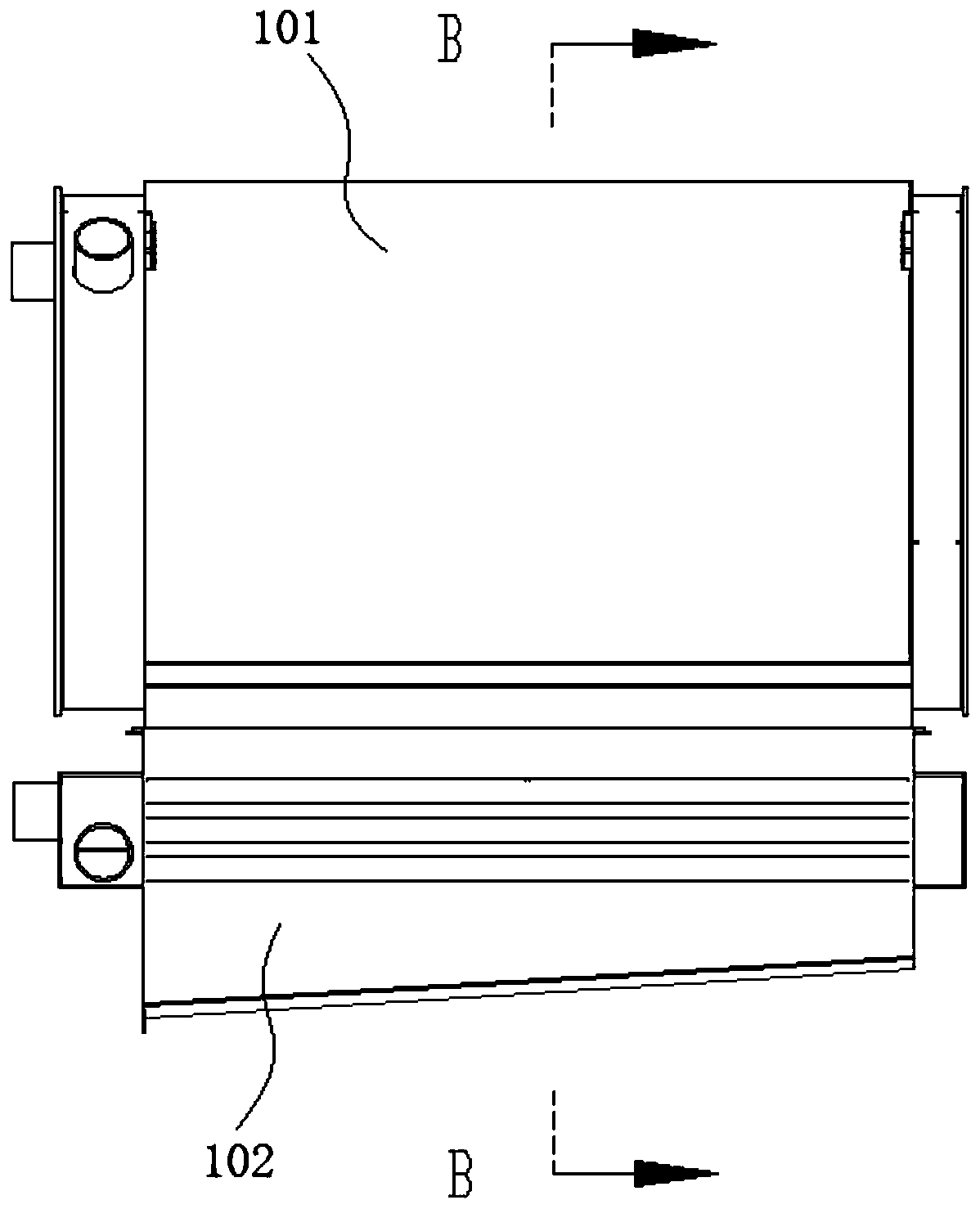

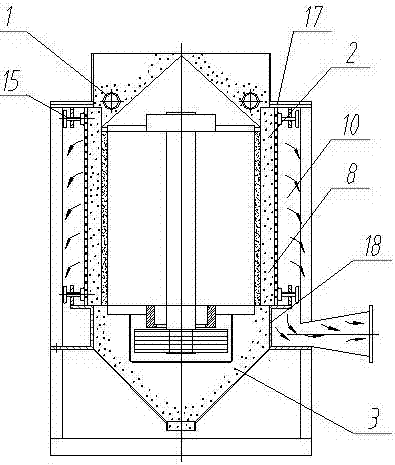

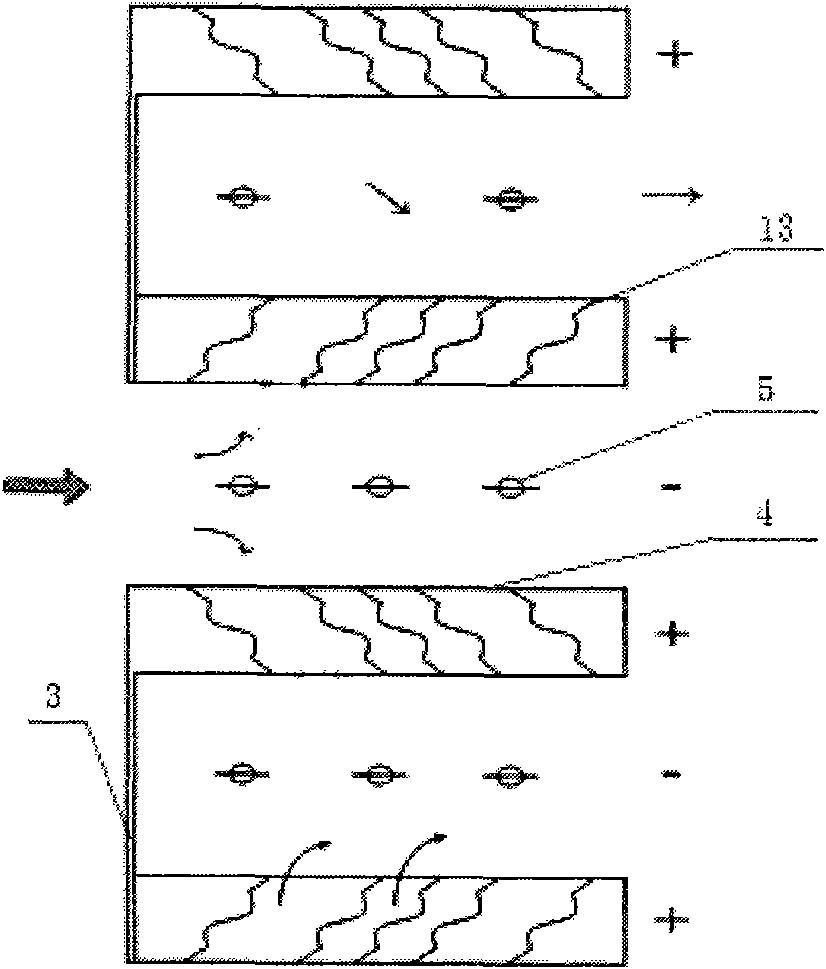

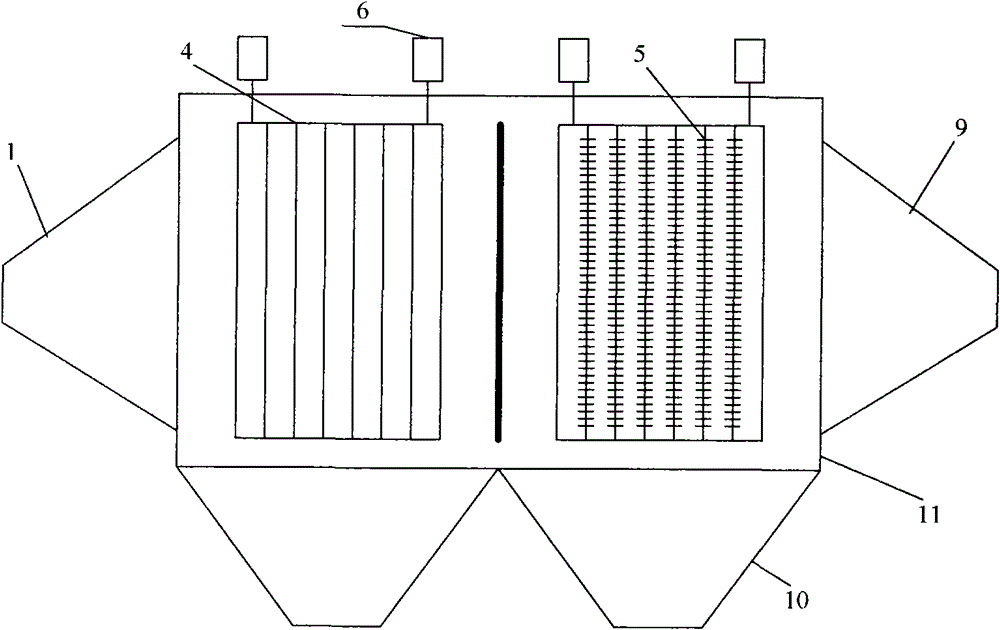

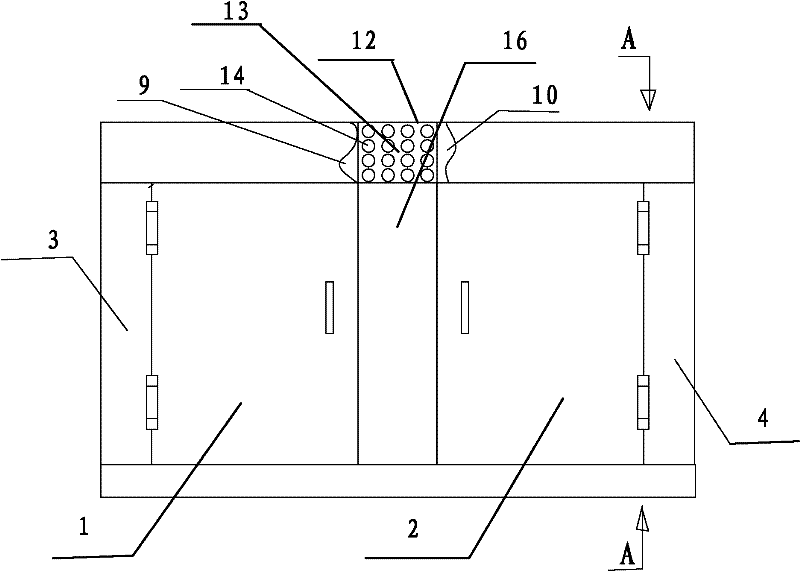

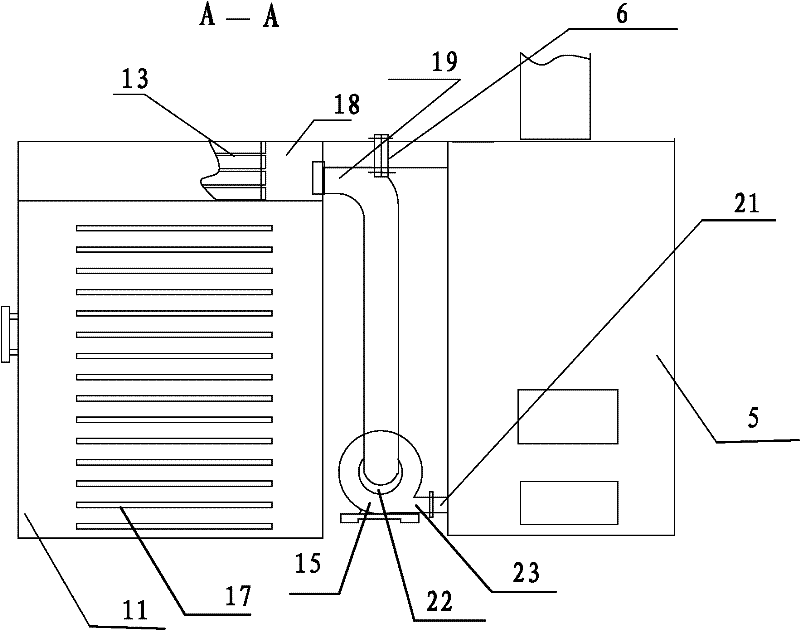

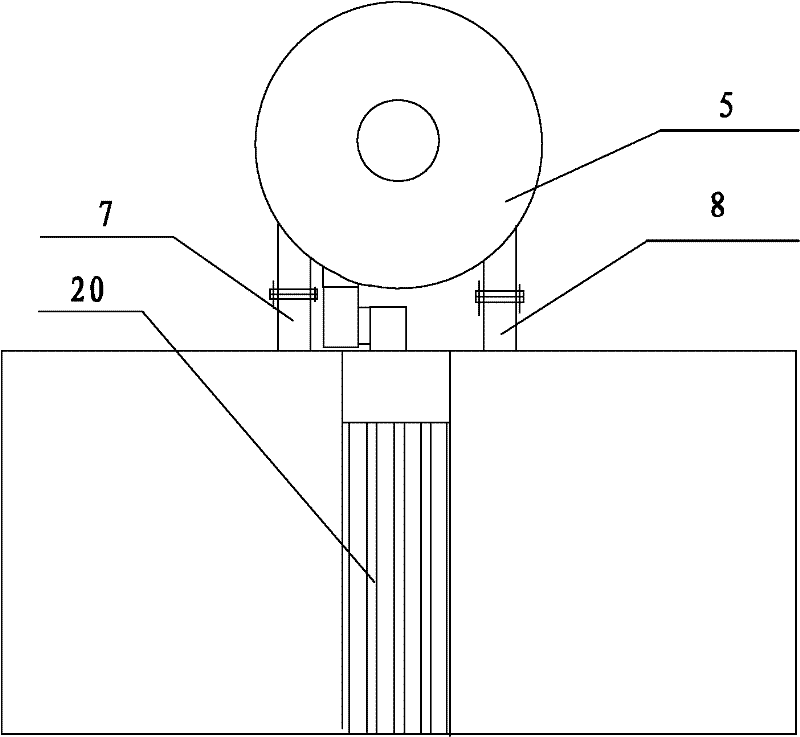

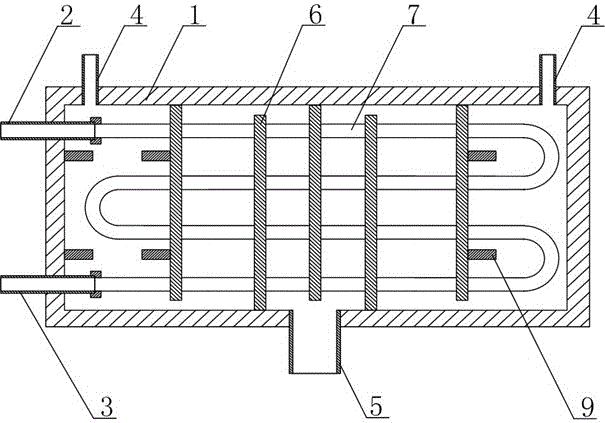

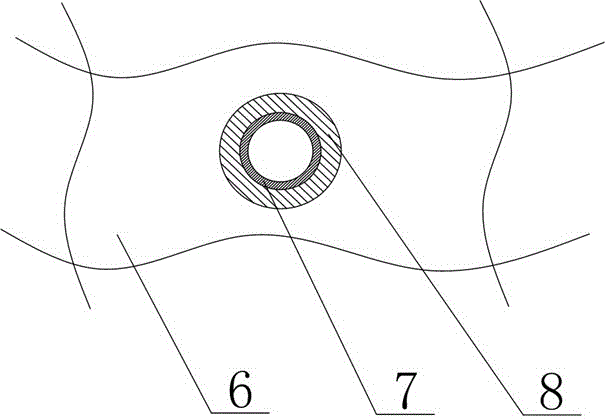

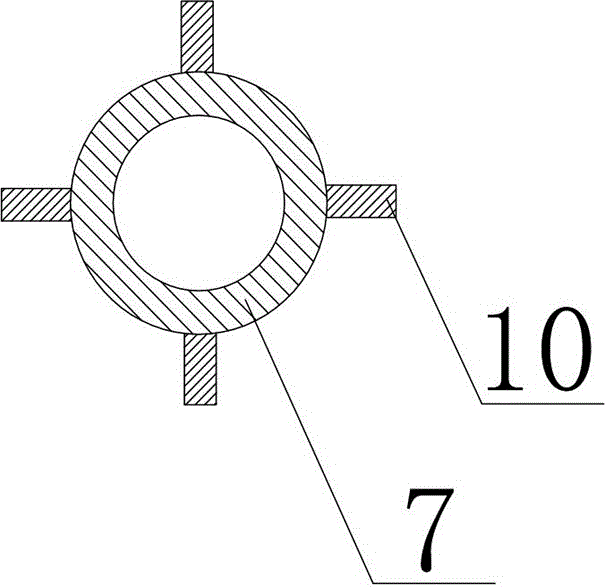

The invention relates to a mixed-flow electric dust collector, wherein an air flow distribution plate is arranged at the joint of a dust removing chamber and a smoke inlet; a first vertical electric field and a second vertical electric field, through which an air flow flows, are arranged in the dust removing chamber; parallel dust collecting electrodes are distributed in the electric fields at equal interval; main air flow channels are formed among the dust collecting electrodes; a corona electrode is arranged between adjacent dust collecting electrodes; some of the air flow channels are provided with an incoming air flow baffle at an air flow inlet, and the other air flow channels are provided with an outgoing air flow baffle at an air flow outlet; a plurality of dust collecting electrode plates are arranged on the dust collecting electrodes and fixed in the dust collecting electrode in a separated manner; and the main air flow channels are provided with a plurality of air equalization plates having through holes on the surface at the outlet of the first electric field and baffles at the outlet of the second electric field. With simple structure and few electric fields, the invention solves the problem that the conventional dust collector has poor dust removal effect, large size, complicated structure and high cost.

Owner:浙江海宁经编产业园区开发有限公司

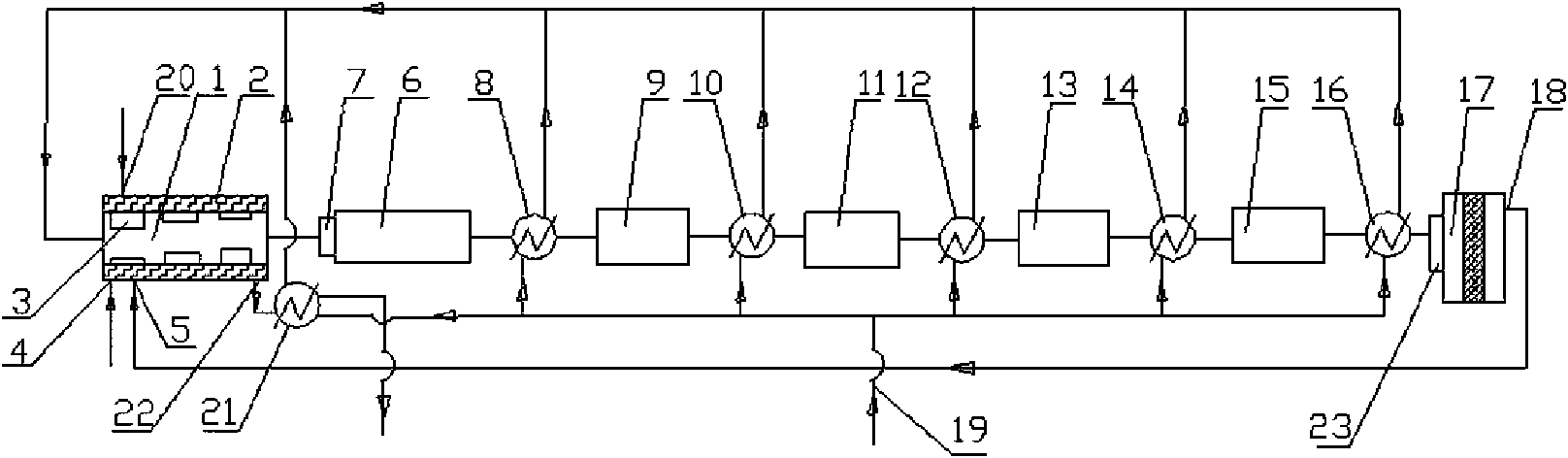

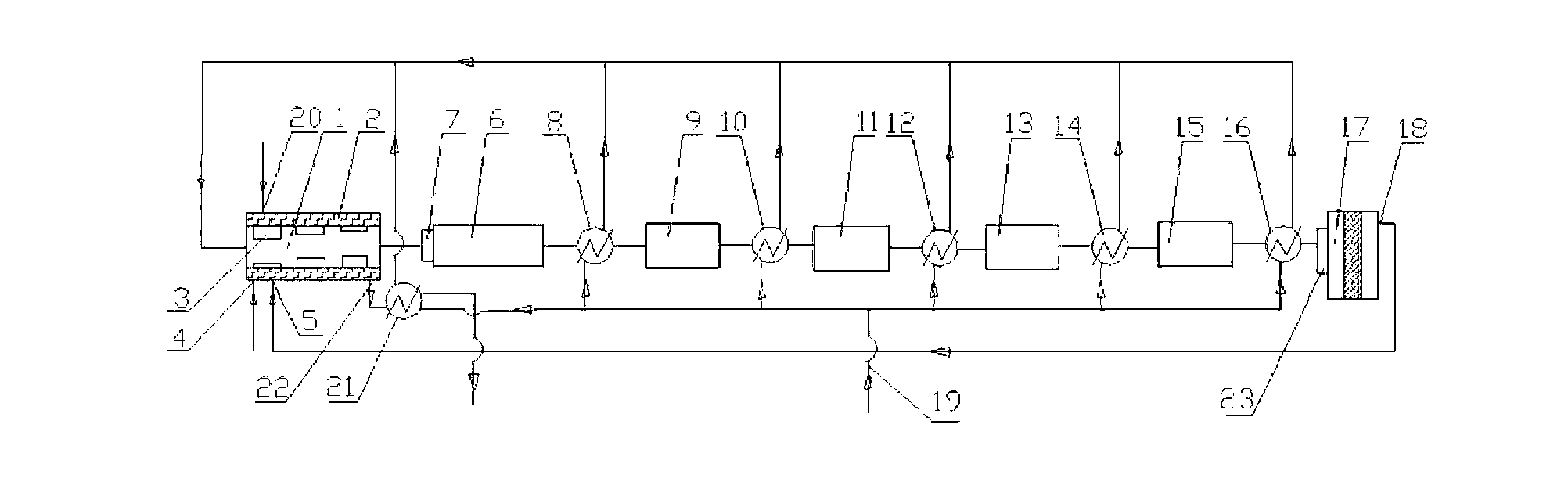

Hydrogen production system employing reforming technology

ActiveCN101624178AReasonable structureBurns and heats evenlyHydrogenChemical industryExhaust gasProcess engineering

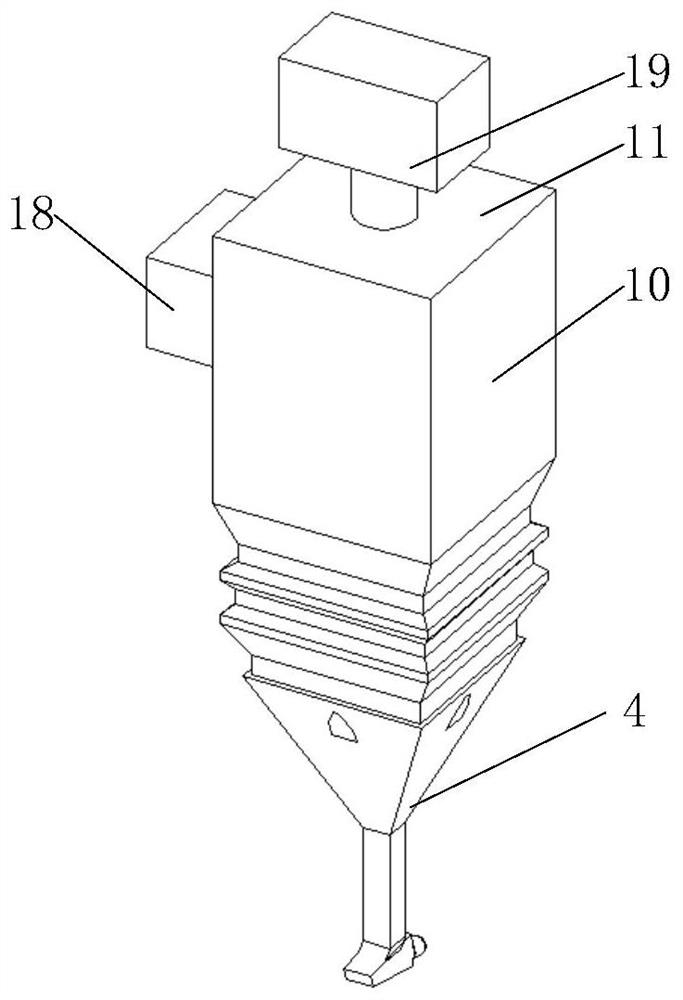

The invention discloses a hydrogen production system employing reforming technology, in particular to a sleeve type hydrogen enriched fuel hydrogen production system employing reforming technology with highly efficient heat and mass transfer. The system comprises a heat supply unit, a reformer and a CO purification and elimination unit; wherein, the outlet of the reformer is communicated with theinlet of the CO purification and elimination unit through a heat exchanger, the outlet of the CO purification and elimination unit is communicated with the hydrogen inlet of a fuel cell; the heat supply unit has a two-layer sleeve barrel structure, the outer cavity is a combustion heat-providing cavity, the inner cavity is a raw material heating cavity, an enriched fuel inlet, an oxidant gas inlet and a hydrogen inlet are arranged on the combustion heat-providing cavity, the exhaust gas outlet of the fuel cell is communicated with the hydrogen inlet on the combustion heat-providing cavity; the outlet of the raw material heating cavity is communicated with the inlet of the reformer; at least two groups of fins are arranged on the inner wall of the raw material heating cavity axially. The system has reasonable structure, the burning and the heating are uniform, the catalyst is not easy to sinter, the performances of the mass transfer and the heat transfer are good and the energy efficiency is high.

Owner:HANERGY TECH

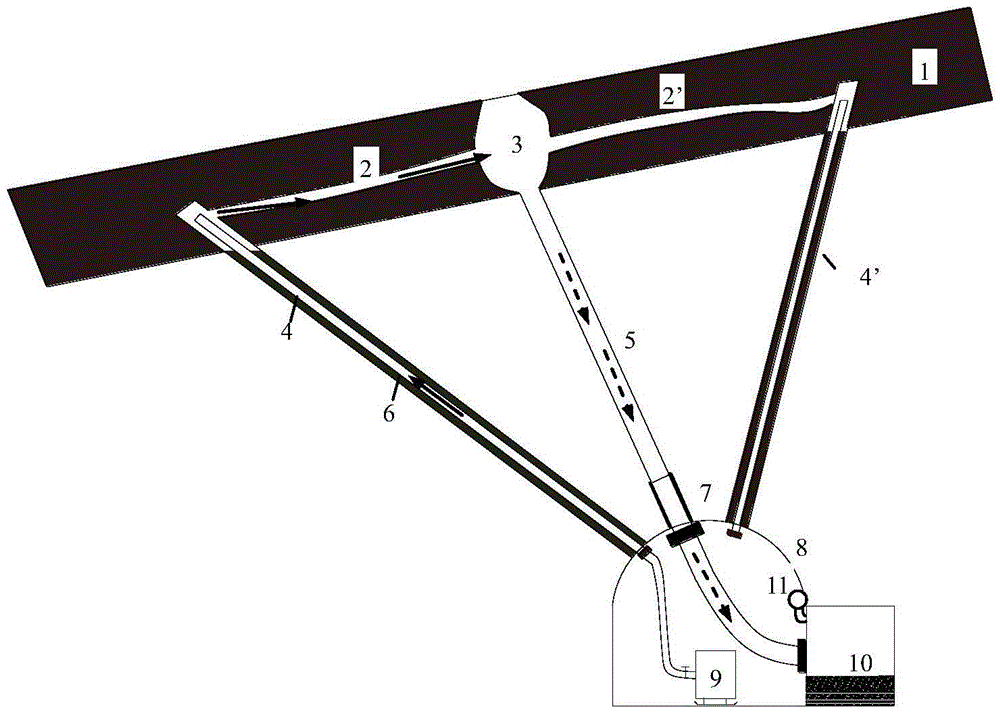

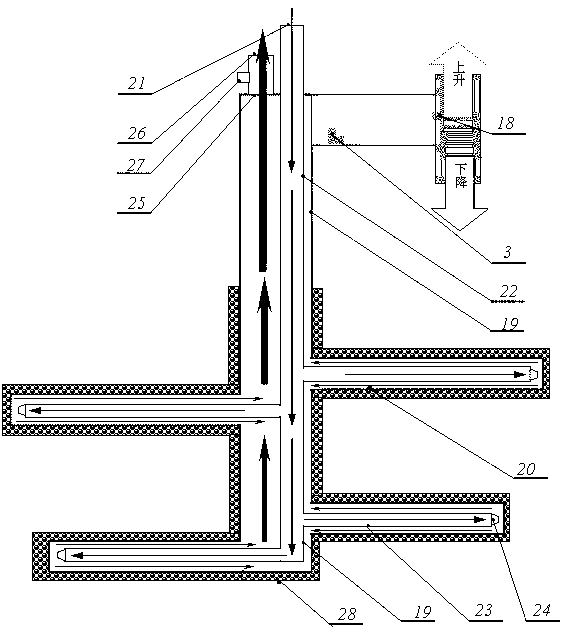

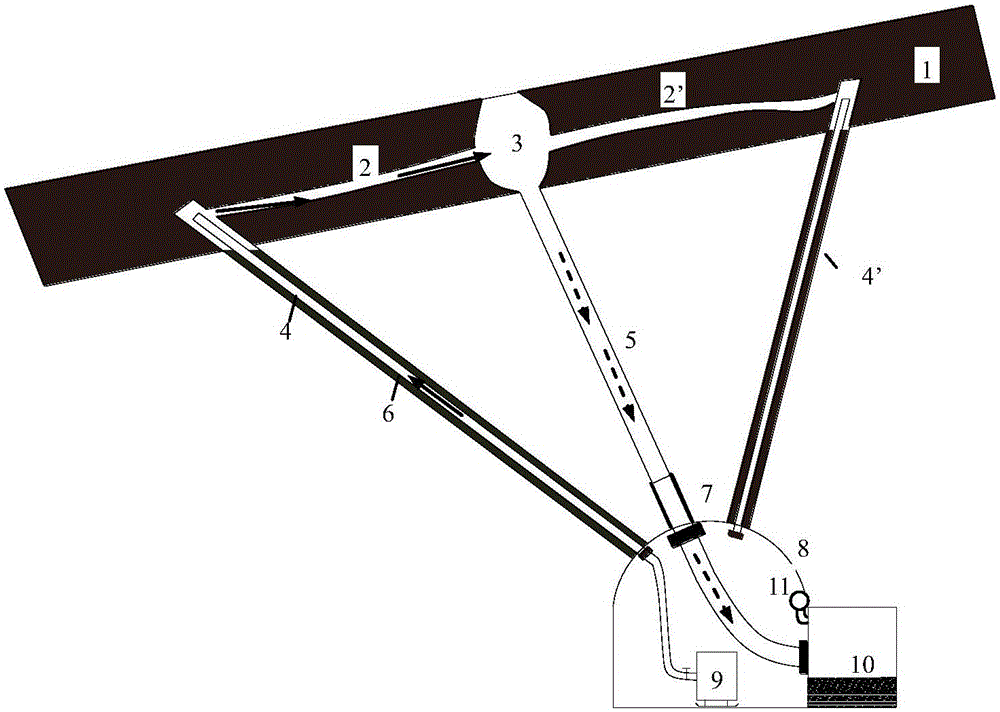

Seam-penetrating drilling hydrofracturing gas extracting method

Provided is a seam-penetrating drilling hydrofracturing gas extracting method. The method includes that a target drill hole and a hole for penetrating a coal seam are preset as a hydrofracturing free surface; a chambering section of the target drill hole is expanded, and a sleeve is put into the drill hole, fixed and connected with a separating chamber. High-pressure water enters the fracturing drill hole to fracture a coal body, and a fracturing gap is gradually expanded until the gap is communicated with the hole. The water pressure and water amount are increased, and the coal body around the gap is washed. Water flow carries gas and the coal body to pass through the target drill hole to enter the chamber, the gas is extracted, and separation of the gas is achieved. After the coal body is washed, a macro gap communicating the fracturing drill hole and the target drill hole is formed. During extraction, the gas leaks into the gap, flows into the target drill hole and the hydrofracturing drill hole, and a gas flowing mode is changed fundamentally. The gap is equivalent to extension of the length of the target drill hole and the hydrofracturing drill hole in the coal seam, contact area between the gap and the coal body is increased, and a gas extraction effect can be improved.

Owner:CHINA UNIV OF MINING & TECH

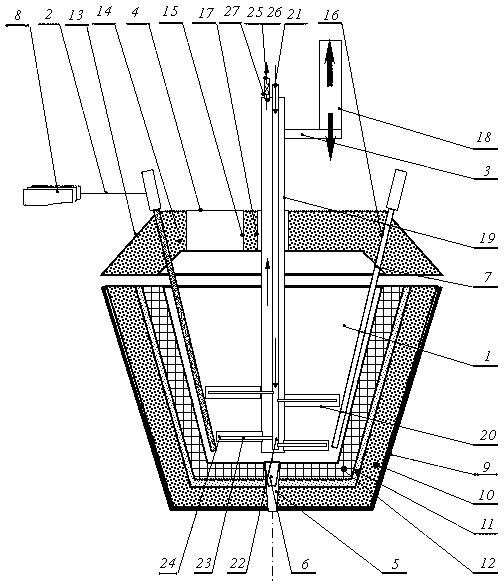

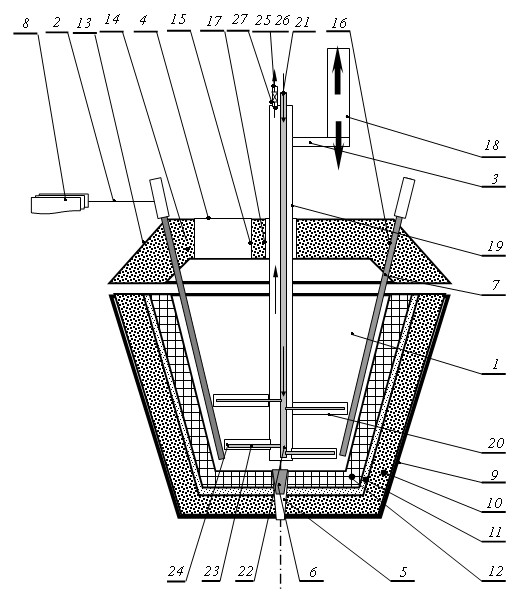

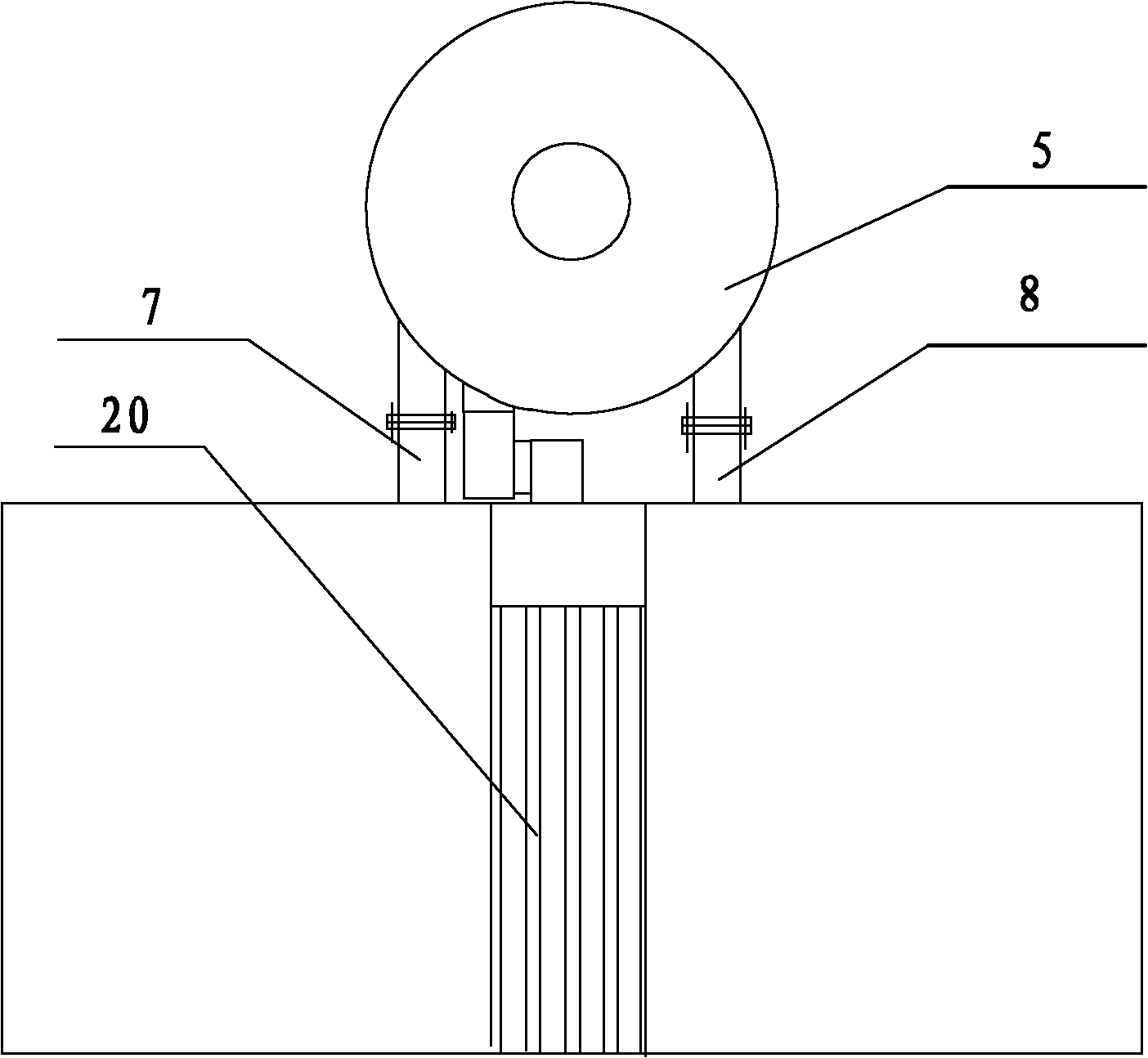

Device and method for homogenizing high-temperature melt

InactiveCN102698634AStirring power is smallIncrease the stirring areaRotary stirring mixersTransportation and packagingSlagHeating system

The invention provides a device and a method for homogenizing high-temperature melt and belongs to the technical field of melt homogenization. The device provided by the invention consists of three parts, namely a melting tank, a stirring system and a heating system. The detailed steps for homogenizing high-temperature melt carried out by the device provided by the invention are as follows: adding hot silicate slag and quenching-tempering material into the melting tank; after heating to melt the raw material, turning off the power supply; enabling the stirring part of the cooled stirring system to fall into the high-temperature melt, and finishing fall-rise-fall operating actions for stirring the melt in order, wherein the stirring process and the heating process are carried out alternatively; and under the condition that the test result of the samples shows that the composition uniformity and viscosity of the melt are suitable for the process conditions that the fiber is formed or the glass ceramics is prepared, opening a choke plug of the melting tank and making the melt flow out via the flow hole by the gravity of the melt to finish the homogenization process. The homogenizing device and the homogenizing method, provided by the invention, have the advantages of good homogenizing effect, good high-temperature strength and long service life of the stirring part.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

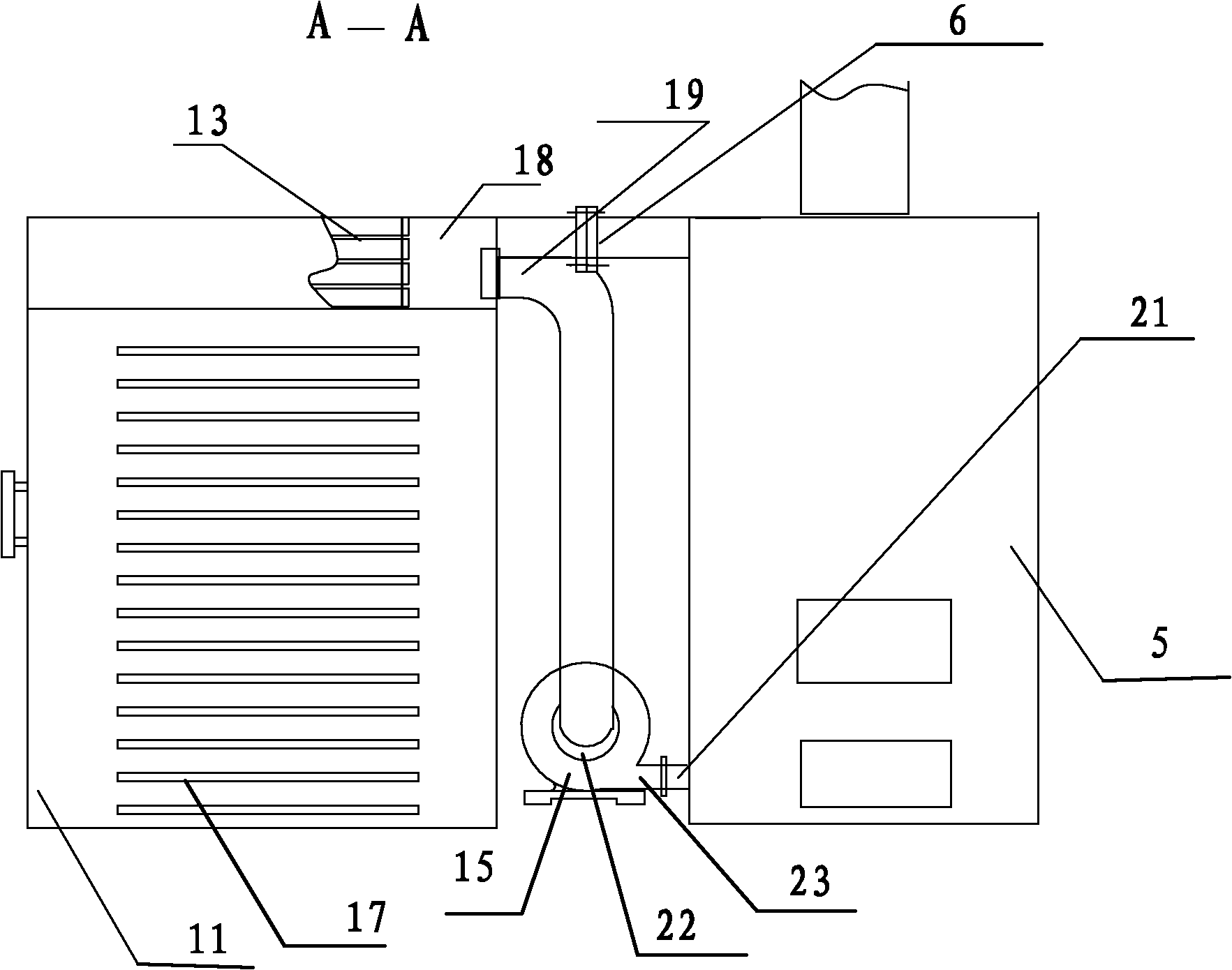

Drying boxes for hot-blast air furnace

InactiveCN102072619AUniform temperatureChange flow patternDrying gas arrangementsDrying machines with local agitationElectricityPulp and paper industry

The invention relates to drying boxes for a hot-blast air furnace. A humidity-discharging box is arranged in the middle of left and right drying boxes; balanced hot-blast air boxes are arranged at left and right ends of the left and right drying boxes; a waste heat recovery box is arranged on the top of the humidity-discharging box; a tube type heat exchanger is arranged in the waste heat recovery box; the bottom of the tube type heat exchanger is communicated with the humidity-discharging box; a fresh air suction inlet is formed at the front end of the tube type heat exchanger, and an air-collecting box is arranged at the rear end of the tube type heat exchanger; the end part of the air-collecting box is connected with the air inlet of a centrifugal fan; the air outlet of the centrifugal fan is connected with the air inlet of a hot-blast air furnace; and the top of the waste heat recovery box is opening and is used as a humidity-discharging opening. In the drying boxes, a mode of hot-blast air flowing is changed effectively, so that wind resistance is small; and the relatively-small fan can be selected, electricity is saved, the temperature in the drying boxes is uniform, the drying quality is improved, and energy is saved for a considerable part of heat energy is recovered in discharged damp and hot air.

Owner:如皋市精艺标牌厂

Rotor cover shell structure inside rotating disk cavity and engine comprising same

ActiveCN107725479ALower spin ratioRotation Ratio AdjustmentPump componentsPumpsEngineeringProcessing cost

The invention relates to a bent-type rotor cover shell structure inside a centripetal inflow rotor-stator system rotating disk cavity. The bent-type rotor cover shell structure can be applied to the fields such as ground gas turbines and aero-engines. According to the unique characteristics of the bent-type rotor cover shell structure, the bent-type rotor cover shell structure formed through metalplates is applied to the low-radius position inside the rotor-stator system rotating disk cavity, through the light rotor cover shell structure, the rotating ratio of an air flow flowing inwards at the low-radius position is decreased, and thus the purpose that the flowing loss of the air flow in the inward flowing process is reduced is achieved. The bent-type rotor cover shell structure suitablefor the interior of the centripetal rotor-stator system rotating disk cavity has the effects that lightweight is achieved, the structure is simple, the processing cost is low, the rotating ratio of the air flow is reduced, and the air flow pressure in the disk cavity is increased, so that the great prospects of engineering application are achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

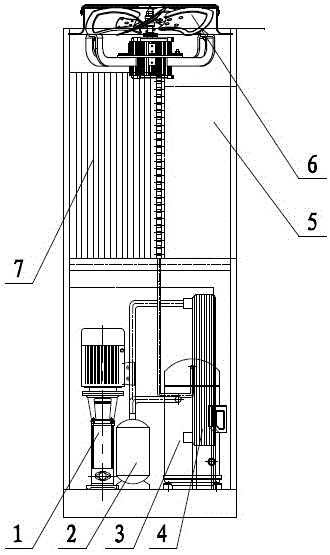

Outdoor unit body of air conditioner

InactiveCN102721122AIncrease the heat transfer area outside the tubeImprove heat transfer efficiencyLighting and heating apparatusAir conditioning systemsElectrical controlHeat transfer efficiency

The invention discloses an outdoor unit body of air conditioner, which belongs to the field of air conditioner. The outdoor unit body of air conditioner comprises a circulation water pump, a gas-liquid separator, a compressor, a brazed heat exchanger, an electrical control box, a condenser fan, a U type condenser, wherein the circulation water pump, the gas-liquid separator, the compressor, and the brazed heat exchanger are arranged at the bottom of the outdoor unit body. The compressor and the circulation water pump are separated from each other. The U type condenser is in the form of internal-thread external-ripple fin and is arranged on the upper part of the outdoor unit body. The electrical control box is arranged on the front part of the U type condenser. The condenser fan is located at the top of the outdoor unit body. The left, right and back of the outdoor unit body are provided with gas inlet channels. Due to the adoption of air inlet and outlet design, condenser design and structure design different from traditional outdoor units of air conditioner, the heat transfer efficiency of the outdoor unit body of air conditioner provided by the invention is greatly improved, and the COP value of the whole machine is more than 3.8.

Owner:CHANGZHOU CHILLTECH AIR CONDITIONING & REFRIGERATING PROD

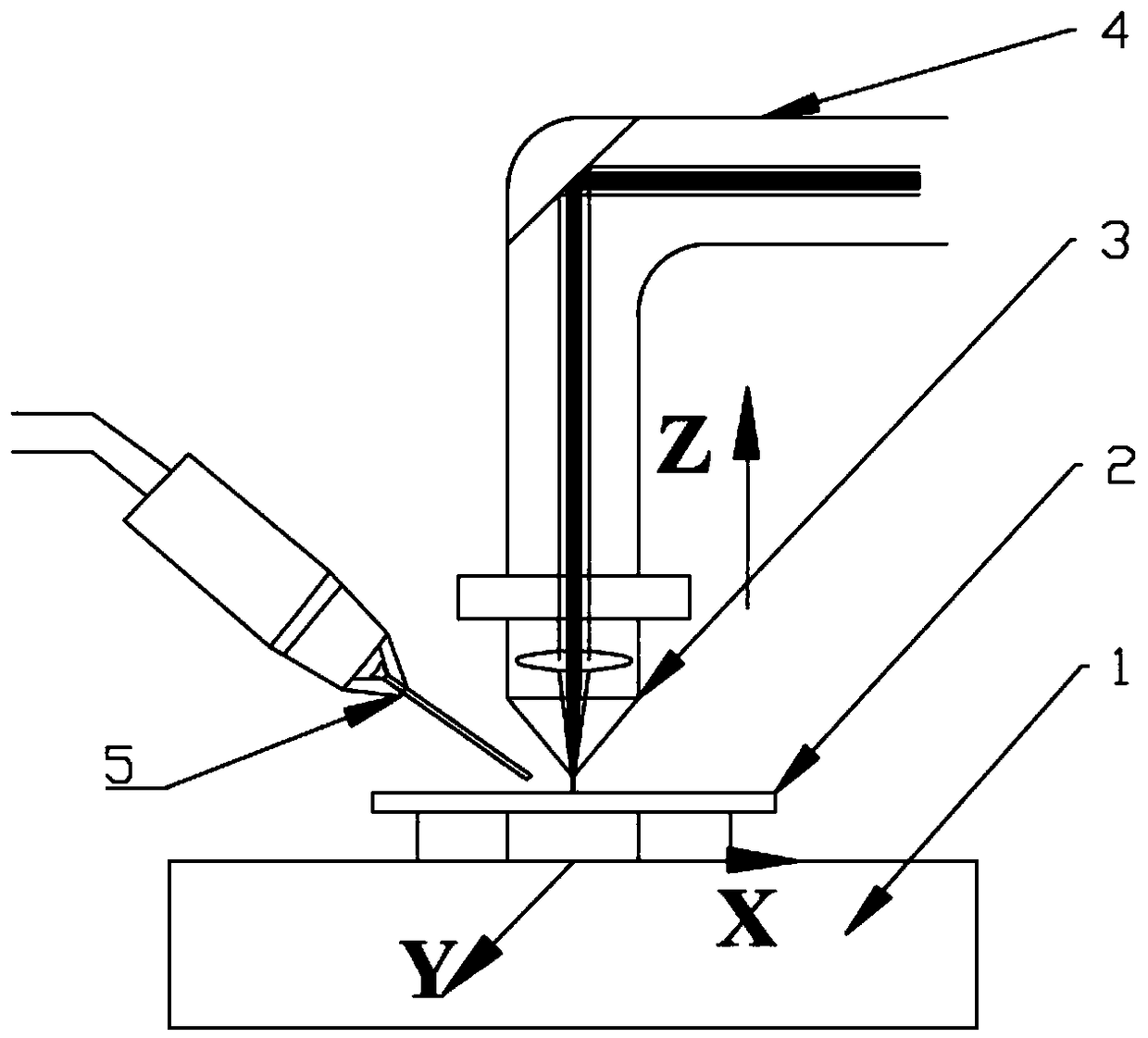

Laser-induced arc cladding high-boron wear resistant alloy processing method

The invention relates to a laser-induced arc cladding high-boron wear resistant alloy processing method, and a high power arc heat source cooperates with a low power (less than 500W) laser heat source. Through reasonable parameter setting, the heat of the molten high-boron wear-resistant alloy powder is mainly provided by arcs, and the low-power laser has less effect on the melting of the alloy powder, but can stir the molten pool and change the flow mode of the molten pool so as to granulate coarse columnar borides, and to easily obtain a dense structure. At the same time, the main function of the low-power laser is to establish a channel with the arc plasma by the laser photo-induced plasma, thereby improving the stability of the arc and facilitating the improvement of the stability of the process. Moreover, the required laser power is small, and the process cost is saved.

Owner:JIANGNAN UNIV

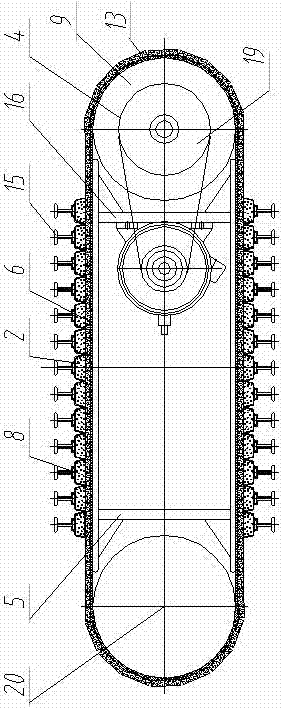

A method of using gas to purify steel ingot and reduce a segregation

The invention relates to the field of steel ingot manufacture, in particular to a method for purifying steel ingots and relieving A-segregation by using gas. By rotary argon-blowing ventilating equipment is arranged at a steel ingot riser, impurities in the steel ingots are removed and A-segregation is relieved, so that a difficulty of impurity removal after the steel ingot are cast in the prior art is overcome and a new means for inhibiting the A-segregation in the steel ingot solidifying process is provided. The method mainly comprises a rotary argon blowing technology, a riser ventilating technology, and a technology of selecting adding positions, number and argon blowing time according to ingot shapes. In the method, after molten steel is cast into steel ingot molds, the impurities inthe steel ingots are removed and the A-segregation defect of the steel ingots is overcome by the rotary stirring argon-blowing technology, and the method is simple and practical for improving the internal quality of the steel ingots.

Owner:中科西王特钢有限公司

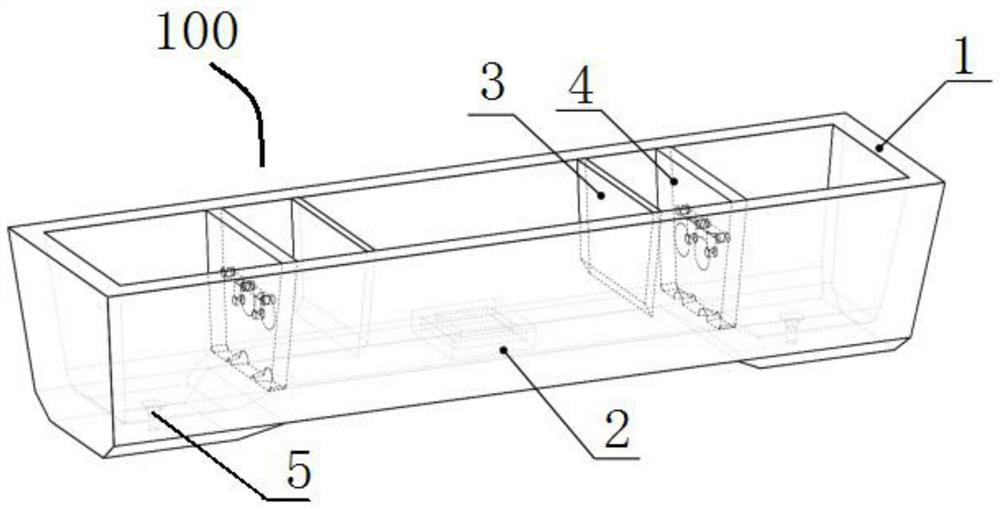

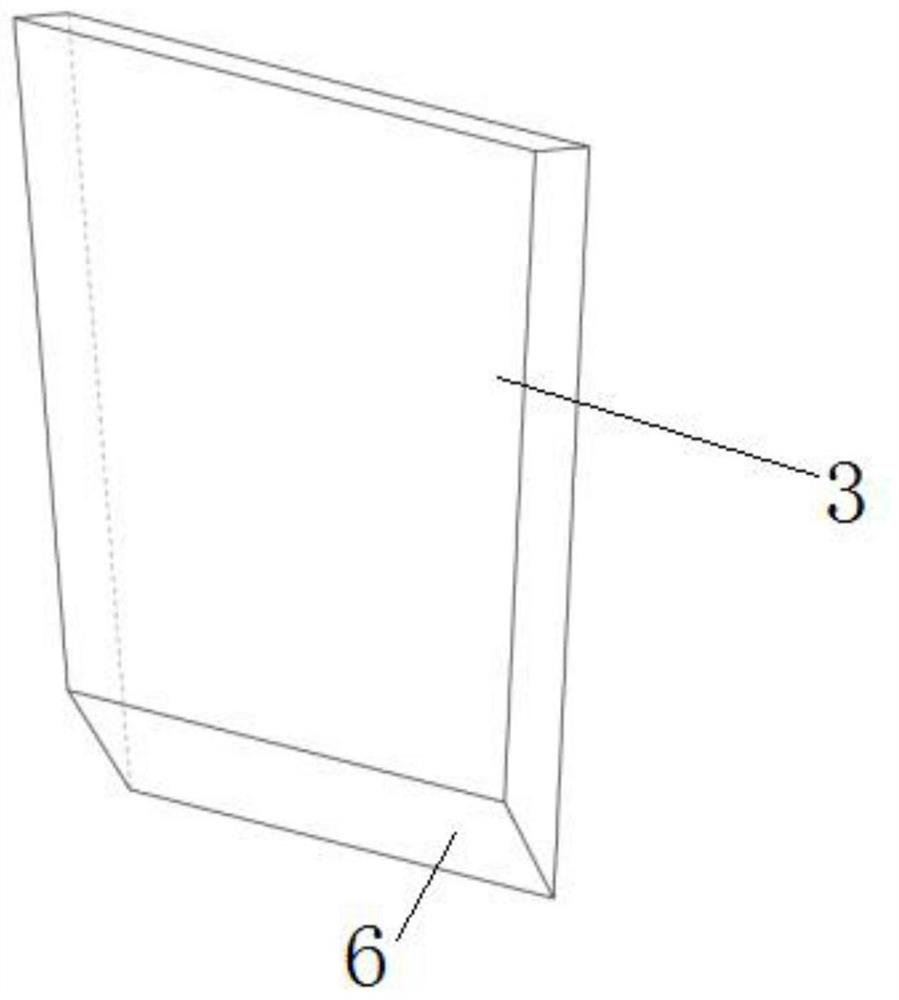

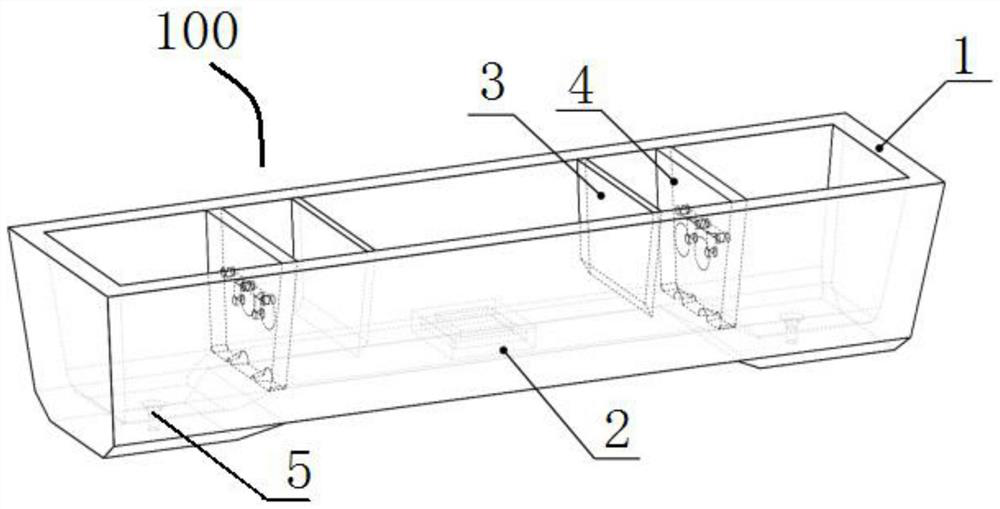

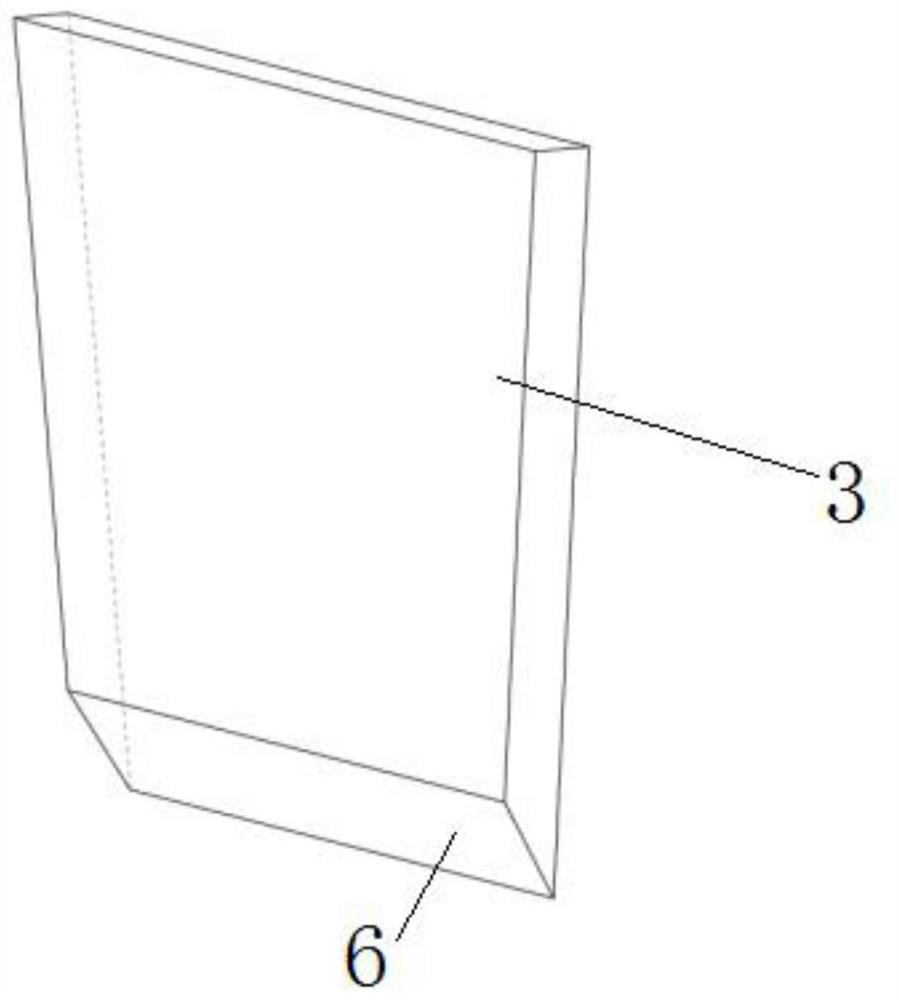

Tundish impurity removal and flow control device assembly for casting

ActiveCN113333722AImprove room temperature strengthEasy to transportMelt-holding vesselsCasting cleaning apparatusMicro nanoMechanical engineering

The invention discloses a tundish impurity removal and flow control device assembly for casting, and relates to the technical field of metal casting. The tundish impurity removal and flow control device assembly comprises a weir and a filter which are vertically arranged in a tundish, wherein an incident flow inclined surface is arranged at the bottom of the weir; two horizontally arranged semi-circular-truncated-cone-shaped discharge holes are symmetrically formed in the bottom of the filter; two conical holes are formed in the incident flow surface of the filter; three circular holes are formed in the back flow surface of the filter; the conical holes are connected with the circular holes through circular channels; and the surface of the weir, the surface of the filter, the circular holes, the conical holes, the semi-circular-truncated-cone-shaped discharge holes and the wall surfaces of the circular channels are coated with micro-nano-scale oxide functional coatings. The tundish impurity removal and flow control device assembly for casting is resistant to high-temperature thermal impact, high in impurity removal rate and low in cost.

Owner:WUHAN UNIV OF SCI & TECH +1

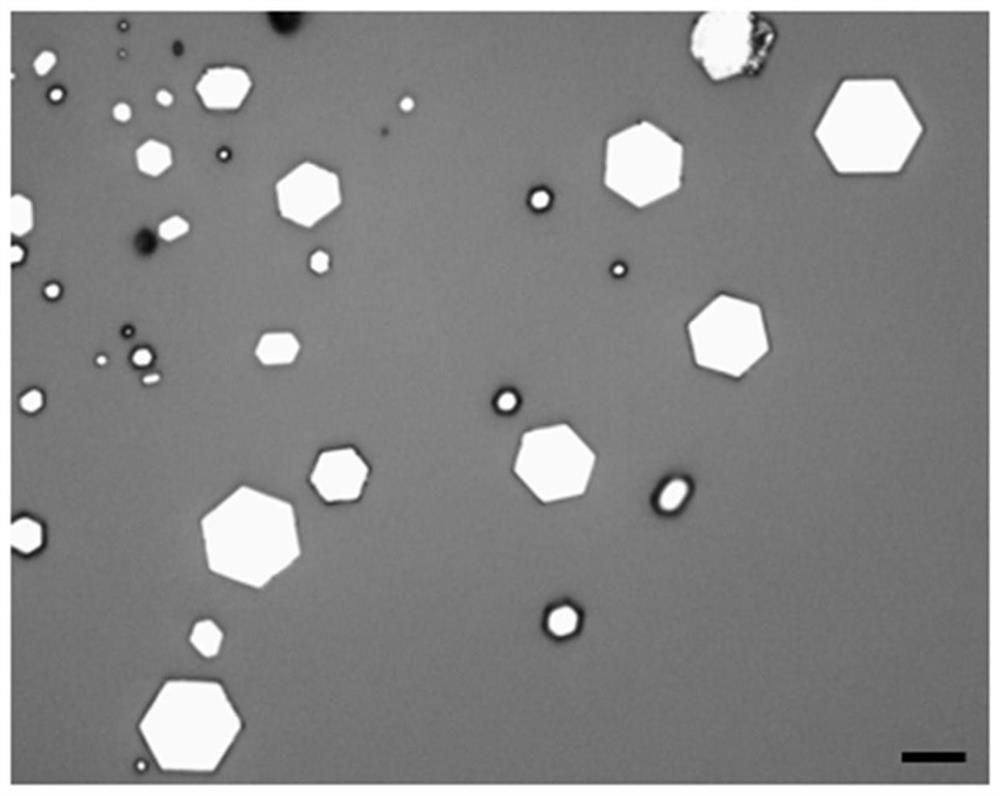

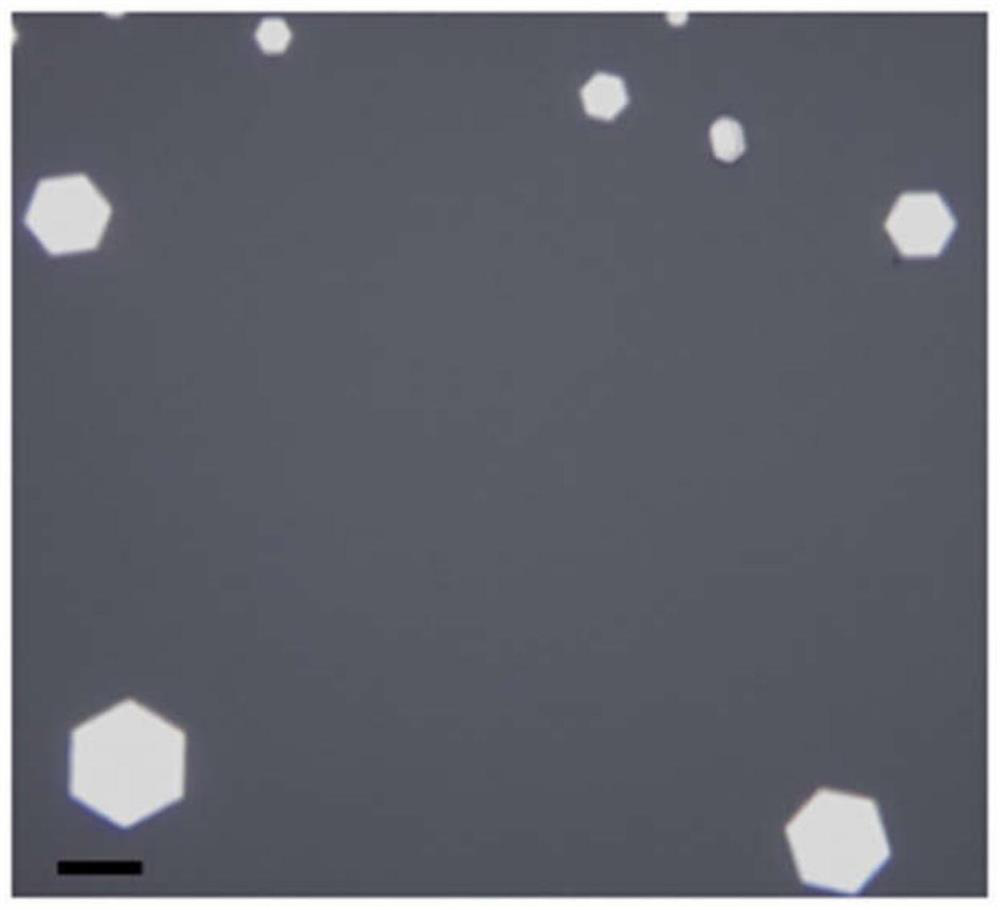

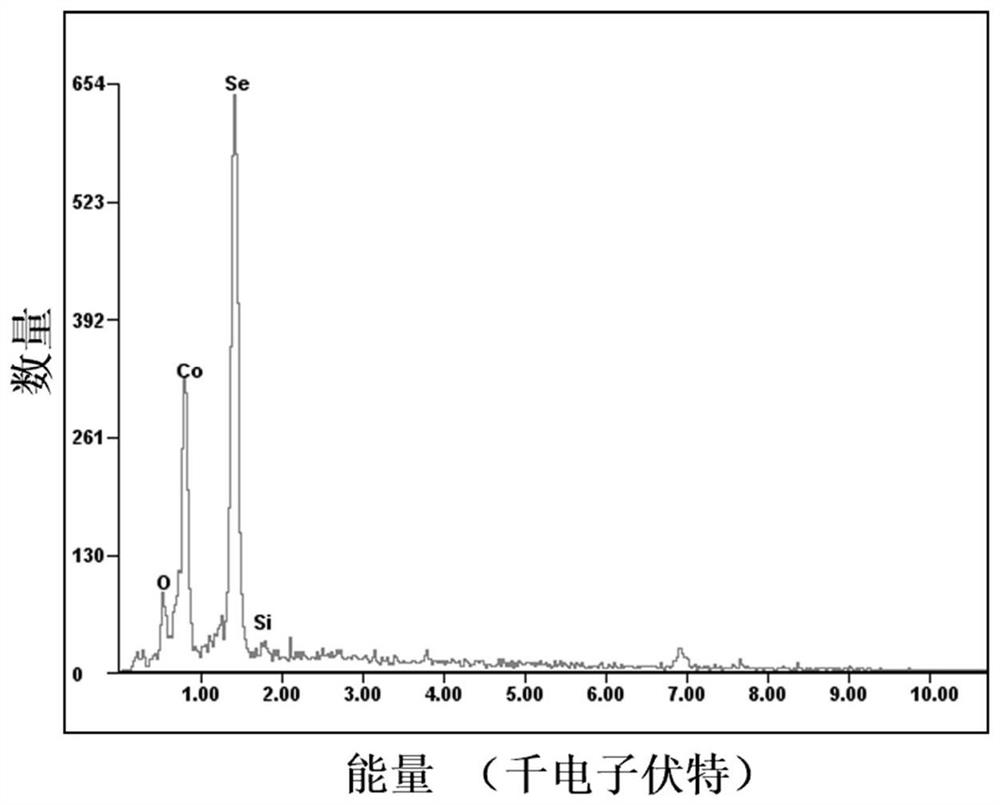

Room temperature wide spectrum photoelectric detector based on two-dimensional cobalt selenide thin film and preparation method

ActiveCN111850556ALow melting pointFacilitate depositionFinal product manufactureVacuum evaporation coatingChemistryWave band

The invention discloses a room temperature wide spectrum photoelectric detector based on a two-dimensional cobalt selenide thin film and a preparation method. A cobalt film with certain thickness is grown by sputtering on a substrate using dual-ion-beam sputtering technology; and on the basis, with cobalt selenide power and selenium powder being reaction source and argon as carrier gas, the cobaltselenide thin film is prepared using chemical vapor deposition method. Metal electrodes in ohmic contact with the cobalt selenide thin film are arranged on the cobalt selenide thin film as a source electrode and a drain electrode, and the photoelectric detector based on the two-dimensional cobalt selenide thin film is constituted. The obtained photoelectric detector based on the two-dimensional cobalt selenide thin film can realize an initial wide spectrum response waveband of 450 nanometer to 10.6 micrometer laser under room temperature, and the response rate reaches 2.58 watt / ampere. According to the provided room temperature wide spectrum photoelectric detector based on novel high-performance two-dimensional materials, the application of two-dimensional cobalt selenide materials is widened in the fields photoelectricity and magnetic-optical technology.

Owner:EAST CHINA NORMAL UNIVERSITY

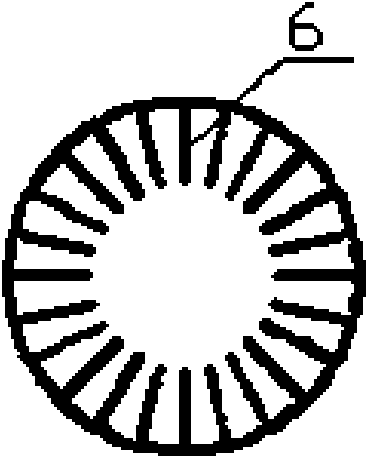

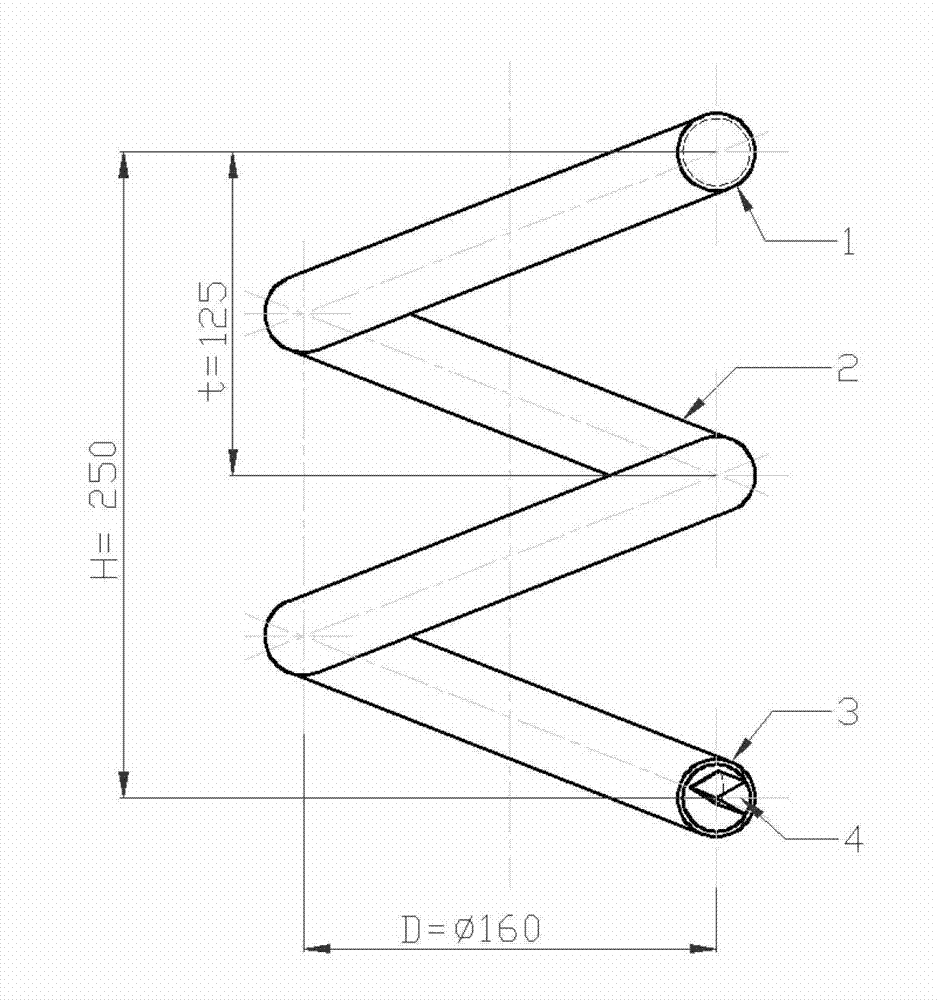

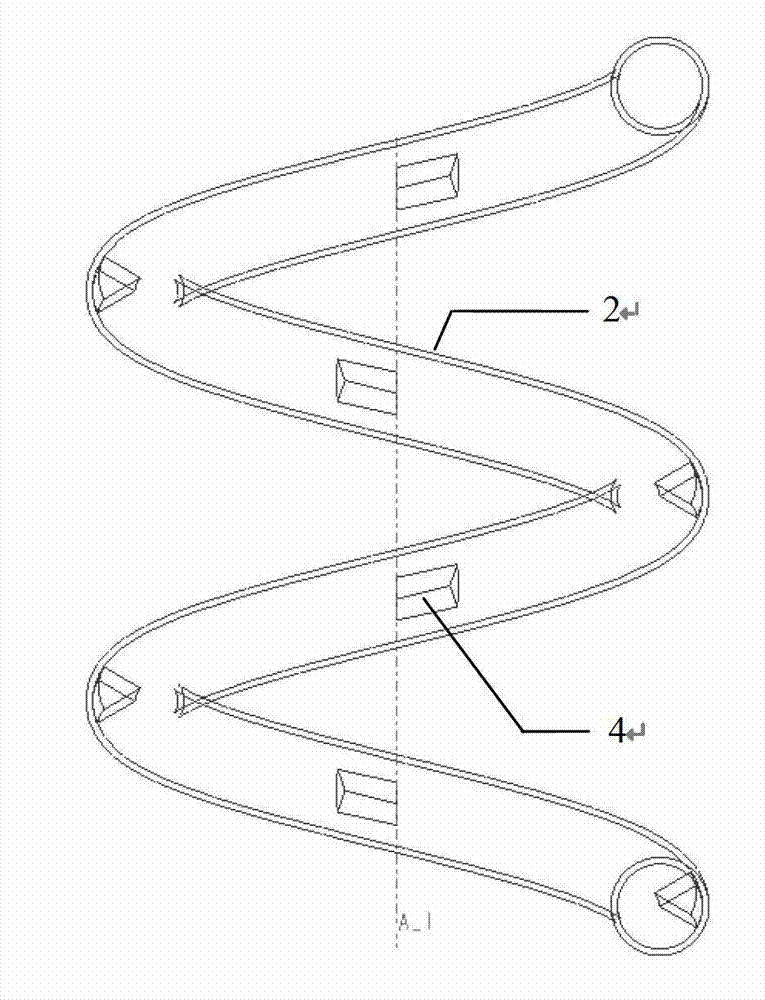

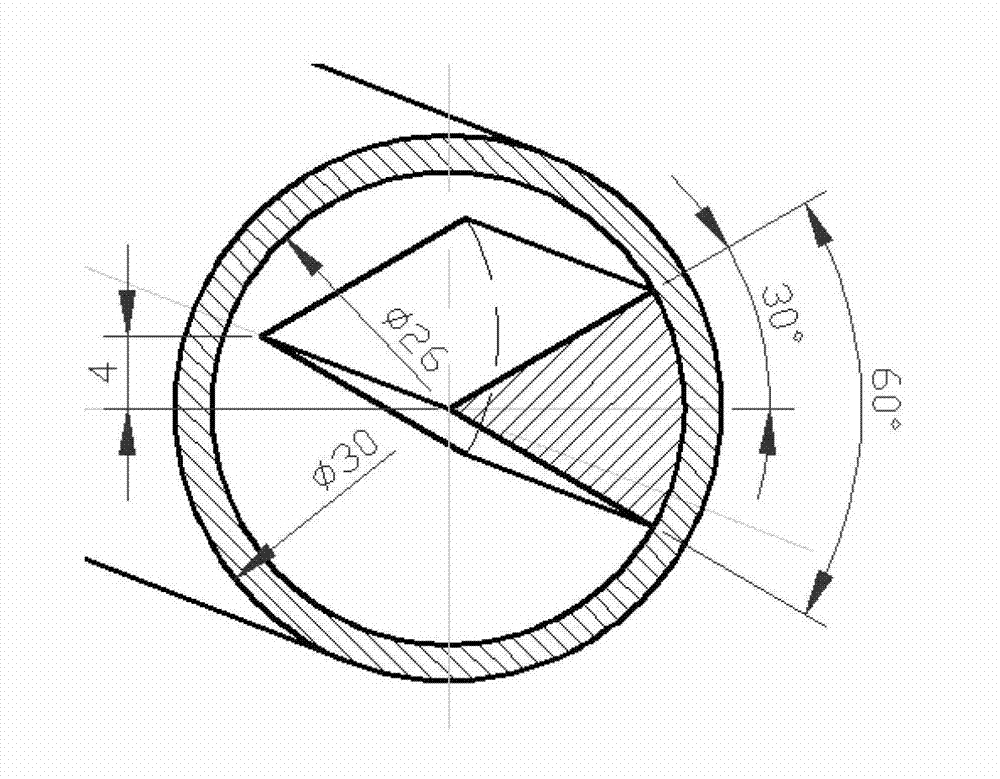

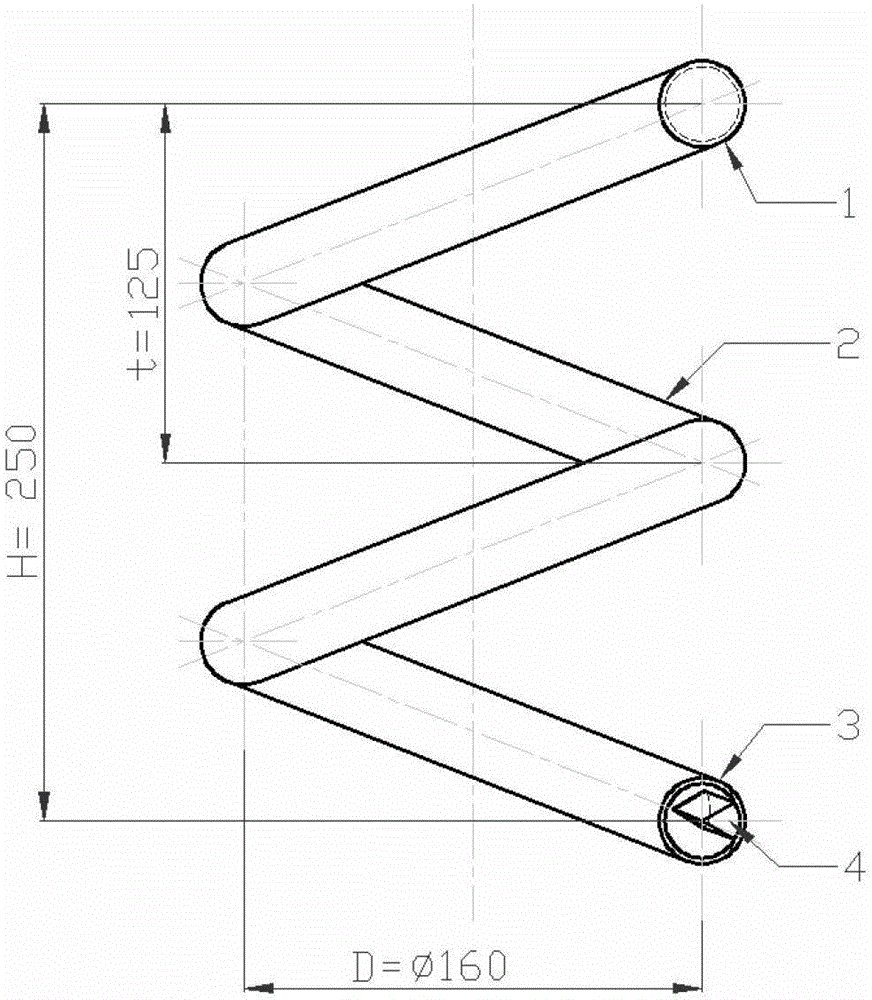

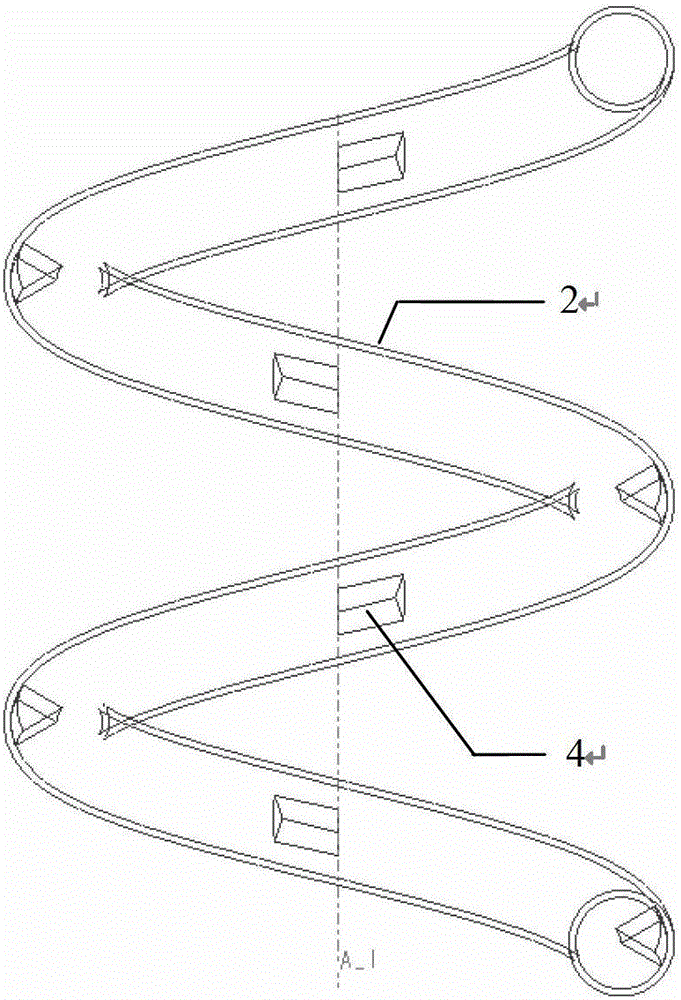

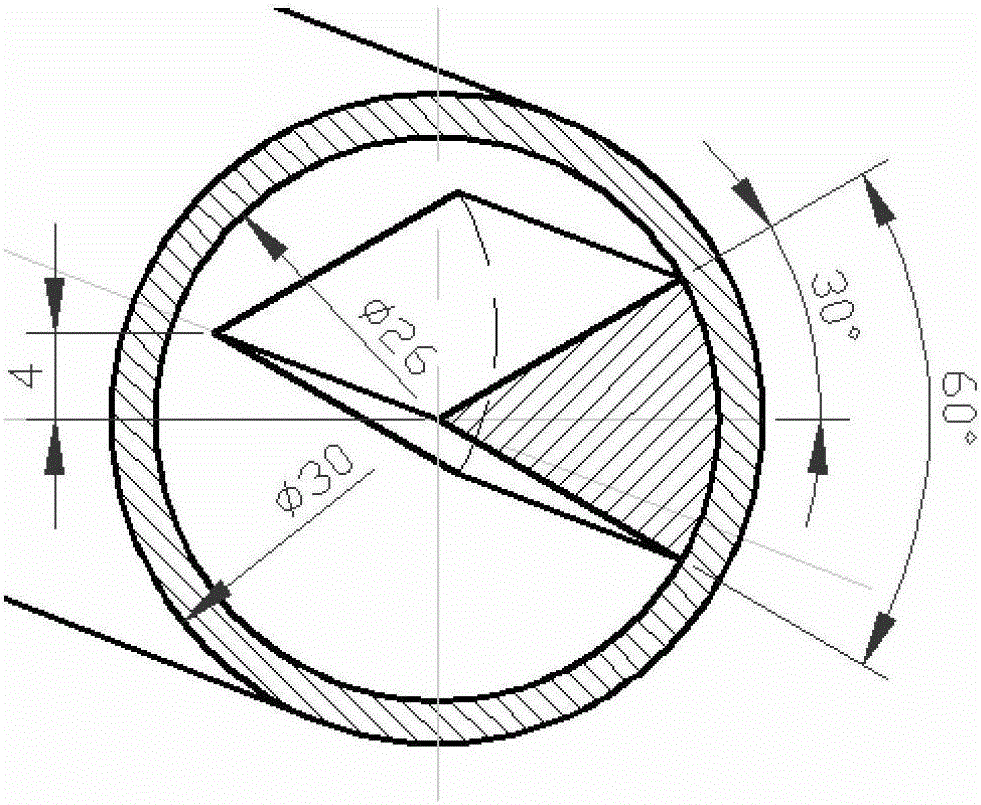

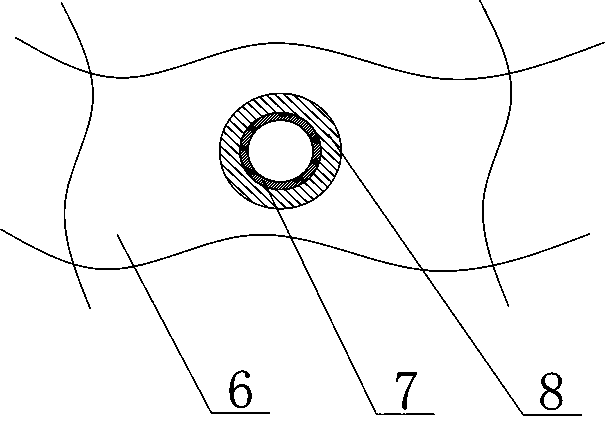

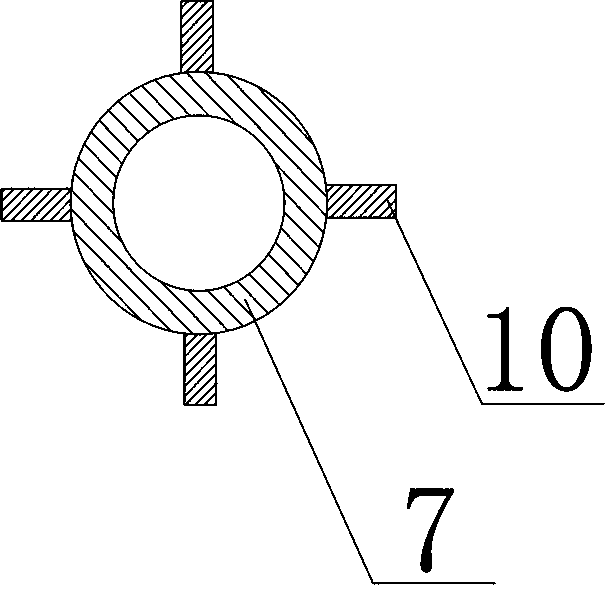

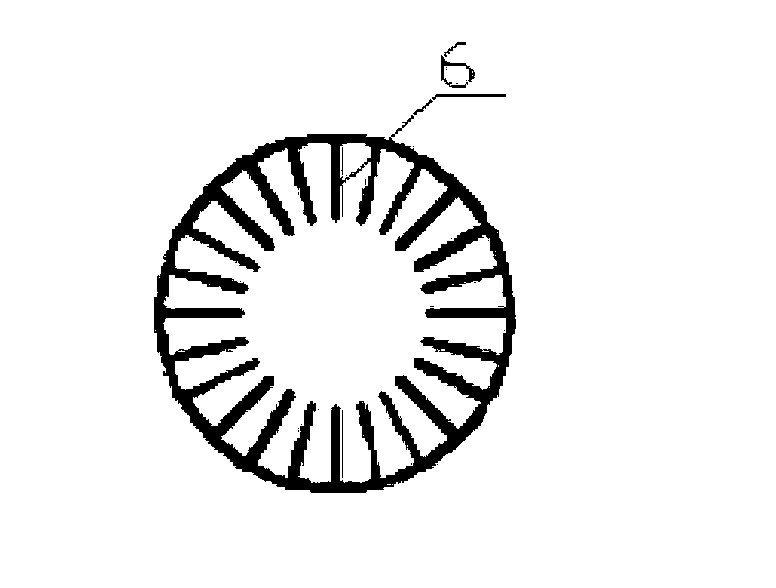

Finned spiral pipe

ActiveCN103206883AIncreased turbulenceEnhanced mass transferHeat transfer modificationTubular elementsEngineeringCircular surface

The invention discloses a finned spiral pipe. The finned spiral pipe comprises a spiral pipe with a circular section, wherein a plurality of fins are evenly distributed on the inner wall of the spiral pipe, and the fins have the same spiral structure as that of the lead of the spiral pipe; the sections of the fins are shaped like a fan, and the radius of the section of each fin is equal to that of the circular surface of the inner wall of the section of the spiral pipe.

Owner:无锡苏惠信息技术服务有限公司

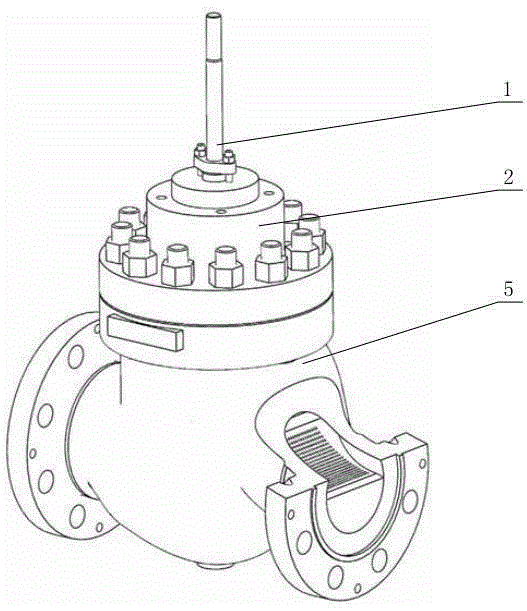

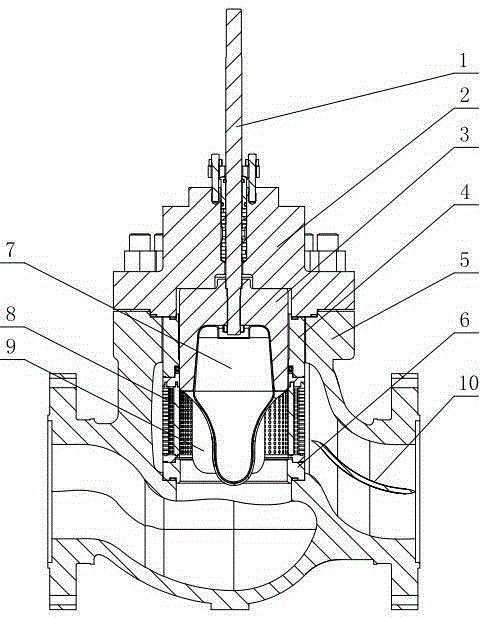

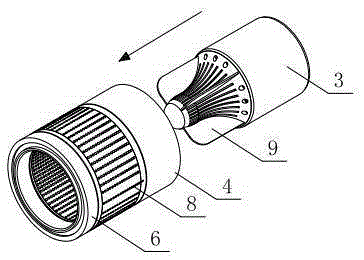

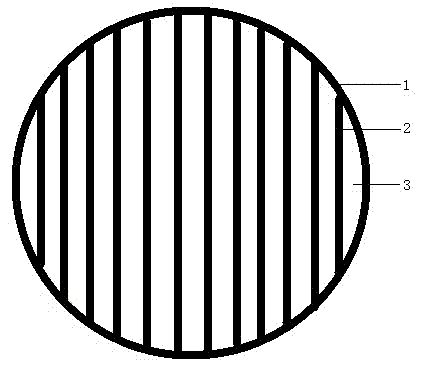

low noise control valve

ActiveCN104048102BReduce pulsating pressureCompact structureValve members for absorbing fluid energyLow noiseCavitation

Owner:中国船舶重工集团公司第七〇二研究所

Ascending coal gas dust blocker

InactiveCN102391894ASimple structureEasy to makeGas dust removalCombustible gas productionSlagEngineering

The invention aims to provide an ascending coal gas dust blocker for solving the problems of purifying gas, prolonging the service lives of pipelines and equipment and balancing gas distribution. Dust blocking plates are arranged on a circular shell, air outlets are formed between the dust blocking plates, and the dust blocking plates are 'V'-shaped and bent inwards. The dust blocker is simple in structure and convenient for manufacturing and installing; through the dust blocker, the dust carried in the coal gas can be effectively blocked to a furnace body and discharged together with slag at the up-blowing stage; when the steam passes through the dust blocker at the down-blowing stage, the steam can be uniformly distributed, so that the original steam flowing mode is changed; and by reducing the dust in the ascending coal gas, the coal gas is purified, meanwhile, scouring to an ascending coal gas pipeline and a lining of a dust collector is relieved, safe and stable operation of equipment is ensured, and the operating cost is saved.

Owner:SHANDONG JINMEI MINGSHENGDA CHEM CO LTD

Heat exchanger and condensing boiler

PendingCN110926026AIncrease the heat exchange areaImprove heat transfer effectAir heatersSustainable buildingsEngineeringMechanical engineering

The invention provides a heat exchanger and a condensing boiler. The heat exchanger includes an inner heat exchange tube and an outer heat exchange tube located on an outer ring of the inner heat exchange tube. The inner heat exchange tube has a receiving cavity. The direction of the central axis of the receiving cavity is consistent with the directions of the central axes of the inner and outer heat exchange tubes. The inner and outer heat exchange tubes are both light tubes. The heat exchanger has high heat exchange efficiency and is beneficial to a high-power boiler.

Owner:VALPO ENERGY & ENVIRONMENT TECH CO LTD +1

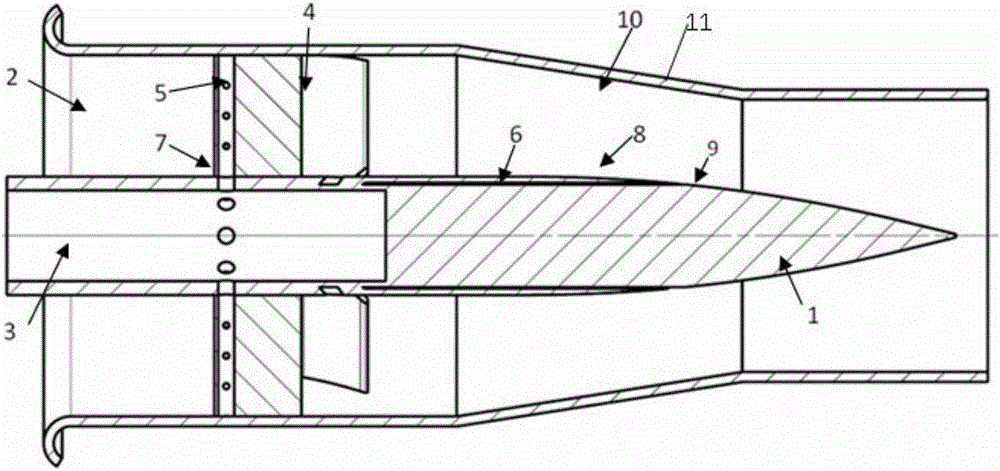

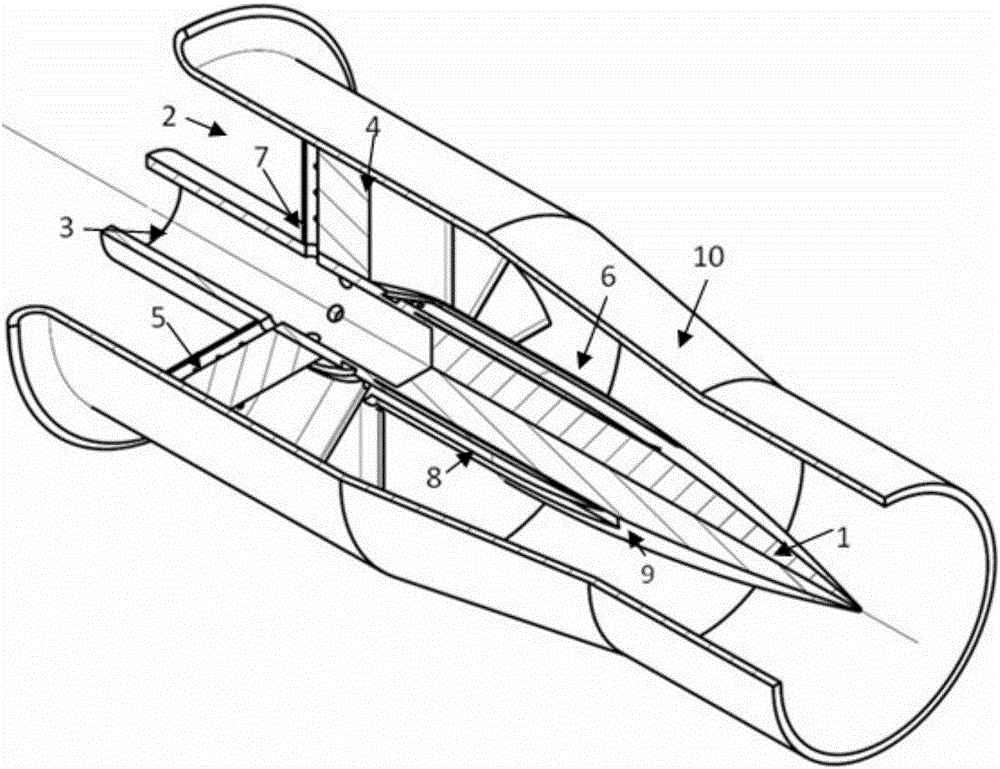

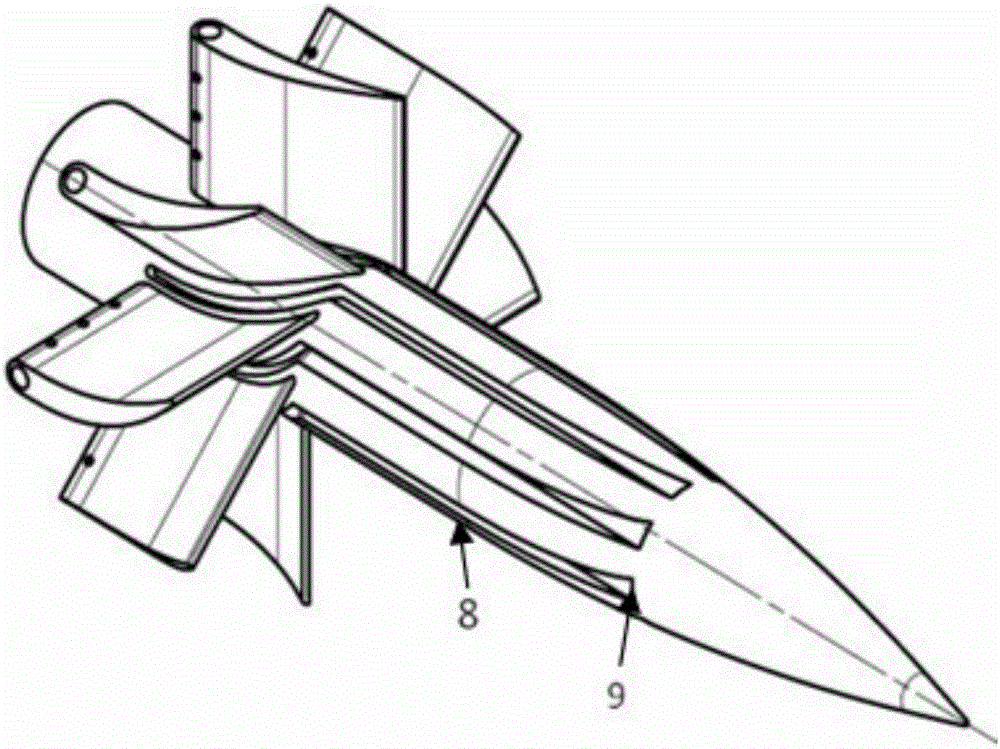

Slotted swirl nozzle in center body of gas turbine combustor

ActiveCN104373963BChange flow patternIncrease axial speedContinuous combustion chamberCombustion chamberCombustor

The invention relates to the technical field of gas turbines and discloses an inner body slotting type swirl nozzle for a combustion chamber of a gas turbine. The nozzle comprises a conical inner body, a shell body and multiple swirl blades, wherein the conical inner body is arranged in the shell body, an annular peripheral air channel is formed between the conical inner body and the shell body, the swirl blades are arranged on the conical inner body in the peripheral direction of the conical inner body, multiple slots are formed in the outer circumference of the conical inner body, and the slots and the swirl blades are arranged in a spaced mode. According to the inner body slotting type swirl nozzle for the combustion chamber of the gas turbine, due to the fact that the multiple slots are formed in the conical inner body, the flowing mode of the inner side of the conical inner body is changed, and the strength of mixed cyclonic air current is reduced and axial speed is increased so as to be matched with fuel concentration and speed distribution on an outlet of the nozzle. The nozzle has the advantages that combustion organization is achieved reasonably and effectively and pollutant discharge is controlled reasonably and effectively.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

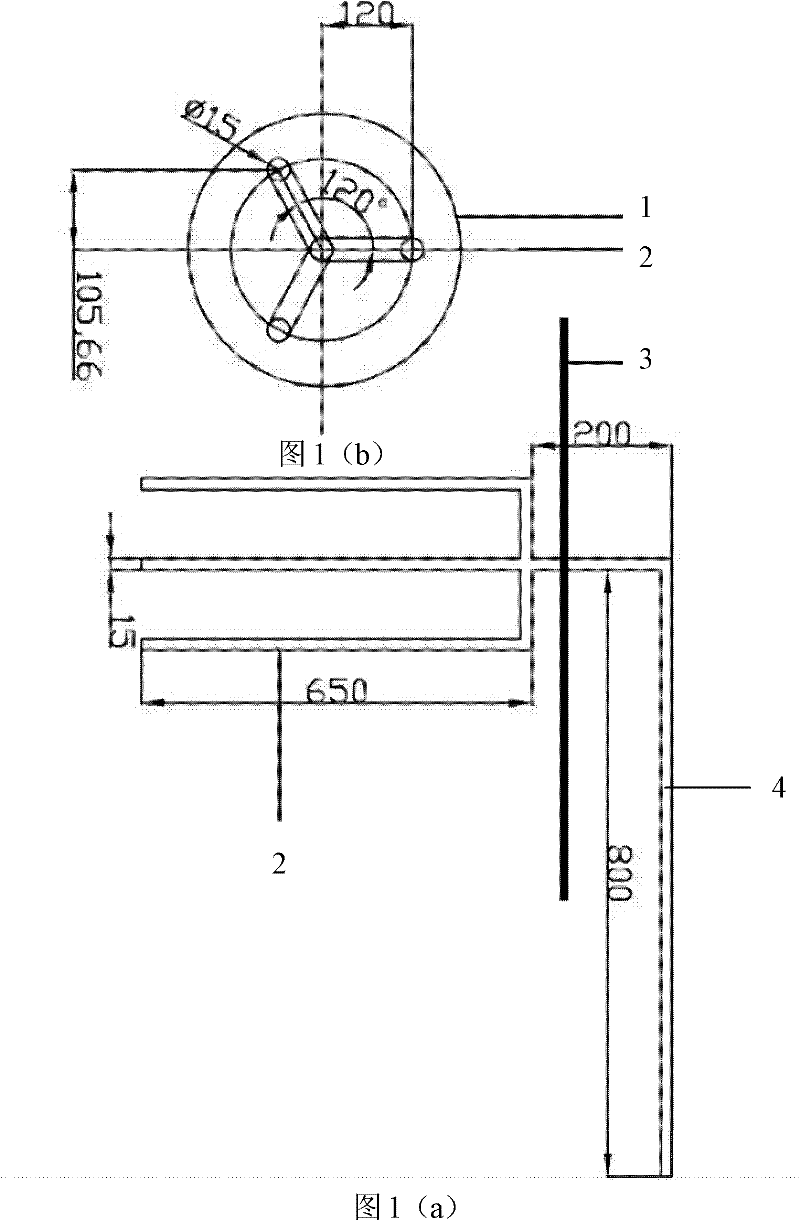

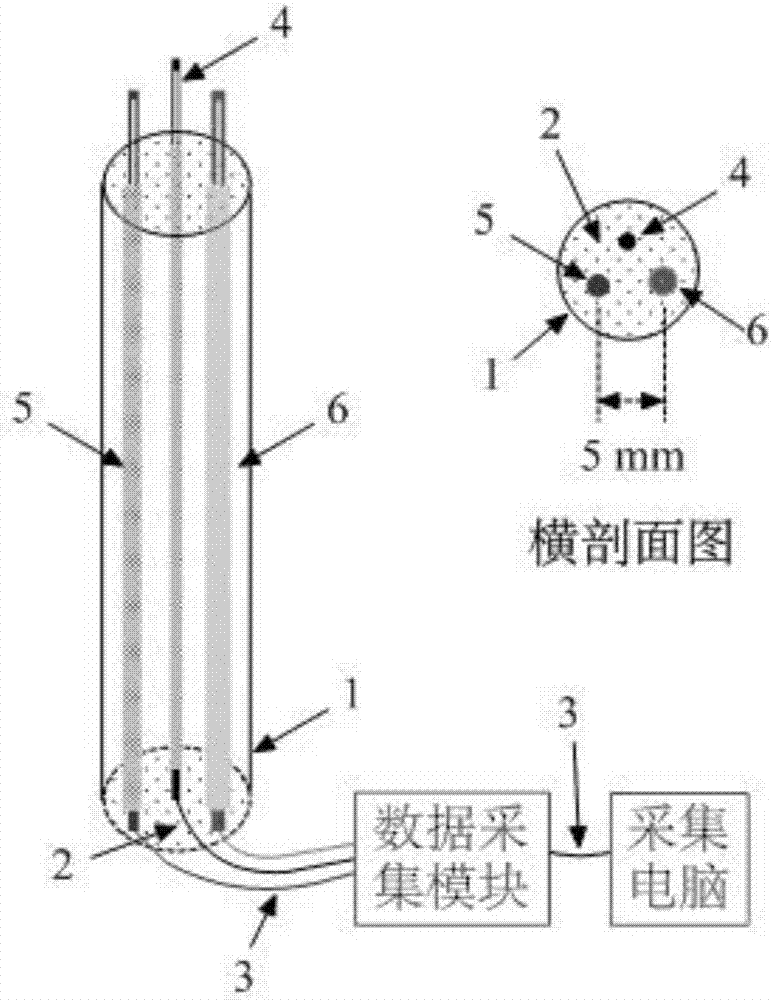

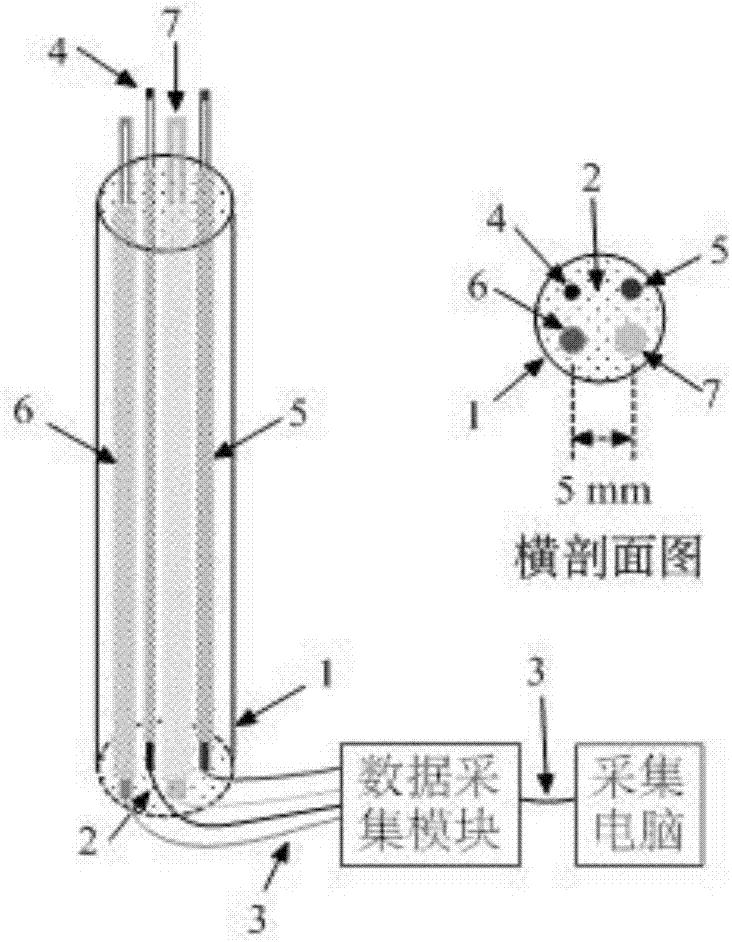

Multi-thermocouple assembled temperature sensor and measurement correction algorithm thereof

PendingCN107167259AEasily brokenLow costThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermocouple device

The invention relates to the technical field of temperature measurement for a fire or a similar high-temperature air flow, and specifically relates to a multi-thermocouple assembled temperature sensor and a measurement correction algorithm thereof. The multi-thermocouple assembled temperature sensor and the measurement correction algorithm thereof can be used for correcting an error brought about by thermocouple exposed nodes and environmental radiation heat exchange for thermocouple temperature measurement, and eliminate influences imposed on the correction process by turbulent fluctuations of a high temperature air flow based on a heat transfer theory and algorithm, so that the corrected temperature is enabled to be closer to the actual temperature of the air, and turbulent fluctuation conditions of the actual temperature can be provided.

Owner:NANJING UNIV OF TECH

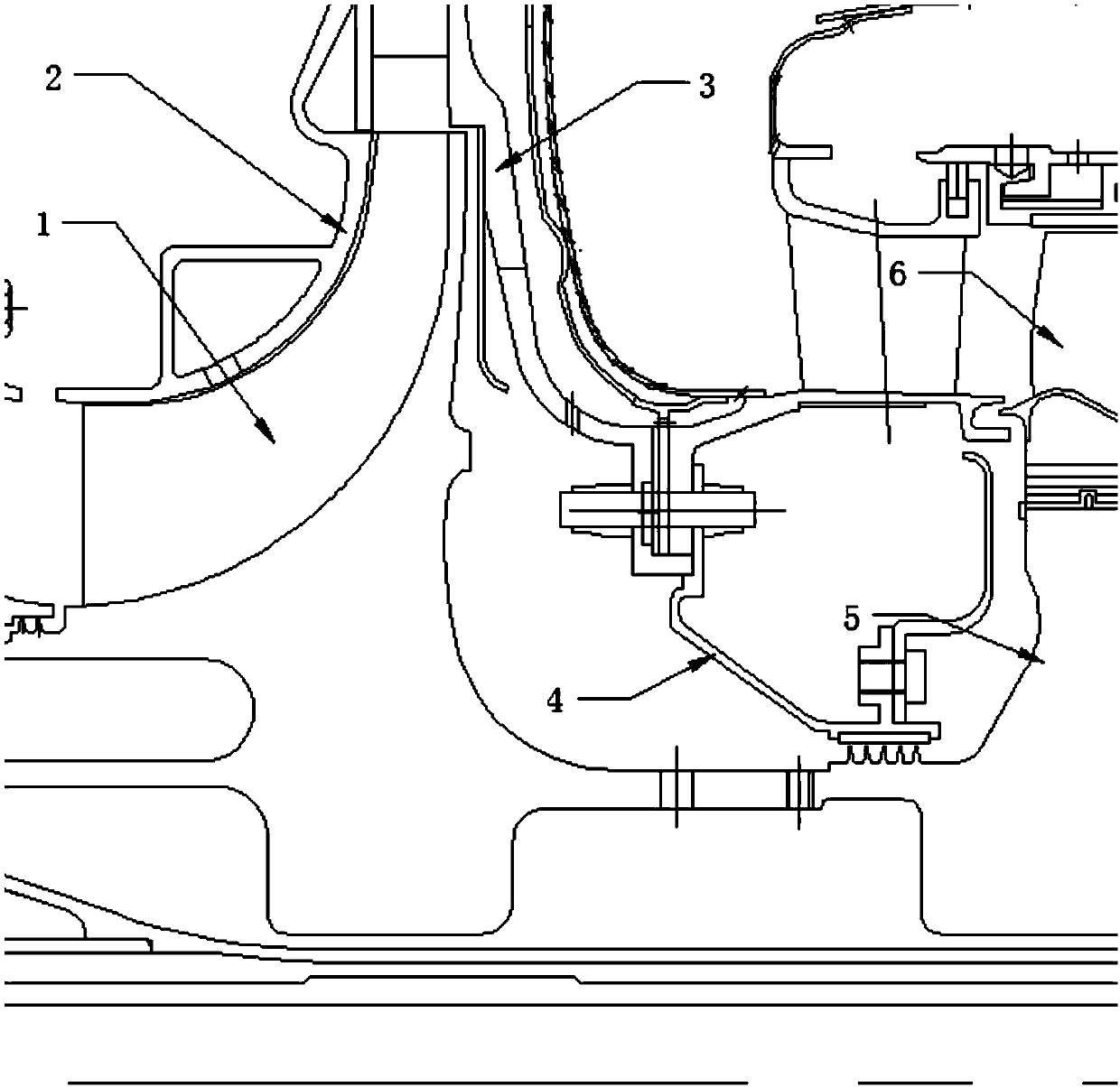

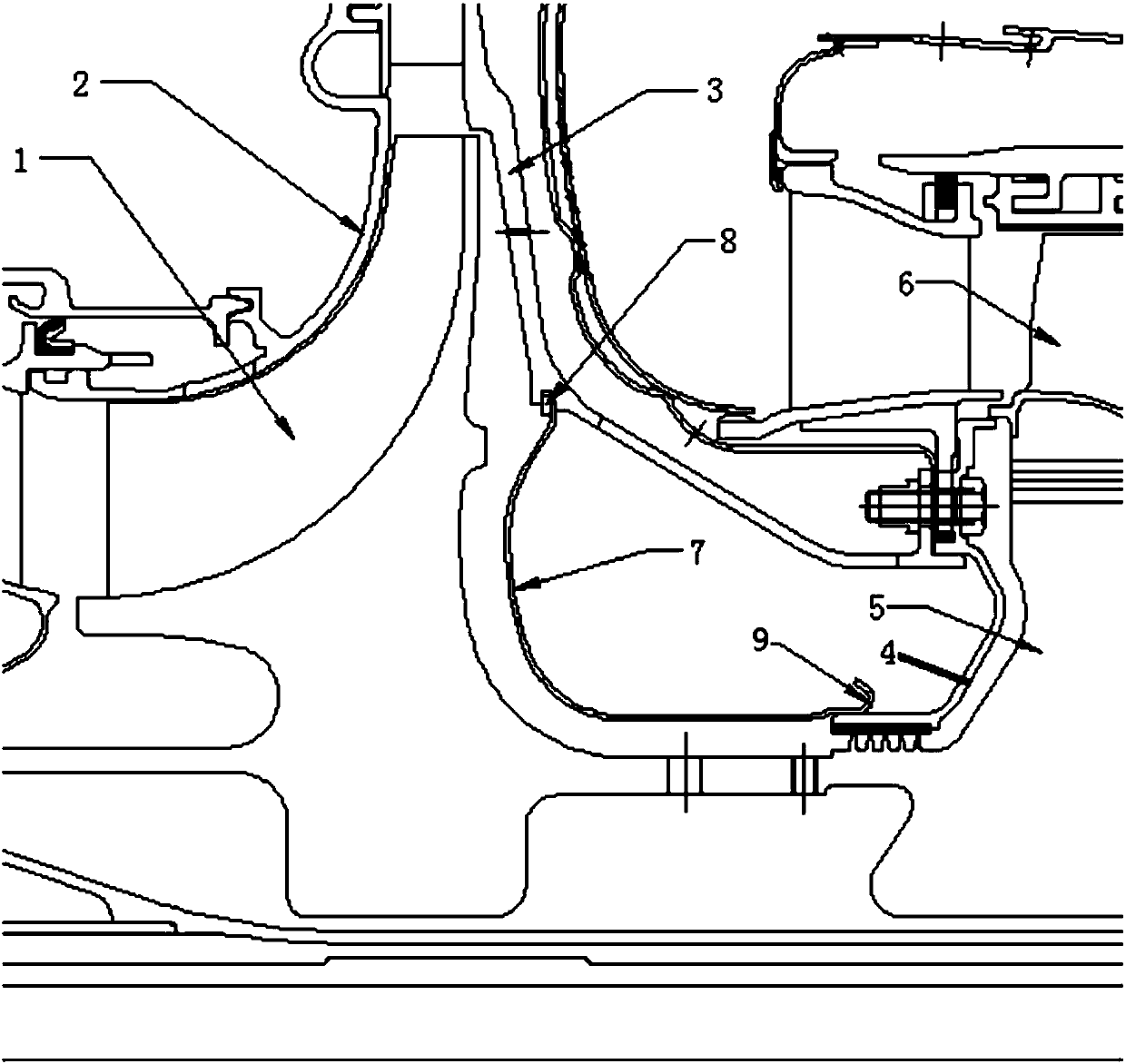

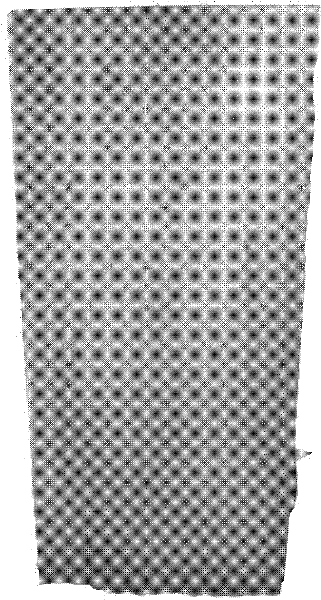

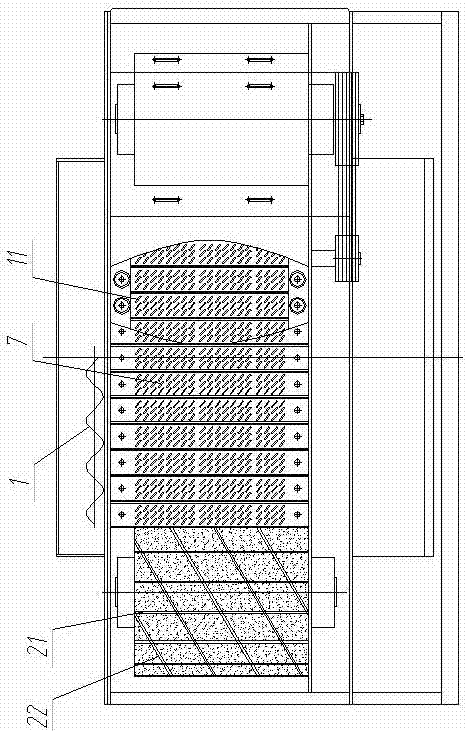

Belt type separated flow rice mill and rice milling method

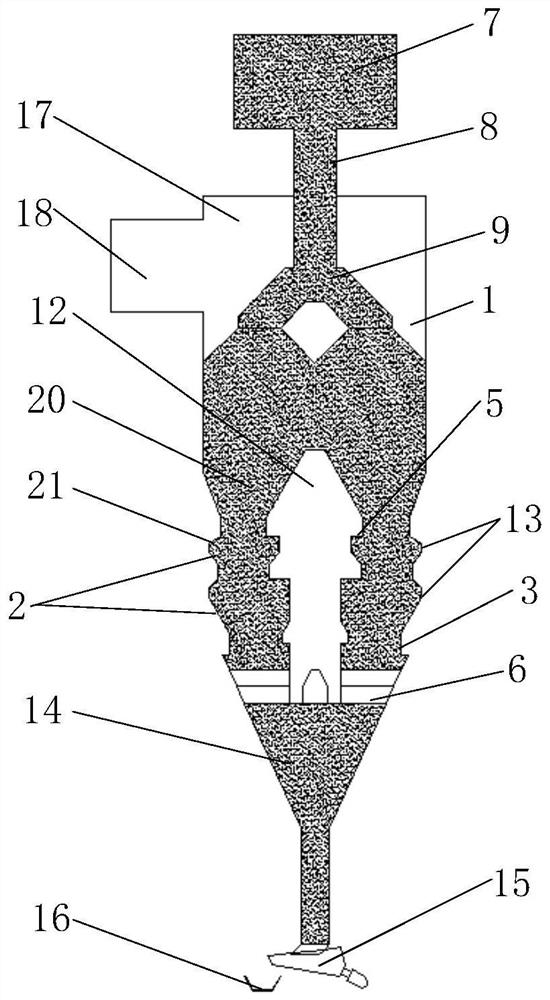

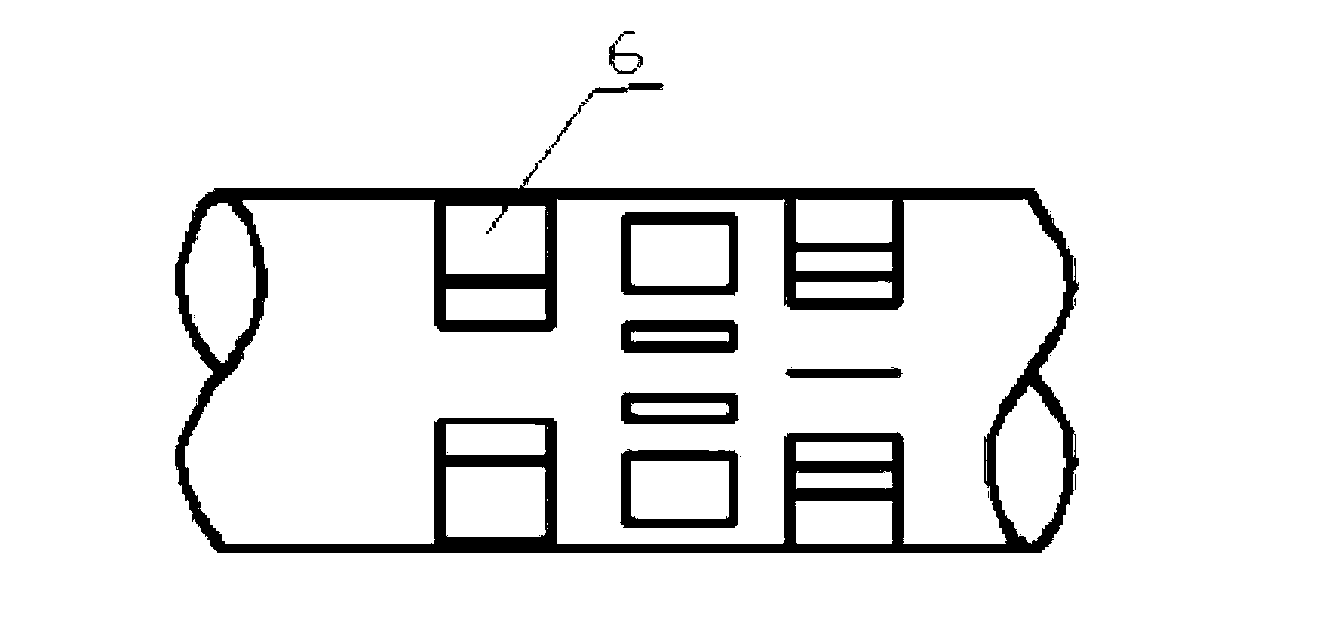

ActiveCN104338573BChange flow patternReduce power consumptionGrain huskingGrain polishingEngineeringStraight segment

The main problems of the traditional whitening method of the belt-type separated flow rice mill and the rice milling method are high energy consumption and a lot of broken rice. A belt-type split-flow rice mill, which consists of: a feeding device (1), a whitening chamber (2), a discharge device (3), a transmission device (4) and a frame (5). The chamber includes 2 sets of rice milling rooms (8) that are arranged opposite to each other and surrounded by a milling belt (6) and a screening body (7). The milling belt bypasses the frame (5 ) The rollers (9) at both ends are connected end to end to form a ring belt. The screening body is installed in two rows on both sides of the straight section of the grinding belt. The screening body (7) and the There is a gap between the grinding belts (6), and the gap is less than 2 mm. There is a negative pressure space between the outside of the screening body and the casing, and the negative pressure space (10) is connected to a suction fan. The invention is used for rice milling.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

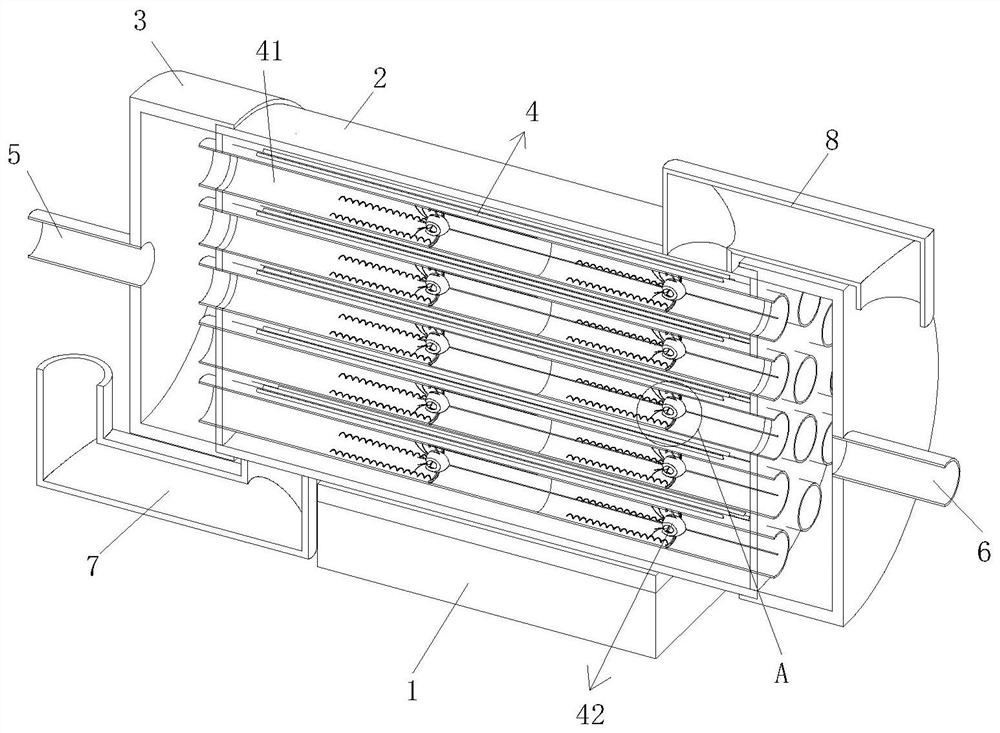

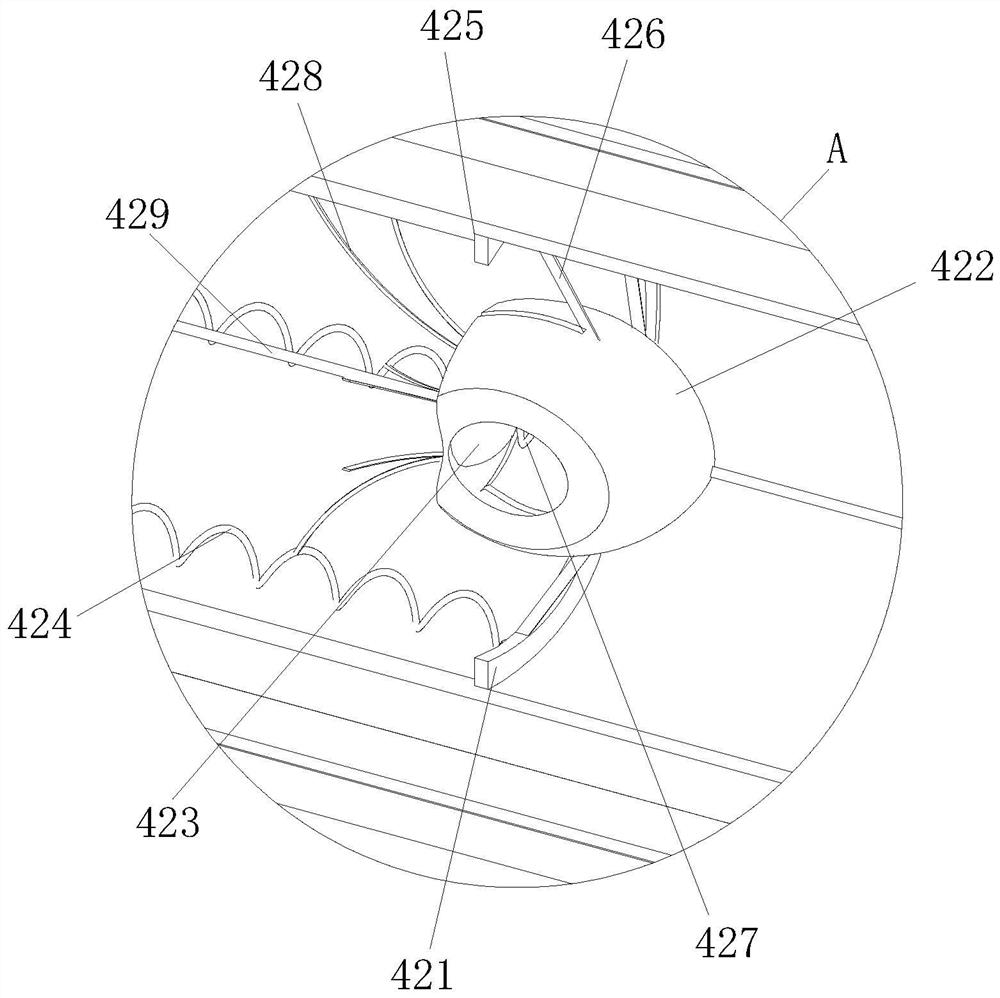

High-temperature waste water waste heat recycling device

InactiveCN113701527AAvoids the accumulation of lint and knotsAvoid too steady flowCorrosion preventionStationary tubular conduit assembliesPhysicsEngineering

The invention provides a high-temperature waste water waste heat recycling device, and relates to the field of waste heat recycling. The high-temperature waste water waste heat recycling device comprises a base, a heat exchange barrel, two sealing covers and a self-cleaning heat exchange mechanism used for heat exchange, the heat exchange barrel is fixedly connected to the base, the two ends of the heat exchange barrel are each in threaded connection with one sealing cover, the surface of the sealing cover on the left side is sleeved with a waste water outlet pipe, the surface of the sealing cover on the right side is sleeved with a waste water inlet pipe, and the left side of the bottom of the heat exchange barrel is sleeved with a clear water inlet pipe. According to the high-temperature waste water waste heat recycling device, a special structure capable of avoiding dirt adhesion, enhancing the heat exchange effect and rapidly cleaning is designed according to the problems that dirt is prone to being accumulated and difficult to remove in an existing heat exchange device, and therefore the problems that impurities and dye precipitates in printing and dyeing waste water are prone to being adhered to a common heat exchange device, the heat exchange efficiency of a pipeline of the heat exchange device is directly influenced, and the cleaning work is frequent and difficult are effectively solved.

Owner:何光辉

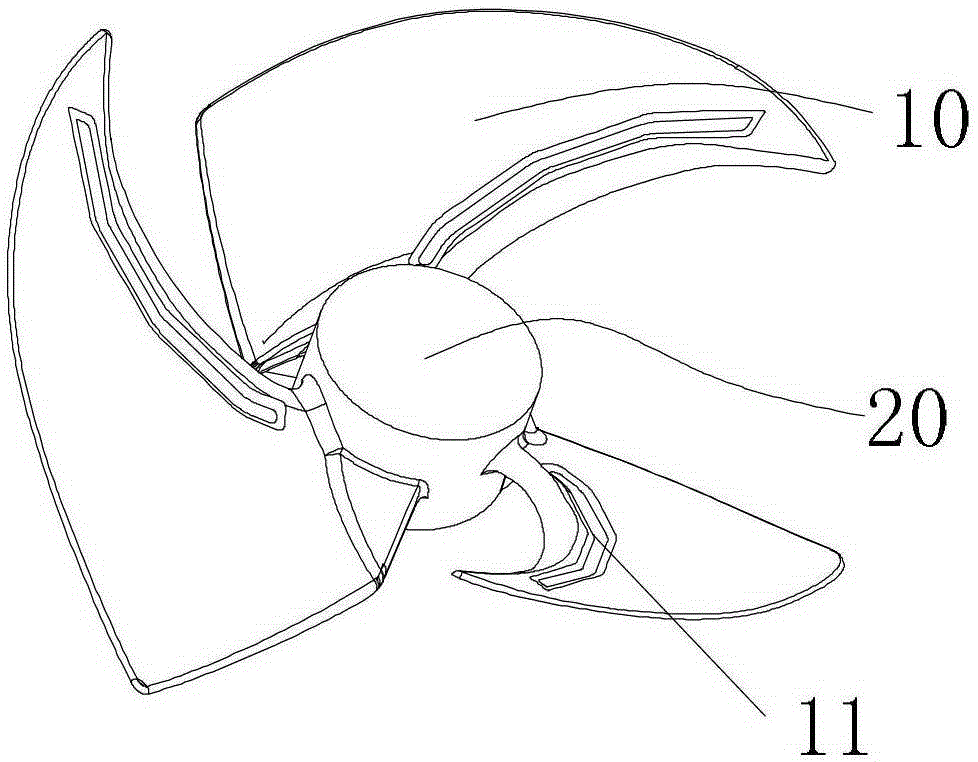

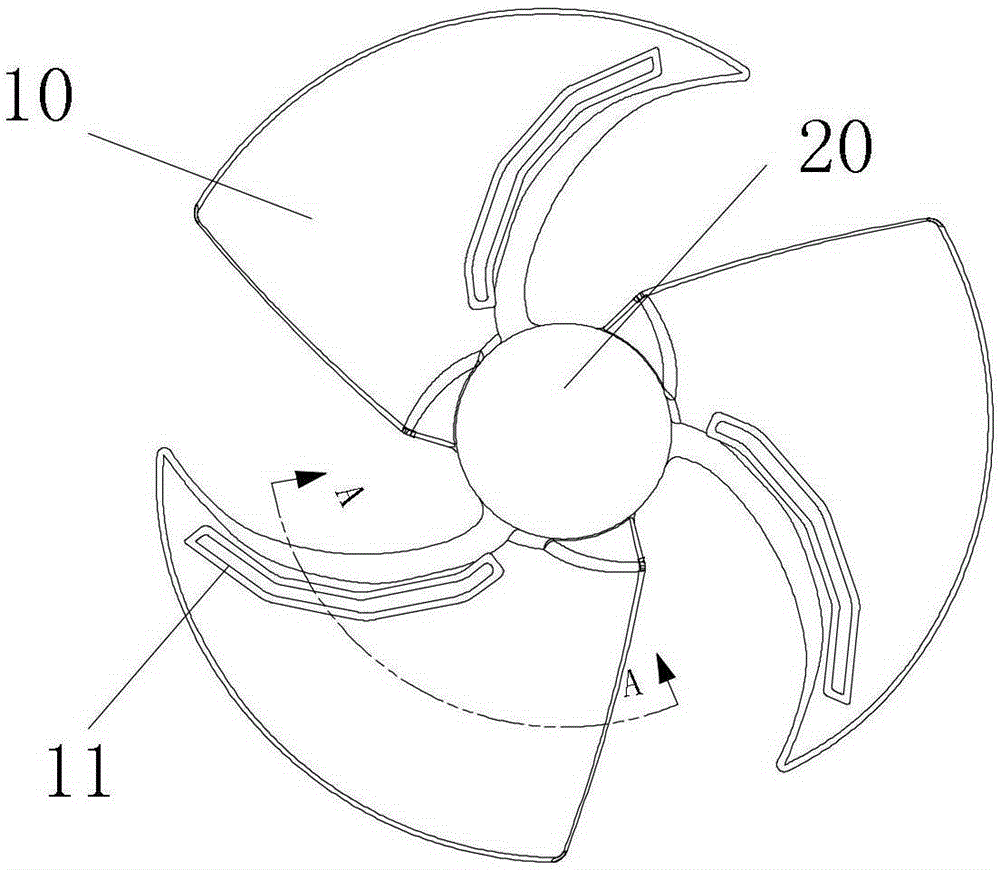

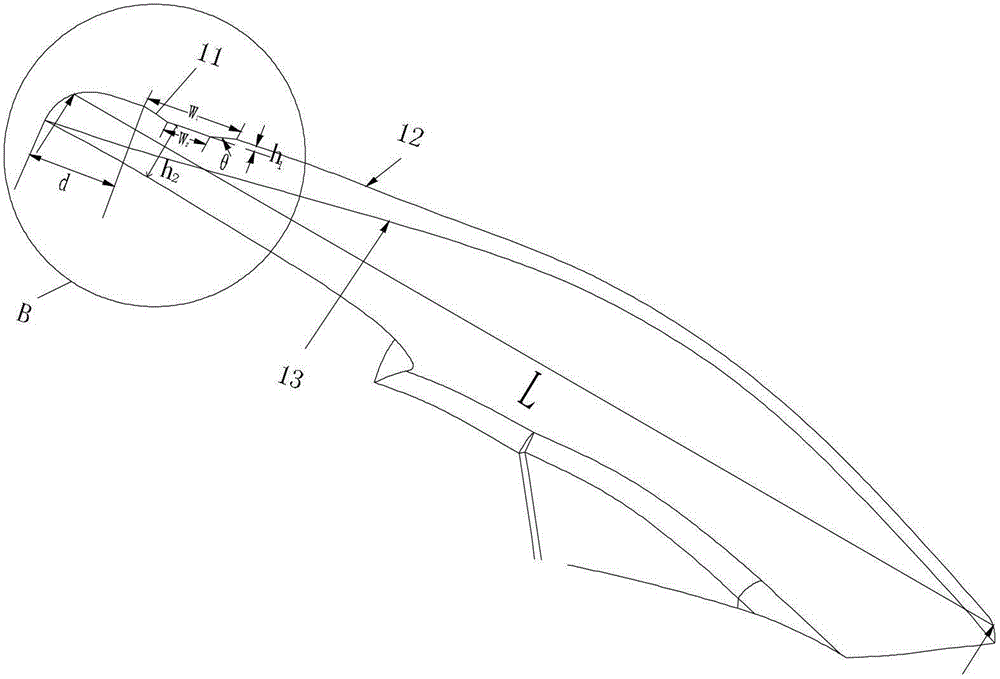

Axial-flow fan blade and air conditioner including the axial-flow fan blade

ActiveCN103511340BChange flow patternPromote productionPump componentsPumpsAir conditioningFront edge

The invention provides an axial-flow fan and an air conditioner comprising the axial-flow fan. The axial-flow fan comprises a hub and a plurality of blades arranged at the periphery of the hub in the axial direction, the blades are same in structure, and grooves are formed in the positions, close to the front edges, of the suction surfaces of the blades. According to the axial-flow fan and the air conditioner, the grooves are formed in the positions, close to the front edges, of the suction surfaces of the blades to enable the structures of the suction surfaces of the blades to be adjusted, the airflow flowing modes of the suction surfaces are further changed, the vortex generation and shedding modes are improved, and the aim of lowering noise is finally achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Mixed-flow electric dust collector

ActiveCN101862705BChange flow patternIncrease dust collection areaExternal electric electrostatic seperatorElectrode constructionsMixed flowEqualization

Owner:浙江海宁经编产业园区开发有限公司

Drying boxes for hot-blast air furnace

InactiveCN102072619BUniform temperatureChange flow patternDrying gas arrangementsDrying machines with local agitationThermal energyElectricity

The invention relates to drying boxes for a hot-blast air furnace. A humidity-discharging box is arranged in the middle of left and right drying boxes; balanced hot-blast air boxes are arranged at left and right ends of the left and right drying boxes; a waste heat recovery box is arranged on the top of the humidity-discharging box; a tube type heat exchanger is arranged in the waste heat recovery box; the bottom of the tube type heat exchanger is communicated with the humidity-discharging box; a fresh air suction inlet is formed at the front end of the tube type heat exchanger, and an air-collecting box is arranged at the rear end of the tube type heat exchanger; the end part of the air-collecting box is connected with the air inlet of a centrifugal fan; the air outlet of the centrifugalfan is connected with the air inlet of a hot-blast air furnace; and the top of the waste heat recovery box is opening and is used as a humidity-discharging opening. In the drying boxes, a mode of hot-blast air flowing is changed effectively, so that wind resistance is small; and the relatively-small fan can be selected, electricity is saved, the temperature in the drying boxes is uniform, the drying quality is improved, and energy is saved for a considerable part of heat energy is recovered in discharged damp and hot air.

Owner:如皋市精艺标牌厂

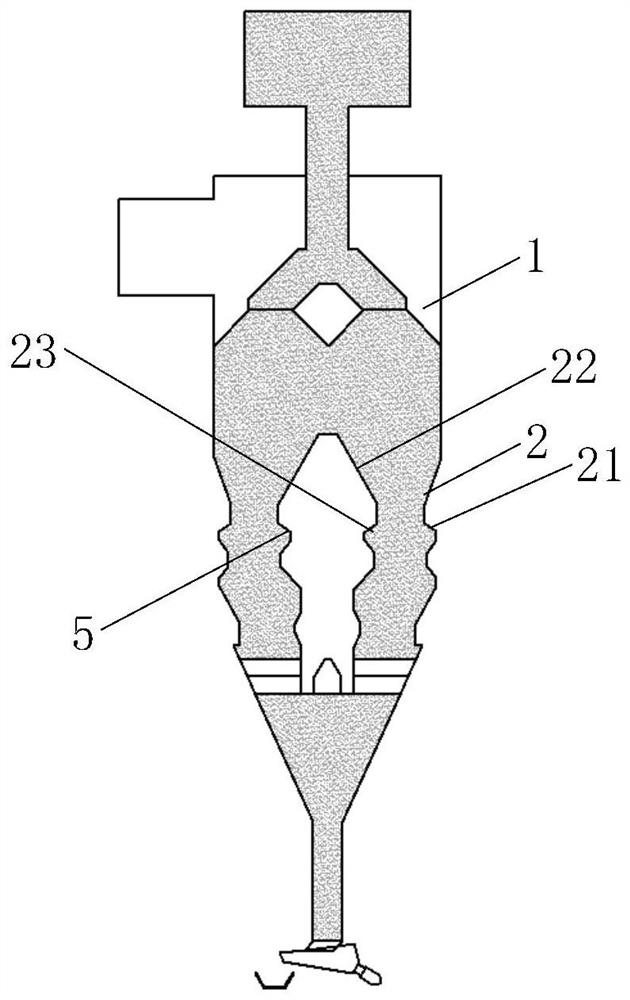

A vertical cooling furnace and its cooling method

ActiveCN113048796BChange flow patternIncrease profitHandling discharged materialGas solidProcess equipment

A vertical cooling furnace and a cooling method thereof belong to the technical field of waste heat recovery process equipment in the metallurgical industry. The vertical cooling furnace, along the material flow direction, sequentially includes: a feeding unit; a furnace chamber, through which the material to be cooled flowing in through the feeding unit enters into the furnace chamber, and a hot air duct is arranged on the furnace chamber, and the hot air duct communicates with the The furnace cavity and the outside; the air supply unit is arranged in the furnace cavity, the air supply unit is suitable for connecting with the air supply unit, and the air supply unit is provided with at least one air outlet; along the height direction, at least a part of the inner wall of the furnace cavity is provided with a depression The concave part extends toward the air supply unit; the cooling method of the vertical cooling furnace includes the following steps: feeding, cooling by heat exchange for the first time, cooling by heat exchange for the second time, and discharging. The vertical cooling furnace and its cooling method can change the gas flow rate and particle flow rate in the furnace cavity, so that the gas-solid heat transfer coefficient in the furnace cavity can be improved, thereby improving the gas-solid heat transfer and increasing the recovery rate of waste heat.

Owner:NORTHEASTERN UNIV LIAONING

A component of a casting tundish impurity removal and flow control device

ActiveCN113333722BImprove room temperature strengthEasy to transportMelt-holding vesselsCasting cleaning apparatusMicro nanoEngineering

The invention discloses a casting tundish impurity removal and flow control device assembly, which relates to the technical field of metal casting; it includes a weir and a filter vertically arranged in the tundish, the bottom of the weir is provided with a flow-facing inclined surface, and the filter The bottom of the filter is symmetrically provided with two horizontally arranged semi-circular frustum-shaped discharge holes, the upstream surface of the filter is provided with two conical holes, and the backflow surface of the filter is provided with three circular holes. The shape hole and the circular hole are connected by a circular channel; the surface of the weir, the surface of the filter, the circular hole, the tapered hole, the semi-circular truncated discharge hole and the wall of the circular channel are all coated with a layer of micro-nano oxide functional coating. The impurity removal and flow control device component of the casting tundish provided by the invention has high temperature thermal shock resistance, high inclusion removal rate and low cost.

Owner:WUHAN UNIV OF SCI & TECH +1

Finned spiral tube

ActiveCN103206883BIncreased turbulenceEnhanced mass transferHeat transfer modificationTubular elementsEngineeringCircular surface

The invention discloses a finned spiral pipe. The finned spiral pipe comprises a spiral pipe with a circular section, wherein a plurality of fins are evenly distributed on the inner wall of the spiral pipe, and the fins have the same spiral structure as that of the lead of the spiral pipe; the sections of the fins are shaped like a fan, and the radius of the section of each fin is equal to that of the circular surface of the inner wall of the section of the spiral pipe.

Owner:无锡苏惠信息技术服务有限公司

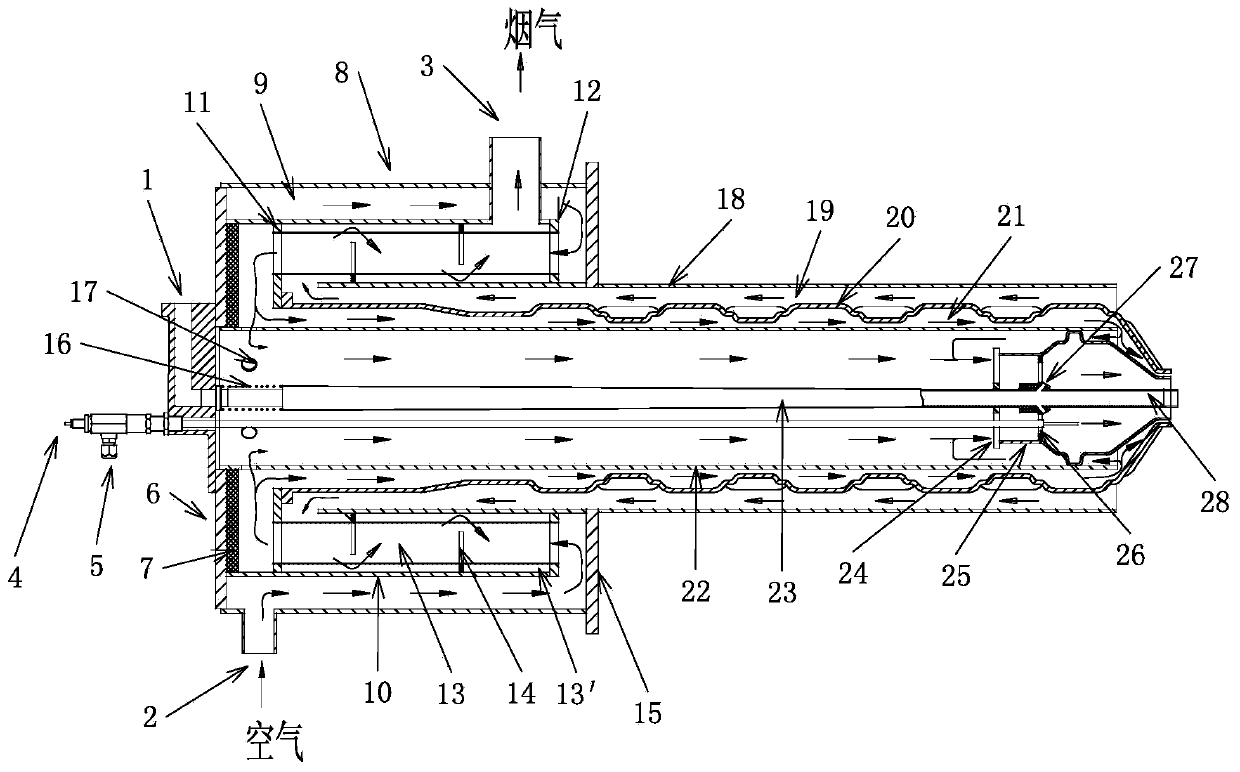

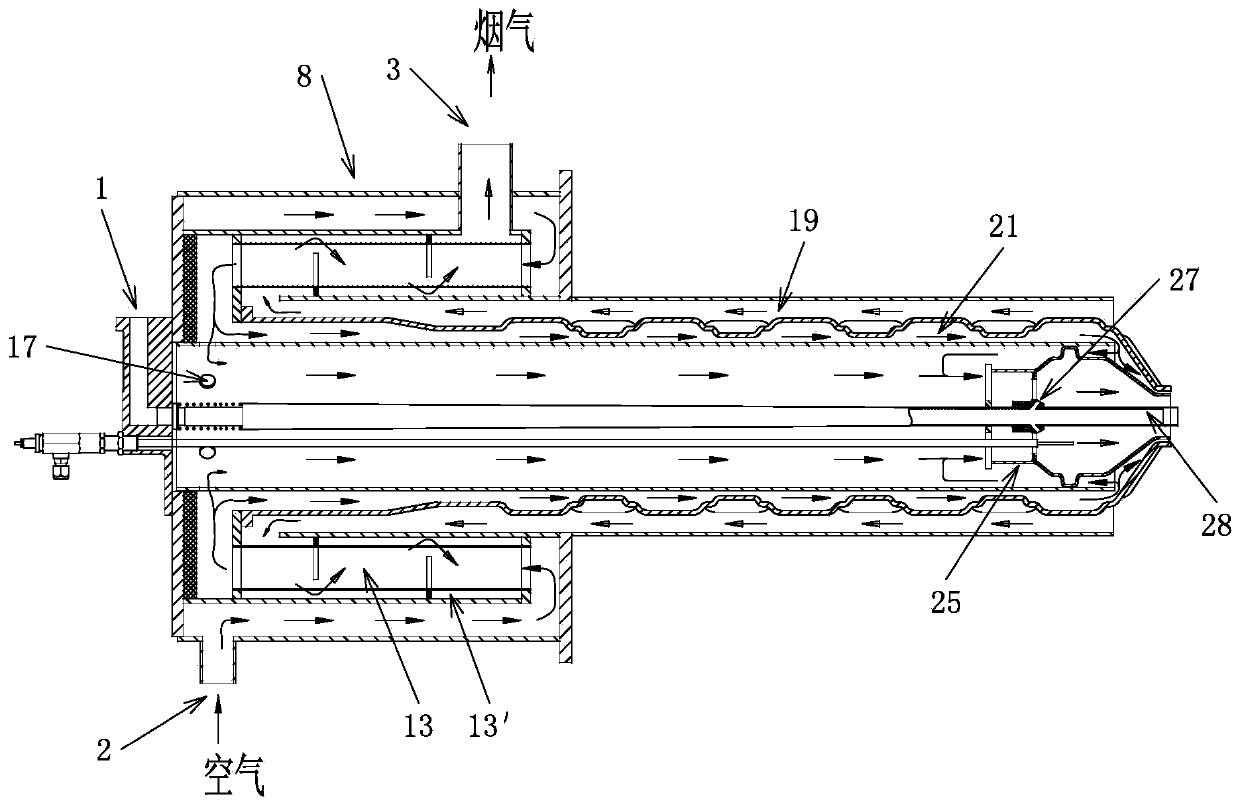

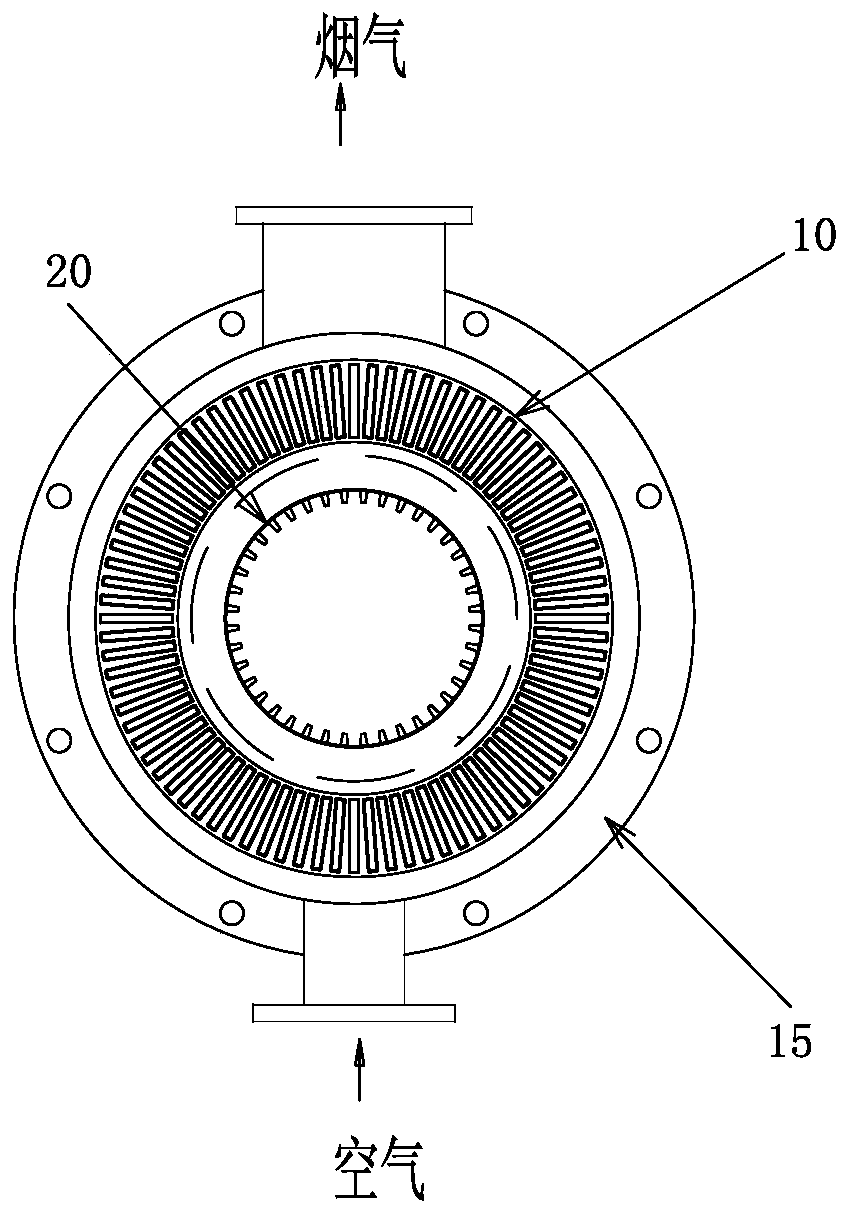

High-efficiency low-NOx two-stage self-preheating burner

PendingCN110440256AImprove the level of energy savingImprove heat transfer efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberFlue gas

The invention relates to a high-efficiency low-NOx two-stage self-preheating burner comprising a shell, an air guide pipe, a gas guide pipe, a flue gas guide pipe, a combustion chamber and a self-cooling electrode. An air inlet, a flue gas outlet and a gas inlet are formed in the shell, the gas guide pipe is fixed in the air guide pipe and communicates with the gas inlet, the air guide pipe is sleeved with a primary heat exchanger matched with the air guide pipe to form an air passage, the flue gas guide pipe is arranged on the surface of the primary heat exchanger in a sleeving manner to forma flue gas passage communicating with the flue gas outlet, the shell is internally provided with a secondary heat exchanger installed on the surface of the air guide pipe in a sleeving manner, the secondary heat exchanger is provided with a plurality of heat exchanger passages I and a heat exchanger passage II communicating with the flue gas passage, and the two ends of each heat exchanger passage I are in communication with the air inlet and the air passage. The high-efficiency low-NOx two-stage self-preheating burner can perform two-stage heat exchange on air, the heat exchange efficiency is effectively improved, the temperature of the preheated air is improved to the greatest extent, the air is fully preheated by utilizing waste heat of flue gas, the combustion efficiency is improved,and the energy saving level of the self-preheating burner us greatly improved.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

A method of hydraulic fracturing gas extraction by drilling through layers

InactiveCN103912302BChange flow patternImprove the extraction effectGas removalWater flowHigh pressure water

Provided is a seam-penetrating drilling hydrofracturing gas extracting method. The method includes that a target drill hole and a hole for penetrating a coal seam are preset as a hydrofracturing free surface; a chambering section of the target drill hole is expanded, and a sleeve is put into the drill hole, fixed and connected with a separating chamber. High-pressure water enters the fracturing drill hole to fracture a coal body, and a fracturing gap is gradually expanded until the gap is communicated with the hole. The water pressure and water amount are increased, and the coal body around the gap is washed. Water flow carries gas and the coal body to pass through the target drill hole to enter the chamber, the gas is extracted, and separation of the gas is achieved. After the coal body is washed, a macro gap communicating the fracturing drill hole and the target drill hole is formed. During extraction, the gas leaks into the gap, flows into the target drill hole and the hydrofracturing drill hole, and a gas flowing mode is changed fundamentally. The gap is equivalent to extension of the length of the target drill hole and the hydrofracturing drill hole in the coal seam, contact area between the gap and the coal body is increased, and a gas extraction effect can be improved.

Owner:CHINA UNIV OF MINING & TECH

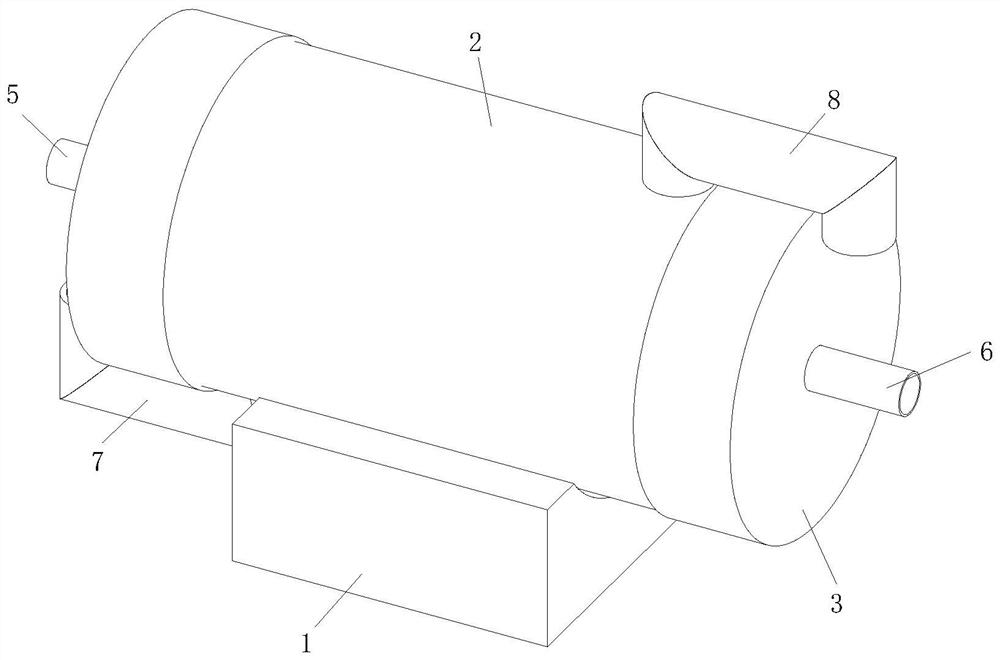

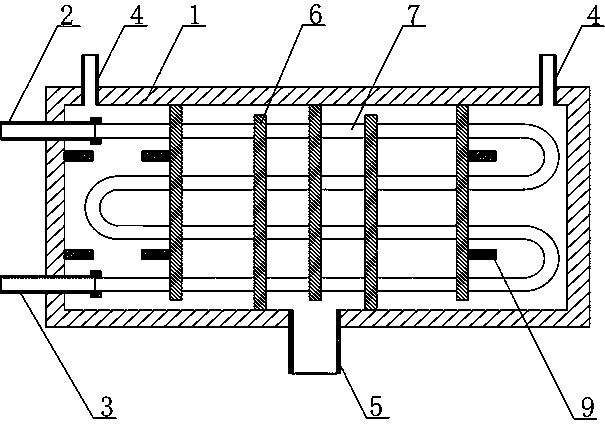

Engine Auxiliaries for Natural Gas Extraction Processes

The invention discloses an engine assistant device used for a natural gas extraction technique. The engine assistant device used for the natural gas extraction technique comprises a tank body, a liquid inlet pipe and a liquid outlet pipe, wherein a bent heat exchange pipe is arranged in the tank body; a plurality of spoilers are arranged on the heat exchange pipe; a plurality of separation plates are fixed on the inner wall of the tank body at equal intervals; through holes are formed in each separation plate; the heat exchange pipe penetrates through the through holes; sealing rings are arranged between the heat exchange pipes and the through holes; the space in the tank body is divided into a plurality of air cooling areas which communicate with one another by the separation plates; the side wall of the first air cooling area and the side wall of the last air cooling area are separately provided with an air inlet; and the tank body is provided with an air outlet. According to the engine assistant device, an air flowing path in the tank body is reasonably designed, and air inlet is realized by utilizing the two air inlets, so that resource of cooling liquid is saved, and exploitation cost is lowered; the problem of a traditional air cooler that low-temperature cooling liquid is heated by high-temperature air in the last half flowing path is also avoided; and the heat exchange efficiency is effectively improved.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

Engine assistant device used for natural gas extraction technique

ActiveCN106123621AReduce volumeDecrease in size and gradually increaseSteam/vapor condensersCooling fluidNatural gas

The invention discloses an engine assistant device used for a natural gas extraction technique. The engine assistant device used for the natural gas extraction technique comprises a tank body, a liquid inlet pipe and a liquid outlet pipe, wherein a bent heat exchange pipe is arranged in the tank body; a plurality of spoilers are arranged on the heat exchange pipe; a plurality of separation plates are fixed on the inner wall of the tank body at equal intervals; through holes are formed in each separation plate; the heat exchange pipe penetrates through the through holes; sealing rings are arranged between the heat exchange pipes and the through holes; the space in the tank body is divided into a plurality of air cooling areas which communicate with one another by the separation plates; the side wall of the first air cooling area and the side wall of the last air cooling area are separately provided with an air inlet; and the tank body is provided with an air outlet. According to the engine assistant device, an air flowing path in the tank body is reasonably designed, and air inlet is realized by utilizing the two air inlets, so that resource of cooling liquid is saved, and exploitation cost is lowered; the problem of a traditional air cooler that low-temperature cooling liquid is heated by high-temperature air in the last half flowing path is also avoided; and the heat exchange efficiency is effectively improved.

Owner:CHENGDU ZHENGSHENG ENERGY TECH DEV CO LTD

Hydrogen production system employing reforming technology

The invention discloses a hydrogen production system employing reforming technology, in particular to a sleeve type hydrogen enriched fuel hydrogen production system employing reforming technology with highly efficient heat and mass transfer. The system comprises a heat supply unit, a reformer and a CO purification and elimination unit; wherein, the outlet of the reformer is communicated with theinlet of the CO purification and elimination unit through a heat exchanger, the outlet of the CO purification and elimination unit is communicated with the hydrogen inlet of a fuel cell; the heat supply unit has a two-layer sleeve barrel structure, the outer cavity is a combustion heat-providing cavity, the inner cavity is a raw material heating cavity, an enriched fuel inlet, an oxidant gas inlet and a hydrogen inlet are arranged on the combustion heat-providing cavity, the exhaust gas outlet of the fuel cell is communicated with the hydrogen inlet on the combustion heat-providing cavity; the outlet of the raw material heating cavity is communicated with the inlet of the reformer; at least two groups of fins are arranged on the inner wall of the raw material heating cavity axially. The system has reasonable structure, the burning and the heating are uniform, the catalyst is not easy to sinter, the performances of the mass transfer and the heat transfer are good and the energy efficiency is high.

Owner:HANERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com