Laser-induced arc cladding high-boron wear resistant alloy processing method

A wear-resistant alloy and processing method technology, applied in the field of alloy processing, can solve the problems of high process cost, easy cracks, stress concentration, etc., achieve the effect of low laser power, improve stability, and save process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

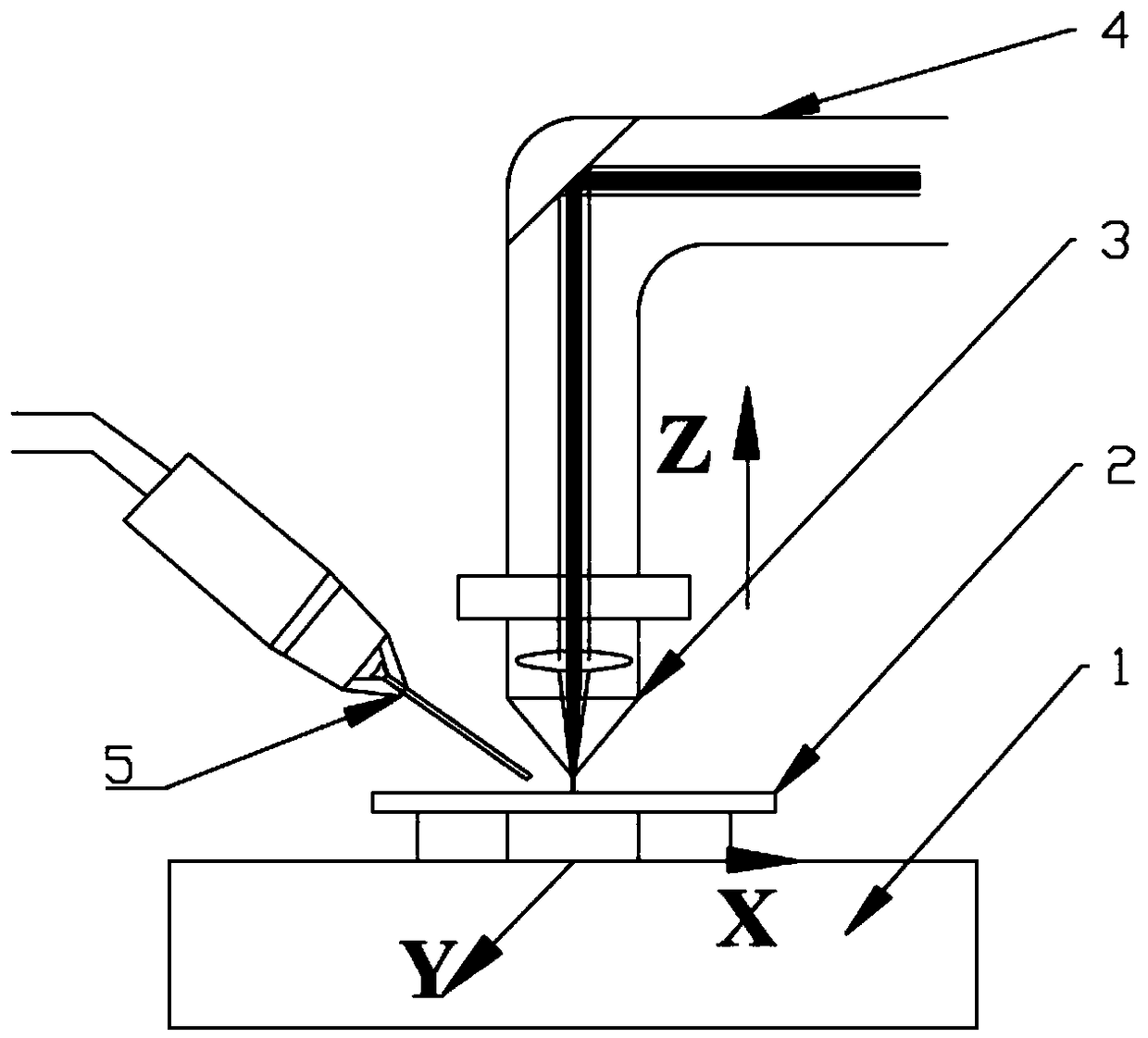

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, in the laser-induced arc cladding method for high-boron wear-resistant alloys in this embodiment, the workpiece 2 to be repaired is placed on the workbench 1, and a laser head is installed above the workbench 1 through the optical transmission system 4 of the laser. 3. It also includes the electrode 5 of the arc system, and the laser output energy of the laser is less than or equal to 500w; the specific process includes the following steps:

[0027] The first step: determine the cladding position, size and cladding powder thickness, determine the cladding size of the upper surface of the workpiece 2 to 100x30mm, and set the thickness of the high boron alloy powder to 1-2mm;

[0028] Step 2: Calculate the mass of high-boron alloy powder, calculate the volume and mass of high-boron alloy powder according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com