Mixed-flow electric dust collector

An electrostatic precipitator and mixed-flow technology, which is applied in the field of mixed-flow electrostatic precipitators, can solve the problems of large volume, poor dust removal effect, and complex structure of the dust removal device, and achieve the effects of simple structure, improved dust collection effect, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

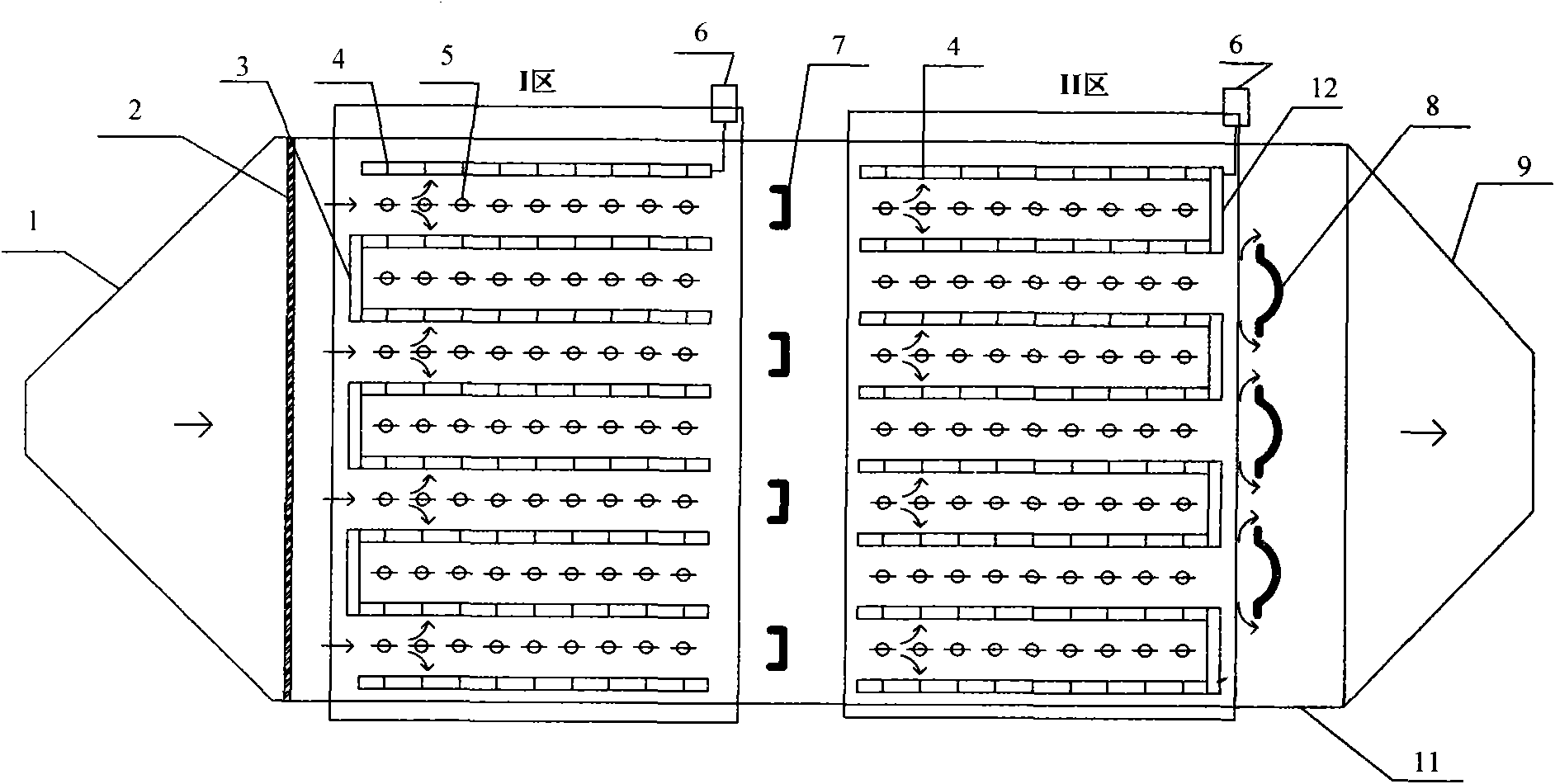

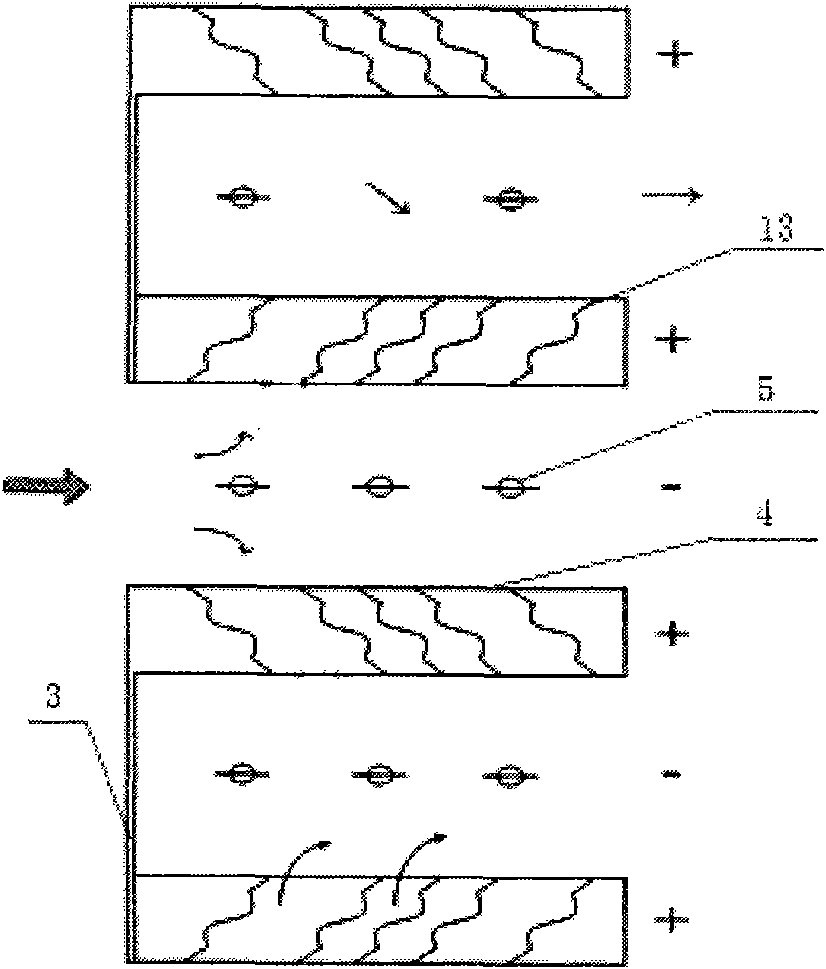

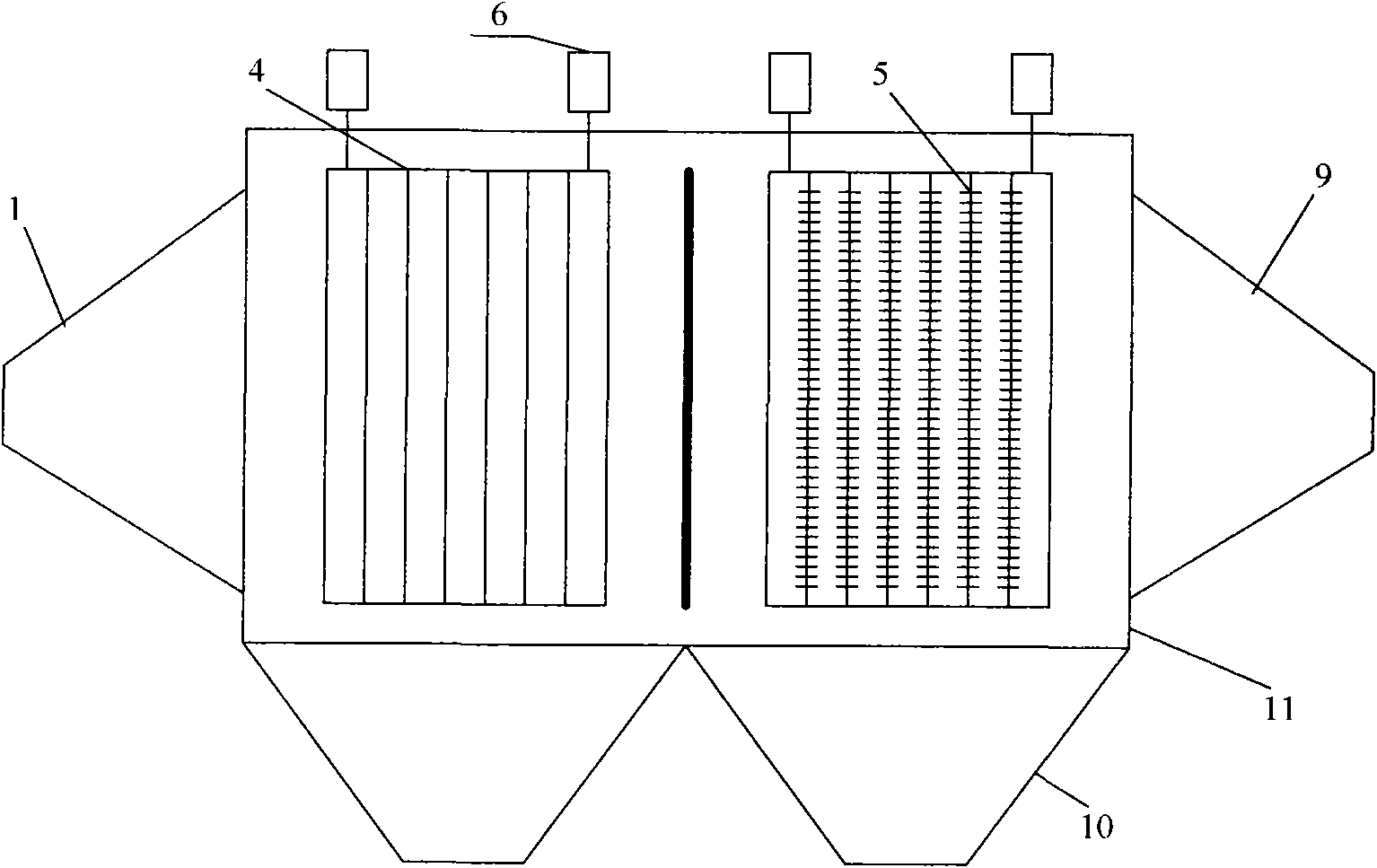

[0037] Embodiment: a kind of mixed-flow electric precipitator (referring to attached figure 1 , 3 ), consisting of an electrostatic dust chamber and a high-voltage power supply, the two ends of the dust chamber are respectively connected to the flue gas inlet part 1 and the flue gas outlet part 9, and the dust removal chamber includes a shell 11, a dust collection pole 4 with a dust collection pole plate 13, a dust collector The dust electrode rapping device 6, the corona electrode 5 matched with the dust collector, the corona electrode rapping device and the ash hopper 10 for receiving the falling dust, and the connection between the dust removal chamber and the flue gas inlet part 1 is provided with an airflow distribution plate 2. There are uniform through holes on the surface of the air distribution plate 2 to make the intake air flow evenly distributed; there are two longitudinal electric fields, the first electric field and the second electric field, in the dust removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com