Plate polishing device with automatic cleaning capacity

A plate polishing device and automatic cleaning technology, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of generating a large amount and affecting the health of workers, and achieve the effect of adjusting the size of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

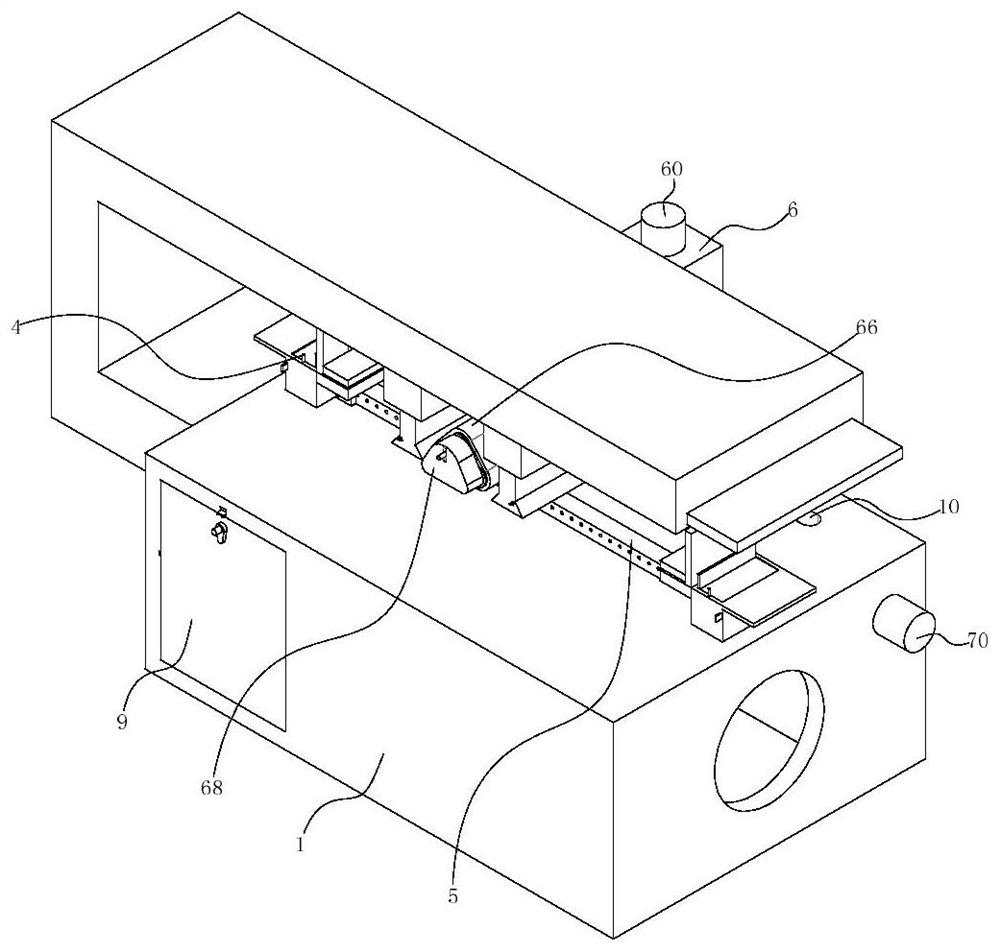

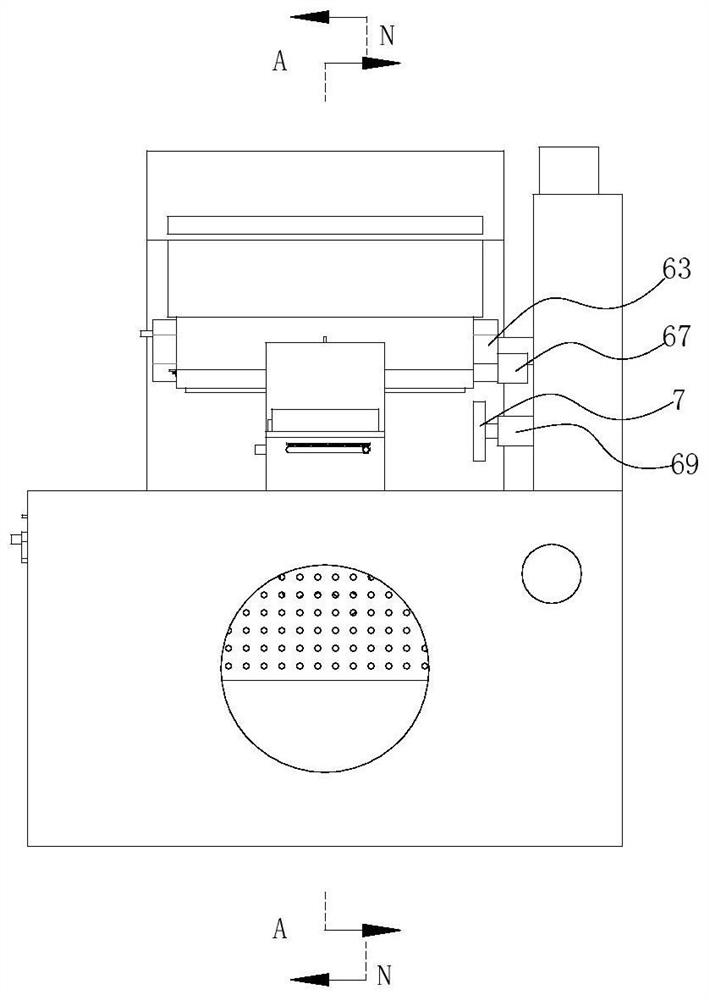

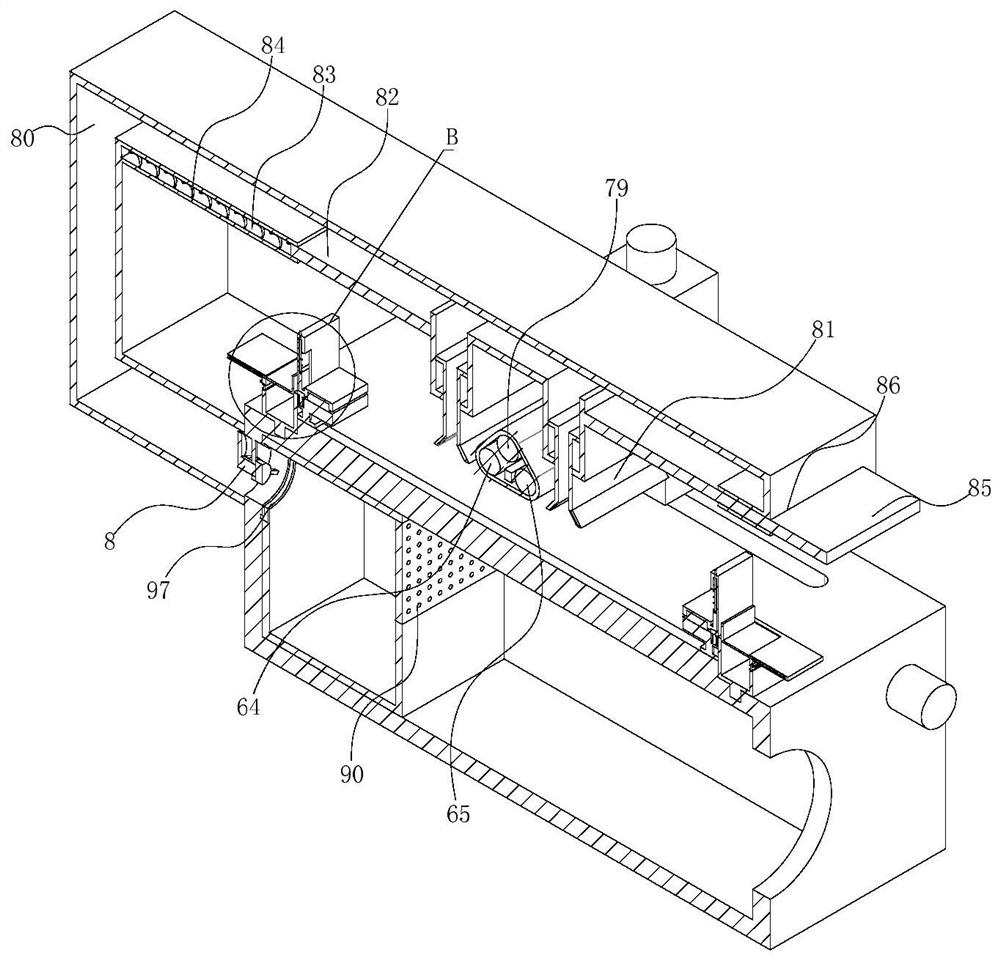

[0028] Such as Figure 1-17 As shown, a plate polishing device with automatic cleaning capability includes a frame 1, a clamping mechanism, a polishing mechanism, a dust suction mechanism and a collecting mechanism.

[0029] Specifically, the clamping mechanism includes a base 2, a bottom plate 20, a positioning assembly, an upper plate assembly and a cleaning assembly; the bottom plate 20 is located on the top surface of the base 2; the upper plate assembly includes an upper plate 21, a splint 22, a pull rod 23, Pull bar spring 24, splint groove 25, rubber plate 26 and rotating parts; Upper plate 21 is positioned on the upper top surface of bottom plate 20; Clamping plate 22 can slide up and down in splint groove 25 in the middle of upper plate 21; Rubber plate 26 is positioned at splint 22 Bottom surface; pull bar 23 can rotate on clamping plate 22; Pull bar spring 24 one ends are fixedly connected on the upper top surface of clamping plate 22, and the other end is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com