A suction device for a vacuum feeder

A technology of vacuum feeder and suction device, which is applied in conveyors, transportation and packaging, and conveying bulk materials, etc., can solve the problems of lack of air circulation in conveying pipelines, repeated manual operations, and inability to absorb materials. Multiple manual operations, easy to use, and the effect of improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

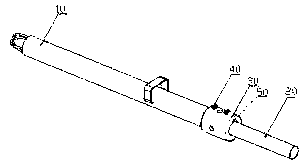

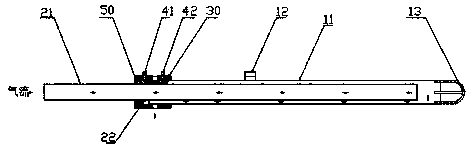

[0024] figure 1 It is the three-dimensional structural diagram of suction device of the present invention, as figure 1 As shown, the suction device of the vacuum feeder of the present invention includes an outer gun 10 , an inner gun 20 , a connecting sleeve 30 , a locking stud 40 and a cylindrical pin 50 . Depend on image 3 It can be seen that the outer gun 10 includes: an outer gun barrel 11, a gun handle 12 and a gun point 13, wherein the gun handle 12 and the gun point 13 are fixed on the outer gun barrel 11, preferably, the gun handle 12 and the gun point 13 are welded Or the mode of bonding is fixed on the outer gun barrel 11, and described outer gun barrel 11, gun point 13 are metal profiles, processed parts or sheet metal parts; The material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com