Engine assistant device used for natural gas extraction technique

An auxiliary device and natural gas technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as poor cooling effect, achieve the effects of increasing passing speed, reducing mining costs, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

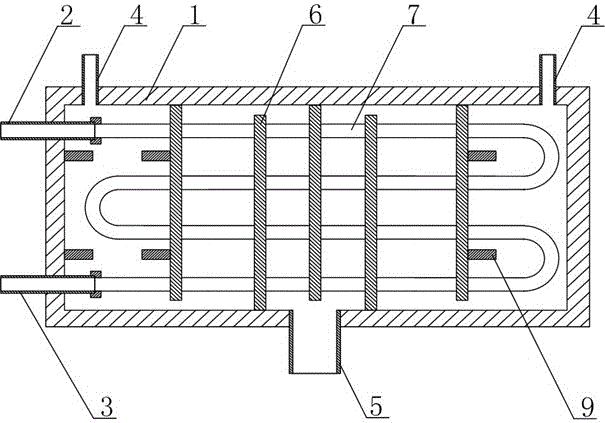

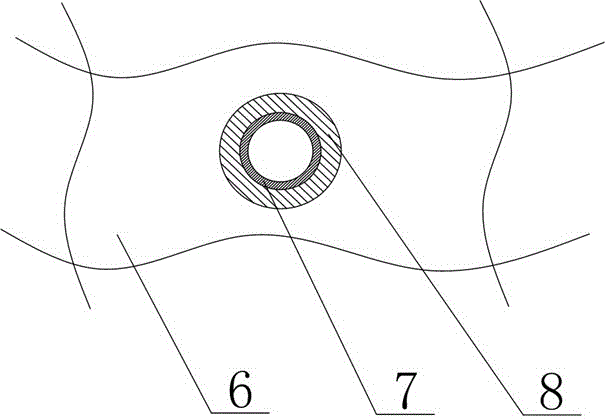

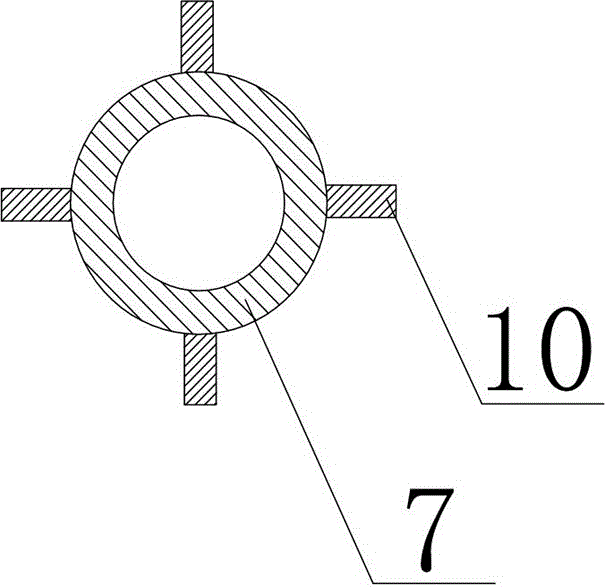

[0030] like figure 1 , figure 2 and image 3 As shown, the present invention is an engine auxiliary device for a natural gas extraction process, including a box body 1, a liquid inlet pipe 2 and a liquid outlet pipe 3 are arranged on the same side of the box body 1, and a heat exchange pipe is arranged inside the box body 1. The two ends of the pipe 7 and the heat exchange pipe 7 are respectively connected to the liquid inlet pipe 2 and the liquid outlet pipe 3, and a plurality of partition plates 6 are fixed on the inner wall of the box body 1, and a plurality of through holes are arranged on the partition plate 6, and the heat exchange pipe 7 passes through the through hole, a sealing ring 8 is arranged between the heat exchange tube 7 and the through hole, the partition plate 6 is parallel to the side of the box body 1 where the liquid inlet pipe 2 is located, and the partition plate 6 divides the inner space of the box body 1 Divided into several connected air-cooling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com