A method of using gas to purify steel ingot and reduce a segregation

A technology for gas purification and steel ingots, applied in the field of steel ingot manufacturing, can solve the problems of affecting the mechanical properties of materials, difficulty in operation, decrease in qualification rate, etc., and achieve the effect of increasing the adsorption area of inclusions, improving the quality of steel ingots, and ensuring the argon blowing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. The steel ingot is made of No. 45 medium carbon steel, and the specific chemical composition is shown in Table 1. The ingot mold material is ordinary water glass sand; the height-to-diameter ratio of the riser is 2 (height-to-diameter ratio: H is the height of the riser, D is the diameter of the top of the riser, and d is the diameter of the root of the riser); the molten steel is fired at a high temperature, the temperature of the furnace is 1620-1640°C, the pouring temperature is 1580±10°C, and the cavity is filled with argon before pouring , pouring under the protection of argon; the steel ingots are fully baked before sand casting to prevent gas hole defects caused by gas generation. The design goal of the above process parameters is to ensure good internal quality of the steel ingot and prolong the solidification time of the steel ingot appropriately.

[0038] Chemical composition of table 145# steel (wt%)

[0039]

[0040] 2. Select two 500kg steel ingots...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] In this example, the liquid mold flux can use SiO 2 -Al 2 o 3 -CaO-CaF 2 Slag system, by weight percentage, 20% SiO 2 ;25%Al 2 o 3 ;35%CaO;20%CaF 2 .

[0051] 1. The pouring weight of steel ingot is 700kg, and the specific size is Φ400mm×800mm.

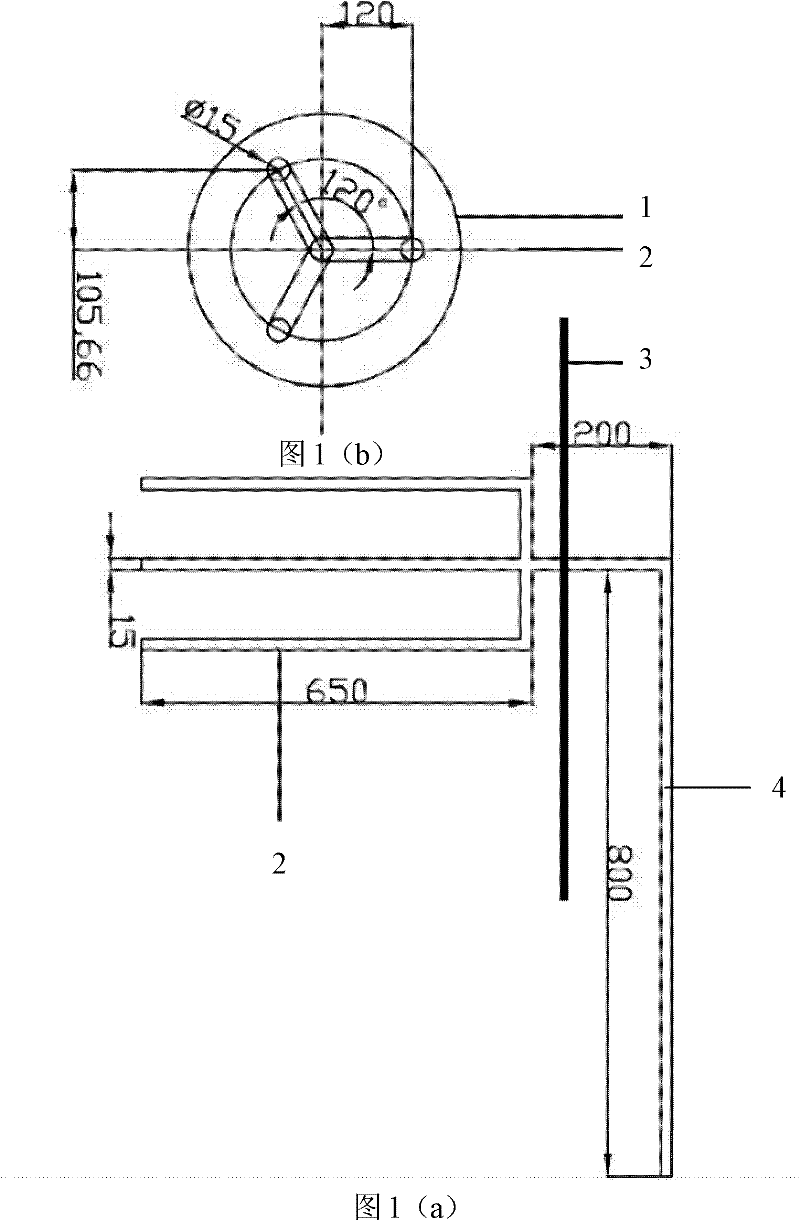

[0052] 2. According to the specific size of the steel ingot, the rotary argon blowing ventilation equipment is designed, and three ventilation pipes are selected. The inner diameter of the ventilation pipes is

[0053] 3. The material of the ventilation pipe is corundum pipe, and the preheating temperature is 900°C.

[0054] 4. During the pouring process, extend the preheated air pipe from the top of the steel ingot riser to half of the height of the steel ingot, and keep the argon pressure at 3 standard atmospheric pressure. When the molten steel is full of the ingot mold, quickly add the ingot Liquid mold slag commonly used for risers of steel.

[0055] 5. The argon blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com