Hydrogen production system employing reforming technology

A technology for reforming hydrogen production and reformer, applied in the fields of hydrogen, sustainable manufacturing/processing, inorganic chemistry, etc., can solve the lack of flexibility in temperature adjustment of catalytic reaction units, the inability to ensure the safety of reactors and heat exchangers, Heat can not be transferred and other problems, to achieve the effect of ensuring power generation performance, not easy to sinter, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

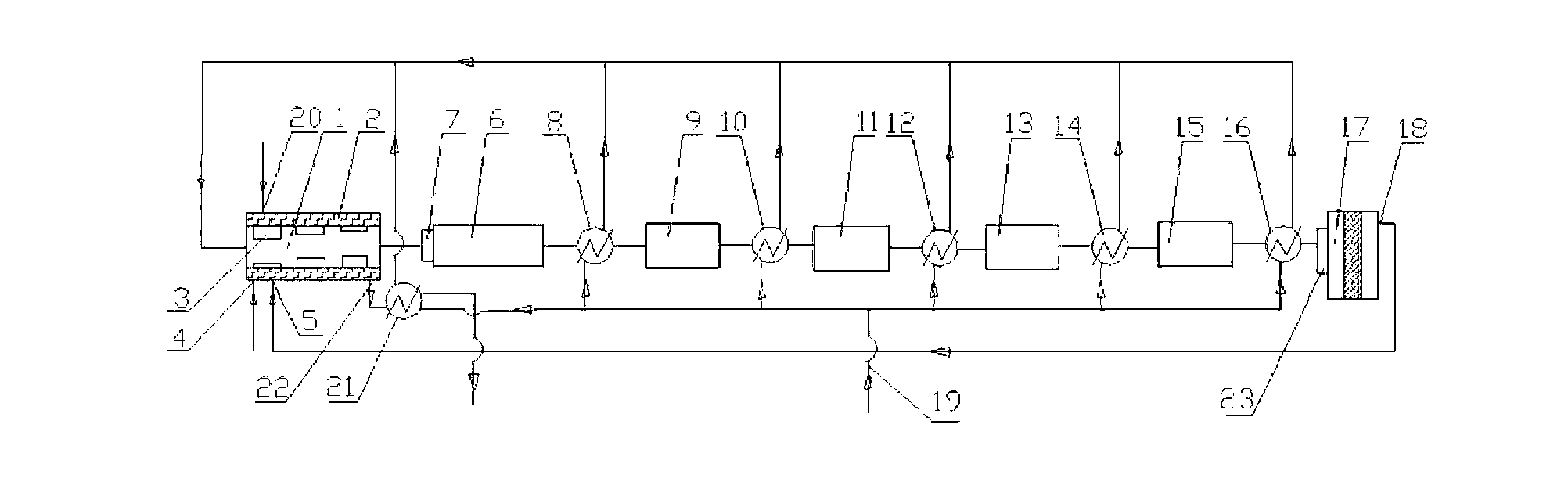

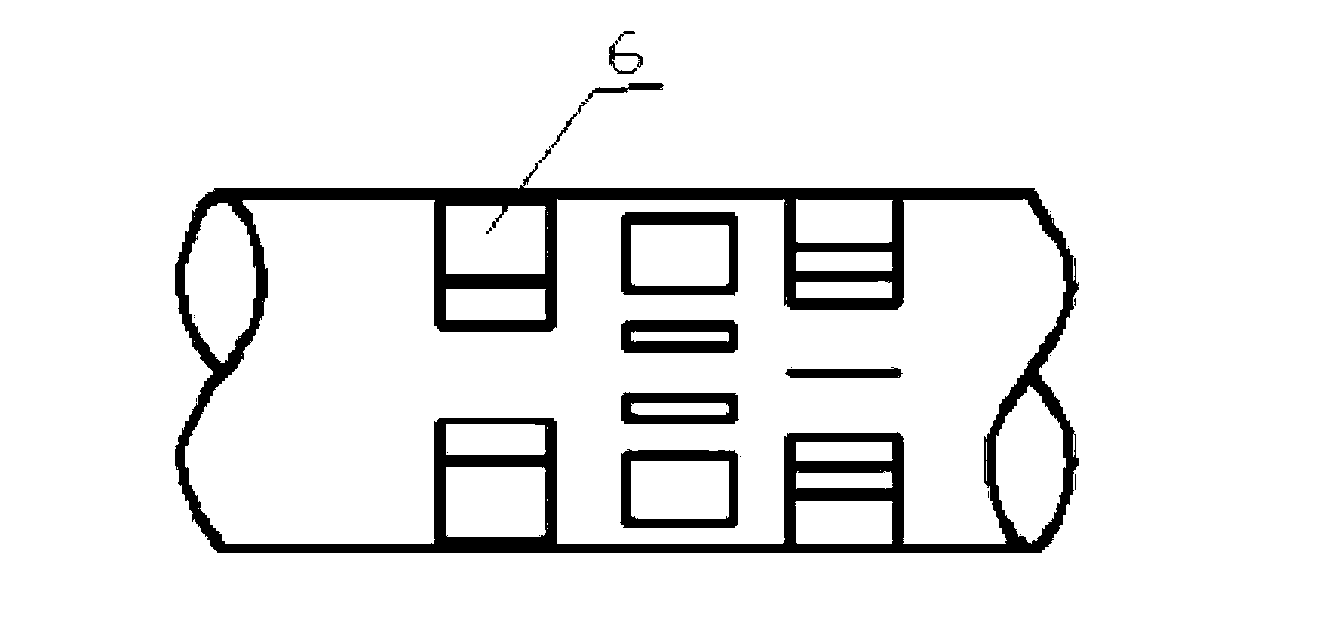

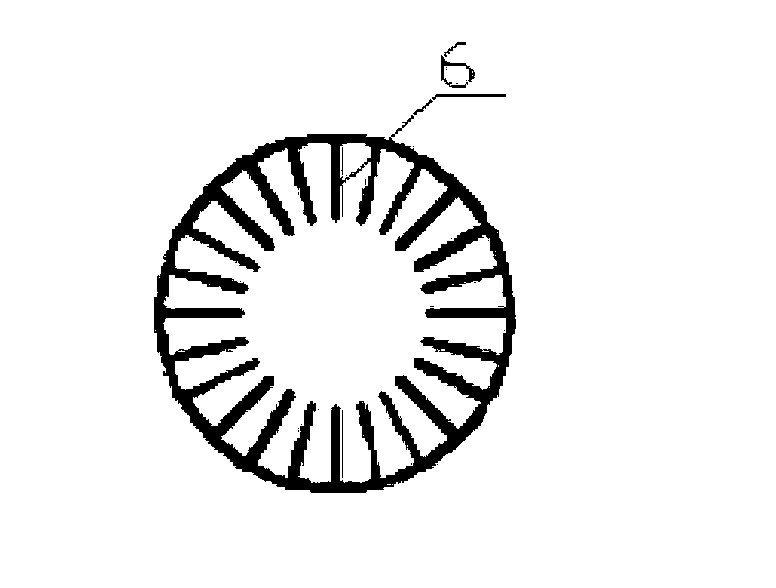

[0037] A reforming hydrogen production system, such as figure 1 , 2 , 3, including a heat supply unit, a reformer 6, and a CO purification and removal unit, the outlet of the reformer 6 communicates with the inlet of the CO purification and removal unit through a heat exchanger 12, and the outlet of the CO purification and removal unit passes through a heat exchange The device 16 communicates with the hydrogen inlet of the fuel cell 17; the heating unit is a two-layer sleeve structure, the outer cavity is the combustion heating cavity 2, and the inner cavity is the raw material heating cavity 1, and the combustion heating cavity 2 is provided with methanol Inlet 4, air inlet 20 and hydrogen inlet 5, the tail gas outlet 18 of the fuel cell 17 communicates with the hydrogen inlet 5 on the combustion heating chamber 2; the outlet of the raw material heating chamber 1 communicates with the inlet of the reformer 6; Three groups of fins 3 are axially arranged on the inner wall of t...

Embodiment 2

[0054] The system structure and operation method are basically the same as in Embodiment 1, except that two groups of ribs 3 are axially arranged on the inner wall of the raw material heating chamber 1, and the groups are staggered radially along the central axis of the chamber, and each group is 5 pieces , the adjacent fins between each group are staggered at an angle of 36° in the radial direction along the central axis of the cavity; the oxidant gas is oxygen; the CO purification and removal unit is a CO methanation reactor; the The regenerator is quartz sand; each fin has 12 holes, and the area of the holes is 60% of the area of the fin.

Embodiment 3

[0056] The system structure and operation method are basically the same as in Embodiment 1, except that each fin has two holes, and the area of the holes is 10% of the area of the fin.

[0057] The hydrogen-rich fuel for combustion and raw materials is not limited to methanol in the above examples, but can also be methane, dimethyl ether, hydrogen, ethanol, natural gas, city gas, liquefied petroleum gas, gasoline, kerosene or diesel oil, etc. Embodiment, wherein, the hydrogen-rich fuel used as a raw material can also be a methanol solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com