Method for preparing calcium-based CO2 adsorbent by doping of rare earth waste

A rare earth doping and waste technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of affecting adsorbent adsorption, reducing adsorption effect, hindering gas diffusion, etc., to improve adsorbent performance, solve the Easy sintering, obvious adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

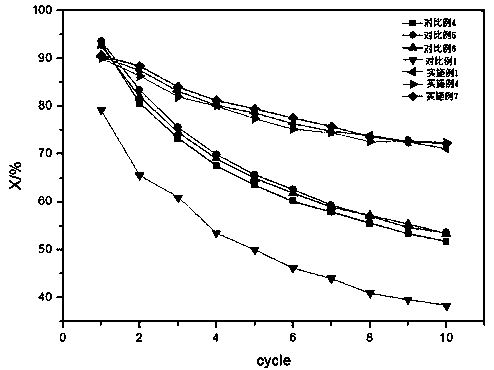

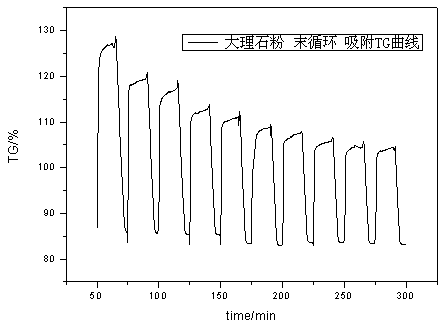

[0042] Example 1: The rare earth waste in this example is waste rare earth polishing powder, and the waste calcium-based precursor is the marble powder in Comparative Example 1;

[0043] A preparation of calcium-based CO by doping rare earth waste 2 The method of adsorbent, concrete steps are as follows:

[0044] (1) Cleaning the impurities on the surface of rare earth waste (waste rare earth polishing powder), and then dissolving with sodium hydroxide (NaOH), roasting, drying, grinding, dissolving in concentrated hydrochloric acid, oxalic acid precipitation, filtering and roasting to obtain rare earth doping Dopant powder, the composition of waste rare earth polishing powder is shown in Table 4, wherein the oxides of rare earth elements in the rare earth dopant (CeO 2 ) mass percentage content is 51.979%;

[0045]

[0046] (2) Clean the impurities on the surface of the waste calcium-based precursor (waste marble), dry, crush, and then place it at a temperature of 800°C f...

Embodiment 2

[0051] Example 2: The rare earth waste in this example is the same as that in Example 1, and the calcium-based precursor of the waste is the carbide slag calcium-based in Comparative Example 2;

[0052] A preparation of calcium-based CO by doping rare earth waste 2 The method of adsorbent, concrete steps are as follows:

[0053] (1) Cleaning the impurities on the surface of rare earth waste (waste rare earth polishing powder), and then dissolving with sodium hydroxide (NaOH), roasting, drying, grinding, dissolving in concentrated hydrochloric acid, oxalic acid precipitation, filtering and roasting to obtain rare earth doping Dopant powder, the composition of rare earth dopant powder is as shown in Table 4 of embodiment 1, wherein the oxide (CeO 2 ) mass percentage content is 51.979%;

[0054] (2) Clean the impurities on the surface of the waste calcium-based precursor (waste calcium carbide slag), dry, crush, and then place it at a temperature of 950°C for 6 hours to obtain ...

Embodiment 3

[0059] Example 3: The rare earth waste in this example is the same as in Example 1, and the calcium-based precursor of the waste is the egg shell of Comparative Example 3;

[0060] A preparation of calcium-based CO by doping rare earth waste 2 The method of adsorbent, concrete steps are as follows:

[0061] (1) Cleaning the impurities on the surface of rare earth waste (waste rare earth polishing powder), and then dissolving with sodium hydroxide (NaOH), roasting, drying, grinding, dissolving in concentrated hydrochloric acid, oxalic acid precipitation, filtering and roasting to obtain rare earth doping Dopant powder, the composition of rare earth dopant powder is as shown in Table 4 of embodiment 1, wherein the oxide (CeO 2 ) mass percentage content is 51.979%;

[0062] (2) Clean the impurities on the surface of the waste calcium-based precursor (egg shell), dry, crush, and then place the temperature at 900°C for 5 hours to obtain the calcium-based precursor; see Comparativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com