Au@CeO2 nanocomposite material having hollow core-shell structure, and preparation method thereof

A technology of nanocomposite material and core-shell structure, which is applied in the field of hollow core-shell structure AuCeO2 nanocomposite material and its preparation, which can solve the problems such as the easy sintering of active component Au, and achieve the effect of facilitating adsorption and desorption and reducing diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

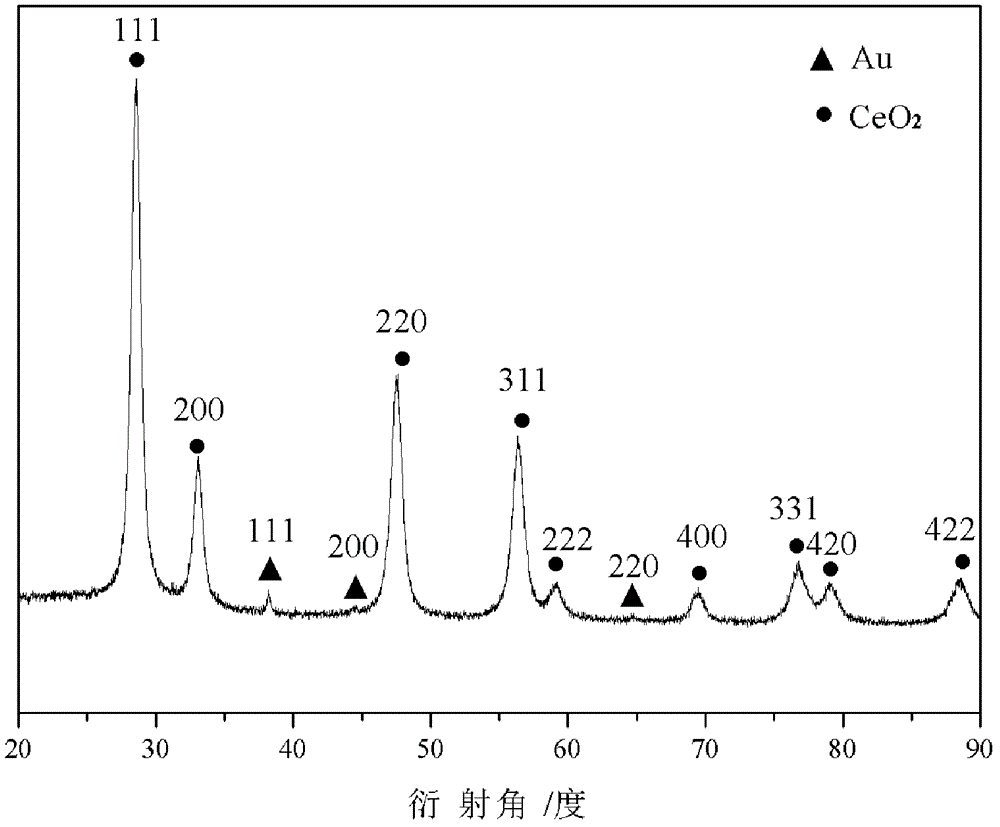

[0021] The invention provides a hollow core shell structure AuCeO 2 A method for preparing a nanocomposite, wherein the method comprises the following steps,

[0022] 1) After the cerium source, urea and distilled water are mixed and dissolved to obtain a dissolved solution, the sodium citrate solution is first contacted with the dissolved solution, and the product after the first contact is first contacted with a hydrogen peroxide solution. The second contact is to crystallize the product after the second contact and dry to obtain a solid product;

[0023] 2) After uniformly mixing gold source, stabilizer and distilled water to obtain a mixed solution, adding the solid product obtained in step 1) to the mixed solution for the third contact, separating the solid-liquid product after the third contact to obtain The first solid, the obtained first solid is dispersed in distilled water to obtain a dispersion, the dispersion is contacted with sodium citrate for the fourth time, a...

Embodiment 1

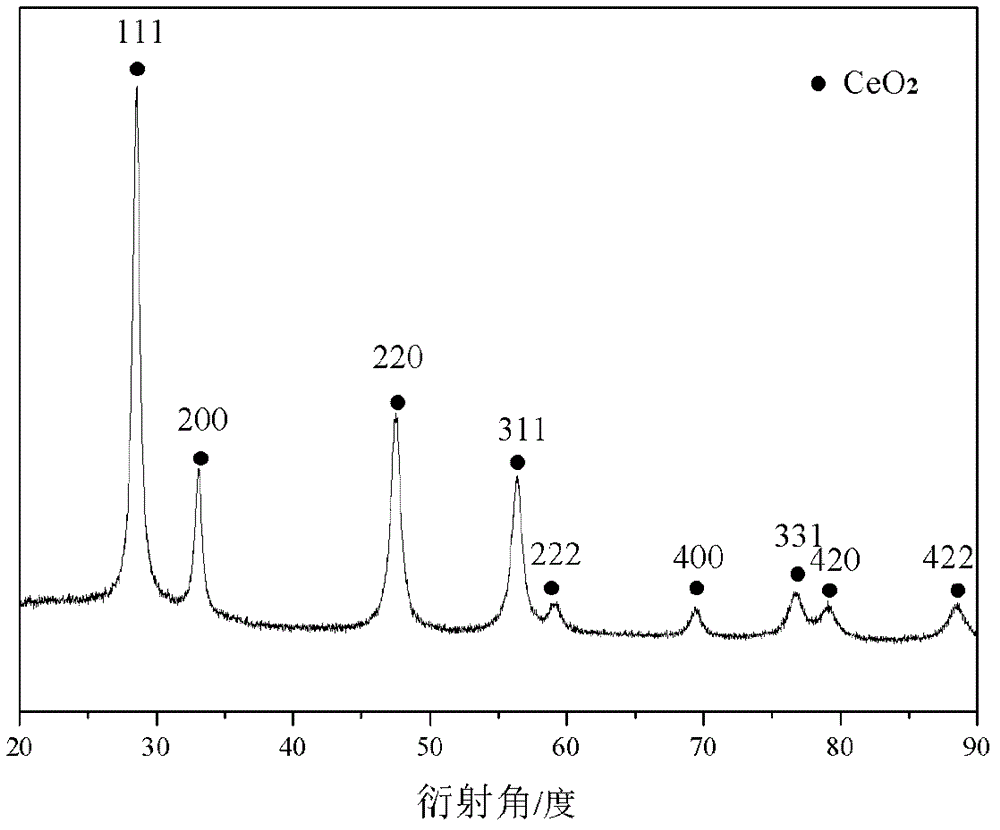

[0050] 1) At 25°C, put 1.24g of cerous chloride, 1.5g of urea and 238mL of distilled water in a 500mL small beaker, stir magnetically to make the solution appear colorless and transparent, add dropwise 120mL of sodium citrate aqueous solution (concentration: 10mmol / L), after stirring for 10min, dropwise add 30% by weight of hydrogen peroxide aqueous solution (the addition of hydrogen peroxide is 15mmol), continue stirring for 30min, put into a 200mL crystallization kettle, crystallize at 180°C for 22h, crystallize After the completion of the crystallization, the crystallization kettle was quenched, and the crystallized product was suction-filtered with 500 mL of distilled water, and the product was dried at 100° C. for 12 hours to obtain 0.5 g of light yellow solid powder. Its X-ray powder diffraction pattern is as follows figure 1 As shown, (110), (200), (220), (311), (222), (400), (331), (420) and (422) belong to CeO 2 The characteristic diffraction peaks belong to the cub...

Embodiment 2

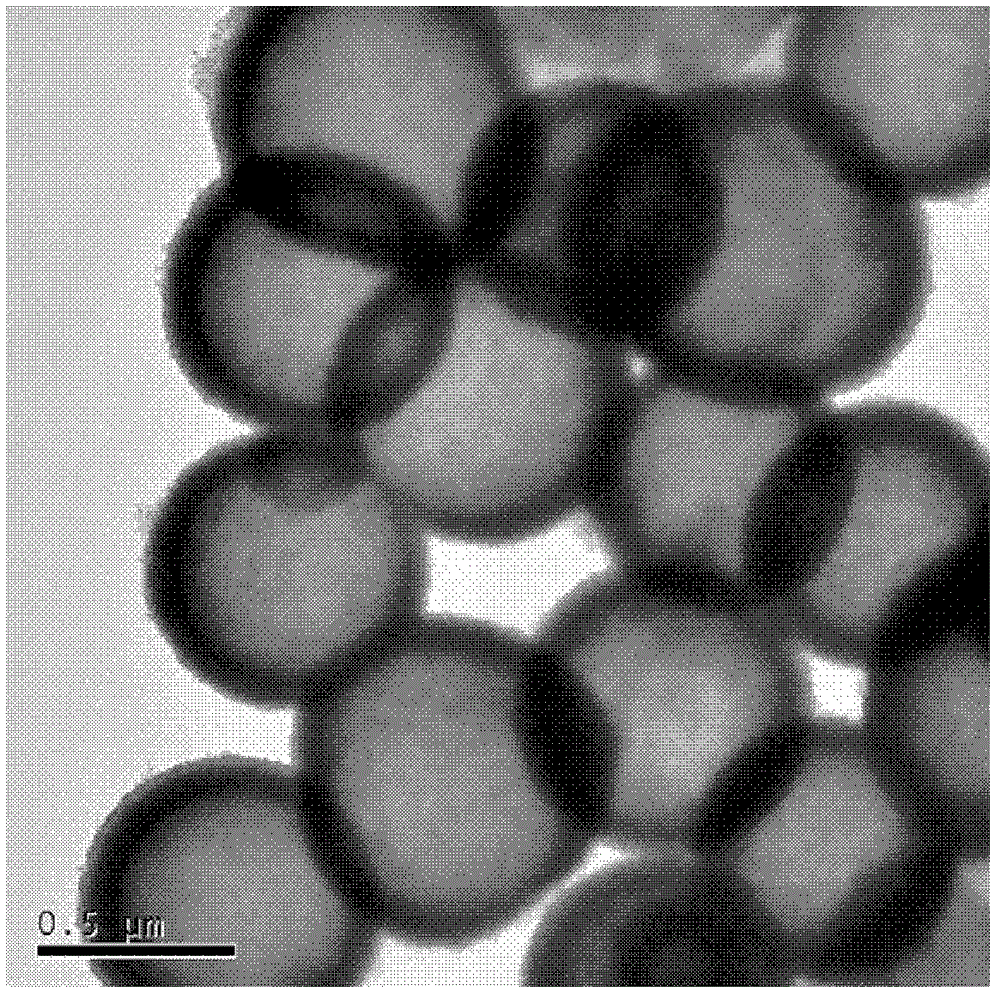

[0053] 1) At 25°C, put 1.24g of cerous chloride, 0.75g of urea and 135mL of distilled water in a 500mL small beaker, stir magnetically to make the solution appear colorless and transparent, add dropwise 120mL of sodium citrate aqueous solution (concentration: 10mmol / L), after stirring for 20min, dropwise add 30% by weight of hydrogen peroxide aqueous solution (the addition of hydrogen peroxide is 20mmol), continue stirring for 20min, put into a 200mL crystallization kettle, crystallize at 180°C for 22h, crystallize After the crystallization was completed, the crystallization kettle was quenched, and the crystallized product was suction-filtered with 500 mL of distilled water, and the product was dried at 100° C. for 12 hours to obtain 0.49 g of light yellow solid powder. Its transmission electron microscope pictures are as Figure 8 As shown, the hollow CeO 2 The size of the microspheres is between 540-770nm, and the shell thickness is about 100nm.

[0054]2) Mix chloroauri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com