A vertical cooling furnace and its cooling method

A cooling furnace, vertical technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of low gas-solid heat transfer efficiency, insufficient contact between sinter particles and cooling gas, etc., and achieve the degree of dense particle accumulation Improve and improve the efficiency of gas-solid heat exchange and avoid the effect of pipeline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

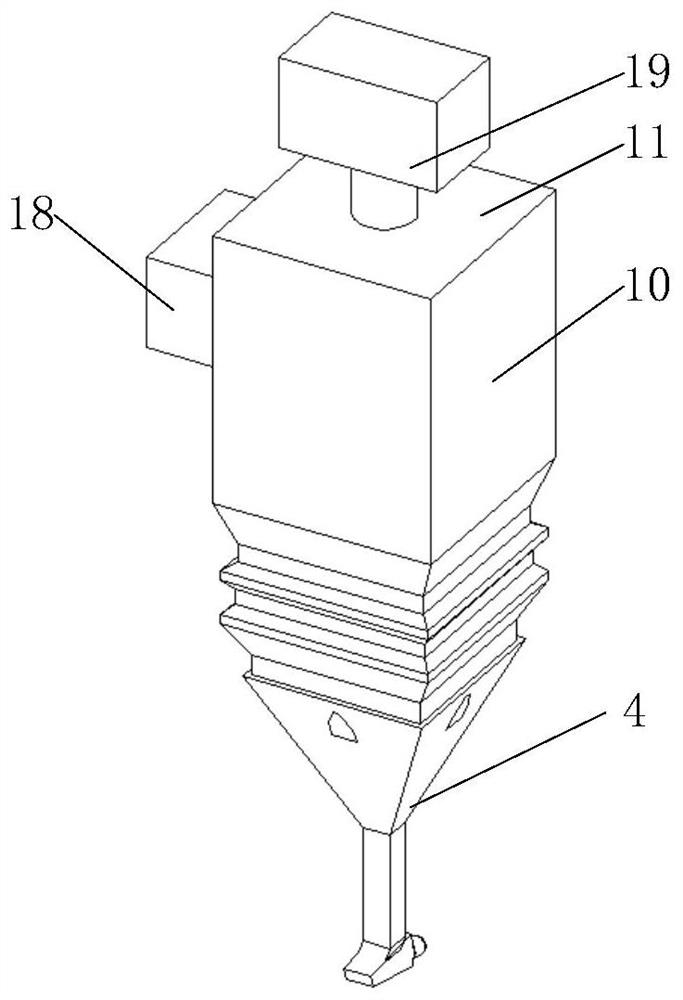

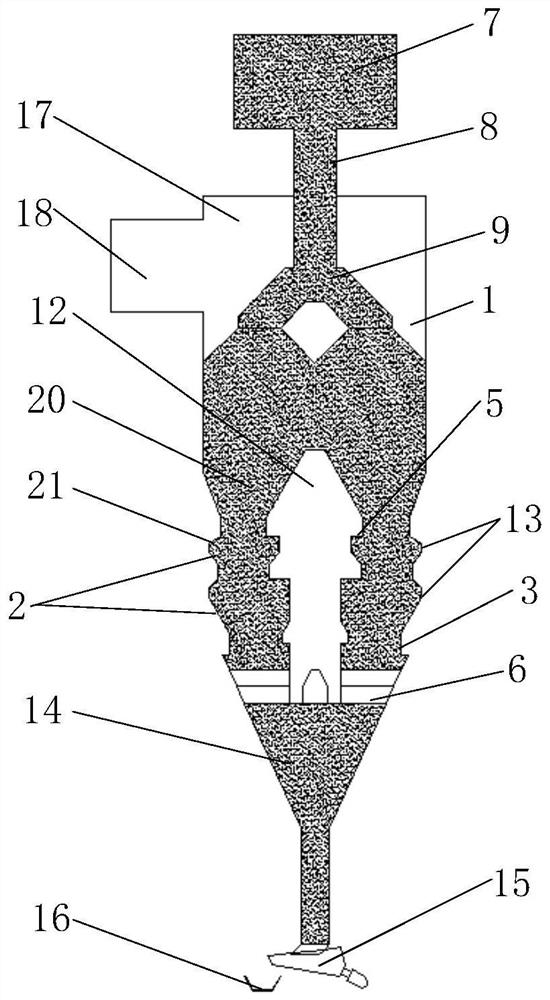

[0073] Such as Figure 1 to Figure 5 As shown, a vertical cooling furnace, the material to be cooled is sintered ore, along the flow direction of the material, sequentially includes:

[0074] Feeding unit 19, the feeding unit 19 includes a buffer bin 7, a material guide pipe 8 and a feeding pipe 9 connected in sequence, the feeding pipe 9 extends into the furnace chamber 1, and the feeding unit 19 is arranged above the furnace chamber 1 , used to load high-temperature sintered ore into the furnace cavity 1, wherein the buffer bin 7 is used to receive the high-temperature sintered ore transported by the loading trolley, and the material guide pipe 8 is arranged at the bottom of the buffer bin 7 to connect the buffer bin 7 and the unloading Pipe 9, in this embodiment, the feeding pipe 9 is an inverted V-shaped structure, and in actual use, different forms of material distribution devices such as central feeding and side feeding can also be used;

[0075] Furnace cavity 1, the m...

Embodiment 2

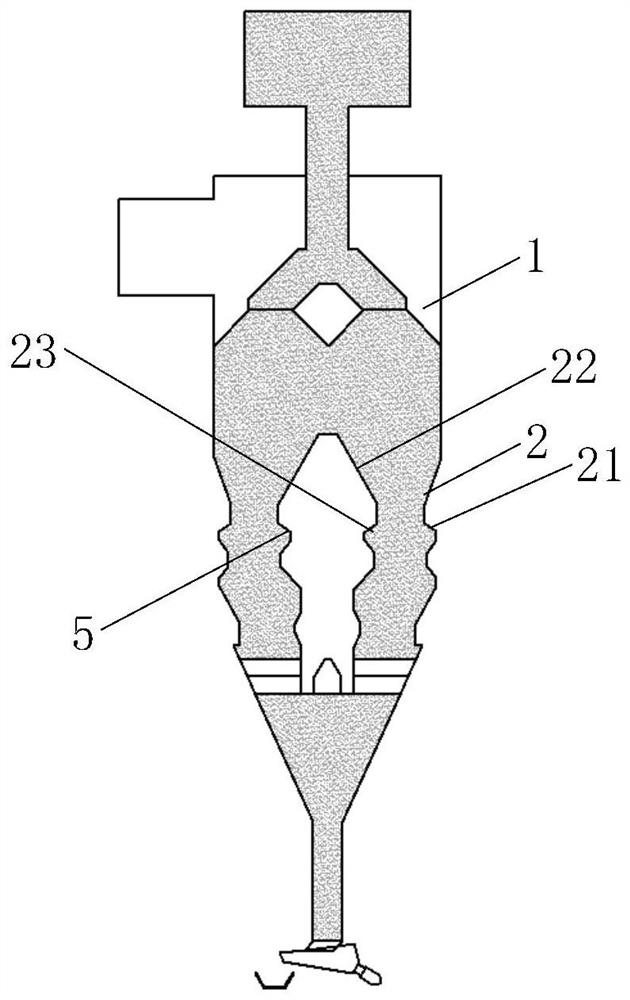

[0093] Such as Figure 6 to Figure 13 As shown, this embodiment provides a vertical cooling furnace and a cooling method thereof. The structure of this embodiment is basically the same as that of Embodiment 1, except for the following differences: two sets of depressions are provided, and two layers of the central air cap 12 are provided. The annular air outlet 5, and in this embodiment, the connection section 3 of the uppermost recessed part is arranged coaxially with the furnace cavity 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com