High-efficiency low-NOx two-stage self-preheating burner

A two-stage heat exchanger, high-efficiency technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of difficult to meet environmental protection standards, large amount of pollutants, single combustion method, etc., to reduce control costs, exchange The effect of large thermal coefficient and simple control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

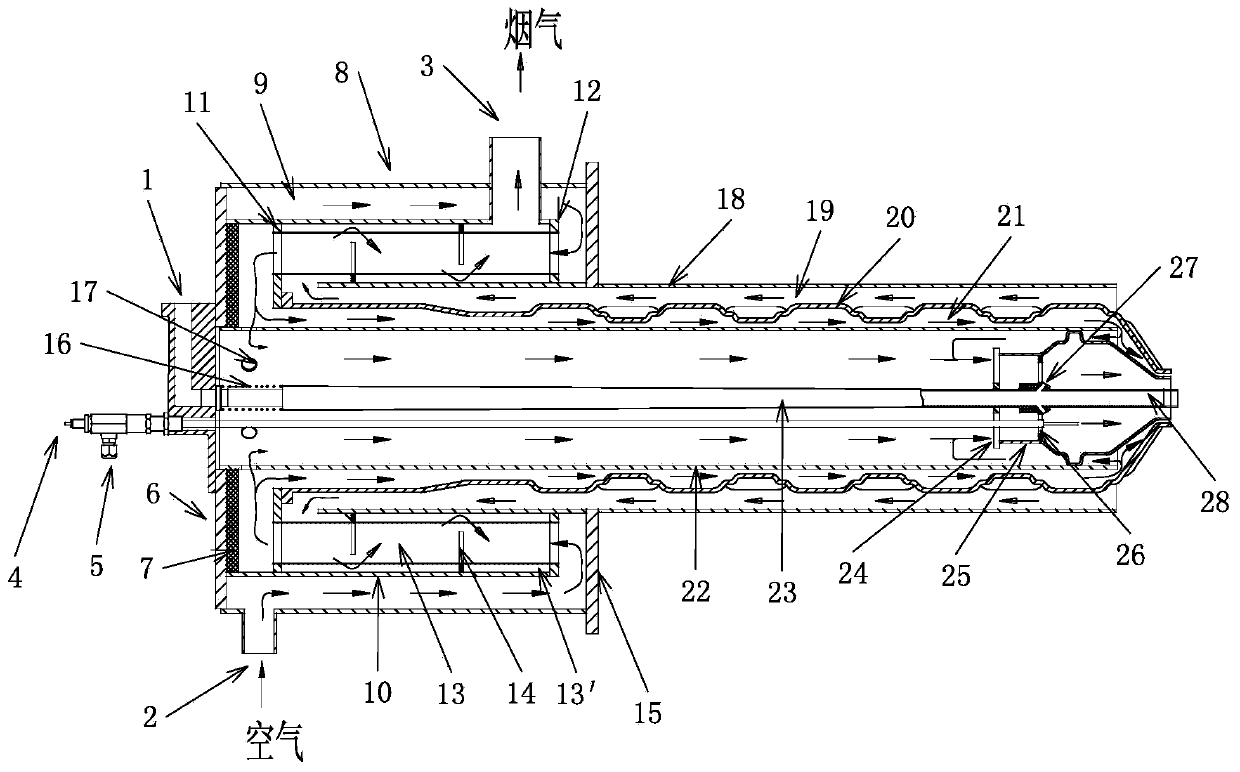

[0044] refer to Figure 1~8, a high-efficiency and low-NOx secondary self-preheating burner, including a housing, an air duct 22, a gas duct 23, a flue gas duct 18, a combustion chamber 25, and a self-cooling electrode 4; 22 on the outside of the rear end of the air housing 8 and the gas housing 6 fixed on the outer surface of the air housing 8, the air housing 8 is provided with an air inlet 2 and a smoke outlet 3, the air inlet 2 and the smoke outlet The relative position of the gas outlet 3 is adjustable to meet applications in different environments. The gas casing 6 is provided with a gas inlet 1, and an insulating lining 7 is arranged between the air casing 8 and the gas casing 6; the gas conduit 23 One end of one end is fitted with a mounting spring 16 and fixed in the air conduit 22 through the mounting spring 16, and communicated with the gas inlet 1 at the same time, the gas conduit 23 is fixed in the air housing 8 through the mounting spring 16, and can be installed...

Embodiment 2

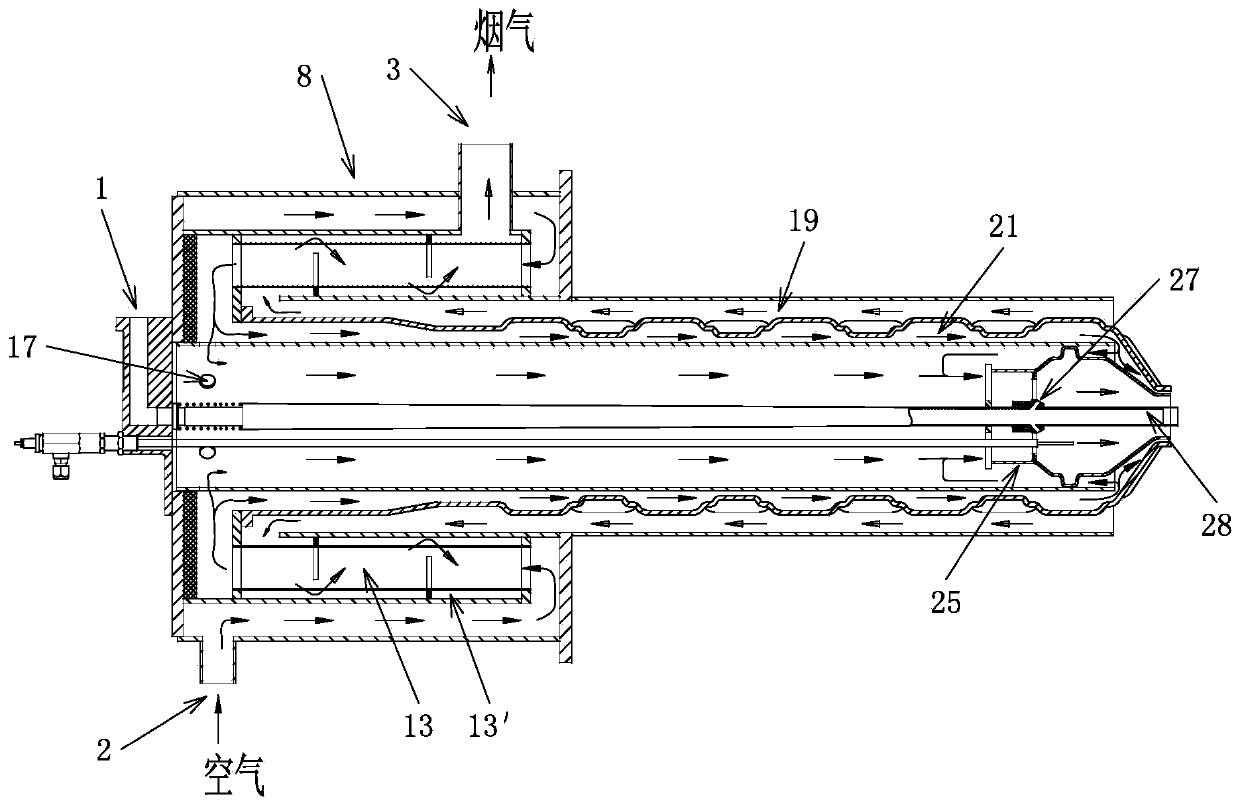

[0061] refer to Figure 12~17 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the gas pipe 23 is provided with a gas pipe 31, one end of the gas pipe 31 extends to the outside of the housing, and the gas pipe 23 and the gas pipe 31 are both The gas supply equipment is connected separately, so that one of the gas conduit 23 and the gas pipe 31 can supply gas separately or the gas conduit 23 and the gas pipe 31 can supply gas simultaneously. Further, the channel member 33 is a heat exchange conduit, and the two ends of the heat exchange conduit are respectively connected to the first flange 11 and the second flange 12, and the heat exchanger channel I13 is formed by the circular lumen of each heat exchange conduit , that is, the cross-sectional shape of a single heat exchanger channel I13 is circular, and the heat exchange pipe can be made of any one of straight pipe, spiral pipe, surface-shaped treatment pipe and finned ...

Embodiment 3

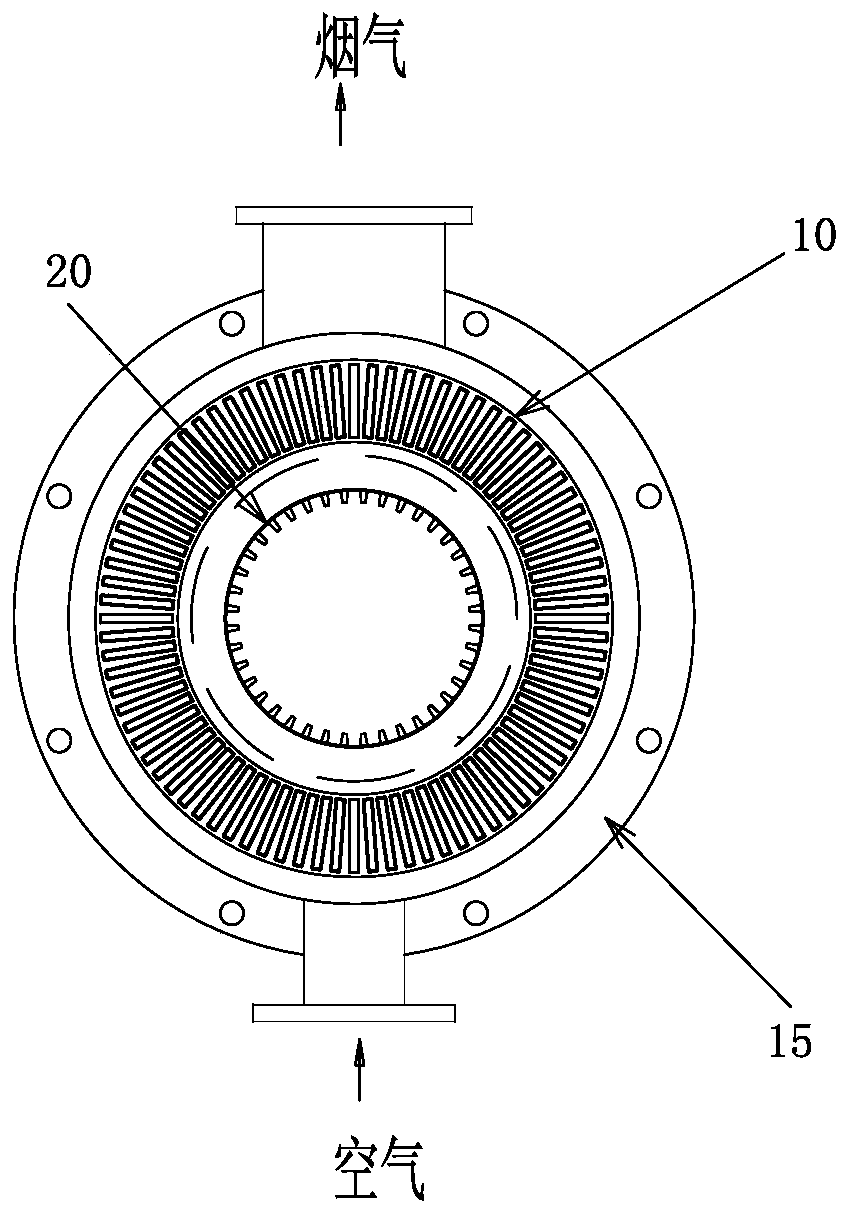

[0069] refer to Figure 18 , the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that: the secondary heat exchanger 10 does not include a shell, and the secondary heat exchanger 10 includes a first flange 11, a second flange 12, several parallel arrangement The bypass baffle 14 and the channel member 33, the channel member 33 is a heat exchange conduit, the heat exchange conduit runs through the bypass baffle 14, the first flange 11 and the second flange 12 are sleeved on the surface of the air conduit, And fixed on both ends of the air shell 8, the flow-around baffles 14 are fixed in the air shell 8 and distributed alternately along the extending direction of the air shell 8, and one end of the heat exchange conduit is fixedly arranged on the first flange 11 The other end of the heat exchange pipe is fixed on the second flange 12 . And in concrete implementation, must add thermal insulation liner 7 on the inner wall of air shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com