Efficient, low-NOx and compact type self preheating type burner nozzle

A compact and high-efficiency technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of low heat exchange efficiency, difficulty in meeting environmental protection standards, single combustion method, etc., and achieve the effect of reducing NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

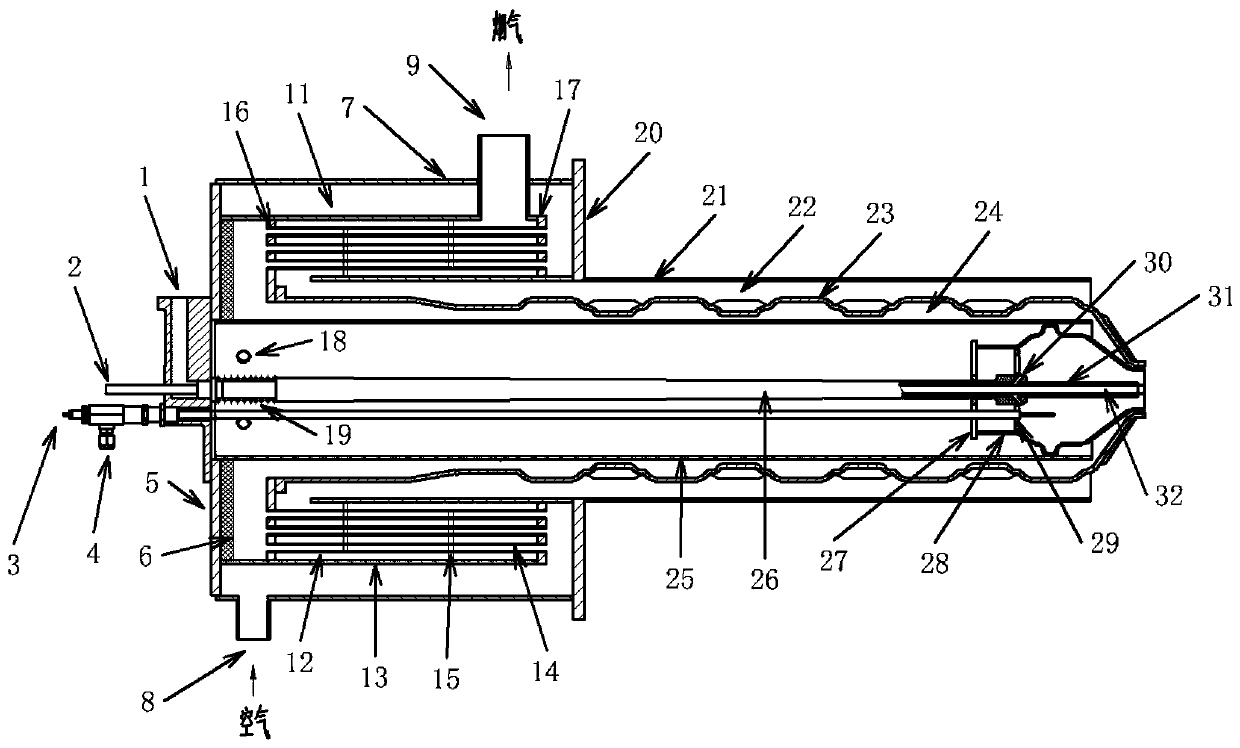

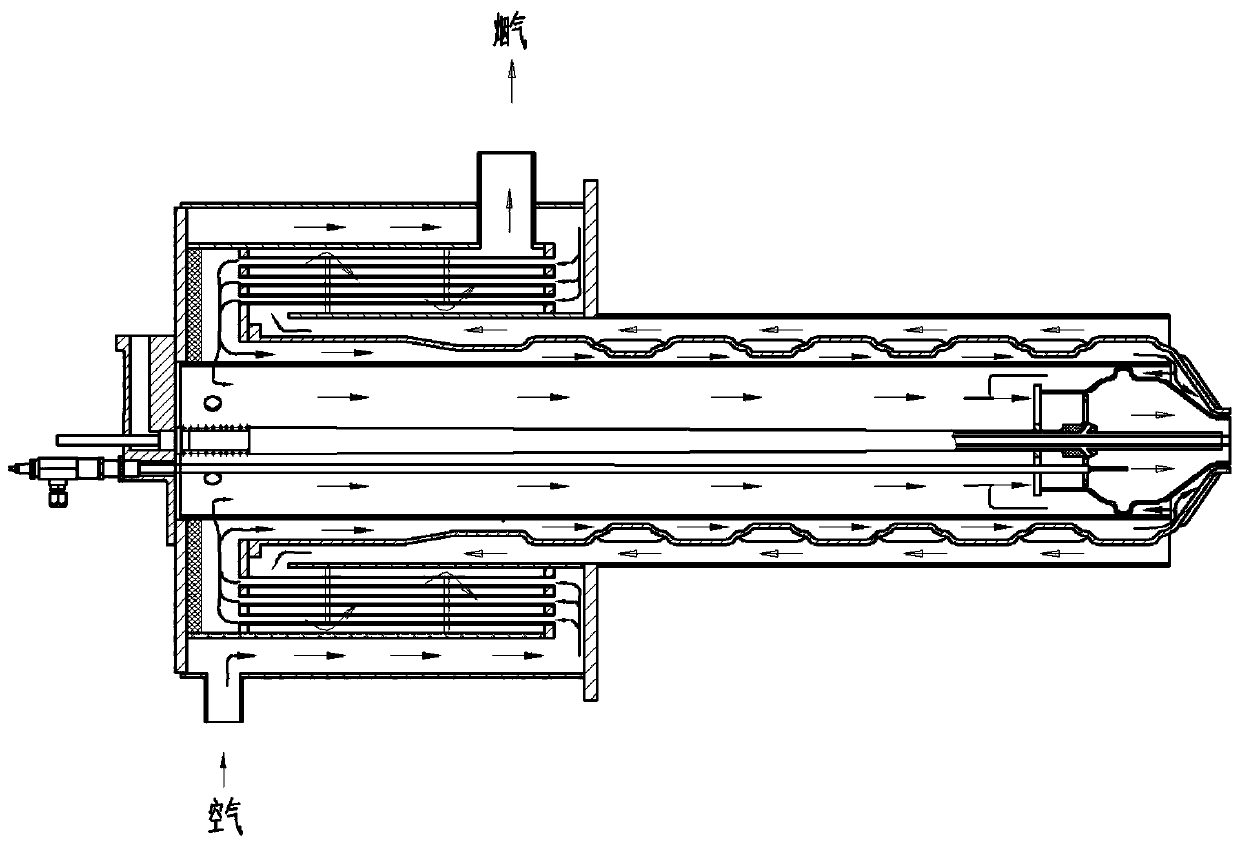

[0033] see figure 1 As shown, this embodiment is about a high-efficiency, low-NOx compact self-preheating burner, including an air pipe 25, a gas channel 26, a flue gas pipe 21, a combustion chamber 28 and an ignition electrode 3, and the combustion chamber 28 is placed in the air pipe At the opening of the front end in 25, a first ring gap is formed between the combustion chamber 28 and the air pipe 25, the ignition end of the ignition electrode 3 is arranged in the combustion chamber 28, the surface of the air pipe 25 is covered with a heat exchange tube 23, and the surface of the air pipe 25 is opened There is an air hole 18, one end of the heat exchange tube 23 extends to the combustion chamber 28 and forms a second ring gap with the outlet of the combustion chamber 28, and the rear end of the air pipe 25 is equipped with an air shell with an air inlet 8 and a smoke outlet 9 7. The flue gas pipe 21 is set on the surface of the heat exchange pipe 23, and the outer surface o...

Embodiment 2

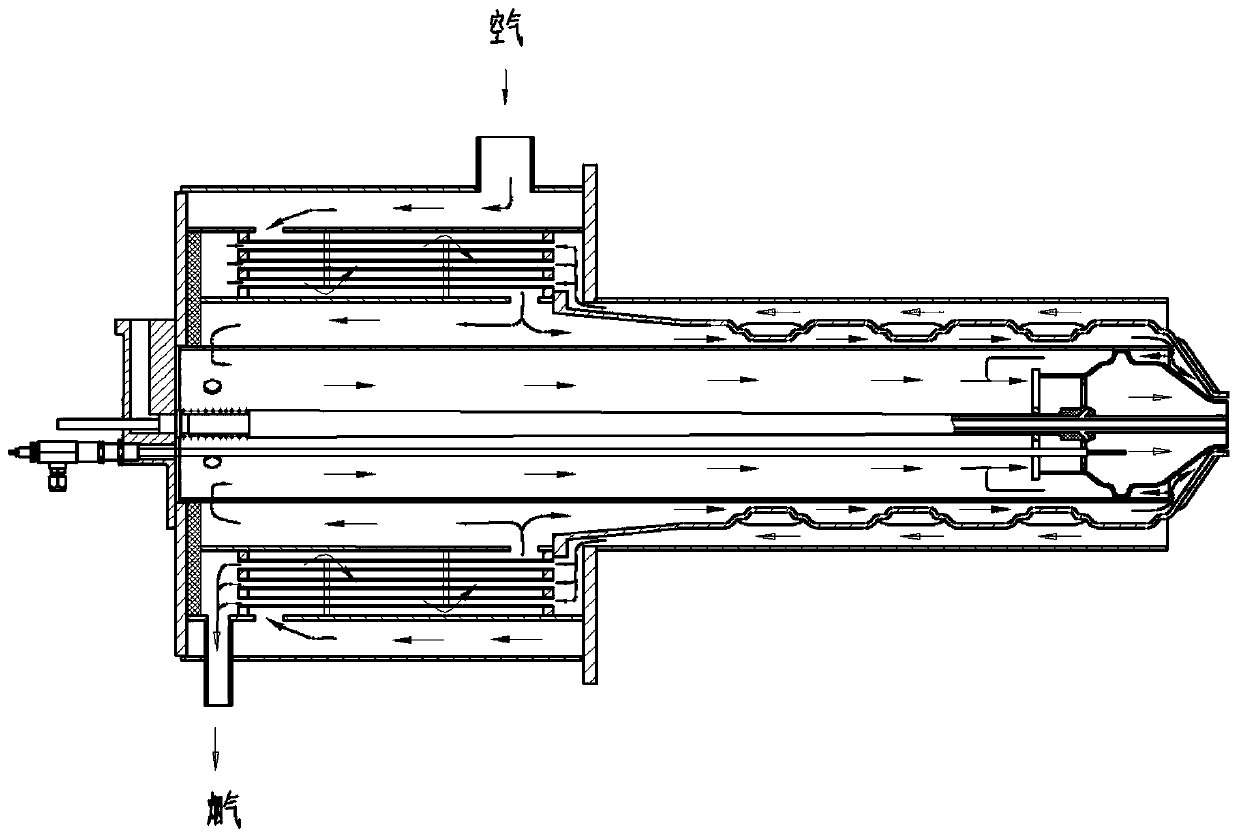

[0044] see Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the compact heat exchanger 12 does not include a shell, and the first flange 16 and the second flange 17 are ringed on the surface of the air pipe 25 and fixed to the air shell 7, the flow-around baffles 15 are fixed in the air casing 7 and distributed alternately along the extending direction of the air casing 7, one end of the heat exchange conduit 14 is fixedly arranged on the first flange 16, and the end of the heat exchange conduit 14 The other end is fixed on the second flange 17. During specific implementation, an insulating lining 6 must be added to the inner wall of the air housing 7.

[0045] Such as Figure 4 As shown, in this embodiment, the front ends of several heat exchange conduits 14 communicate with the air inlet 8 as the air heat exchange inlet, and the rear ends of the heat exchange conduits 14 communicate with the heat exchange tube 23 as the air heat exchange o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com