Solar auxiliary heat pump system integrating functions of waste heat recovery and self-cleaning

A technology of waste heat recovery and heat pump system, which is applied in the direction of machines using solar energy, heating and cooling combination, refrigeration and liquefaction, etc. It can solve the problems of reducing the efficiency of absorber to prepare hot water, reducing the temperature of lithium bromide dilute solution, and the preheating effect is not obvious, etc. problems, to achieve the effect of saving power resources and operating costs, omitting labor costs, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention is described in further detail:

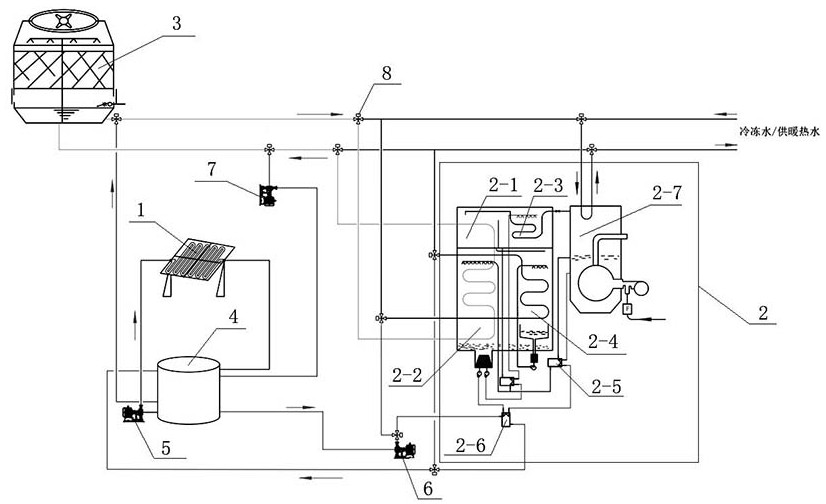

[0042] Such as Figure 1-9 As shown, a solar-assisted heat pump system integrating waste heat recovery and self-cleaning functions, including solar panel integration device 1, direct-fired absorption heat pump unit 2, and solar panel integration device 1 and direct-fired absorption heat pump unit 2 connected working condition circuits;

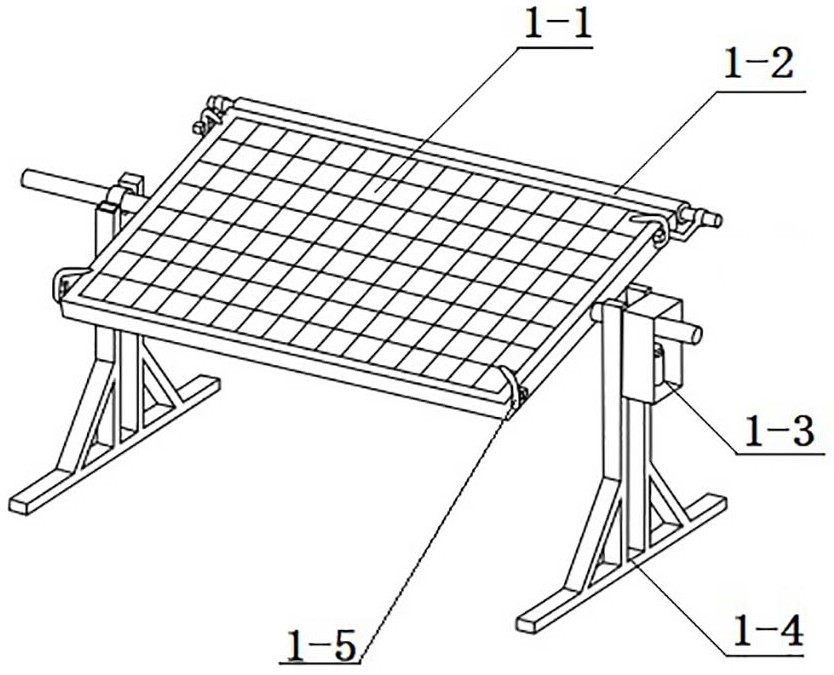

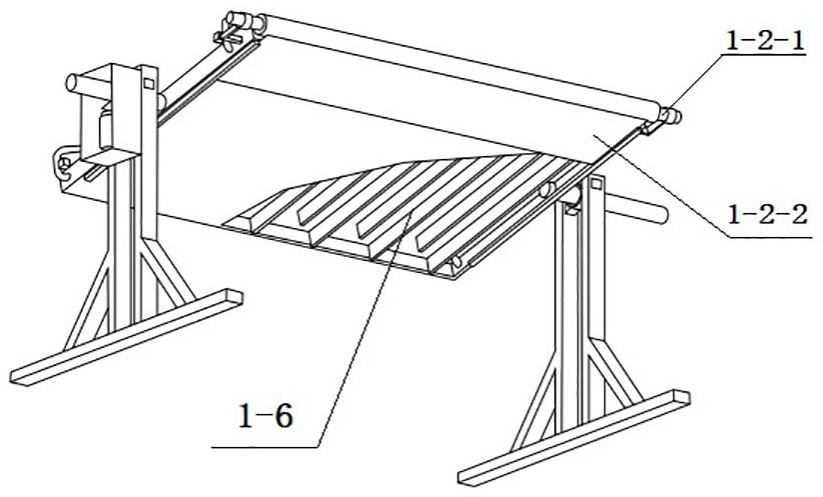

[0043]The solar cell panel integration device 1 includes a solar cell panel 1-1 arranged on two brackets 1-4 through a transmission shaft, a heat insulation device 1-2 arranged on the upper end of the solar cell panel 1-1, and a heat insulation device 1-2 arranged on the bracket The transmission device 1-3 on the 1-4, the automatic cleaning device 1-5 arranged on the solar panel 1-1 and the heat exchanger 1-6 arranged on the back of the solar panel 1-1;

[0044] The solar panel 1-1 is made of monocrystalline silicon or polycrystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com