Novel rectifier bridge for integrating current sampling

An integrated current and rectifier bridge technology, applied in the direction of converting AC power input to DC power output, circuits, electrical components, etc., can solve problems such as difficulties in production, design and development, different sampling resistance values, and lack of versatility in circuit boards. To achieve the effect of enhancing product reliability, reasonable distribution of chips, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

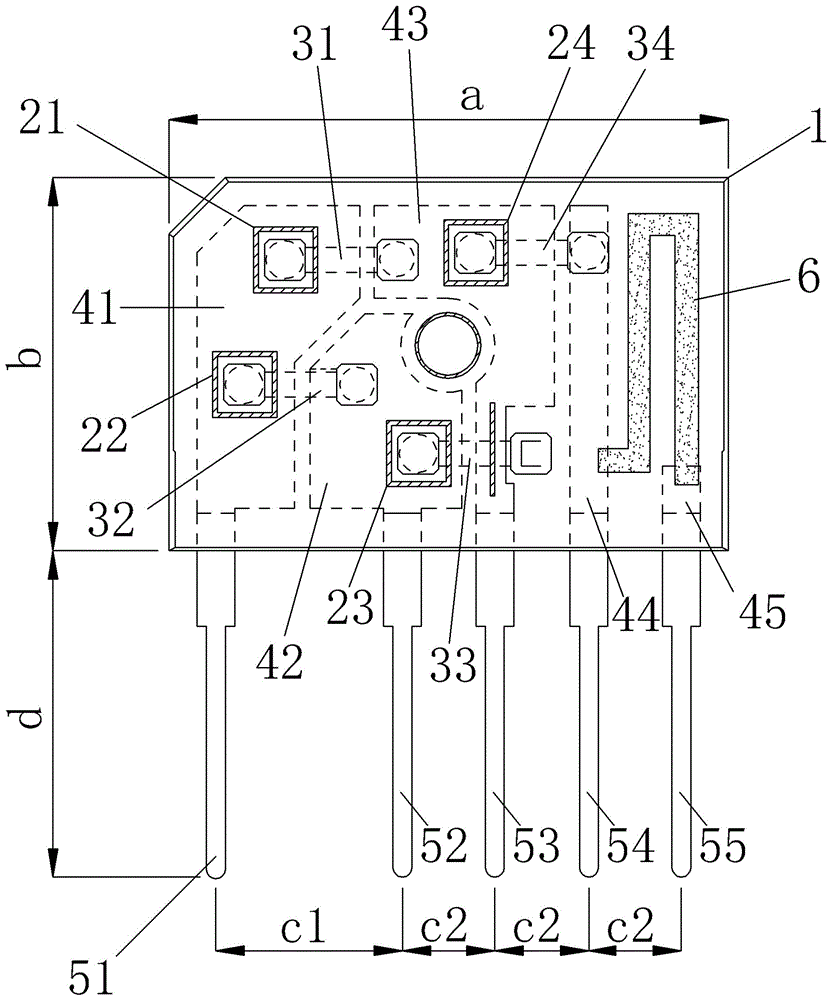

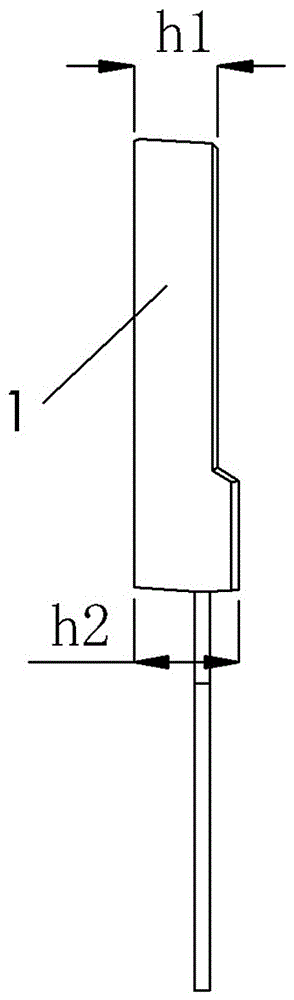

[0020] Such as figure 1 and figure 2 As shown, the new rectifier bridge integrated with current sampling includes an insulating plastic casing 1, five lead pins and four unidirectional conductive chips, one end of each lead pin extends into the insulating plastic casing 1, and is respectively connected to a copper substrate , the copper substrate and the unidirectional conductive chip are packaged in the insulating plastic casing 1, and the copper substrates are separated from each other.

[0021] The four unidirectional conductive chips are all glass-passivated low-power diode chips, the upper and lower ends of the glass-passivated low-power diode chip are electrodes, and the surface area of the lower electrode is larger than the surface area of the upper electrode, and the glass-passivated low-power diode chip The chip is connected to the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com