Patents

Literature

66results about How to "Increase the stirring area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical device for preparing chemical raw material

InactiveCN108854784AStir wellImprove stirring efficiencyShaking/oscillating/vibrating mixersTransportation and packagingPistonSpray nozzle

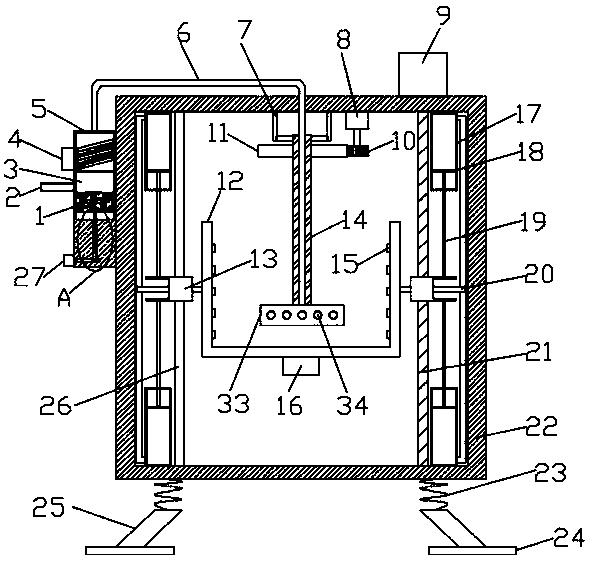

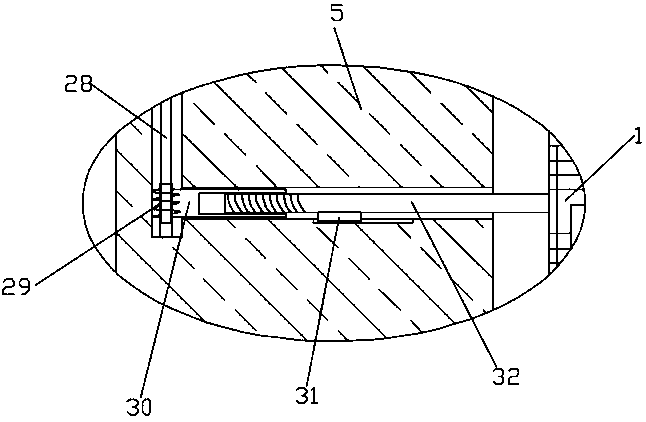

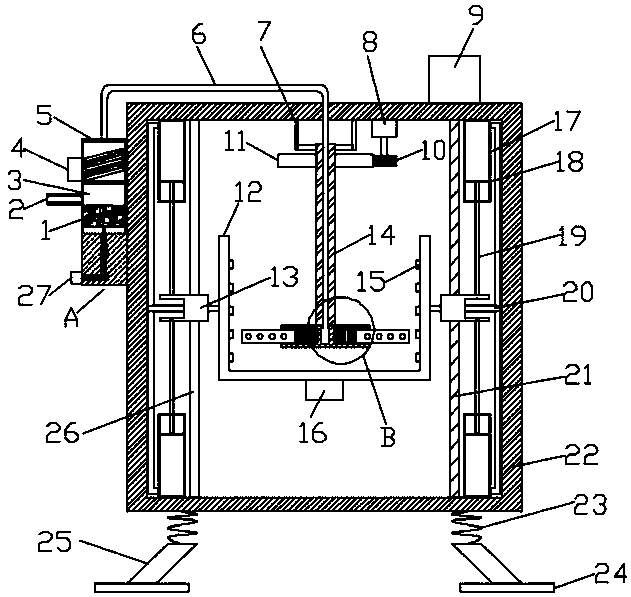

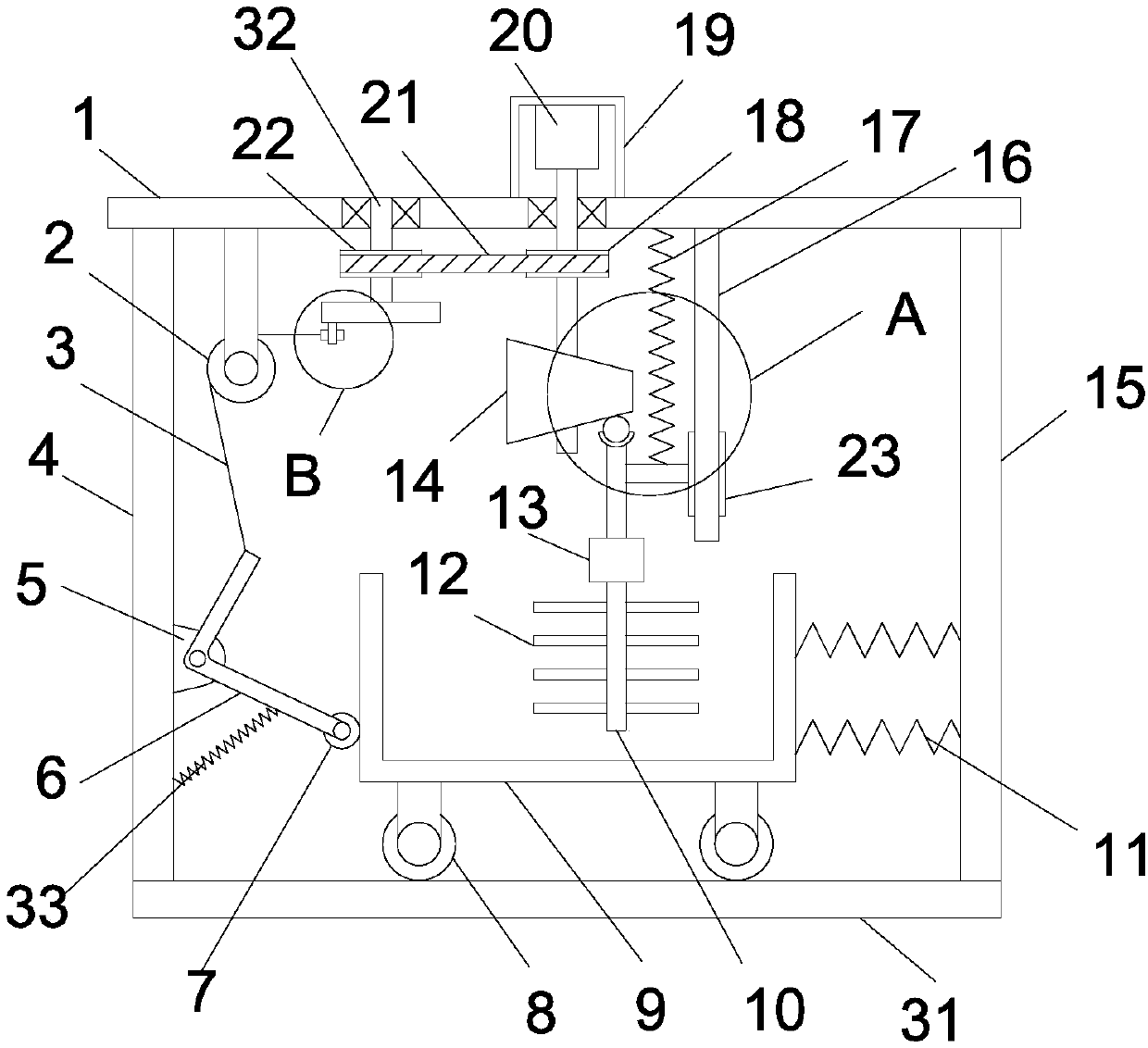

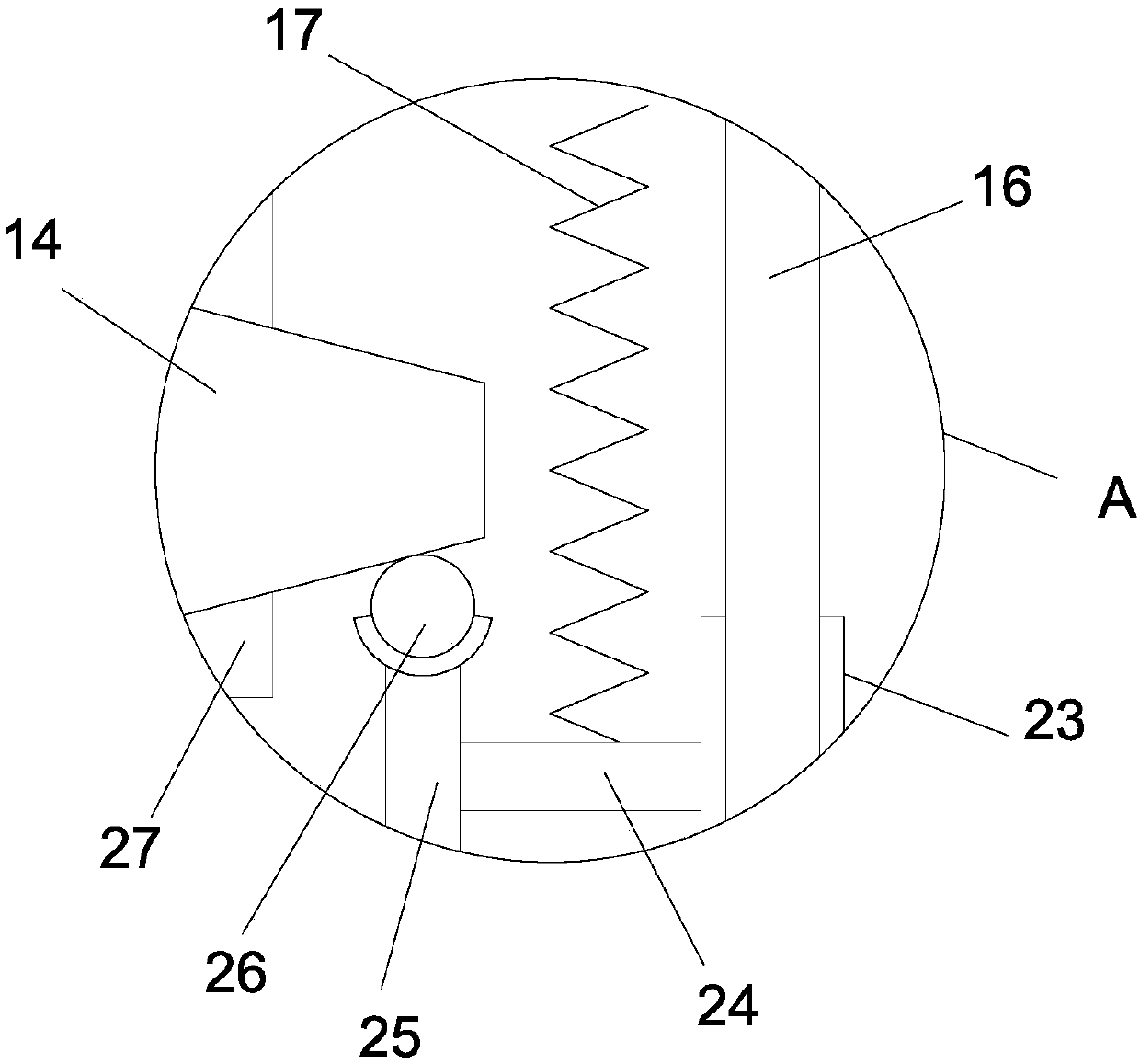

The invention discloses a chemical device for preparing a chemical raw material. The chemical device comprises a machine body, wherein the upper end of the machine body is fixedly connected with a second driving motor, an output shaft of the second driving motor penetrates through the upper end of the machine body and is fixedly connected with a first threaded rod, a guiding rod is fixedly connected between the inner top and inner bottom of the machine body, and the guiding rod and the first threaded rod are respectively sleeved with movable blocks. By adopting the chemical device, the stirring area is increased, more sufficiency in stirring can be realized, and the stirring efficiency is improved; while a barrel body moves up and down, a piston can be driven to move up and down in an aircylinder barrel to compress air in the air cylinder barrel, so that the air is sprayed out from spray nozzles by virtue of an air guiding pipe, and raw materials are mixed more rapidly under the pushing of the air; when a stirring rod rotates, an exhaust pipe extends under the effect of a centrifugal force, so that while the stirring range is enlarged, and the high-temperature steam is more uniformly scattered; and the raw materials are preheated while being fed, so that the raw material does not need to be canned after being preheated, and the working efficiency is improved.

Owner:管振平

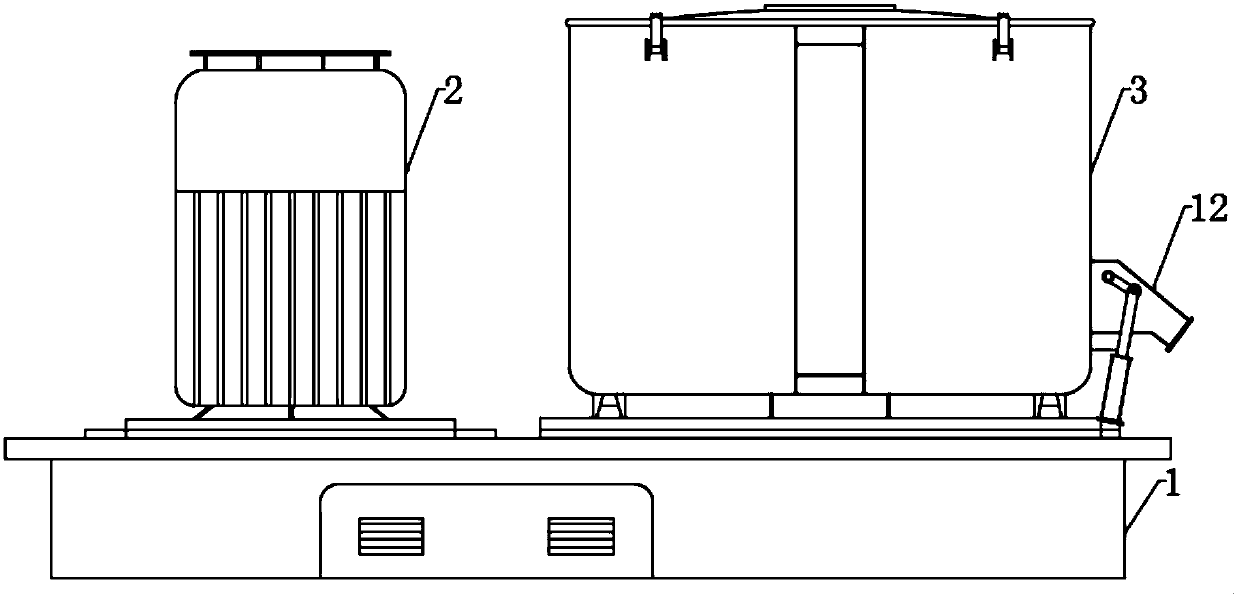

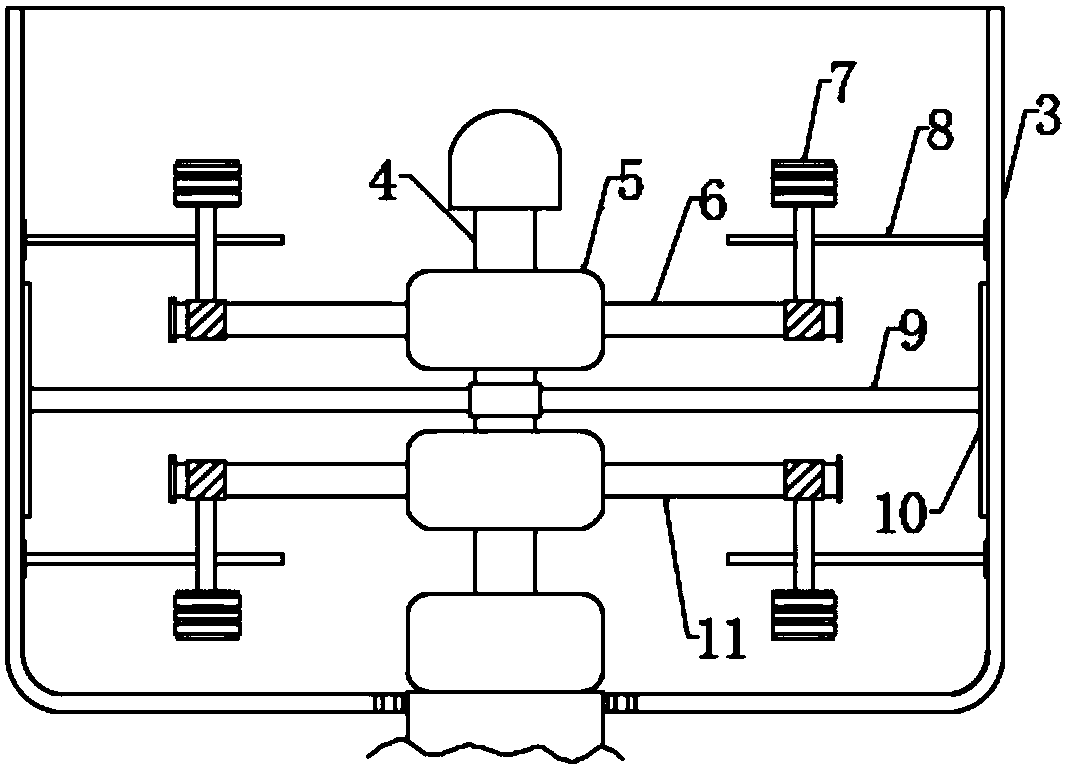

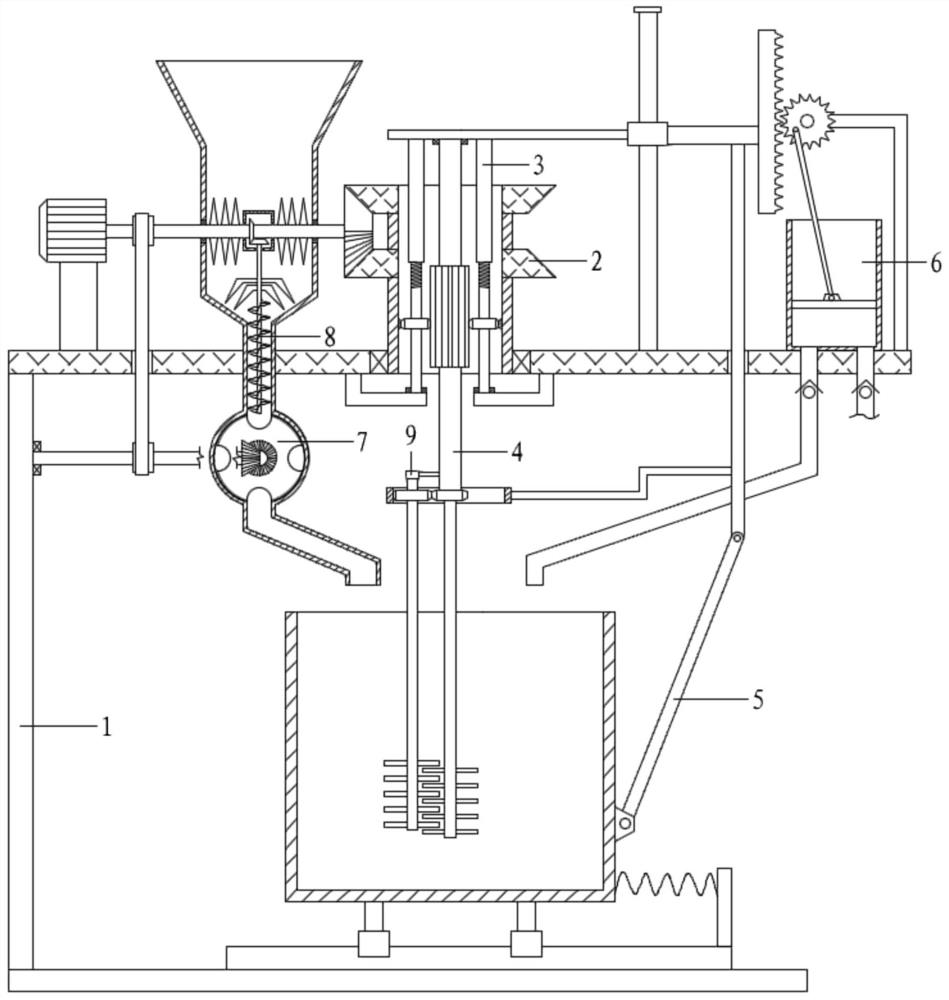

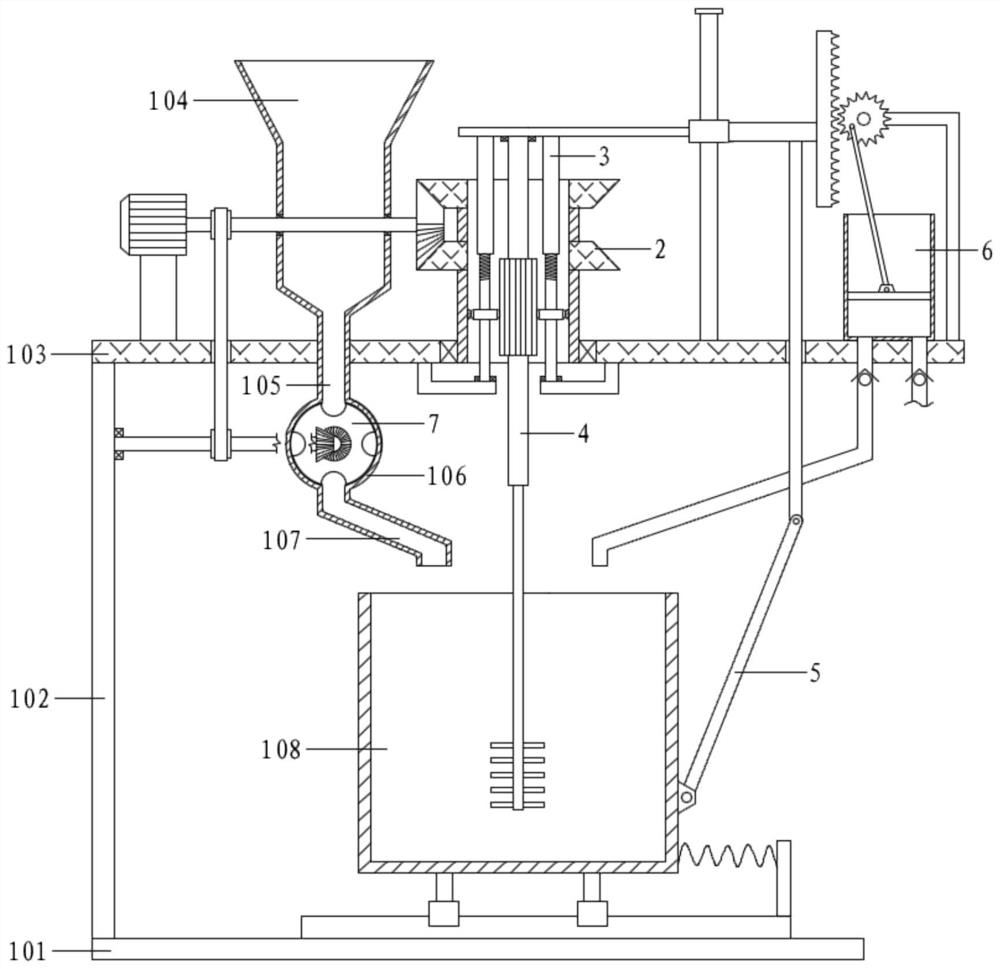

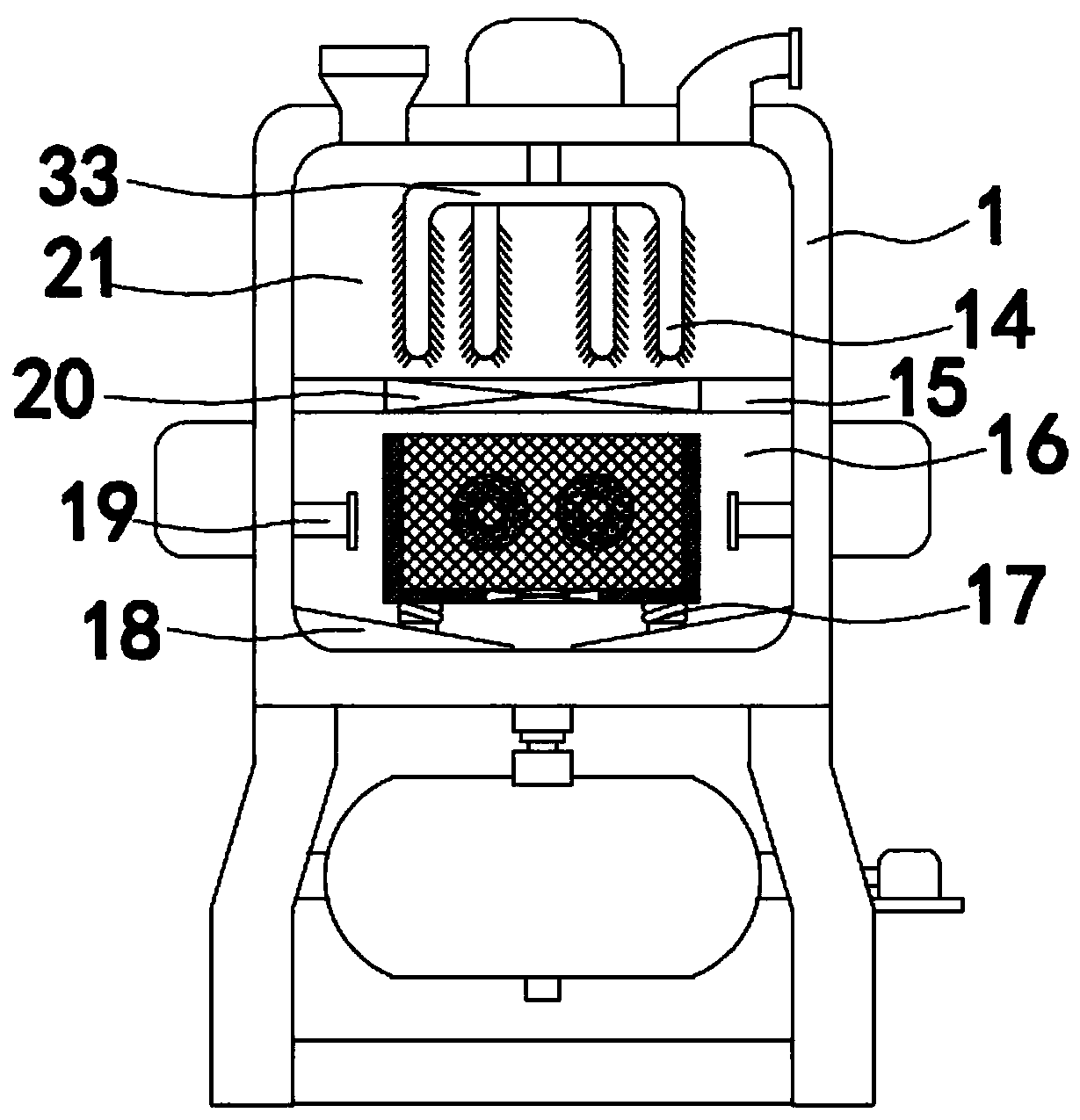

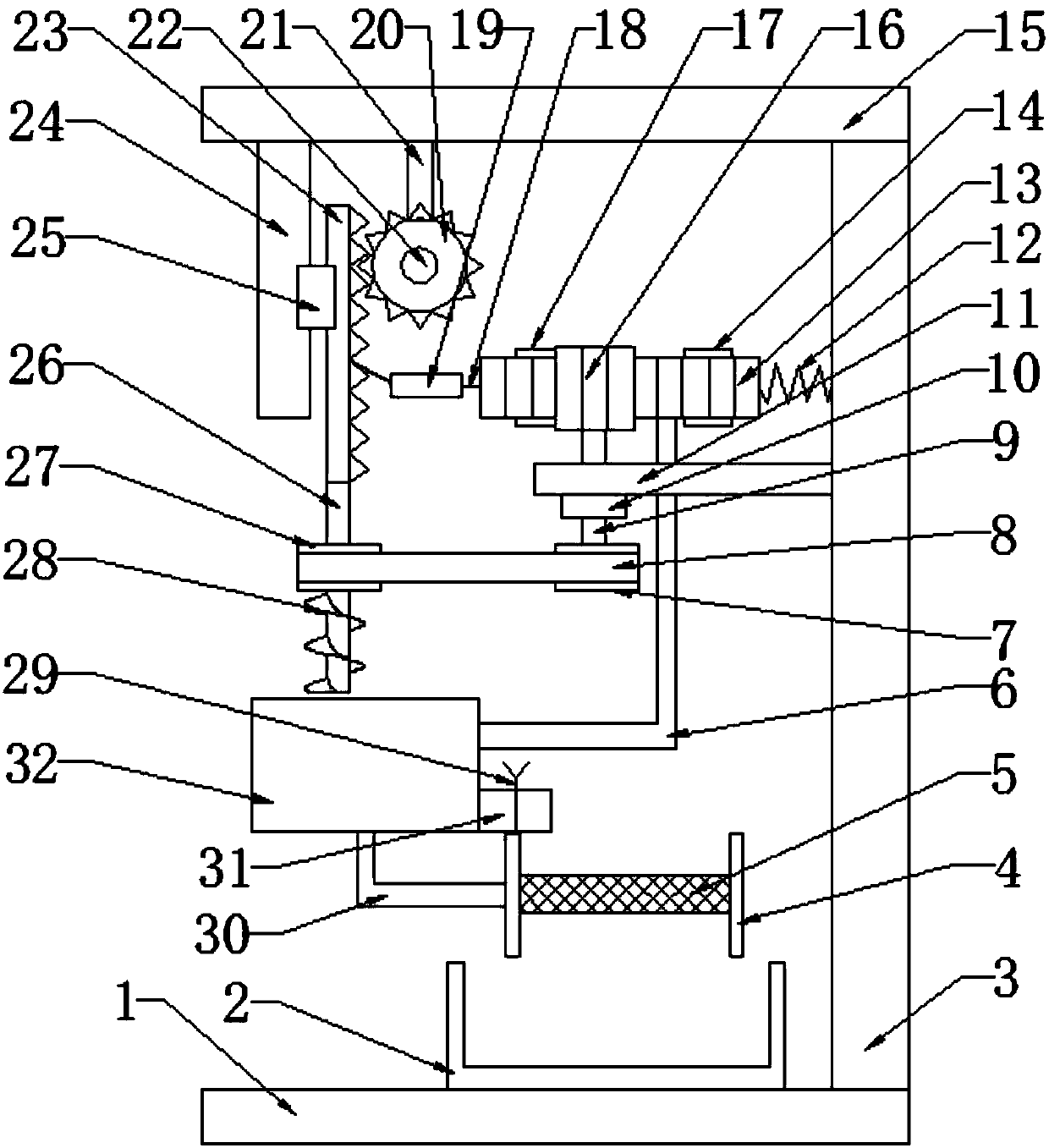

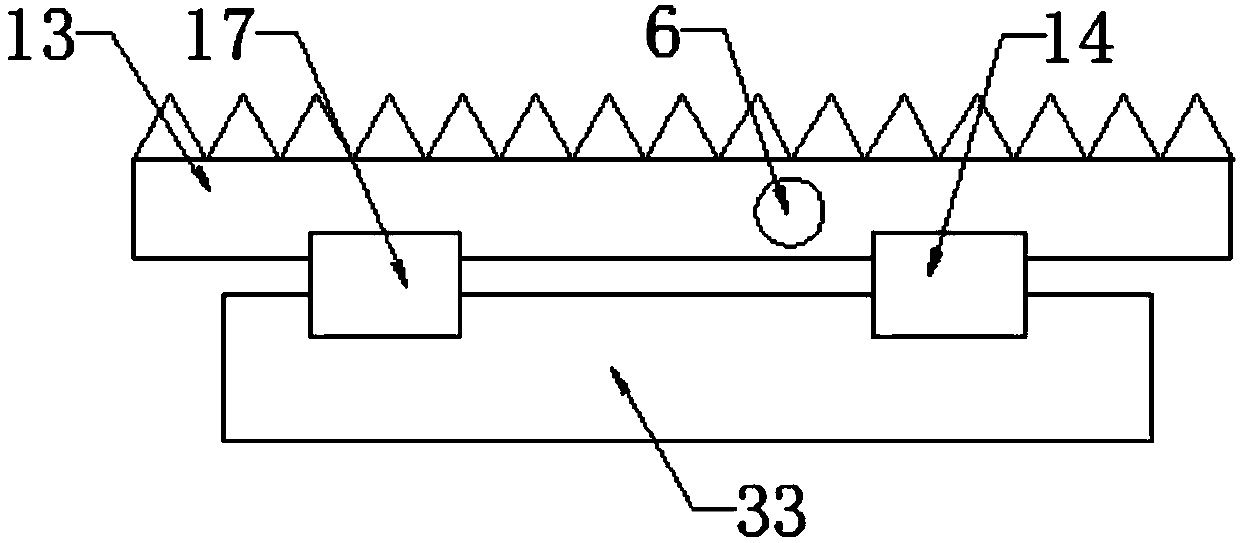

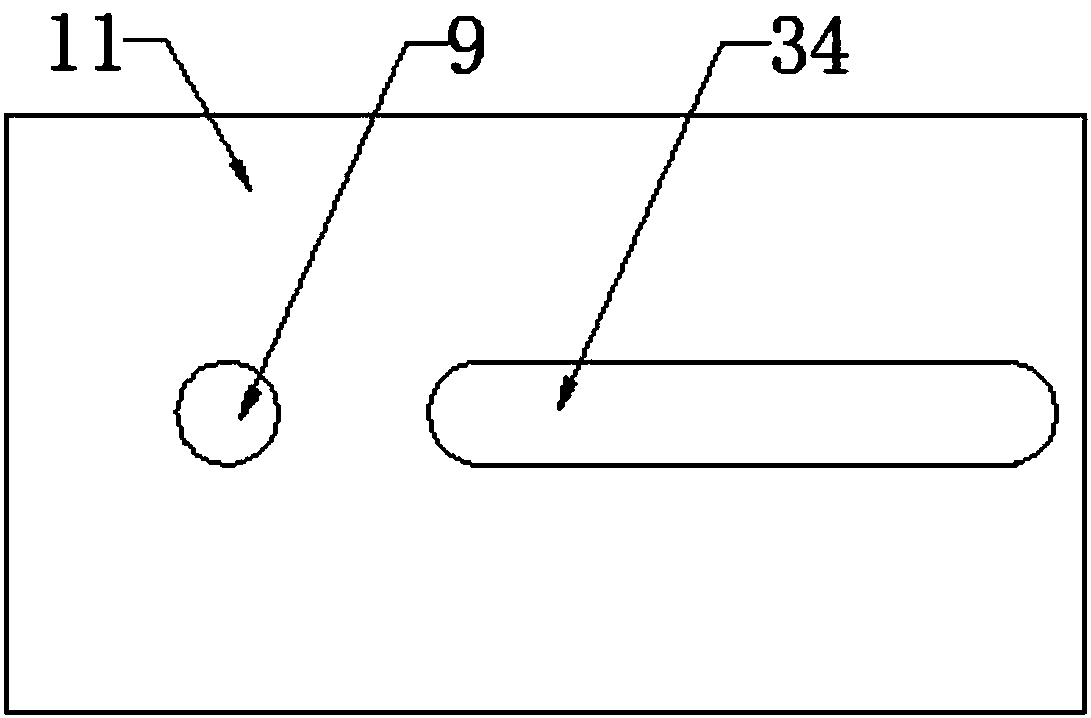

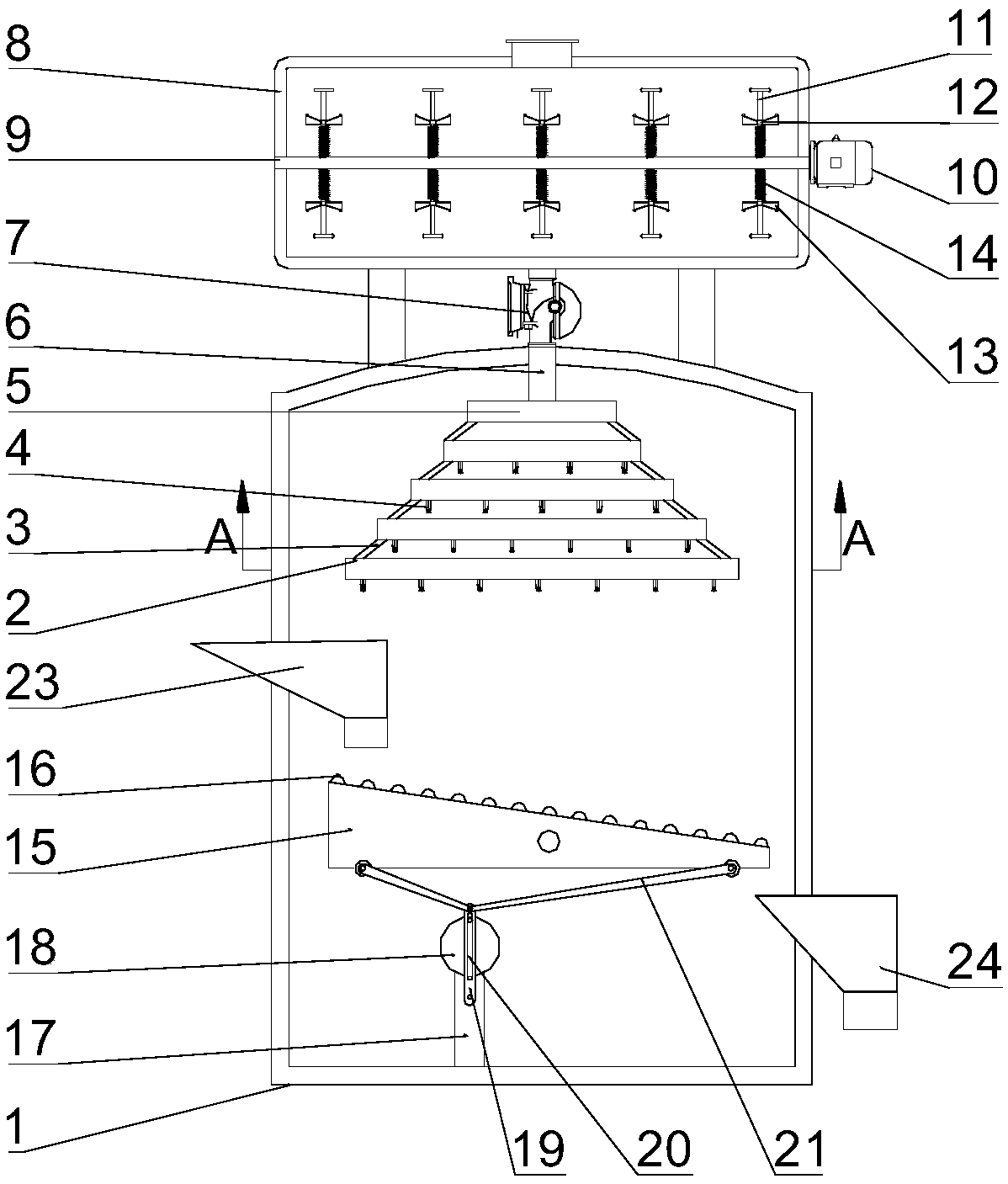

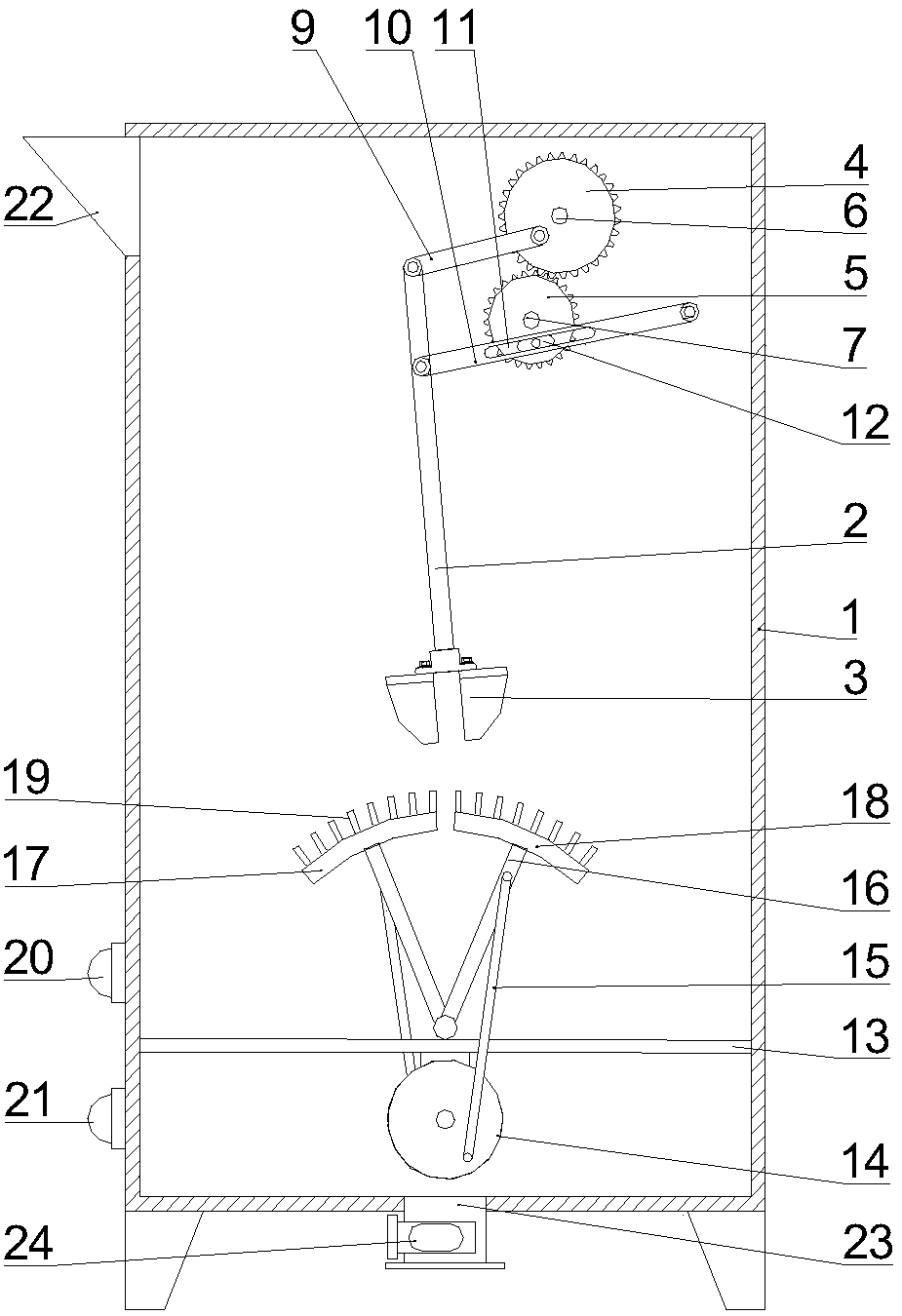

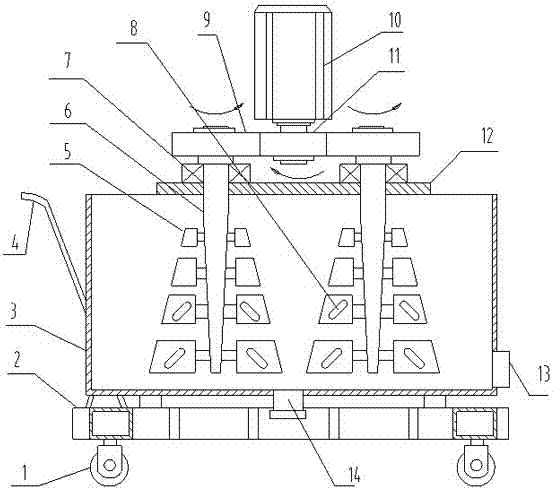

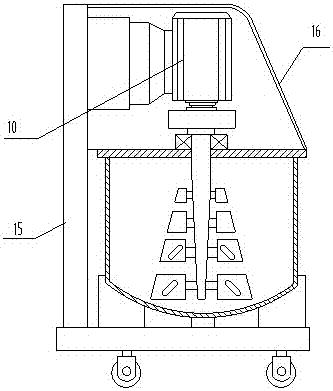

Chemical raw material stirring and drying device

InactiveCN107983248AIncrease the stirring areaStir wellShaking/oscillating/vibrating mixersTransportation and packagingPistonSpray nozzle

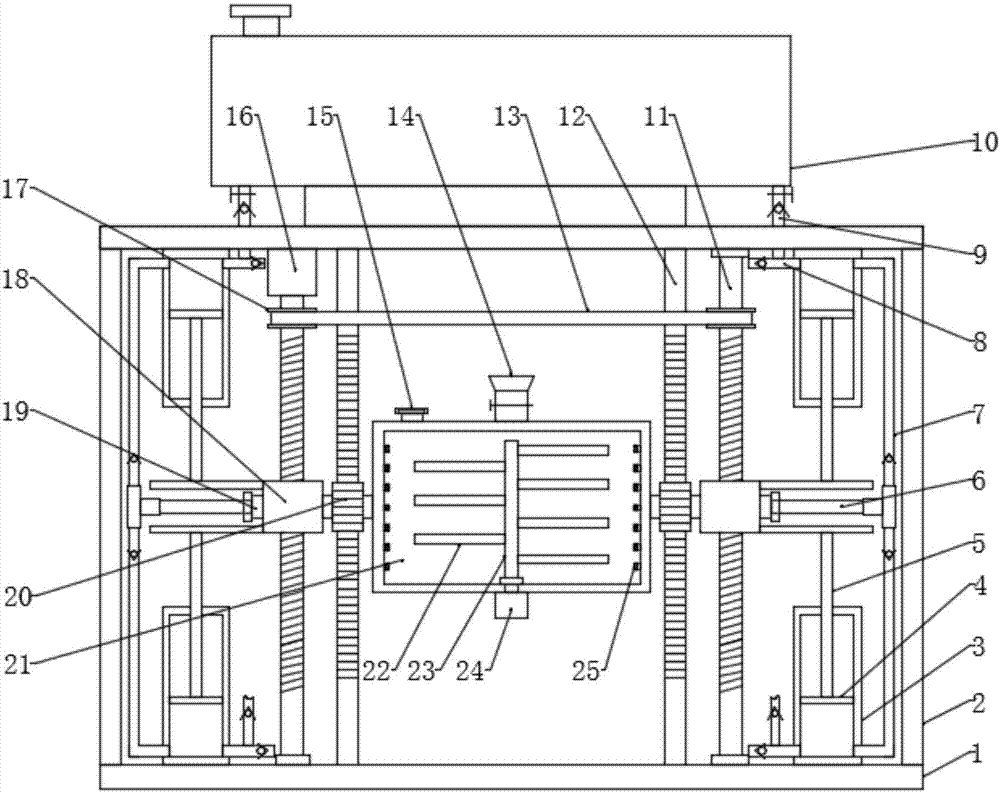

The invention discloses a chemical raw material stirring and drying device. The chemical raw material stirring and drying device comprises a bottom plate, a stirring box, a first motor, a stirring shaft, a stirring rod, a hollow rotary shaft, a movable block, a thread rod, a second motor, a belt wheel, a belt, a gear, a rack, a T-shaped rod, a piston, a cylinder body, a first pipeline, a gas inletpipe, a second pipeline and a spraying nozzle. According to the chemical raw material stirring and drying device disclosed by the invention, the first motor, the second motor, the stirring shaft, thestirring rod, the belt wheel, the belt, the movable block, the thread rod, the hollow rotary shaft, the gear, the rack and the stirring rod are arranged in a staggered manner, so that a stirring region is enlarged; when the stirring box moves up and down, the stirring box rotates frontward and backward, so that chemical raw materials in the stirring box are continuously overturned; furthermore, the stirring and mixing efficiency is improved; the T-shaped rod, the piston, the cylinder body, the water tank and the spraying nozzle are arranged so that continuous gas-spraying drying is realized and the drying efficiency is improved; the inner part of the stirring box also can be washed so that a phenomenon that the chemical raw materials are used for a long period so that the stirring box iscorroded and the service life of the stirring box is influenced is avoided.

Owner:长沙德科投资管理咨询有限公司

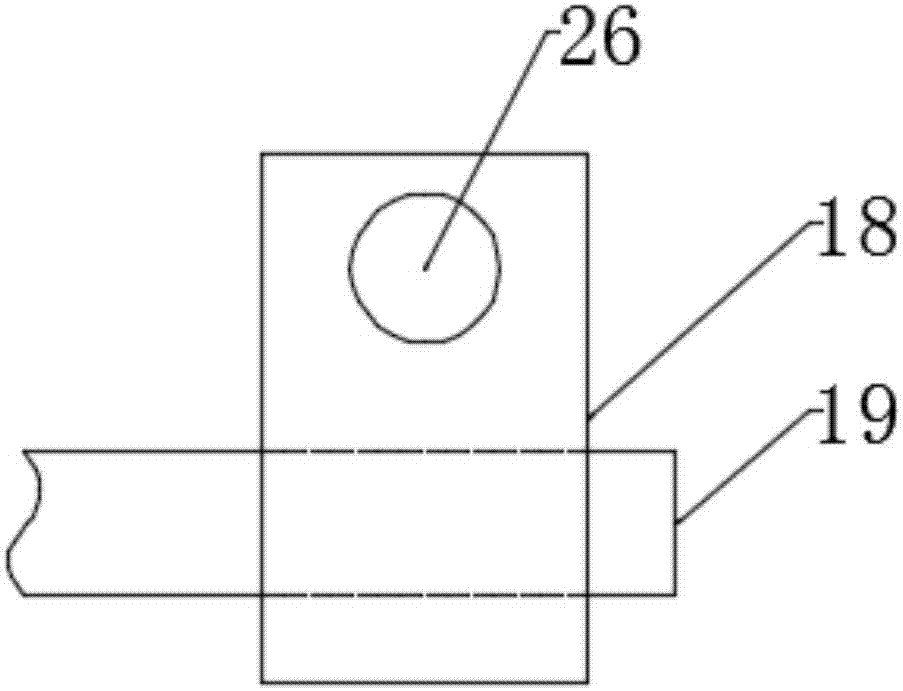

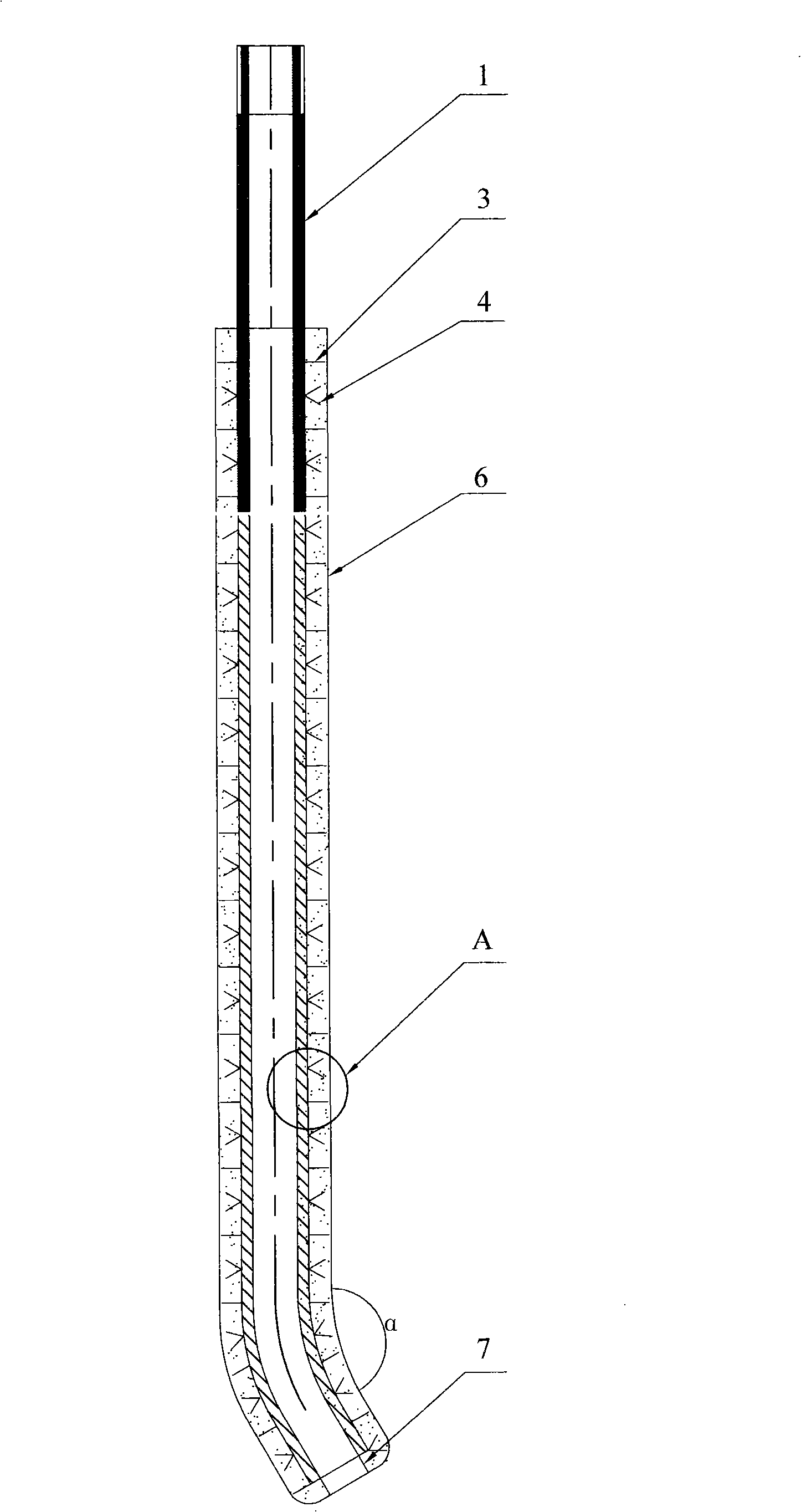

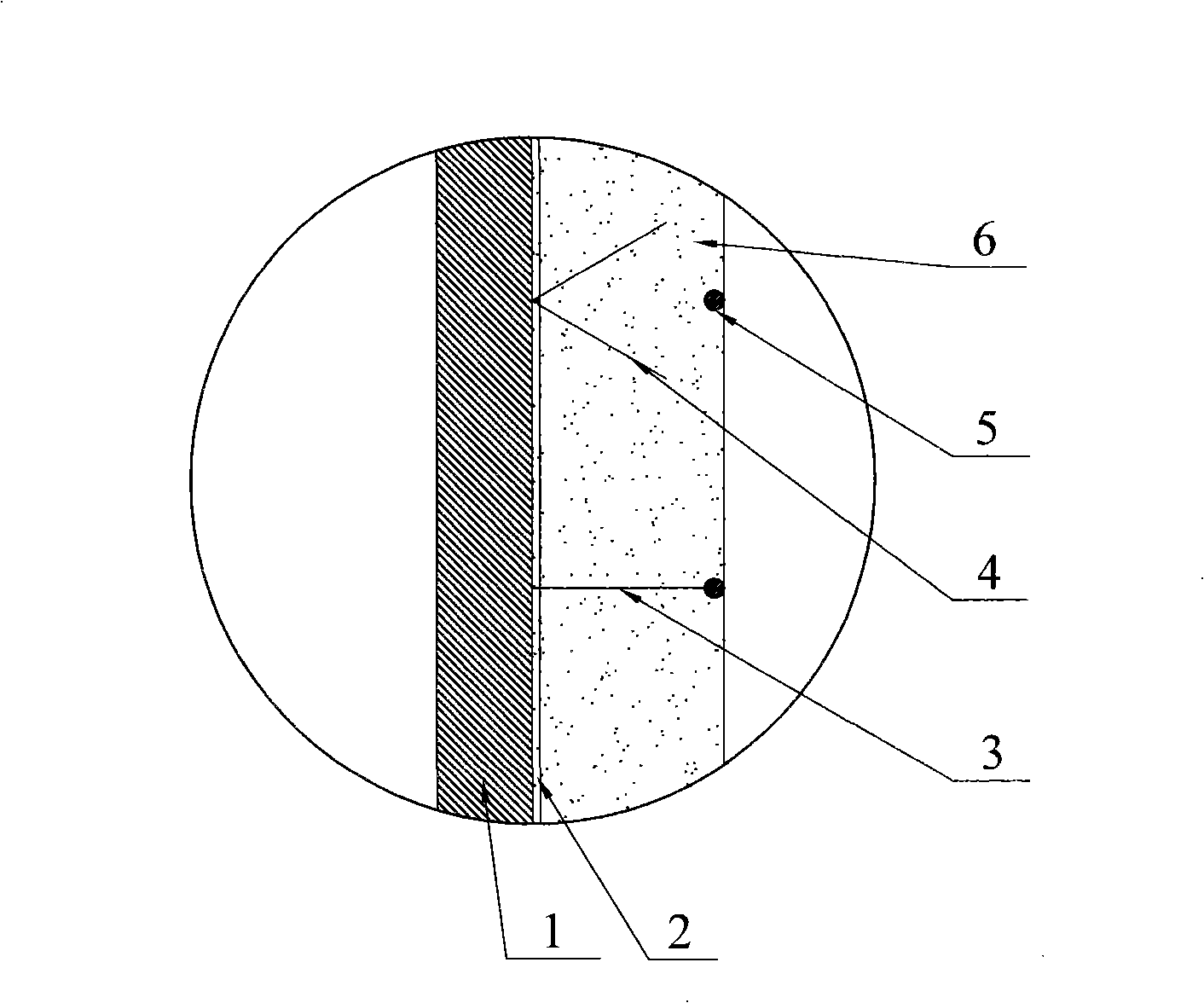

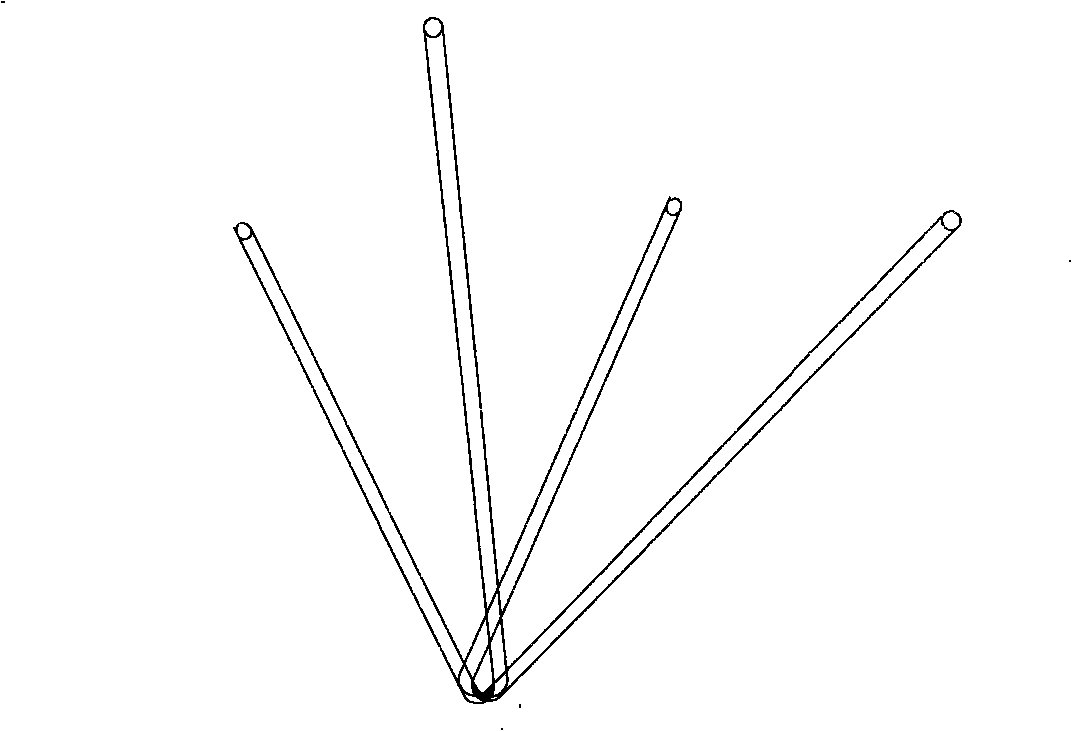

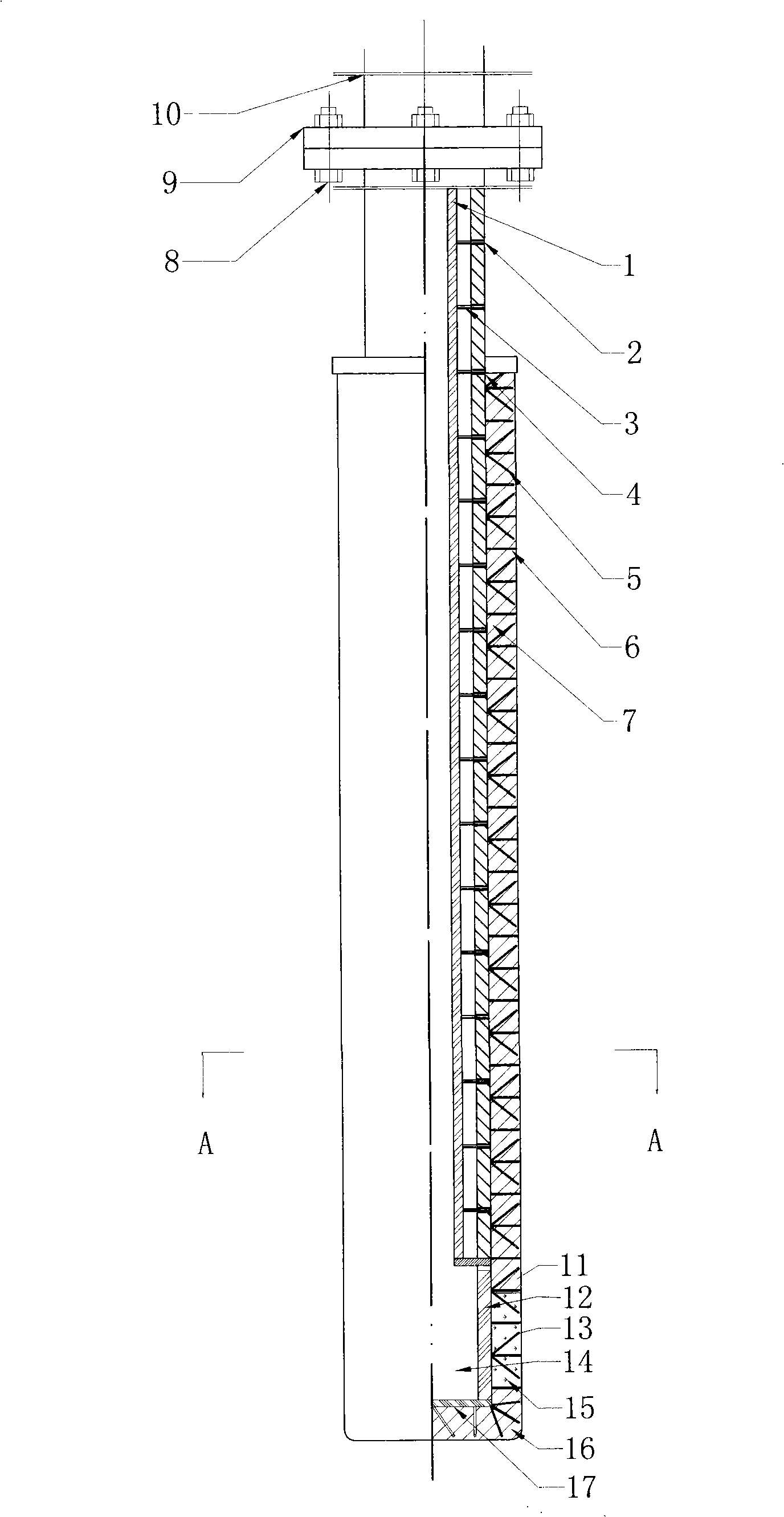

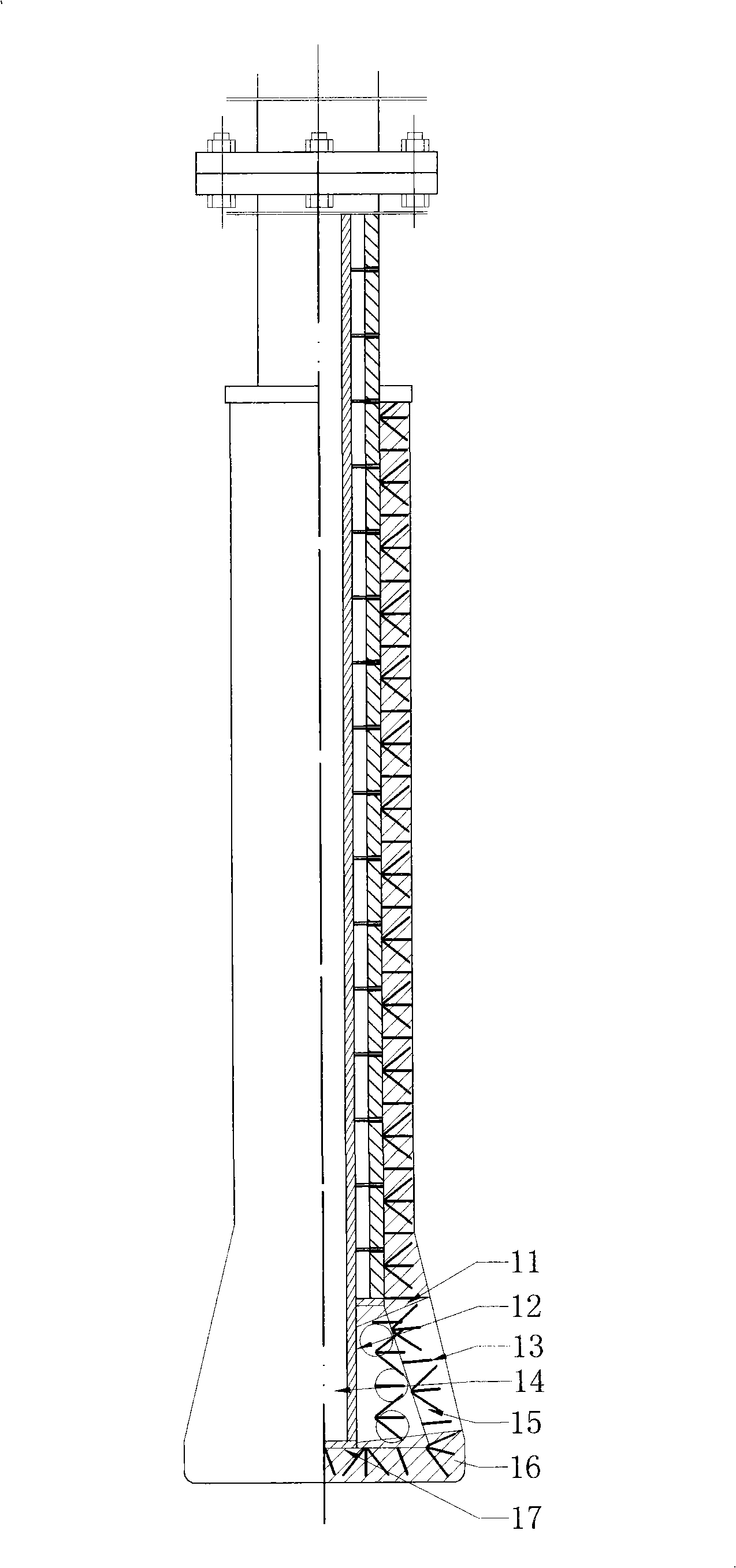

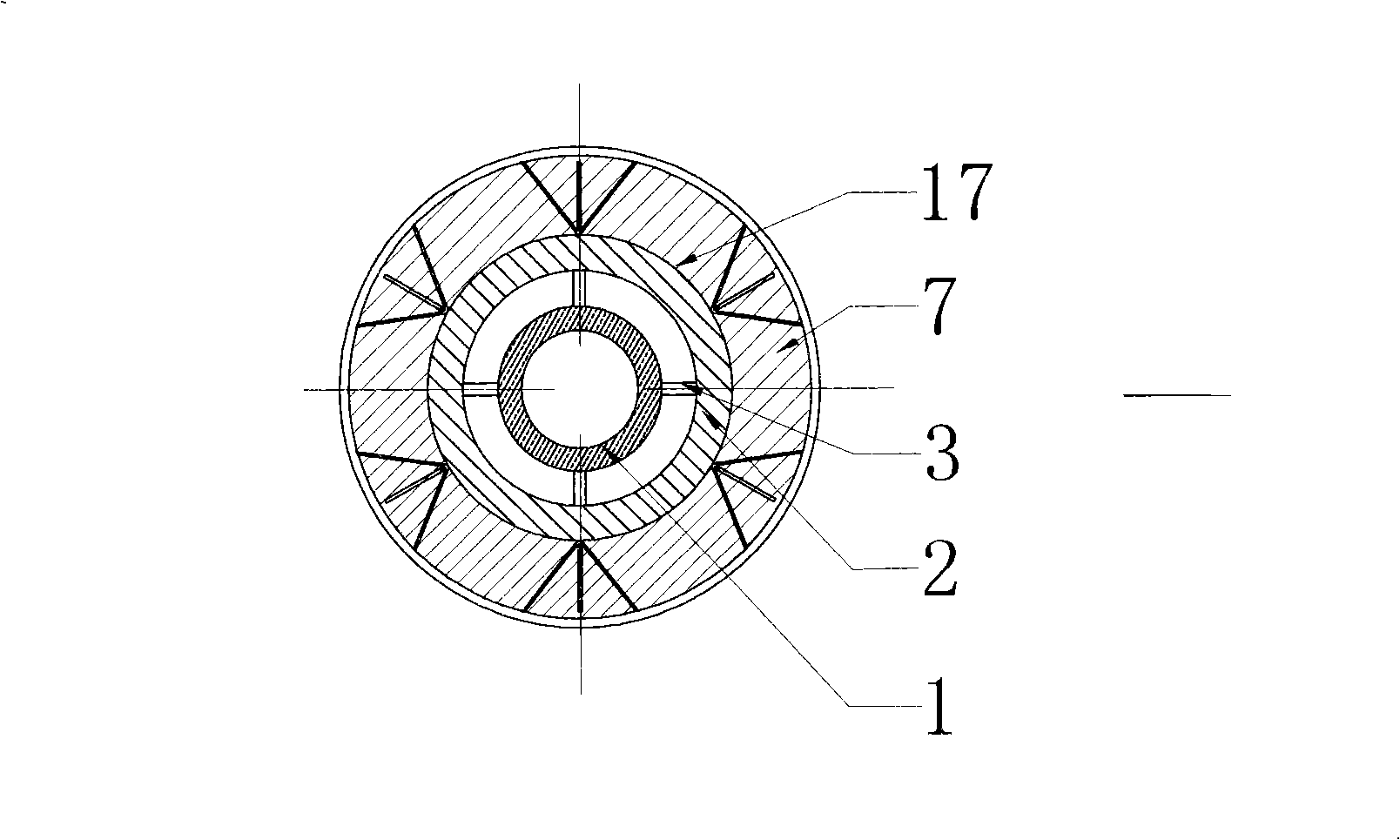

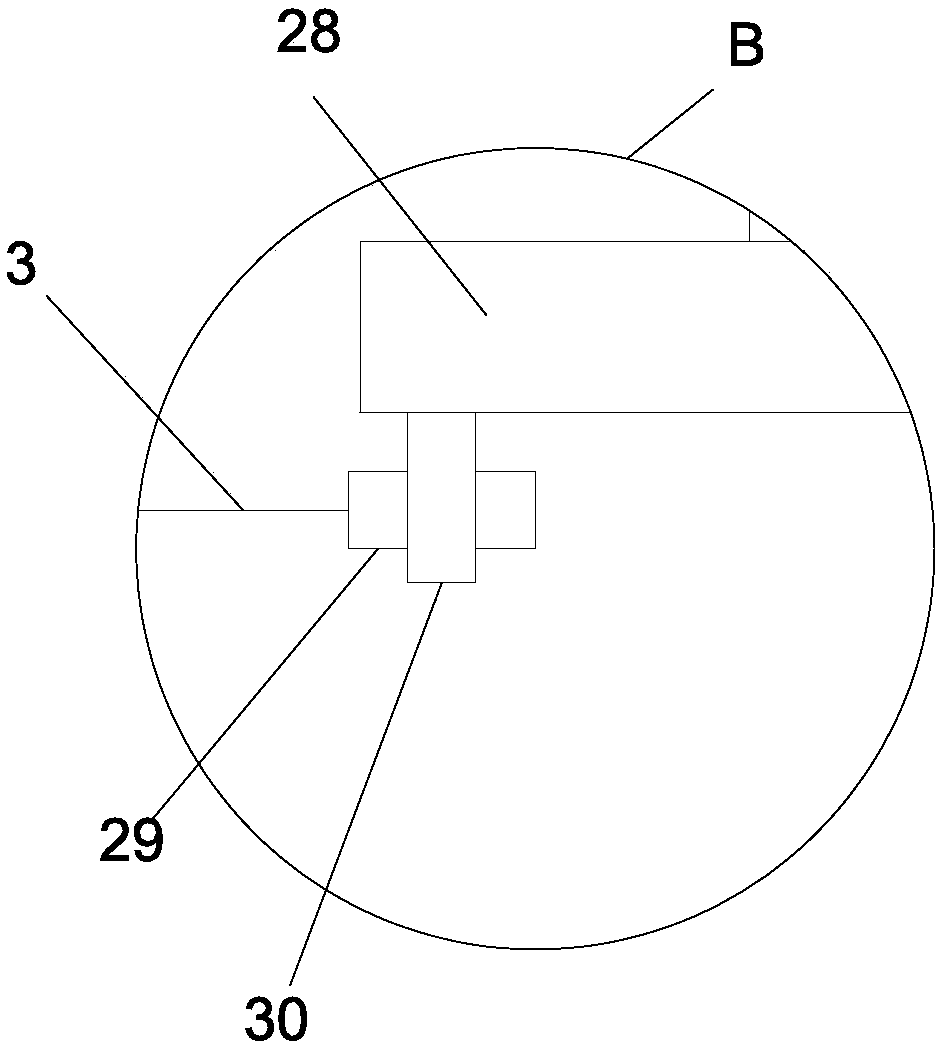

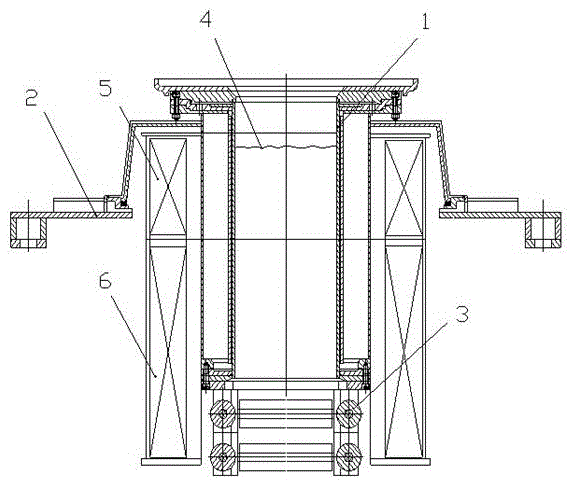

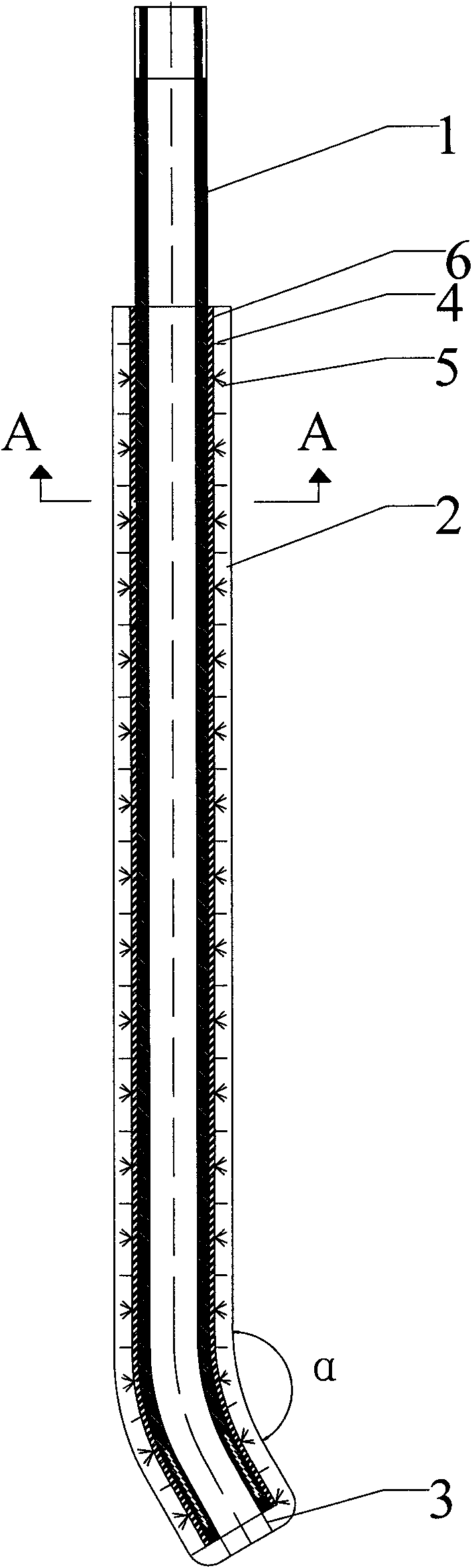

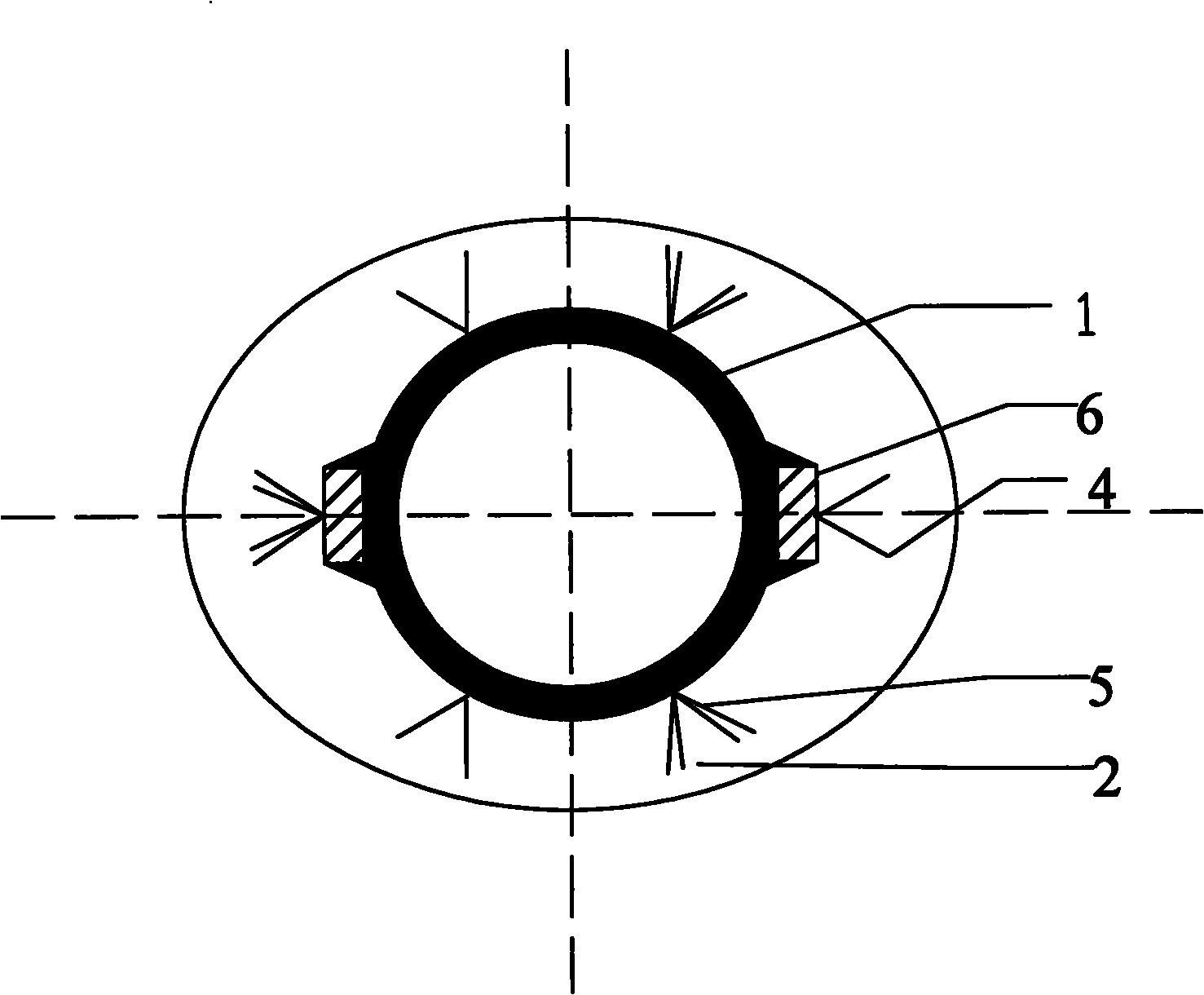

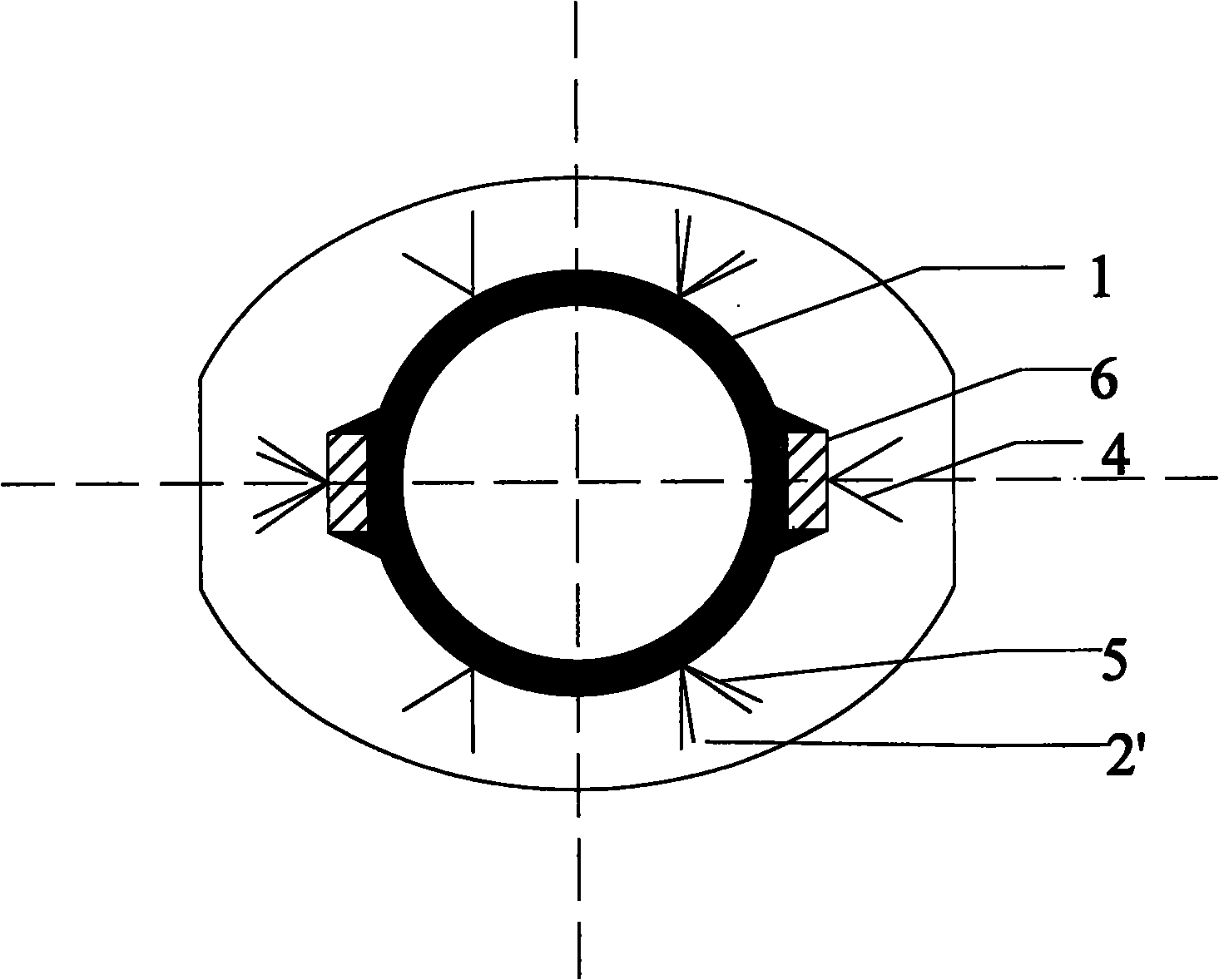

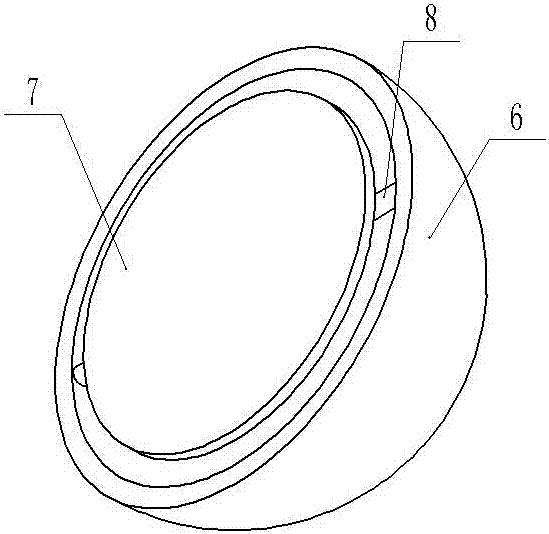

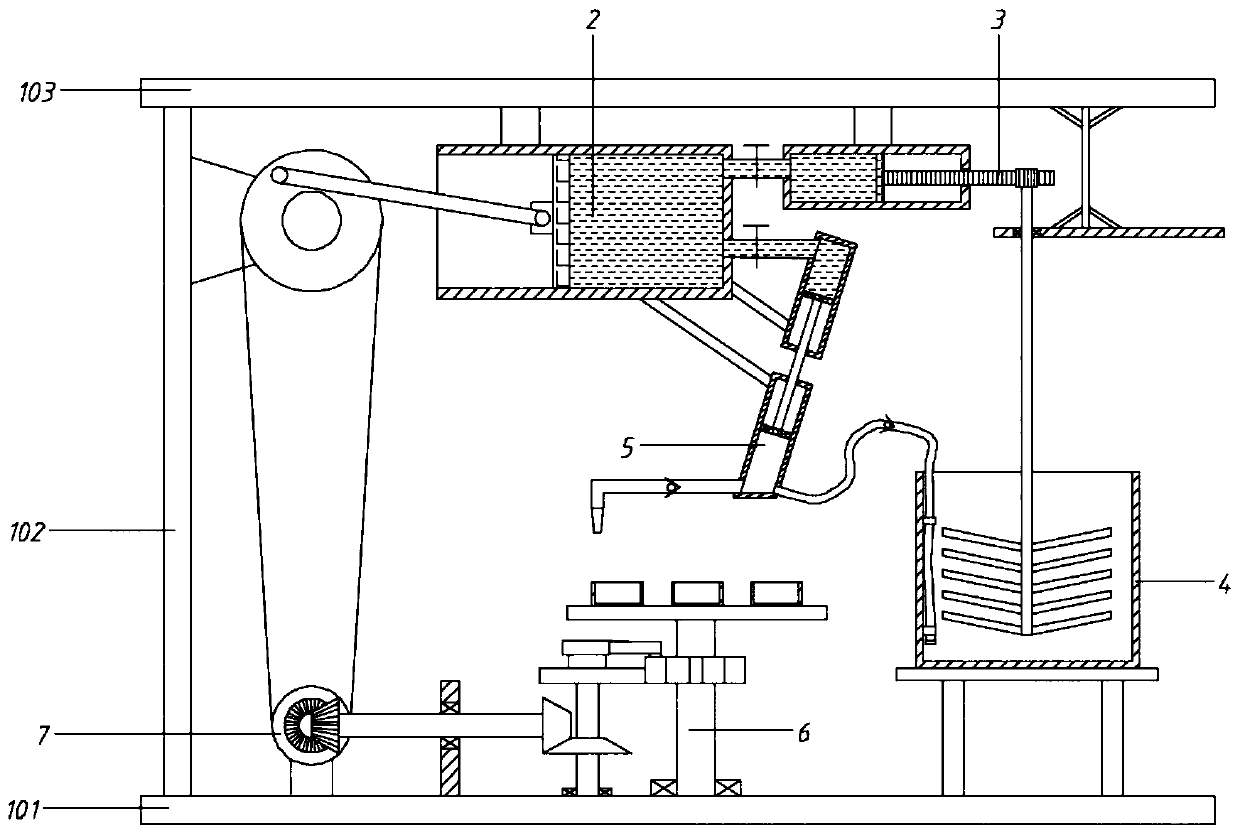

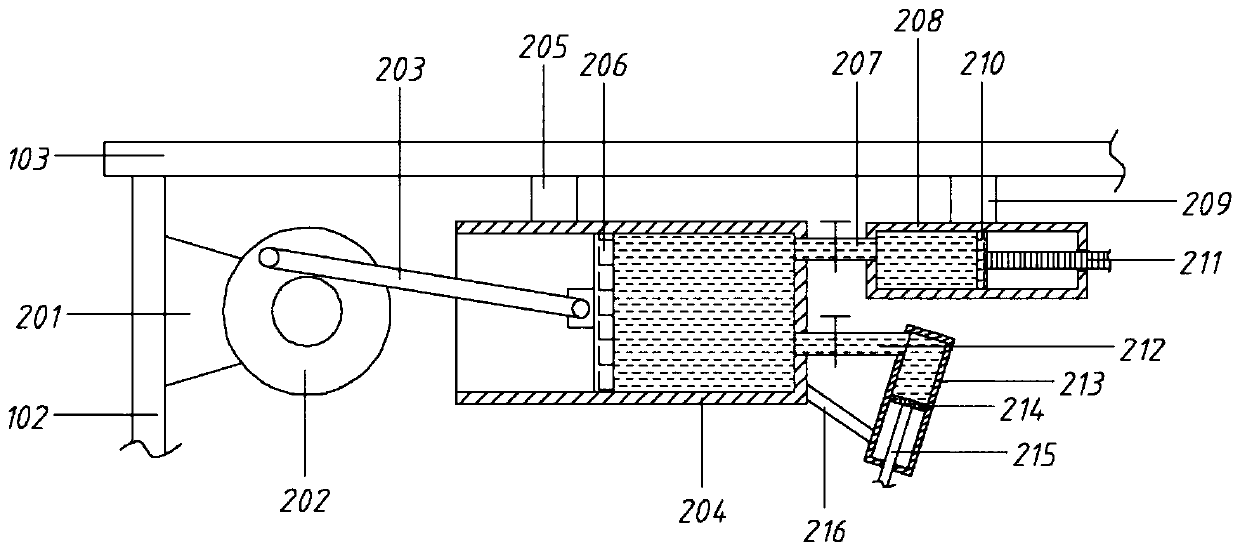

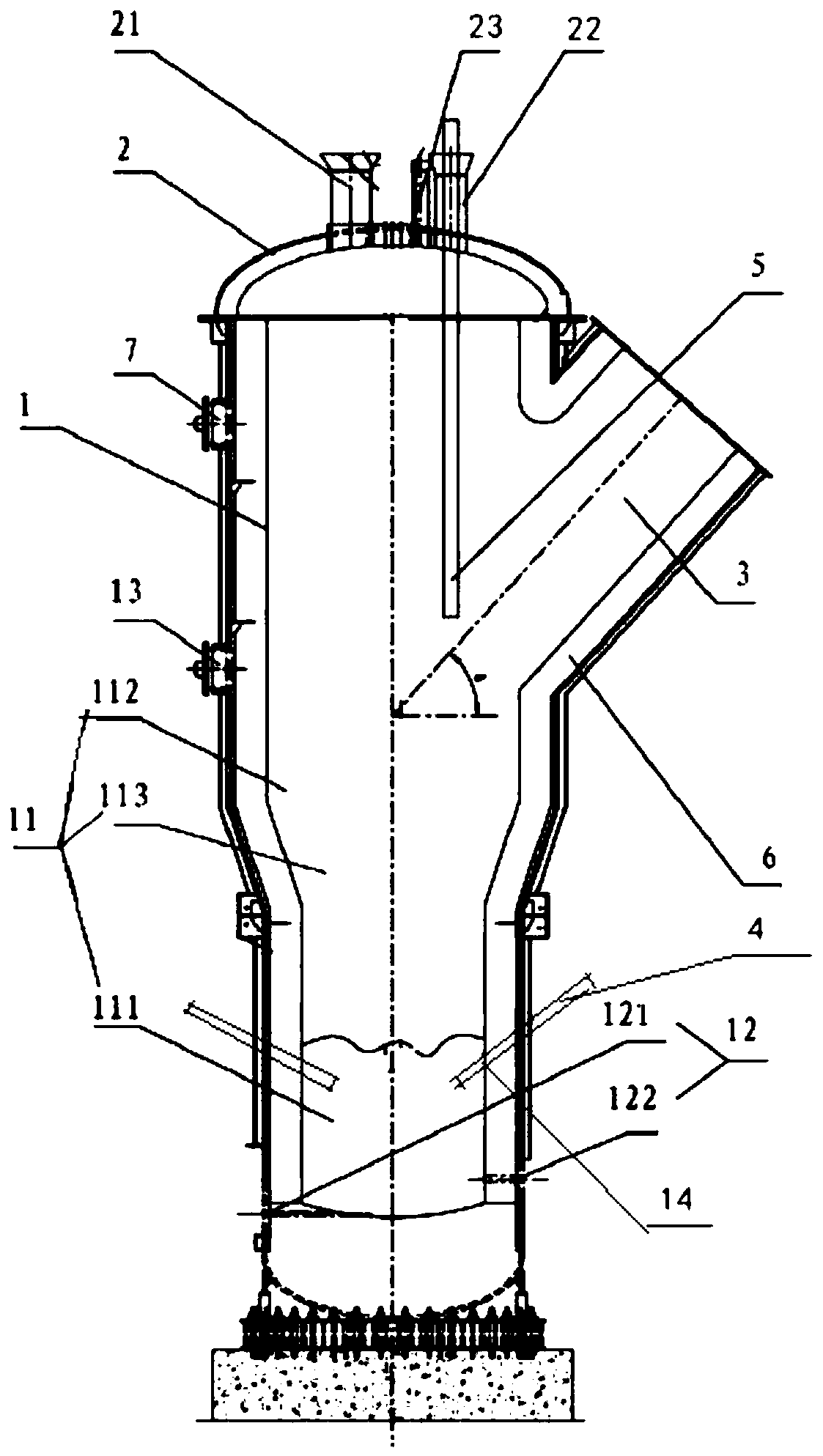

Angle-inserting type hot metal pretreatment spray gun

InactiveCN101337210AExtended service lifeEasy to paintCharge manipulationLiquid spraying apparatusBogieRefractory

The invention discloses an inclined-inserting hot metal pretreatment spraying gun, which is used for jetting treatment for hot metal on a mixing bogie with torpedo retort. The spraying gun comprises a gun core steel pipe, a gun lining made of refractory material, and a plurality of rivet clasping pieces; the lower end of the gun core steel pipe tilts and forms an included angle of 120 to 140 degrees with the longitudinal axial line of the gun core steel pipe; the outer surface of the gun core steel pipe is covered with the gun lining made of the refractory material; each rivet clasping piece is composed of a V-shaped rivet clasping piece, a double-V butterfly-shaped rivet clasping piece and an annular rivet clasping piece, wherein the V-shaped rivet clasping piece and the double-V butterfly-shaped rivet clasping piece are respectively arranged in a working lining made of the refractory material at intervals along the circumferential direction and the axial direction of the gun core steel pipe, and welded with the external circumference surface of the gun core steel pipe; the annular rivet clasping piece is welded at the outer end of the V-shaped rivet clasping piece; the outer surface of the gun core steel pipe is coated with a burning weight-loss coating layer formed by mechanical lubricating oil and polypropylene powder, wherein the weight percentage of the mechanical lubricating oil is 90 to 99 percent, and the weight percentage of the polypropylene powder is 1 to 10 percent. Finally, the purposes of prolonging the service life of the spray gun and improving the service performance of the spray gun are achieved.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

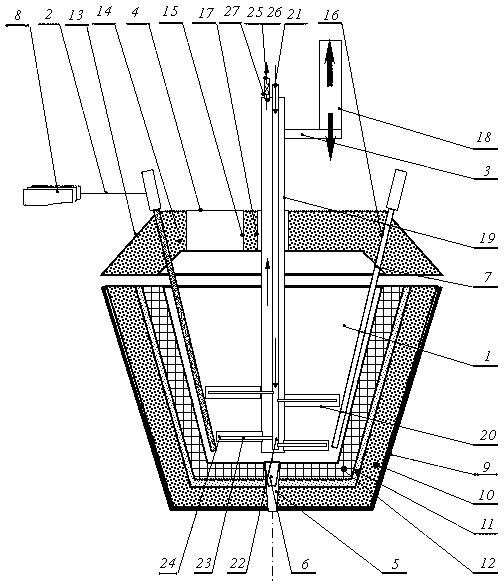

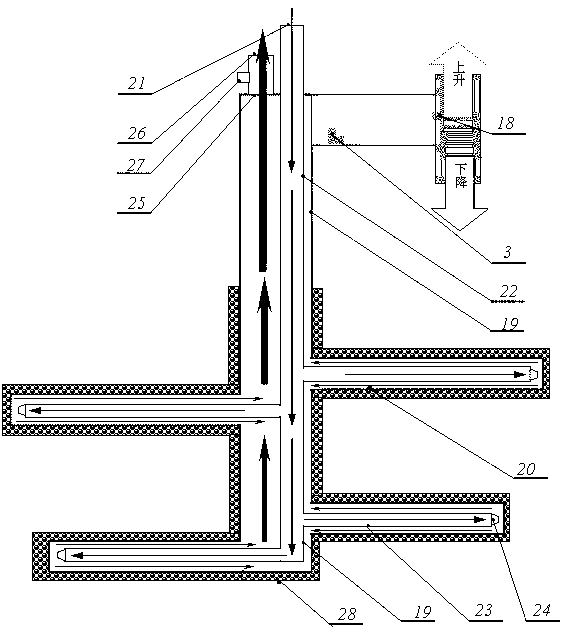

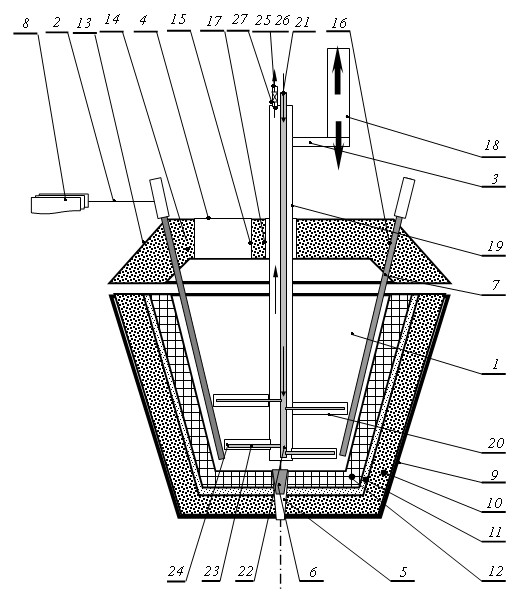

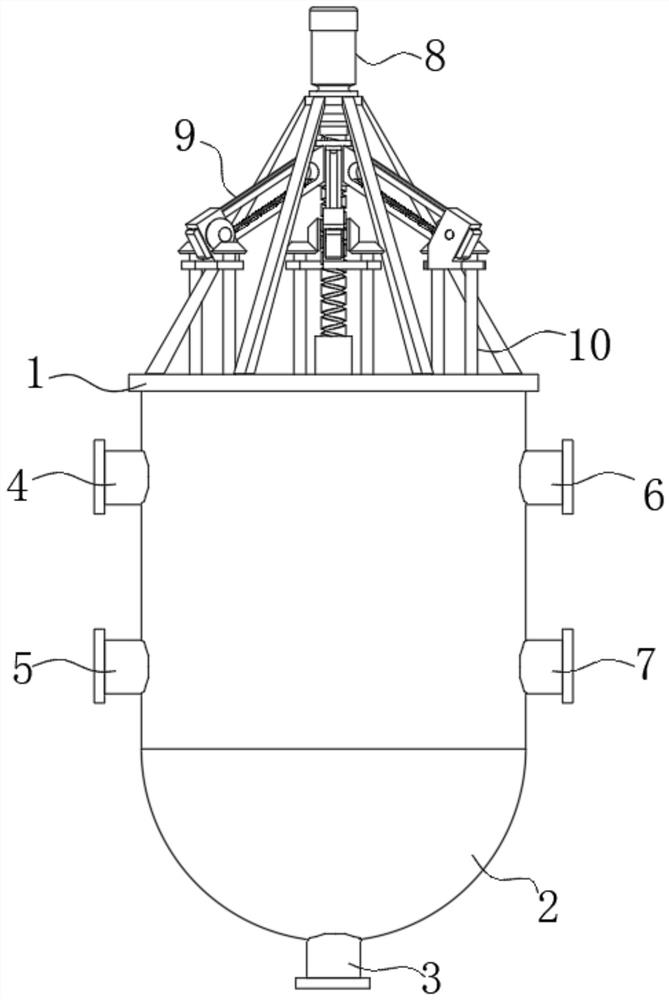

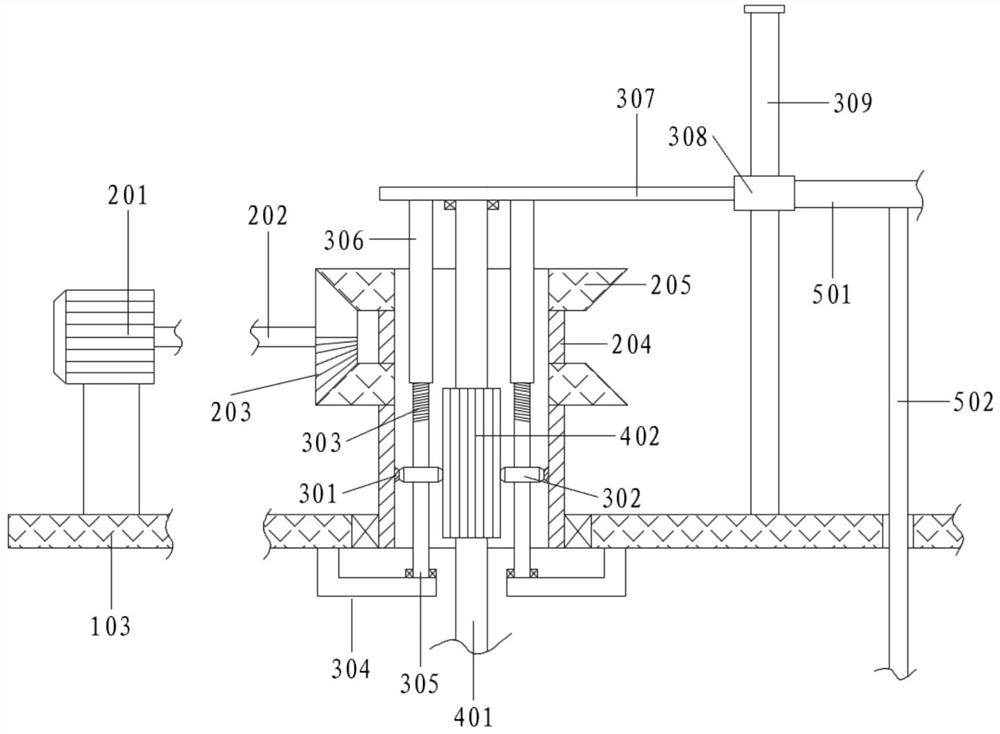

Device and method for homogenizing high-temperature melt

InactiveCN102698634AStirring power is smallIncrease the stirring areaRotary stirring mixersTransportation and packagingSlagHeating system

The invention provides a device and a method for homogenizing high-temperature melt and belongs to the technical field of melt homogenization. The device provided by the invention consists of three parts, namely a melting tank, a stirring system and a heating system. The detailed steps for homogenizing high-temperature melt carried out by the device provided by the invention are as follows: adding hot silicate slag and quenching-tempering material into the melting tank; after heating to melt the raw material, turning off the power supply; enabling the stirring part of the cooled stirring system to fall into the high-temperature melt, and finishing fall-rise-fall operating actions for stirring the melt in order, wherein the stirring process and the heating process are carried out alternatively; and under the condition that the test result of the samples shows that the composition uniformity and viscosity of the melt are suitable for the process conditions that the fiber is formed or the glass ceramics is prepared, opening a choke plug of the melting tank and making the melt flow out via the flow hole by the gravity of the melt to finish the homogenization process. The homogenizing device and the homogenizing method, provided by the invention, have the advantages of good homogenizing effect, good high-temperature strength and long service life of the stirring part.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

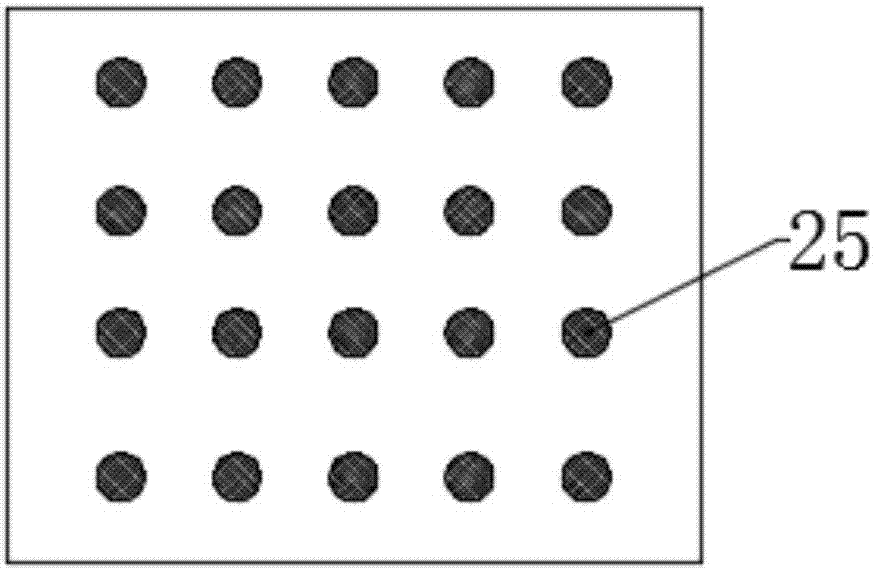

Argon-blowing spray gun for refining ladle and making method thereof

The invention discloses an argon blowing lance which includes a metal lance rod and a lance body that are connected together by a flange; the lower part of the lance body is provided with a dispersion nozzle; the lance body includes a main tube, a reinforcing tube, a plurality of bridging welding pieces, a plurality of rivet pieces and the working liner of a fire-proof material; the reinforcing tube is sheathed on the outside of the main tube; besides, a plurality of bridging welding pieces are uniformly welded between the reinforcing tube and the main tube; the rivet pieces of V shape and double V-shape are respectively and alternatively arranged in the working liner of the fire-proof material outside the reinforcing tube along the surrounding direction and the coaxial direction of the reinforcing tube; besides, the top points of the two are respectively welded with the outer surface of the reinforcing tube. The measures of the invention of sheathing the reinforcing tube and the bridging welding pieces outside the main tube of the core of the lance improve the intensity and the rigidness of the core structure of the lance; the rivet pieces of V shape and double V-shape enhance the bonding intensity between the core of the metal core of the lance and the working liner of the fire-proof casting material; the dispersion nozzle improves the blowing stirring intensity and finally achieves the goals of prolong the service life of the lance and improving the use performance of the lance.

Owner:武钢集团有限公司 +1

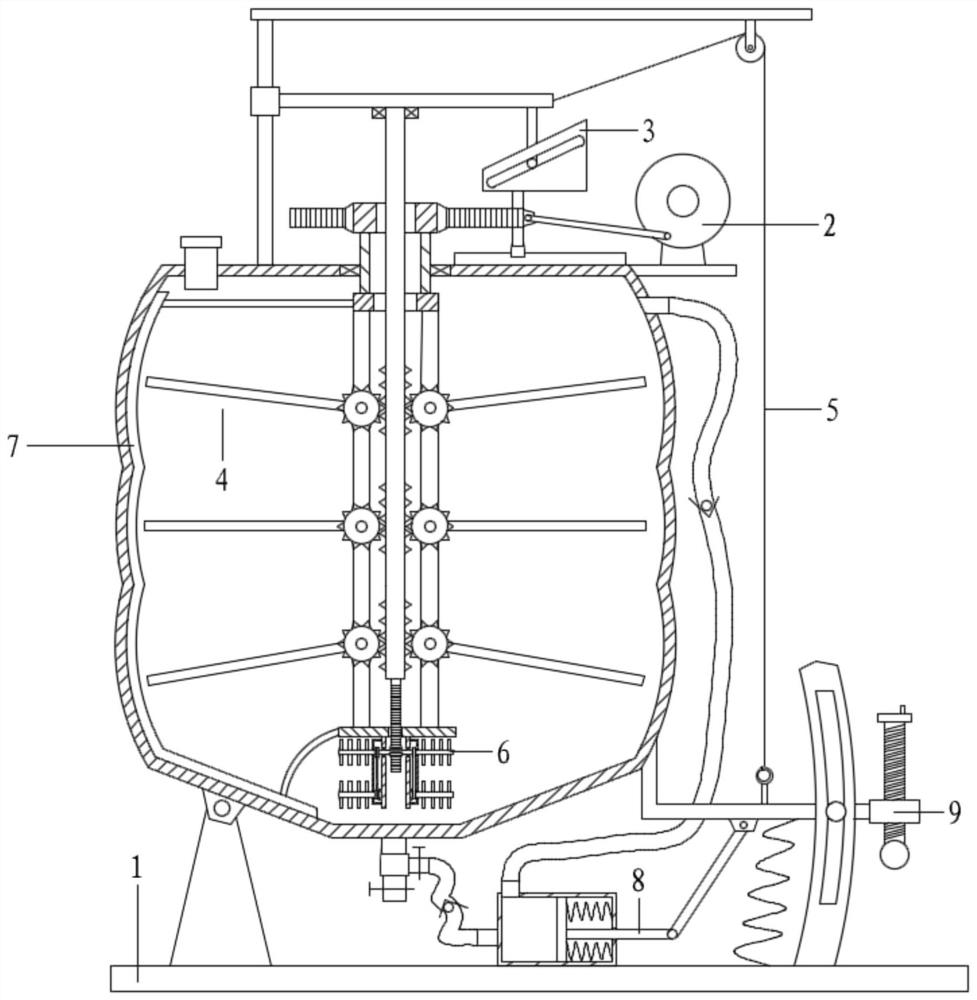

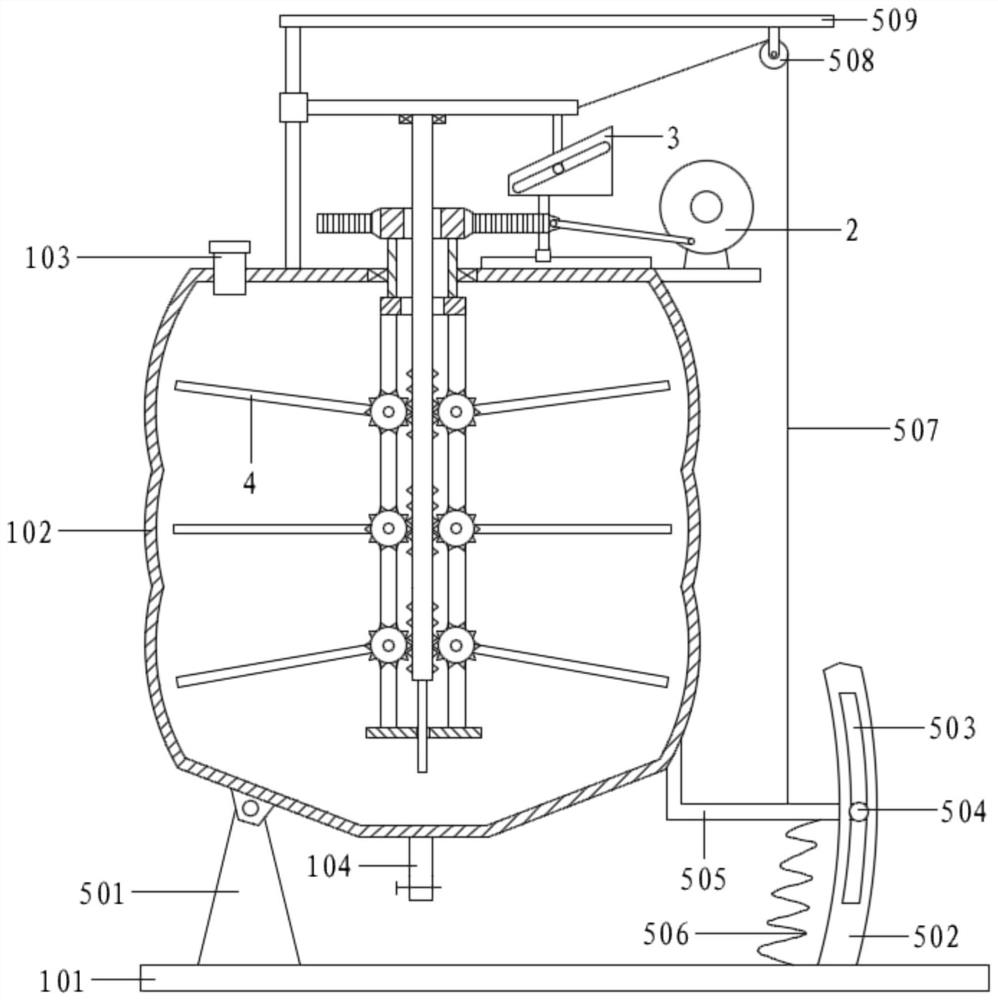

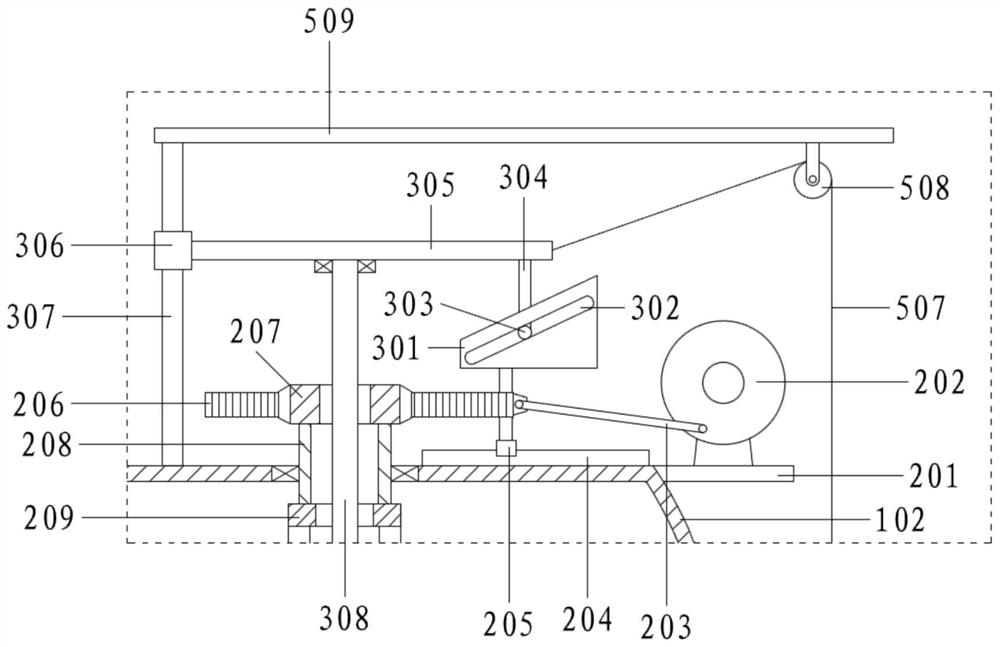

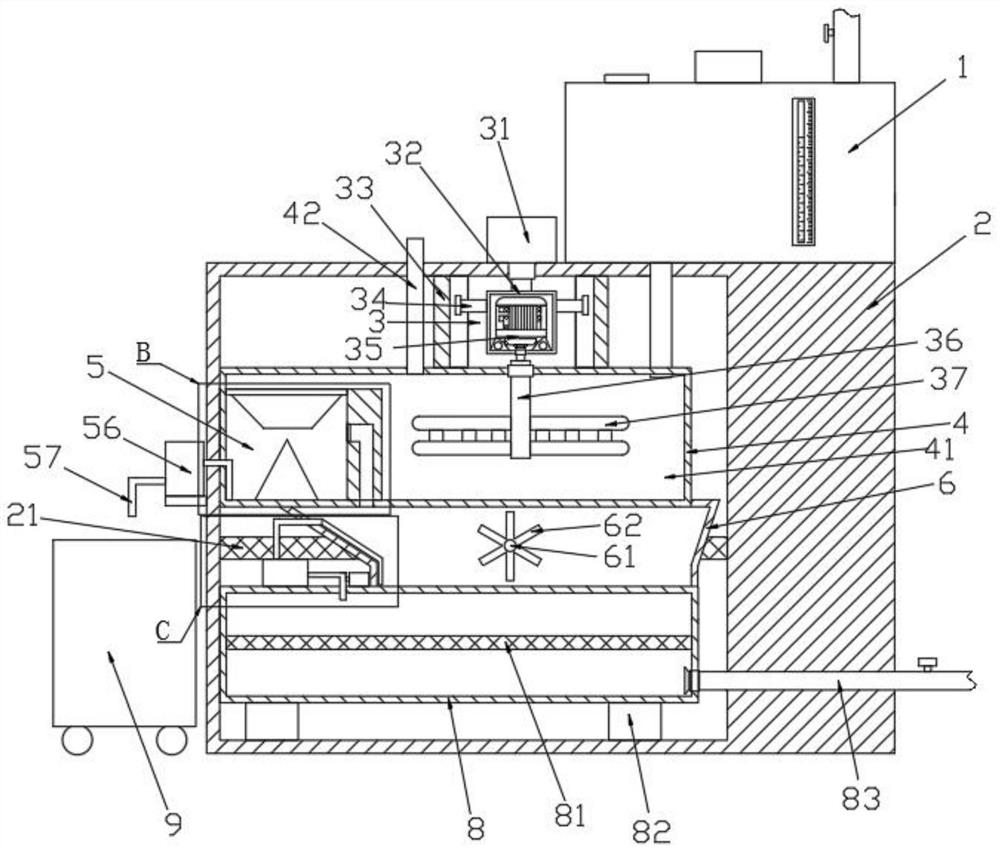

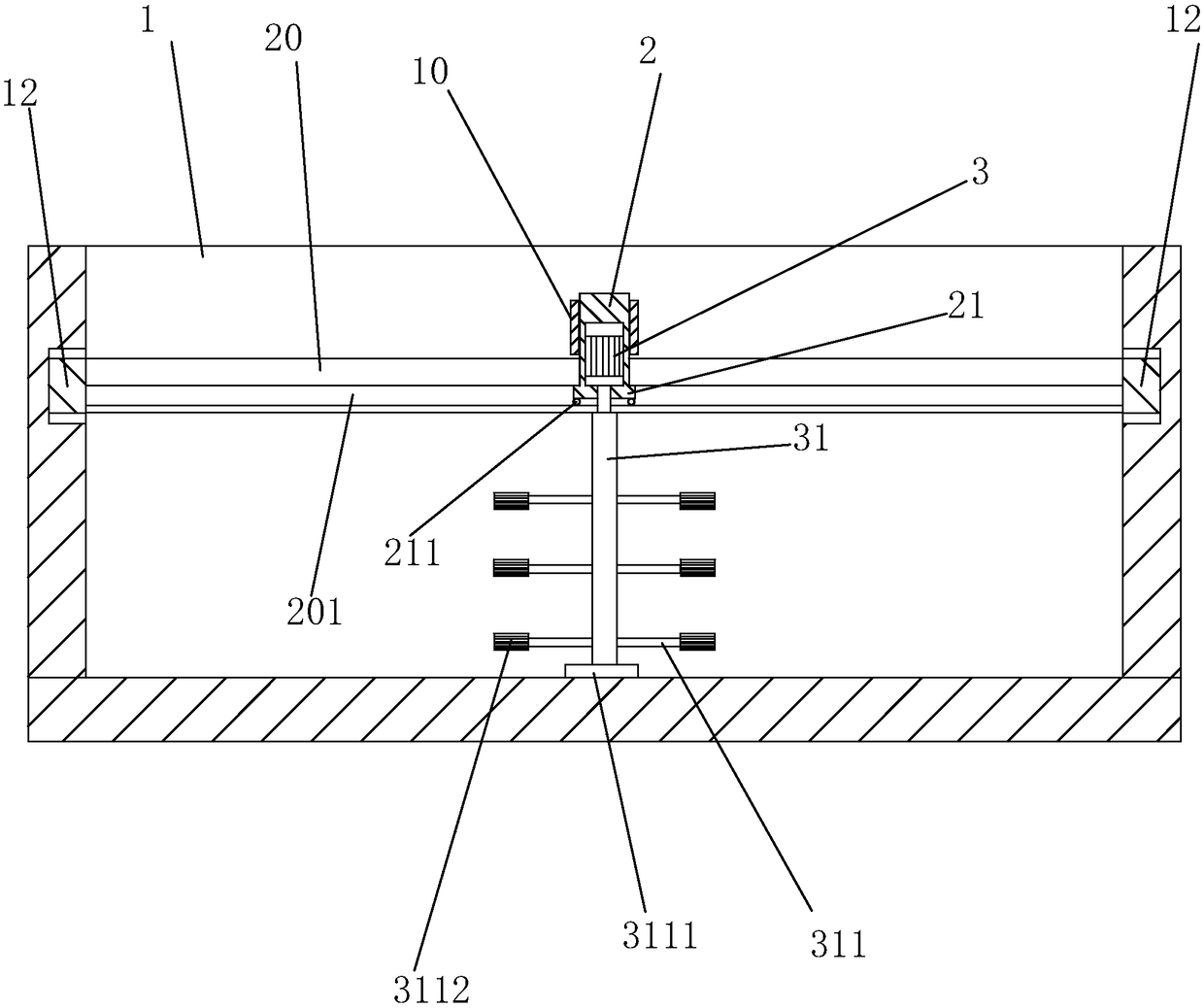

Power plant wastewater chloride ion removal device

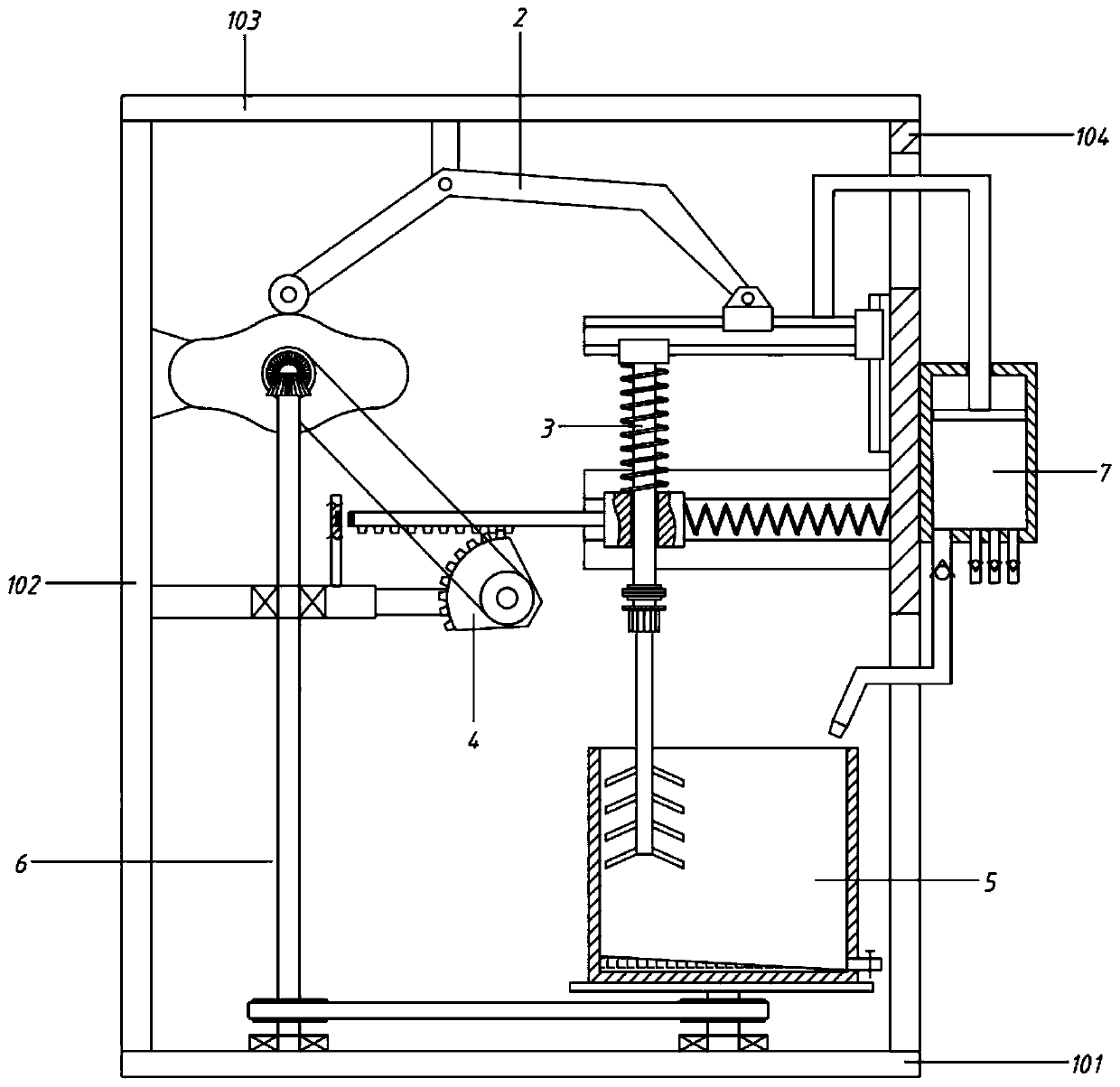

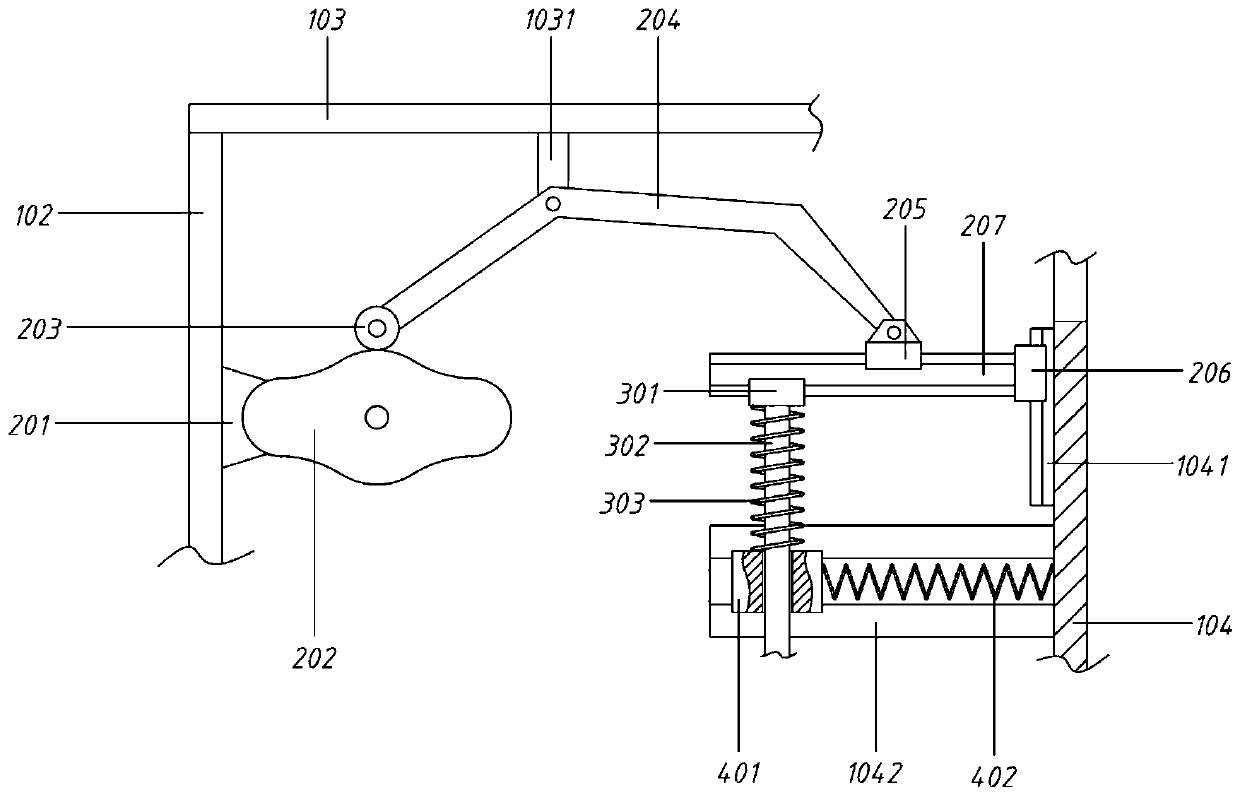

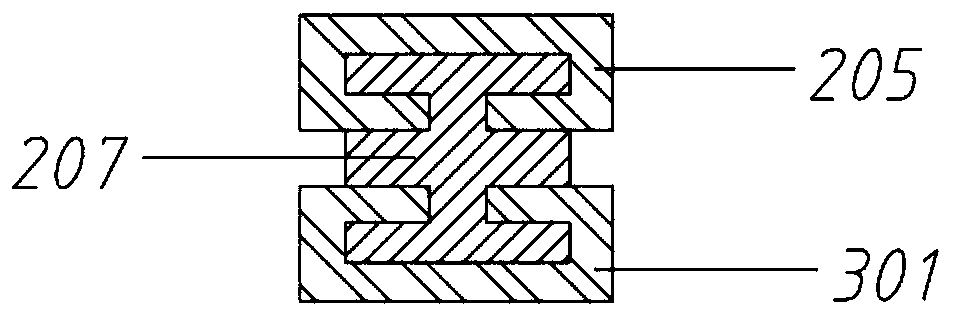

PendingCN112010383AImprove the mixing effectAchieve translationRotary stirring mixersTransportation and packagingElectric machineryDrive motor

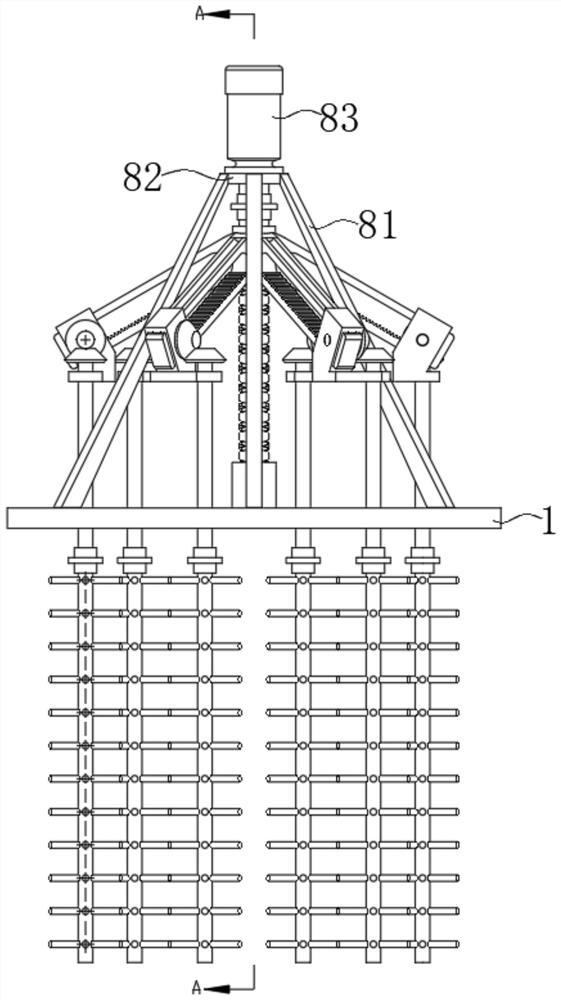

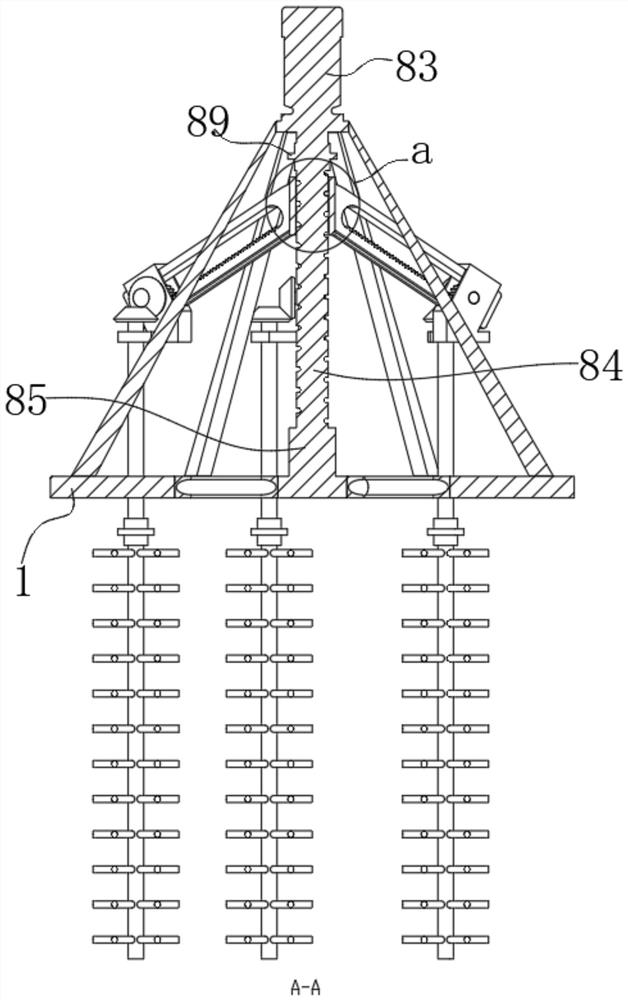

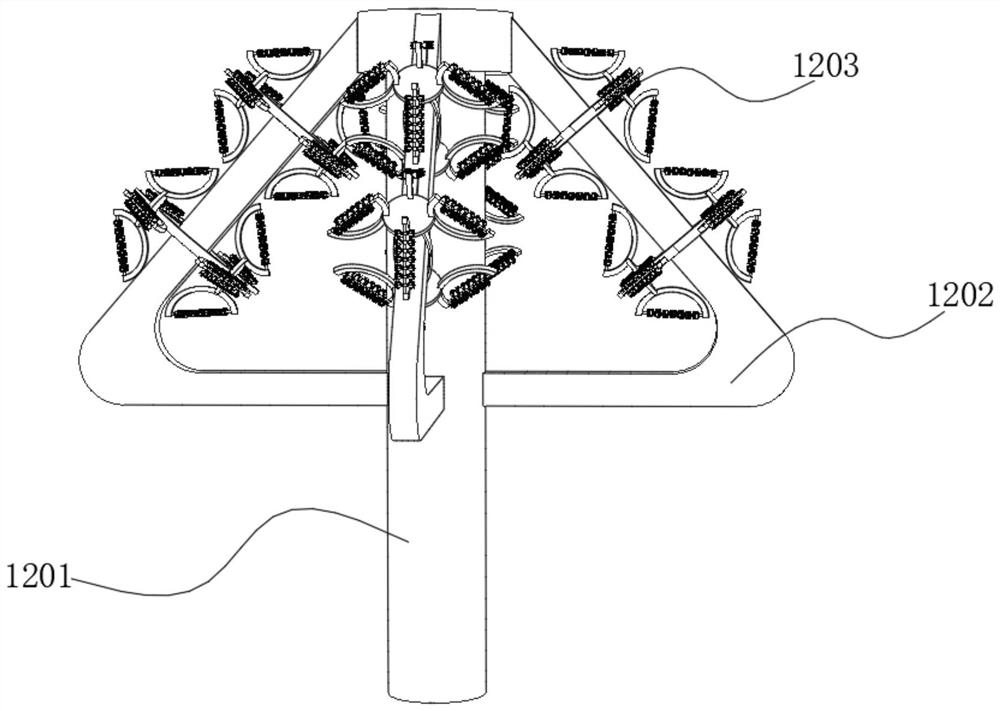

The invention relates to a power plant wastewater chloride ion removal device. The device comprises a kettle body and a kettle cover fixedly mounted above the kettle body, and an adjustable stirring mechanism is mounted on the kettle cover; the adjustable stirring mechanism sequentially comprises a lifting device, a driving device and a stirring device from top to bottom; and a driving motor in the lifting device drives a stirring rod in the stirring device to translate and rotate through a driving device, so that the stirring area and range are increased, the mixing effect of extract liquor and wastewater is improved, and the chloride ion extraction and removal effect is improved. According to the present invention, by arranging the plurality of the inclined rods, the area and the range are increased, and the number of the inclined rods is set, such that the effect equivalent to the omnibearing stirring can be almost achieved during the operation so as to significantly improve the mixing effect of an extraction liquid and the wastewater.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

Livestock feed mixing device for agricultural cultivation

InactiveCN107583543AIncrease the range of mixing up and downIncrease the stirring areaShaking/oscillating/vibrating mixersFeeding-stuffIsosceles trapezoidDrive shaft

The invention discloses a livestock feed mixing device for agricultural cultivation. The livestock feed mixing device comprises a mixing tank and a bottom plate, wherein a left column and a right column are vertically and fixedly arranged on the bottom plate, a top plate is horizontally and fixedly arranged at the top end of the left column and the top end of the right column, a motor frame is fixedly arranged on the top plate, a wedge block is fixedly arranged on a driving shaft in a sleeving mode, a longitudinal section of the wedge block is in an isosceles trapezoid shape, a guide rod is sleeved by a limiting slide sleeve in a slide mode, a connection block is arranged on a left lateral wall of the limiting slide sleeve, a rotating shaft is connected to an output shaft of a stirring motor, a driven shaft is arranged at the lower end of the top plate in a rotary mode, a driven belt wheel is coaxially and fixedly arranged on a driven shaft, and the wedge block can rotate to drive a lifting rod to reciprocate up and down through a universal ball. Therefore, up-down reciprocating movement of a stirring blade is achieved when the stirring blade is used for rotating and stirring feedin the mixing tank, a range for the stirring blade to stir and mix the feed up and down is improved, an up-down stirring and mixing effect on the feed is achieved at the same time, a feed mixing degree is improved, and a feed mixing efficiency is higher.

Owner:季彪

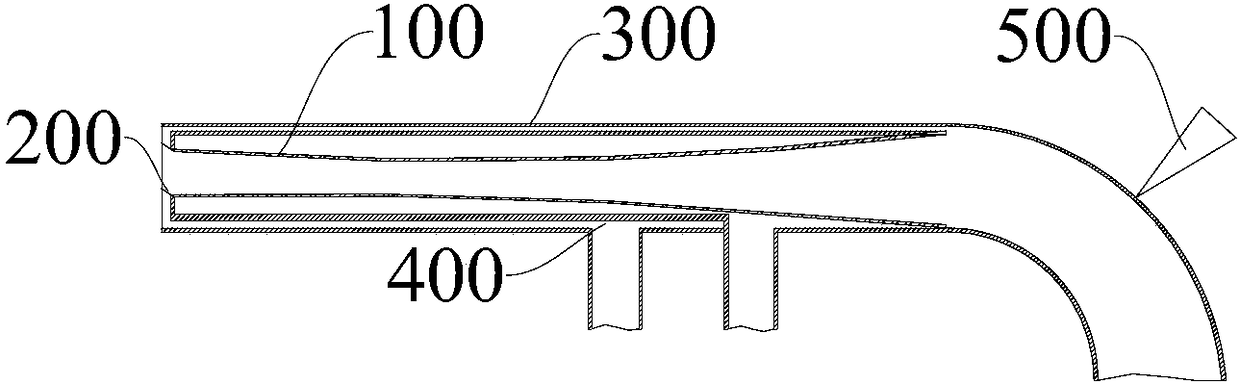

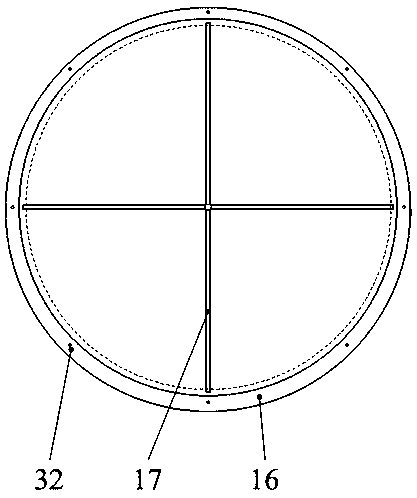

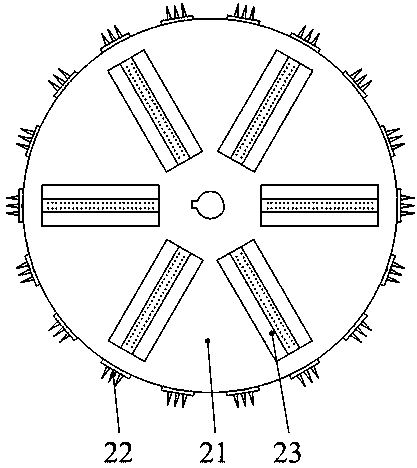

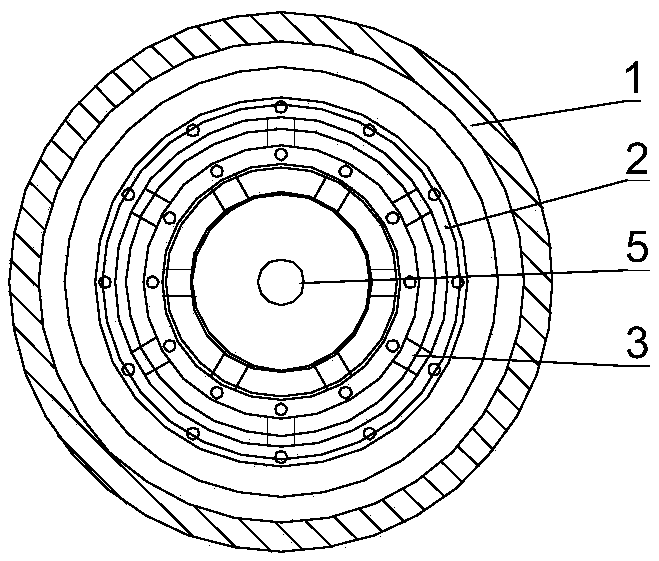

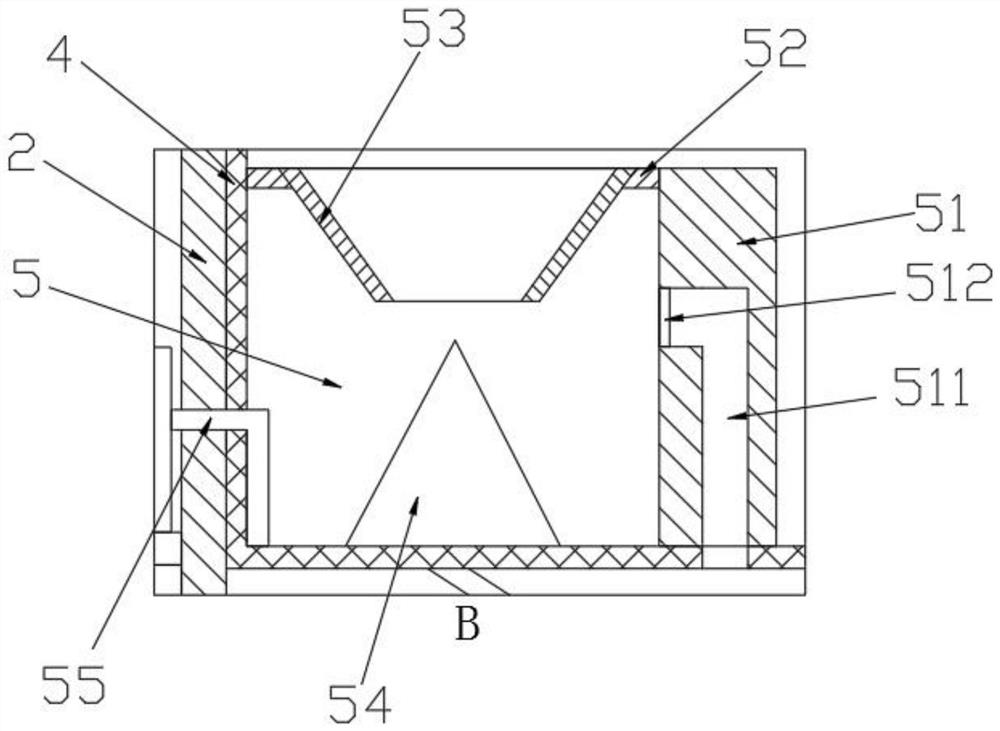

Multi-zone electromagnetic stirring device and method for continuous casting machine crystallizer

The invention discloses a multi-zone electromagnetic stirring device and a multi-zone electromagnetic stirring method for a continuous casting machine crystallizer, and belongs to the technical field of continuous casting equipment and the continuous casting method, and the device and the method are used for improving the electromagnetic stirring effect of the whole crystallizer area. According to the technical scheme, the invention adopts a combined structure of an upper electromagnetic stirring coil and a lower electromagnetic stirring coil, and a stirring method, so that the stirring effect of molten steel at the meniscus of the crystallizer is guaranteed, and the stirring zone of the molten steel is prolonged. The upper electromagnetic stirring coil can be started for steel types with high surface quality requirements, the lower electromagnetic stirring coil can be started for steel types with strict subcutaneous and segregation requirements, and the two groups of electromagnetic stirring coils are simultaneously started to work for the steel types with casting blank surface quality requirements and internal quality requirements. The structure of the conventional electromagnetic stirring device and the stirring method are broken through, the electromagnetic stirring metallurgical requirements of different zones of the crystallizer can be improved in a targeted mode, requirements of different steel types on equipment performances can be met, the quality of the casting blank can be effectively improved, and the economic benefits are remarkable.

Owner:SHIJIAZHUANG IRON & STEEL

Slant-insert type molten iron pretreatment lance and manufacturing method thereof

InactiveCN101786159AIncreased Strength and RigidityImprove bending resistanceMelt-holding vesselsLiquid spraying apparatusSteel tubeCarbon steel

The invention discloses a slant-insert type molten iron pretreatment lance and a manufacturing method thereof. The lance comprises a lance core steel tube, a refractory lance lining and a plurality of anchoring parts, wherein one end of the lance core steel tube is bent into the lance head; the refractory lance lining covers the outside surface of the lance core steel tube; and the anchoring parts are fixed on the outside surface of the lance core steel tube and positioned in the refractory lance lining; Axial reinforcing ribs are arranged at two sides of an axial section in the bending direction of the lance head on the outside surface of the lance core steel tube and are also covered in the refractory lance lining. The following steps are correspondingly added in the manufacturing method: clipping common carbon steel plates, polishing the two sides of the carbon steel plates into slants which are easy to weld to prepare the axial reinforcing ribs; and welding the axial reinforcing ribs at the two sides of the axial section in the bending direction of the lance head on the outside surface of the lance core steel tube. The lance is good in bending resistant effect, long in service life, good in injection pretreatment effect and simple in manufacturing process.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

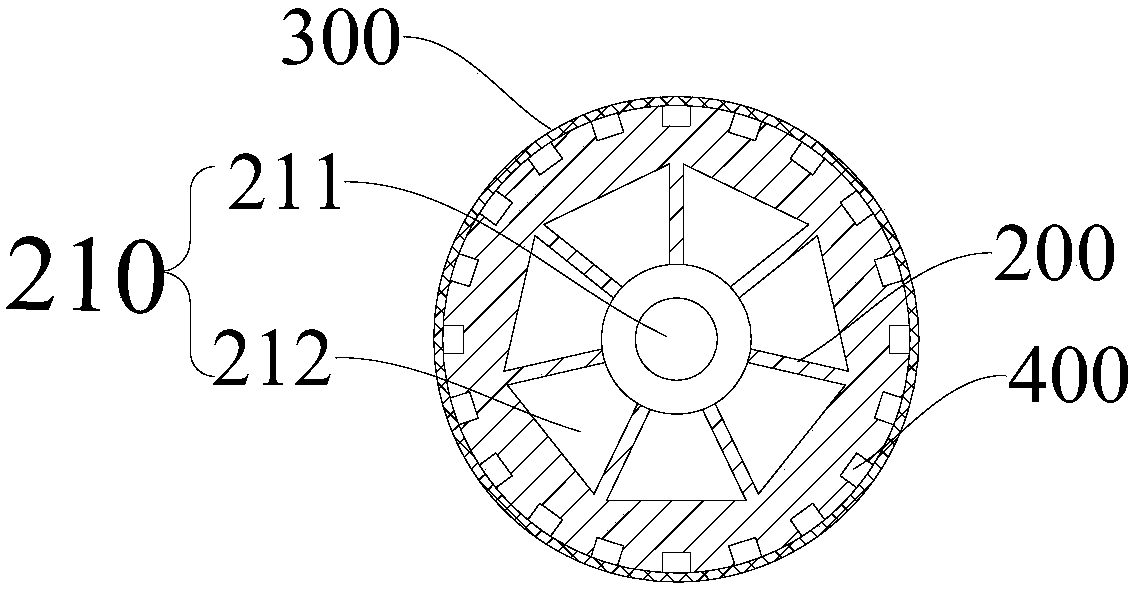

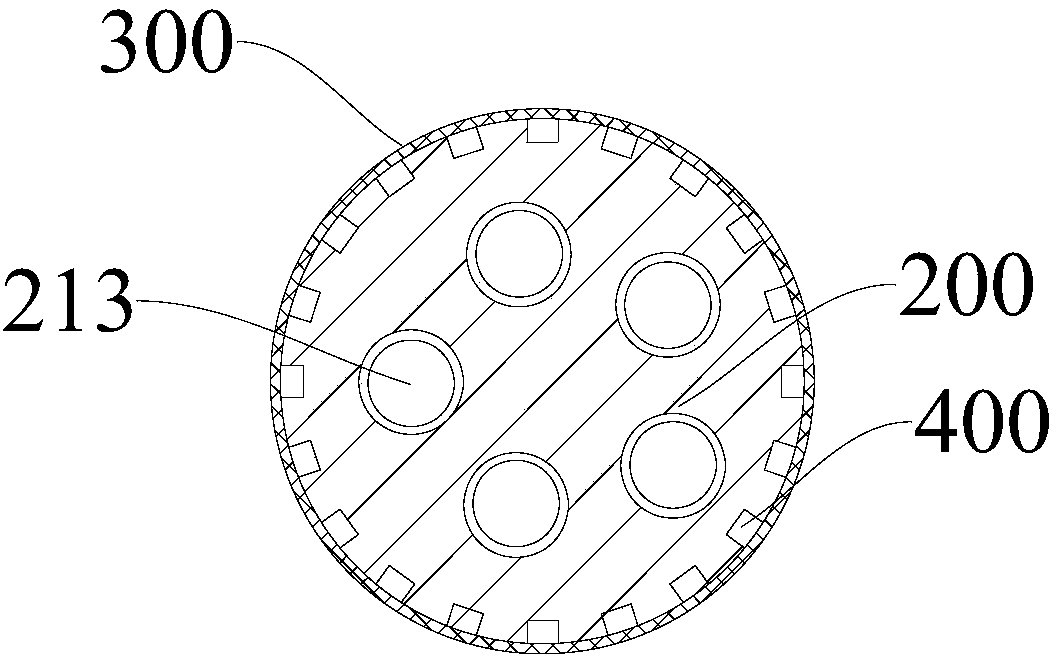

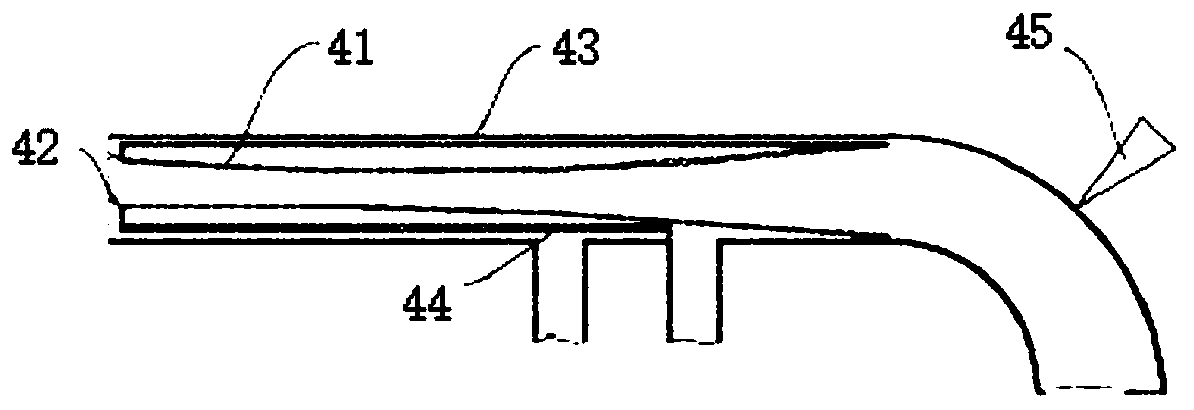

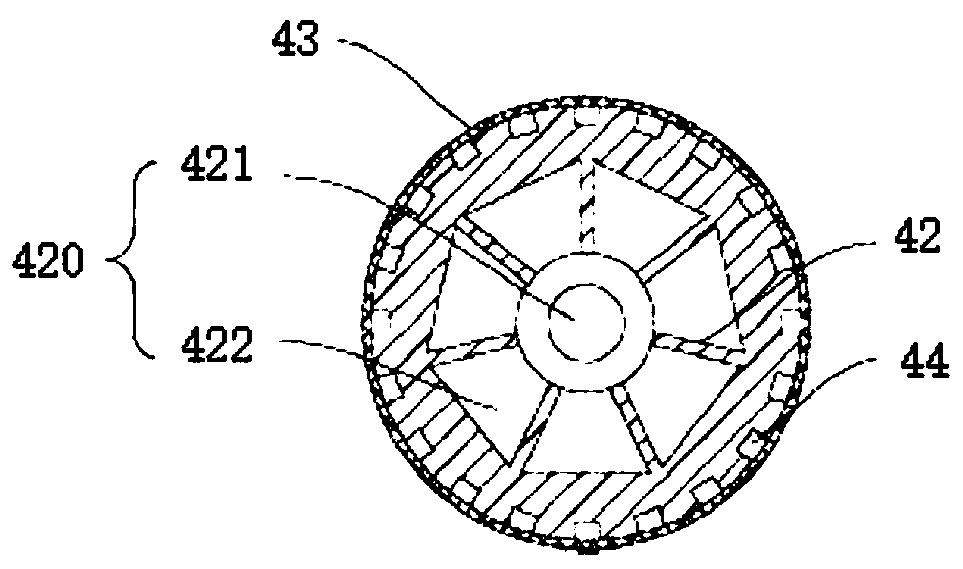

Side-blowing spray gun

PendingCN108253799AExtended stayIncrease the stirring areaCharge manipulationCharge treatment typeJet flowEngineering

The invention discloses a side-blowing spray gun which comprises a central pipeline, a diffluence cover, a sleeve and a cooling medium pipeline, wherein the diffluence cover is arranged at the outletof the central pipeline; diffluence holes are formed in the diffluence cover; the sleeve is arranged out of the central pipeline in a sleeving manner; the inner walls of the sleeve and the outer wallsof the central pipeline define a cooling medium accommodating space; and the cooling medium pipeline is arranged in the cooling medium accommodating space. Through arranging the diffluence cover at the outlet of the central pipeline of the spray gun, the central jet flow is divided into a plurality of rotation jet flows by the diffluence cover, so that the stirring area of the jet flow is increased and the stirring effect to a molten pool is remarkably enhanced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Rapid preparation device for cooling liquid used for machining tool

InactiveCN111085133AGuaranteed stirring effectRealize suction and dischargeRotating receptacle mixersTransportation and packagingProcess engineeringCam

The invention relates to the technical field of cooling liquid preparation equipment, specifically to a rapid preparation device for a cooling liquid used for a machining tool. According to the invention, a first servo motor is adopted to drive a cam to rotate; through rotation of the cam and cooperation of components like a rocker, position change of a stirring assembly in a vertical direction isachieved, and the stirring area is enlarged; stirring power is provided through a second servo motor, and when the stirring assembly moves, the second servo motor drives a second shaft to drive a stirring rod to mix and stir raw materials, so the stirring effect is guaranteed; through arrangement of a reciprocating assembly, the stirring assembly moves leftwards and rightwards, so the stirring area is further enlarged; through arrangement of a rotating assembly, a rotating table and a stirring barrel on the rotating table are driven to rotate, so the stirring effect is enhanced conveniently;and through arrangement of a feeding assembly, raw materials are sucked and discharged, so automatic feeding is achieved, and convenience and rapidness are achieved.

Owner:安徽携尚数据科技有限公司

Peucedanum praeruptorum Dunn cultivation method

InactiveCN107006260ALower center of gravityPrevent water hardeningGeneral water supply conservationSelf-acting watering devicesRoot rotPeucedanum praeruptorum

The invention relates to the technical field of peucedanum praeruptorum Dunn planting and discloses a peucedanum praeruptorum Dunn cultivation method. The peucedanum praeruptorum Dunn cultivation method comprises the steps of land selection and preparation, planting, watering and daily management, the step of land selection and preparation includes planting hole digging, the step of planting includes that pipe burying is performed, spiral water pipes are buried in planting holes, a plurality of water sucking holes are formed in the water pipes, cotton threads are put in the water pipes and extend along the water pipes, and the steps of planting and watering further include a step of support erection. The specific operation of the peucedanum praeruptorum Dunn cultivation method: (A) supports are erected on the outer sides of planting pits, the lower ends of the supports are inserted into soil, and elastic water collecting grooves are erected at the upper ends of the supports and are formed above the planting pits; (B) first pipes are connected to the water collecting grooves, valves are arranged on the first pipes, and the other end of each first pipe faces the corresponding planting pit; (C) second pipes are arranged on the outer sides of the water collecting grooves and are connected to the water pipes, so that the cotton threads extend out of the outer sides of the second pipes. The water draining effect of the soil can be improved and peucedanum praeruptorum Dunn root rotting caused by waterlogging is prevented by adopting the method.

Owner:道真自治县茂峰中药材发展有限公司

Mixing machine for resin production

The invention discloses a mixer for resin production, comprising a mixer base, a stirring motor arranged on the left side of the upper surface of the mixer base, and a mixer tank body arranged on the right side of the upper surface of the mixer base, the mixer tank The center of the inner cavity of the body is fixedly installed with a rotating shaft through a mechanical seal bearing. The lower end of the rotating shaft is connected to the stirring motor through a coupling. Two sets of fixed turntables are fixedly installed on the rotating shaft. In the area, the symmetrical vertical stirring rods set on the two sets of horizontal stirring rods can increase the mixing and stirring in the vertical direction; the setting of the driving rod and the torsion spring can make the vertical stirring rods have a positive effect during the rotation process. With a certain swing, the effect of layered mixing is more obvious. At the same time, the setting of the scraper and scraper in the middle can mix the resin at the edge of the tank.

Owner:重庆皓玥新材料有限公司

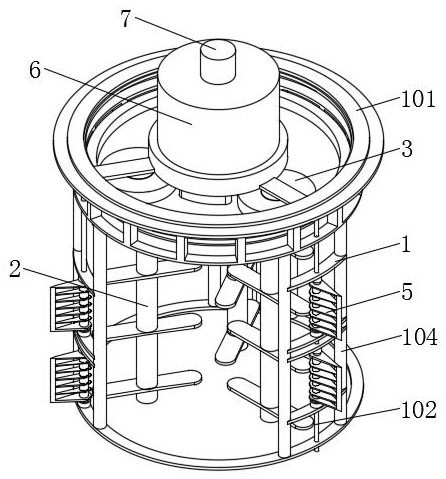

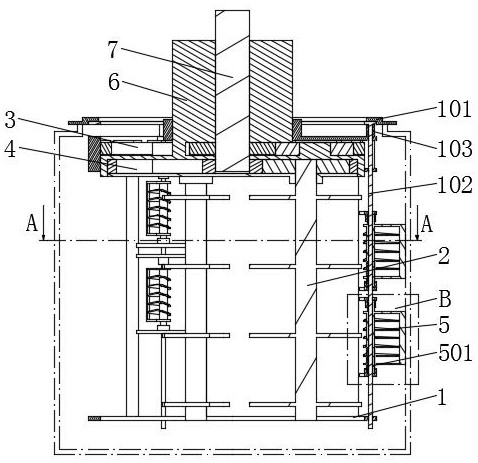

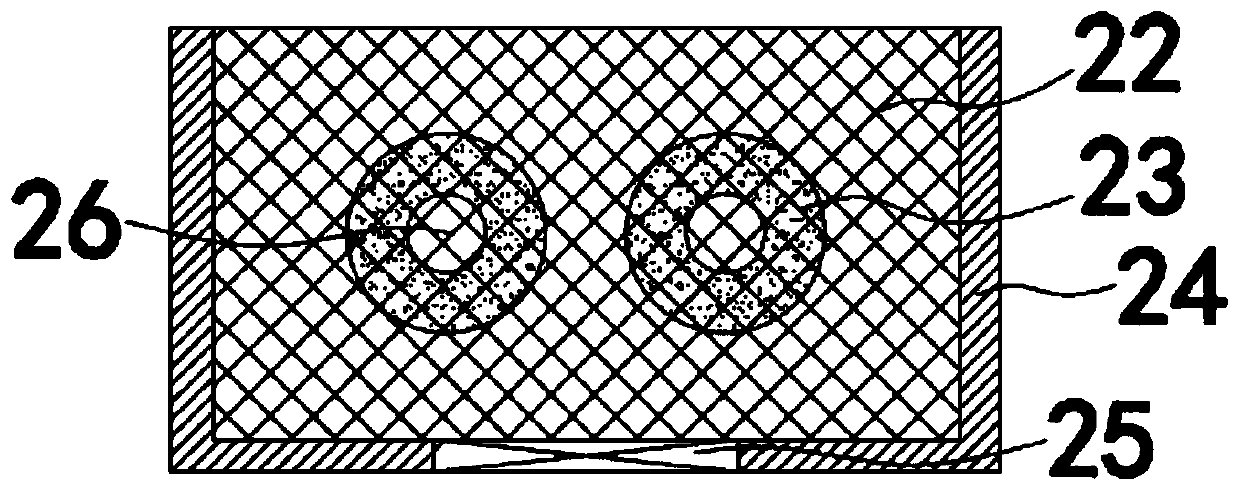

Spinning flushing-screening-type slurry screening equipment based on self-supercharging

InactiveCN109082922AIncreased shear crushing rangeImprove primary shear crushing efficiencyRaw material divisionSlurryEngineering

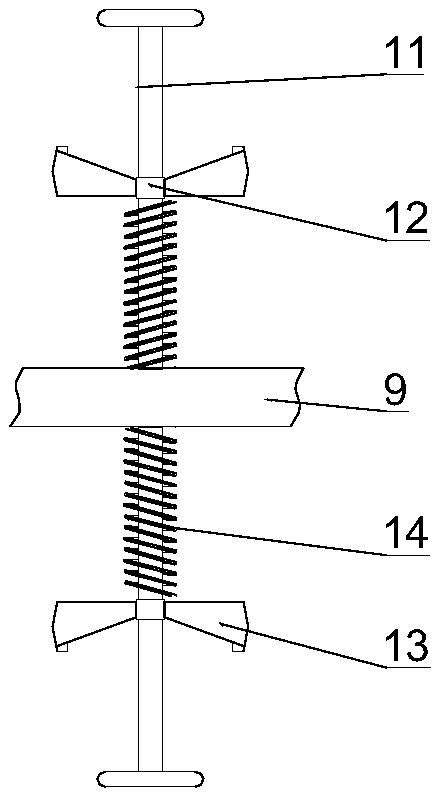

The invention provides spinning flushing-screening-type slurry screening equipment based on self-supercharging. The device mainly comprises a fine slurry generation device, a power driving device, anautomatic supercharging device composed of springs and spring bases, a spinning flushing-screening-type device composed of a press plate and a screening plate, a turbulent flow smashing device composed of turbulent flow plates, a turbulent flow side saw plate and a turbulent flow lower saw plate and a flow guide smashing device composed of a flow guide cover, a guide flow upper saw plate and a guide flow side saw plate. The spinning flushing-screening-type slurry screening equipment is characterized in that on the basis of helping turbulent flow smashing, fine slurry is extruded and screened through self-supercharging vortexes. According to the equipment, coarse slurry and fine slurry are input; through the flow guide smashing device, flow guide and primary cutting smashing of the coarse slurry are achieved; through the power driving device, the spinning flushing-screening-type device is driven; through the automatic supercharging device, automatic supercharging of the coarse slurry between the screening plate and the press plate is achieved; through the spinning flushing-screening-type device, vortex extrusion and screening of the coarse slurry is achieved; through the turbulent flow smashing device, the turbulent flow and secondary cutting smashing of the coarse slurry are achieved.

Owner:UNIV OF JINAN

Stirring mechanism of emulsifying machine for cosmetic production

InactiveCN112169684AReduce frictionReduce wearRotary stirring mixersMixing methodsEngineeringSmall hole

The invention discloses a stirring mechanism of an emulsifying machine for cosmetic production, which comprises a fixed seat, a first stirring mechanism and a second stirring mechanism are coaxially and rotatably arranged outside the fixed seat, the rotation directions of the first stirring mechanism and the second stirring mechanism are opposite, the first stirring mechanism comprises a scraper frame with a rotary structure, a long shaft capable of being vertically pulled is arranged in the circumferential wall of the scraper frame, a circular ring is fixedly arranged at the upper end of thelong shaft, a first elastic piece is arranged between the circular ring and the scraper frame, the rotation axis of the circular ring and the rotation axis of the scraper frame are overlapped, and a coaxial movable ring is connected to the upper portion of the circular ring in a relatively rotating mode, the turning radius of the movable ring is greater than that of the scraper frame, and a scraper is arranged in the scraper frame. According to the stirring mechanism of the emulsifying machine for cosmetic production, due to the design of the foldable scraping plates, the turning radius is reduced after the stirring mechanism is folded, the stirring mechanism can conveniently pass through an opening of a pot body with a small hole diameter, and the scraping and stirring requirements of rawmaterials on the inner wall of the pot body are met after the stirring mechanism is unfolded; the design of reducing the opening diameter of the pot body is facilitated, and the sealing performance of the emulsifying pot is improved.

Owner:济南艾雅贸易有限公司

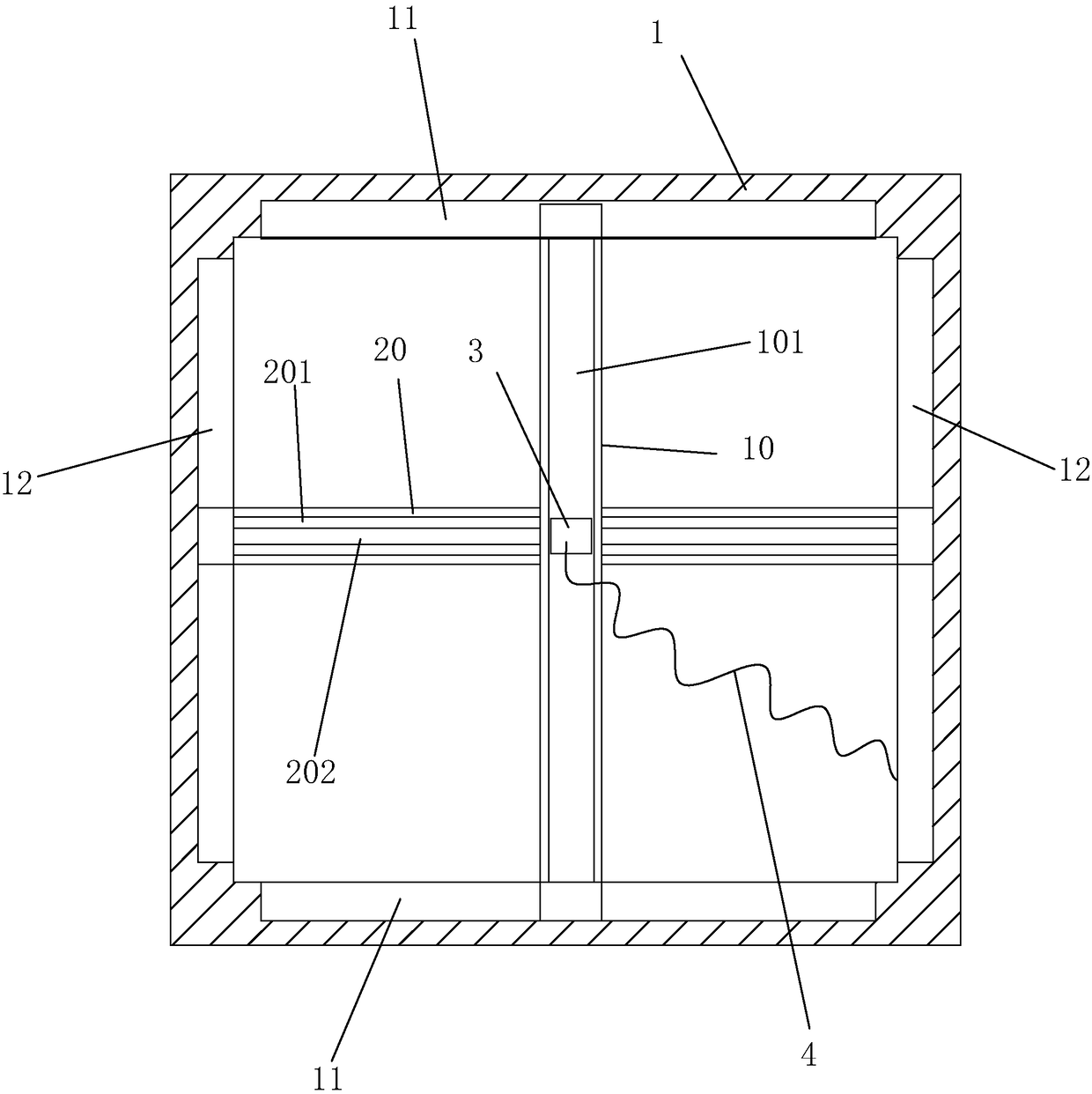

Homogenizing and emulsifying system for cosmetic production and using method

InactiveCN111715084AIncrease the stirring areaGuaranteed homogeneityShaking/oscillating/vibrating mixersMixing methodsEngineeringManufacturing engineering

The invention relates to the technical field of emulsifying equipment for cosmetic production, in particular to a homogenizing and emulsifying system for cosmetic production and a using method. A servo motor is adopted for driving a rotary disc to rotate, a push-pull rod drives a first rack to reciprocate, a first gear is driven to drive a hollow shaft to rotate, and a part below a first plate drives a rocker to stir and emulsify materials; the first rack drives a moving block to reciprocate, so an oblique hole and a first sliding shaft act to allow a lifting plate to drive a lifting shaft tomove up and down; a tooth section on the lifting shaft acts with a second-class gear, so the second-class gear drives the rocker to swing, a stirring area is enlarged, and homogenization is guaranteed; when the lifting plate moves up and down, a pull rope moves to act on a second connecting rod, so a emulsifying tank rotates by taking the hinged part of the top end of a left supporting seat as anoriginal point; along with the up-down movement of the lifting plate, the right end of the emulsifying tank is periodically lifted and put down, so the emulsifying tank shakes; and through cooperationbetween the shaking of the emulsifying tank and above stirring, emulsification is accelerated, and homogenizing effect is further improved.

Owner:陈益飞

Quantitative filling equipment for enzyme beverage production

InactiveCN111115532AReduce settlementImprove uniformityLiquid bottlingLiquid storage tankPressure balance

The invention relates to the technical field of enzyme beverage quantitative filling equipment, in particular to quantitative filling equipment for enzyme beverage production. A servo motor is adoptedfor driving a first turning wheel to rotate, so that a push-pull rod drives a first piston plate to move left and right. Due to pressure balance, a second piston plate follows to move left and right,and a third piston plate follows to move up and down. A rack moves left and right along with the second piston plate and further drives a first gear to rotate together with a first rotating shaft, astirring rod can stir beverage in a liquid storage tank, settling is reduced, and subsequent filling homogeneity is improved. The third piston plate drives a moving rod to move up and down with a fourth piston plate, and check valves on the two sides are further matched to pump the beverage into a fourth piston barrel from the liquid storage tank and then to be discharged. The moving distance forthe push-pull rod to drive the first piston plate is definite, the moving distance of the third piston plate is also fixed, the fourth piston plate moves in a fixed-distance mode, and thus the fourthpiston barrel can complete quantitative beverage pumped discharging.

Owner:安徽博数源通网络科技有限公司

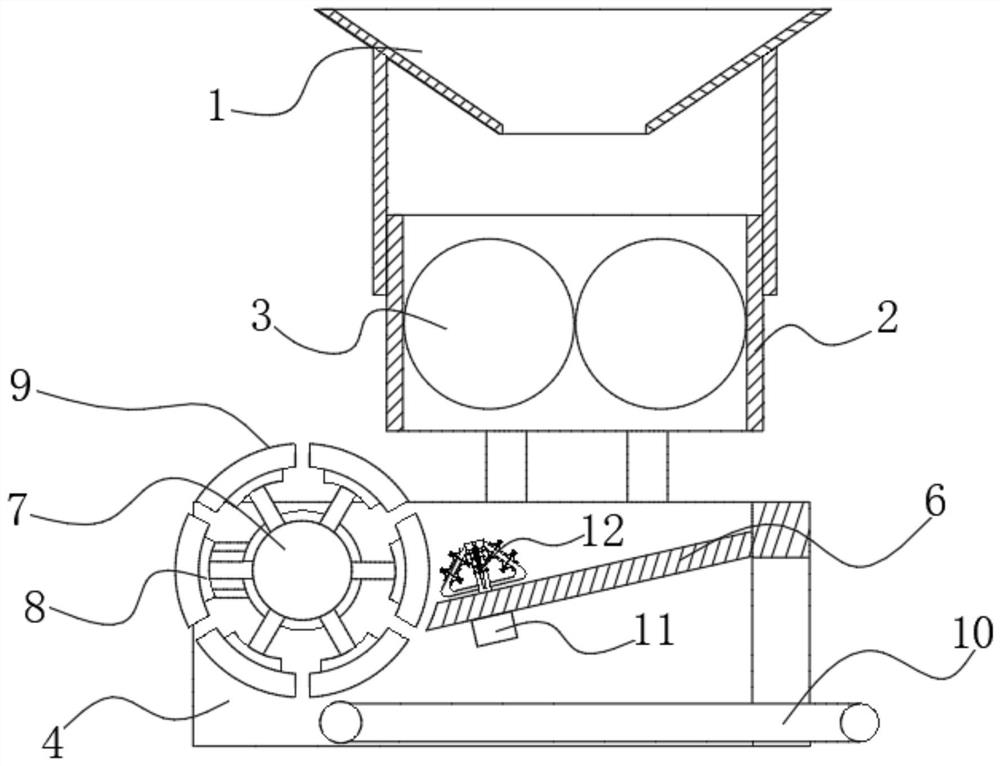

Construction waste screening device for screening iron products

InactiveCN112844587AEasy to absorbEasy to collectMagnetic separationGrain treatmentsEnvironmental engineeringMechanical engineering

The invention discloses a construction waste screening device for screening iron products, and relates to the technical field of construction waste screening devices. The construction waste screening device for screening the iron products comprises a feeding hopper, the lower side of the feeding hopper is fixedly connected with a first support, the lower side of the feeding hopper is fixedly connected with a crushing box body through the first support, the front side and the rear side of the inner wall of the crushing box body are provided with two crushing rollers, the two crushing rollers are horizontally and tangentially arranged, second supports are fixedly connected to the left side and the right side of the crushing box body, and a body box shell is fixedly connected to the lower side of the crushing box body through the second supports. According to the construction waste screening device for screening the iron products, a stirring mechanism can stir construction waste on a material falling plate back and forth, so that the contact rate of the iron products and an electromagnetic plate is increased, the screening efficiency of the electromagnetic plate on the the iron products is improved, and the situation that the iron products is buried, volatilized and blocked by the construction waste and cannot be sucked by the electromagnetic plate is prevented.

Owner:马永华

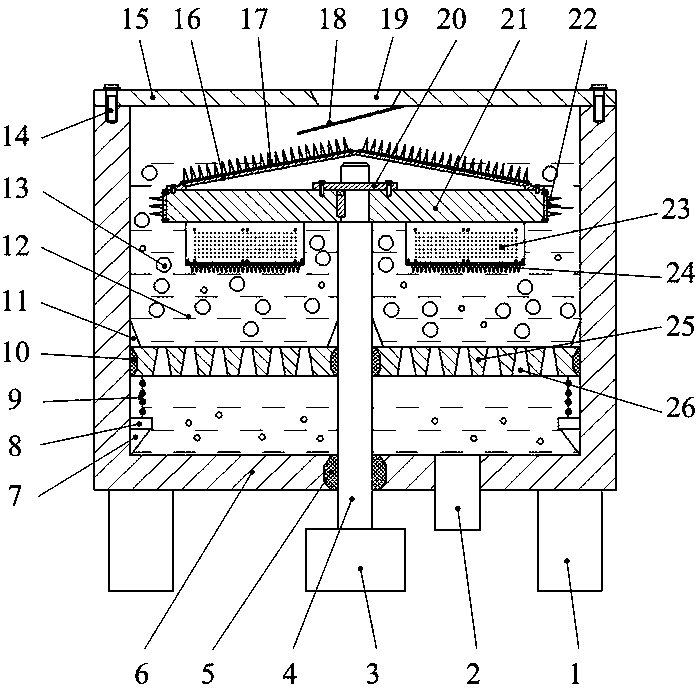

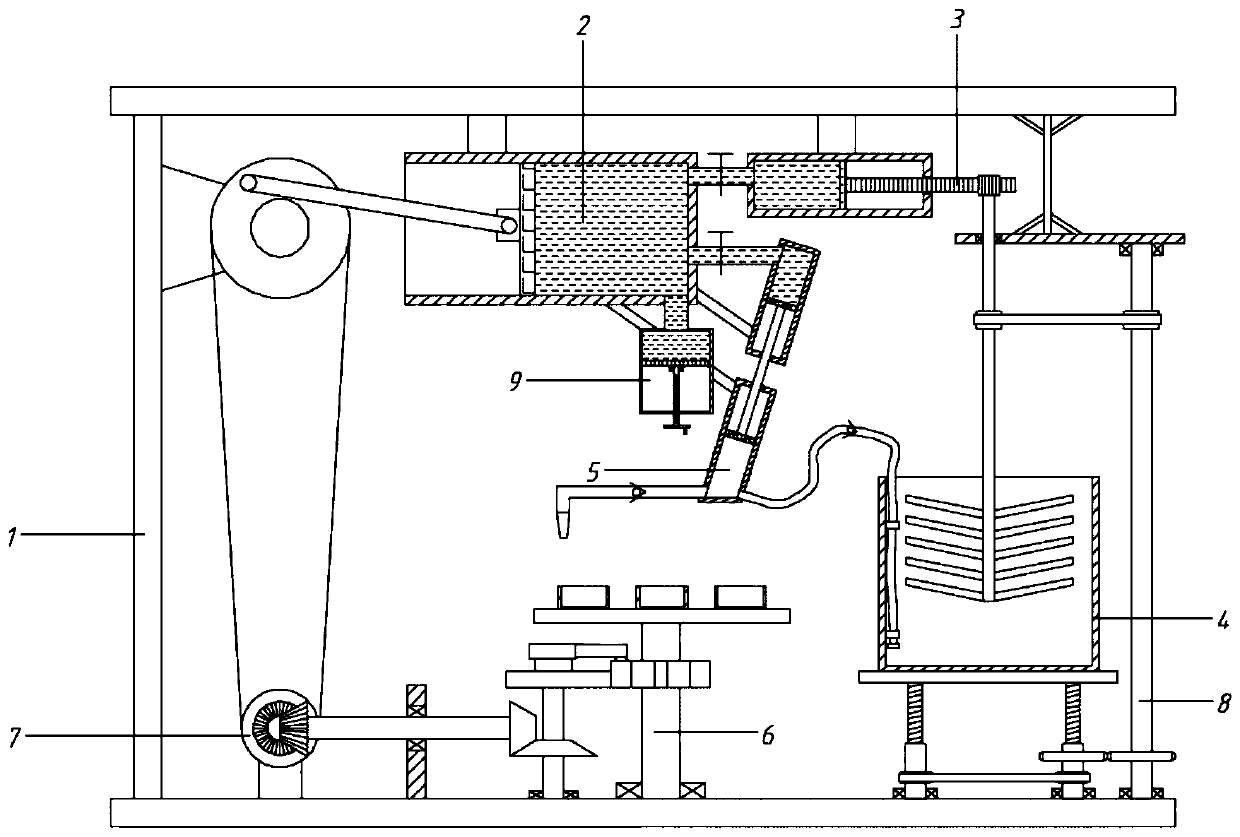

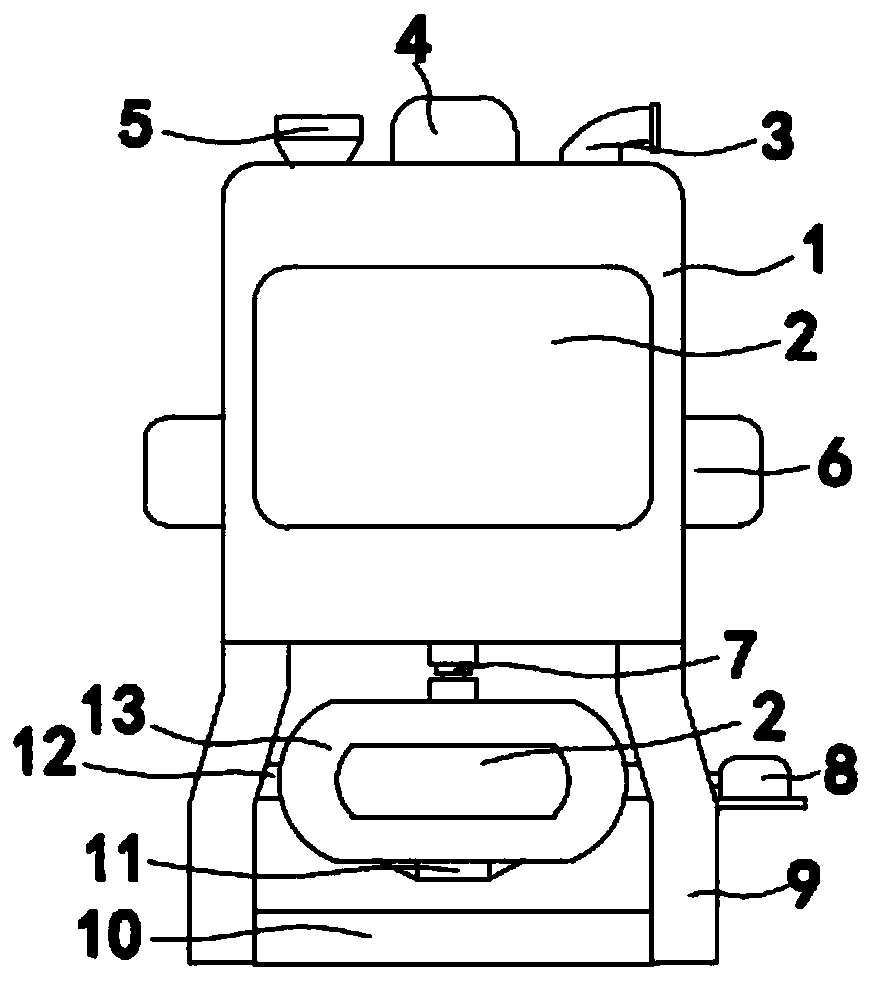

Diatom ooze preparation machine for house building engineering and using method thereof

InactiveCN111804220AEfficient preparationIncrease the stirring areaRotary stirring mixersTransportation and packagingHouse buildingBevel gear

The invention relates to a diatom ooze preparation technology, and in particular, relates to a diatom ooze preparation machine for house building engineering and a using method thereof. According to the preparation machine, diatom ooze solid raw materials and water can be added while being stirred, each time of feeding of the diatom ooze solid raw materials and the water is controlled to be quantitative, and efficient and high-quality preparation of diatom ooze is achieved in cooperation with a first stirring assembly moving up and down and the preparation box moving left and right; a servo motor drives a first rotating shaft to rotate, a first transmission wheel on the first rotating shaft rotates immediately, and a second transmission wheel is driven by a transmission belt to rotate, sothat a second rotating shaft rotates; a first bevel gear at the right end of the second rotating shaft rotates along with the second rotating shaft, a second bevel gear drives a rotary disc to rotatethrough transmission of a bevel gear, a notch in the rotary disc is periodically communicated with a material guide pipe and a discharging pipe, diatom ooze solid raw materials are quantitatively received from a feeding hopper, and the diatom ooze solid raw materials are quantitatively discharged into a preparation box.

Owner:野虎企业管理(上海)有限公司

Cleaning equipment for tea leaves

ActiveCN110170485AImprove qualityReduce consumptionPre-extraction tea treatmentDrying solid materials without heatBristleEngineering

The invention discloses cleaning equipment for tea leaves, and belongs to the technical field of cleaning equipment. The cleaning equipment comprises a cleaning chamber, a bracket and a spin-drying barrel, wherein a partition plate is arranged in the cleaning chamber, a first electromagnetic valve is arranged in the middle of the partition plate, the partition plate divides the cleaning chamber into an upper cleaning chamber and a lower cleaning chamber, a stirring disc is arranged in the upper cleaning chamber, a stirring rod is connected under the stirring disc, soft bristles are arranged onthe surface of the stirring rod, and the top of the stirring disc is connected with a first motor through an output shaft. According to the equipment, the residue of pesticides and the pollution of heavy metals can be remarkably reduced, the leaf temperature can be rapidly reduced, so that the quality of the tea leaves can be ensured, and the quality of the tea leaves is improved; and meanwhile,the cleaning and dehydration time is greatly shortened, and the working efficiency is improved.

Owner:ZHEJIANG OCEAN UNIV

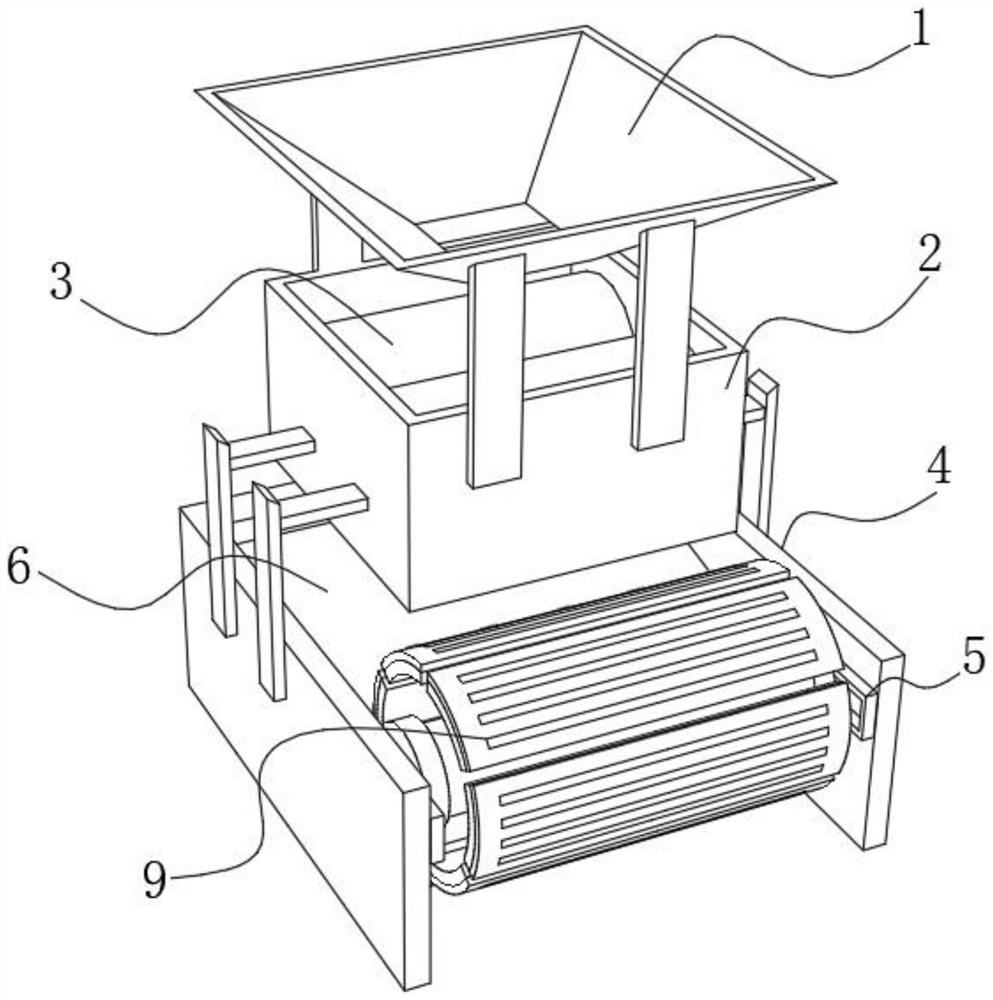

Sausage raw material mixer

InactiveCN107372750AChange connection methodIncrease the stirring areaMeat mixing apparatusGear wheelElectric machinery

The invention discloses a sausage raw material mixer. The sausage raw material mixer comprises a mixer, a top shell of the mixer is upwardly convex, a motor is fixedly mounted inside the convex shell, a rotating shaft of the motor extends into the interior of the mixer, a protective cover is arranged at the end part of the rotating shaft, the shaft lever end of the rotating shaft extends into the interior of the protective cover and is connected with a gear, through holes are symmetrically formed in a cover body of the protective cover, the inner sides of the through holes are fixedly connected with the outer rings of bearings, the inner rings of the two bearings are fixedly connected together, the inner rings are located below the gear, a ferrule is fixedly sleeved in the position, close to the gear, of the inner rings, the outer side wall of the ferrule is connected with transmission plates by surrounding an axis, the transmission plates are in contact with a gear phase of the gear in turn, one side, close to each through hole of the protective cover, of each inner ring is set to be a closed side, the closed side is coaxially connected with a connecting rod, the connecting rod penetrates through the through holes and is connected with a circular plate, and the connecting rod penetrates through the through holes and is connected with circular plates. The sausage raw material mixer disclosed by the invention is high in mixing efficiency, low in cost, and difficult to stick raw materials on the side wall of the mixer while mixing.

Owner:贵州从江生态七香精品农业发展有限公司

Waste residue cooling device for steel and iron smelting and capable of improving cooling efficiency

InactiveCN111928669AImprove cooling efficiencyNot easy to pile upHandling discharged materialGrain treatmentsThermodynamicsMechanical engineering

The invention relates to the technical field of steel and iron smelting and discloses a waste residue cooling device for steel and iron smelting and capable of improving cooling efficiency. The wasteresidue cooling device comprises an equipment main body. A bearing disc is rotationally connected to the upper portion of an inner cavity of the equipment main body. Symmetrical guide columns are slidably connected to the lower end of the bearing disc. Transmission toothed rods extending into an inner cavity of the bearing disc are rotationally connected to inner cavities of the guide columns. A water storage disc is fixedly connected to the lower ends of the guide columns. According to the waste residue cooling device for steel and iron smelting and capable of improving the cooling efficiency, a driving disc rotates, thus a bearing disc rotates through teeth on the inner wall of the equipment main body, a breaking column is driven to do revolution and is synchronously matched with the driving disc to utilize rack, a threaded tooth rod is driven to rotate in a reciprocating mode, thus the guide columns on the two sides drive the breaking column to expand and contract in a reciprocatingmode, the breaking column rotates on the way, cooling water is released from the breaking column in a matched mode, thus the cooling efficiency of waste residues is promoted effectively, and the effective utilization ratio of the cooling water is increased.

Owner:胡献敏

Mixed stirring and sieving device of fodder

InactiveCN107551898AIncrease the stirring areaPromotes thorough mixingSievingFeeding-stuffAgricultural engineeringFodder

The invention provides a mixed stirring and sieving device of fodder, and belongs to the technical field of fodder processing. The mixed stirring and sieving device comprises a bottom plate, a vertical plate and a top plate, wherein the right side of the bottom plate is fixedly connected with the vertical plate; the top of the vertical plate is welded with the top plate; the left lower part of thetop plate is fixedly connected with a first sliding rail; the right side of the first sliding rail is connected with a first sliding block in a sliding way; the right side of the first sliding blockis sheathed with a first rack; the first rack is vertically arranged; the right side of the first rack is meshed with a first gear. The first rack is driven by the first gear to vertically move, the first rack pulls a soft rope to enable the second rack to horizontally move, a second gear meshed with the second rack rotates, the second gear rotates to drive a first belt pulley to rotate, and the first belt pulley drives a second belt pulley to rotate through a transmission belt; the second belt pulley controls a spindle to rotate, and the fodder in a mixing box is stirred and mixed by a spiralstirring vane below the spindle so as to be favorable for improving transmission and mixing efficiency.

Owner:高明飞

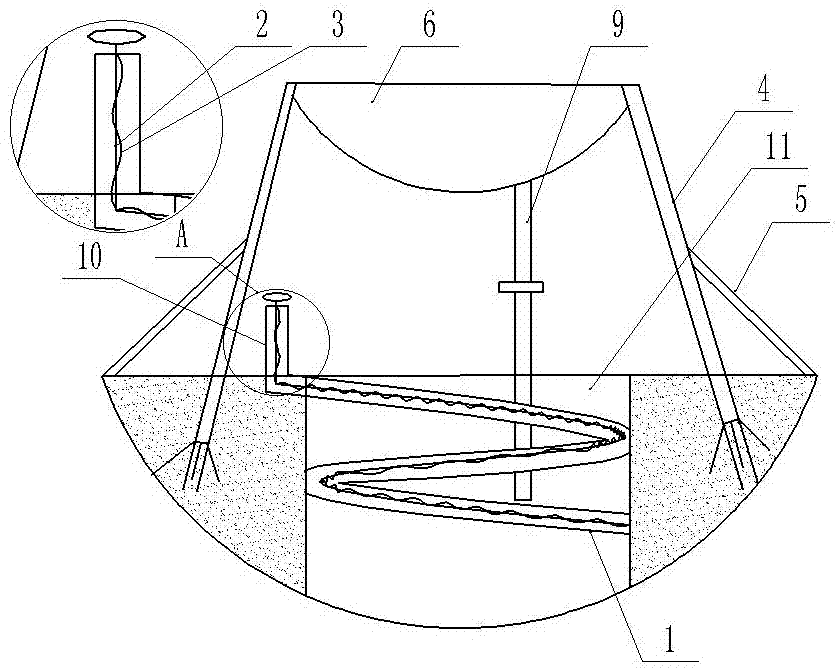

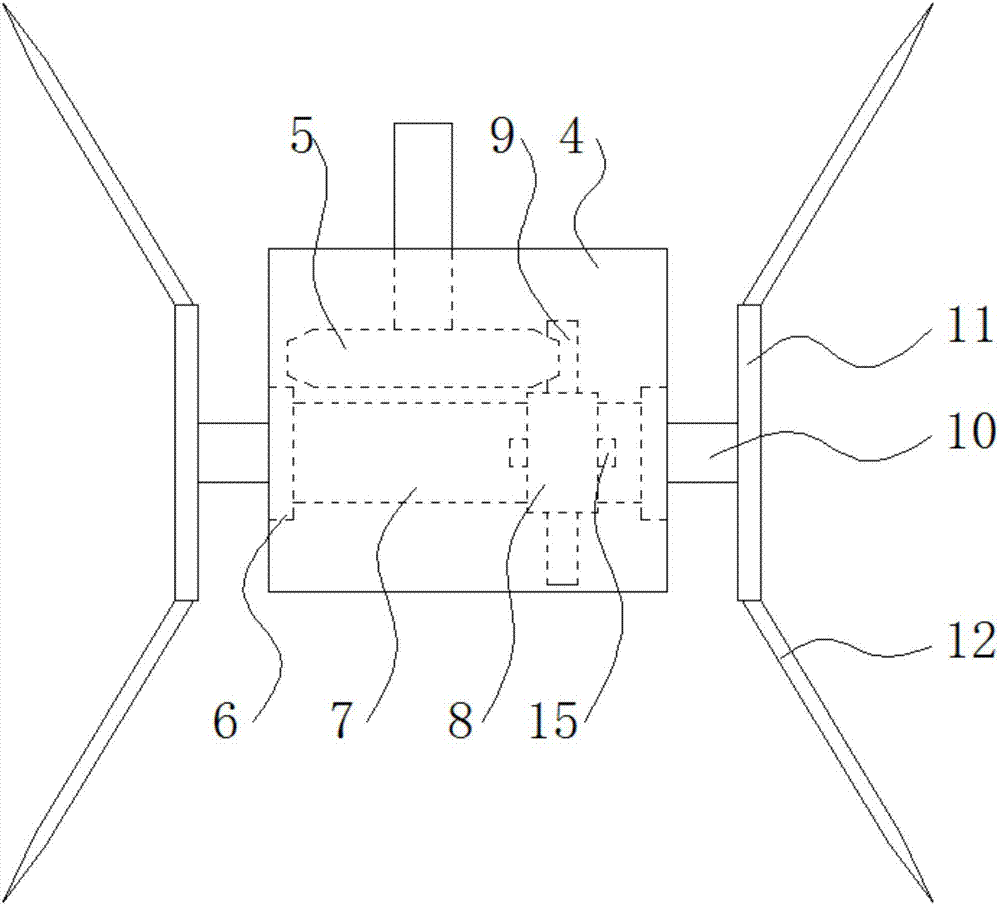

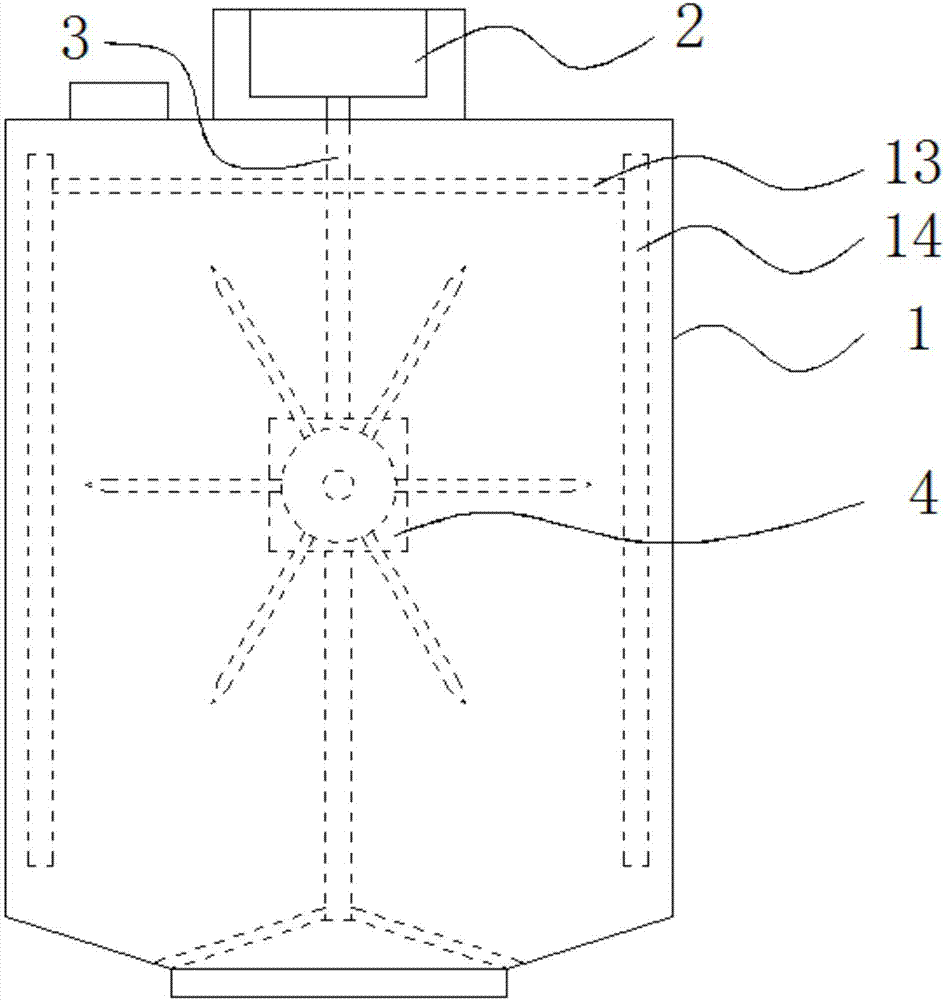

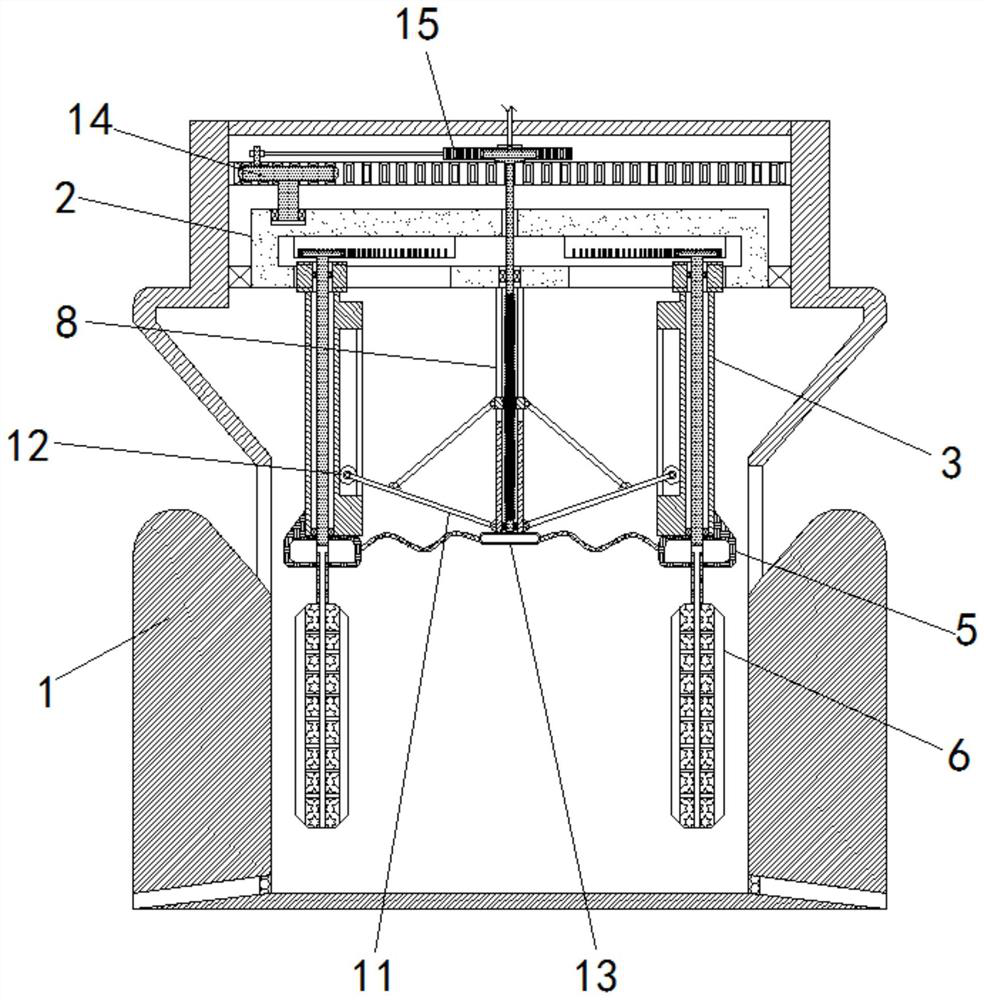

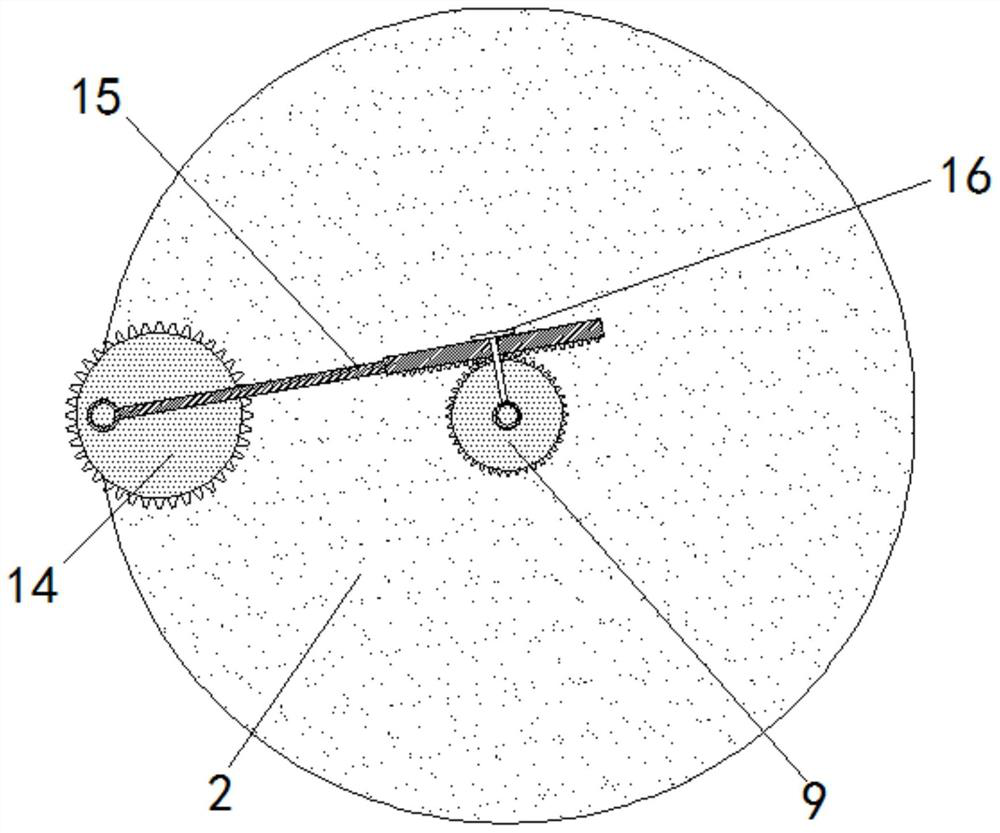

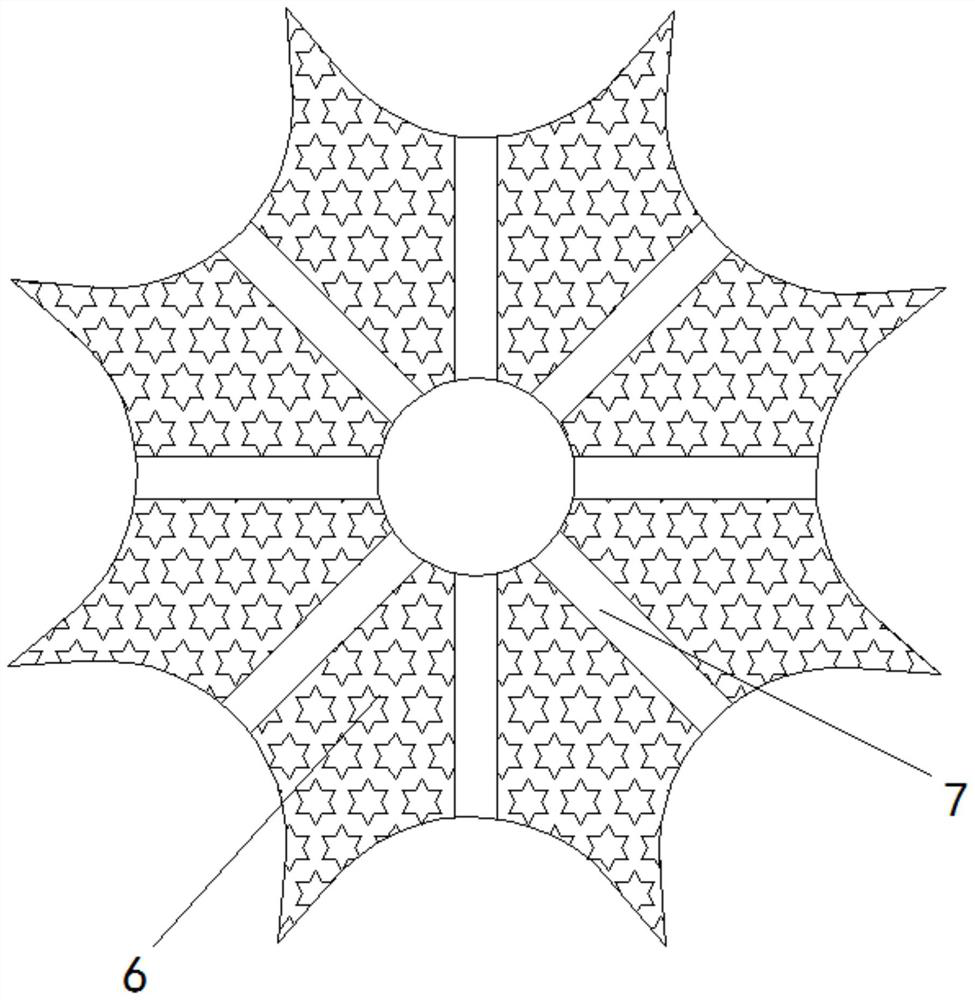

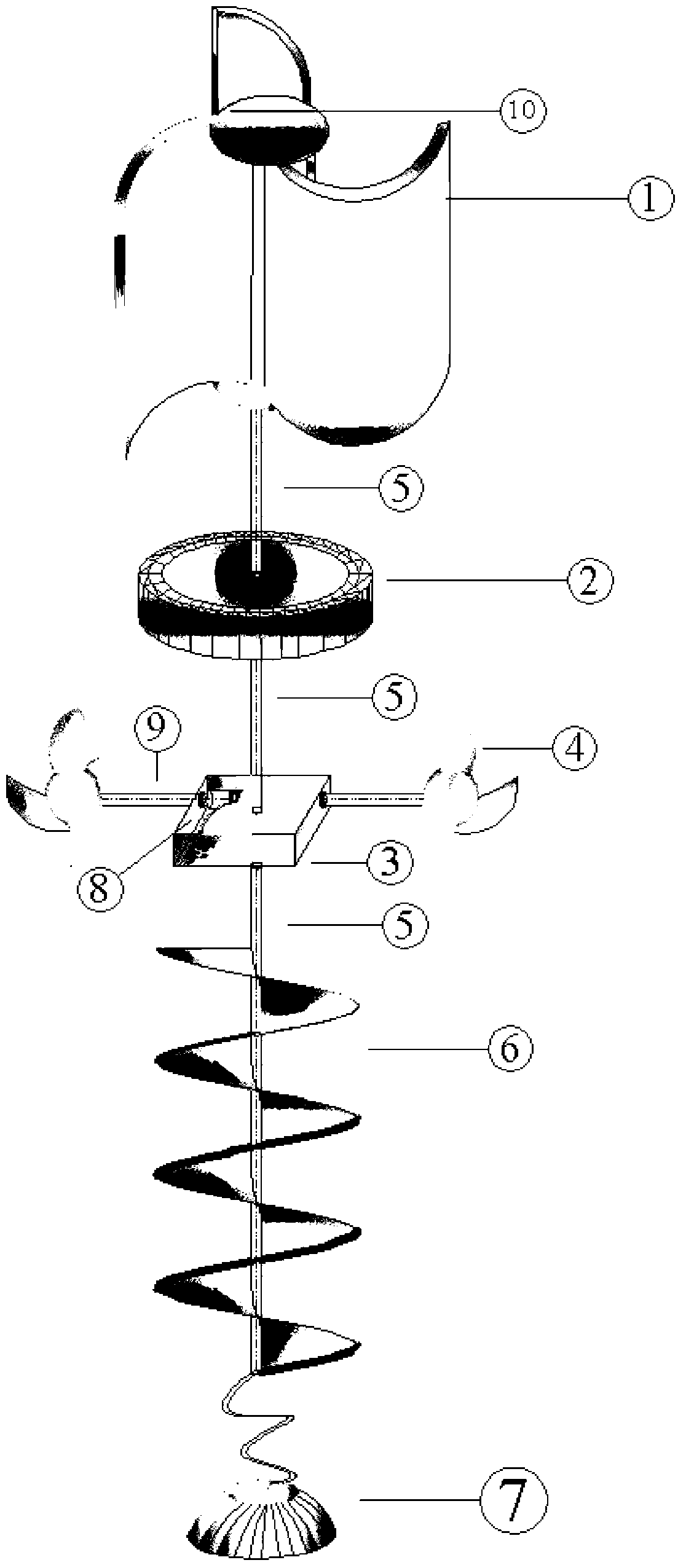

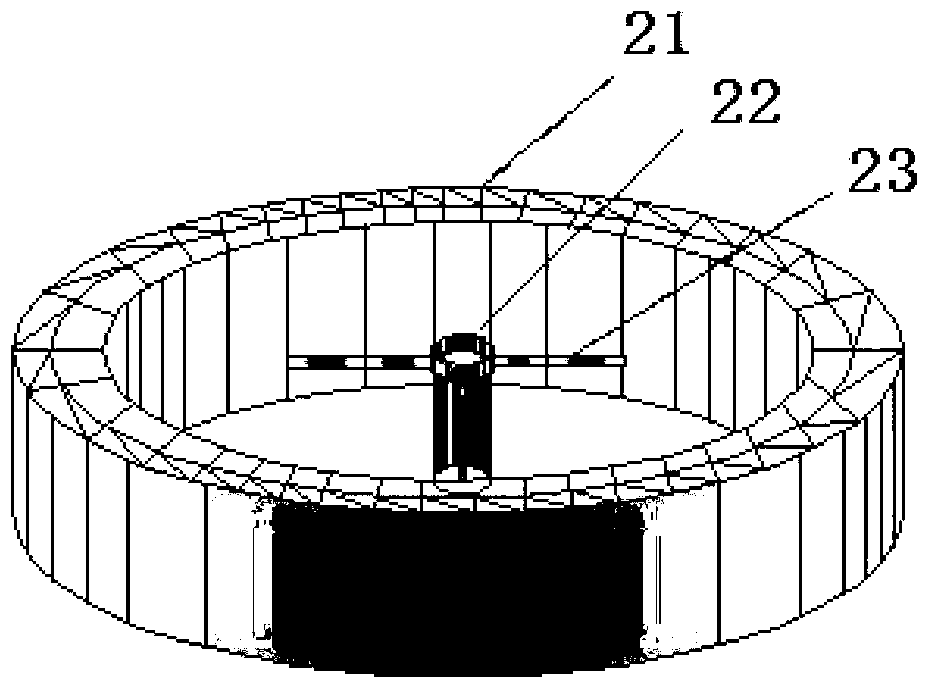

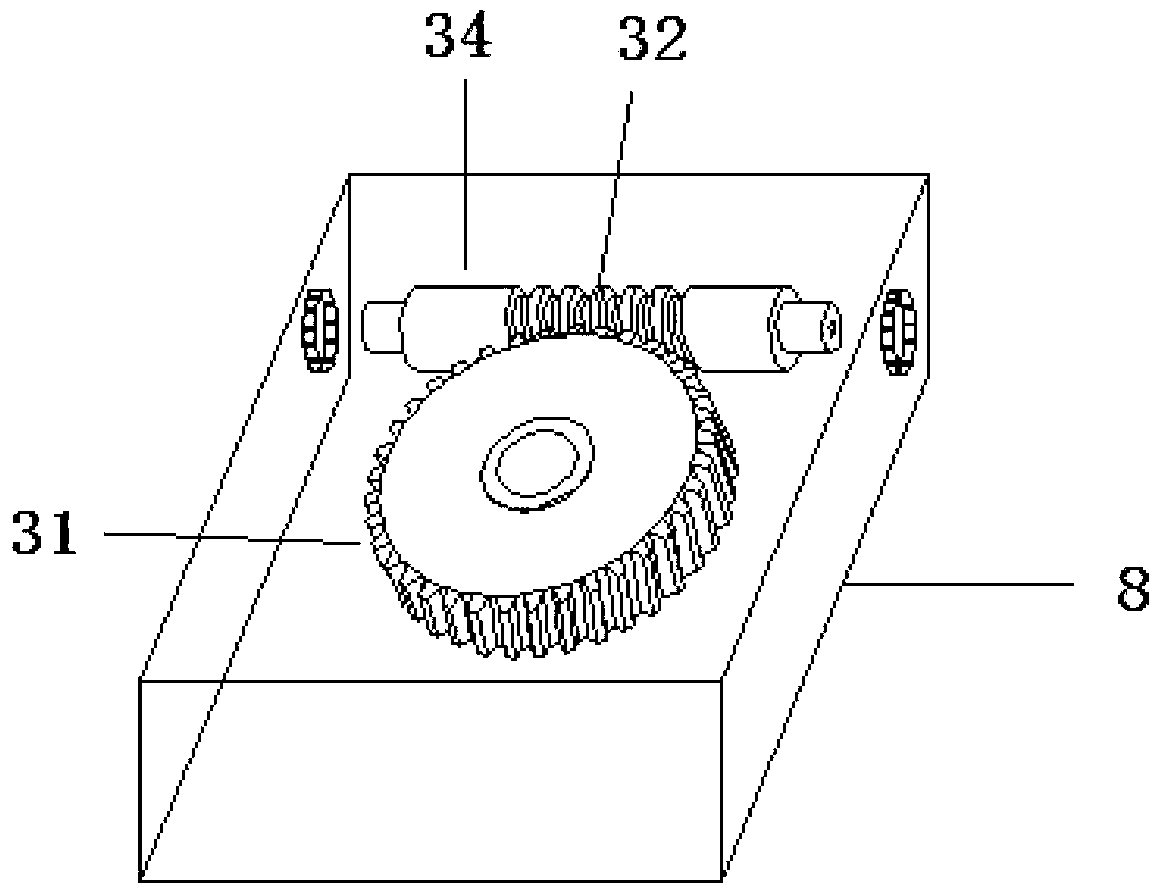

Wind power directly-driven circulated oxygen inflating equipment

ActiveCN102765823BIncrease the stirring areaIncrease agitation rangeWater aerationSustainable biological treatmentWater qualityEngineering

The invention relates to wind power directly-driven circulated oxygen inflating equipment comprising a vertical force transmission shaft, wherein a wind wheel, a floating system, a gear switching device, a water lifting worm wheel and a fixing block are sequentially arranged on the vertical force transmission shaft from top to bottom, wherein the gear switching device comprises a gear box and the gear box is internally provided with a main gear and a secondary gear; the main gear is connected with the vertical force transmission shaft; the secondary gear is connected with a transverse force transmission shaft; and two ends of the transverse force transmission shaft are provided with a pair of flow pushing impellers with blades in opposite directions. According to the equipment disclosed by the invention, the wind wheel rotates under the effect of wind power to convert wind energy into power; a bottom water body is upwards circulated through transmitting force by an axial agitating worm wheel and the water lifting worm wheel of the vertical force transmission shaft; and shallow-layer water is transversely dispersed under the effect of the agitating worm wheel to be exchanged with a surface layer water body, so that large-area water body disturbance is realized. The wind power directly-driven circulated oxygen inflating equipment has the advantages of simple structure, compact arrangement, convenience for operation and energy source saving, and is suitable for improving the water quality of a river and a water pond.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

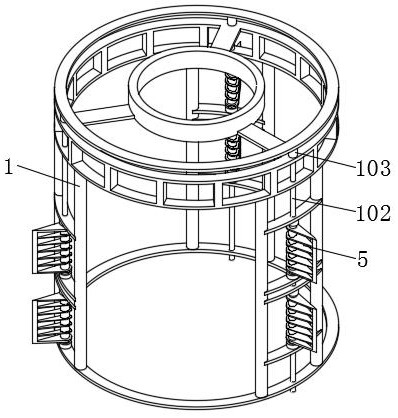

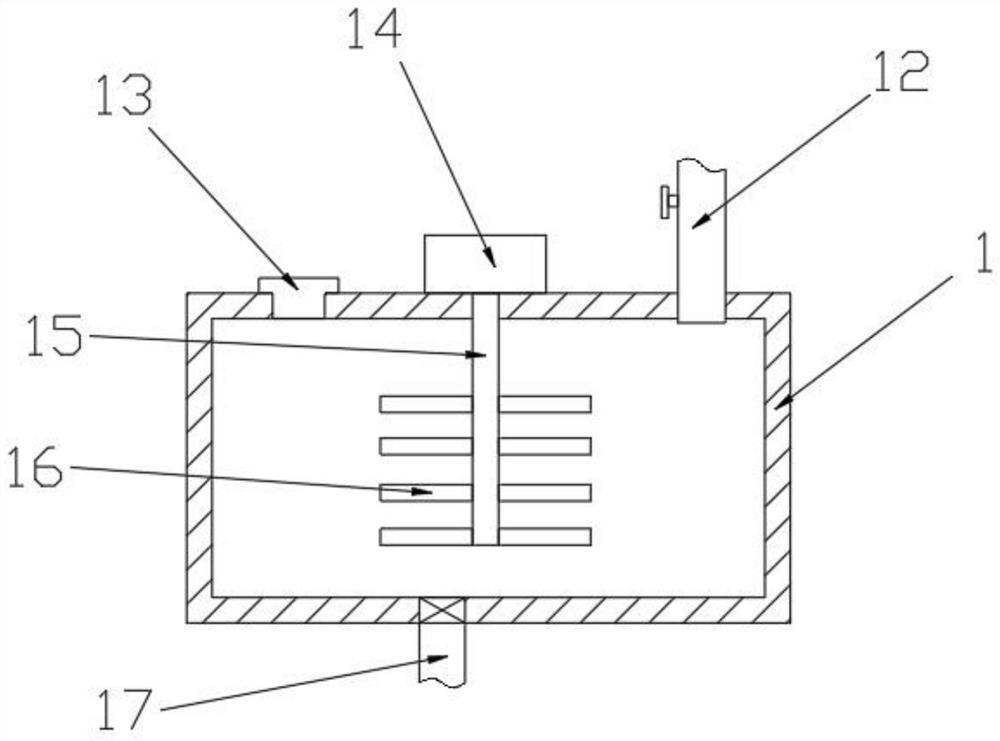

Coating machine capable of mixing coating liquid evenly for biological and medical experiments

InactiveCN108721114AUniform thicknessIncrease the stirring areaPharmaceutical product form changeCoatingsAgricultural engineeringCoil spring

The invention discloses a coating machine capable of mixing a coating liquid evenly for biological and medical experiments, and relates to the technical field of biomedicine. The coating machine comprises a casing. The upper side in the casing is provided with a plurality of layers of round tubes, and adjacent round tubes are communicated through fixing tubes. Each spiral spring has a different elastic coefficient, the extending distance of each stirring plate is different accordingly, the stirring area is increased, and the coating liquid maintains homogeneous, so that the coating thickness is uniform on the surface of the biomedicine. As annular tubes are arranged in a plurality of layers, a material curtain of the coating liquid sprayed by a nozzle is uniform, and the biomedicine located on a coating table can fully and uniformly contact the coating liquid to improve the coating quality. A disc rotates to enable the coating table to swing left and right in a reciprocating mode underthe transmission effect of a swinging rod and a connecting rod, and the biomedicine rolls on the coating table in the reciprocating mode to be in full contact with the coating liquid, and the coatingquality is further improved.

Owner:广西东创智能科技有限公司

Lead storage battery wastewater environment-friendly treatment equipment and treatment method thereof

InactiveCN112479434AReduce processing timeA increases the rate at which pH is adjustedMultistage water/sewage treatmentWater/sewage treatment by neutralisationWastewaterEngineering

The invention discloses lead storage battery wastewater environment-friendly treatment equipment and a treatment method thereof. The lead storage battery wastewater environment-friendly treatment equipment comprises an adjusting box, a treatment cabinet, a stirring mechanism, a stirring box, a precipitation cavity, a transition box, a water suction pump, a filtering box and a collecting box; one end of the top of the treatment cabinet is provided with the adjusting box; the stirring mechanism, the stirring box, the transition box and the filtering box are sequentially arranged in the treatmentcabinet from top to bottom; a first fixed plate is arranged in the middle of the interior of the treatment cabinet, the transition box is fixedly installed in the first fixed plate, and a collectingbox is arranged on the side, away from the adjusting box, of the bottom of the treatment cabinet; after the structure is adopted, the lead storage battery wastewater can be subjected to harmless environment-friendly treatment, meanwhile, by arranging the stirring mechanism, flocculation of the wastewater is accelerated, the overall wastewater treatment rate is increased, and by arranging the special precipitation structure, the precipitation uniformity is improved, and the wastewater treatment effect is improved.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

High-efficiency side-blowing smelting furnace

InactiveCN110106366AImprove the mixing effectIncrease motivationCrucible furnacesCooling mediumSmelting

The invention provides a high-efficiency side-blowing smelting furnace. The high-efficiency side-blowing smelting furnace comprises a furnace body and a plurality of spray guns. A cavity is defined inthe furnace body, and the upper end of the cavity is open. The cavity is provided with a small-diameter area and a big-diameter area located over the small-diameter area. The inner diameter of the big-diameter area is greater than that of the small-diameter area. The small-diameter area is provided with a discharge port and a plurality of spray gun ports. The spray gun ports are distributed at intervals along the circular cross section of the small-diameter area in the circumferential direction. The spray guns are inserted into the spray gun ports. Each spray gun comprises a center pipe, a flow distribution cover, a sleeve and cooling medium pipes. The high-efficiency side-blowing smelting furnace provided by the invention has the advantages of high efficiency and long service life and can also reduce emission of harmful gas and prevent environmental pollution.

Owner:HAIAN HAITAI CASTING

Raw material stirring device for chemical gas production

InactiveCN109647262AWell mixedIncrease the stirring areaShaking/oscillating/vibrating mixersTransportation and packagingMotor driveCompound (substance)

The invention discloses a raw material stirring device for chemical gas production. The device comprises a stirring tank. A driving gear and a driven gear which are in mesh connection are arranged atthe upper side inside the stirring tank. Mounting holes of the driving gear and the driven gear respectively and fixedly sleeve a first rotating shaft and a second rotating shaft which are rotatably connected to the stirring tank. A stirring rod is arranged inside the stirring tank. The bottom of the stirring rod is fixedly connected with stirring paddles. A single-shaft-extension motor makes thedriving gear and the driven gear rotate, and finally the stirring rod moves along a trajectory in a certain range inside the stirring tank to drive the stirring paddles to move, and then raw materialsin the stirring tank are fully mixed. A two-shaft-extension motor drives a rotating wheel to rotate. Through the action of a connecting rod and a rotating rod, a first arc-shaped rotating block and asecond arc-shaped rotating block drive a stirring plate to swing side to side. Thereby, the stirring area is large, the raw material mixing effect is obvious, and production efficiency is improved.

Owner:TIANJIN HUASAIER GAS

Waste stirring tank structure for livestock and poultry ecological breeding

InactiveCN108211910AIncrease the stirring areaAvoid entanglementRotary stirring mixersTransportation and packagingLivestockRelative slip

The invention discloses a waste stirring tank structure for livestock and poultry ecological breeding. The waste stirring tank structure comprises a tank body, wherein first guide rails which are positioned at the same height and are parallel to each other are arranged on two side walls of the tank body; second guide rails which are positioned at the same height and are parallel to each other arearranged on another two side walls of the tank body; the heights of the first guide rails are higher than those of the second guide rails; a first sliding rod is arranged between the first guide rails; a second sliding rod is arranged between the second guide rails; a sliding chute is formed along the length direction of the second sliding rod; a sliding block is arranged in the sliding chute; thefirst sliding rod penetrates through a first abdicating groove for the upper end of the sliding block to penetrate through along the length direction of the sliding rod; a motor is arranged in the sliding block; a rotor of the motor faces downwards and is connected with a stirring shaft; a second abdicating groove for the stirring shaft to penetrate through is formed in the bottom wall of the sliding chute in a penetrating manner; stirring blades are arranged on the stirring shaft. The waste stirring tank structure disclosed by the invention has the characteristics that the movement of the sliding block at any position above the tank body is driven by relative slip of the two sliding rods, so that stirring can be performed in more areas.

Owner:SUZHOU DINGYU BIOLOGICAL TECH CO LTD

A vertical mortar mixer

InactiveCN104827570BIncrease the stirring areaImprove stirring efficiencyCement mixing apparatusGear wheelEngineering

Owner:LUOYANG INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com