Spinning flushing-screening-type slurry screening equipment based on self-supercharging

A self-pressurizing, screen-type technology, applied in textile and papermaking, fiber raw material processing, raw material separation, etc., can solve the problems of low screening efficiency and low yield of good pulp, etc., to improve efficiency, increase the range of shearing and crushing, increase Effect of Shear Breaking Disintegration Zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

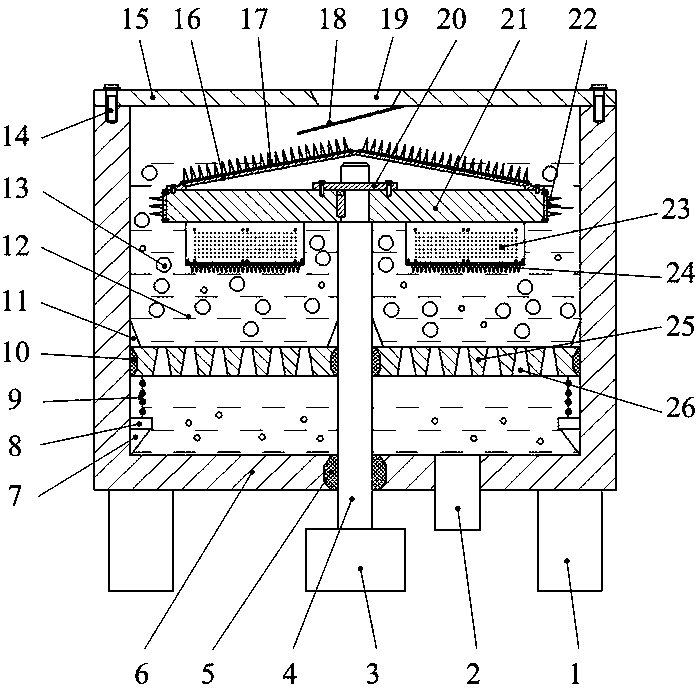

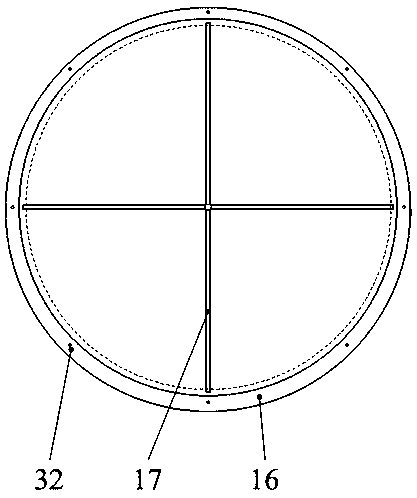

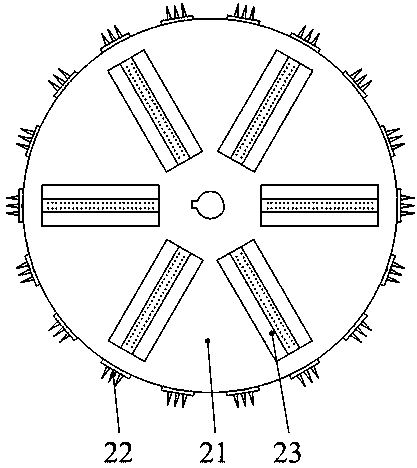

[0044] Such as figure 1 As shown, a self-pressurized spinning and punching screen type pulp screening equipment of the present invention mainly includes a good pulp generating device, a power drive device, an automatic booster device, a spinning and punching device, a turbulent crushing device and a guide The flow crushing device, the automatic pressurization device and the spinning and sieving device are installed on the power drive device and located in the good pulp generating device, the spinning and sieving device is located above the automatic supercharging device, the turbulent crushing device and the diversion crushing device are divided To be installed on the spinning screen flushing device.

[0045] The present invention realizes the input of coarse stock and the output of good stock through the fine stock generating device, that is, the coarse stock is input through the coarse stock inlet 19 in the good stock generating device, and the good stock outlet 2 outputs th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com