Steam Generating Slurry Gasifier for the Catalytic Gasification of a Carbonaceous Feedstock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

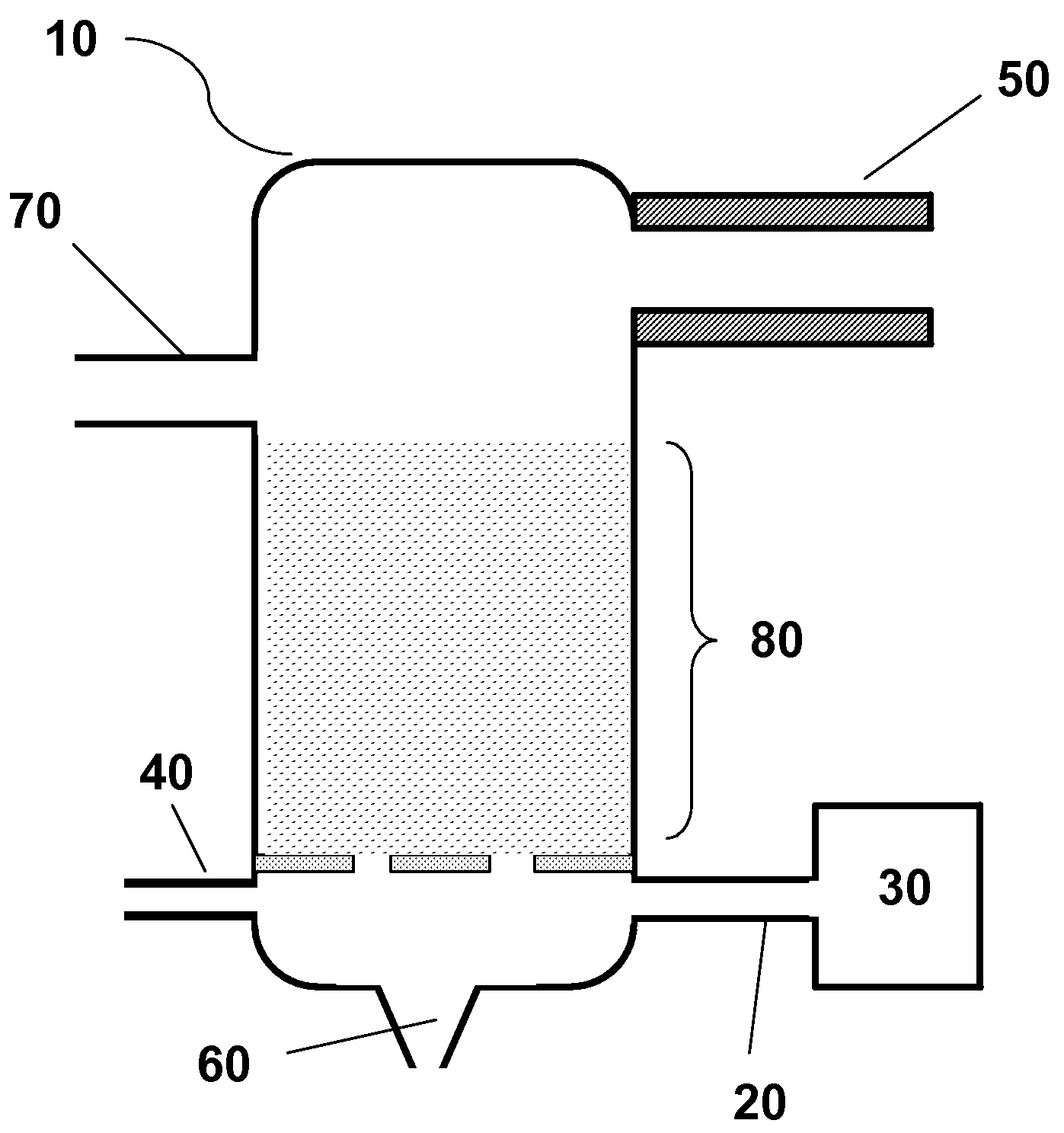

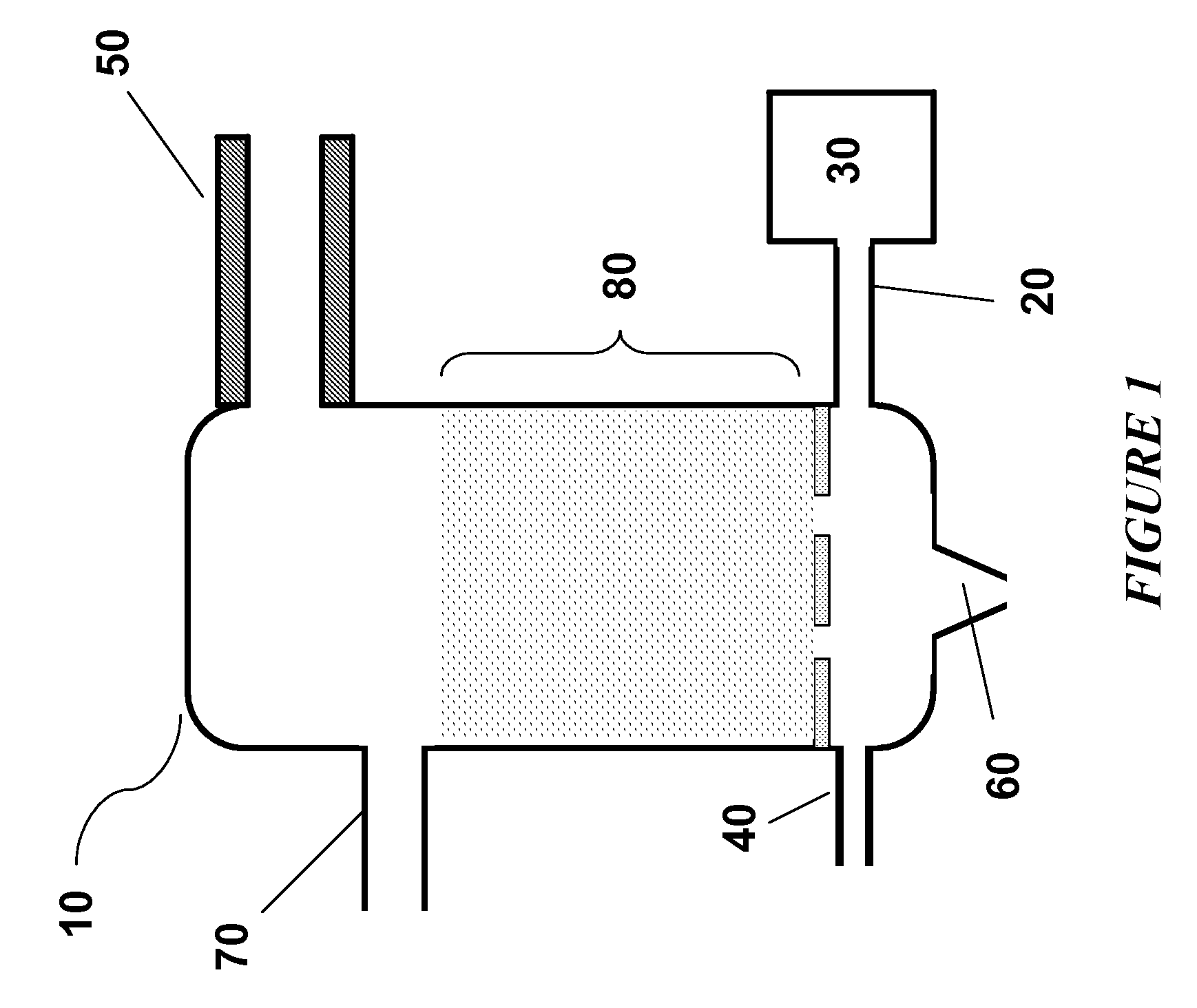

Image

Examples

example 1

[0079]Catalyzed and Slurry Feedstock Preparation

[0080]As-received coal (Powder River Basin) can be stage-crushed to maximize the amount of material having particle sizes ranging from about 0.85 to about 1.4 mm. Fines (<0.85 mm) can be separated from the crushed materials by vibratory screening and directed for preparation of the slurry feedstock.

[0081]The crushed coal can be slurried with an aqueous solution of potassium carbonate, dewatered, and dried via a fluid bed slurry drier to yield a catalyzed feedstock containing 185 lb coal (88 wt %), 14.9 lb catalyst (7 wt %), and 10.5 lb moisture (5 wt %). The coal fines separated at the crushing stage can be slurried with water to a composition of 75 wt % water (263 lb) and 25 wt % coal fines (88 lb) by weight and subsequently can be used as the slurry feedstock for the slurry gasifier.

example 2

[0082]Catalytic Gasification

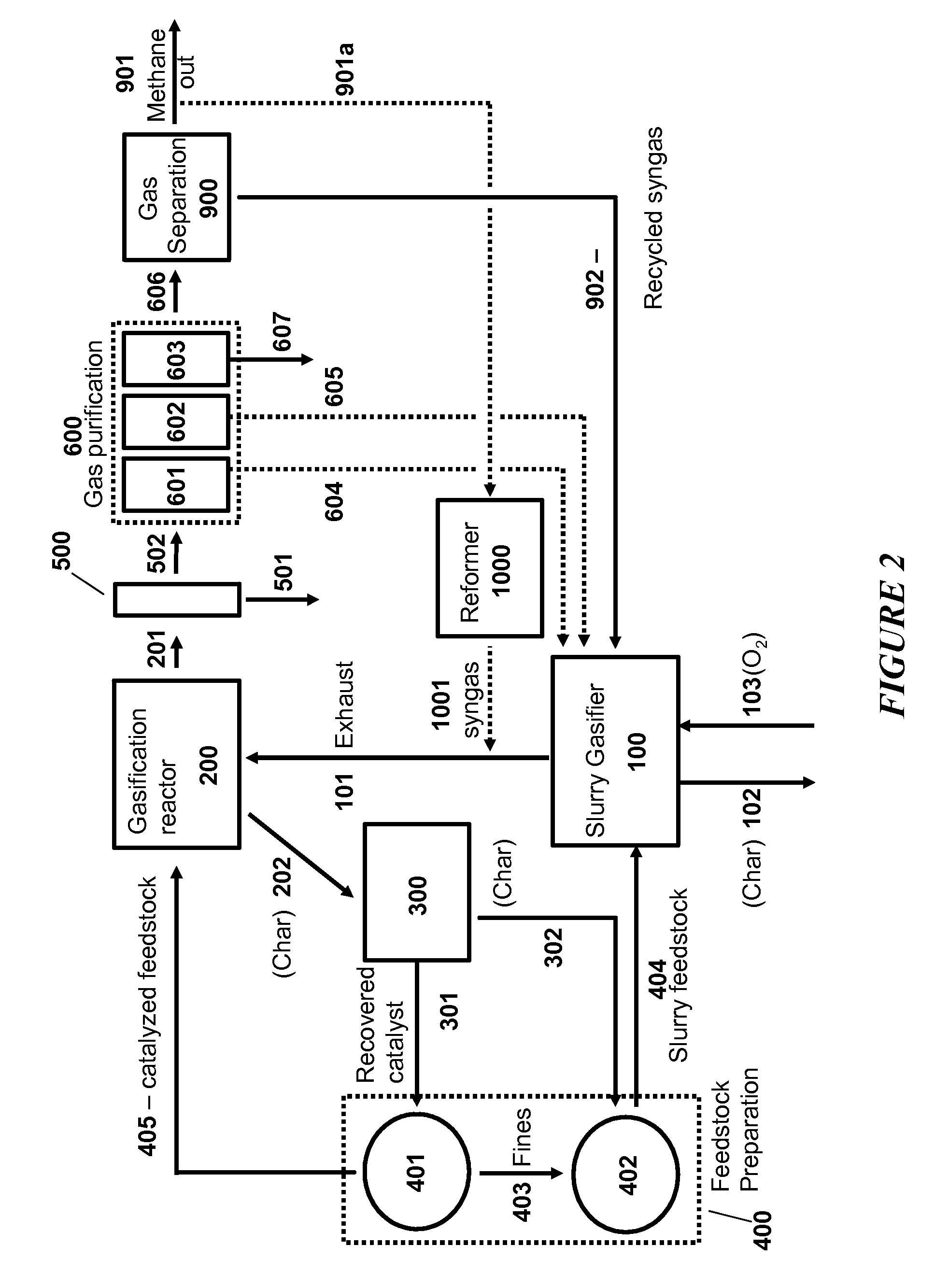

[0083]The slurry feedstock of Example 1 can be provided to a fluidized bed gasification reactor (slurry gasifier) fed by an enriched oxygen source (96 lb / hr) and a syngas source (17.7 w % H2, 82.3% CO; 75.48 lb / hr). Typical gasification conditions for the slurry gasifier would be: total pressure 550 psi, and temperature, 1700-1900° F.; char would be generated at a rate of 12.1 lb / hr.

[0084]The resulting exhaust (561.6 lb / hr) from the slurry gasifier would contain steam (277.5 lb / hr), hydrogen (12.89 lb / hr), CO (62.27 lb / hr), CO2 (187.84 lb / hr) and methane (11.06 lb / hr), and could be provided to a second fluidized bed gasification reactor (catalytic gasifier) supplied with the catalyzed feedstock (210 lb / hr) of Example 1. The catalyzed feedstock would be introduced under a positive pressure of nitrogen (45.8 lb / hr). Typical conditions for the catalytic gasifier would be: total pressure, 500 psi and temperature, 1200° F. The effluent of the catalytic gasifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com