Argon-blowing spray gun for refining ladle and making method thereof

A technology of ladle refining and spray gun, which is applied in the field of ladle refining argon blowing spray gun and its preparation, which can solve the problems of poor stirring effect and low service life of the spray gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

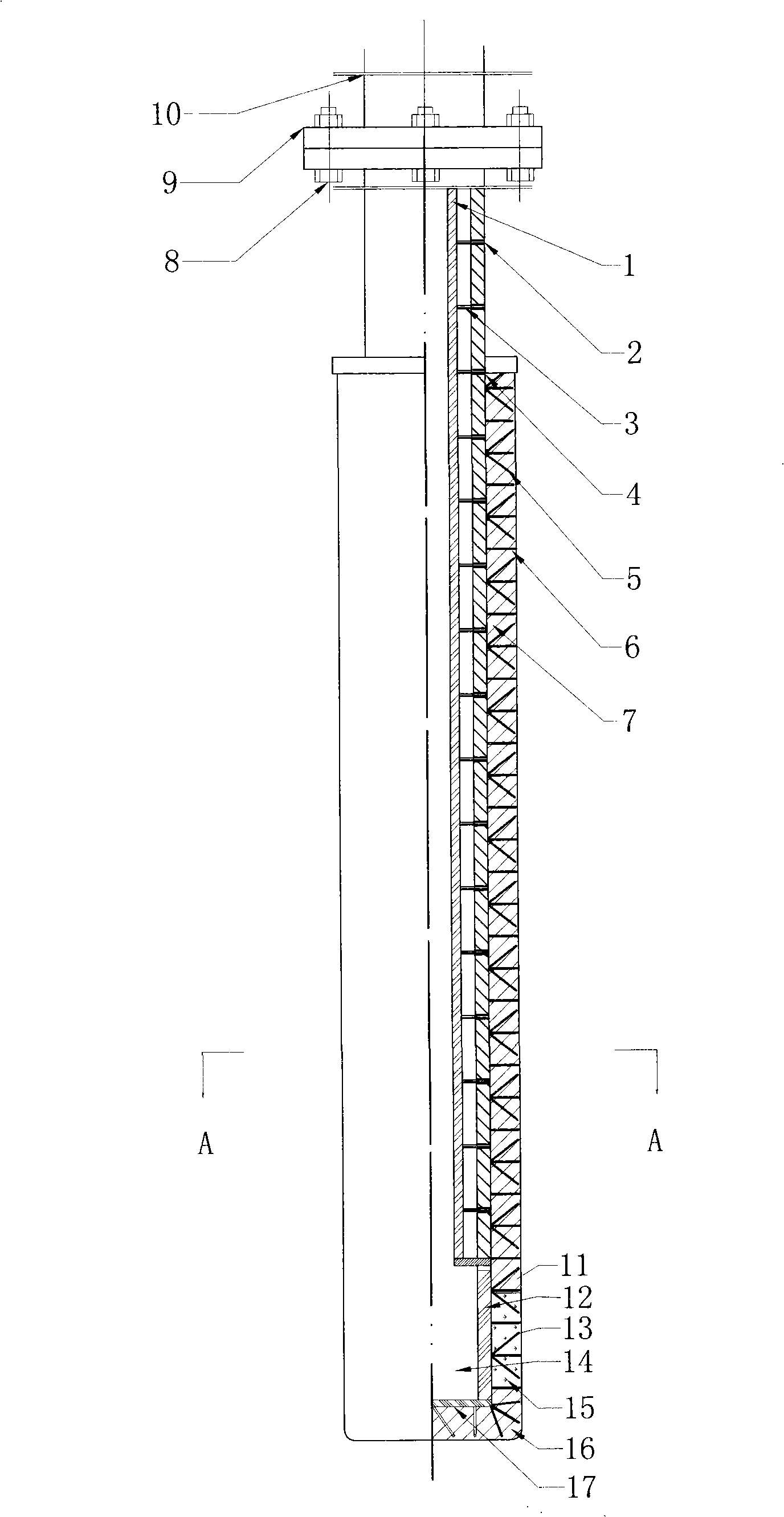

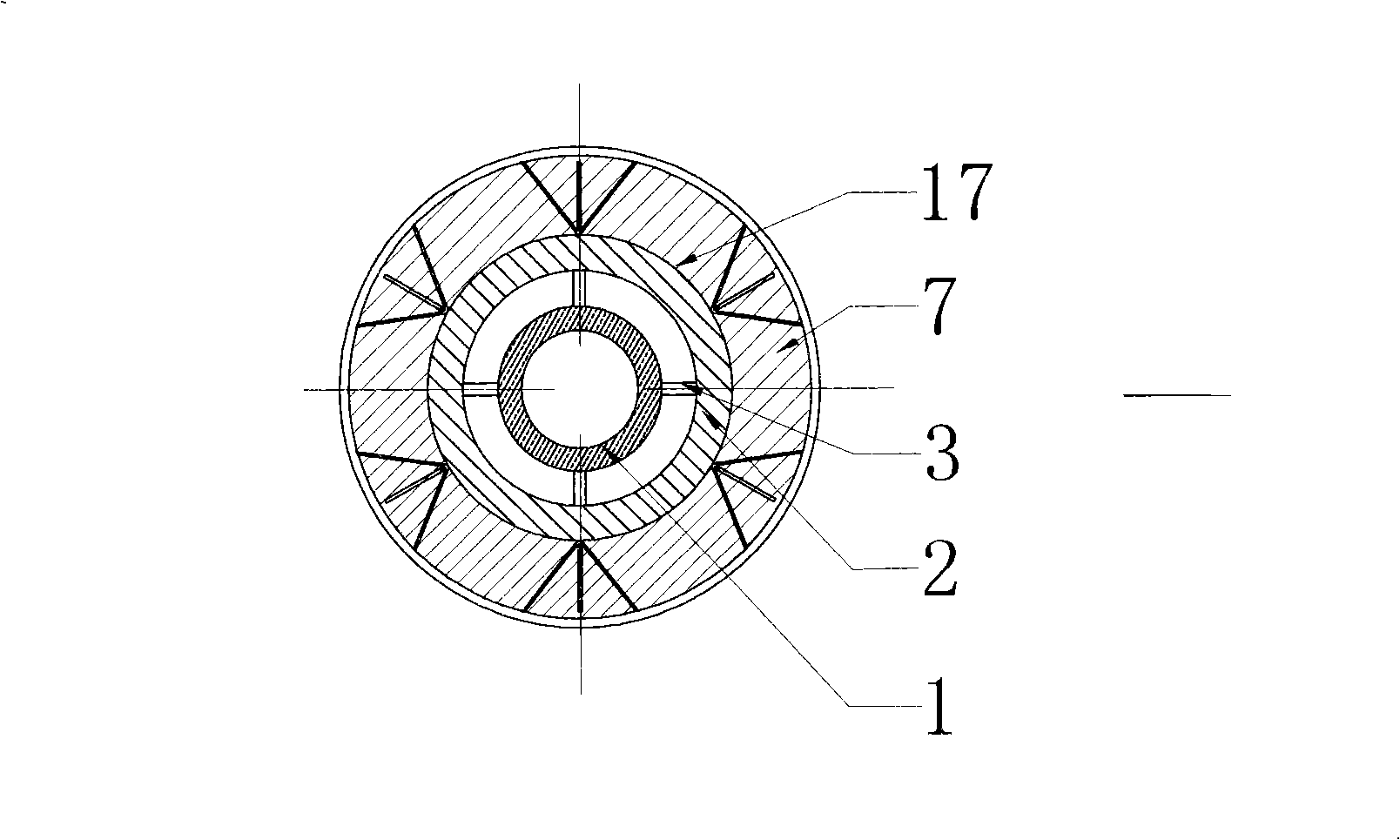

[0023] Such as figure 1 , image 3 Shown, the present invention comprises metal gun shaft 10 and spray gun body, and the bottom end of metal gun shaft 10 and the top end of spray gun body are provided with connecting flange 9 respectively, metal gun shaft 10 and spray gun body are connected together by connecting bolt 8, the spray gun body The lower part is provided with a diffusion nozzle 11 . The spray gun body includes a main pipe 1, a reinforcing pipe 2, a number of bridging weldments 3, a number of rivets and a refractory working lining 7, the main pipe 1 and the reinforcing pipe 2 are ordinary carbon steel seamless steel pipes, and the reinforcing pipe 2 is set outside the main pipe 1 , and a number of bridging weldments 3 are evenly welded between the main pipe 1 and the reinforcing tube 2, the bridging welding pieces 3 are short steel columns shearing rebar or carbon steel wire rods, with a diameter of 8mm; the outer circumference of the reinforcing tube 2 is covered ...

Embodiment 2

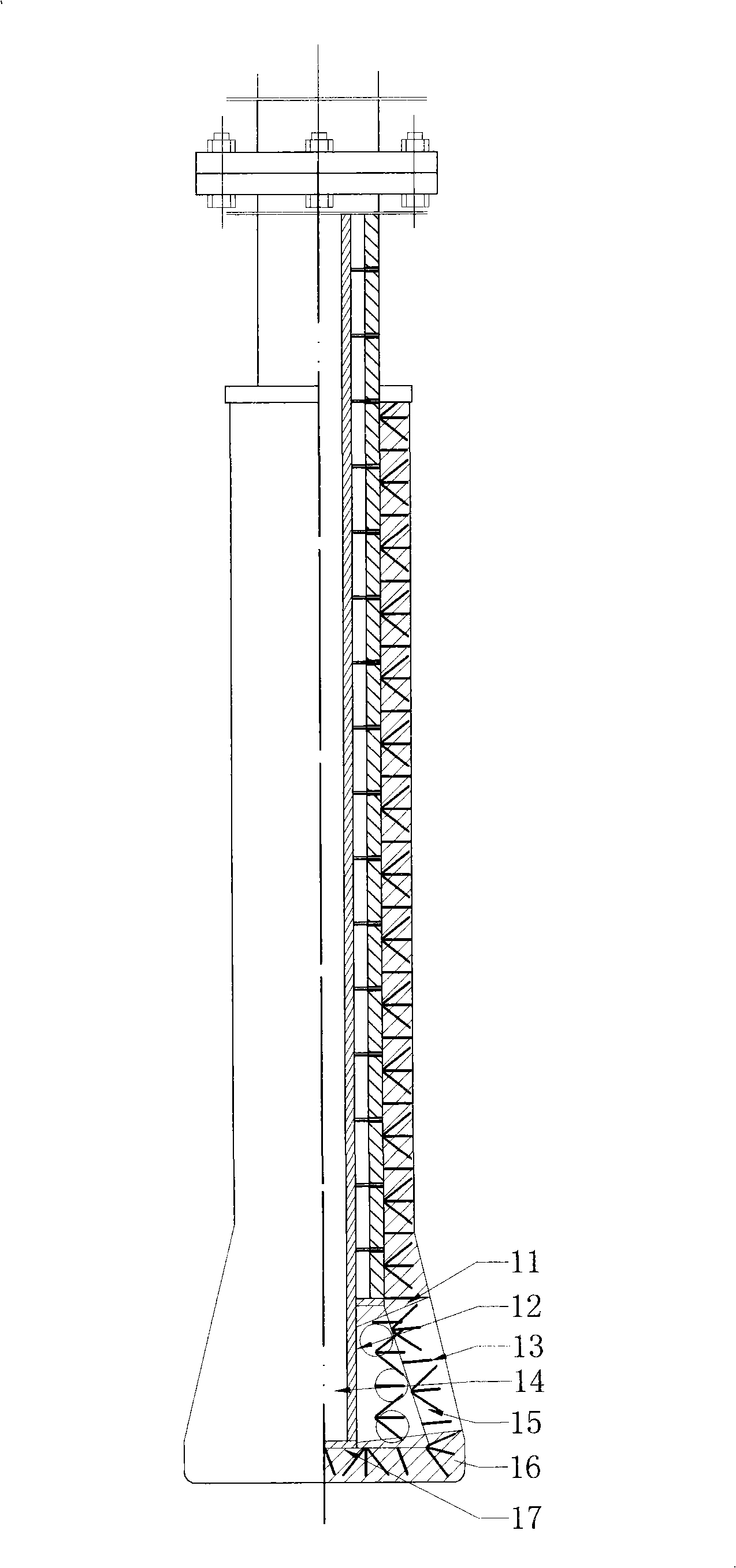

[0028] Such as figure 2 as shown, figure 2 It is a schematic diagram of the structure of this embodiment. The difference between this embodiment and Embodiment 1 is that the diffuse nozzle 11 is in the shape of a truncated cone with a small top and a large bottom, and the diffuse nozzle 15 is in the shape of a capillary hole and is inclined upward with a plane perpendicular to the longitudinal axis of the metal tube 12. 2 to 5 degrees. The upper end of the metal pipe 12 is connected to the spray gun reinforcement pipe 2 by welding, or the metal pipe 12 and the reinforcement pipe 2 are the same pipe.

[0029] The shape of the diffusion nozzle 11 of the present invention is not limited to the shape defined in Embodiment 1 and Embodiment 2, and can also be hemispherical or semi-ellipsoidal. At this time, the diameter of the bottom surface of the diffusion nozzle 11 is greater than or equal to the top surface diameter and the outer surface of the diffusion nozzle 11 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com