Patents

Literature

43results about How to "Reduce facilitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

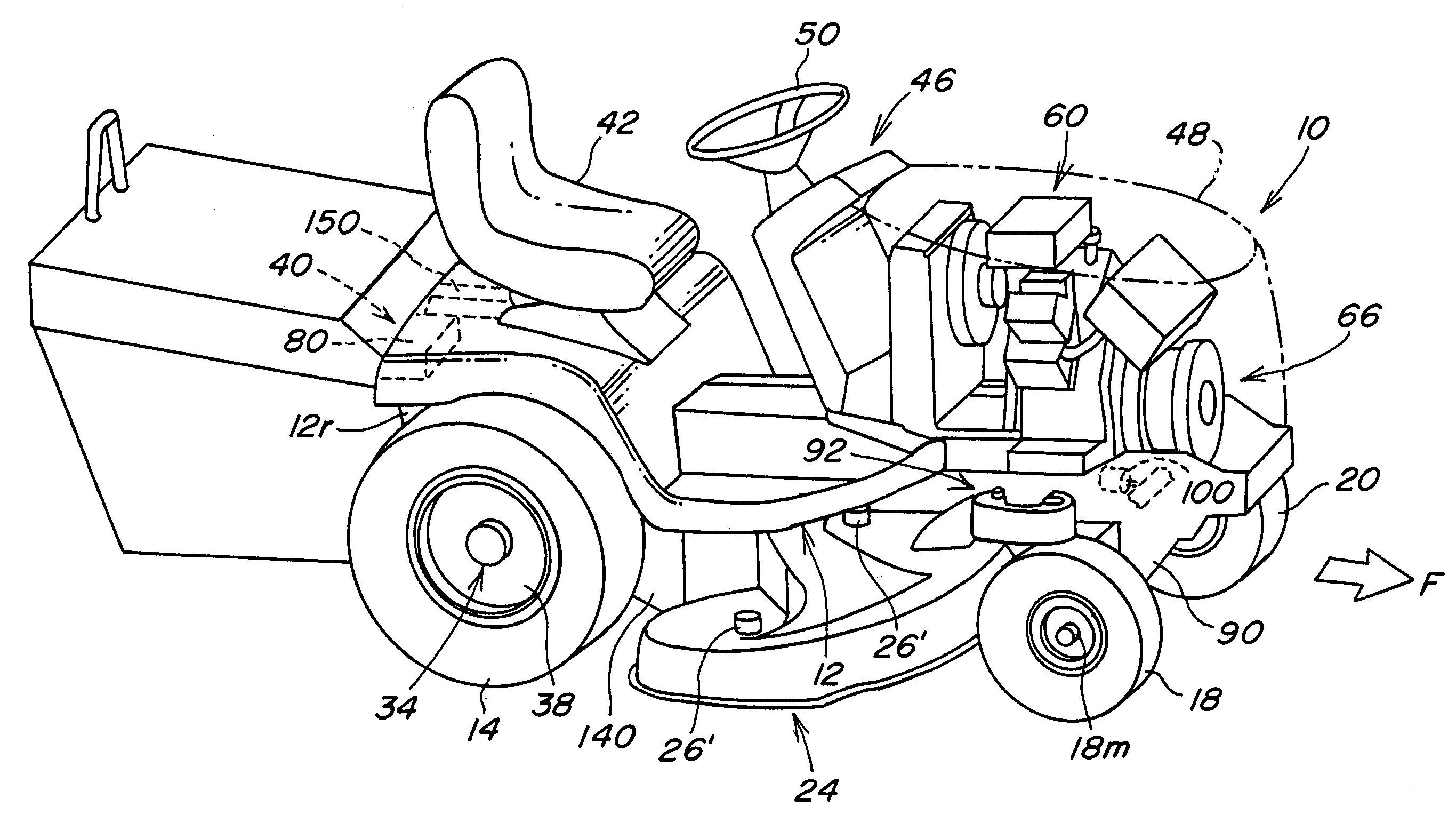

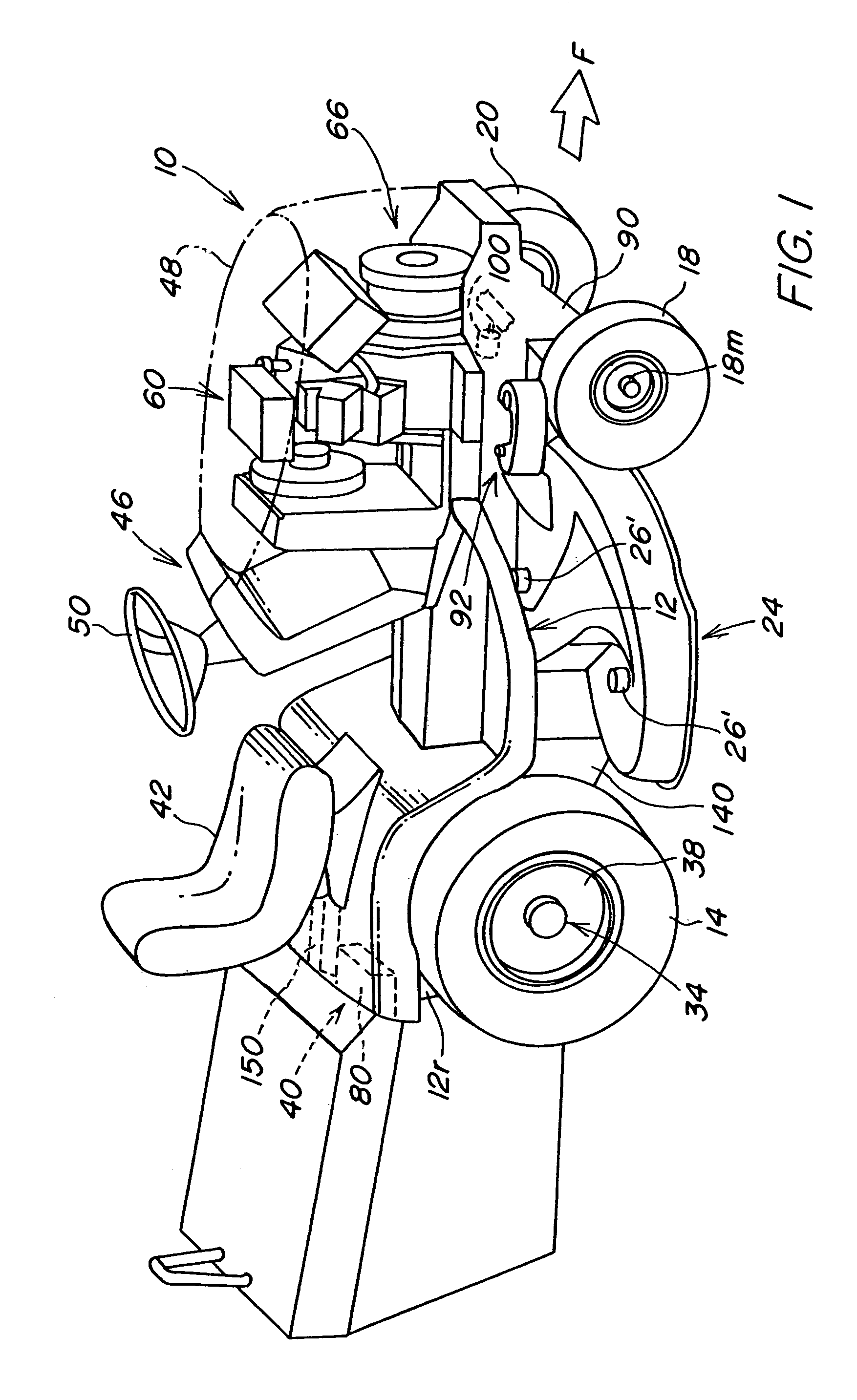

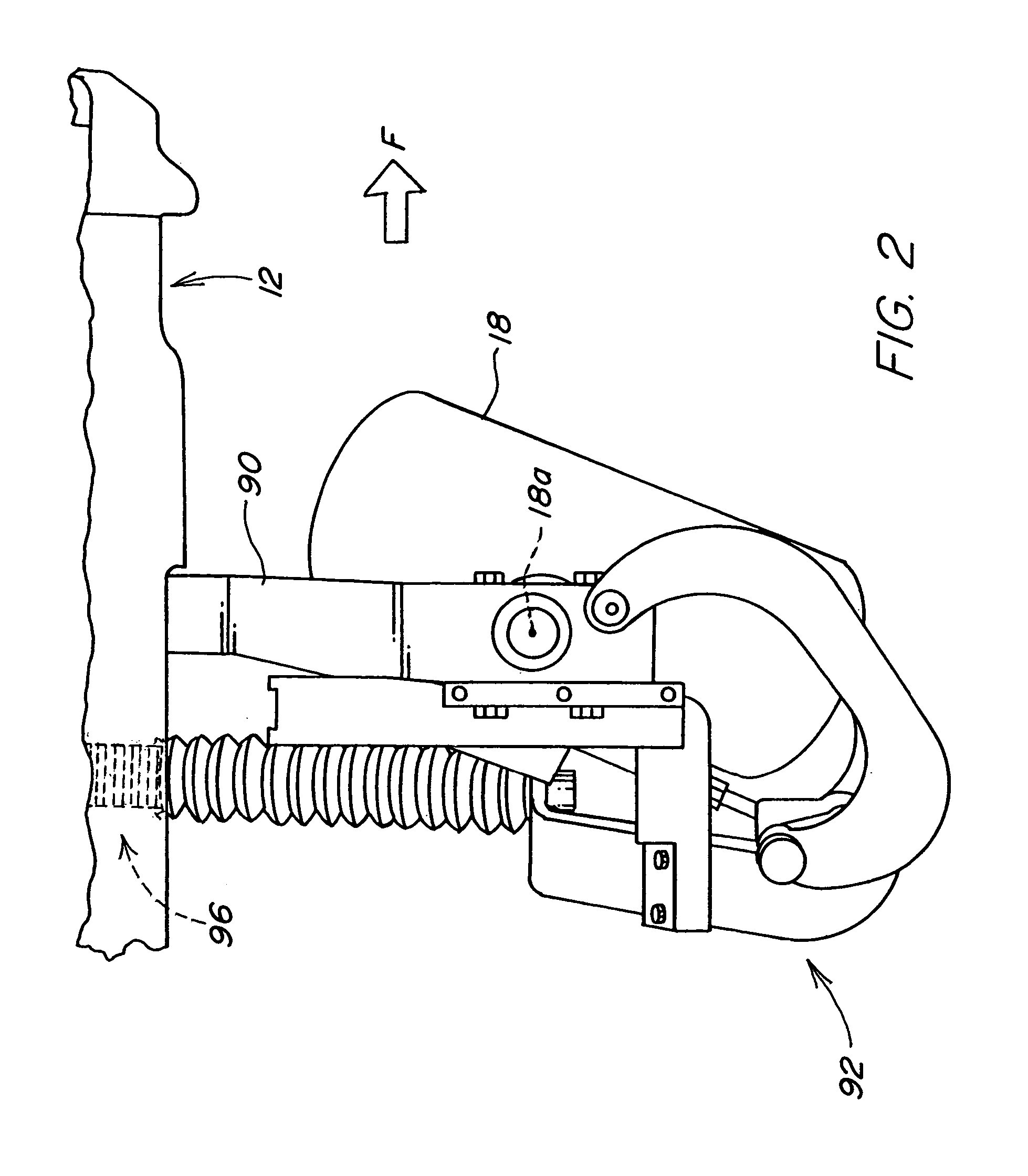

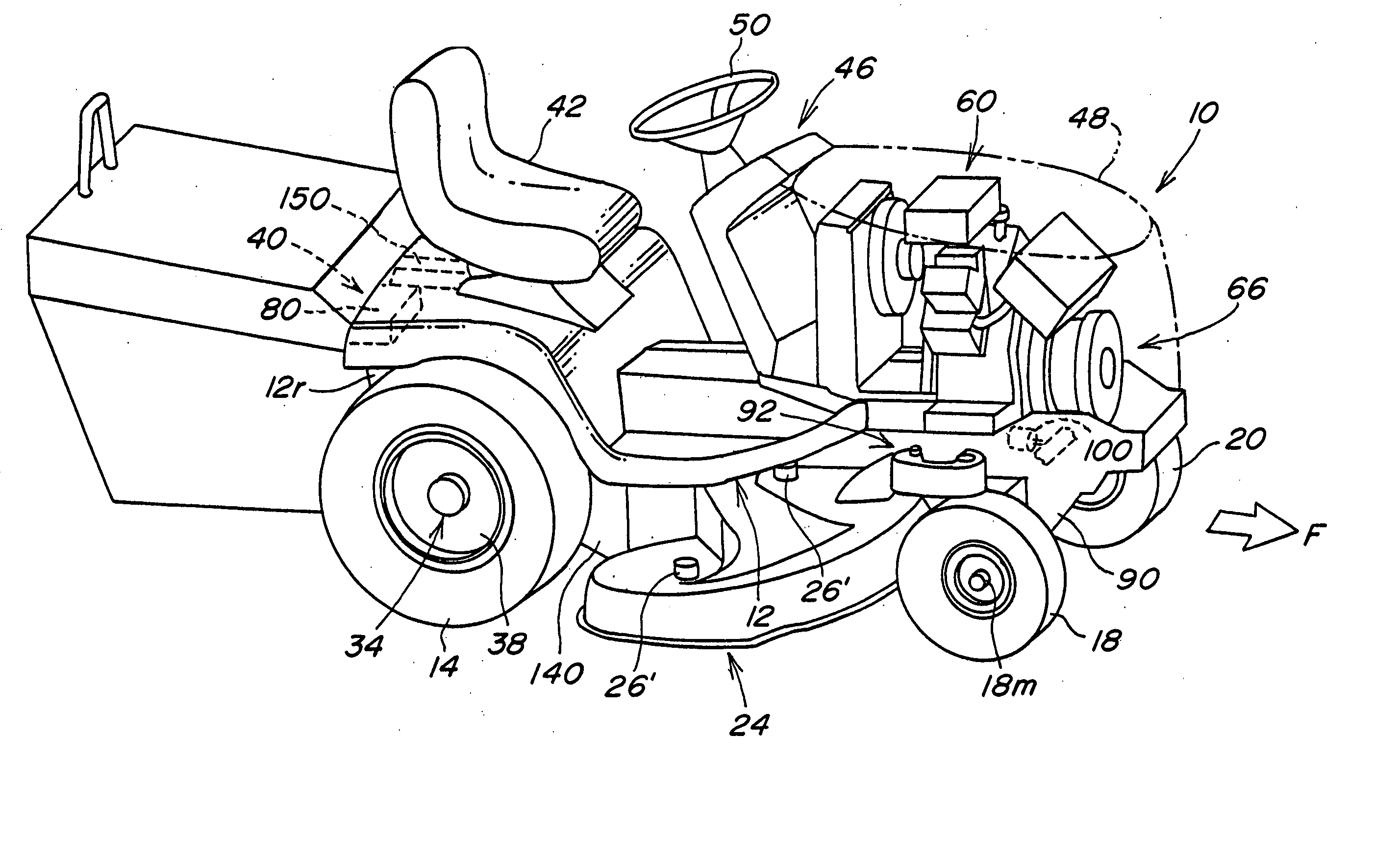

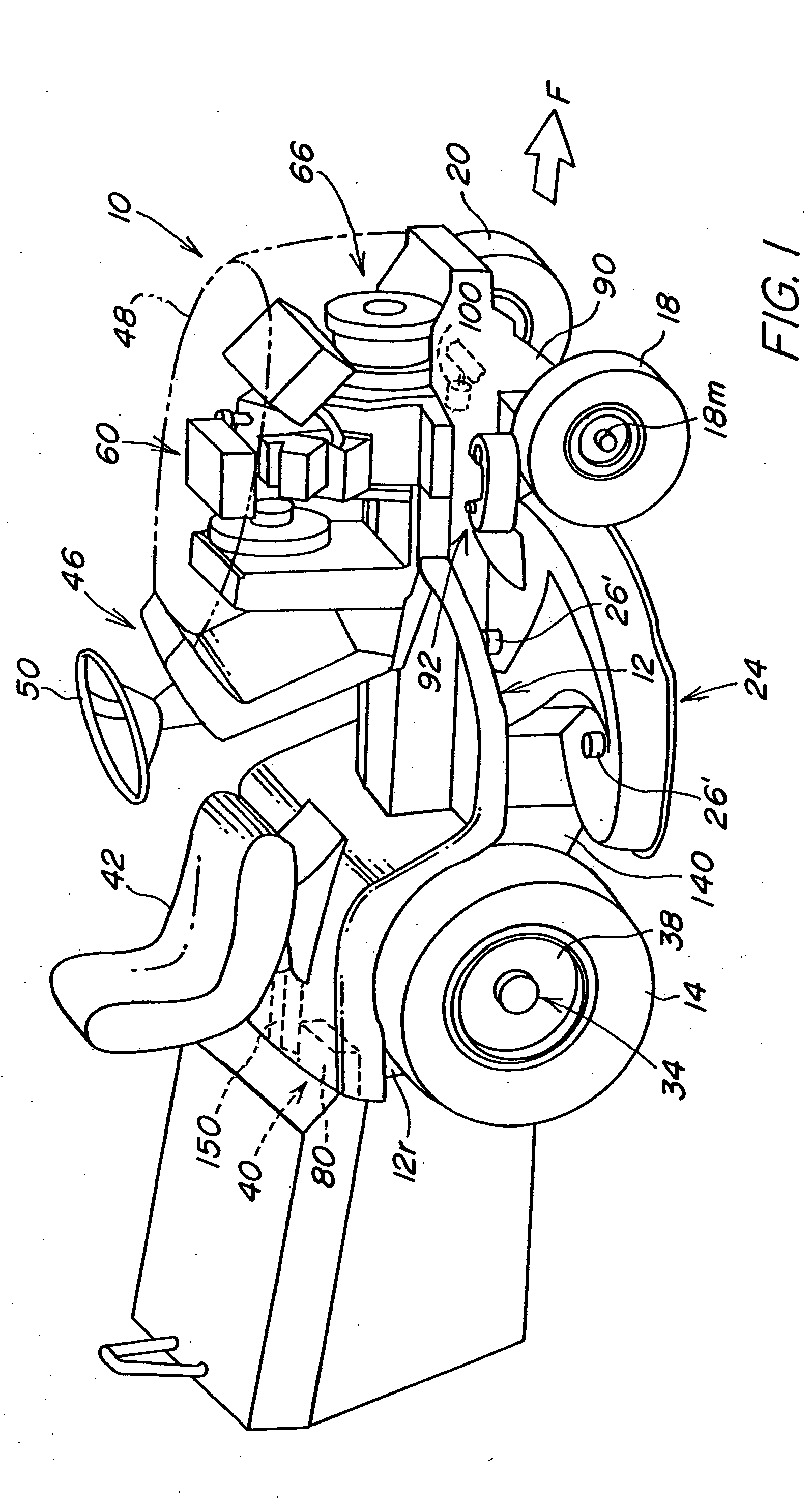

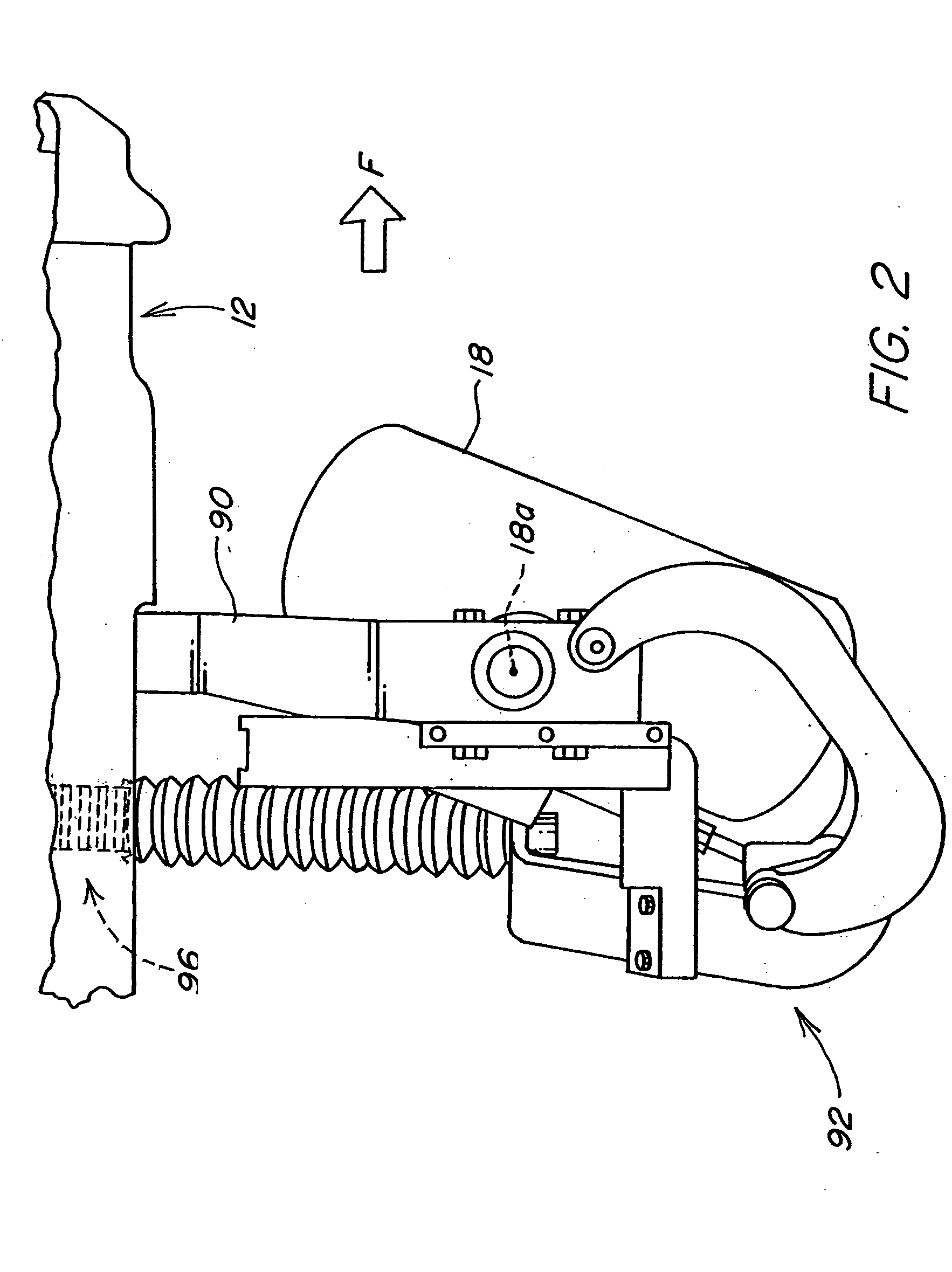

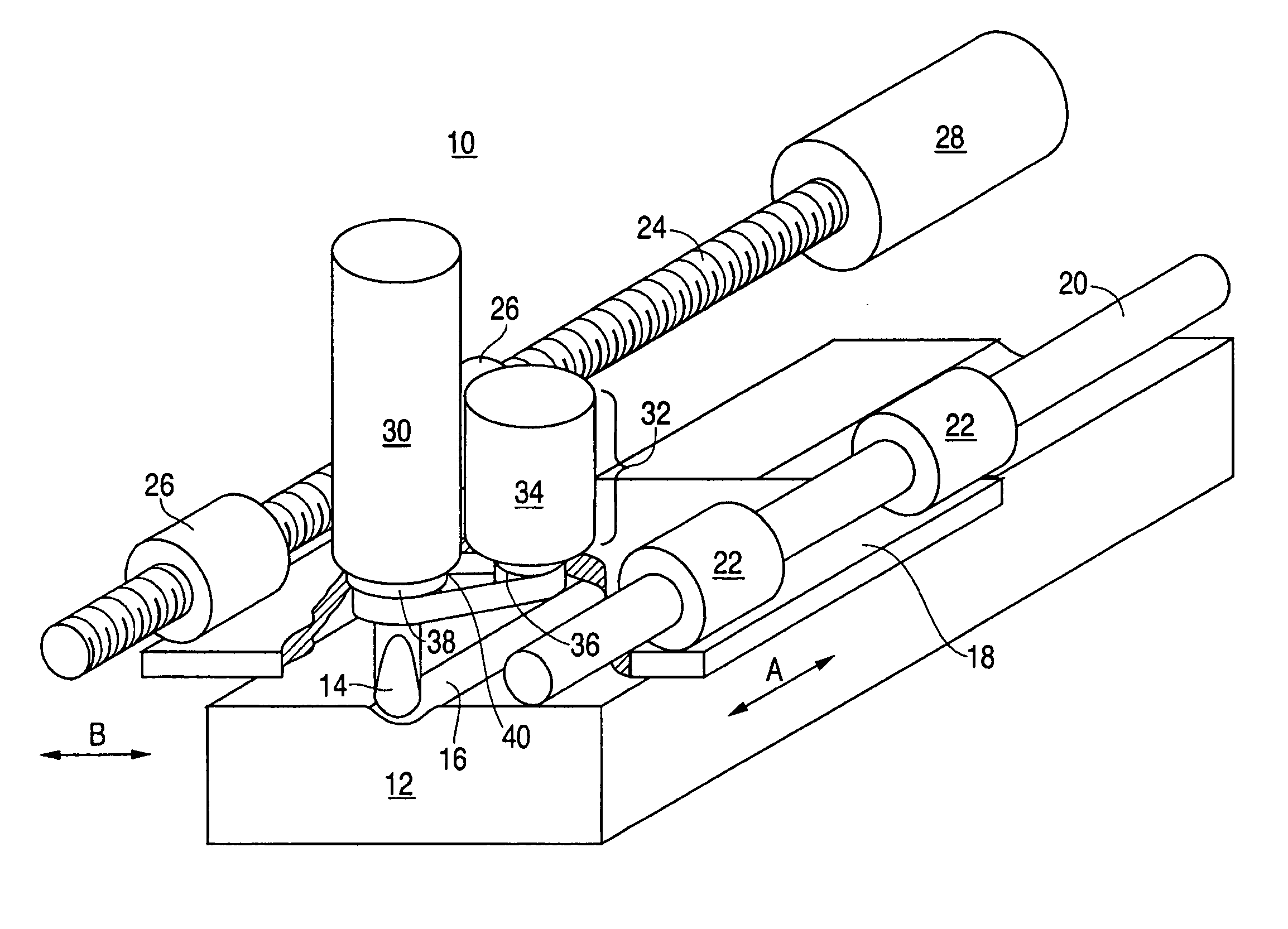

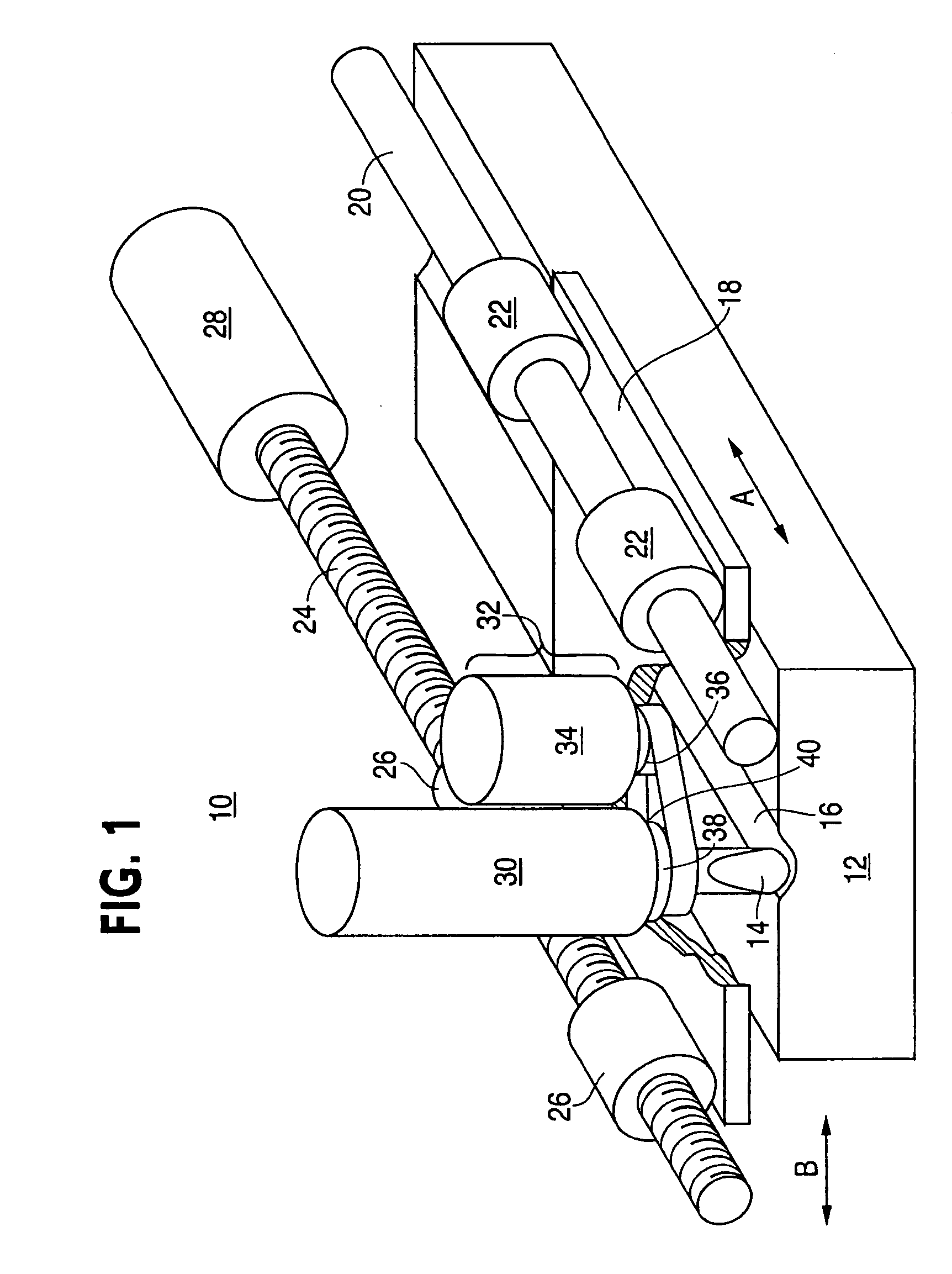

Hybrid electric tool carrier

ActiveUS7017327B2Facilitates better placementSimple structureMowersGas pressure propulsion mountingVehicle frameDrive wheel

A hybrid utility vehicle includes a tool-supporting frame and an electrical power source driven by an engine. Right and left rear wheels independently driven by permanent magnet electric motors and front wheels electrically steerable over a range of approximately 180 degrees operate under the control of a vehicle controller responsive to steering and speed input controls to provide zero turn radius operation with minimum slippage and tire scuffing. Space efficiency provided by the electric steering and an electrically driven tool deck facilitate a variety of tool mounting configurations including a rear discharge deck with a chute passing under the vehicle frame between the driven wheels. An inverter connected to the electrical power source provides 110 / 220 volt output. The power source also functions as a high powered, high rpm, low noise starter motor.

Owner:DEERE & CO

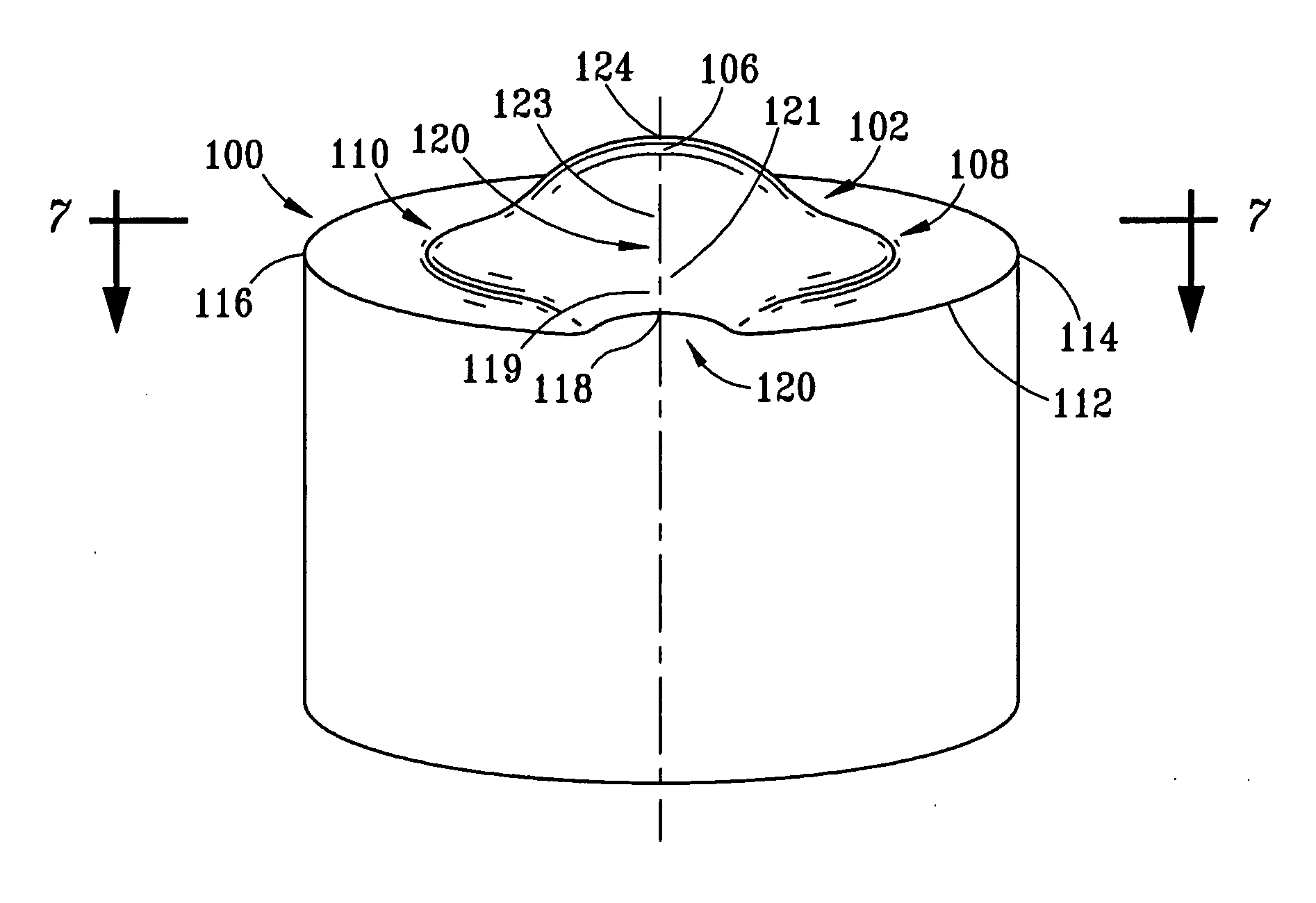

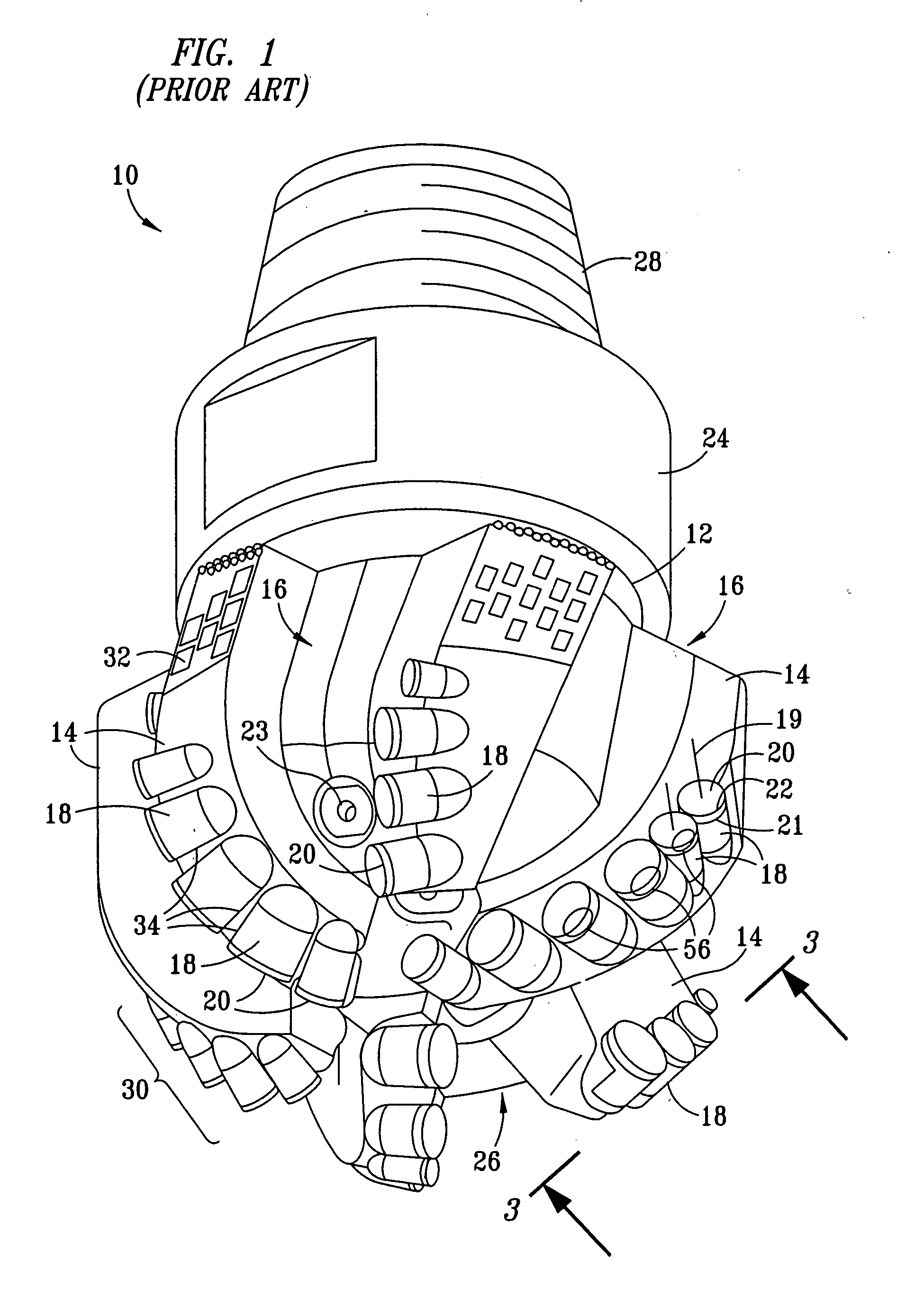

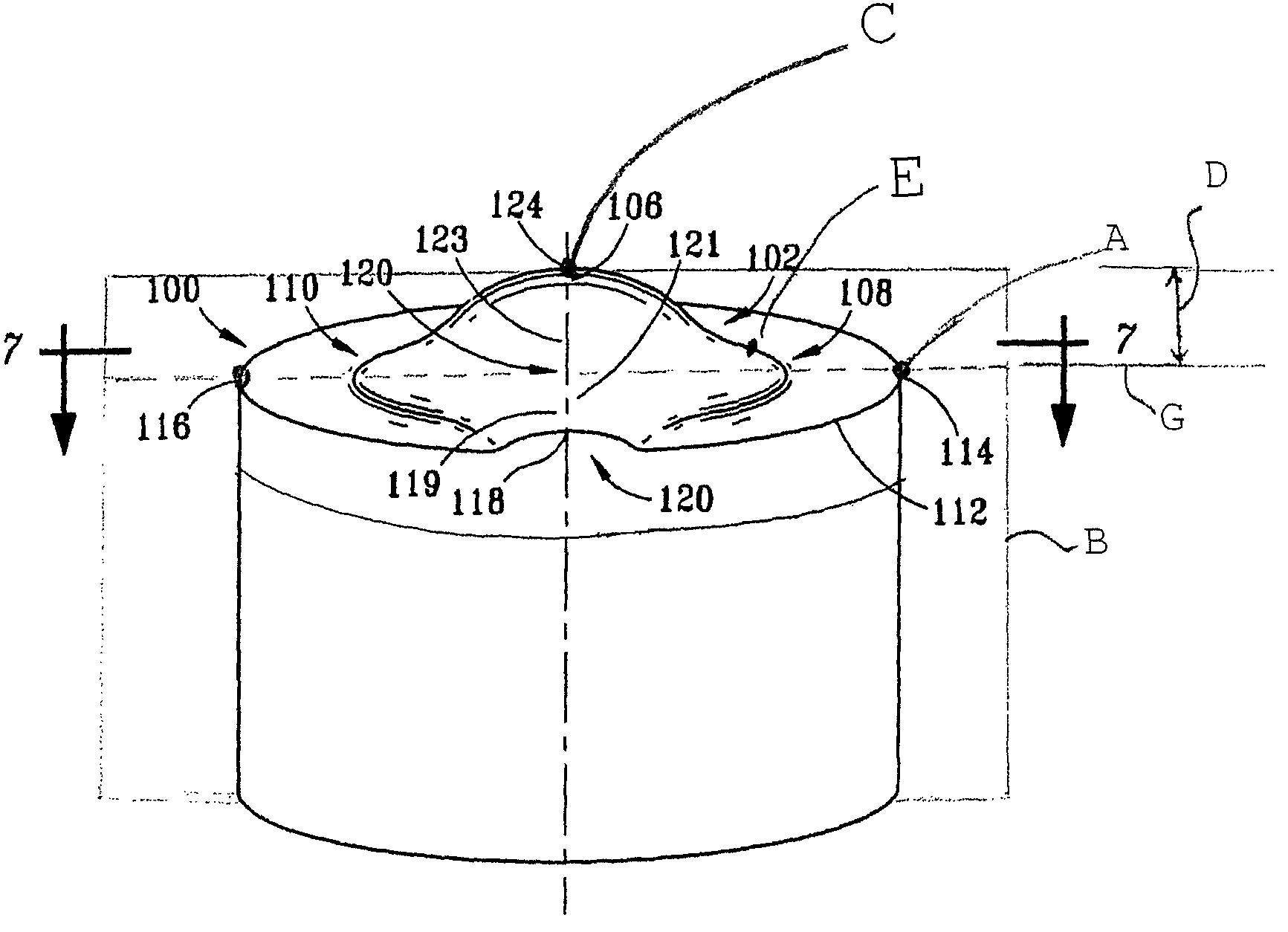

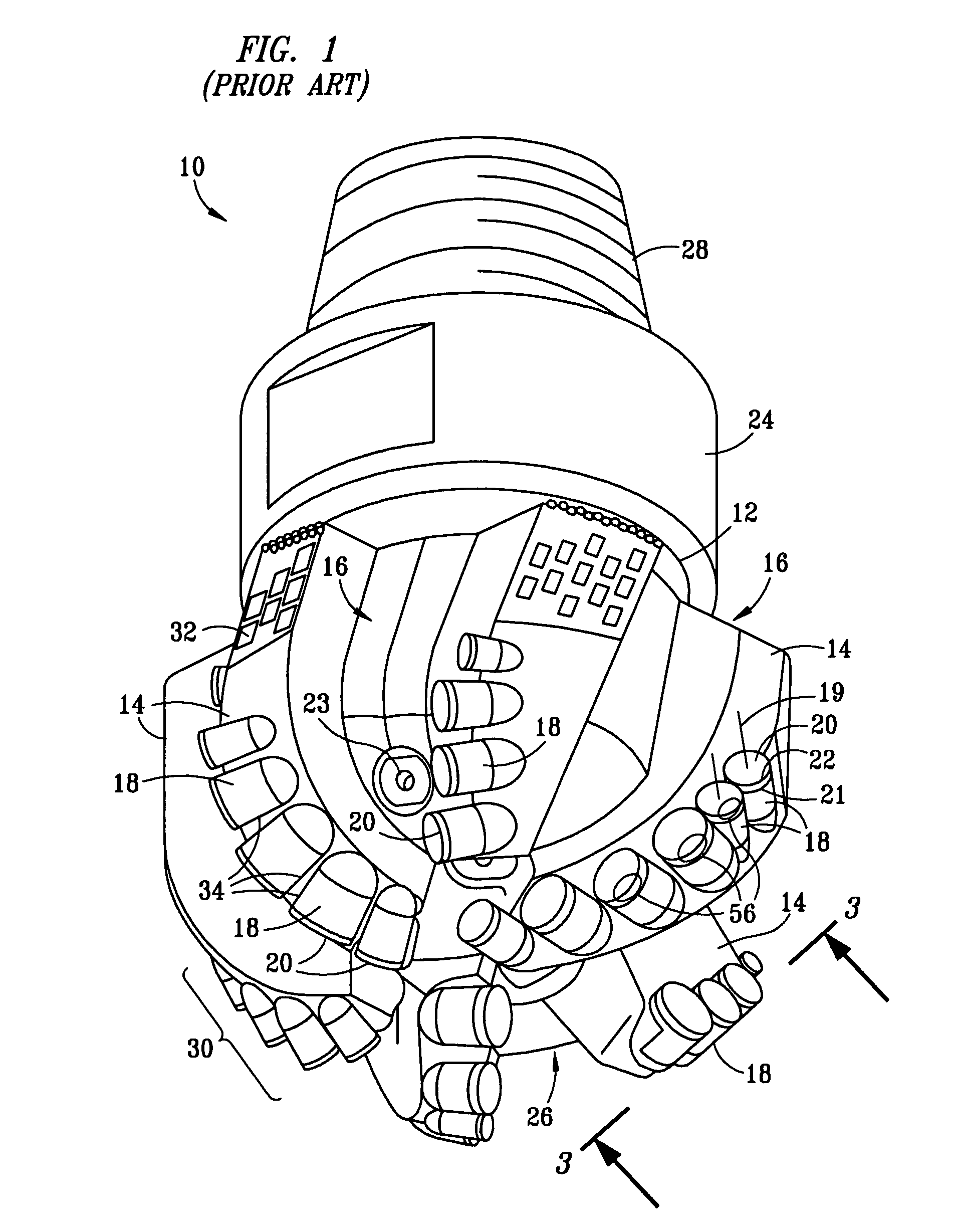

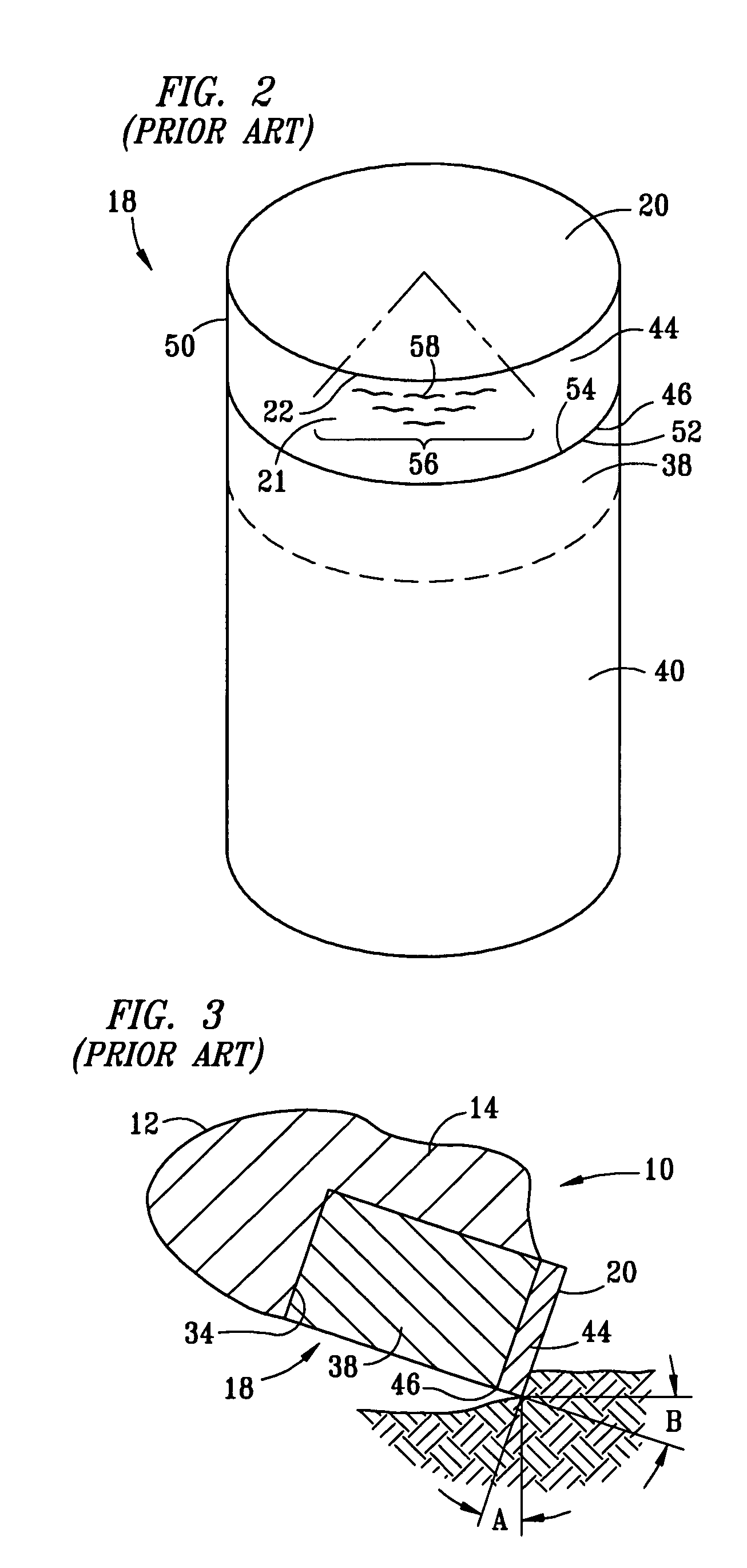

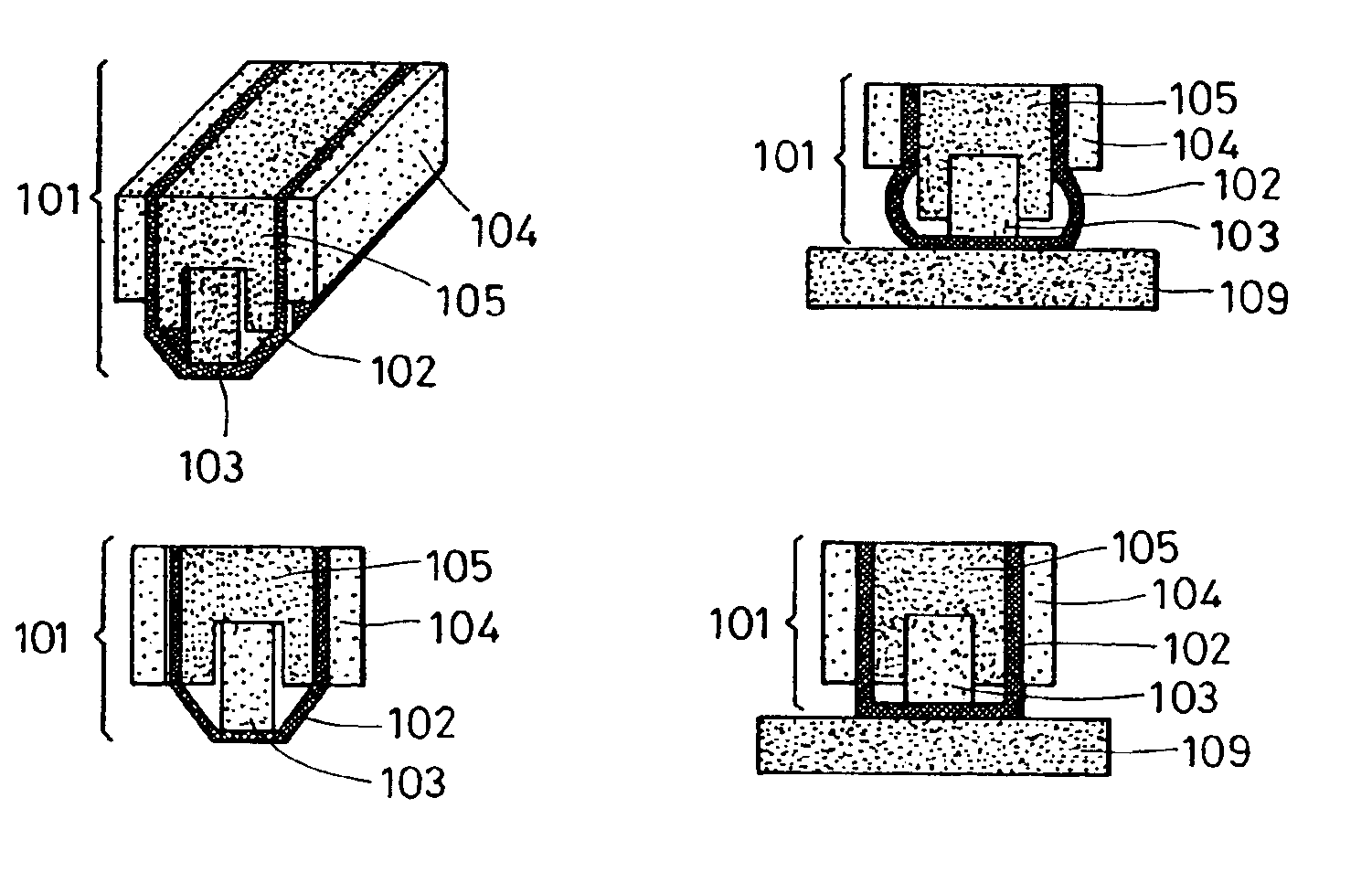

Shaped cutter surface

ActiveUS20050269139A1Reduce certain adverse consequenceSmooth curveDrill bitsConstructionsAbnormal shapedEngineering

A cutter for a drill bit used in a geological formation includes a shaped ultra hard working surface. The cutter with the shaped working surface is mounted on a drill bit to provide desired cutting characteristics. The shaped working surface provides varied cutting characteristics depending upon the shape, and the characteristics can vary depending upon the depth of the cut.

Owner:SMITH INT INC

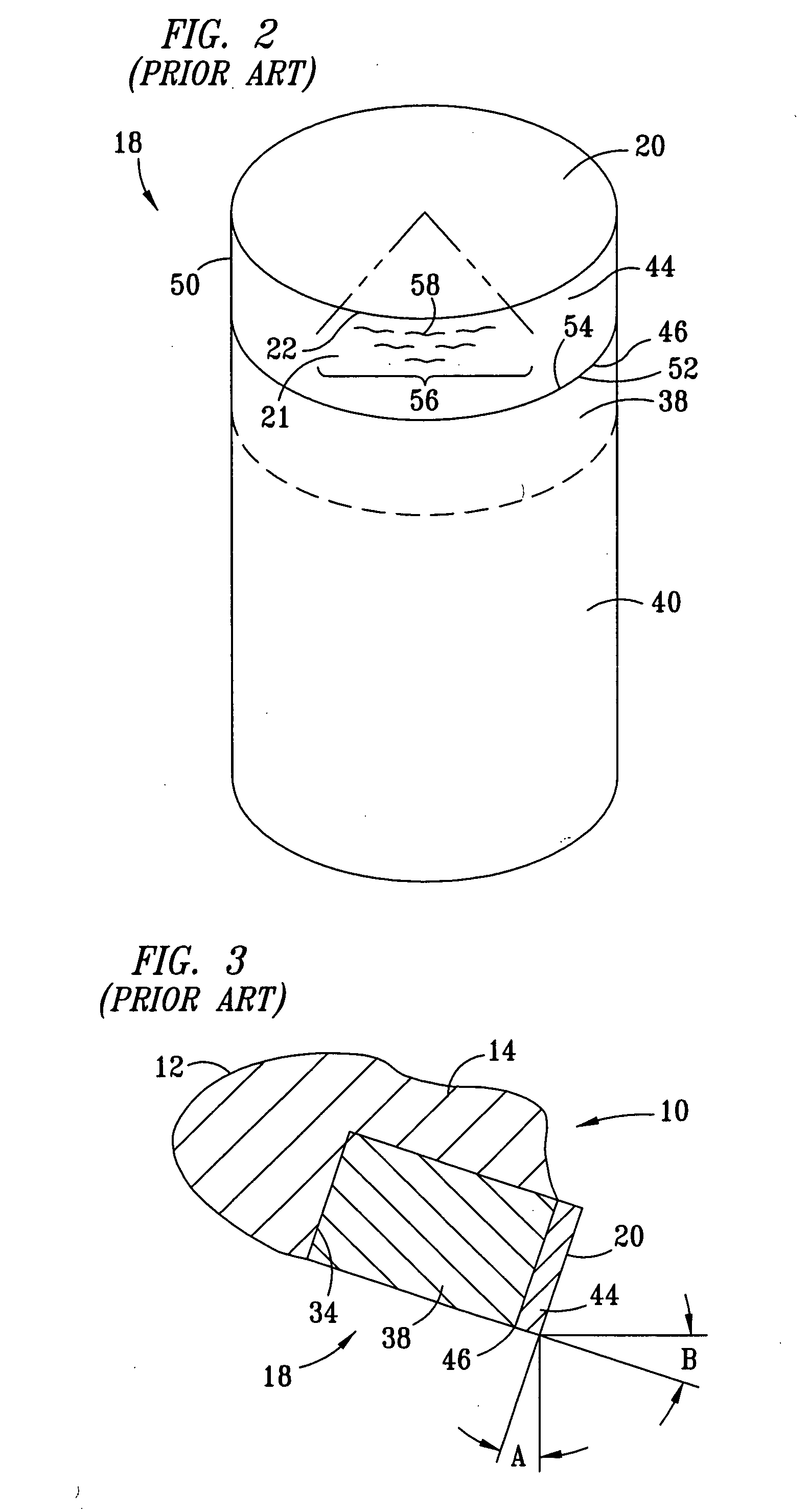

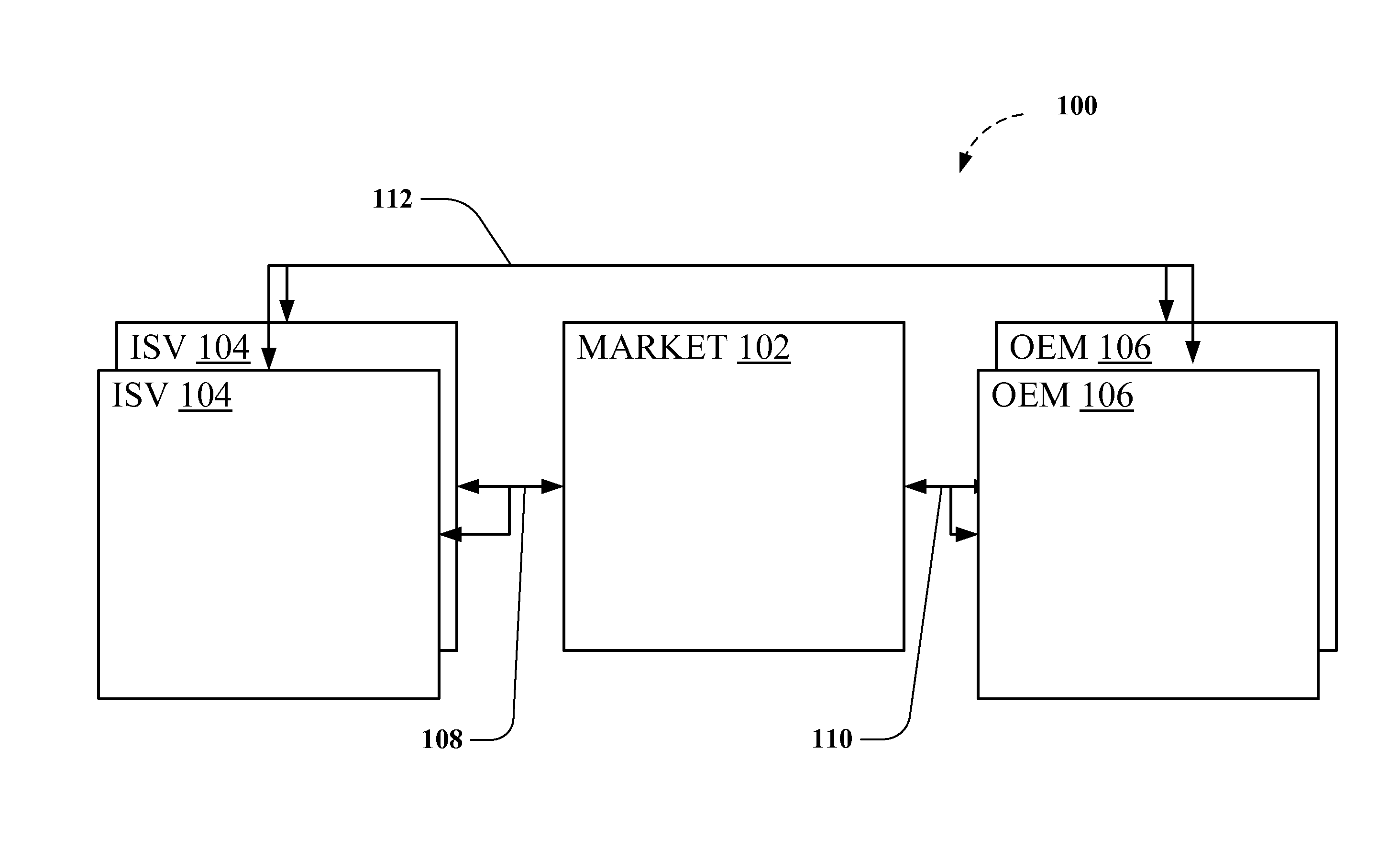

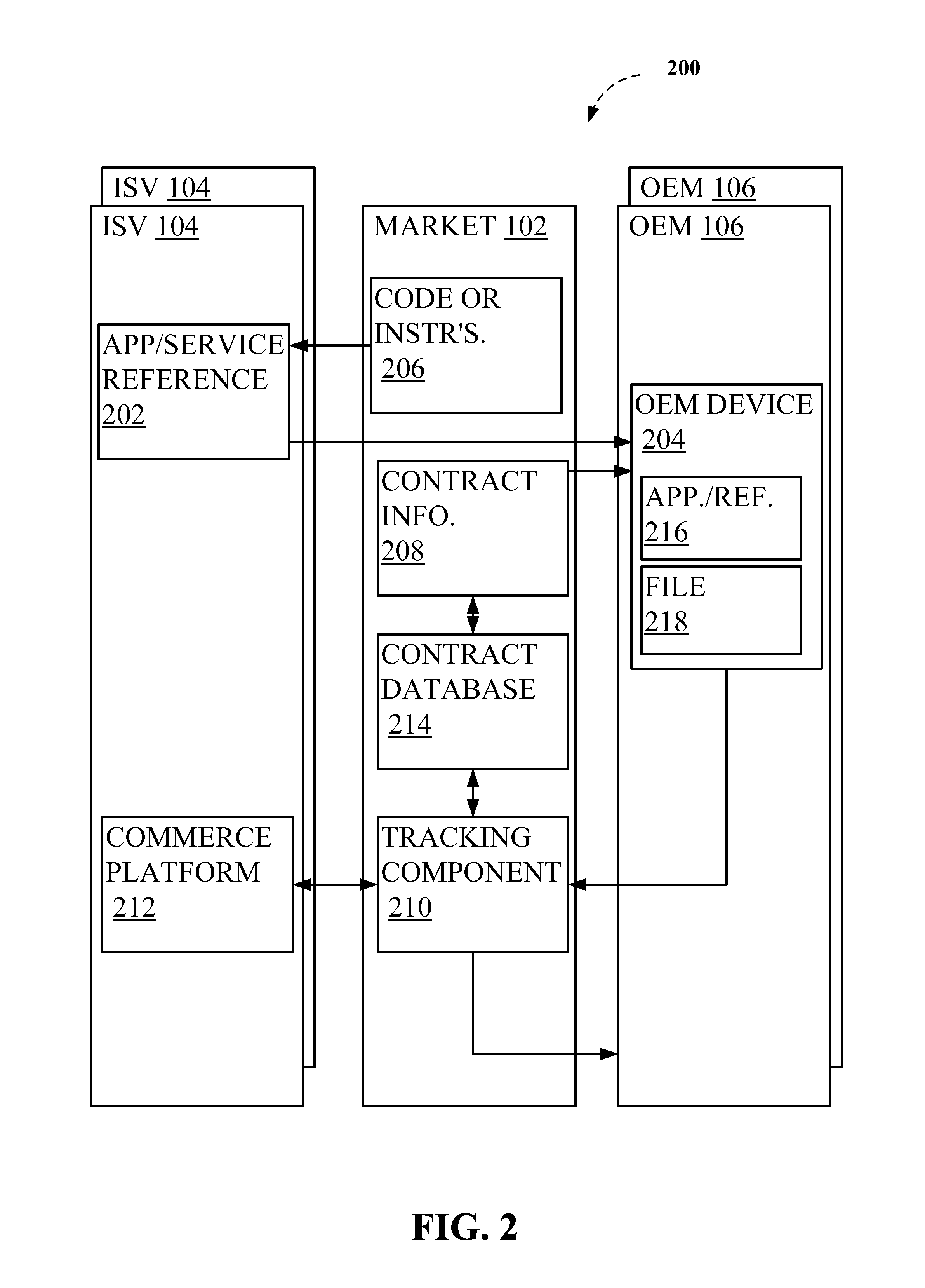

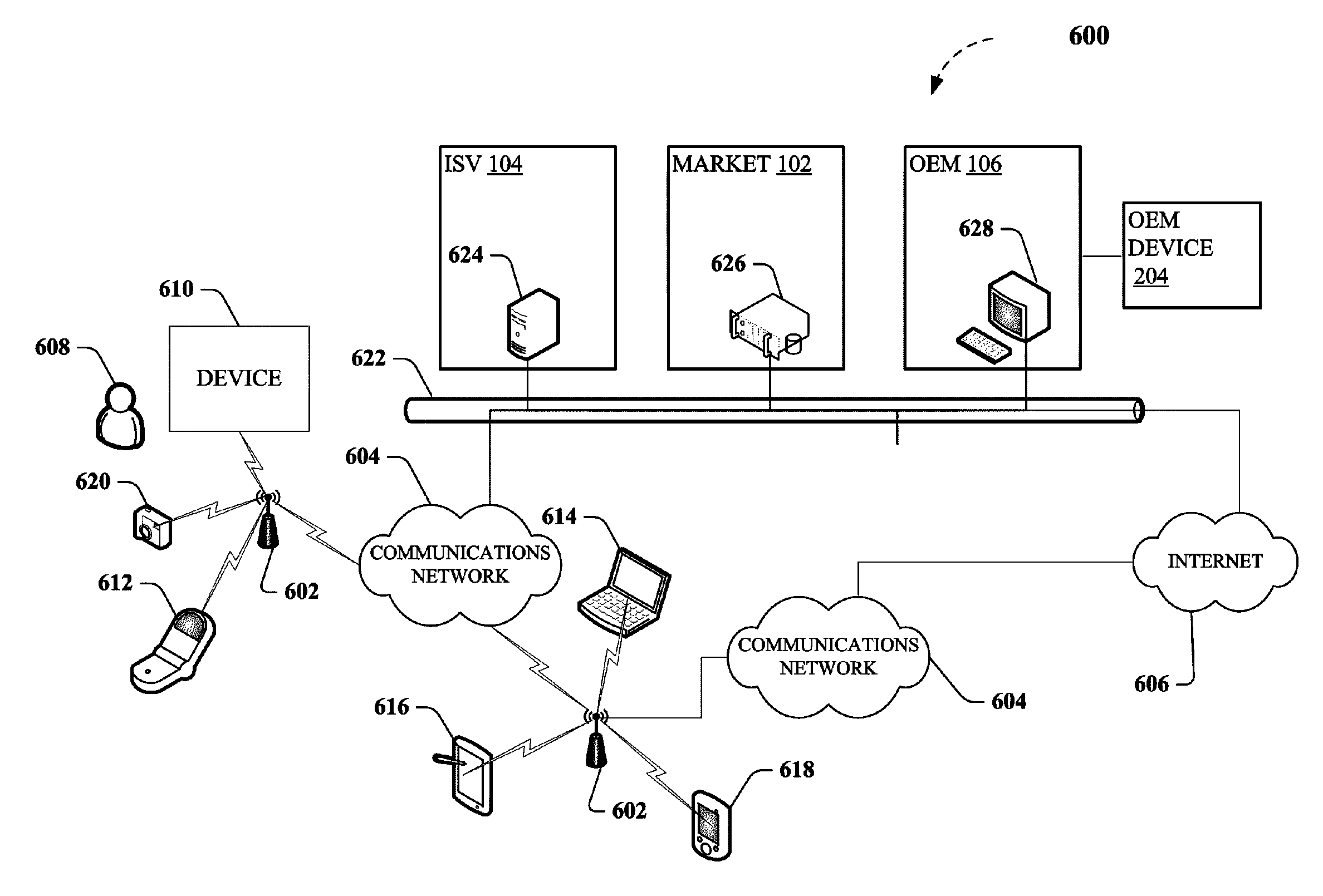

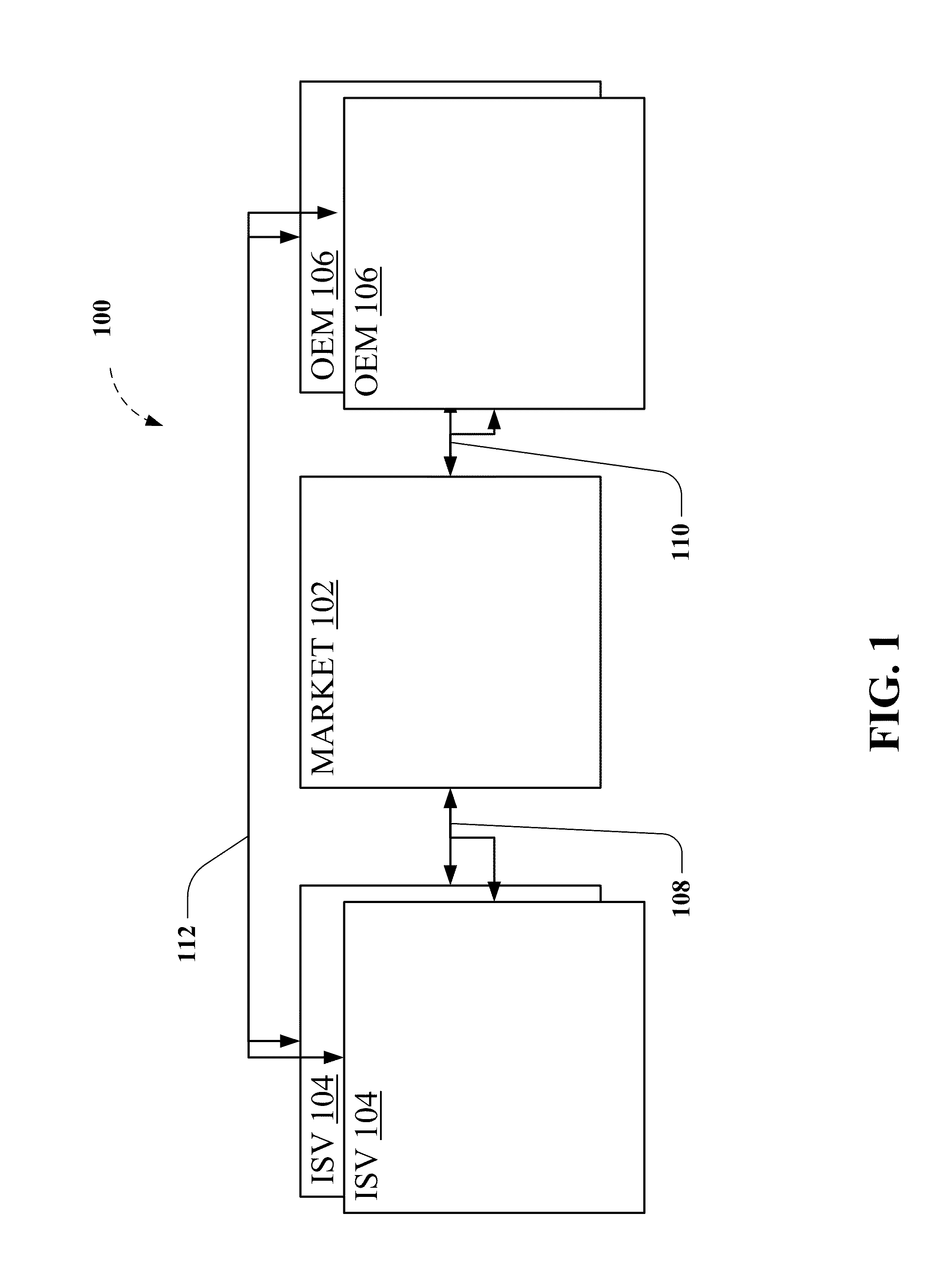

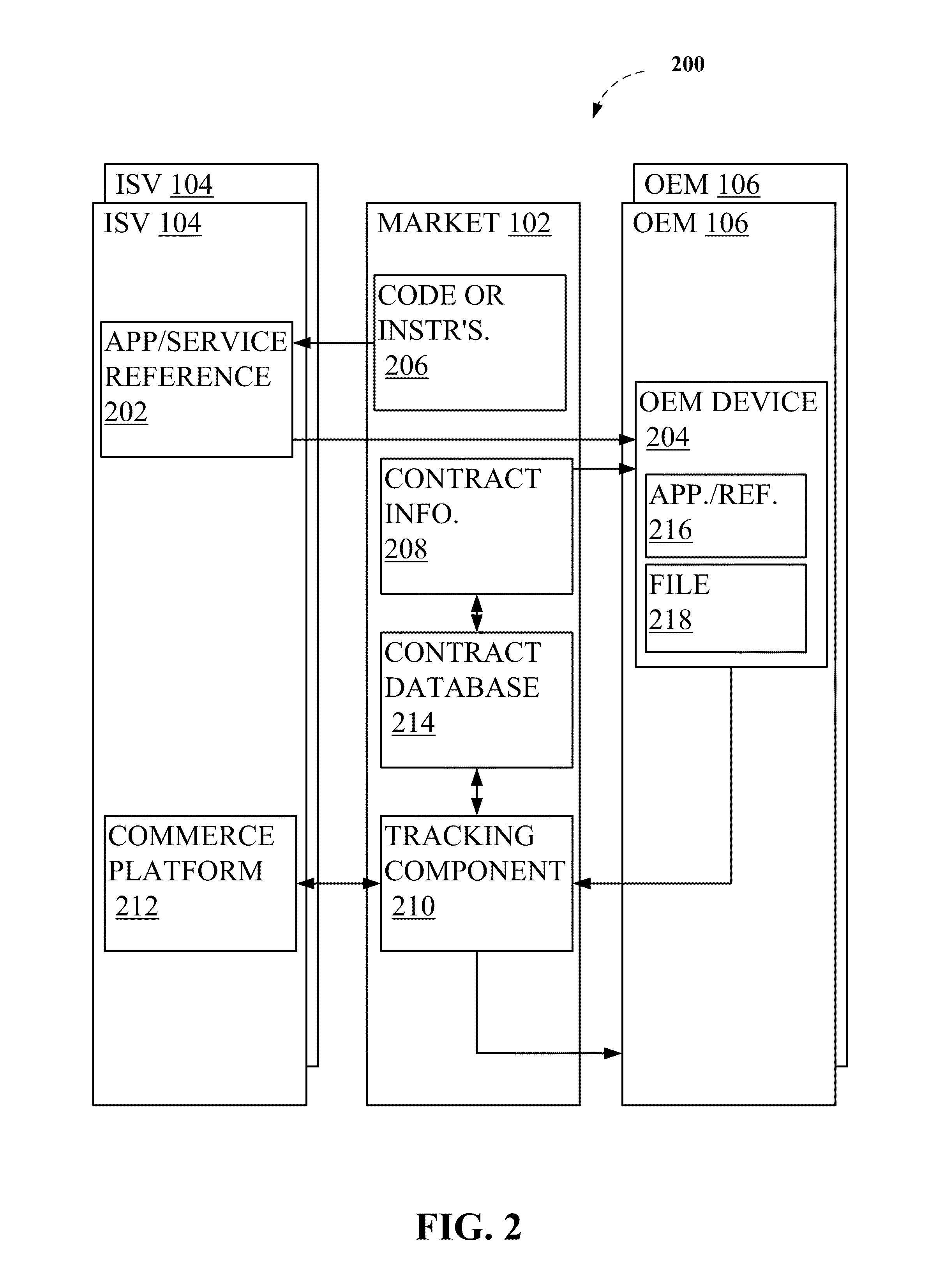

Online marketplace for pre-installed software and online services

ActiveUS20110296401A1Reduce facilitationProviding transparencyProgram loading/initiatingBuying/selling/leasing transactionsSubject matterDevice placement

The subject disclosure relates to pre-installed software and services, such as online services, and markets for pre-installed software and online services. In one aspect, the disclosed subject matter facilitates contracting between software vendors and device manufacturers or redistributors for placement and / or conversion of software applications or services in devices. As further advantages, embodiments of the disclosed subject matter can provide transparency into markets for device placement and can facilitate detailed contract performance tracking. Further non-limiting embodiments are provided that illustrate the advantages and flexibility of the disclosed subject matter.

Owner:SWEETLABS

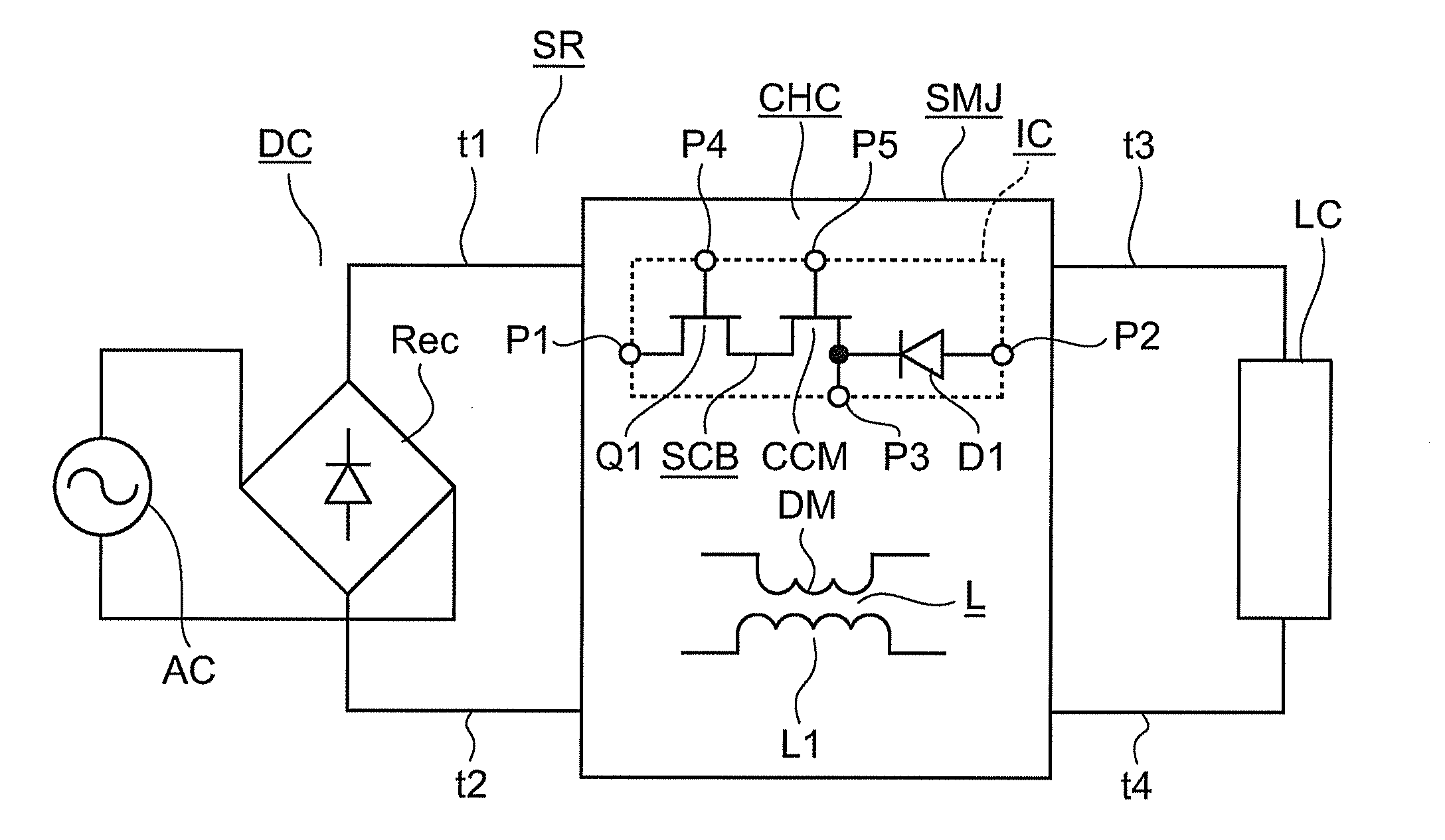

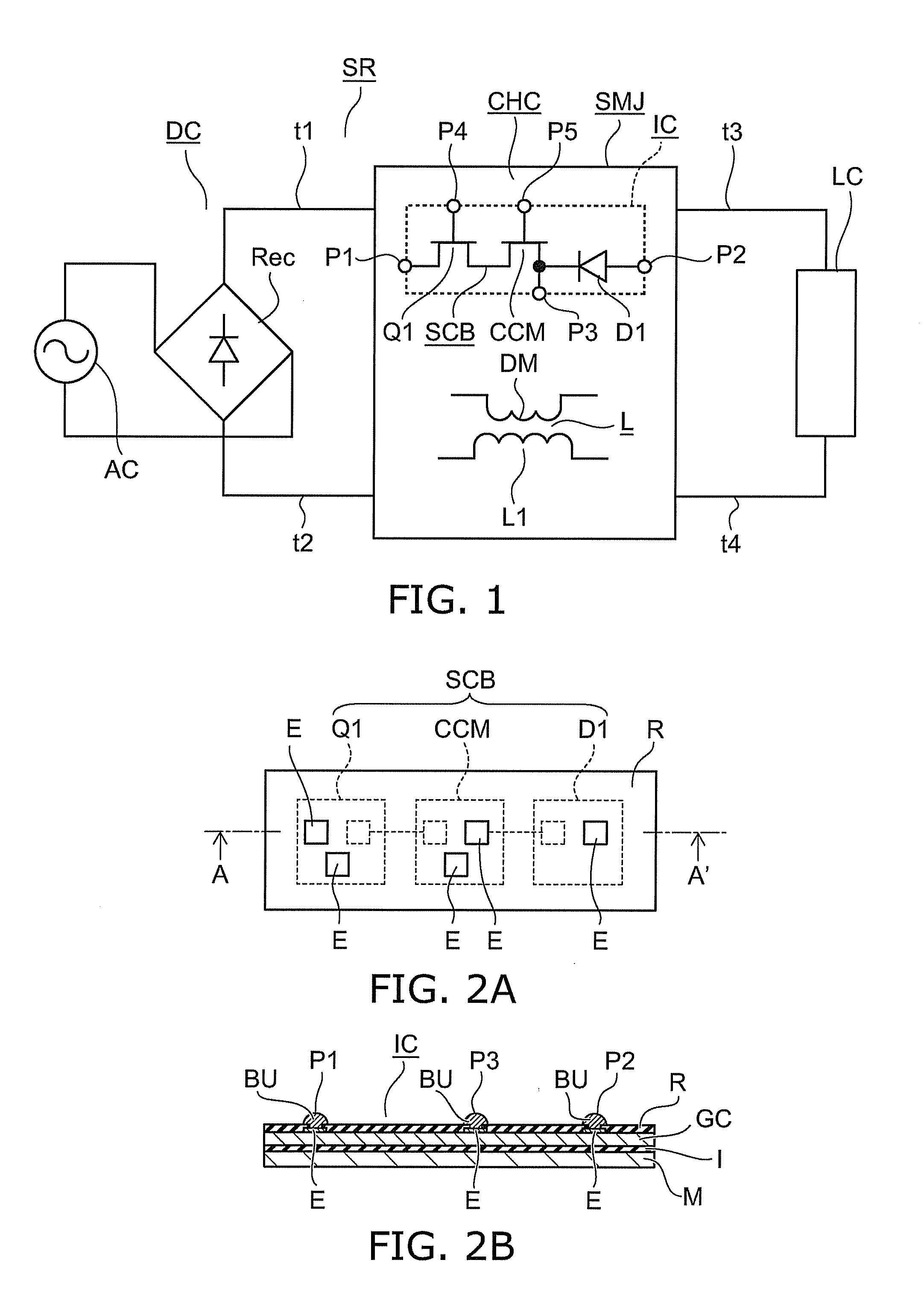

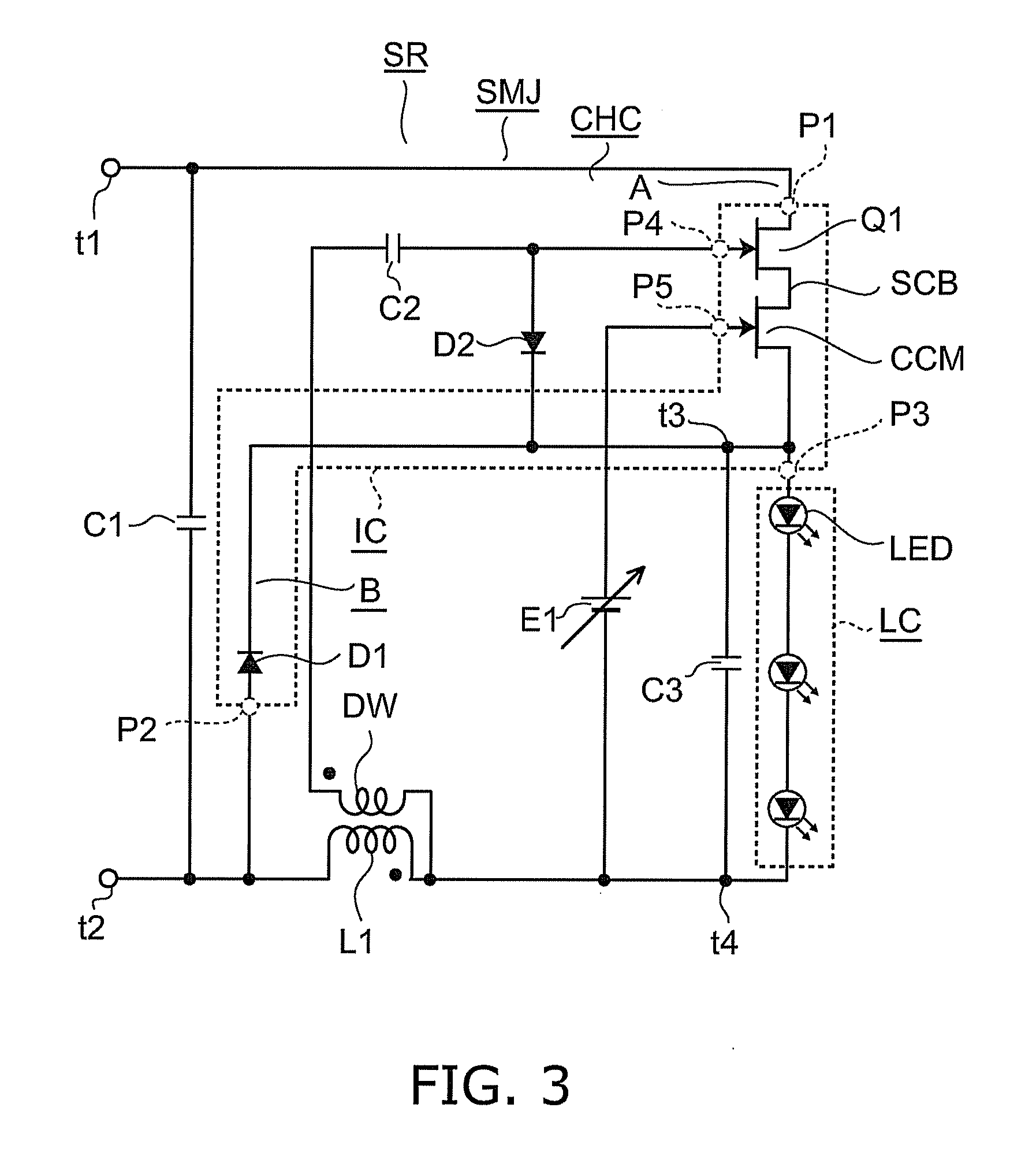

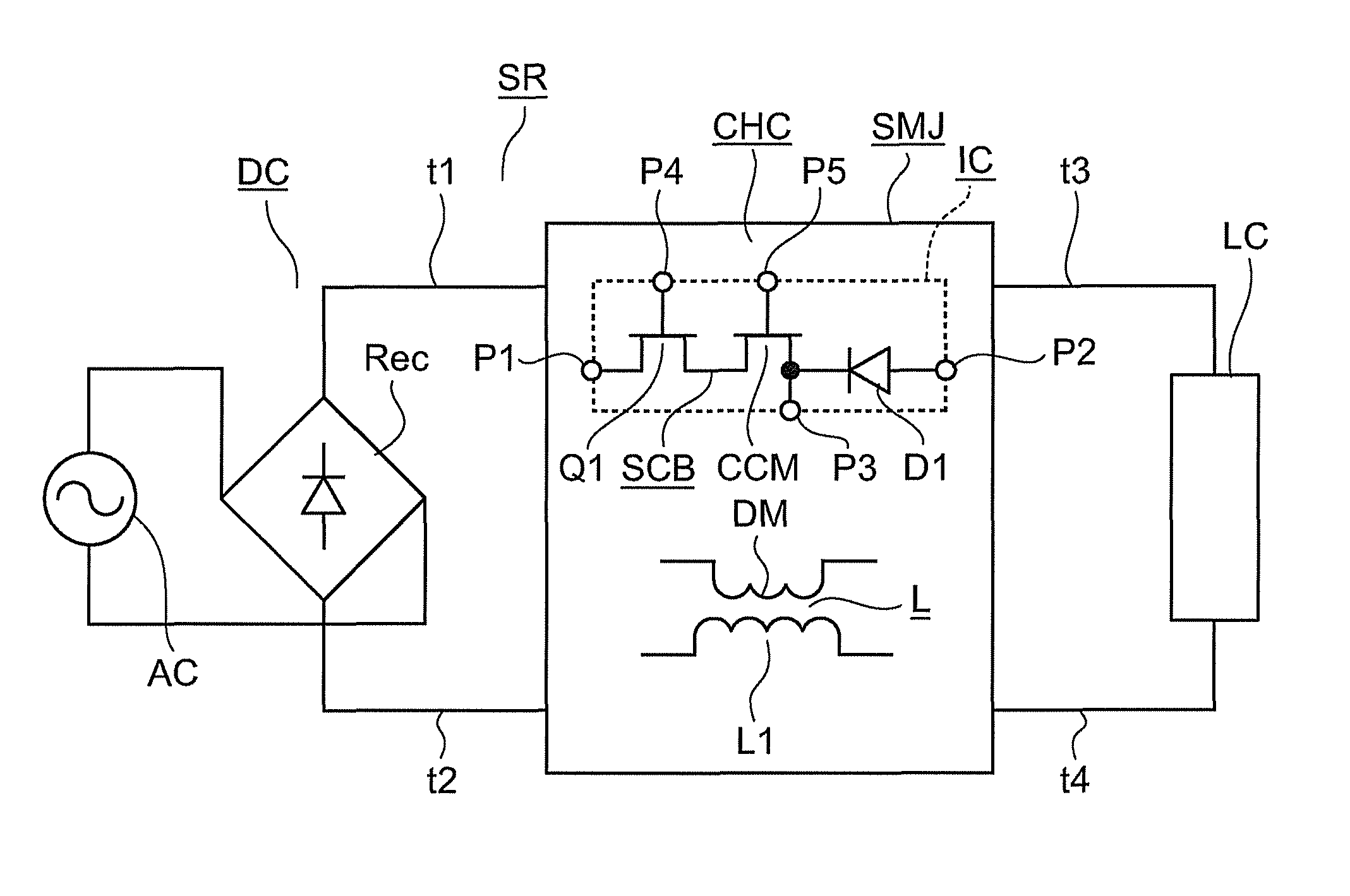

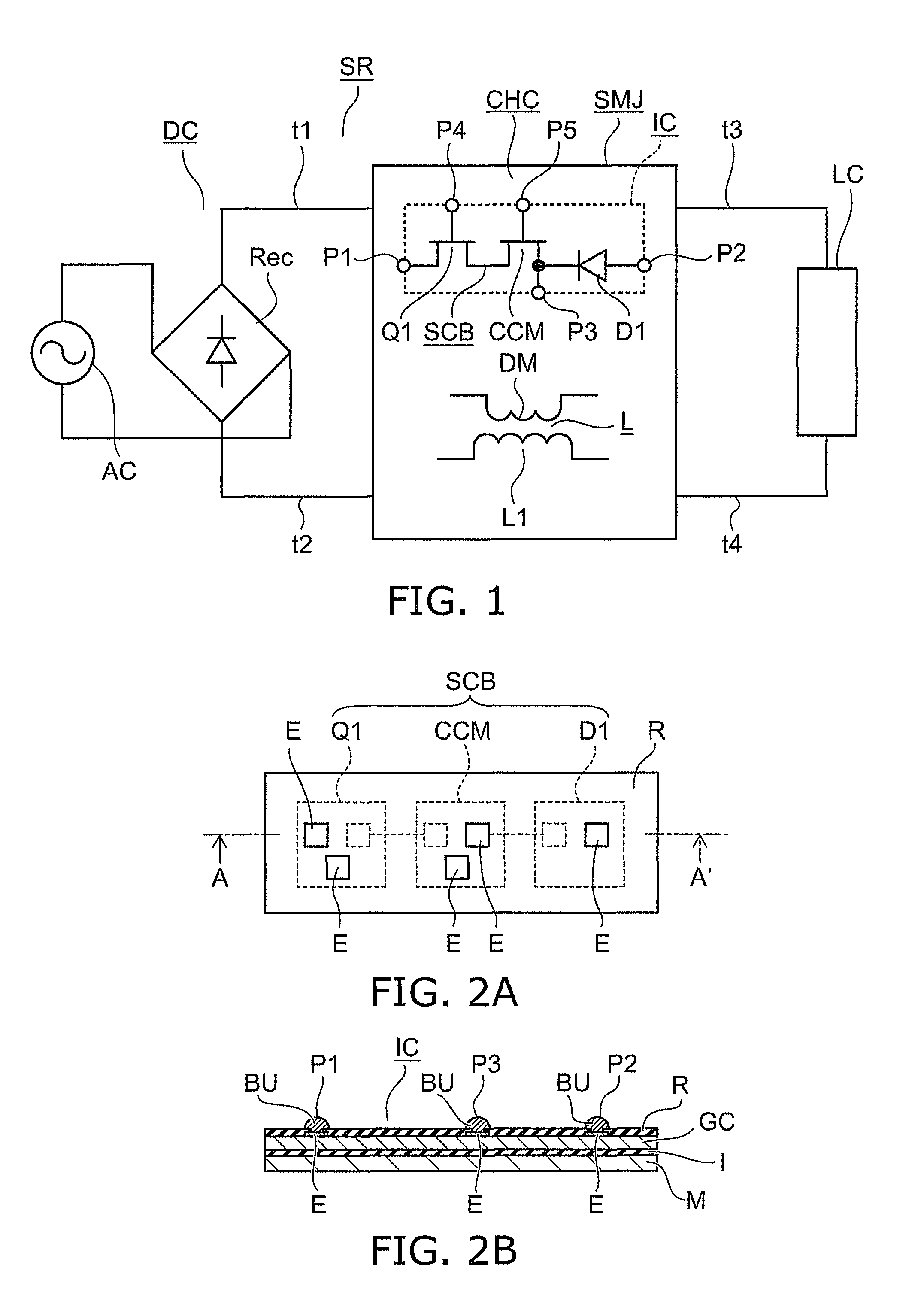

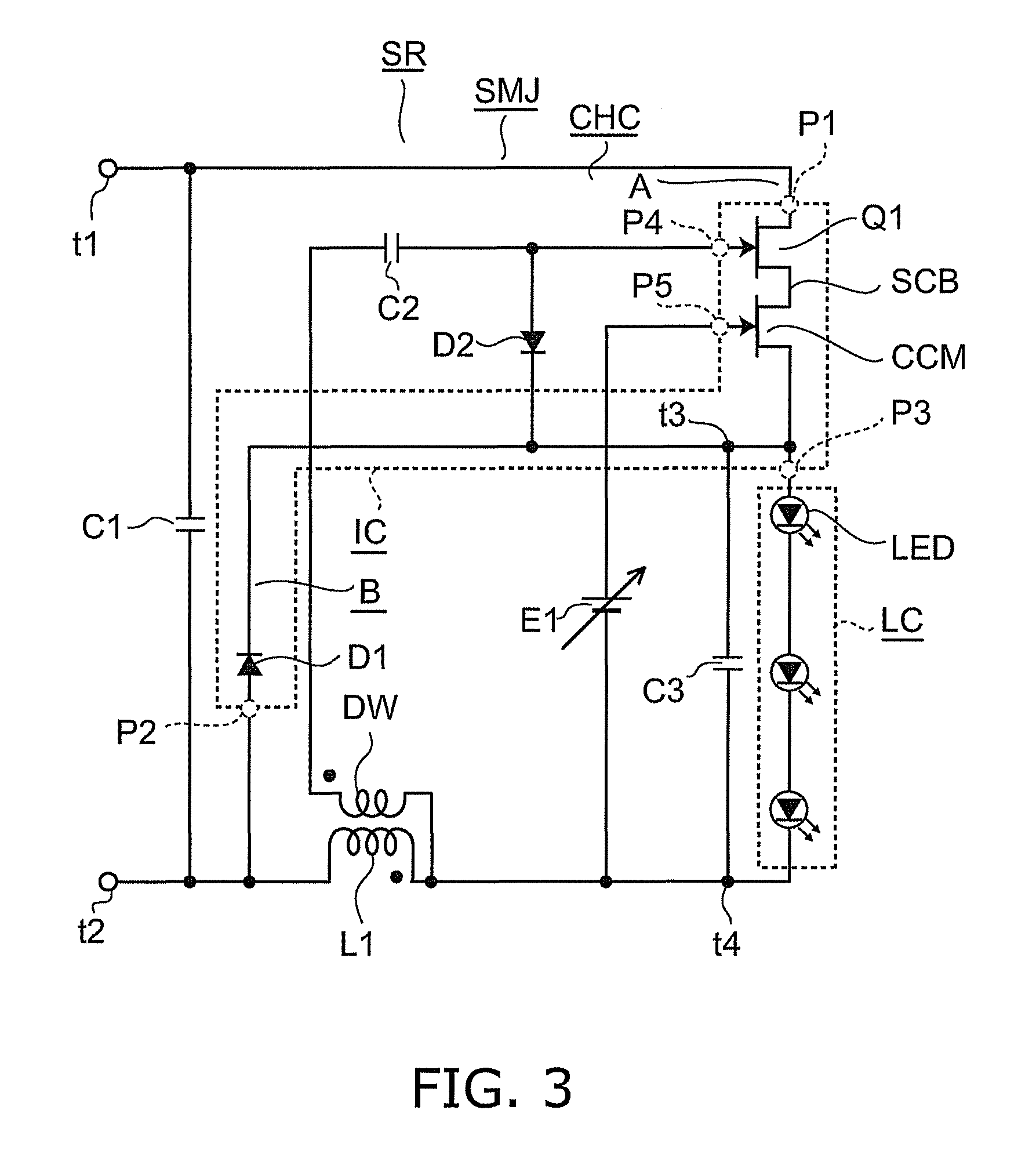

Switching power supply device, switching power supply circuit, and electrical equipment

ActiveUS20110316494A1Reduce switching powerReduce facilitationEfficient power electronics conversionSemiconductor/solid-state device detailsElectrical devicesSwitching power

According to an embodiment of the invention, there is provided a switching power supply device including an integrated body and a plurality of external terminals. In the integrated body, a first switching element, a constant current element, and a diode are connected in series. The plurality of external terminals include a first external terminal connected to a main terminal of an element disposed on one end side of the integrated body and a second external terminal connected to a main terminal of an element disposed on another end side of the integrated body.

Owner:TOSHIBA LIGHTING & TECH CORP

Shaped cutter surface

ActiveUS7798257B2Reduce certain adverse consequenceSmooth curveDrill bitsConstructionsEngineeringAbnormal shaped

Owner:SMITH INT INC

Online marketplace for pre-installed software and online services

ActiveUS8650558B2Reduce facilitationProviding transparencyComputer security arrangementsBuying/selling/leasing transactionsSubject matterDevice placement

The subject disclosure relates to pre-installed software and services, such as online services, and markets for pre-installed software and online services. In one aspect, the disclosed subject matter facilitates contracting between software vendors and device manufacturers or redistributors for placement and / or conversion of software applications or services in devices. As further advantages, embodiments of the disclosed subject matter can provide transparency into markets for device placement and can facilitate detailed contract performance tracking. Further non-limiting embodiments are provided that illustrate the advantages and flexibility of the disclosed subject matter.

Owner:SWEETLABS

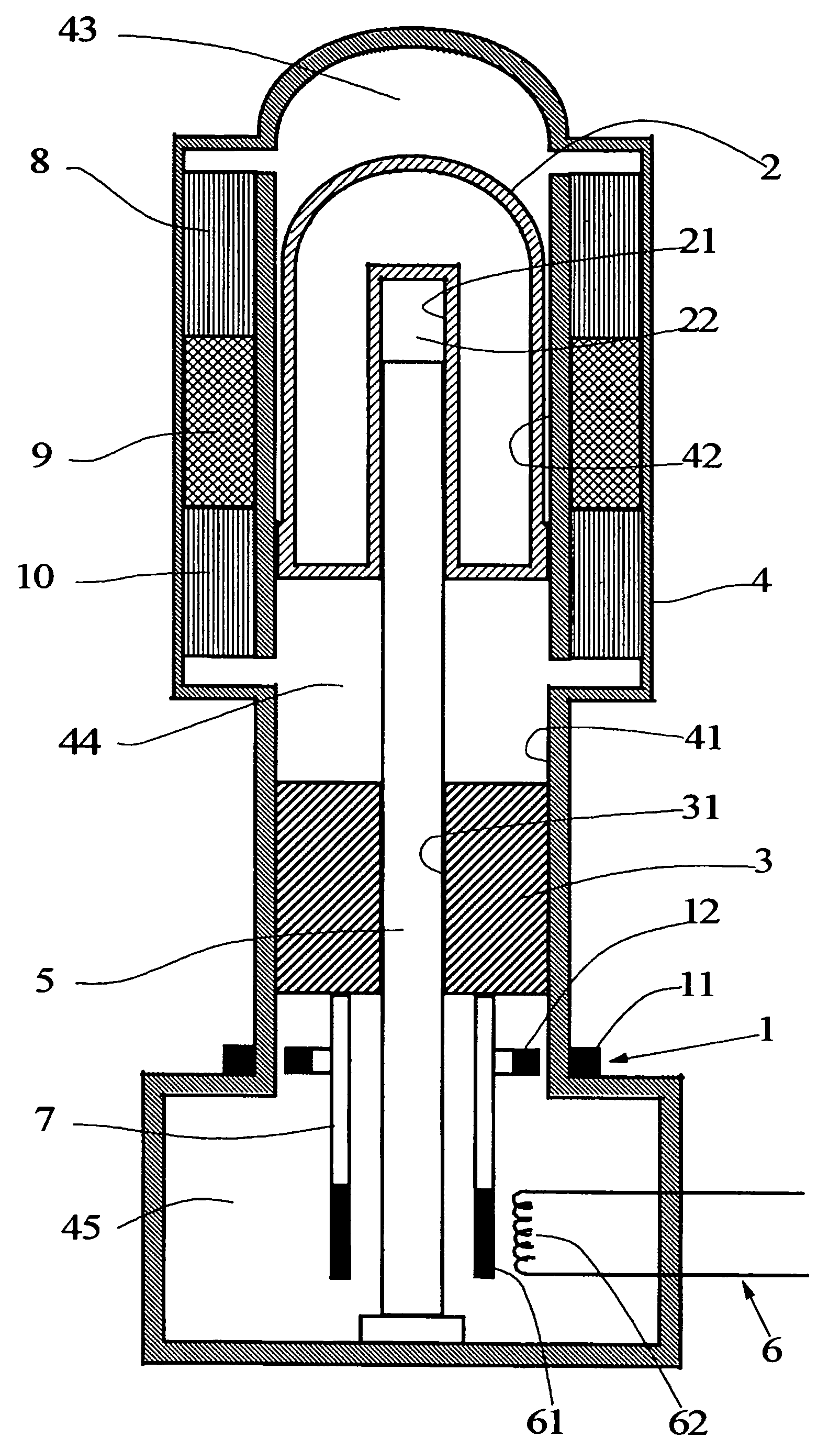

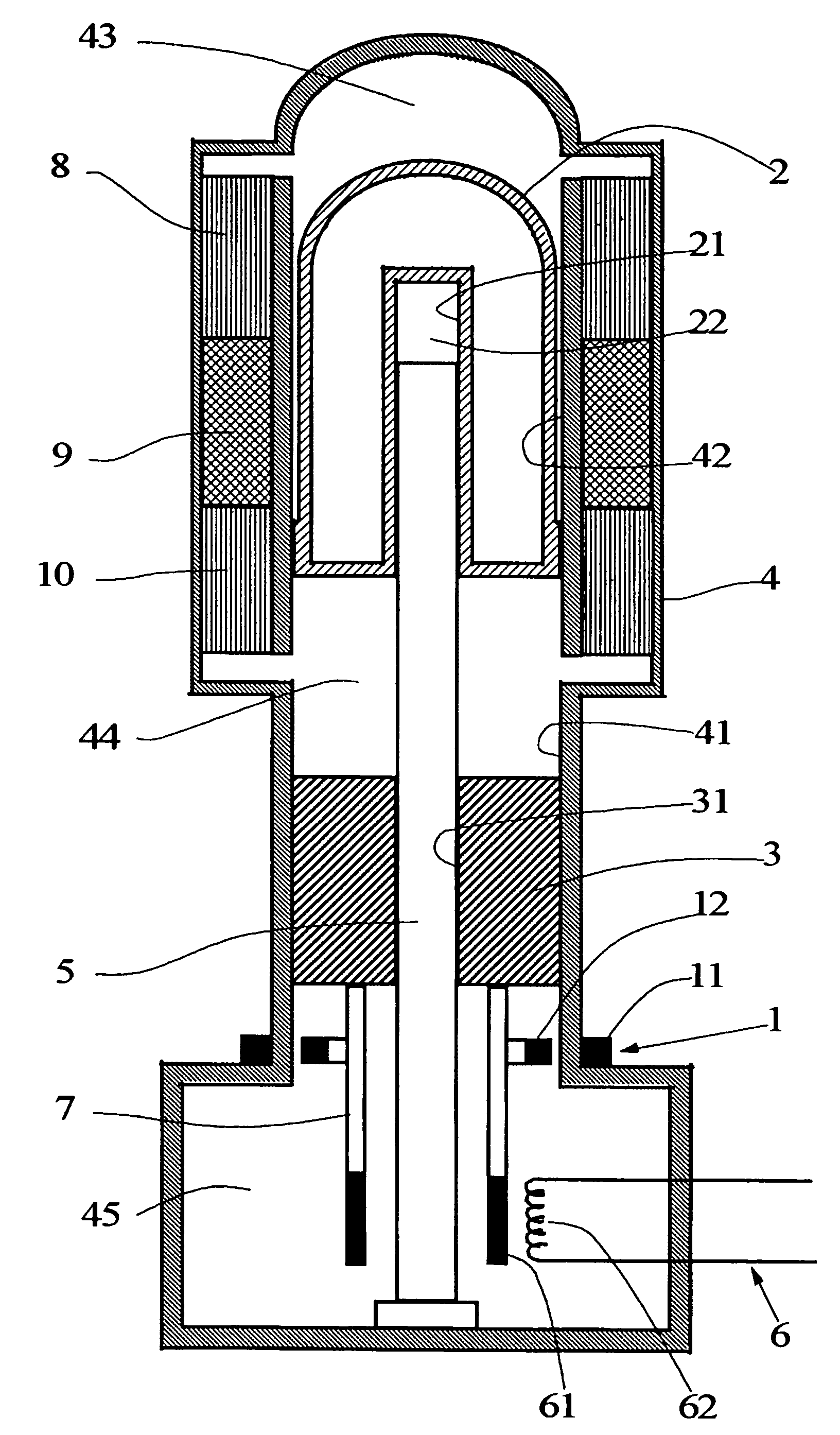

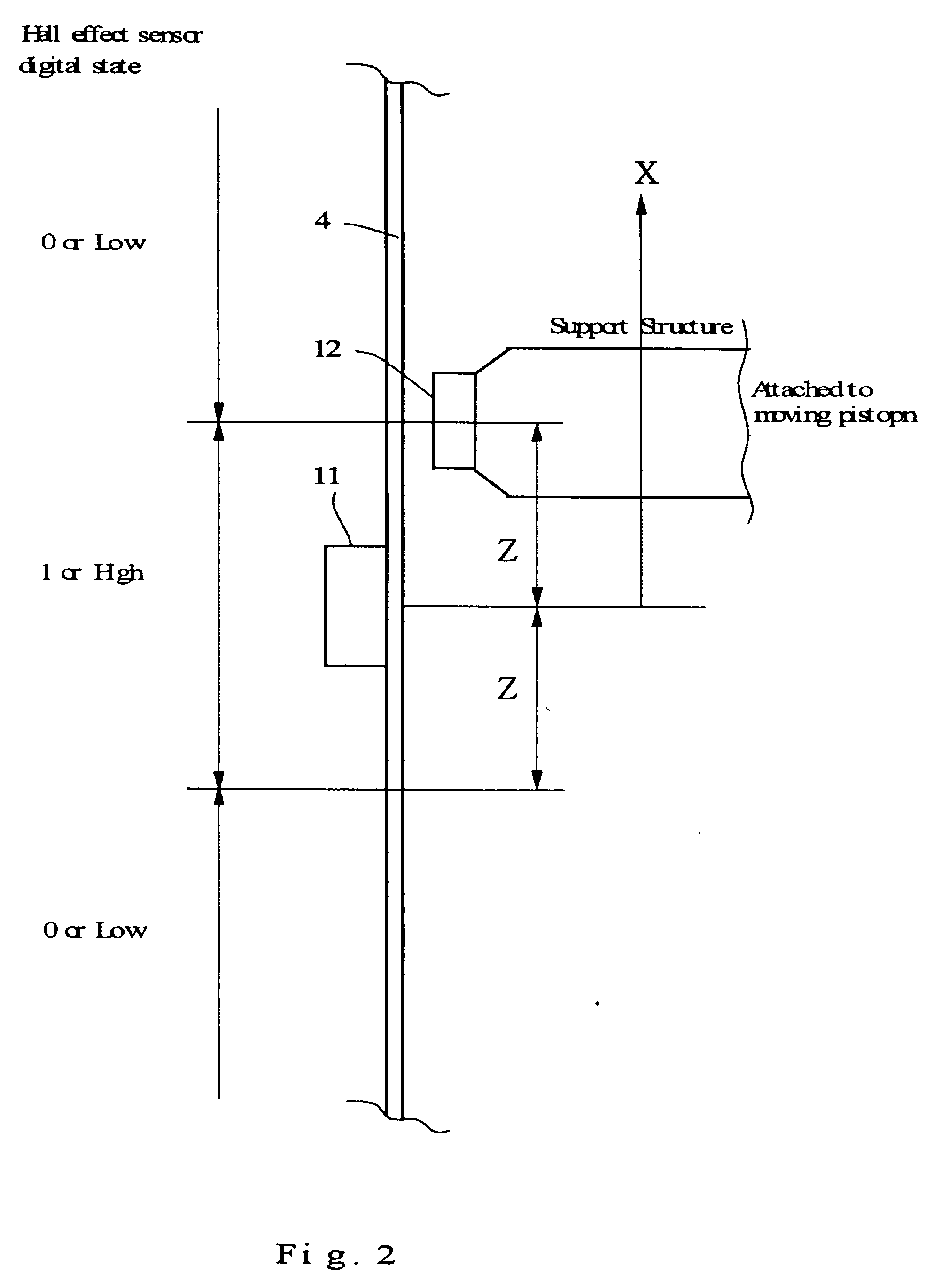

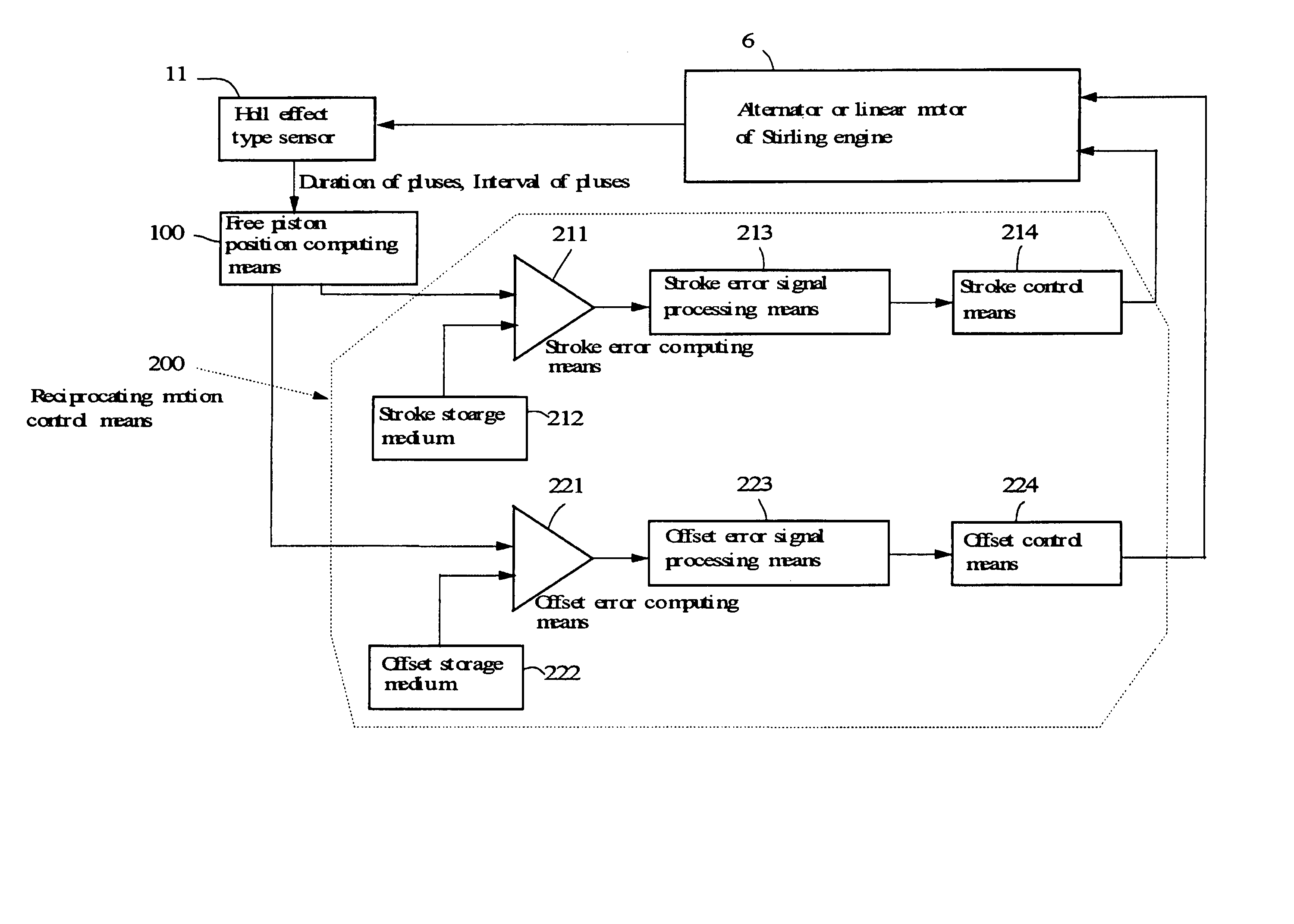

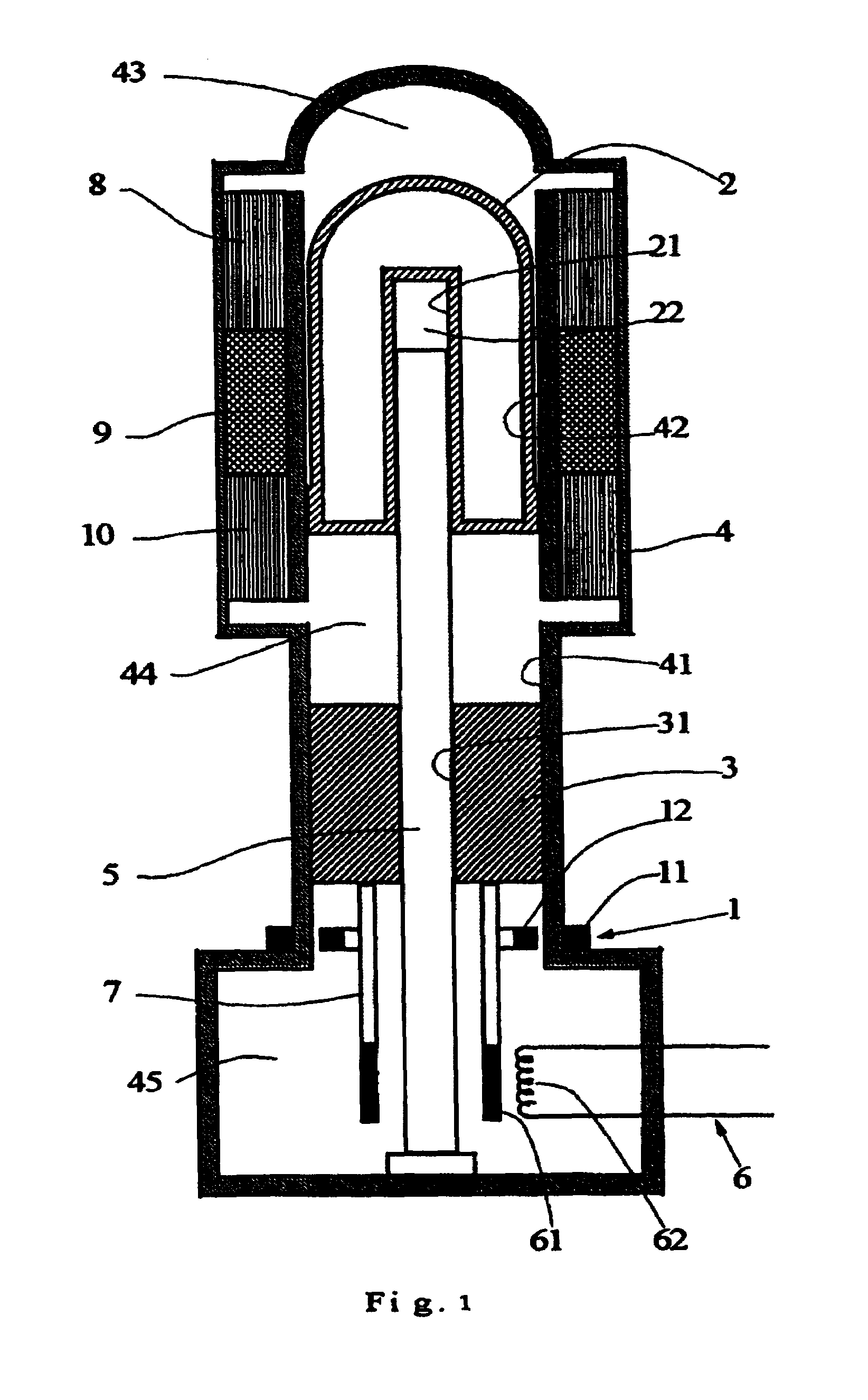

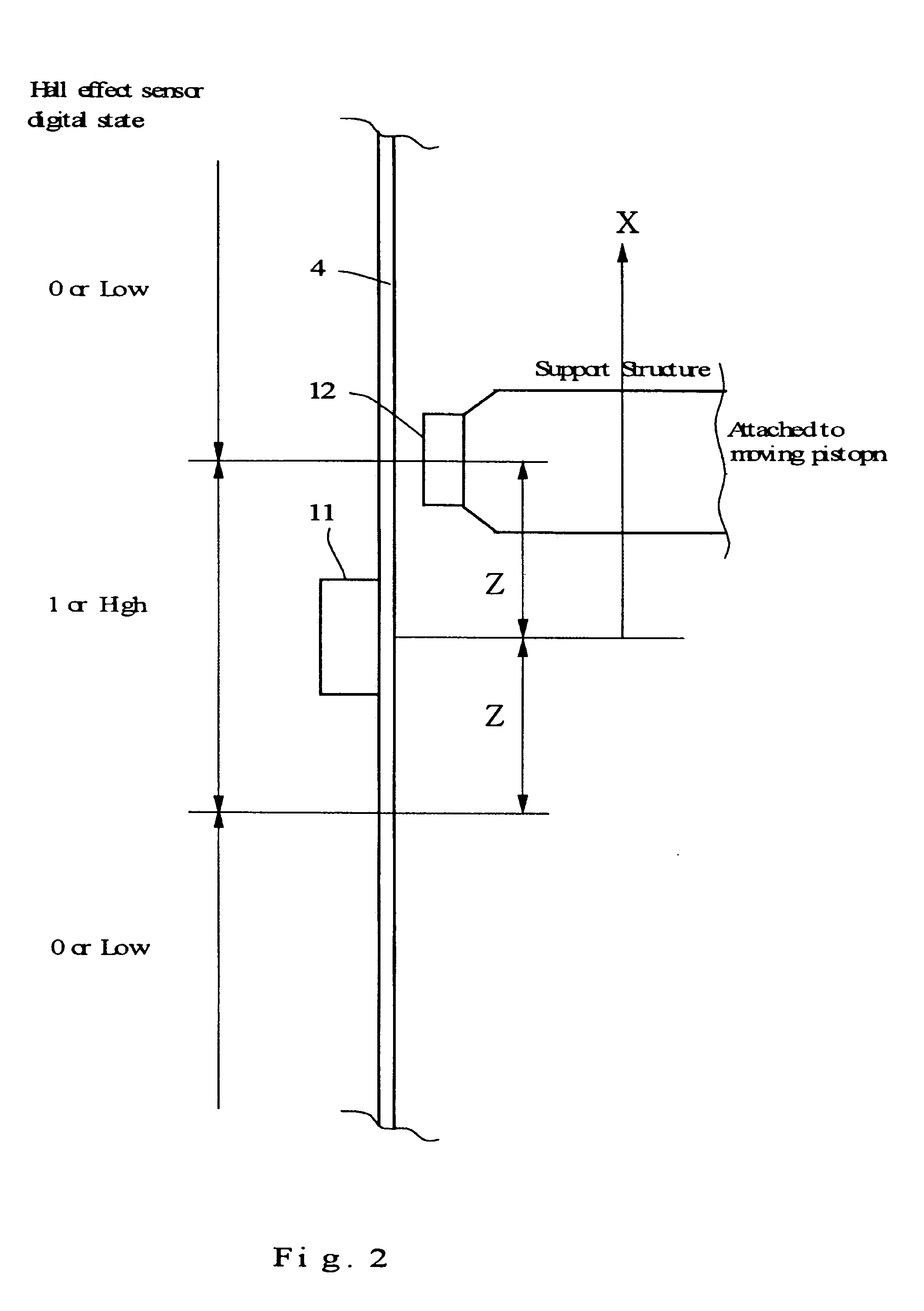

Apparatus for determining free piston position and an apparatus for controlling free piston position

ActiveUS20060119350A1Simple structureIncreased durabilitySolid-state devicesIncline measurementReciprocating motionPulse sequence

An apparatus for determining position of a free piston used in such as hydraulic compressor, which has no mechanical connection with crank shaft, and an apparatus for controlling reciprocating motion of the free piston are disclosed. A free piston position determining apparatus comprises a magnetic sensor disposed in a case containing a free piston, and a magnet disposed on the free piston. The magnet sensor generates pulse train when the magnet is positioned within a pre-determined distance form the magnet sensor. Stroke of the free piston is computed based on duration of the pulse, and offset of the average piston position from designed average position is computed based on interval of the pulse.

Owner:GLOBAL COOLING

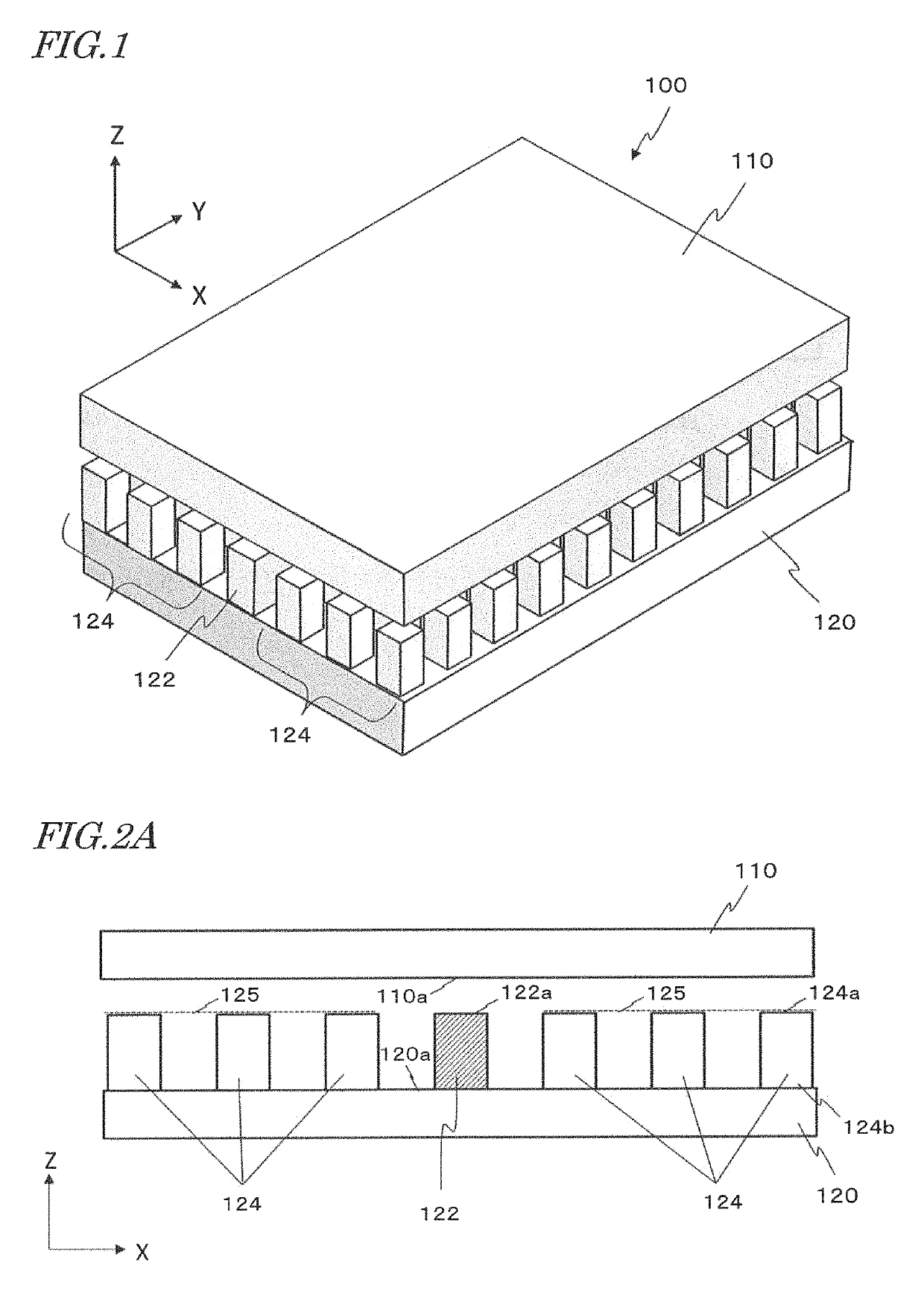

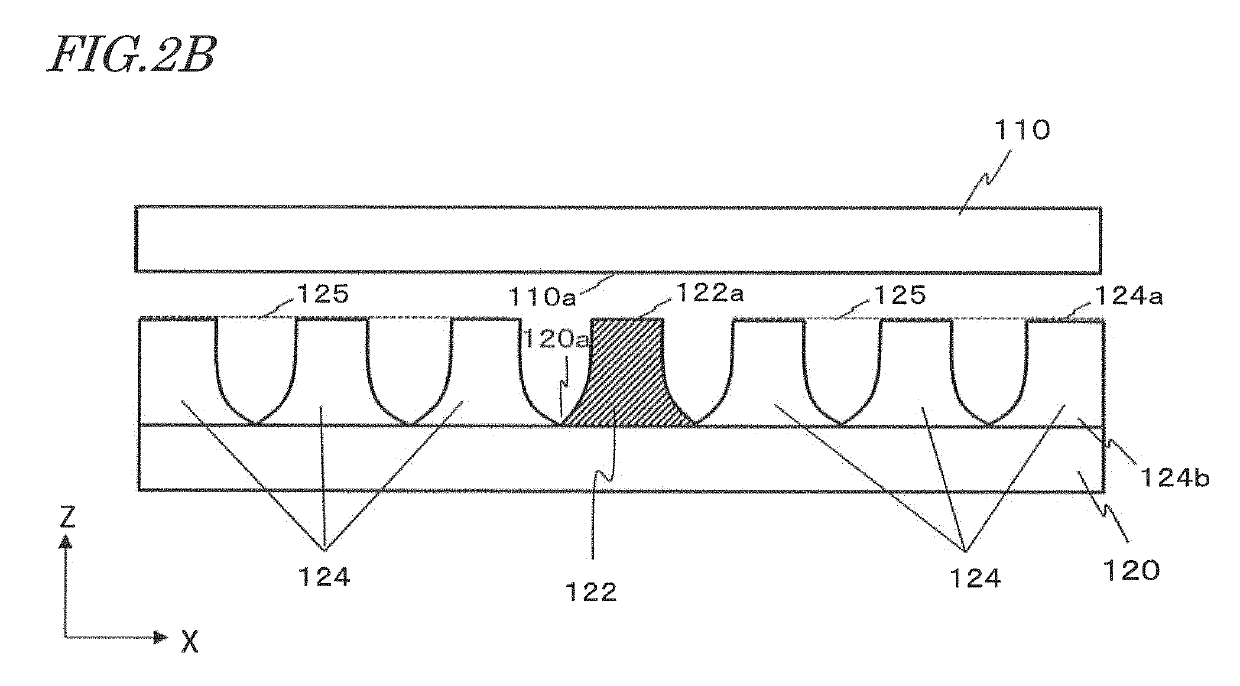

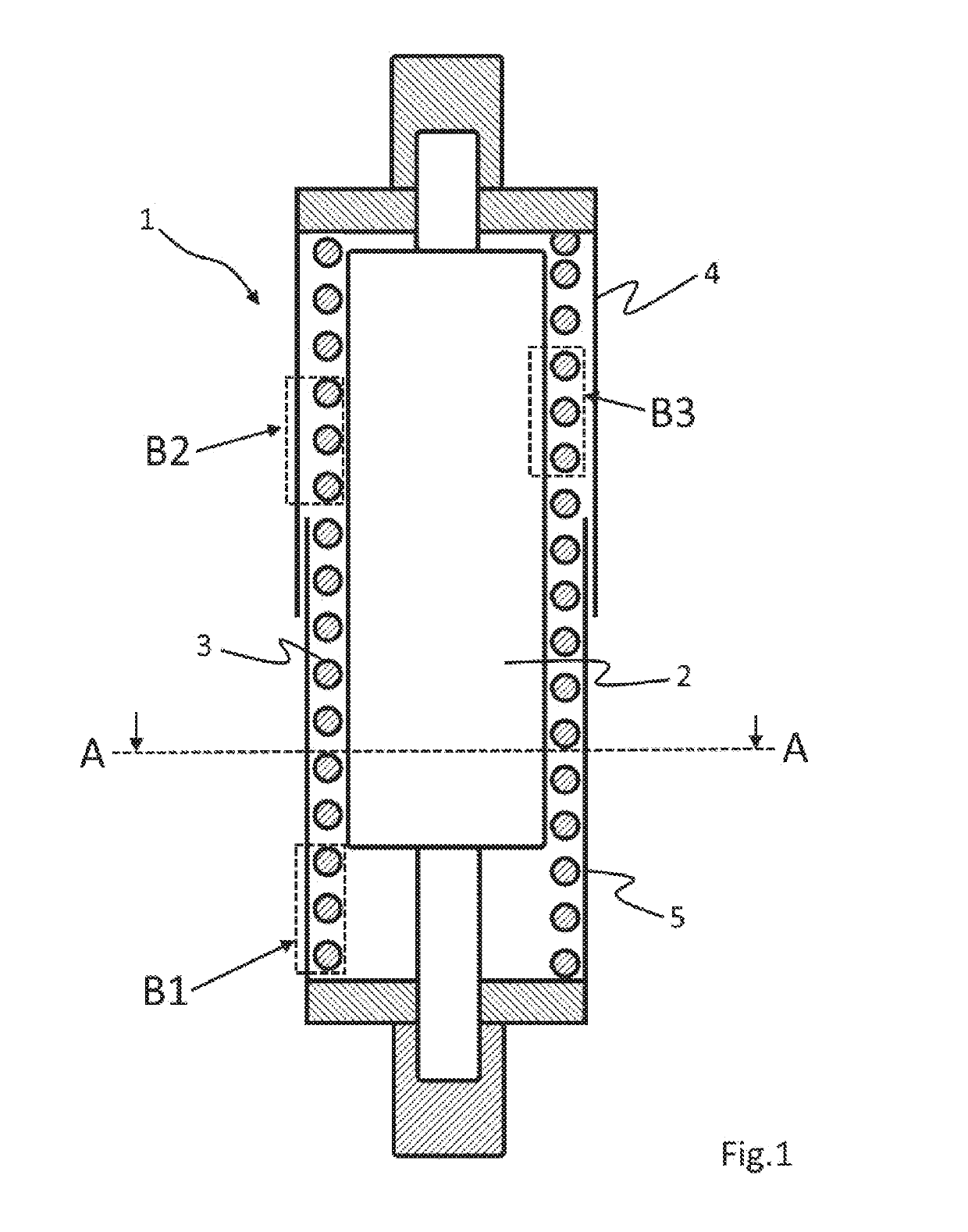

Slot array antenna, and radar, radar system, and wireless communication system including the slot array antenna

ActiveUS10381741B2Improve performanceReduce facilitationAntenna adaptation in movable bodiesLinear waveguide fed arraysCommunications systemRadar systems

A slot array antenna includes: a first conductive member having a first conductive surface and a plurality of slots therein, the slots being arrayed in a first direction and in a second direction which intersects the first direction; a second conductive member having a second conductive surface which opposes the first conductive surface; a plurality of waveguide members arrayed between the first and second conductive members along a direction which intersects the first direction, each waveguide member having an conductive waveguide face which extends along the first direction so as to oppose at least one of the slots; and an artificial magnetic conductor in a subregion which is within a region between the first and second conductive members but outside of a subregion containing the waveguide members. Neither an electric wall nor an artificial magnetic conductor exists in a space between two adjacent waveguide faces among the waveguide members.

Owner:NIDEC ELESYS CORP +1

Apparatus for determining free piston position and an apparatus for controlling free piston position

ActiveUS7075292B2Simple structureIncreased durabilitySolid-state devicesIncline measurementReciprocating motionPulse sequence

An apparatus for determining position of a free piston used in such as hydraulic compressor, which has no mechanical connection with crank shaft, and an apparatus for controlling reciprocating motion of the free piston are disclosed. A free piston position determining apparatus comprises a magnetic sensor disposed in a case containing a free piston, and a magnet disposed on the free piston. The magnet sensor generates pulse train when the magnet is positioned within a pre-determined distance form the magnet sensor. Stroke of the free piston is computed based on duration of the pulse, and offset of the average piston position from designed average position is computed based on interval of the pulse.

Owner:GLOBAL COOLING

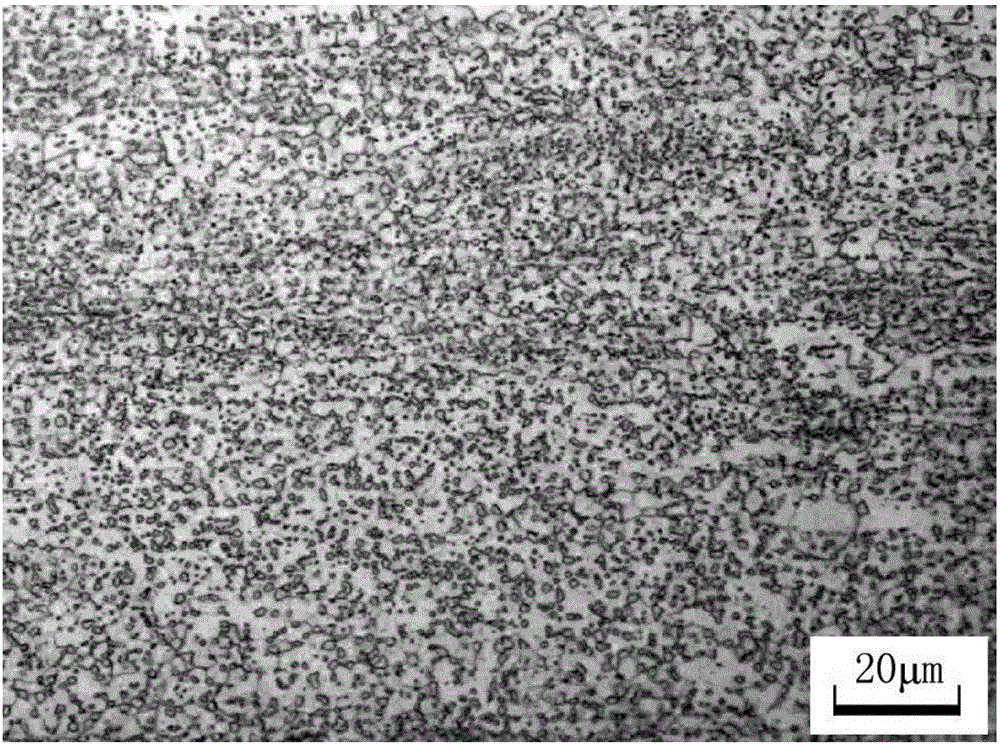

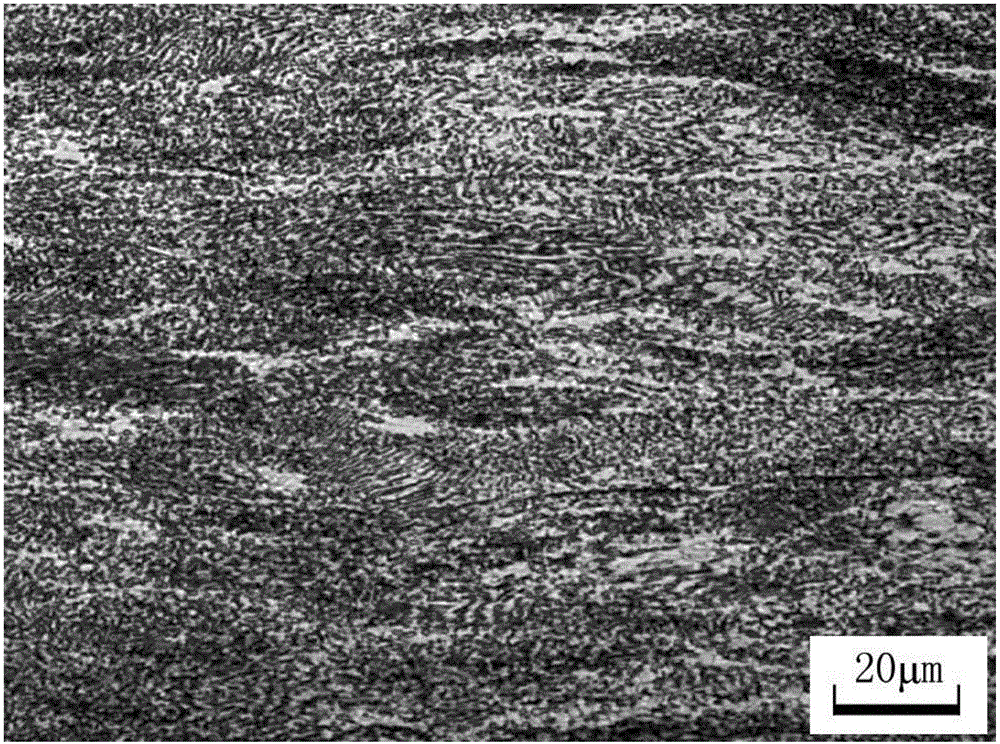

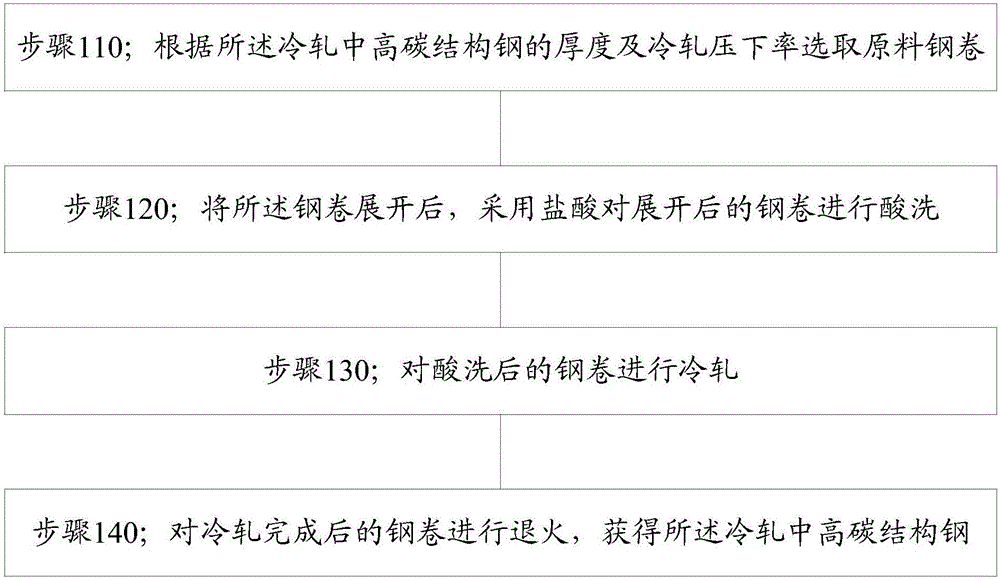

Manufacturing method of cold-rolled medium-high carbon structural steel

The invention discloses a manufacturing method of cold-rolled medium-high carbon structural steel. The steel is prepared from components in percentage by weight as follows: 0.30%-0.70% of C, 0.15%-0.35% of Si, 0.10%-1.20% of Mn, 0.10%-1.10% of Cr, less than or equal to 0.030% of Alt, less than or equal to 0.020% of P, less than or equal to 0.010% of S, no more than 0.3% of other added alloy elements and the balance of Fe and inevitable impurity elements. According to the manufacturing method, one-time annealing and one-time cold-rolling are adopted, a raw material steel coil can be cold-rolled directly by controlling hot rolling process parameters, the cold-rolling reduction ratio is larger than or equal to 50%, deformation can infiltrate the structural core part, lamellar carbide in a hot-rolled raw material pearlite structure is broken through cold-rolling deformation, a lot of dislocation is produced in grains, the broken carbide and defects provide a core for separation of carbide in the annealing process, the uniform structure and the tiny carbide are obtained, and technical effects of improving the production efficiency and reducing the cost are realized.

Owner:武汉钢铁有限公司

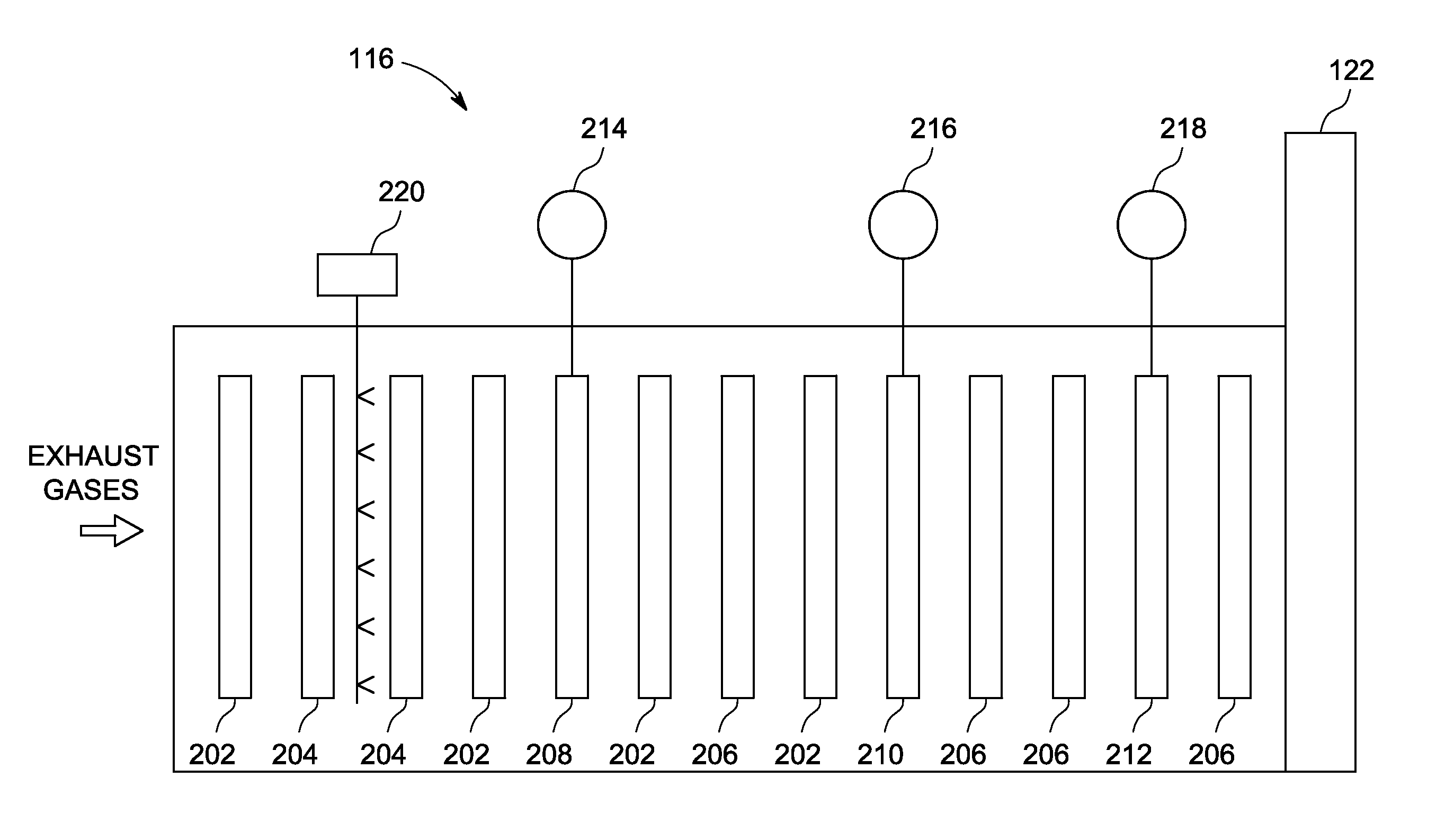

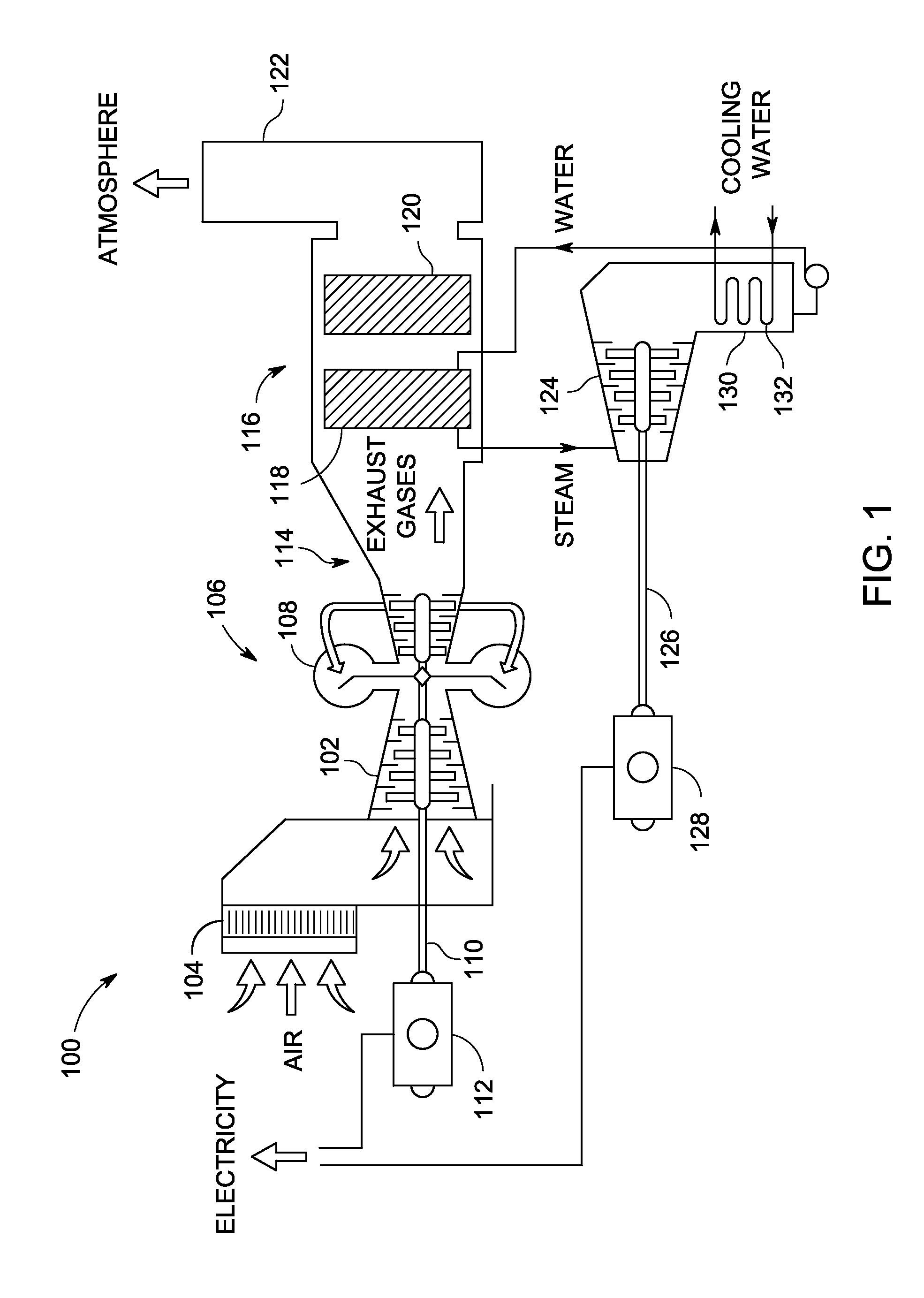

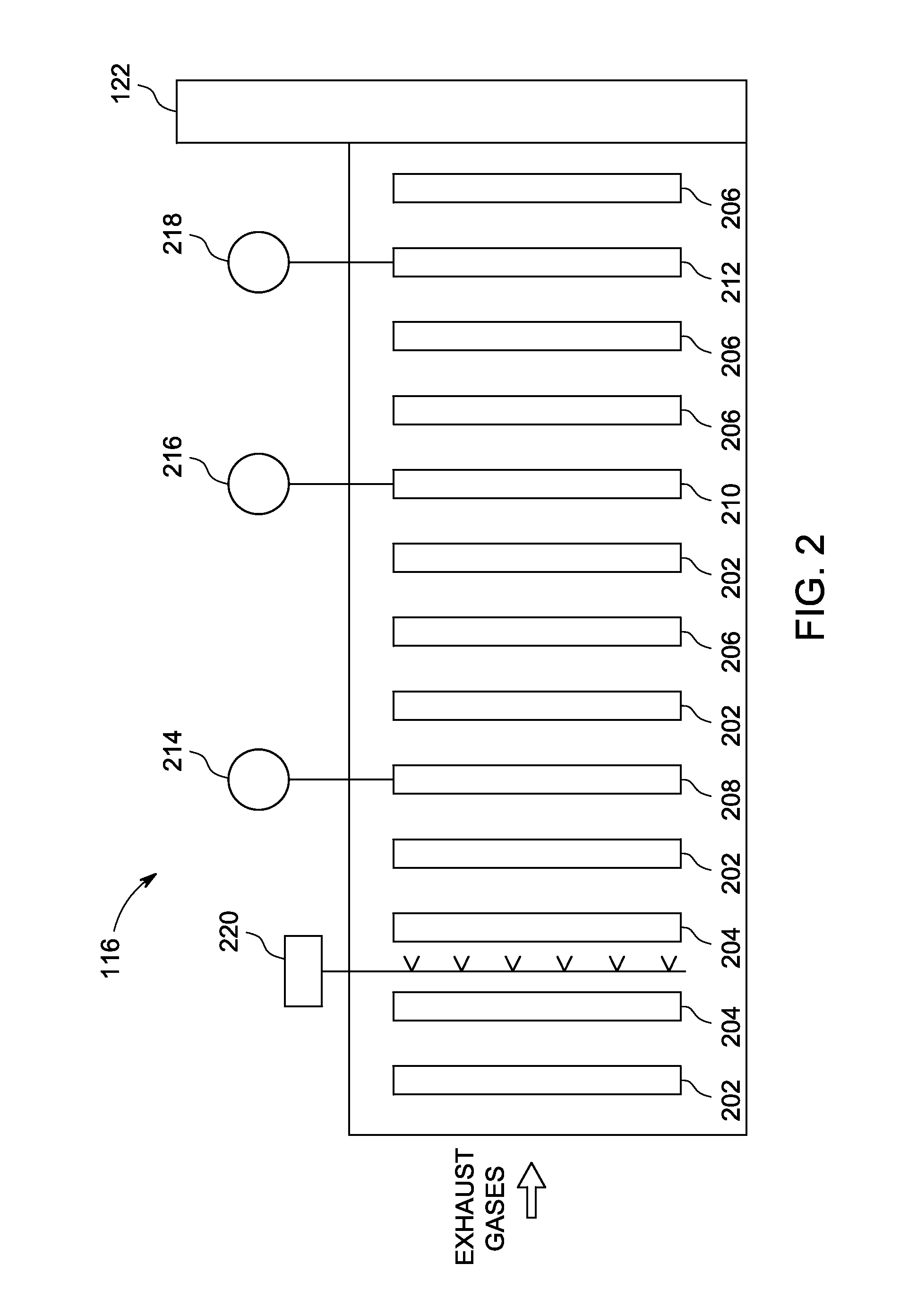

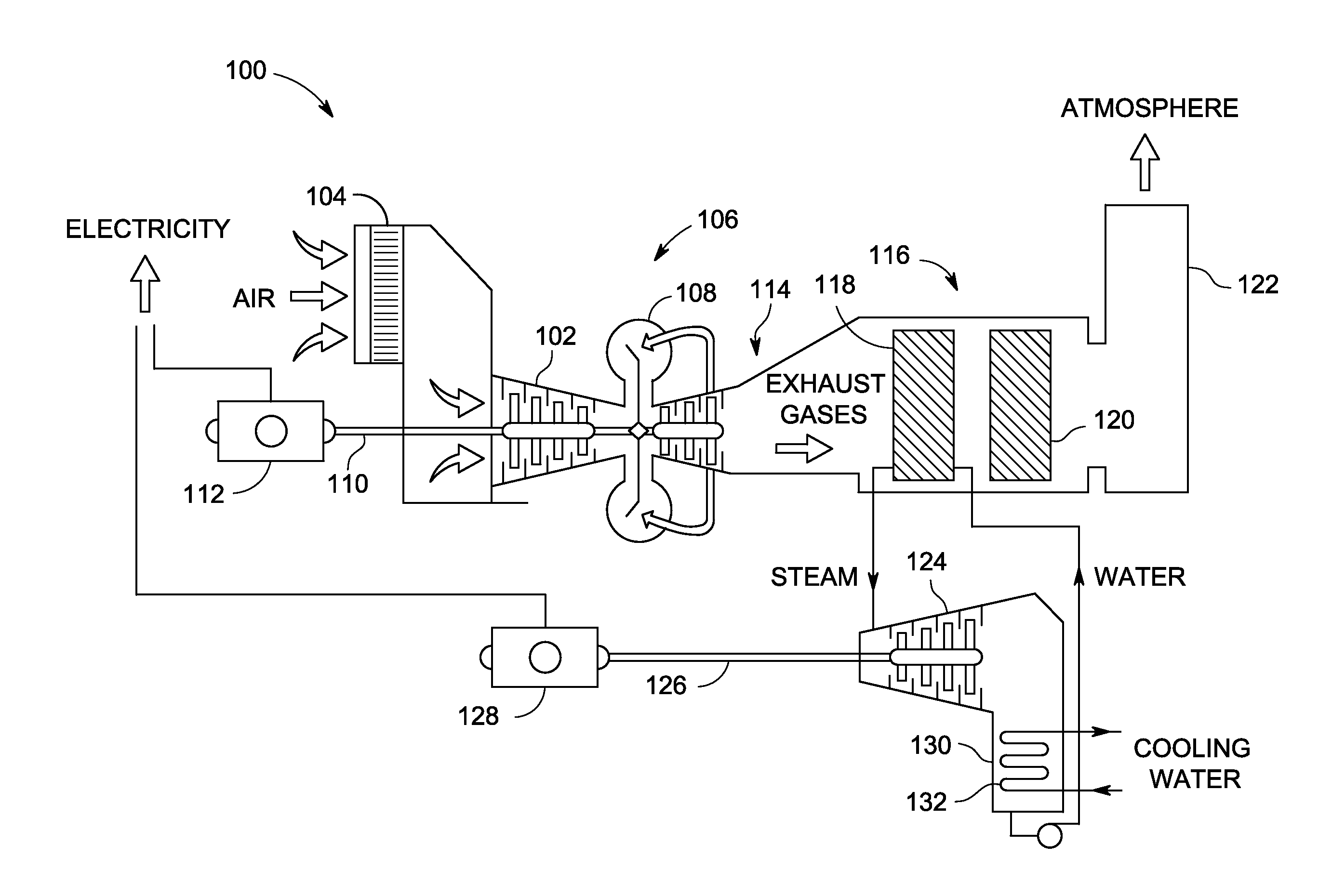

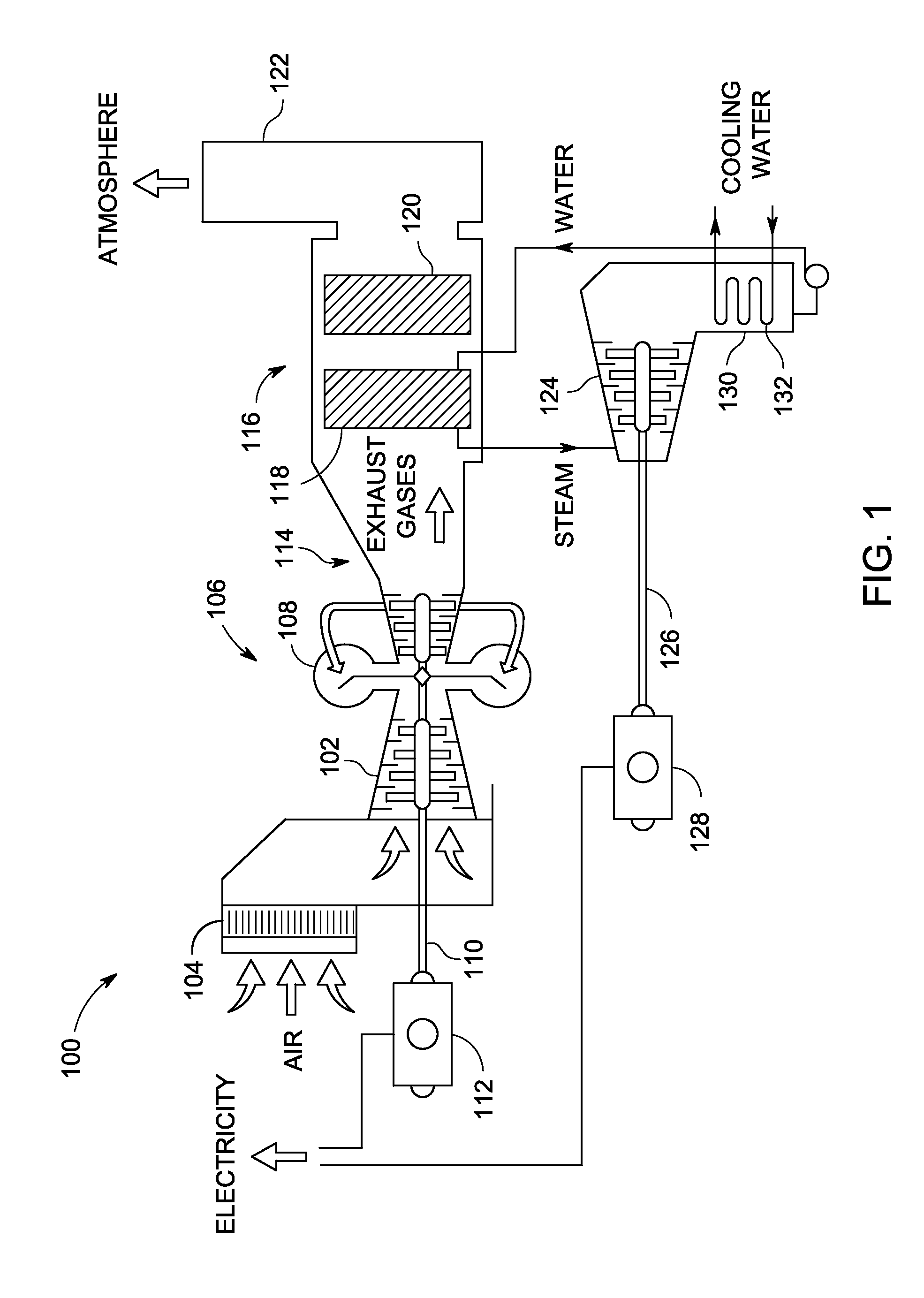

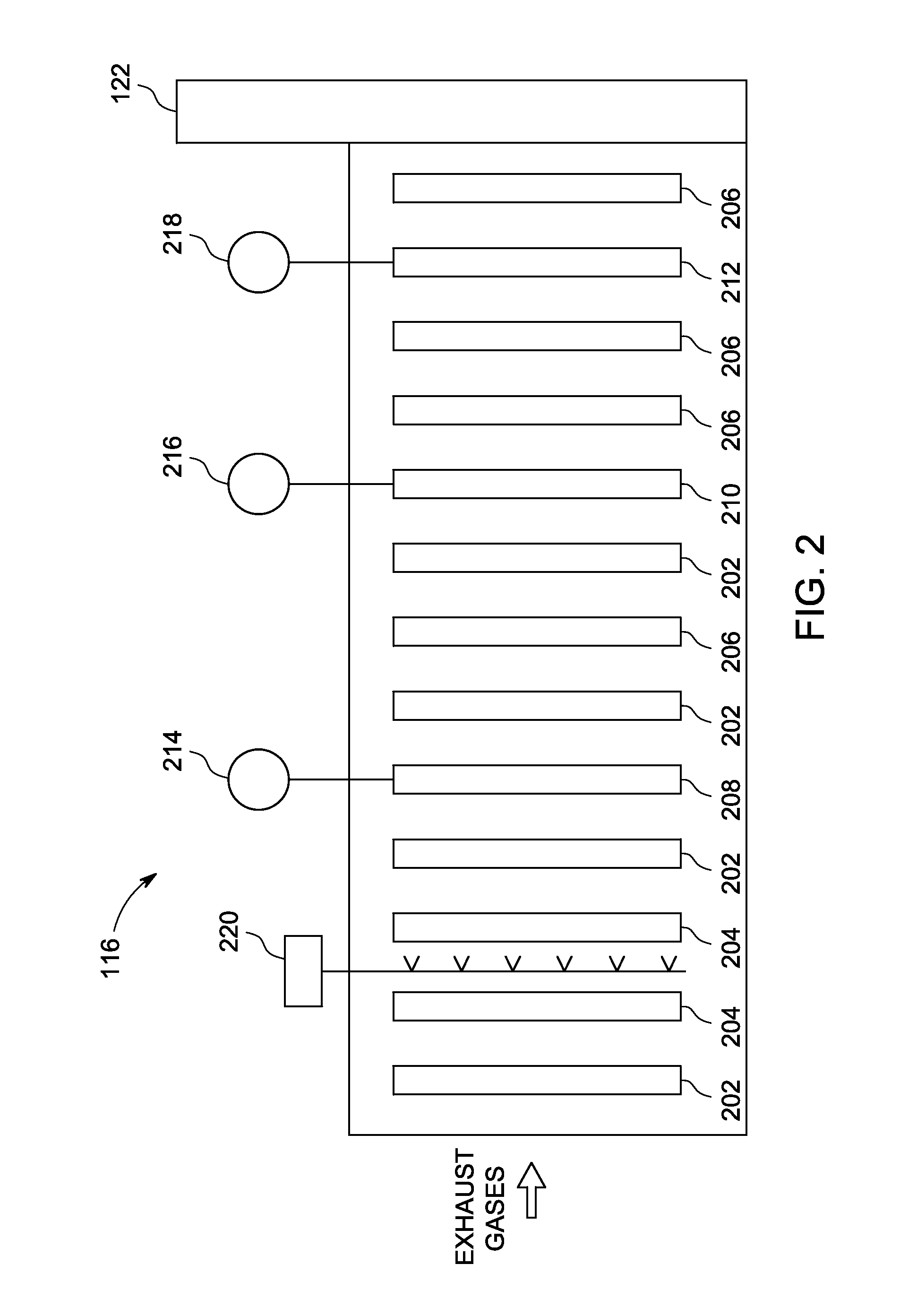

Systems, methods, and apparatus for regenerating a catalytic material

ActiveUS20120102970A1Reduce the amount requiredReduce facilitationExhaust apparatusUsing liquid separation agentCombustionNitrogen

A steam generator coupled in flow communication downstream from a combustion device that produces a flow of exhaust gases includes a heating device configured to heat the exhaust gases that include oxides of nitrogen (NOx), and an oxidation catalyst coupled downstream from the heating device. The oxidation catalyst facilitates reducing an amount of NOx in the exhaust gases channeled into the oxidation catalyst at a first temperature that is less than a thermal regeneration temperature for a catalytic material and at a second temperature that is approximately equal to at least the thermal regeneration temperature such that the catalytic material is simultaneously regenerated.

Owner:GENERAL ELECTRIC CO

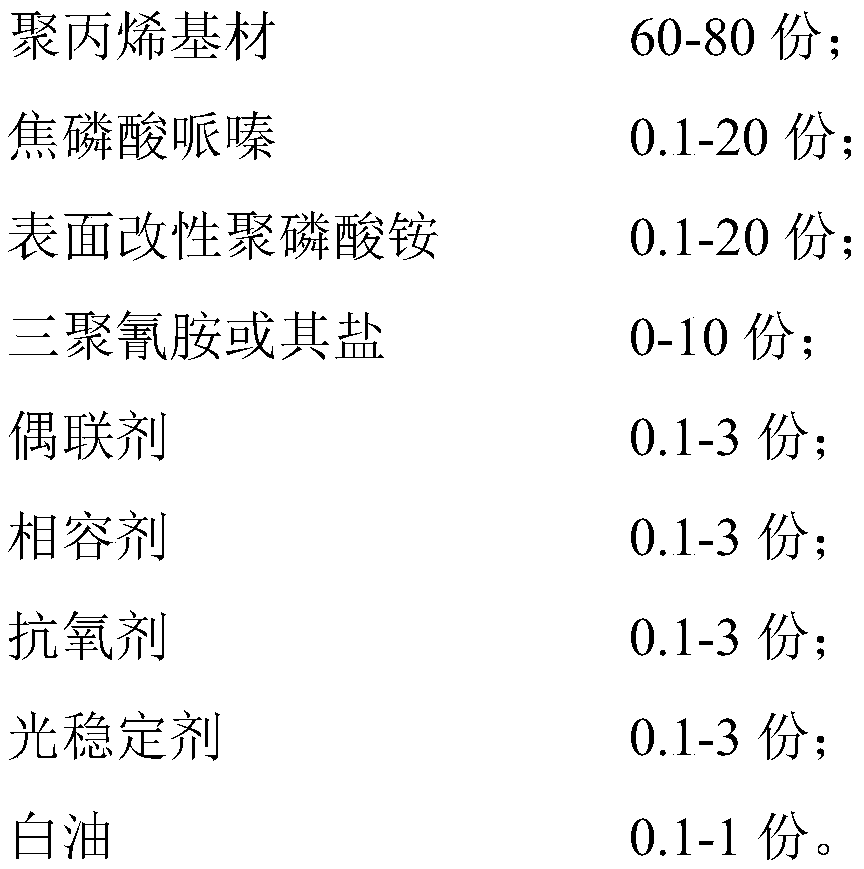

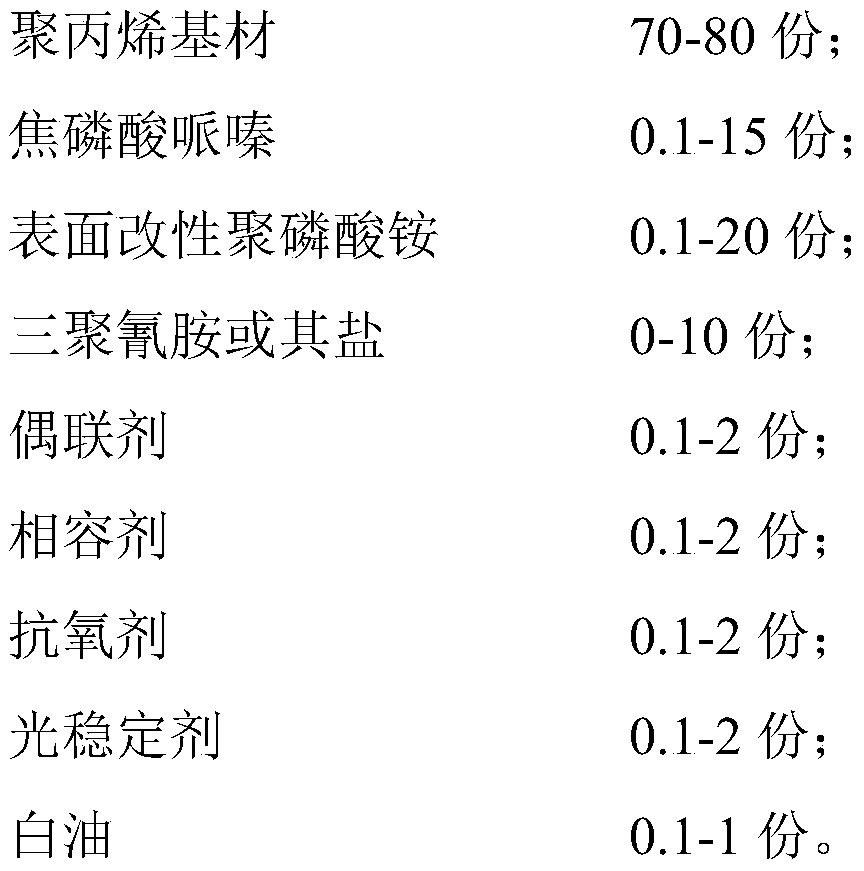

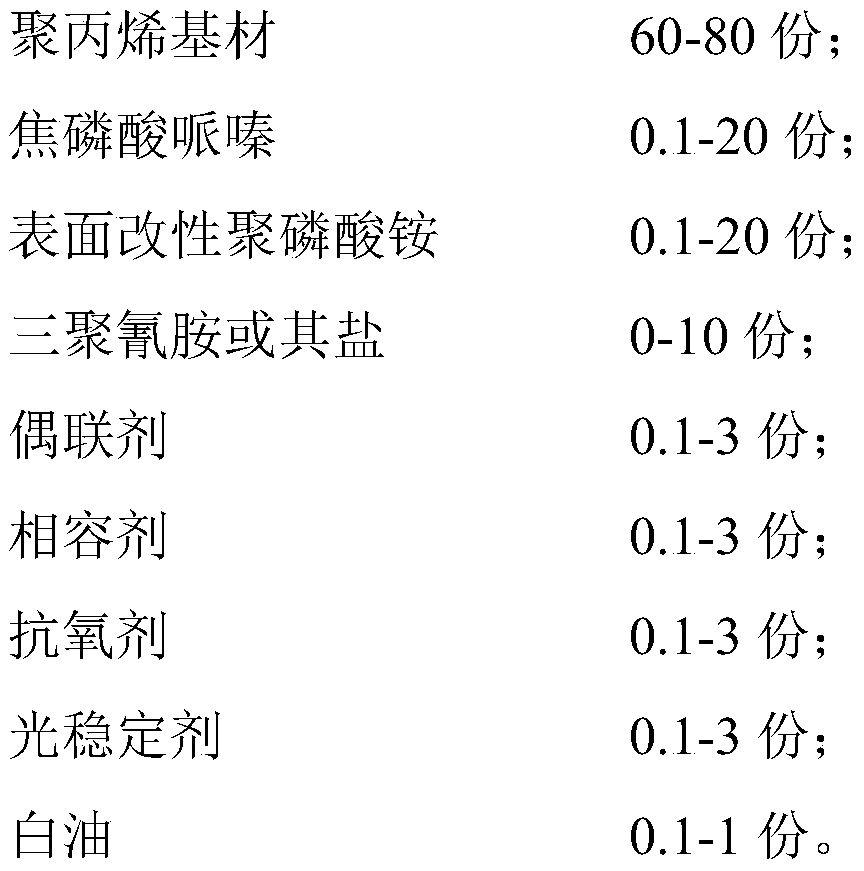

High-melt-index halogen-free flame-retardant polypropylene material and preparation method thereof

The invention relates to a high-melt-index halogen-free flame-retardant polypropylene material and a preparation method thereof. The high-melt-index halogen-free flame-retardant polypropylene materialcomprises the following components in parts by weight: 60 to 80 parts of polypropylene base material, 0.1 to 20 parts of pyrophosphoric acid piperazine, 0.1 to 20 parts of surface modified ammonium polyphosphate, 0 to 10 parts of melamine or salt thereof, 0.1 to 3 parts of coupling agent, 0.1 to 3 parts of compatilizer, 0.1 to 3 parts of antioxygen, 0.1 to 3 parts of light stabilizer, and 0.1 to1 part of white oil. The preparation method comprises the steps of weighing the raw materials in parts by weight, premixing the dried polypropylene base material and the dried white oil in a dual-motion mixer for 5 to 8 minutes, and uniformly mixing; adding the pyrophosphoric acid piperazine, the surface modified ammonium polyphosphate, the melamine or the salt thereof, the coupling agent, the campatilizer, the antioxygen and the light stabilizer according to the parts by weight, and continuously mixing for 5 to 8 minutes so as to obtain a uniform mixture; and putting in a charging hole of a double-screw extruder, mixing and extruding the materials through a screw rod, and extruding from a die head. Compared with the prior art, the halogen-free polypropylene material provided by the invention can effectively solve the problems such as high pollution of a traditional triazine carbon-forming agent system, poor compatibility of a flame retardant and a matrix, and low flame retardant efficiency.

Owner:SHANGHAI RES INST OF CHEM IND

A triptolide composite preparation for treating osteoarthritis by joint intracavity injection

InactiveCN1864662AReduce doseSmall toxicityOrganic active ingredientsPharmaceutical delivery mechanismSide effectAlcohol

The present invention relates to one kind of compound triptolide alcohol preparation for being injected into articular cavity to treat osteoarthritis. It includes triptolide alcohol solution of 1*10<-4> to 5*10<-2> mg / ml concentration and gel liquid mixed in the volume ratio of 1 to 1-9. It has medicine slow releasing effect, and this can prolong the action period of medicine, reduce consumption of triptolide alcohol and lower the toxic side effect of the medicine. It can inhibit the further development of osteoarthritis in early and middle phase, improve the environment inside the joint and promote the regeneration and repair of articular cartilage to reach the aim of cure osteoarthritis.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Hybrid electric tool carrier

InactiveUS20060090437A1Facilitates better placementSimple structureMowersGas pressure propulsion mountingDrive wheelVehicle frame

A hybrid utility vehicle includes a tool-supporting frame and an electrical power source driven by an engine. Right and left rear wheels independently driven by permanent magnet electric motors and front wheels electrically steerable over a range of approximately 180 degrees operate under the control of a vehicle controller responsive to steering and speed input controls to provide zero turn radius operation with minimum slippage and tire scuffing. Space efficiency provided by the electric steering and an electrically driven tool deck facilitate a variety of tool mounting configurations including a rear discharge deck with a chute passing under the vehicle frame between the driven wheels. An inverter connected to the electrical power source provides 110 / 220 volt output. The power source also functions as a high powered, high rpm, low noise starter motor.

Owner:HUNT KENNETH EDWARD +2

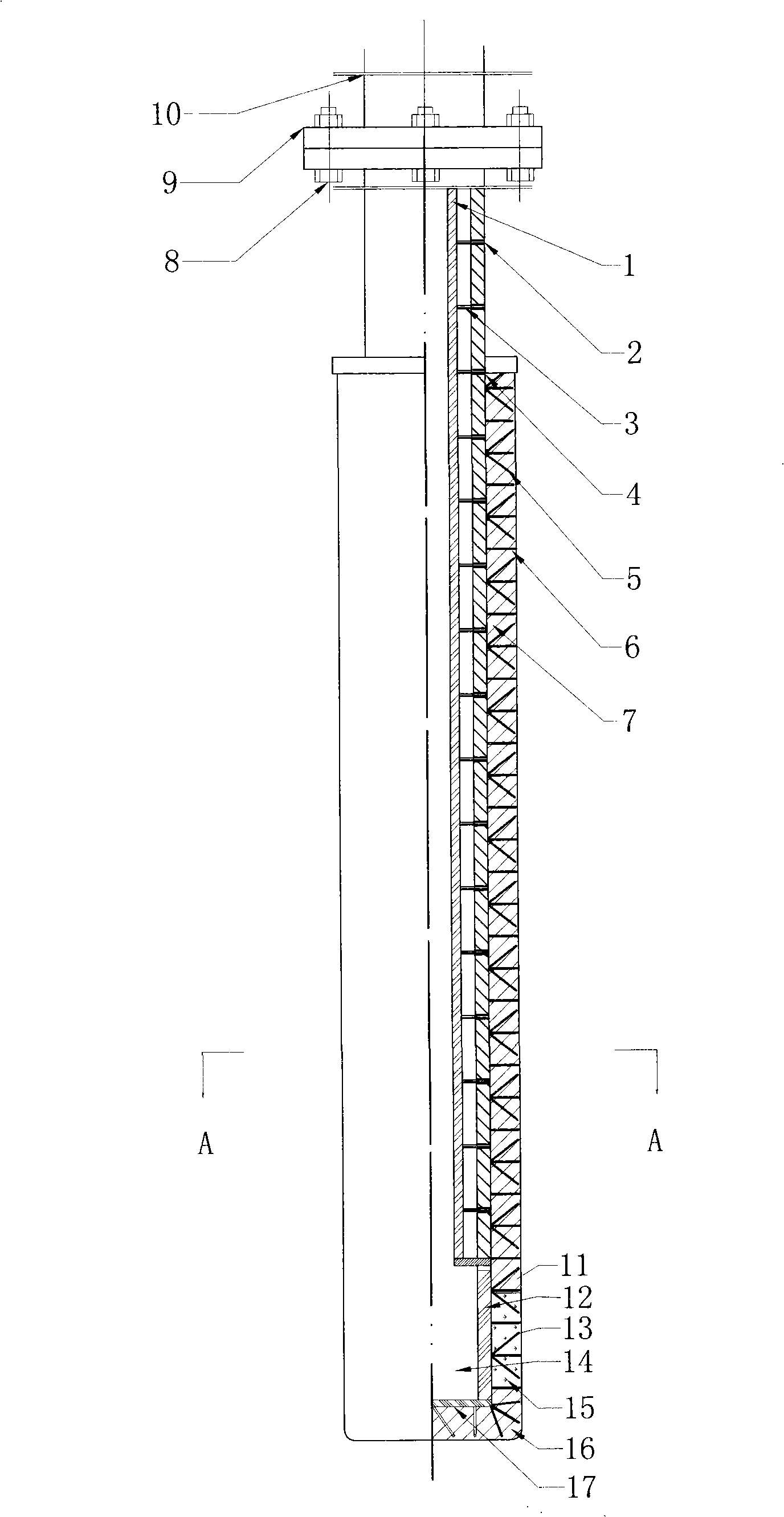

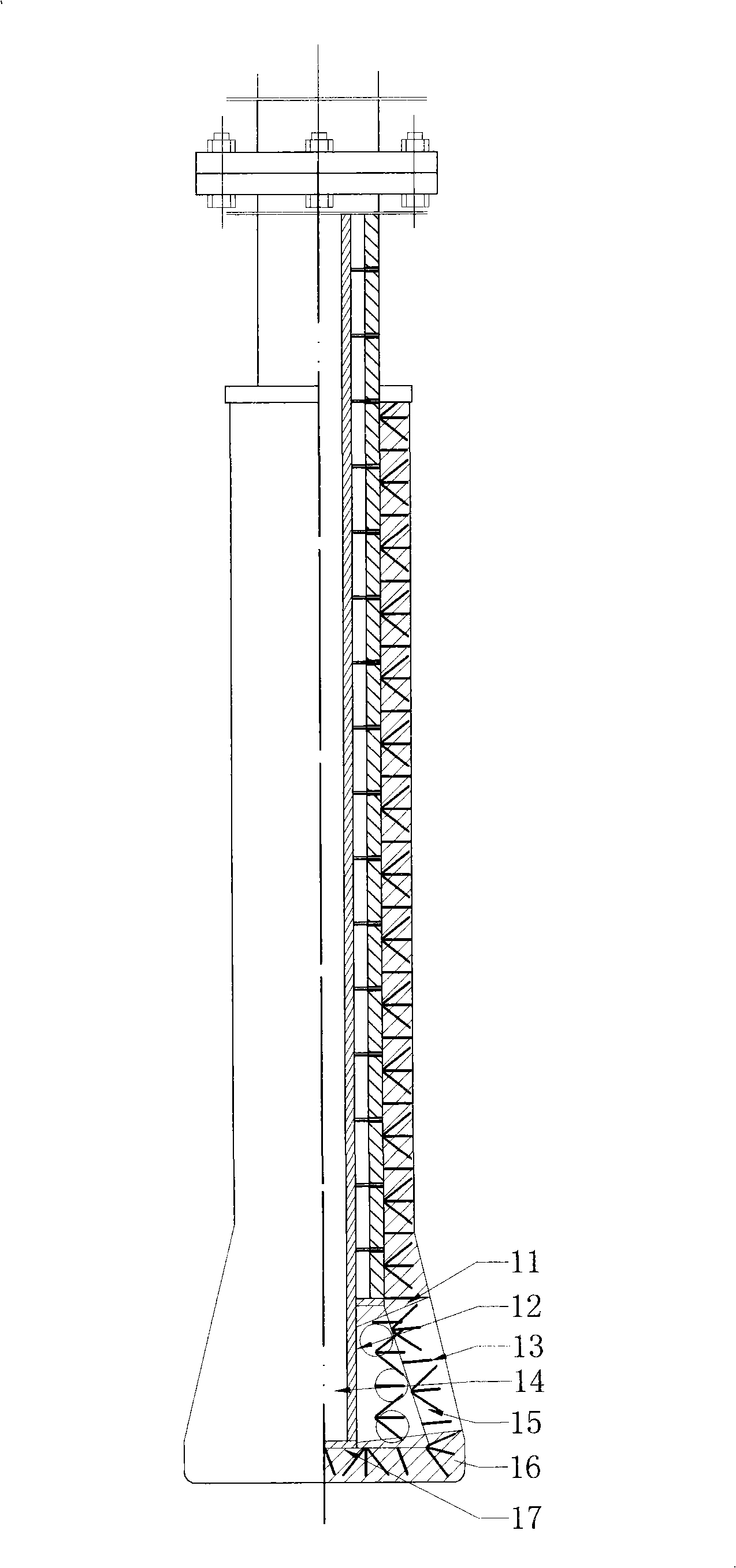

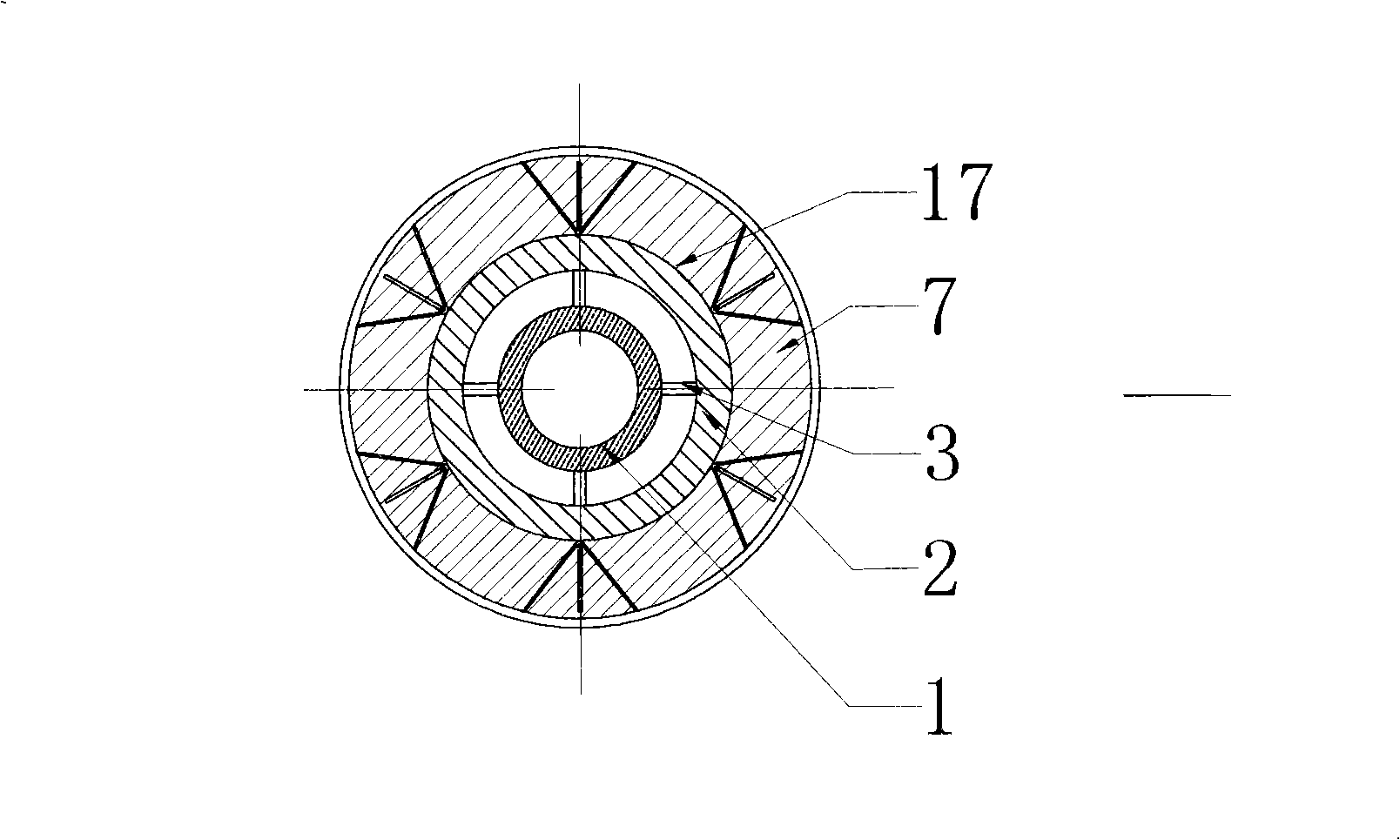

Argon-blowing spray gun for refining ladle and making method thereof

The invention discloses an argon blowing lance which includes a metal lance rod and a lance body that are connected together by a flange; the lower part of the lance body is provided with a dispersion nozzle; the lance body includes a main tube, a reinforcing tube, a plurality of bridging welding pieces, a plurality of rivet pieces and the working liner of a fire-proof material; the reinforcing tube is sheathed on the outside of the main tube; besides, a plurality of bridging welding pieces are uniformly welded between the reinforcing tube and the main tube; the rivet pieces of V shape and double V-shape are respectively and alternatively arranged in the working liner of the fire-proof material outside the reinforcing tube along the surrounding direction and the coaxial direction of the reinforcing tube; besides, the top points of the two are respectively welded with the outer surface of the reinforcing tube. The measures of the invention of sheathing the reinforcing tube and the bridging welding pieces outside the main tube of the core of the lance improve the intensity and the rigidness of the core structure of the lance; the rivet pieces of V shape and double V-shape enhance the bonding intensity between the core of the metal core of the lance and the working liner of the fire-proof casting material; the dispersion nozzle improves the blowing stirring intensity and finally achieves the goals of prolong the service life of the lance and improving the use performance of the lance.

Owner:武钢集团有限公司 +1

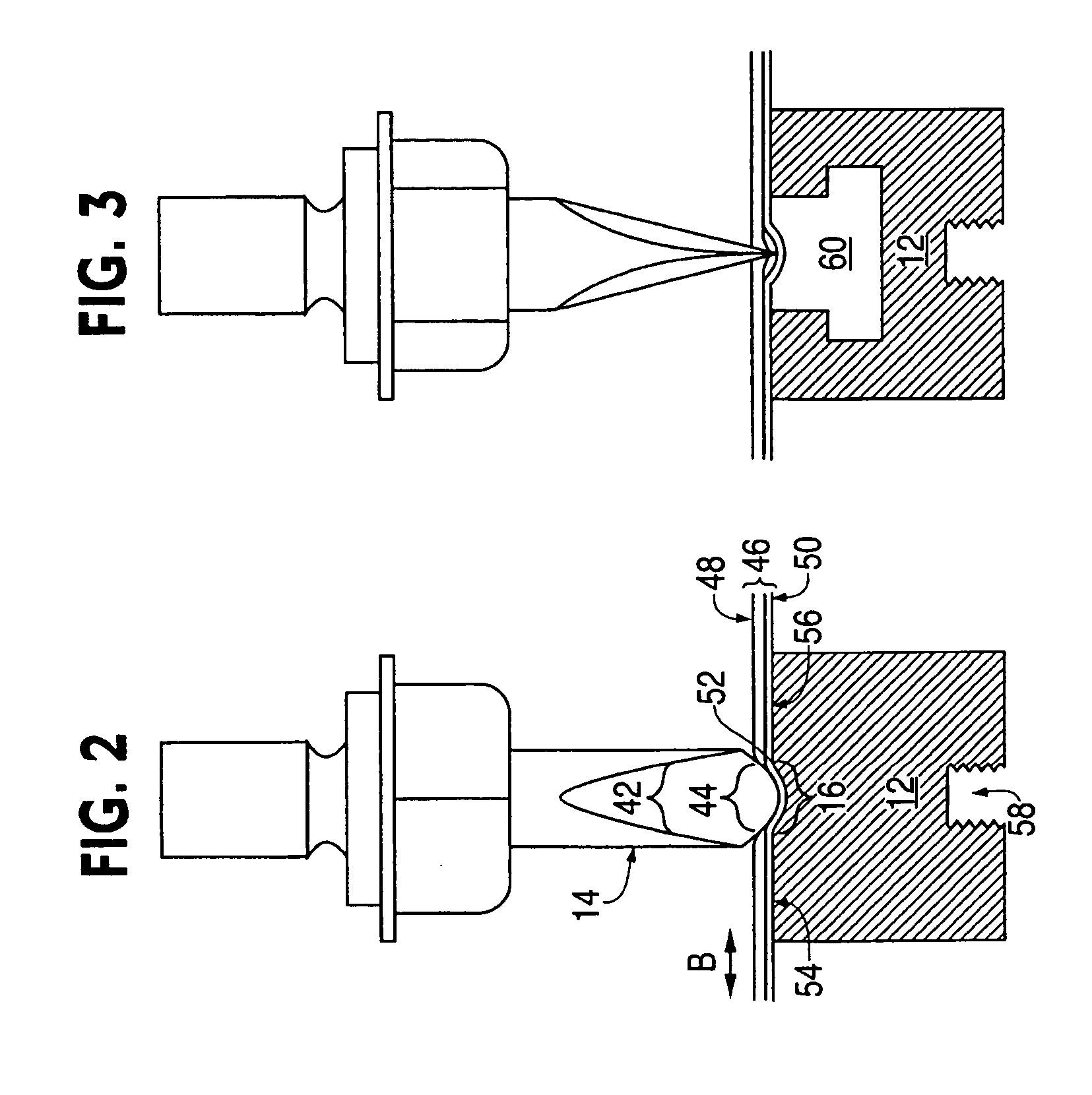

Cutting anvil and method

InactiveUS20050235795A1Reduce facilitationSawing apparatusPlaning/slotting machinesBiomedical engineering

To cut a backed ply material with an ultrasonic blade, an anvil is utilized to provide support. The backed ply material travels in a first direction, the ultrasonic blade includes a tip, and the ultrasonic blade is operable to travel along a path. This path is oriented in a transverse manner relative to the first direction. The anvil includes a rigid base for securing the anvil to a cutting assembly and a surface coinciding with the path. The surface is secured to the base. The anvil further includes a groove disposed upon the surface. This groove is in cooperative alignment with the tip.

Owner:THE BOEING CO

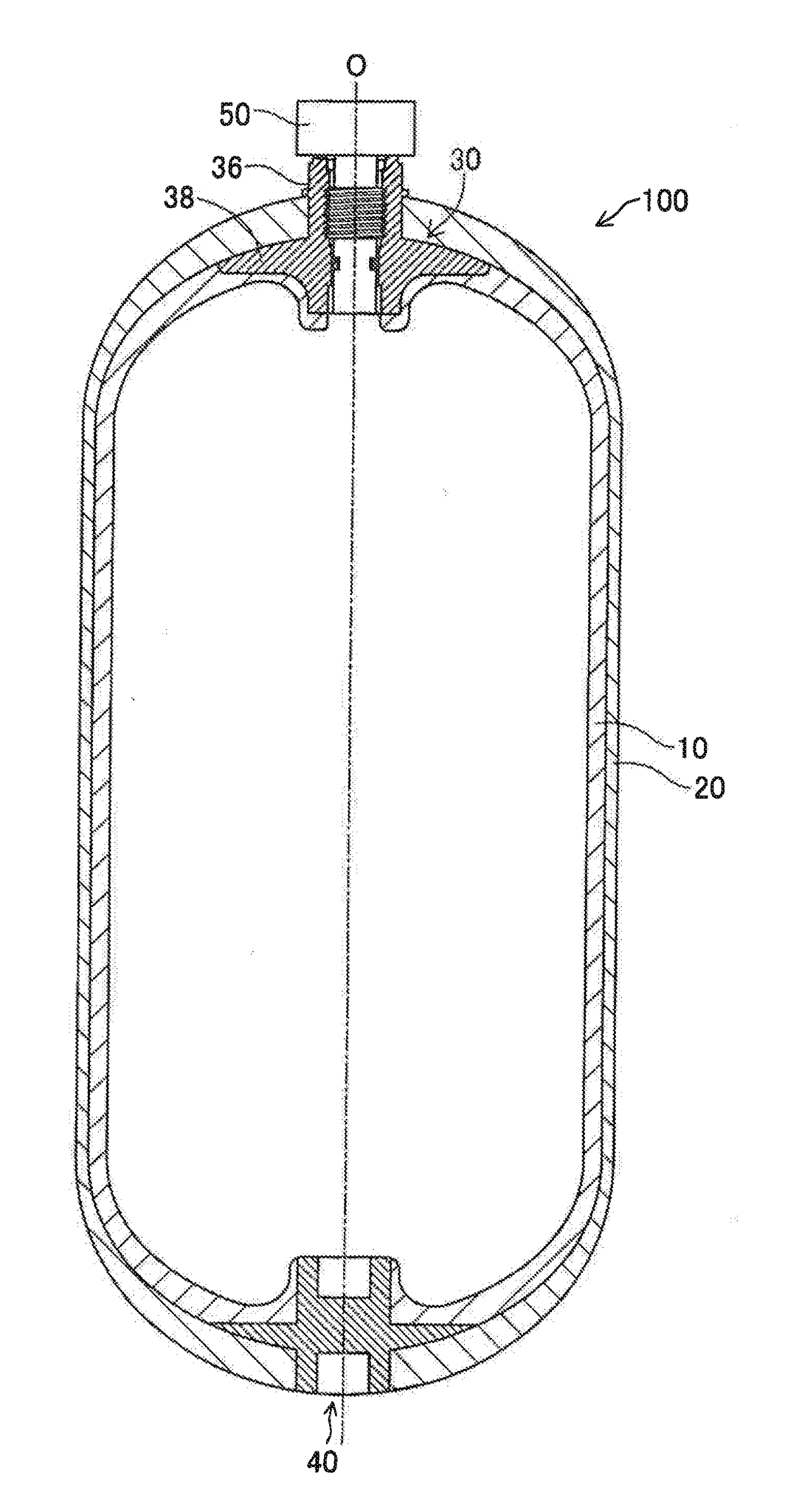

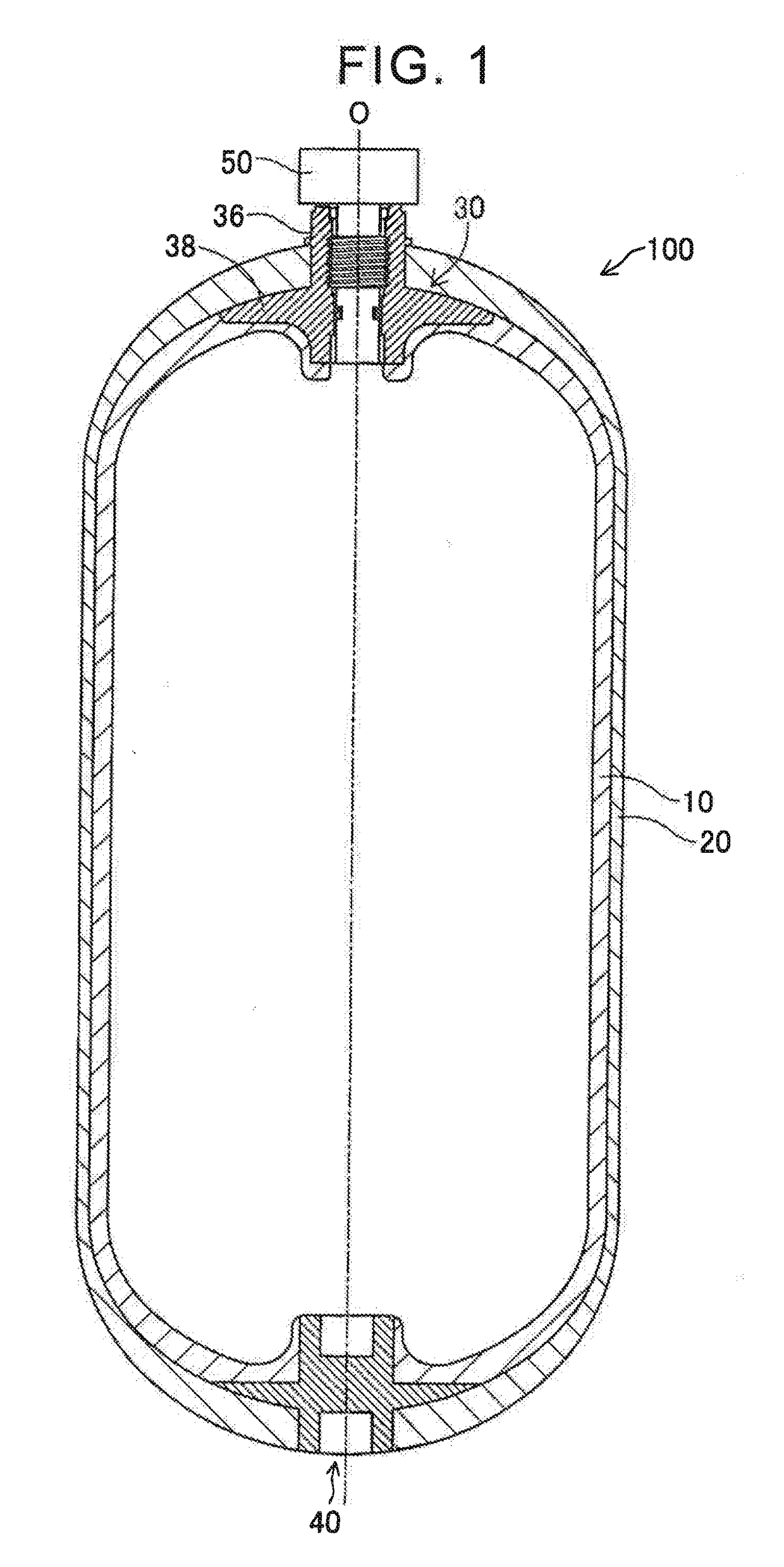

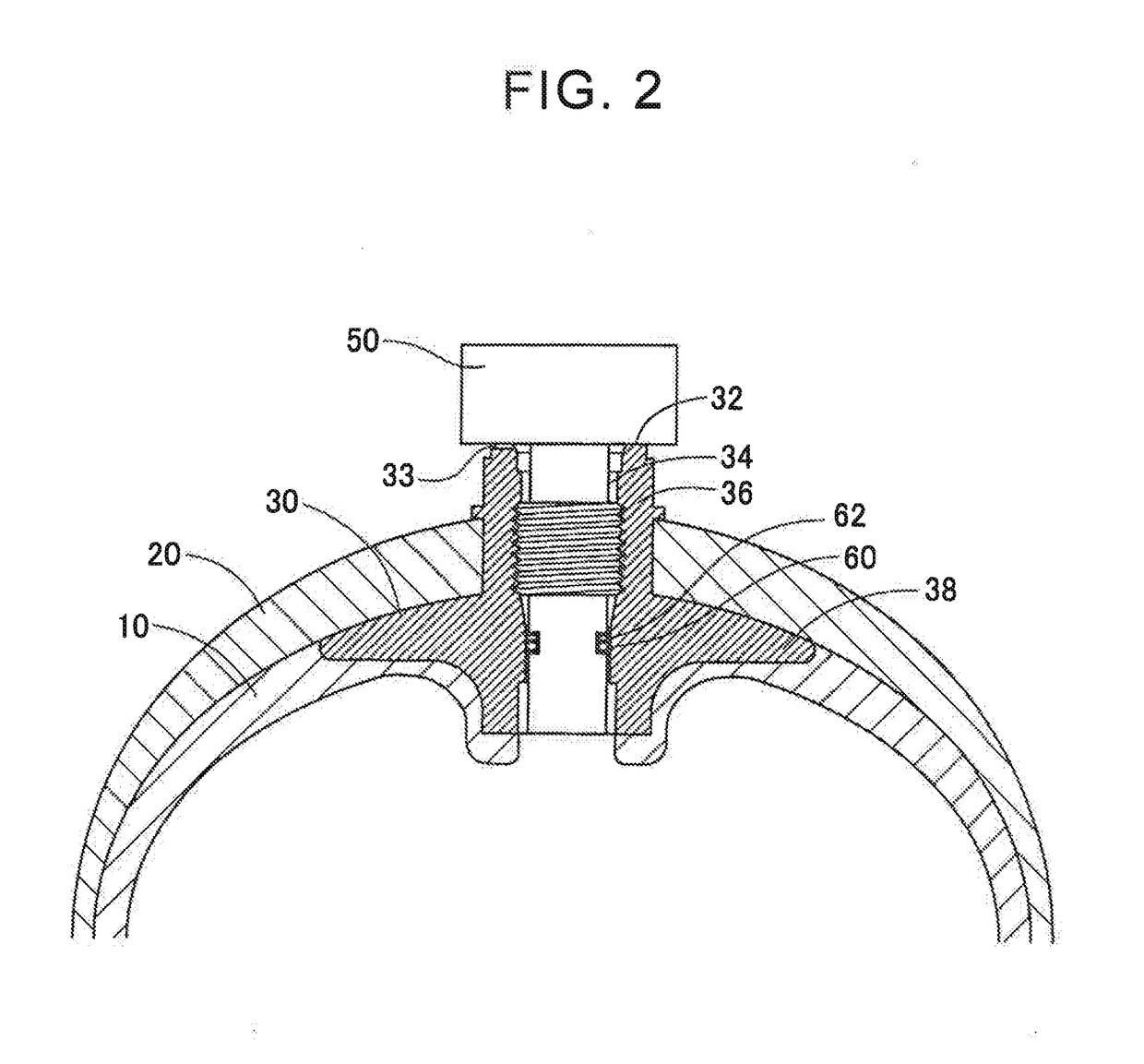

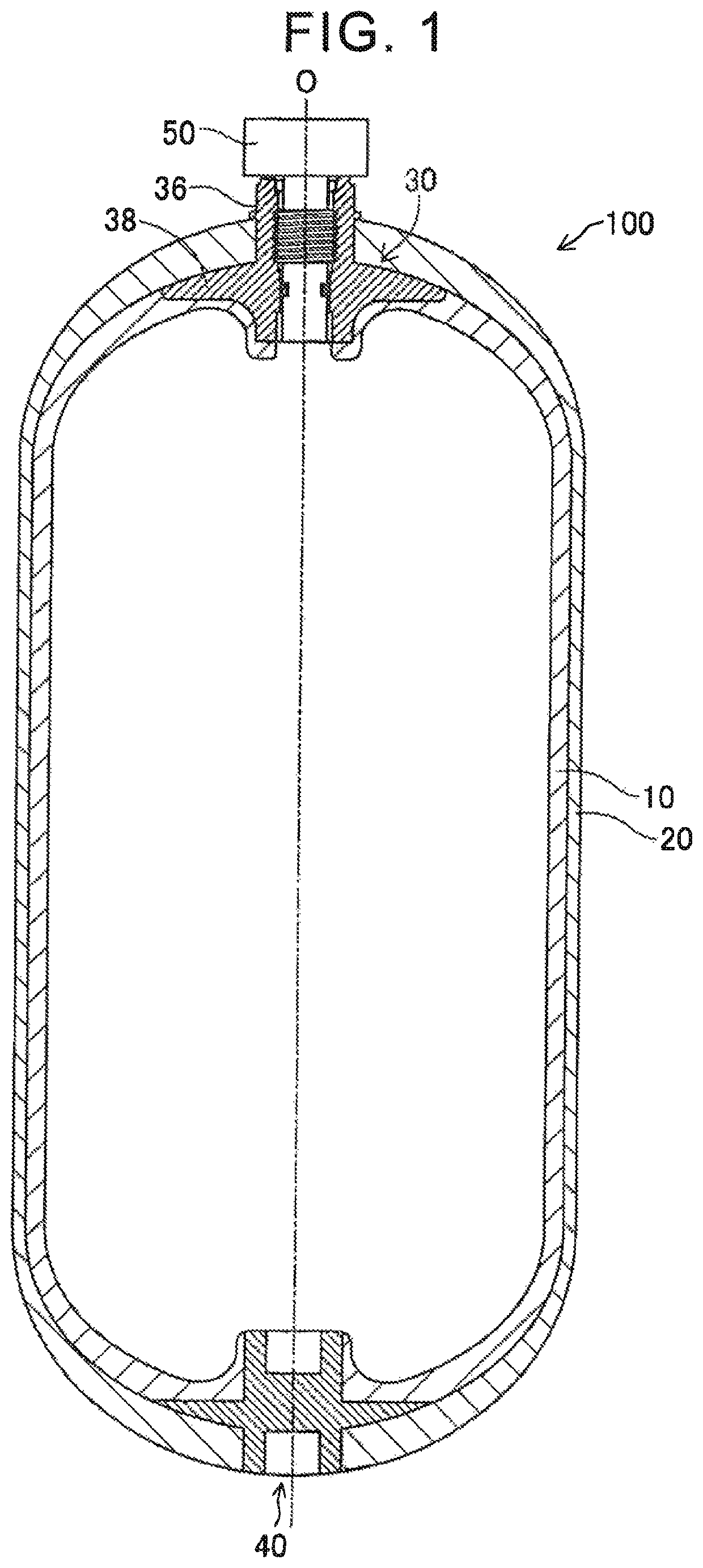

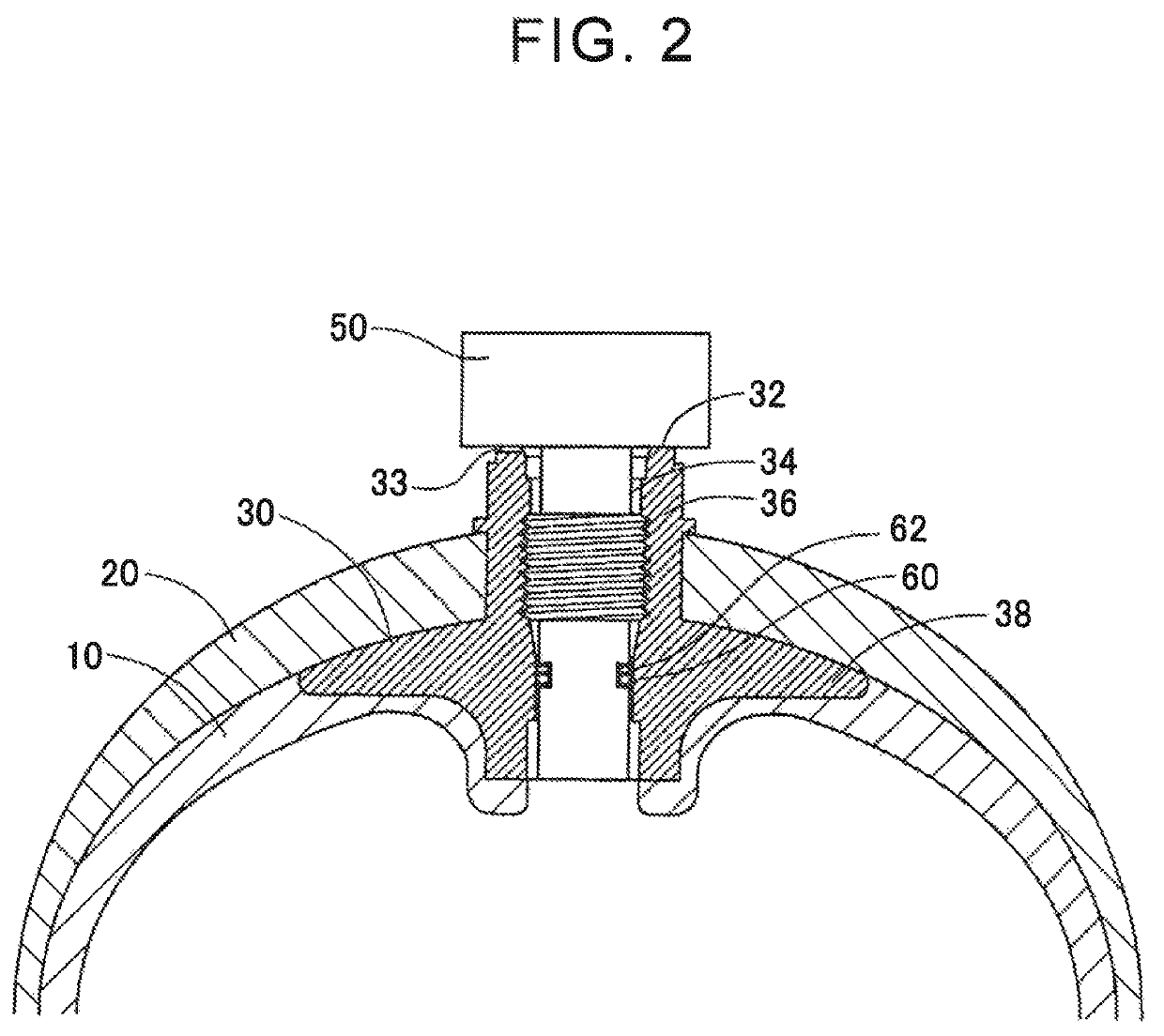

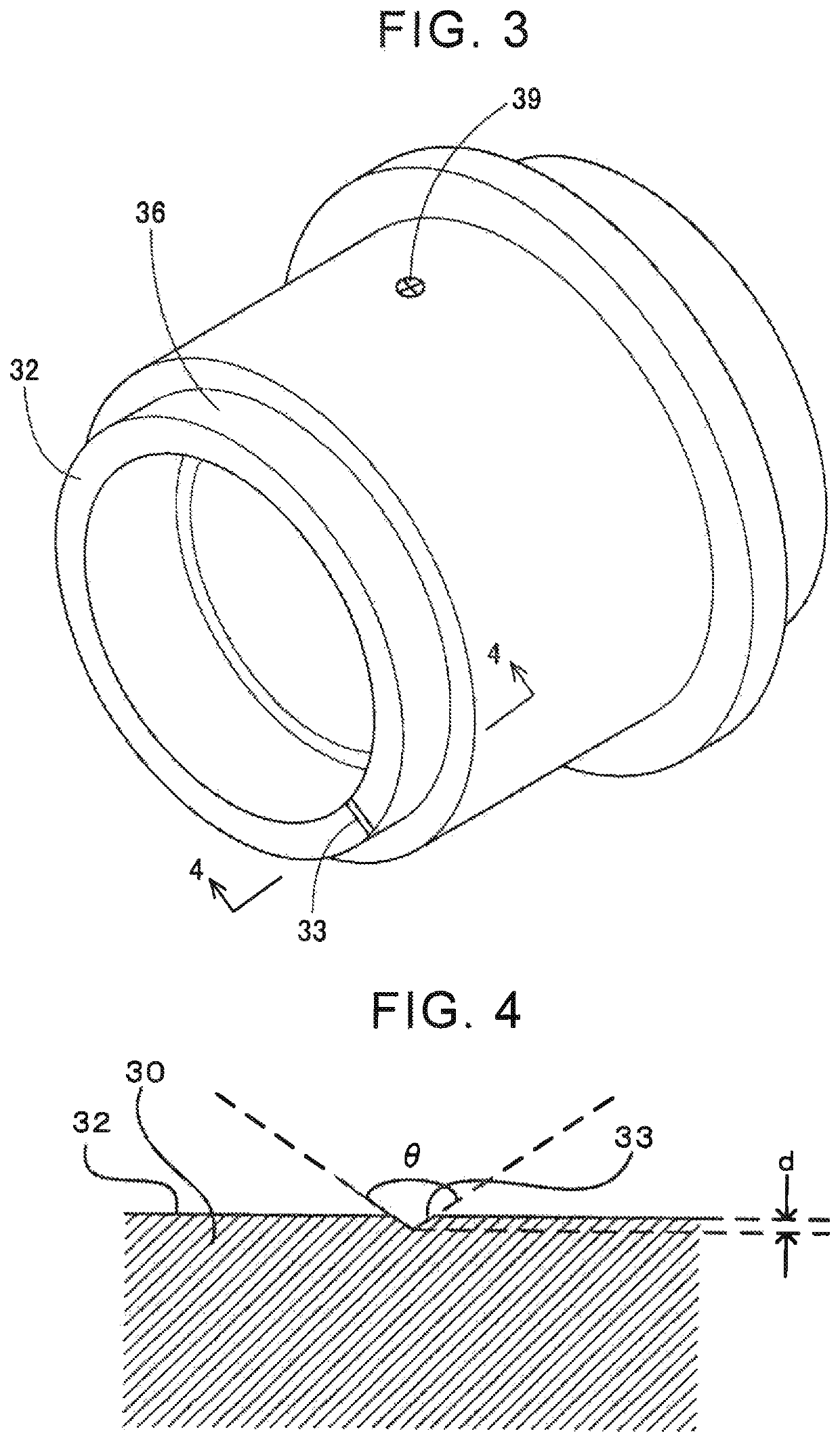

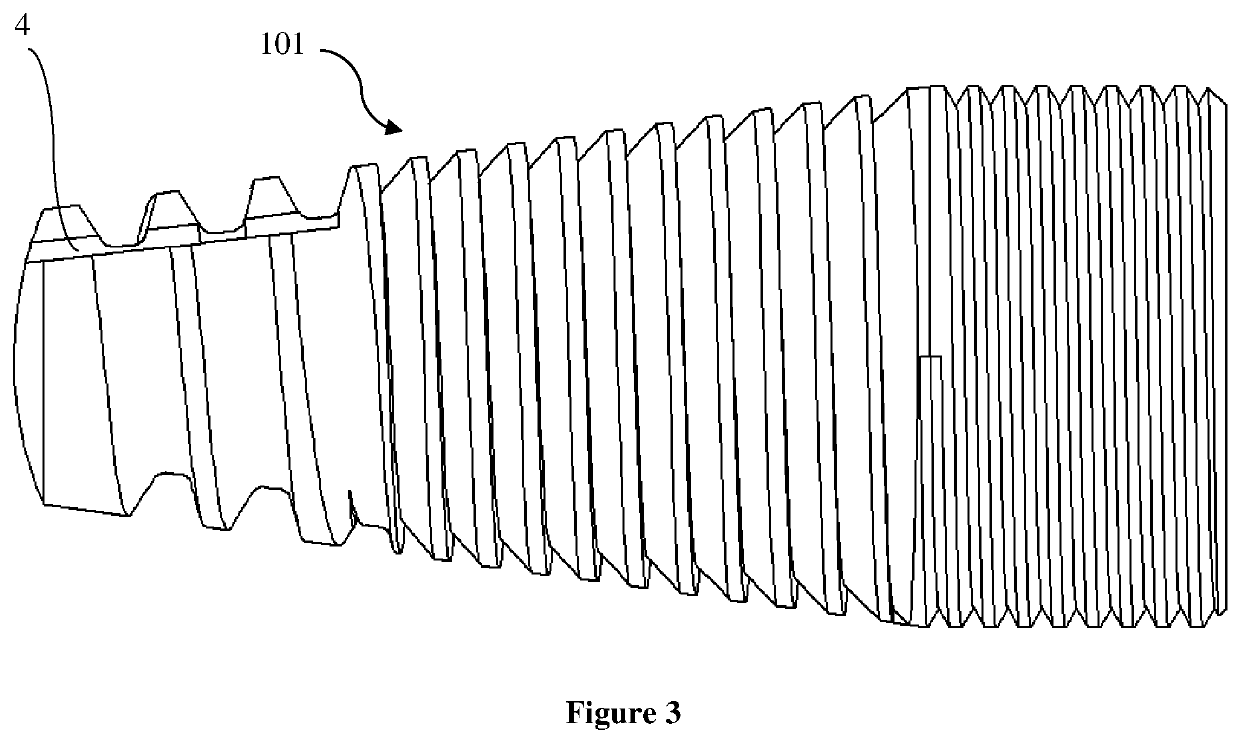

High-pressure gas tank and movable body

ActiveUS20180135807A1Improve reliabilityIncrease pressureContainer filling methodsGas handling applicationsEngineeringHigh pressure

A high-pressure gas tank includes: a tank body section; a base attached to an opening of the tank body section; a valve attached to an opening of the base so as to open and close a gas supply-discharge port of the tank body section, a part of the valve being inserted in the base, and the valve having a contact surface that contacts a seat surface as a surface of an end of the base, the surface of the end of the base forming the opening of the base; and a seal member arranged between an outer peripheral surface of a portion of the valve that is inserted in the opening of the base and an inner peripheral surface of the base. A slit for forming a communication hole communicating between outside of the high-pressure gas tank and a space between the base and valve is provided.

Owner:TOYOTA JIDOSHA KK

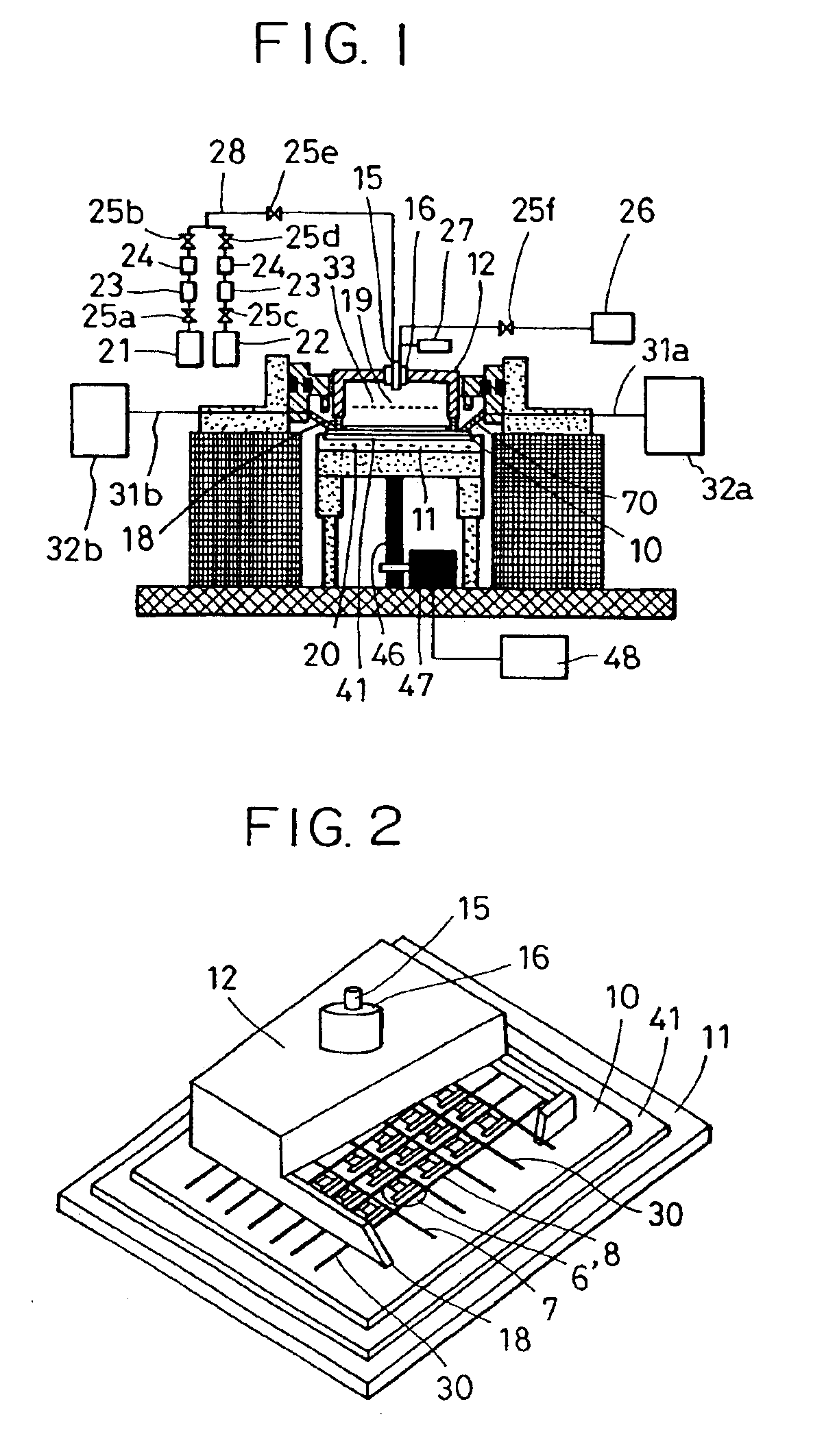

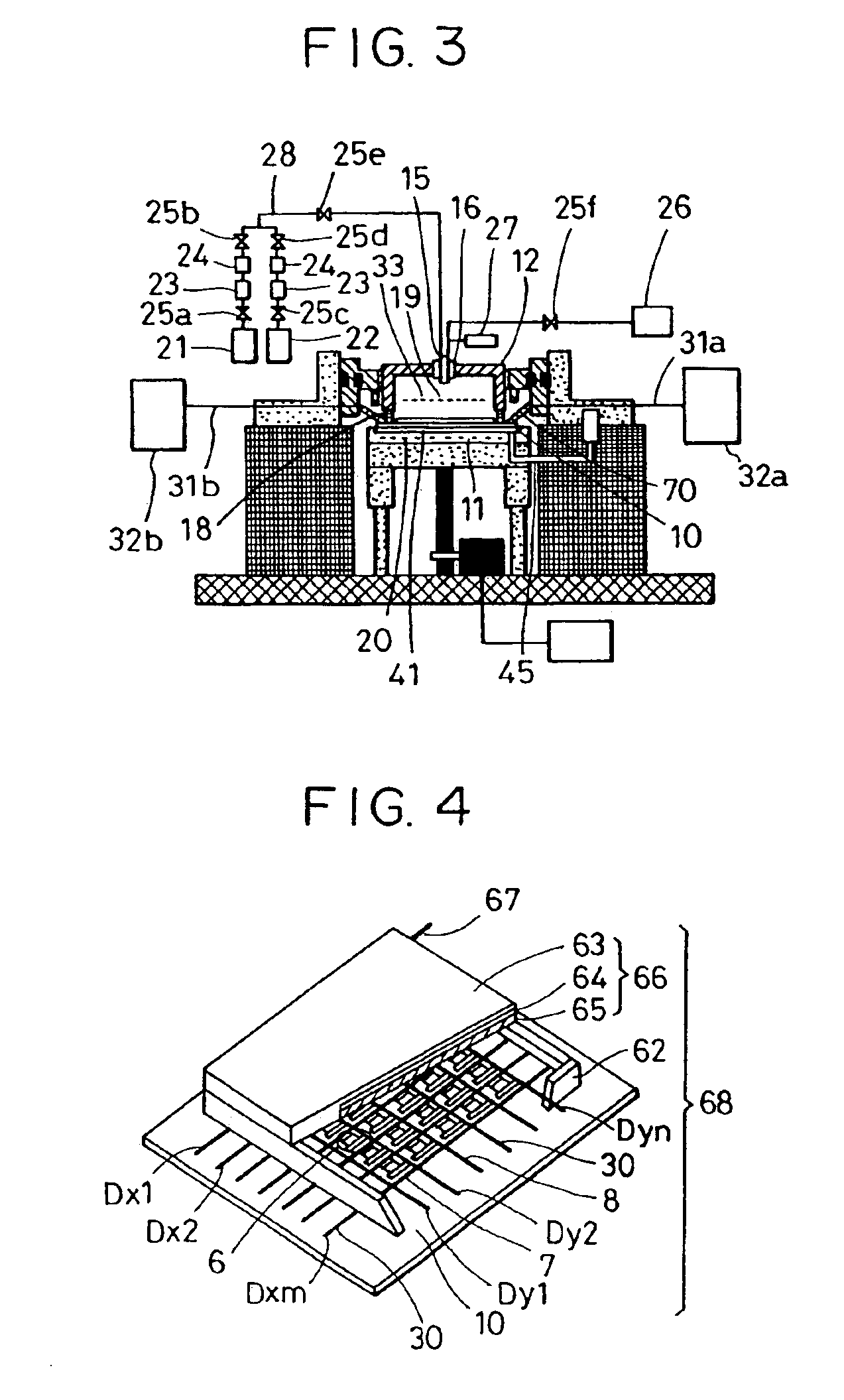

Method for manufacturing a substrate and a display device

InactiveUS6937041B2Improved electrical connectivity and durabilitySuperior electron-emitting characteristicContact member manufacturingElectric discharge tubesElectron sourceDisplay device

A probe for applying a voltage to lines provided on a substrate comprises (a) a conductive sheet, the conductive sheet including a mesh sheet in which linear members are woven into a mesh and a conductive material which coats the mesh sheet, (b) an elastic member for pressing the conductive sheet against the lines, and (c) a holding member for holding the conductive sheet and the elastic member together. The probe has improved electrical connectivity and durability, and achieves a reduction in size and facilitation of operations of an apparatus for manufacturing an electron source.

Owner:CANON KK

A triptolide composite preparation for treating osteoarthritis by joint intracavity injection

InactiveCN100431547CAlleviate early symptomsEarly relief of symptomsOrganic active ingredientsSkeletal disorderSide effectAlcohol

The present invention relates to one kind of compound triptolide alcohol preparation for being injected into articular cavity to treat osteoarthritis. It includes triptolide alcohol solution of 1*10<-4> to 5*10<-2> mg / ml concentration and gel liquid mixed in the volume ratio of 1 to 1-9. It has medicine slow releasing effect, and this can prolong the action period of medicine, reduce consumption of triptolide alcohol and lower the toxic side effect of the medicine. It can inhibit the further development of osteoarthritis in early and middle phase, improve the environment inside the joint and promote the regeneration and repair of articular cartilage to reach the aim of cure osteoarthritis.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

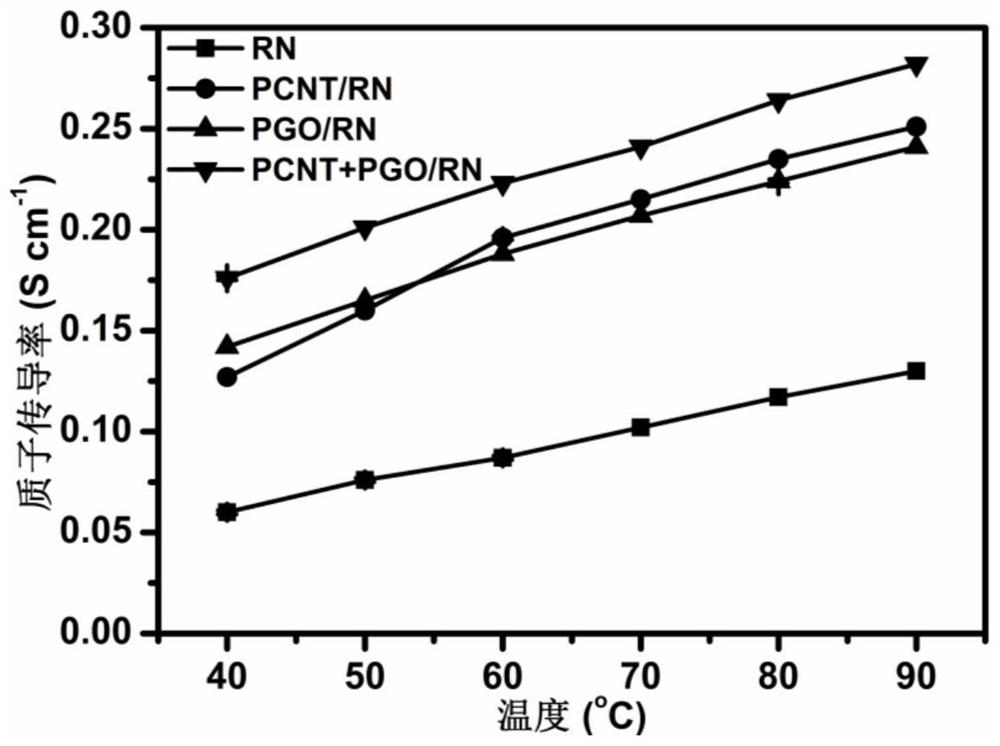

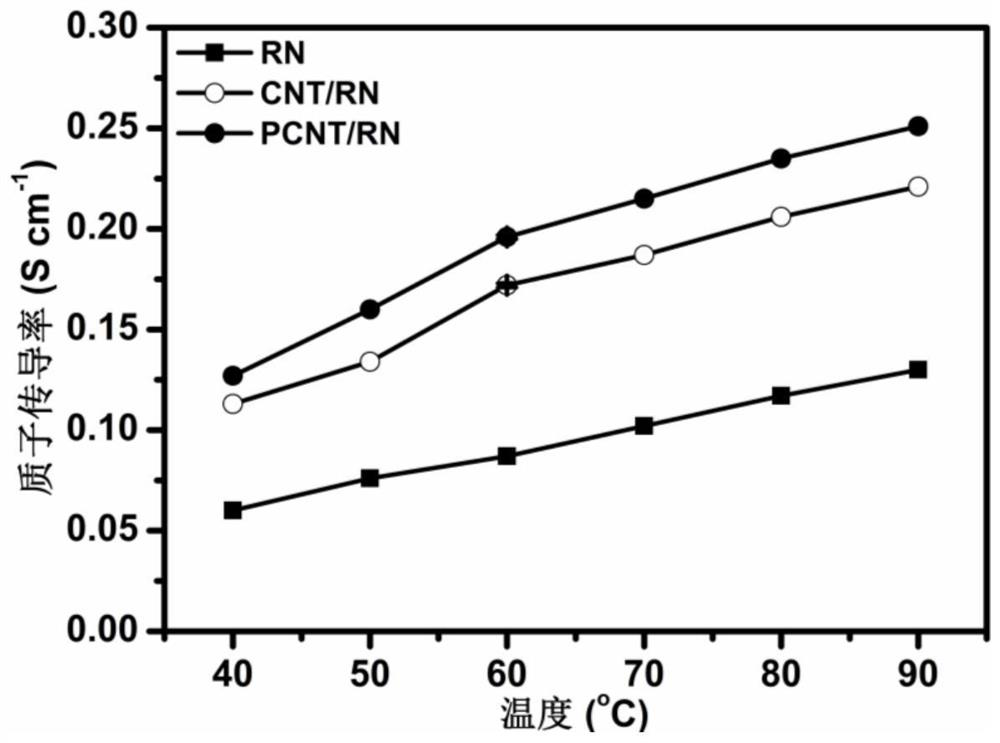

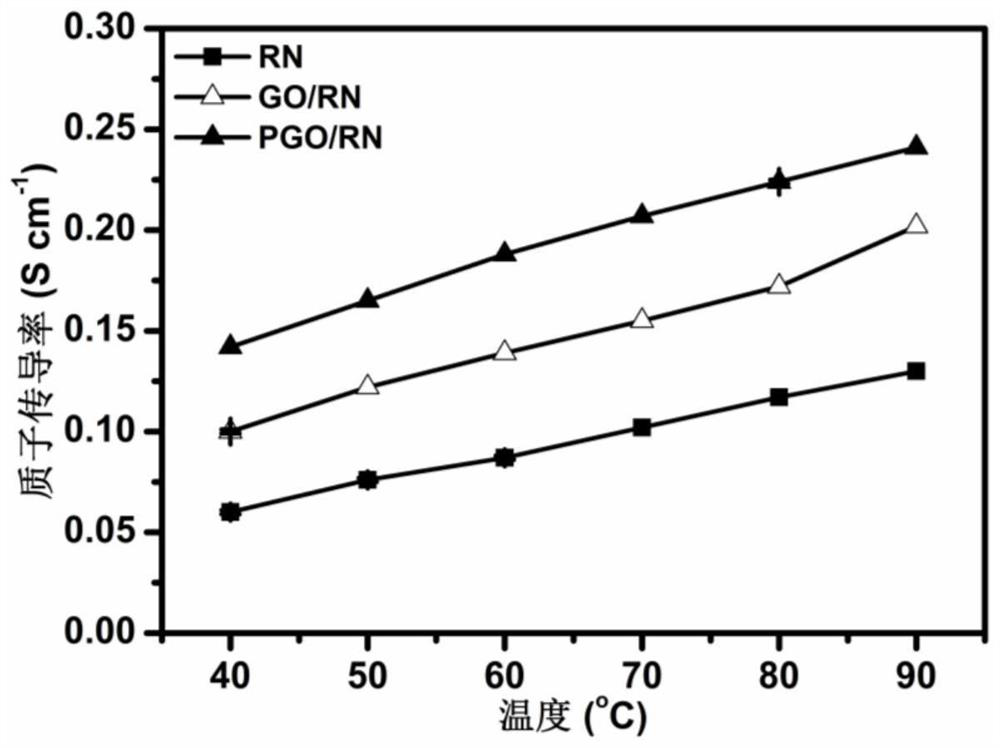

Polymeric hybrid proton exchange membrane synergistically modified by PCNT and PGO and preparation method thereof

ActiveCN114634642AEasy to operateReduce manufacturing costMaterial nanotechnologyFuel cellsModified carbonAcide Alendronique

The invention belongs to the technical field of membranes, and discloses a PCNT and PGO synergistically modified polymer hybrid proton exchange membrane and a preparation method thereof, and the preparation method comprises the following steps: (1) preparing a polydopamine modified carbon nanotube DCNT; (2) preparing graphene oxide DGO modified by polydopamine; (3) carrying out a reaction on alendronate and DCNT to obtain a phosphorylated carbon nanotube PCNT; (4) carrying out reaction on alendronate and DGO to obtain phosphorylated graphene oxide PGO; and (5) obtaining a membrane casting solution based on the sulfonated polymer solution, PCNT and PGO to form a membrane material, and further treating to obtain the PCNT and PGO synergistically modified polymer hybrid proton exchange membrane. The structure and composition of key functional components in the proton exchange membrane are improved, and the proton conductivity of the prepared proton exchange membrane is greatly improved based on the synergistic effect of the functional components PCNT and PGO.

Owner:HUAZHONG UNIV OF SCI & TECH

Systems, methods, and apparatus for regenerating a catalytic material

ActiveUS9062569B2Reduce the amount requiredReduce facilitationExhaust apparatusUsing liquid separation agentCombustionNitrogen

A steam generator coupled in flow communication downstream from a combustion device that produces a flow of exhaust gases includes a heating device configured to heat the exhaust gases that include oxides of nitrogen (NOx), and an oxidation catalyst coupled downstream from the heating device. The oxidation catalyst facilitates reducing an amount of NOx in the exhaust gases channeled into the oxidation catalyst at a first temperature that is less than a thermal regeneration temperature for a catalytic material and at a second temperature that is approximately equal to at least the thermal regeneration temperature such that the catalytic material is simultaneously regenerated.

Owner:GENERAL ELECTRIC CO

High-pressure gas tank and movable body

ActiveUS11009187B2Improve reliabilityIncrease pressureContainer filling methodsGas handling applicationsEngineeringGas supply

Owner:TOYOTA JIDOSHA KK

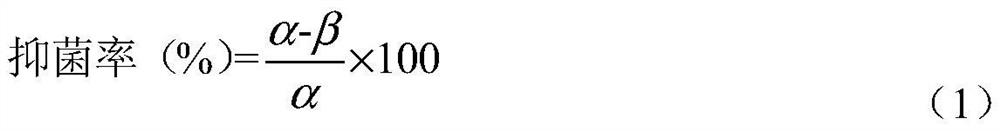

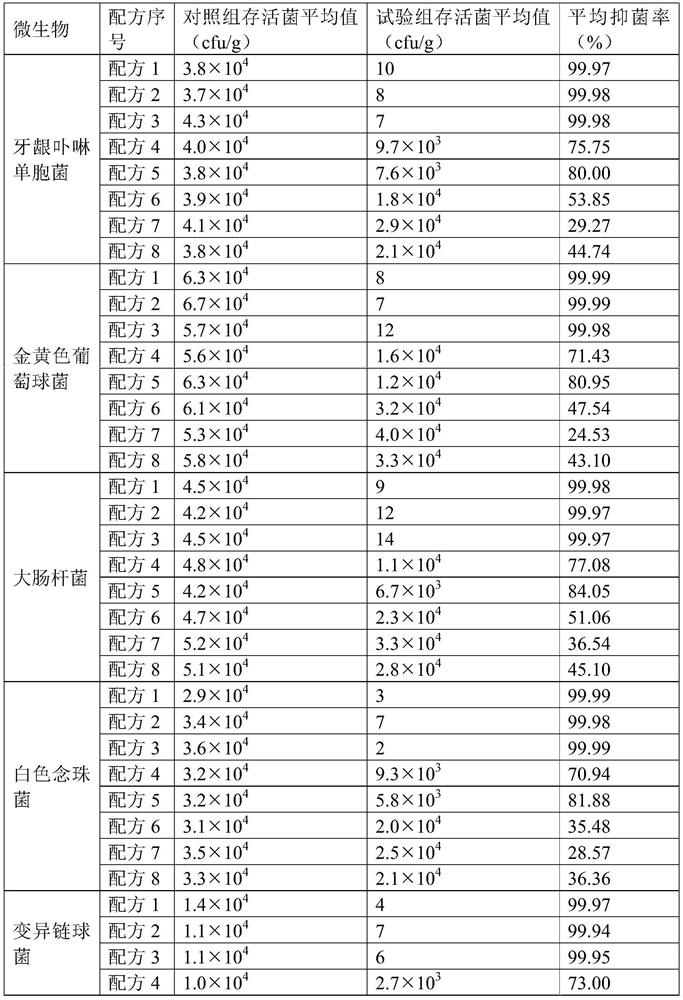

Oral antibacterial composition as well as oral care solution prepared from same and application

InactiveCN111870687AReduce in quantityReduce facilitationAntibacterial agentsCosmetic preparationsStaphyloccocus aureusEnterobacter

The invention discloses an oral antibacterial composition and an oral care product prepared from the same. The oral antibacterial composition comprises lysozyme, fructo-oligosaccharide and a rice germextract, wherein the lysozyme is compounded with the fructo-oligosaccharide and the rice germ extract, the number of oral pathogenic bacteria can be remarkably reduced, and a new choice is provided for development of oral antibacterial products; the composition is further used for preparing an oral care solution, and the obtained care solution product has a relatively strong bacteriostatic effecton streptococcus mutans, porphyromonas gingivalis, staphylococcus aureus, escherichia coli, candida albicans, prevotella intermedia and the like, so that bacteria are prevented from generating drug resistance, the oral microenvironment is improved. The oral care product is free from chemical antibacterial drug components and fluorine, can significantly proliferate beneficial bacteria of intestinal tracts after being continuously used, and is especially beneficial to healthy development of bodies of children.

Owner:HAOYIKANG BIOLOGICAL TECH(GUANGZHOU) CO LTD

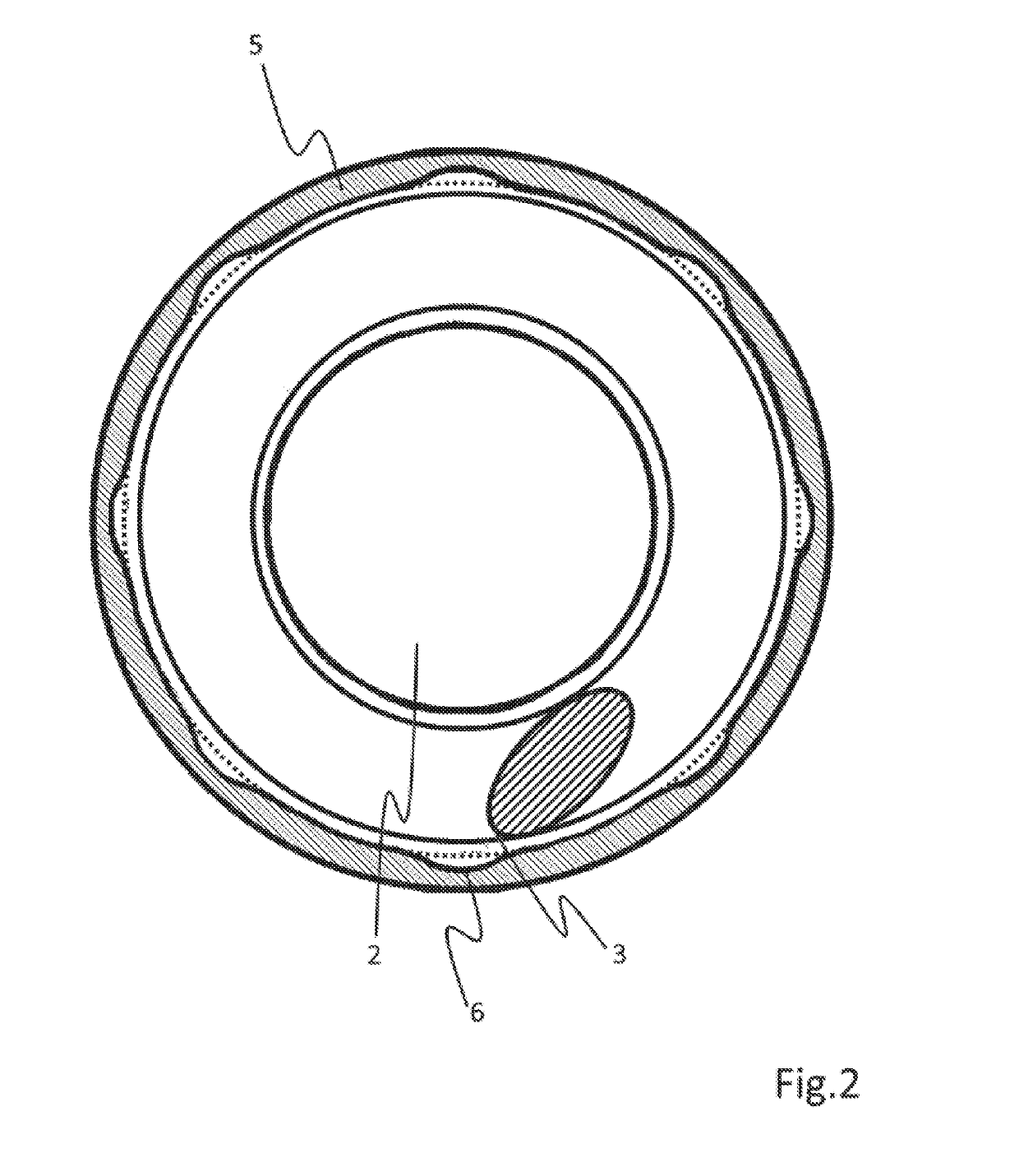

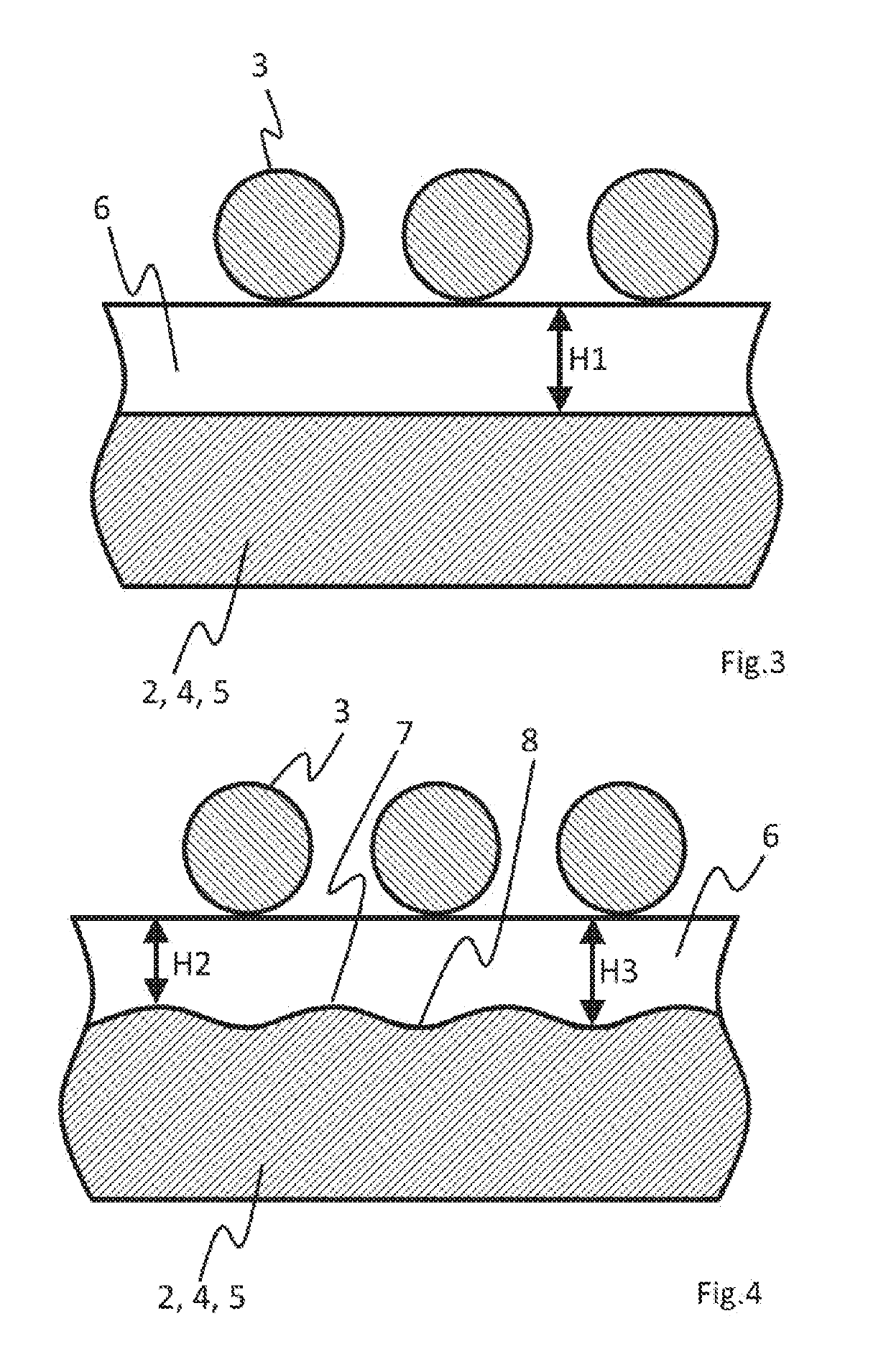

Spring sleeve, cylinder, piston cylinder unit and method of manufacturing a piston cylinder unit

InactiveUS20190178328A1Improve featuresReduce facilitationSprings/dampers design characteristicsSprings/dampers manufactureEngineeringMechanical engineering

Provided is a spring sleeve for a piston cylinder unit, wherein the spring sleeve is adapted to receive a spring, at least partially, and to guide it, wherein the spring sleeve has a cylindrical sleeve inner surface. The embodiment further relates to a cylinder for a piston cylinder unit, wherein the cylinder) is adapted to be arranged inside a spring of a piston cylinder unit. The embodiment also relates to a piston cylinder unit, including a cylinder, a spring arranged concentrically around the cylinder, and an inner spring sleeve and outer spring sleeve each arranged concentrically around the spring, wherein the cylinder and the spring are arranged inside the inner spring sleeve and the outer spring sleeve. Finally, the embodiment relates to a method of manufacturing such a piston cylinder unit.

Owner:STABILUS

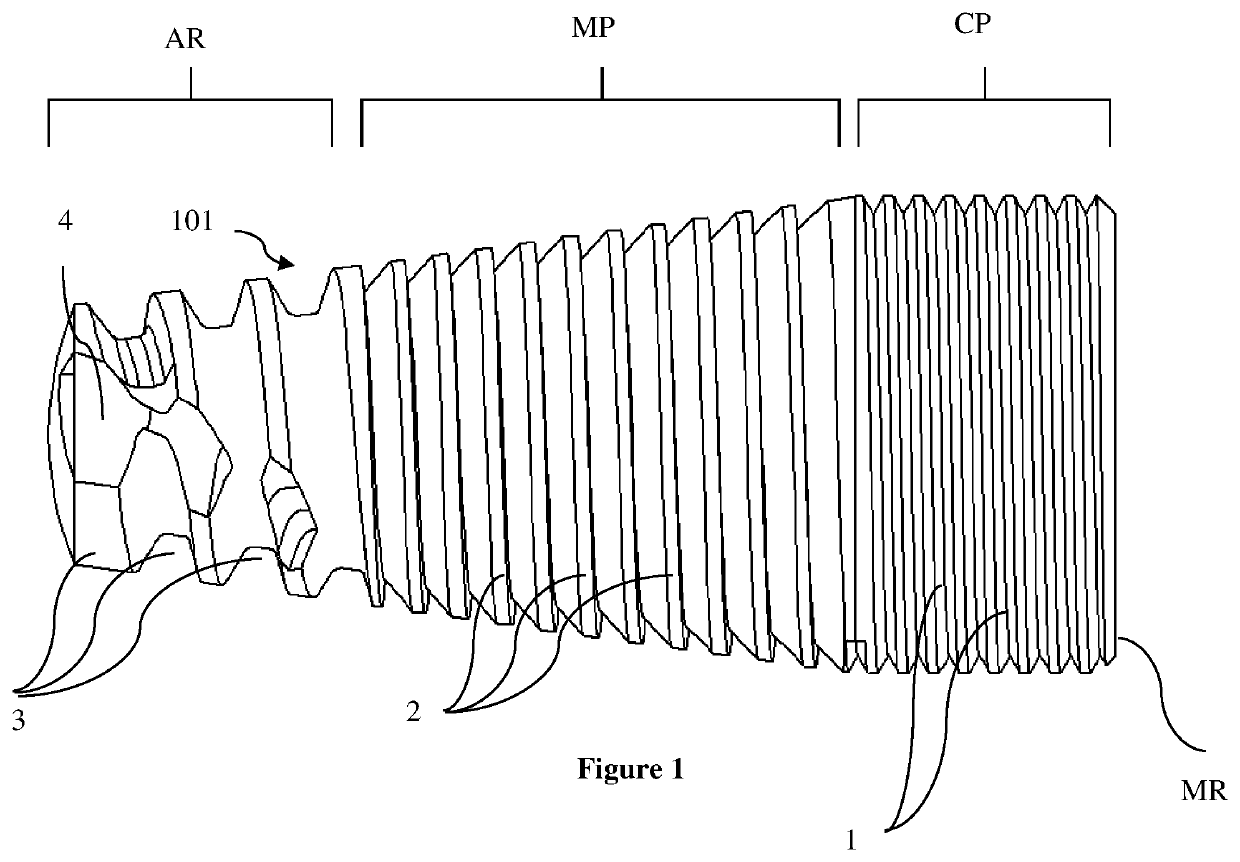

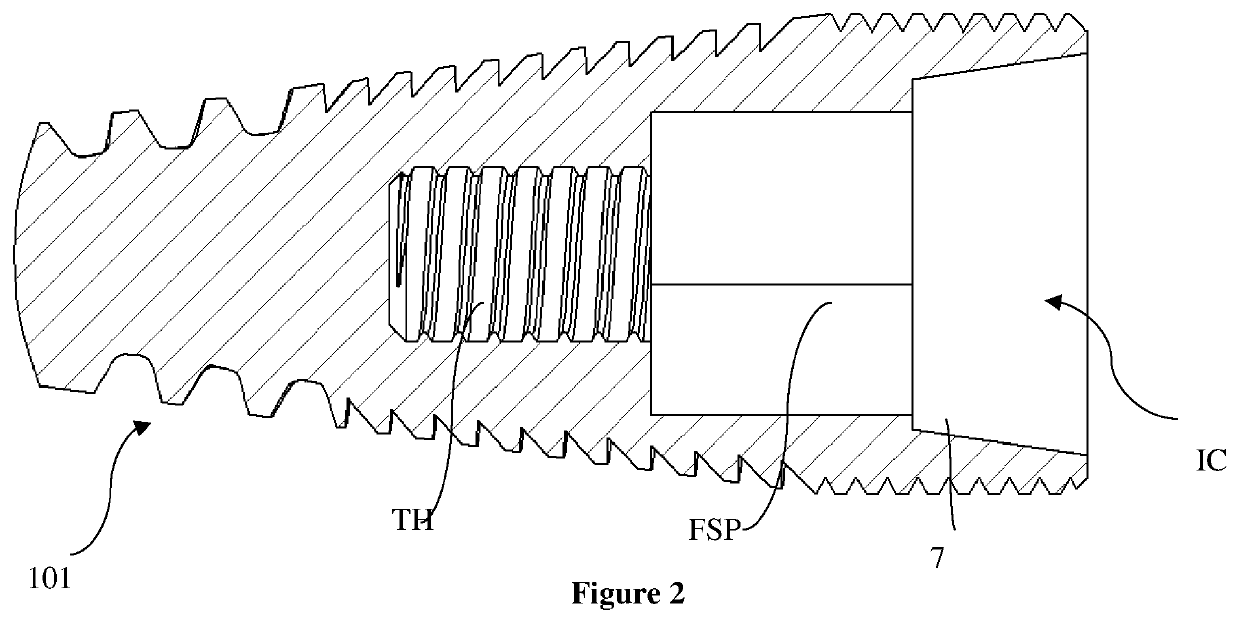

A dental implant assembly

A dental implant assembly comprises, a base member which is rotatably insertable into a jaw-bone. The base member may be defined by a collar portion, a mid-portion and an apical region. The base member in entirety may be configured with a tapered configuration right from the mid-portion to the apical region. Further, the base member is defined with a plurality of threaded profiles on an outer surface. A first thread profile is defined on the collar portion. A second thread profile, defined on the mid-portion and a third thread profile, defined on the apical region. The third thread profile is configured to cut into the jaw-bone during insertion to anchor the base member. As the third thread profile cuts in to the jaw bone, the second thread profile forms a threaded hole within the drilled hole in order to securely anchor the base member within the jaw bone.

Owner:INDIAN INSTITUTE OF SCIENCE +2

Nylon-cotton dyeing method based on one-path process

InactiveCN109082907AWill not affect the effectivenessAct as a catalystBiochemical treatment with enzymes/microorganismsDyeing processSodium silicateMagnesium sulphate heptahydrate

The invention relates to the field of textile dyeing and provides a nylon-cotton dyeing method based on a one-path process, comprising the steps of (1) preparing base cloth; (2) pretreating, to be specific, adding, under the water-bath ratio of 1:10, 5-10 g / L of 30% hydrogen peroxide and 0.5-1.5 g / L of hydrogen peroxide stabilizer, as well as 1-2 g / L of cotton purifying enzymic preparation, wherein the hydrogen peroxide stabilizer is composed of sodium silicate, magnesium sulfate and EDTA in a ratio of 1:1:1; (3) dyeing, to be specific, dyeing a dyeing composition of 0.5-1 g / L of penetrating agent H-95, 1.0-2.0 g / L of dye-retarding agent ERIONAL RF, 1.0-2.0 g / L of sodium dihydrogen phosphate, 20-35 g / L of edible salt, 0.2-1% of leveling agent LD-VRD, 1-2% of EuNeothol dye, 1-2% of NovacronLS dye, and 5 g / L of sodium carbonate under the bath ratio of 1:10; (4) soaping; (5) scutching and drying; (6) setting; (7) inspecting the finished product. The method herein is suitable for the dyeing of base cloths containing 60-80% of nylon and 20-40% of cotton and woven with a nylon-cotton machine.

Owner:石狮市宏兴染整织造有限公司

Yield increasing foliar fertilizer for tobacco and preparation method of foliar fertilizer

InactiveCN109400274AIncrease productionLow costOrganic fertilisersLiquid fertilisersSodium bicarbonateNicotiana tabacum

The invention discloses yield increasing foliar fertilizer for tobacco. The foliar fertilizer is prepared from components in parts by mass as follows: 14-20 parts of urea, 4-6 parts of salicylic acid,2-6 parts of indoleacetic acid, 2-6 parts of abscisic acid, 5-9 parts of sodium bicarbonate, 2-4 parts of a trace element preparation, 3-7 parts of 2-diethylaminoethyl hexanoate, 4-8 parts of a plantamino acid extract preparation and 150-200 parts of deionized water. With the adoption of the foliar fertilizer, tobacco yield can be increased effectively, tobacco growth is promoted by plant growthhormone while tobacco quality cannot be affected, weed growth can be inhibited to a certain extent, and the foliar fertilizer is safe and pollution-free.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

Switching power supply device, switching power supply circuit, and electrical equipment

InactiveUS9071130B2Reduce switching powerReduce facilitationEfficient power electronics conversionSemiconductor/solid-state device detailsElectrical devicesEngineering

According to an embodiment of the invention, there is provided a switching power supply device including an integrated body and a plurality of external terminals. In the integrated body, a first switching element, a constant current element, and a diode are connected in series. The plurality of external terminals include a first external terminal connected to a main terminal of an element disposed on one end side of the integrated body and a second external terminal connected to a main terminal of an element disposed on another end side of the integrated body.

Owner:TOSHIBA LIGHTING & TECH CORP

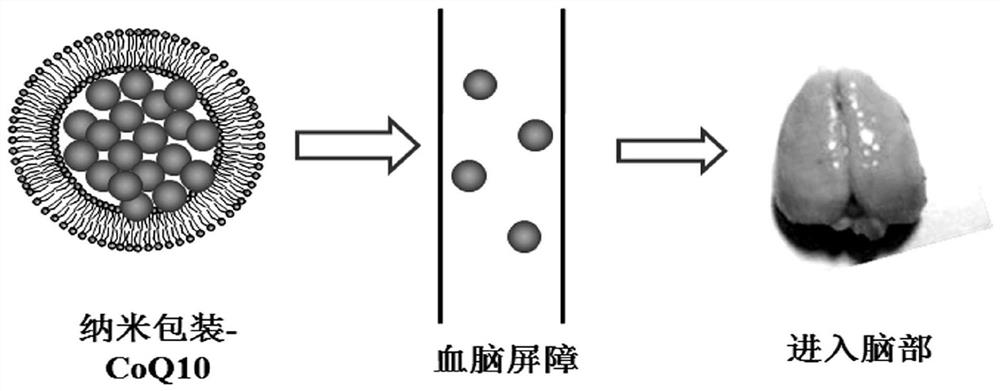

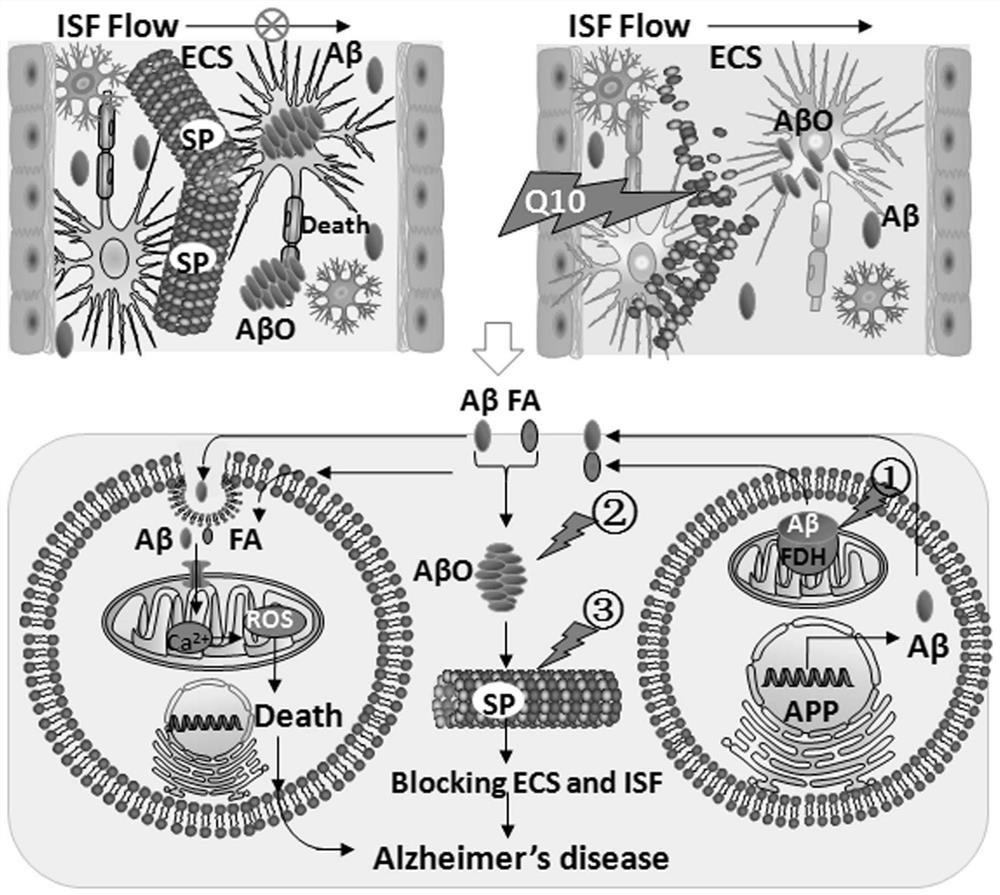

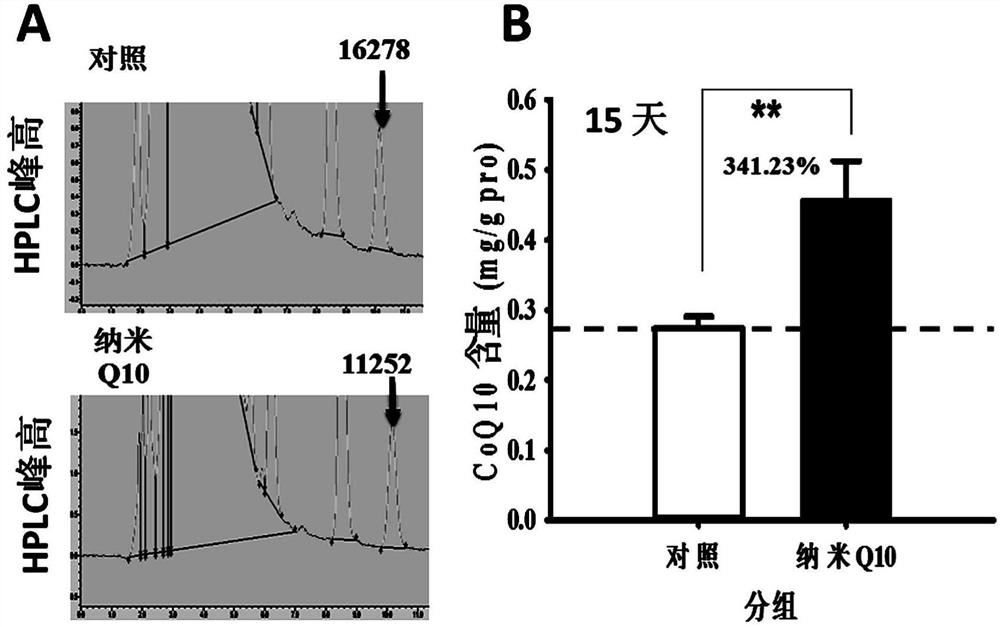

A composition for treating senile dementia, its preparation method and application

ActiveCN109498596BFlow removalFlow recoveryOrganic active ingredientsNervous disorderIntercellular spaceTG - Triglyceride

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES +1

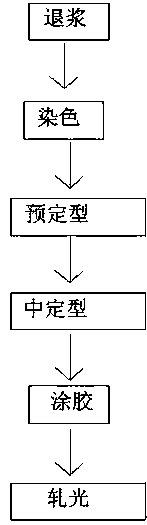

Imitational-nylon handfeel, low-solid content and silver-coated satin and production technology thereof

InactiveCN108716133ASlight creaseNo silver shedding phenomenonHeating/cooling textile fabricsDry-cleaning apparatus for textilesYarnFiber

The invention provides imitational-nylon handfeel, low-solid content and silver-coated satin and a production technology thereof. The production technology comprises the following steps: a, putting satin gray cloth into a desizing machine for cooking pretreatment; b, performing overflowing dyeing treatment to desized fabric; c, washing dyed fabric by using water, and then preshaping the fabric ina drying oven, wherein the temperature is controlled at 200-210 DEG C; d, adding a finishing agent into the preshaped fabric, and performing medium shaping treatment, wherein the medium shaping temperature is controlled at 186-192 DEG C; in percent by weight, the finishing agent comprises 2-4% of a water-proofing agent, 1-2% of a fabric moisture absorbing fluffing agent and 1.3-1.7% of a handfeelfluffing agent; e. coating calendered fabric with prepared coating glue to obtain glue-coated coating cloth. According to the imitational-nylon handfeel, low-solid content and silver-coated satin andthe production technology thereof, after a preshaping process, a medium shaping process is added, so that satin yarns fully open intertwined nodes of fiber under the action of the handfeel fluffing agent and a moisture absorbent so as to endow the fabric with softness and a fluffy feel.

Owner:ZHEJIANG SHENGSHAN TECH TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com