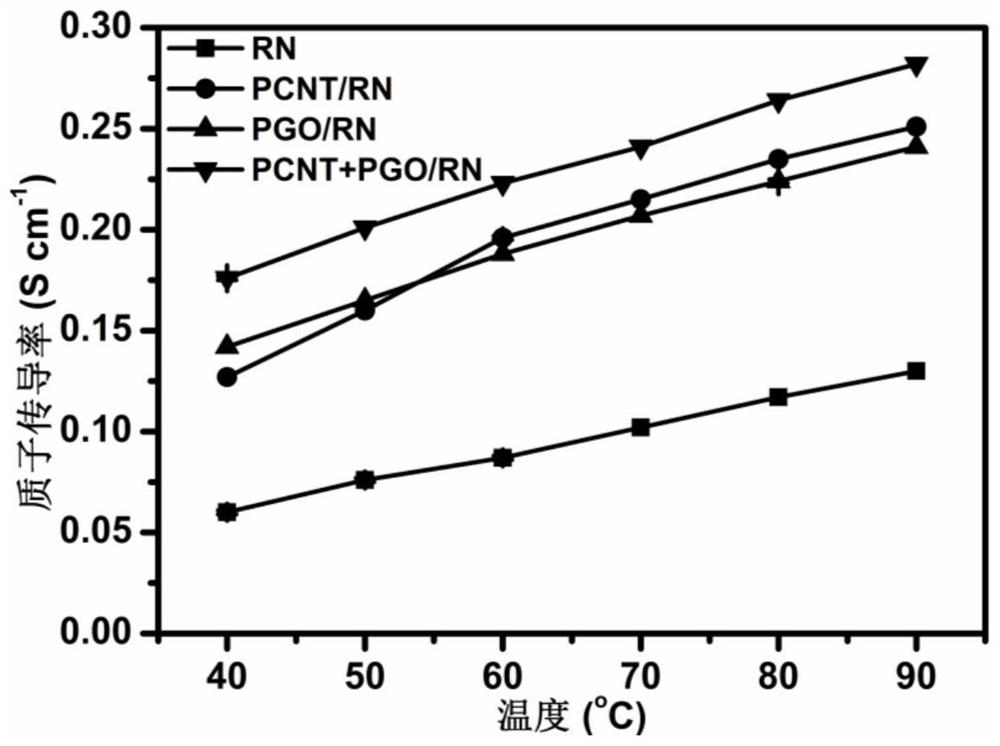

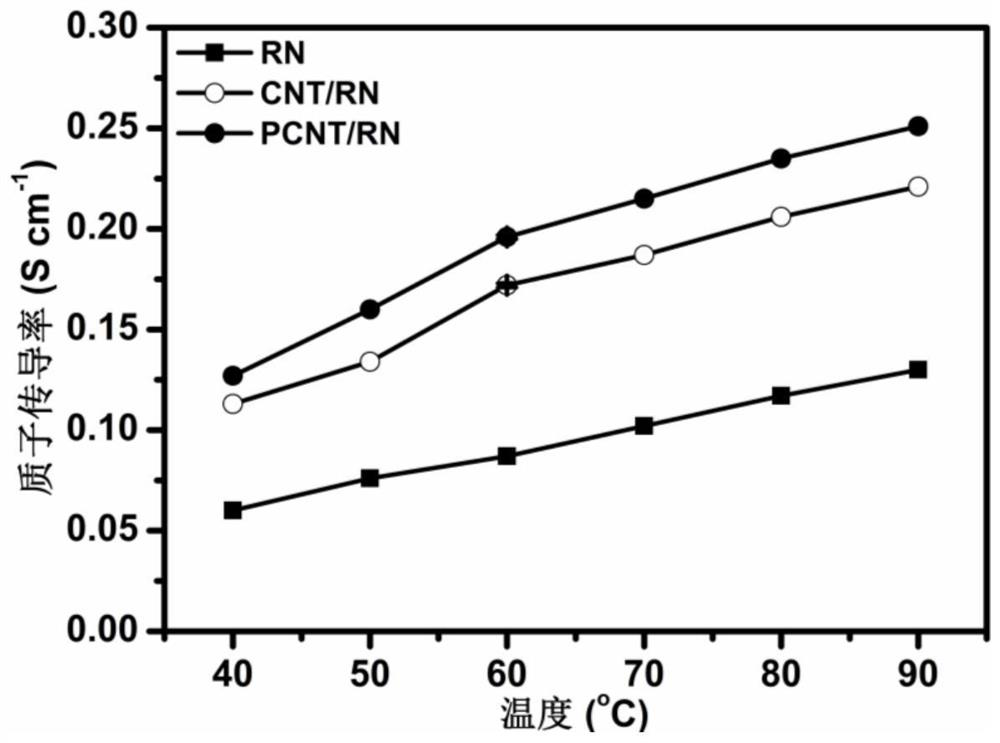

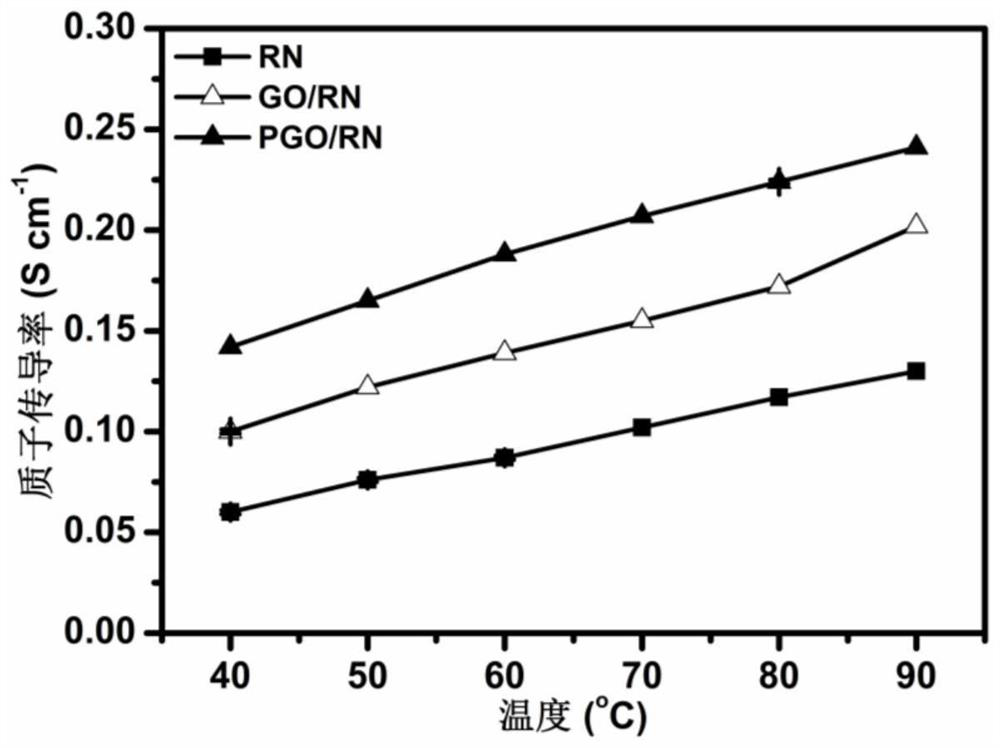

Polymeric hybrid proton exchange membrane synergistically modified by PCNT and PGO and preparation method thereof

A proton exchange membrane and synergistic modification technology, which is applied in the field of polymer hybrid proton exchange membrane and its preparation, can solve the problem of insufficient proton conductivity and achieve broad application prospects, low production cost, and good industrial production basis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Weigh 100 mg of carboxylated CNTs into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse them uniformly, add 50 mg of dopamine hydrochloride to it, place it in an ice-water bath and ultrasonicate for 30 min, then stir at 25°C 24h, centrifuged to separate the product, washed thoroughly with deionized water, and freeze-dried to obtain polydopamine-modified carbon nanotubes (DCNTs);

[0041] 2. Weigh 100 mg of GO into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse it uniformly, add 50 mg of dopamine hydrochloride to it, place it in an ice-water bath for 30 min, and then stir at 25°C for 24 h. The product was separated by centrifugation, washed thoroughly with deionized water, and freeze-dried to obtain polydopamine-modified graphene oxide (DGO);

[0042] 3. Weigh 30 mg of DCNT and 90 mg of alendronic acid, respectively, add them to 90 mL of Tris buffer solution (pH 8.5), stir at 25°C for 24 h, separate the product by centrifugation, and ...

Embodiment 2

[0047] 1. Weigh 100 mg of carboxylated CNTs into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse them uniformly, add 50 mg of dopamine hydrochloride to it, place it in an ice-water bath and ultrasonicate for 30 min, then stir at 25°C 24h, centrifuged to separate the product, washed thoroughly with deionized water, and freeze-dried to obtain polydopamine-modified carbon nanotubes (DCNTs);

[0048] 2. Weigh 100 mg of GO into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse it uniformly, add 50 mg of dopamine hydrochloride to it, place it in an ice-water bath for 30 min, and then stir at 25°C for 24 h. The product was separated by centrifugation, washed thoroughly with deionized water, and freeze-dried to obtain polydopamine-modified graphene oxide (DGO);

[0049] 3. Weigh 30 mg of DCNT and 90 mg of alendronic acid, respectively, add them to 90 mL of Tris buffer solution (pH 8.5), stir at 25°C for 24 h, separate the product by centrifugation, and ...

Embodiment 3

[0054] 1. Weigh 100 mg of carboxylated CNTs into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse them uniformly, add 50 mg of dopamine hydrochloride to it, place it in an ice-water bath and ultrasonicate for 30 min, then stir at 25°C 24h, centrifuged to separate the product, washed thoroughly with deionized water, and freeze-dried to obtain polydopamine-modified carbon nanotubes (DCNTs);

[0055] 2. Weigh 100 mg of GO into 200 mL of Tris buffer solution (pH 8.5), ultrasonically disperse it uniformly, add 50 mg of dopamine hydrochloride to it, place it in an ice-water bath for 30 min, and then stir at 25°C for 24 h. The product was separated by centrifugation, washed thoroughly with deionized water, and freeze-dried to obtain polydopamine-modified graphene oxide (DGO);

[0056] 3. Weigh 30 mg of DCNT and 90 mg of alendronic acid, respectively, add them to 90 mL of Tris buffer solution (pH 8.5), stir at 25°C for 24 h, separate the product by centrifugation, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com