Imitational-nylon handfeel, low-solid content and silver-coated satin and production technology thereof

A production process, low solid content technology, applied in the direction of improved hand-feeling fibers, heating/cooling fabrics, dry-cleaning fiber products, etc., can solve the problem of hard hand-feeling, and achieve the effect of slight creases and close flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

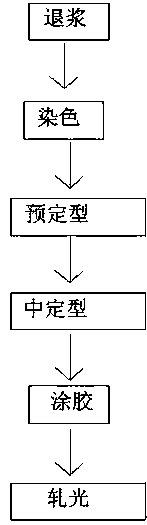

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of imitation nylon feel low solid content silver-colored butyl cloth and its production technology provided by the present invention, described nylon-like feel low solid content silver-color butyl cloth comprises base cloth layer, is positioned at base cloth layer Surface primer coating; Its production process comprises the following steps:

[0034] a. Put the satin gray cloth into the desizing machine for pre-scouring treatment;

[0035] b. The fabric after desizing is subjected to overflow dyeing treatment; the temperature of the desizing tank is 98-100°C; the speed of the desizing car is 50m / min, and the pressure of the paddle car is 1. kg / cm 2 . Add desizing mixed solution in the described desizing process, by weight, described desizing mixed solution comprises 45 parts of desizing agent, 40 parts of liquid alkali, 1 part of refining agent and 1 part of hydrogen peroxide; Add 15 parts at one time when feeding, and then add 10 parts every 10,00...

Embodiment 2

[0040] Embodiment 2: a kind of imitation nylon handle provided by the invention is coated with silver-colored diced cloth with low solid content and production technology thereof, comprises the following steps:

[0041] The present invention provides a nylon-like feel low-solid-content silver-colored butyl cloth and its production process, the nylon-like feel low-solid-content silver-color butyl cloth comprising a base cloth layer and a primer positioned on the surface of the base cloth layer coating; its production process comprises the following steps:

[0042] a. Put the satin gray cloth into the desizing machine for pre-scouring treatment;

[0043] b. The fabric after desizing is subjected to overflow dyeing treatment; the temperature of the desizing tank is 100°C; the speed of the desizing car is 70m / min, and the pressure of the paddle car is 2.0kg / cm 2 . Add desizing mixed solution in the described desizing process, by weight, described desizing mixed solution comprise...

Embodiment 3

[0048] Embodiment 3: a kind of imitation nylon feel low solid content silver-colored butyl cloth and its production technology provided by the present invention, described nylon-like feel low solid content silver-colored butyl cloth comprises base cloth layer, is located in base cloth layer Surface primer coating; Its production process comprises the following steps:

[0049] a. Put the satin gray cloth into the desizing machine for pre-scouring treatment;

[0050] b. The fabric after desizing is subjected to overflow dyeing treatment; the temperature of the desizing tank is 99°C; the speed of the desizing car is 60m / min, and the pressure of the paddle car is 1.75kg / cm 2 . In the desizing process, a desizing mixed solution is added, and in parts by weight, the desizing mixed solution includes 47.5 parts of desizing agent, 50 parts of caustic soda, 1.5 parts of refining agent and 1.5 parts of hydrogen peroxide. The desizing agent is added 17.5 parts at a time when feeding, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com