Patents

Literature

96results about How to "Reduce bend angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

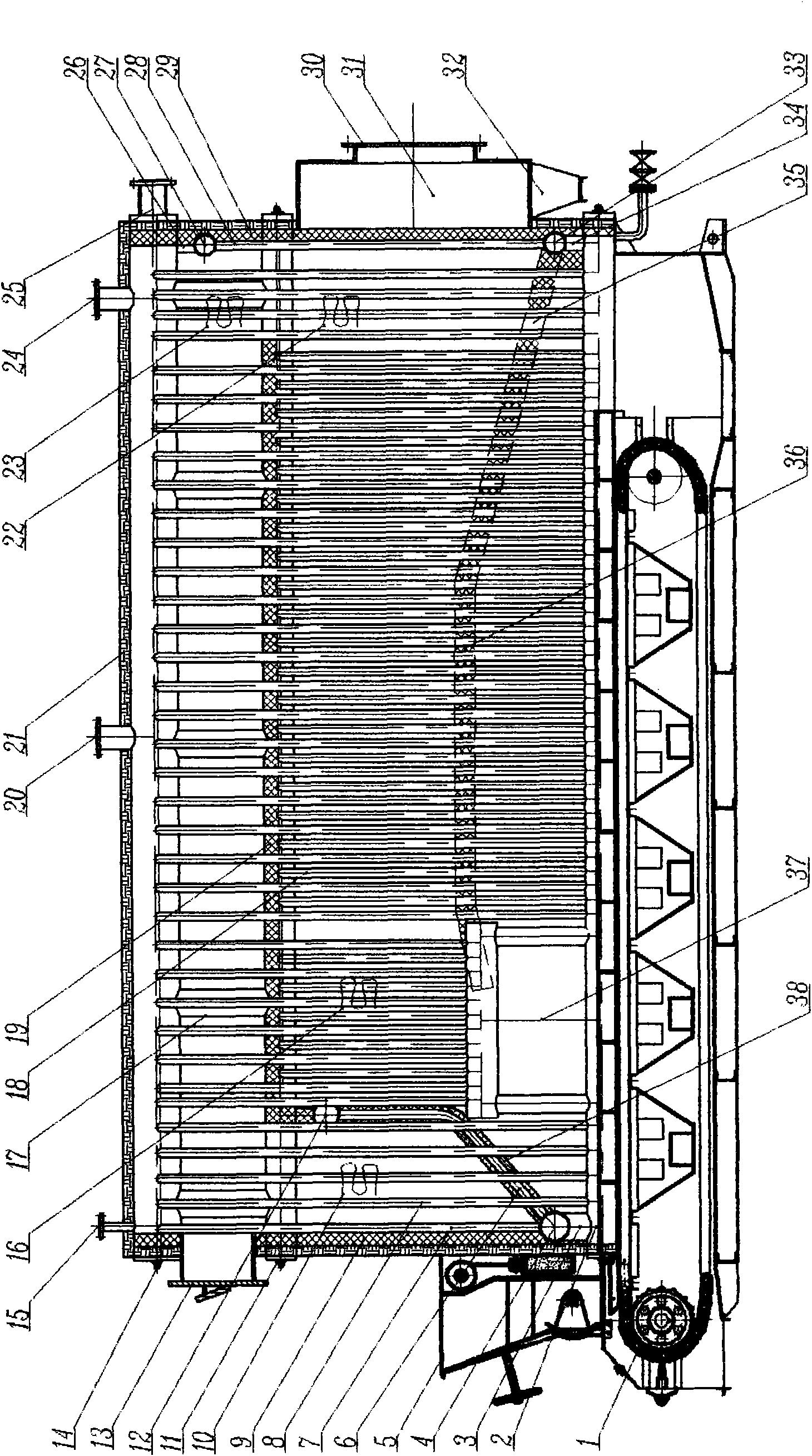

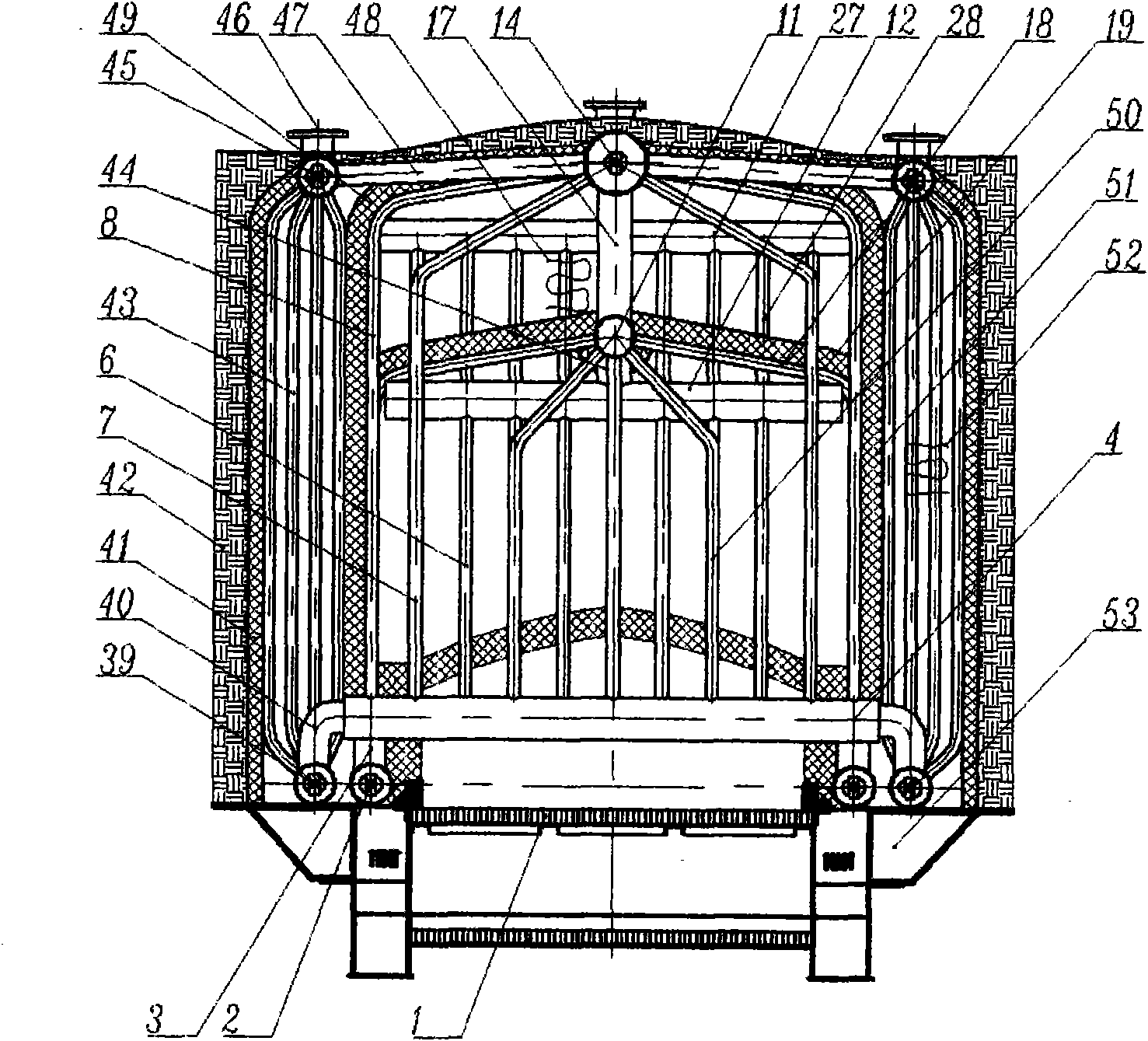

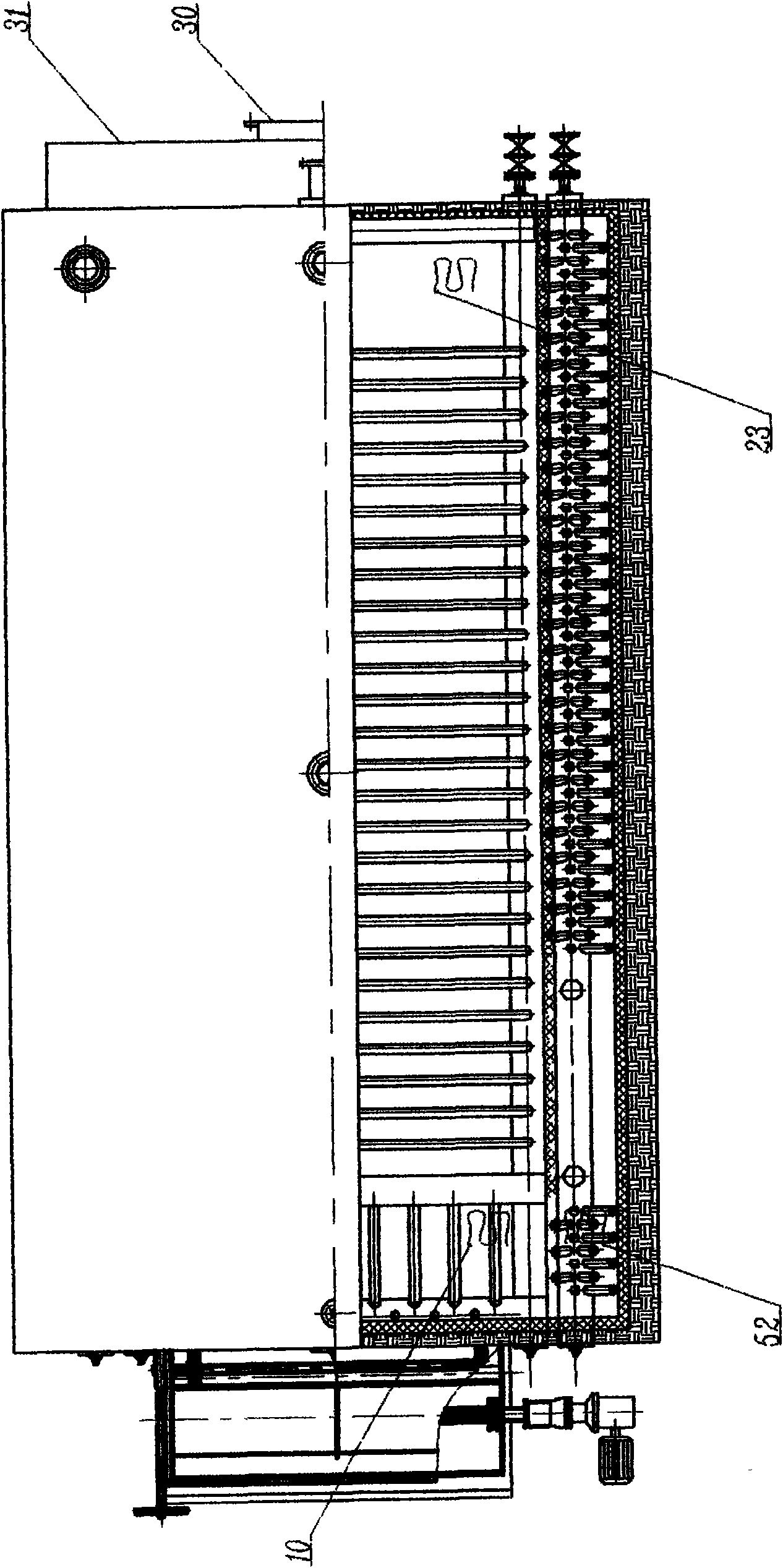

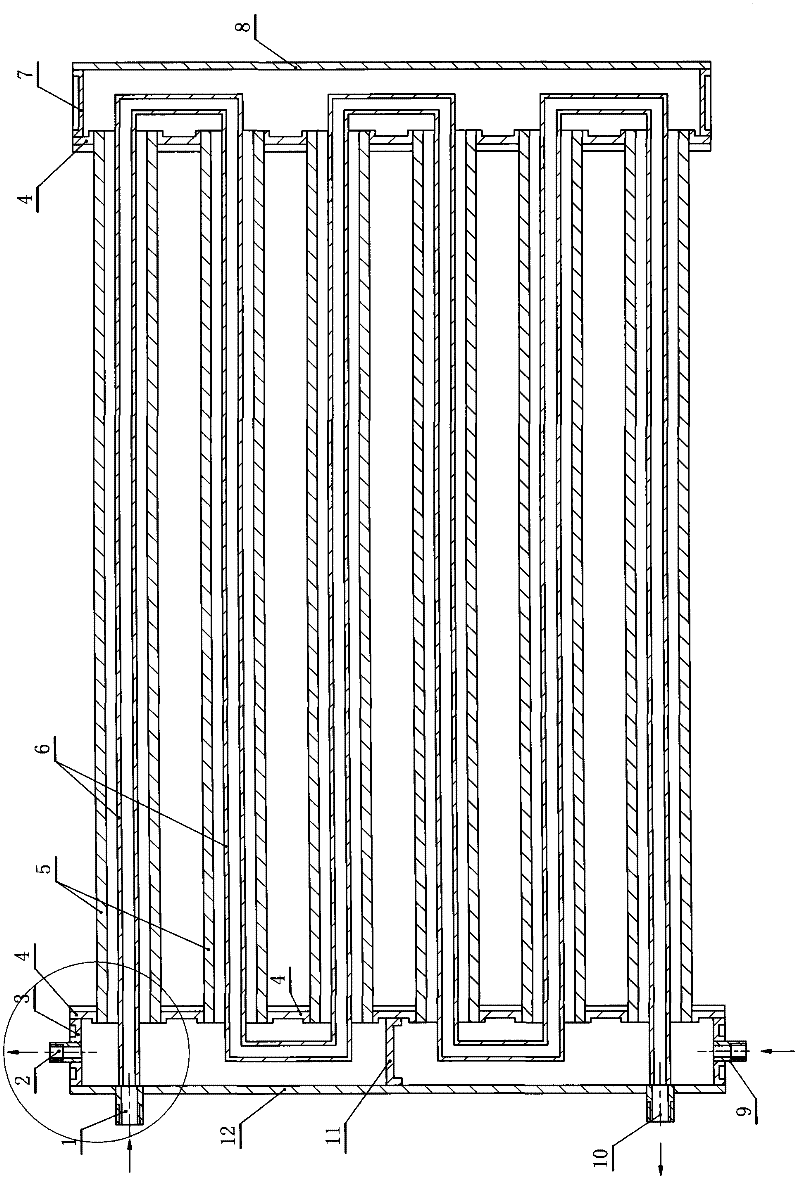

Full reverse convection unsealed water tube boiler

InactiveCN101957059AImprove production efficiencyReduce steel consumptionWater heatersWater channelEngineering

The invention discloses a full reverse convection unsealed water tube boiler. Upper and lower center headers, laterally symmetrical water wall headers, a water wall tube, upper and lower laterally symmetrical convection bank headers, a convection bank, front, rear, upper and lower transverse headers, communicating tubes and the like are respectively communicated to form a radiation convective heating surface and a natural circulation water channel; furnace walls are constructed on the outer side of the water wall and the outer sides of a ceiling and the convection bank to form a hearth and a three-return flue, so that the volume of the hearth can be increased with the same boiler volume to facilitate fully burning and settling dust in a soot furnace; the water channel and a soot channel are subjected to full reverse convection transverse washing to facilitate improving the heat exchange effect and reducing soot formation on the convective heating surface; and because of an unsealed structure, the natural circulation is safe, reliable and small in flow resistance, the overall structure process is advanced, the manufacturing is simple, and large, medium and small tubes can be adopted to replace drums of various boilers, so the steel consumption can be reduced by 30 percent, the manufacturing efficiency can be improved by 40 percent, the power consumption can be reduced by 20 percent, the initial discharge concentration of the soot can be reduced by 70 percent; therefore, the boiler has obvious advantages of energy saving, consumption reduction and emission reduction.

Owner:王森

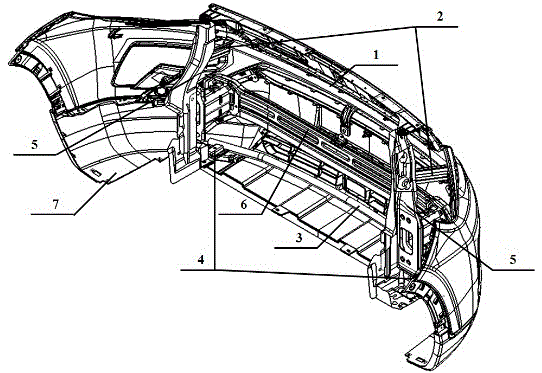

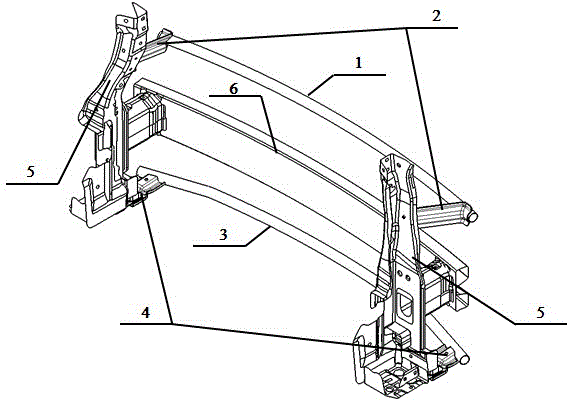

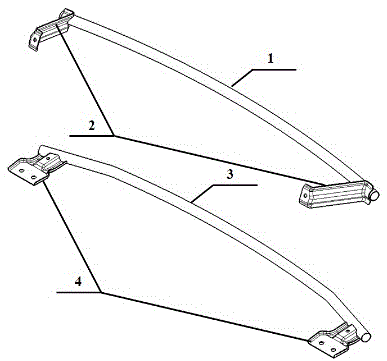

Automobile front anti-collision protecting structure

The invention provides an automobile front anti-collision protecting structure. The automobile front anti-collision protecting structure comprises a front bumper with the two ends connected with the front of an automobile body, a radiator longitudinal beam assembly assembled on a front wall of the automobile body, a front anti-collision beam assembly located behind the front bumper, and an upper supporting beam located behind the top of the front bumper. The two ends of the front anti-collision beam assembly are connected with the radiator longitudinal beam assembly, and the two ends of the upper supporting beam are connected with the radiator longitudinal beam assembly through two upper installing supports. The automobile front anti-collision protecting structure further comprises a lower supporting beam located behind the bottom of the front bumper, wherein the two ends of the lower supporting beam are connected with the radiator longitudinal beam assembly, and the horizontal distance between the front bumper and the lower supporting beam is not larger than 15 mm. The horizontal distance between the upper supporting beam and the front bumper is not larger than 15 mm. Good safety is achieved, when an automobile collides with a pedestrian during running, the upper supporting beam and the lower supporting beam can collide with the shanks and the thighs of the pedestrian respectively at the same time, the bending angle between the shanks and the thighs of the pedestrian is small, and damage, generated to the shanks and the knees of the pedestrian by the front anti-collision beam assembly when the shanks and the knees of the pedestrian collide with the front anti-collision beam assembly can be avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

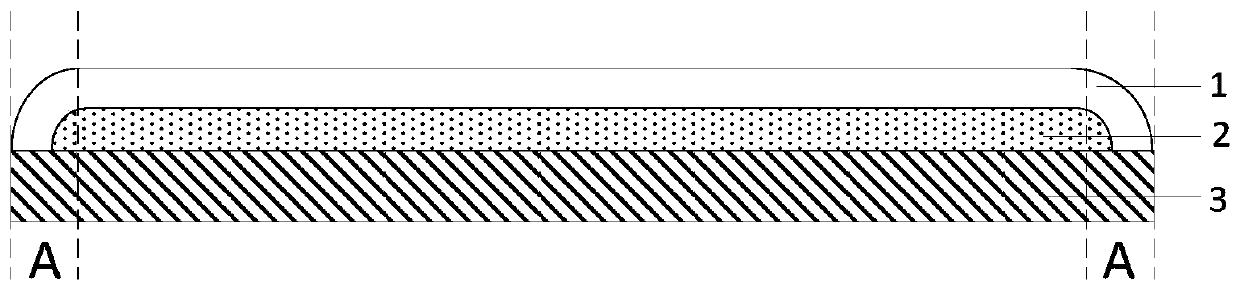

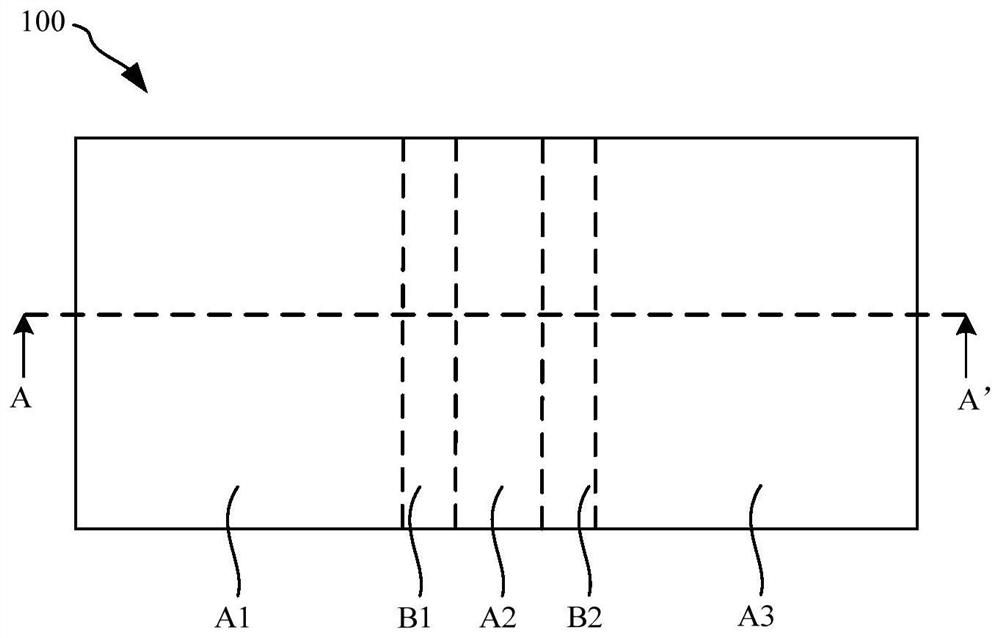

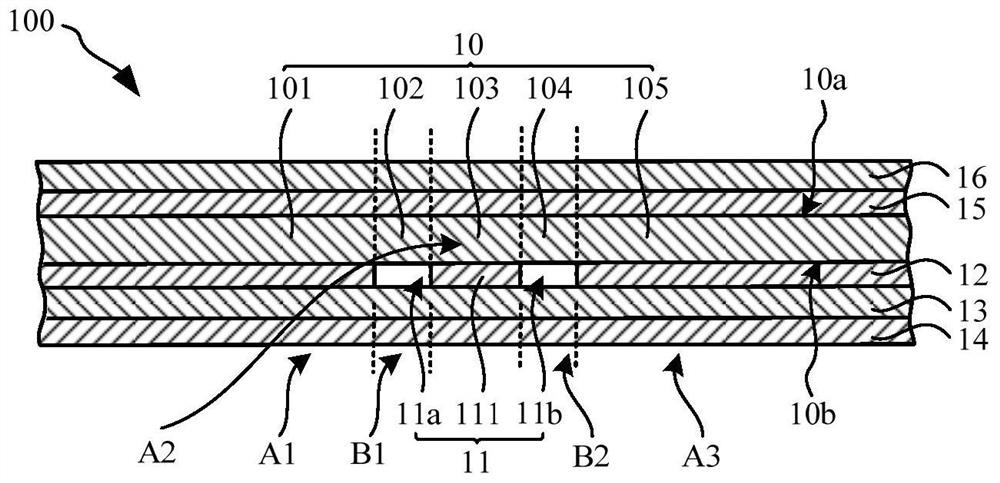

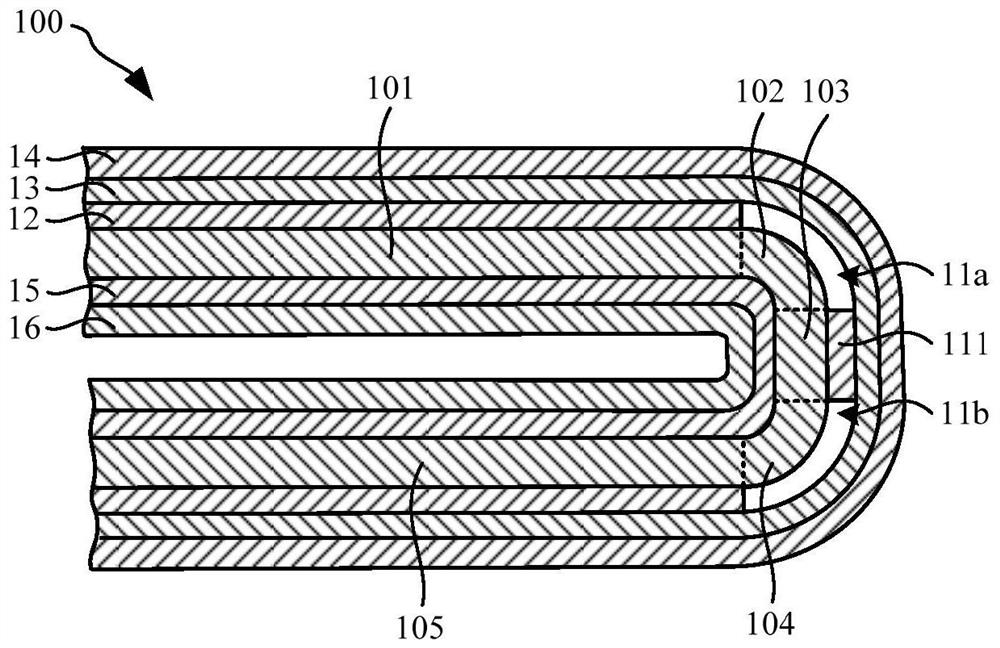

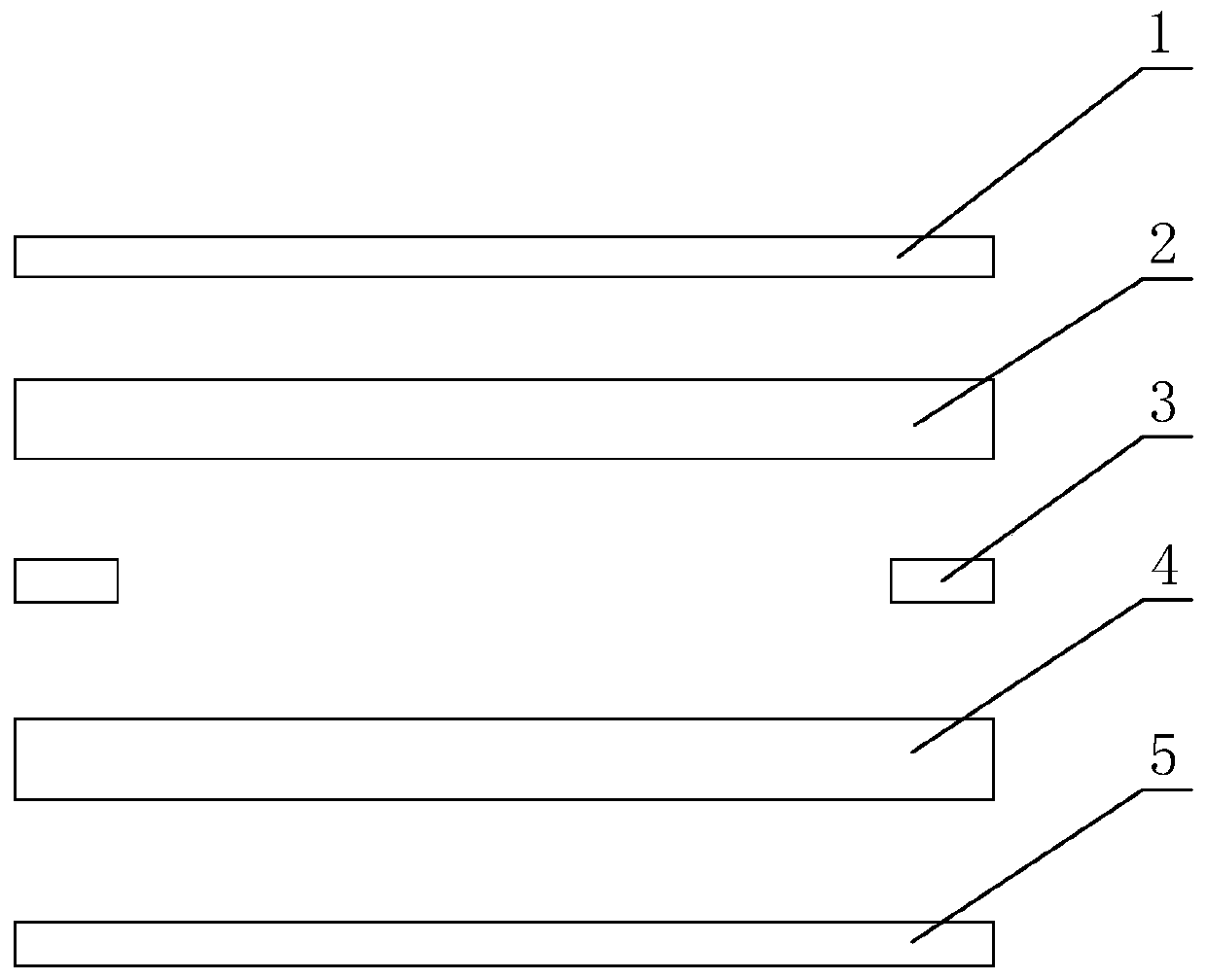

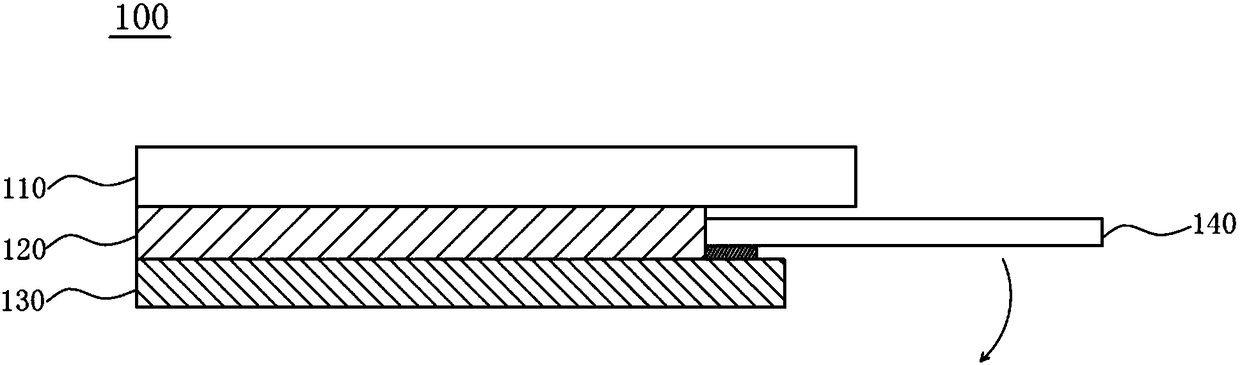

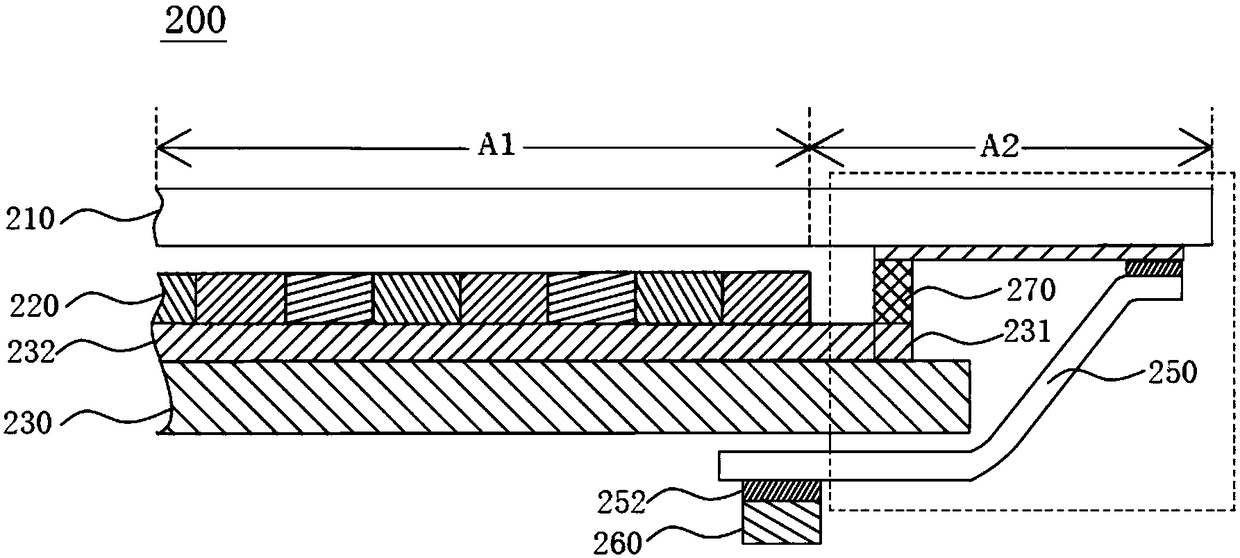

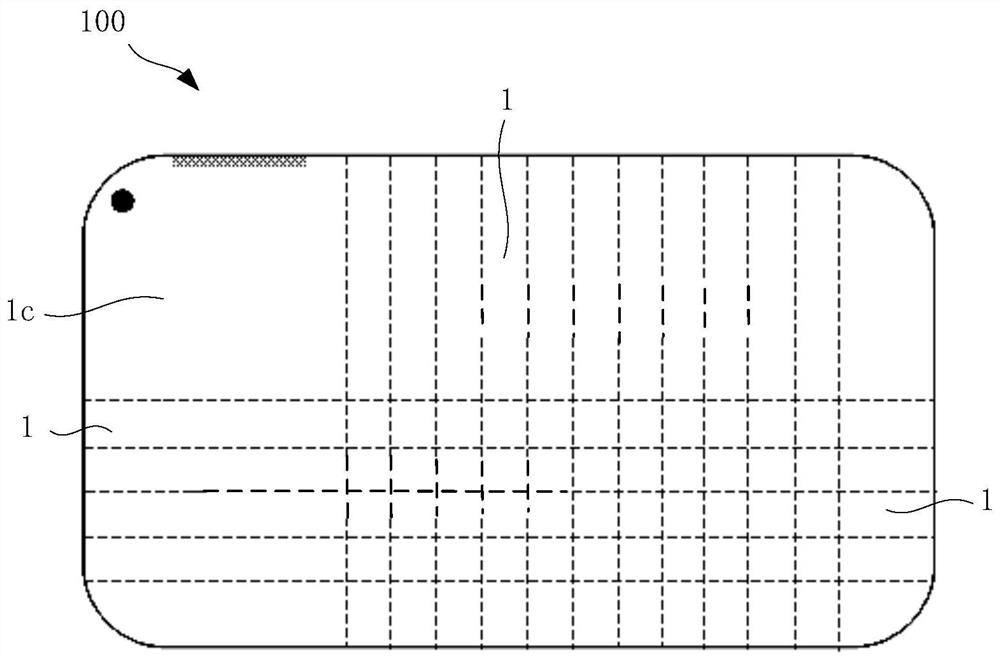

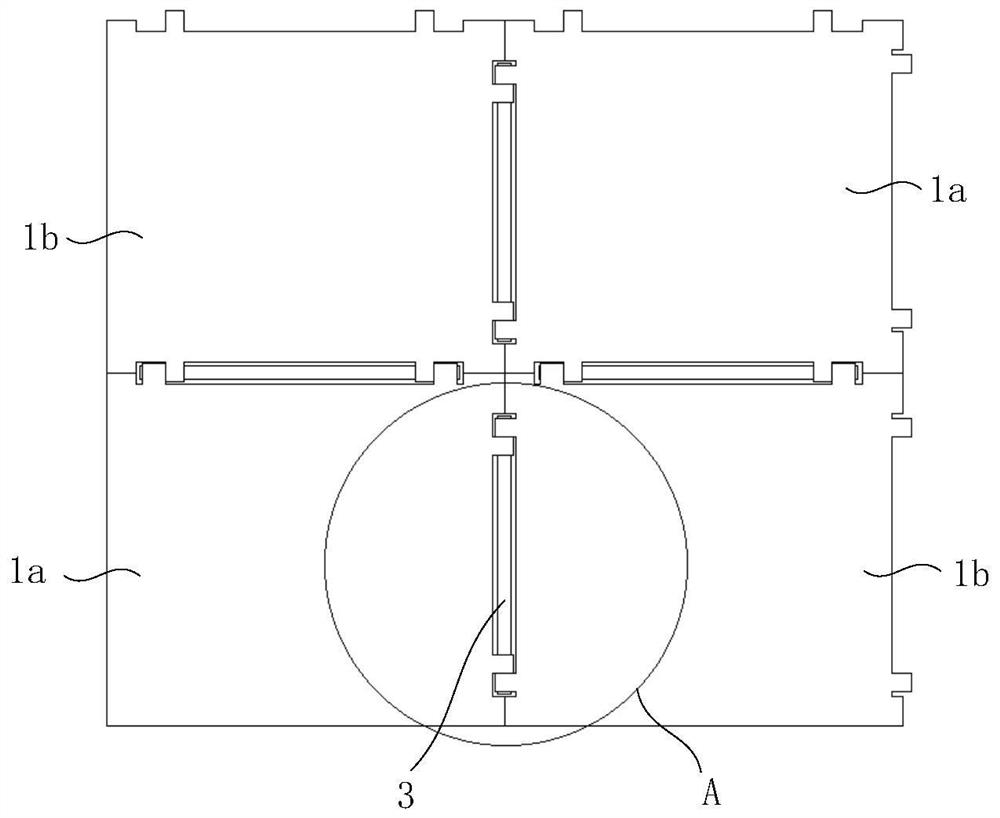

Display panel and terminal equipment

ActiveCN111029393AReduce bend angleReduce deformationSolid-state devicesPhotovoltaic energy generationTerminal equipmentStructural engineering

The invention provides a display panel and terminal equipment, and the problem of film separation between a touch layer and a polarizing layer due to the difference of bending capabilities of materials of the touch layer and the polarizing layer is solved. The display panel comprises a display layer which comprises at least one bending area, a functional film layer arranged on one side of the light emitting direction of the display layer, and an adhesive layer arranged between the display layer and the functional film layer, wherein the adhesive layer comprises at least one arc-shaped structure, and the projection of one arc-shaped structure on the display layer is located in one bending area; the adhesive layer comprises a plurality of sub-adhesive layers which are sequentially arranged in a stacked mode in the light-emitting direction, and portions, corresponding to the bending area, of the sub-adhesive layers are arranged in a stepped mode to form the arc-shaped structure.

Owner:HEFEI VISIONOX TECH CO LTD

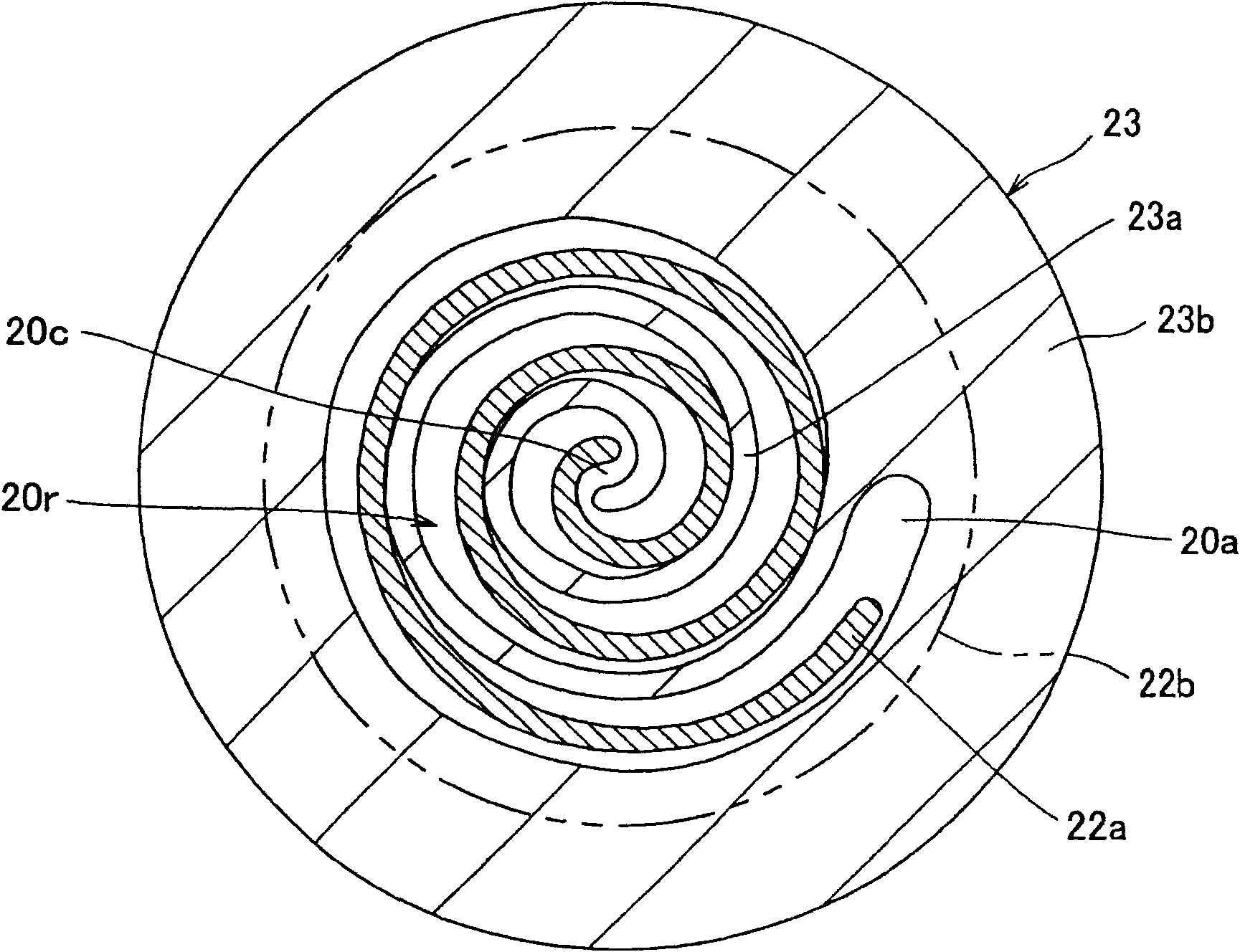

Pneumatic radial tire for heavy load

InactiveCN101977782AQuick wearReduce bend angleTyre tread bands/patternsClassical mechanicsRoad surface

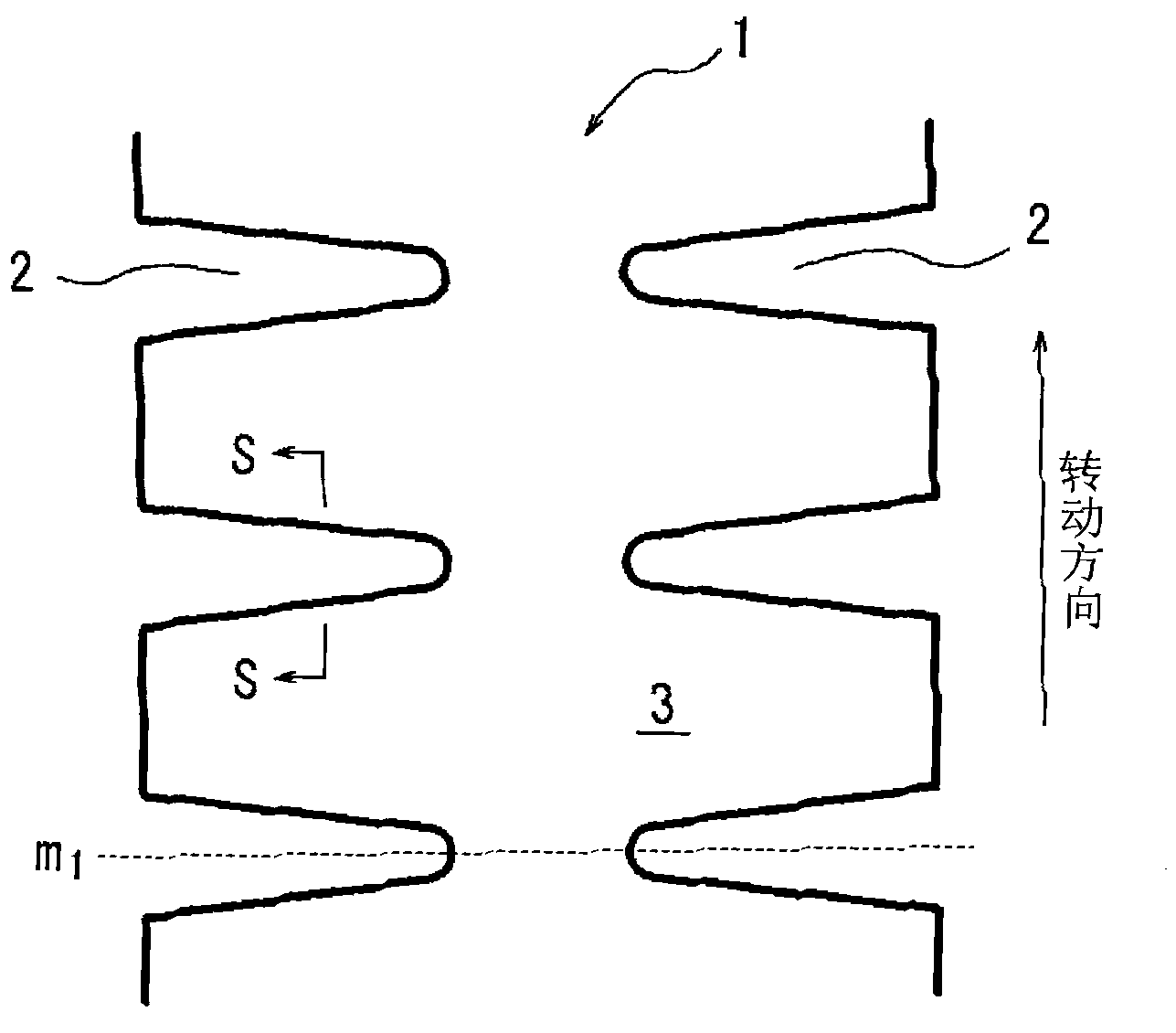

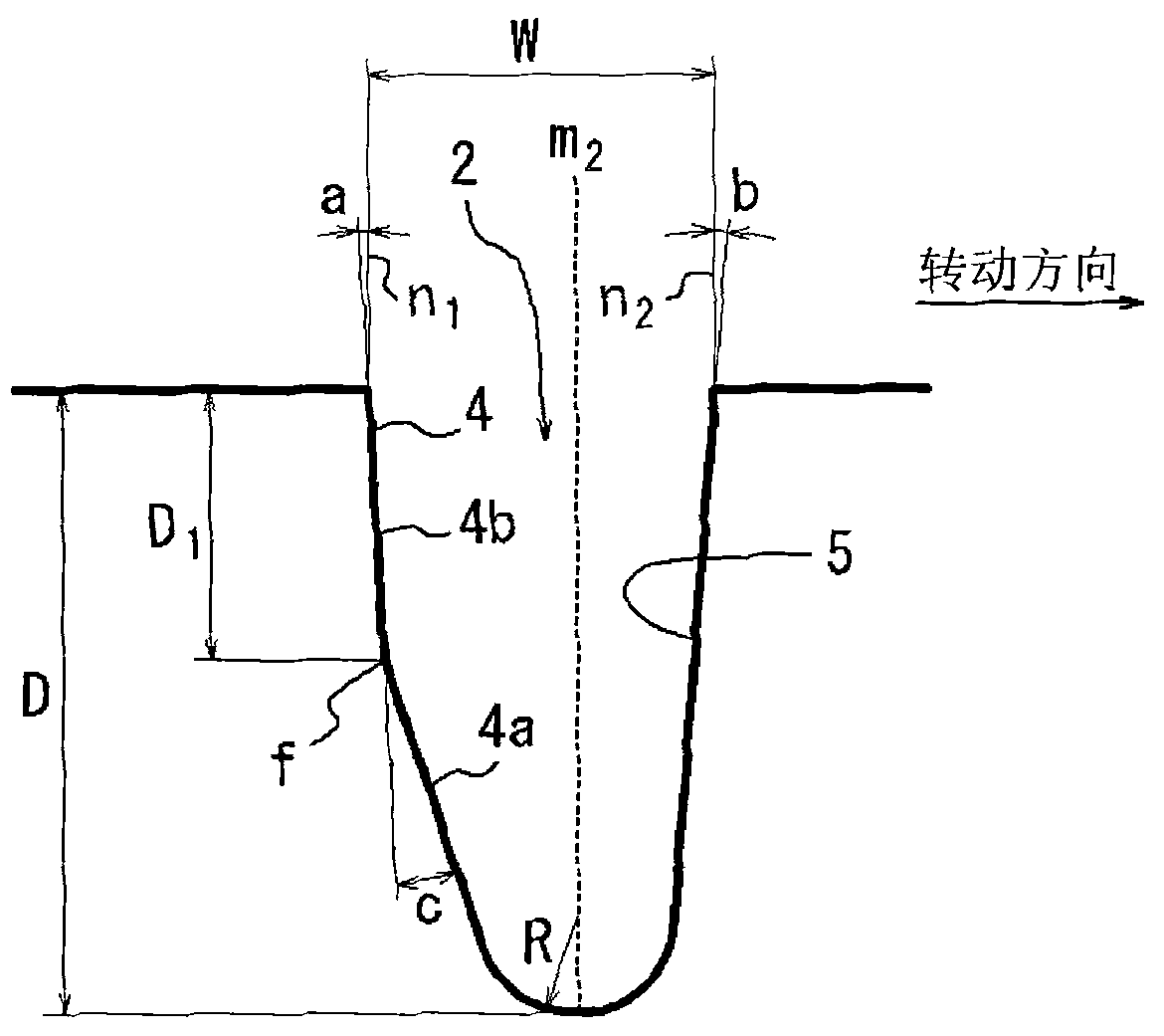

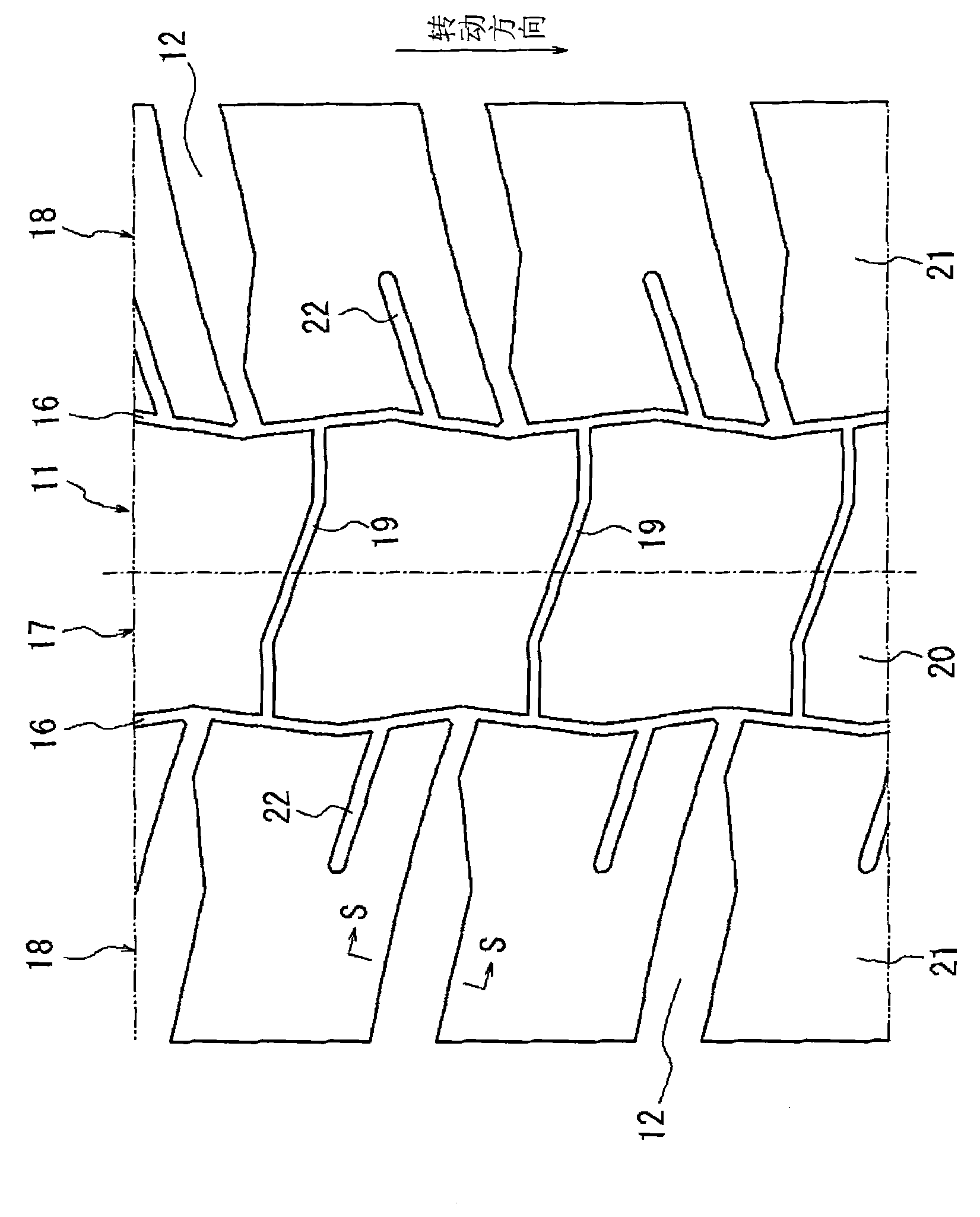

A pneumatic radial tire for heavy load, provided with lug grooves in side regions of a tread surface, wherein the amount of slip of a kick-out end section of a land section, defined by the lug grooves, relative to a road surface when the tire rolls under a load is reduced without a reduction in the resistance to uneven wear of a road surface land section and without possibility of occurrence of cracks in lug groove bottoms. Lug grooves (2) extending in the lateral direction of the tread and open in side edges of a tread surface (1) are arranged in side regions of the tread surface (1), and a land section (3) is defined between the lug grooves (2). In a lateral cross section of a lug groove (2), only a groove wall (4) on the step-in side of the land section (3) is bent at least one portion thereof which is located in the depth direction of the lug groove (2), and that portion (4a) of the groove wall (4) which is located radially inward of the bend (f) is tilted in the direction in which the width of the groove decreases.

Owner:BRIDGESTONE CORP

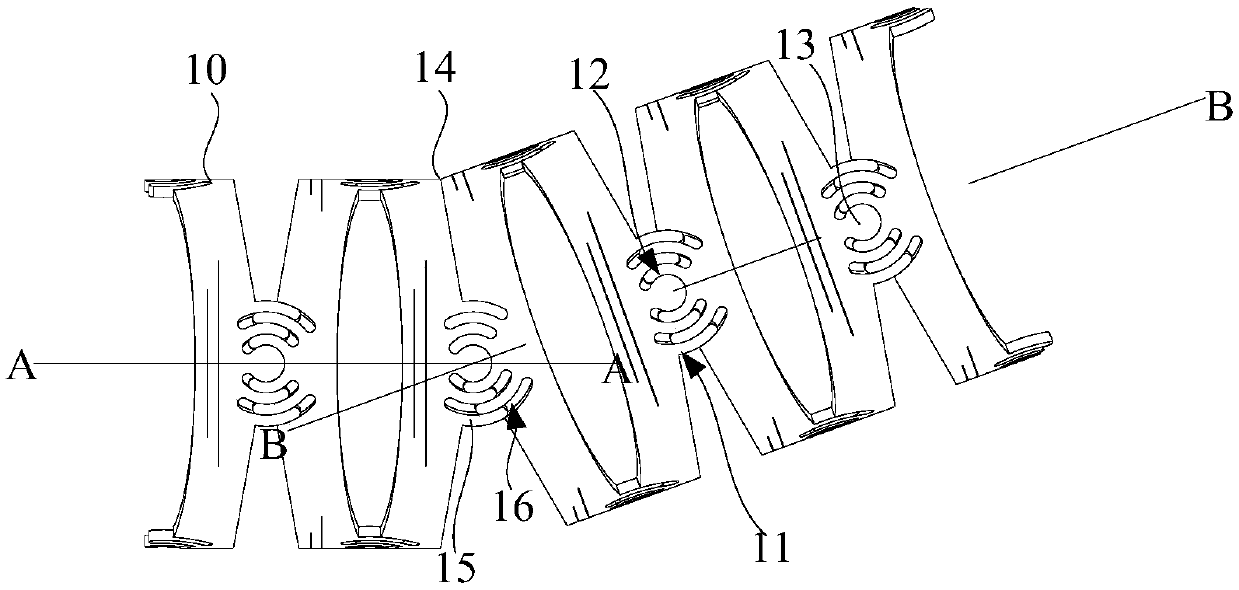

Bent portion of endoscope and endoscope

PendingCN109645937AImprove bending strengthMeet strength requirementsEndoscopesTelescopesEngineeringEndoscope

The invention provides a bent portion of an endoscope and the endoscope. The bent portion of the endoscope includes a plurality of bent blocks connected end to end. Every two adjacent bent blocks arerotatably connected through a connecting portion, and the connecting portion comprises a groove and a protrusion. The protrusions are rotatably accommodated in the grooves, the end faces of the bent blocks are respectively provided with abutting surfaces on the two sides of the connecting portions, the protrusions relatively rotate to the maximum angle in the grooves, the abutting surfaces of every two adjacent bent blocks abut against each other to enable the two bent blocks to be at the maximum bending angle, the heights of the multiple bent blocks are identical, the multiple bent blocks aredivided into multiple bent block groups in the extending direction of the bent portions, and the maximum bending angles of the bent block groups close to the front ends of the bent portions are the maximum. The bent portion of the endoscope and the front end of the endoscope are large in bending angle, thereby providing convenience for the endoscope to be extended in.

Owner:SHENZHEN XZING TECH CO LTD

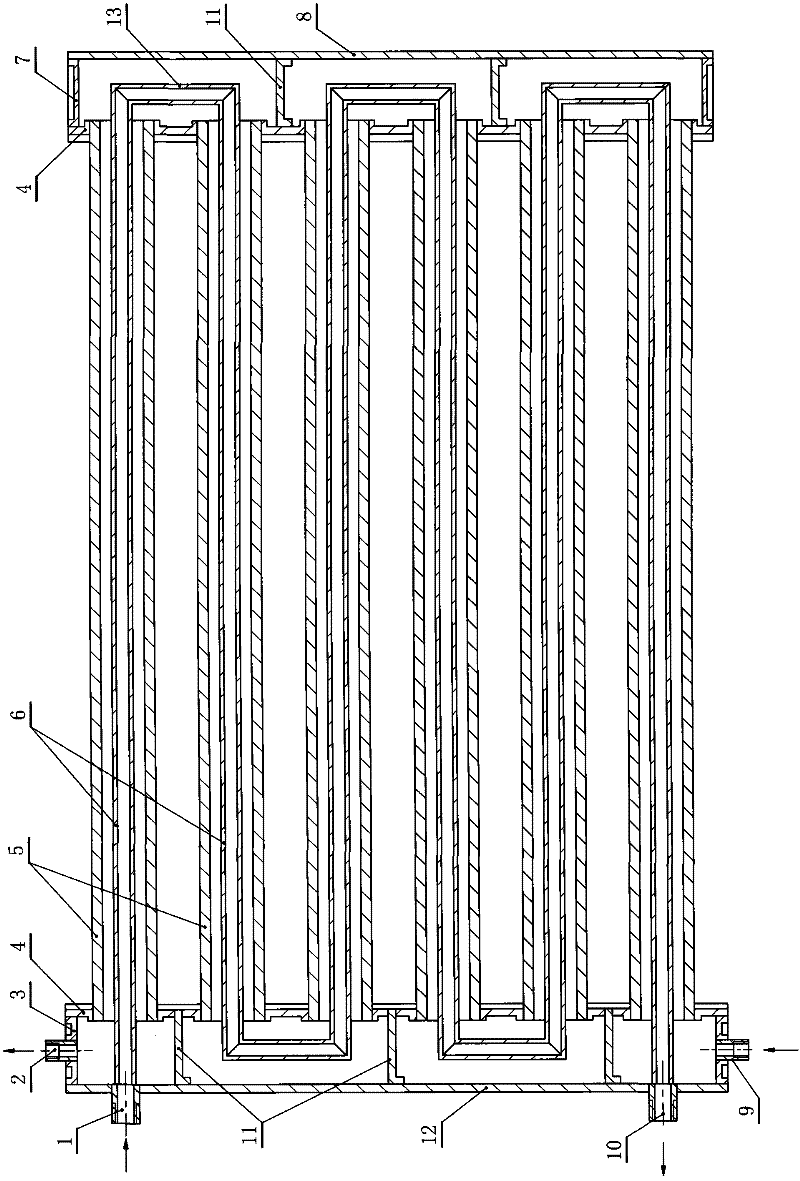

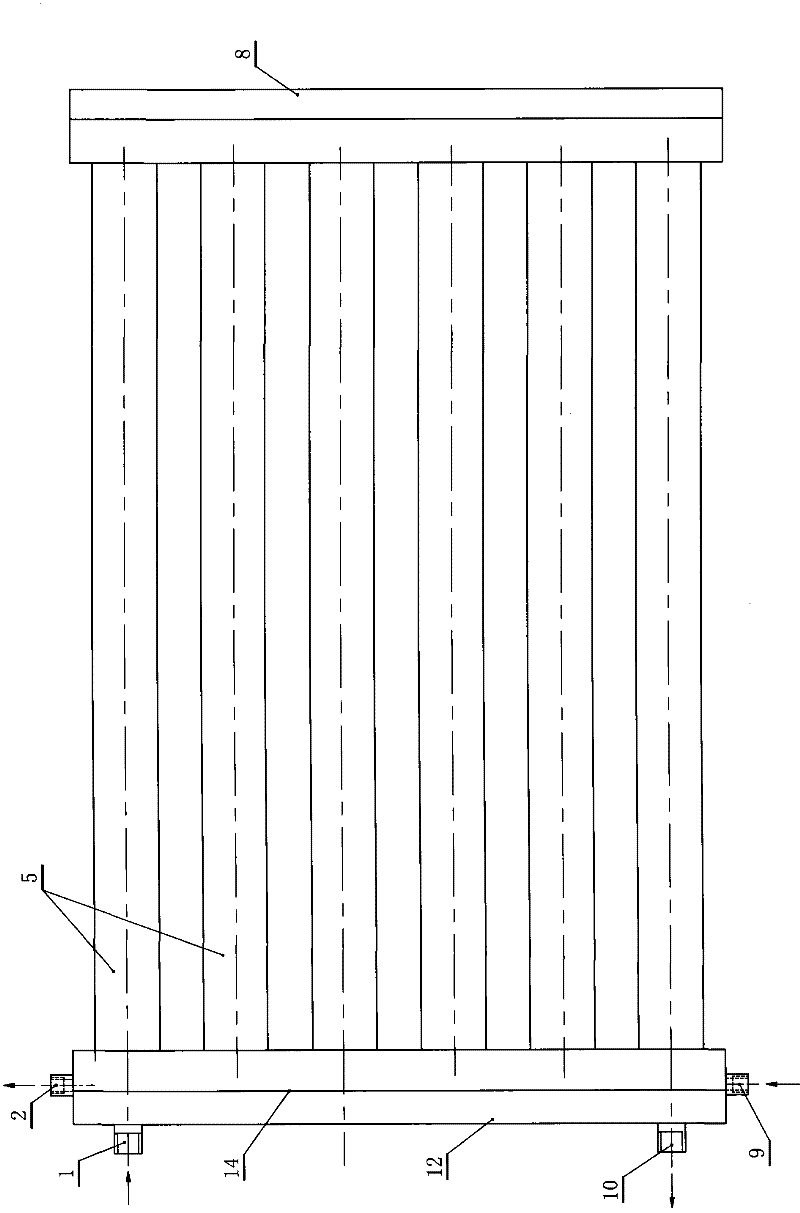

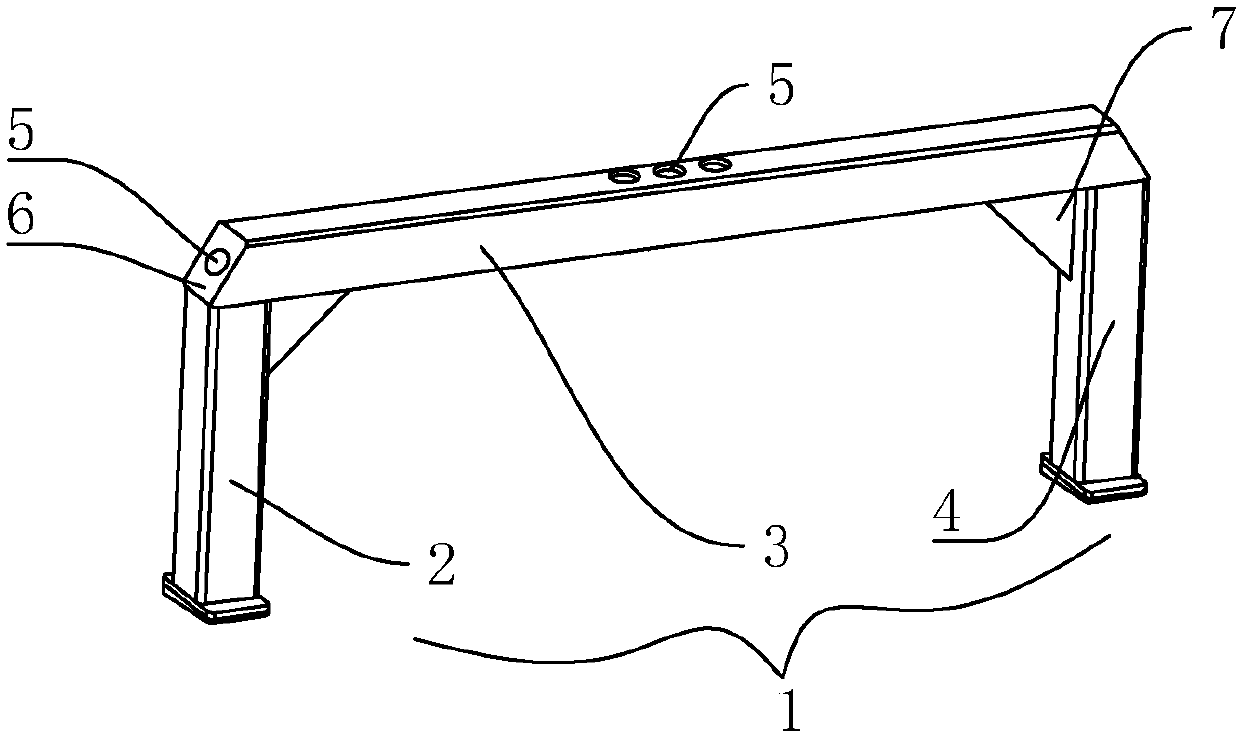

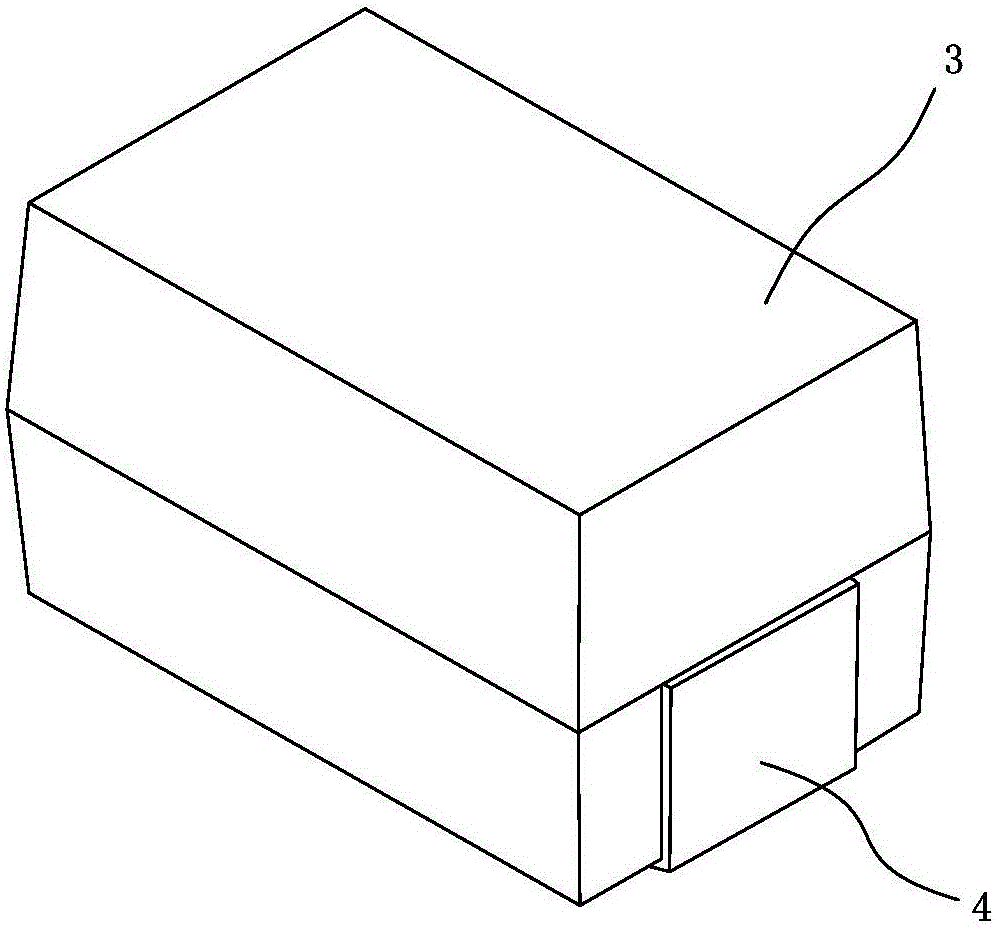

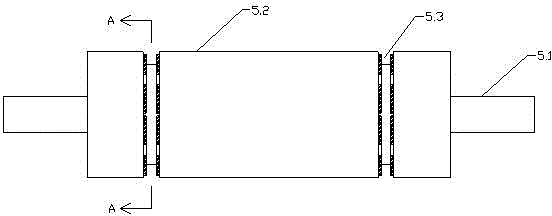

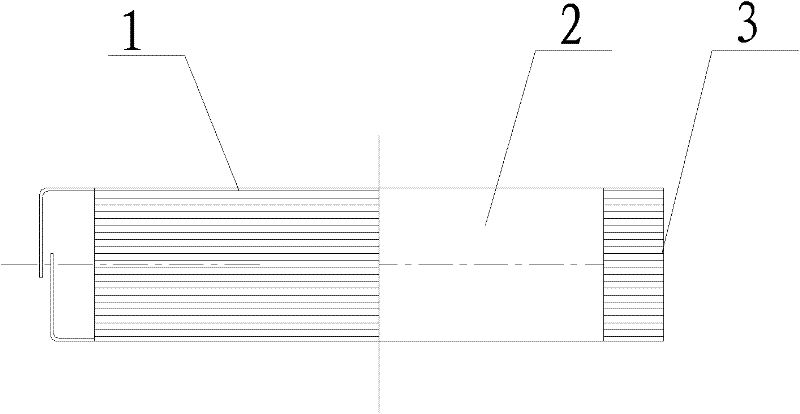

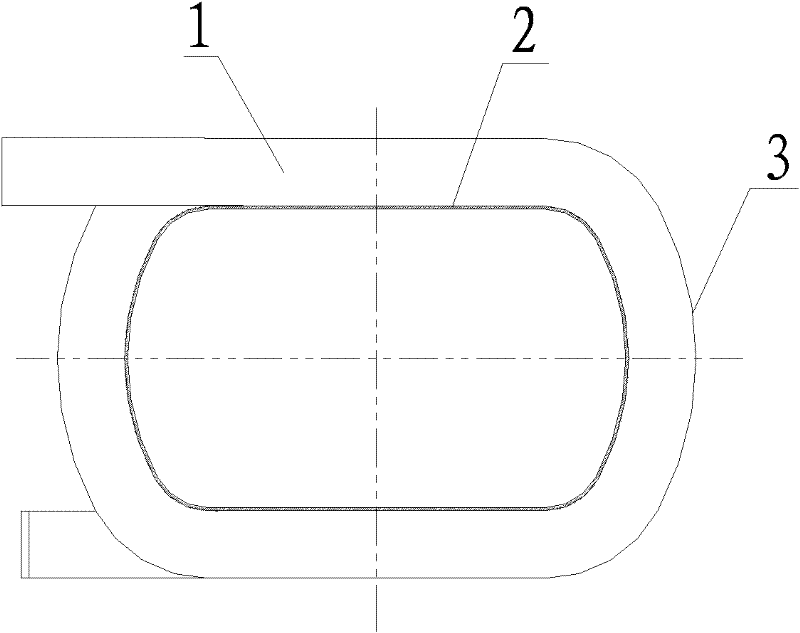

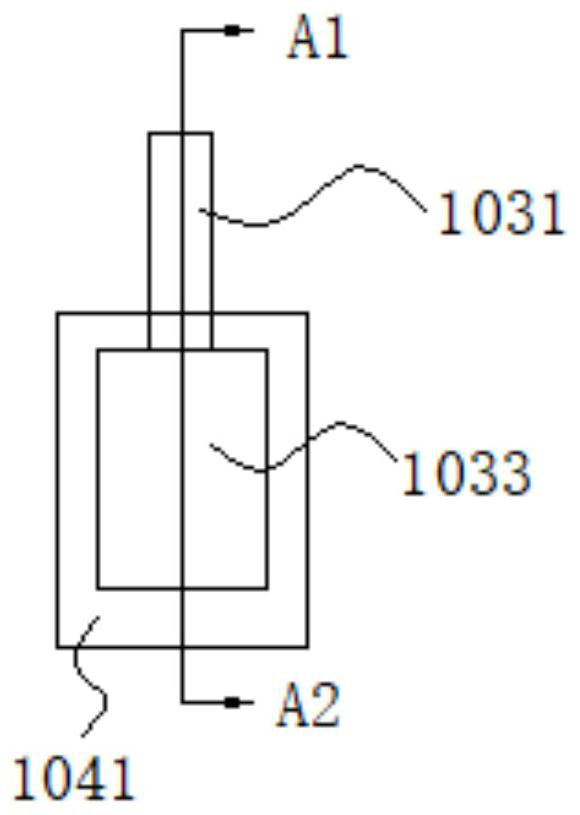

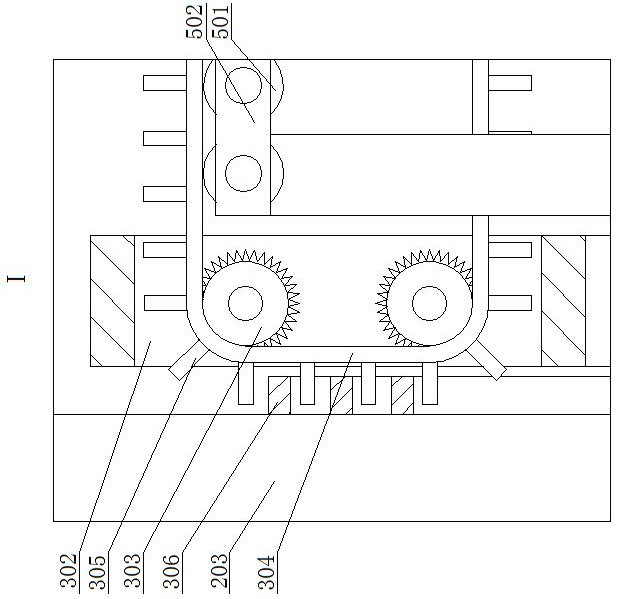

Header pressure heat exchanger

InactiveCN102297613ASolve the bend angleReduce bend angleSpace heating and ventilation detailsStationary conduit assembliesGusset plateEngineering

The utility model relates to a pressure-bearing header heat exchanger, which utilizes heating water for heat exchange to obtain hot tap water. Including: two headers, the header includes header shell, orifice plate and cover plate. Two or more tap water heat-absorbing pipes are fixedly connected between the two headers. The tap water heat-absorbing pipes are pierced with heating pipes. The heating pipes are connected. One end of the heating pipes is connected to the The heating water inlet is connected to the heating water outlet at the other end; one or more water blocking plates are arranged in one of the headers, and one or more water blocking plates are arranged in the other header. There are flanges around the water blocking plate, one side is welded on the orifice plate, and the other side is stuck or welded on the header shell. There are flanges around the cover plate, and the edges on both sides of the orifice plate are folded outwards, and the outwards folded edges on both sides of the orifice plate are welded and connected with the edge of the header shell plate. In the invention, the welded seam of the joint of the tube plate of the header shell is under pressure, the weld seam does not leak water, and the countercurrent heat exchange can also be realized.

Owner:张伟

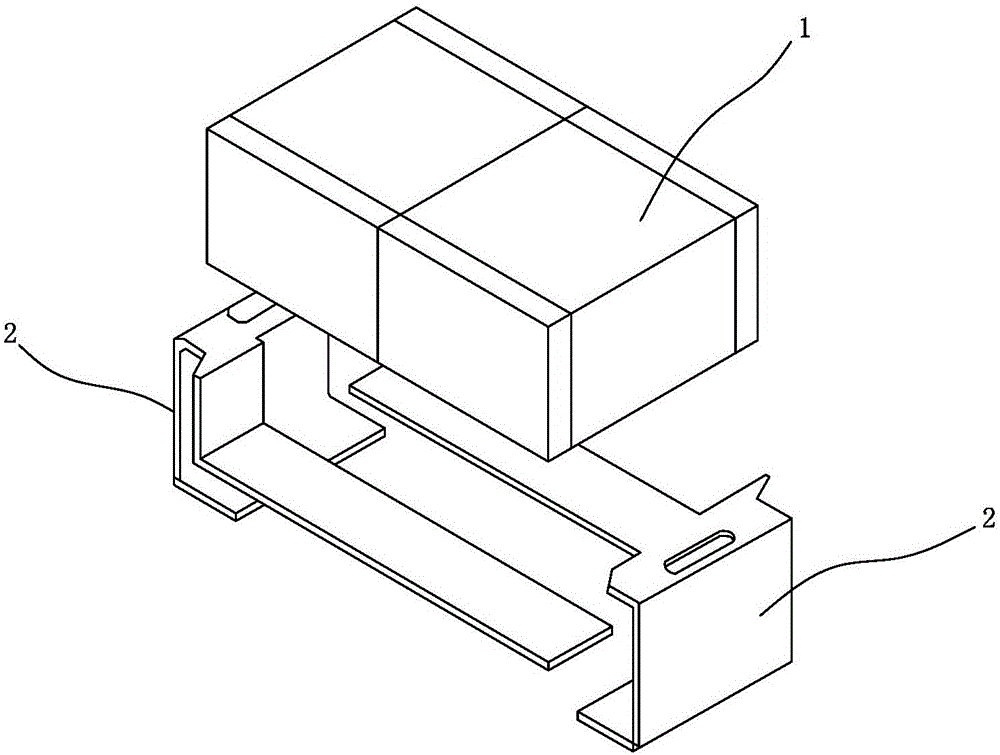

Hidden wiring groove

InactiveCN107863735AReduce bend angleShorten wire lengthElectrical apparatusStructural engineeringMechanical engineering

Owner:WUXI UNITE ENERGY TECH CO LTD

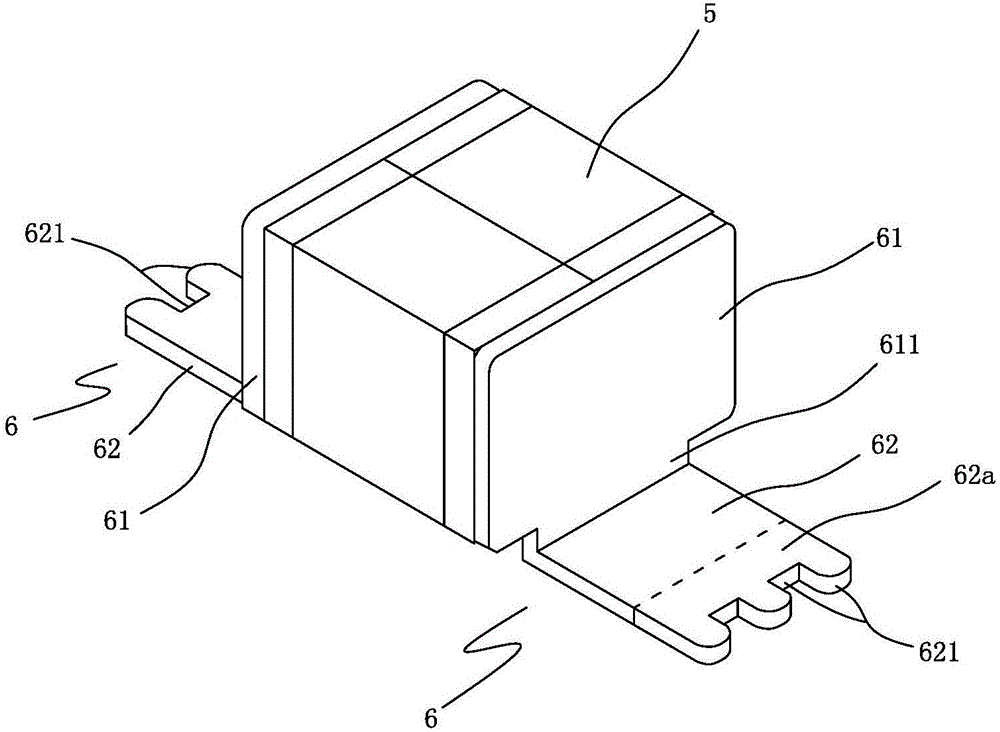

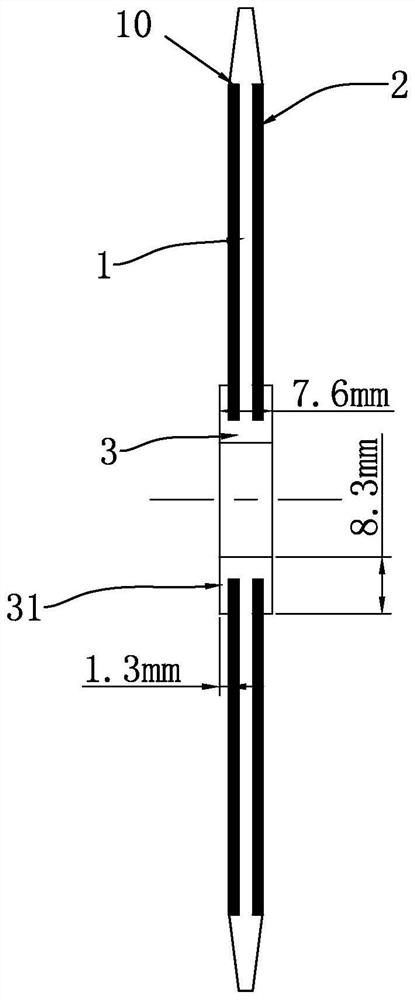

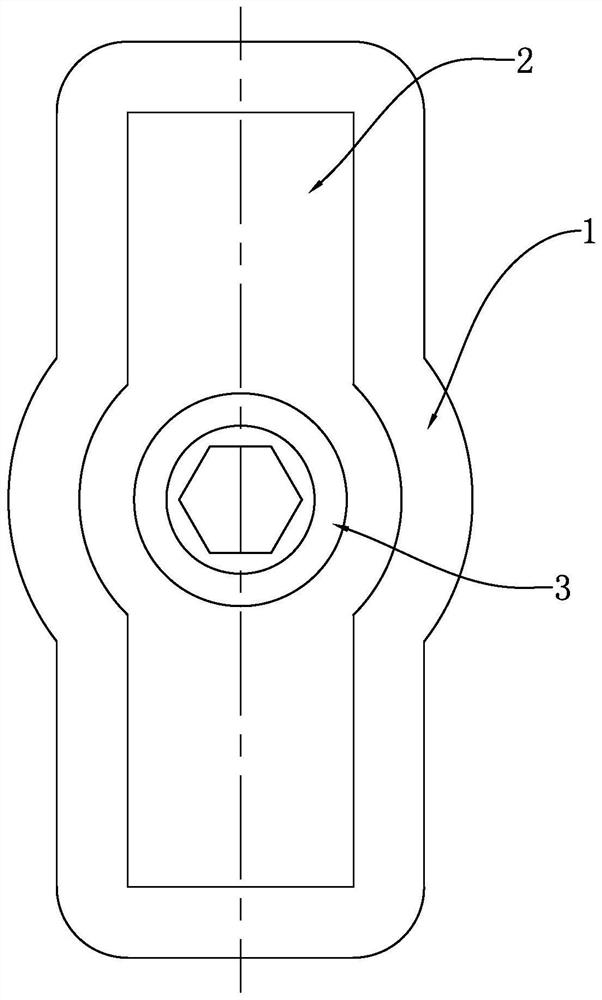

Multilayer ceramic capacitor of low ESL

InactiveCN105914036AShorten the lengthReduce bend angleFixed capacitor dielectricStacked capacitorsCapacitanceCeramic capacitor

A multilayer ceramic capacitor of a low ESL comprises a ceramic core body, two lead wires conductively connected to the ceramic core body and an insulating shell wrapping the ceramic core body. The lead wires are an ''L''-shaped structure formed by a current-conducting plate and a welding plate which are vertically connected to each other. The current-conducting plate and the ceramic core body are conductively connected and are covered by the insulating shell. The welding plate is located at a bottom of the insulating shell and possesses a welding segment which is laterally stretched out of the insulating shell. Through using the ''L''-shaped lead wires, lead wire lengths are greatly reduced and bending angles of the lead wires are decreased so that the ESL can be greatly reduced, a self-resonant frequency of the capacitor is increased and the capacitor can be applied in a high frequency circuit.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

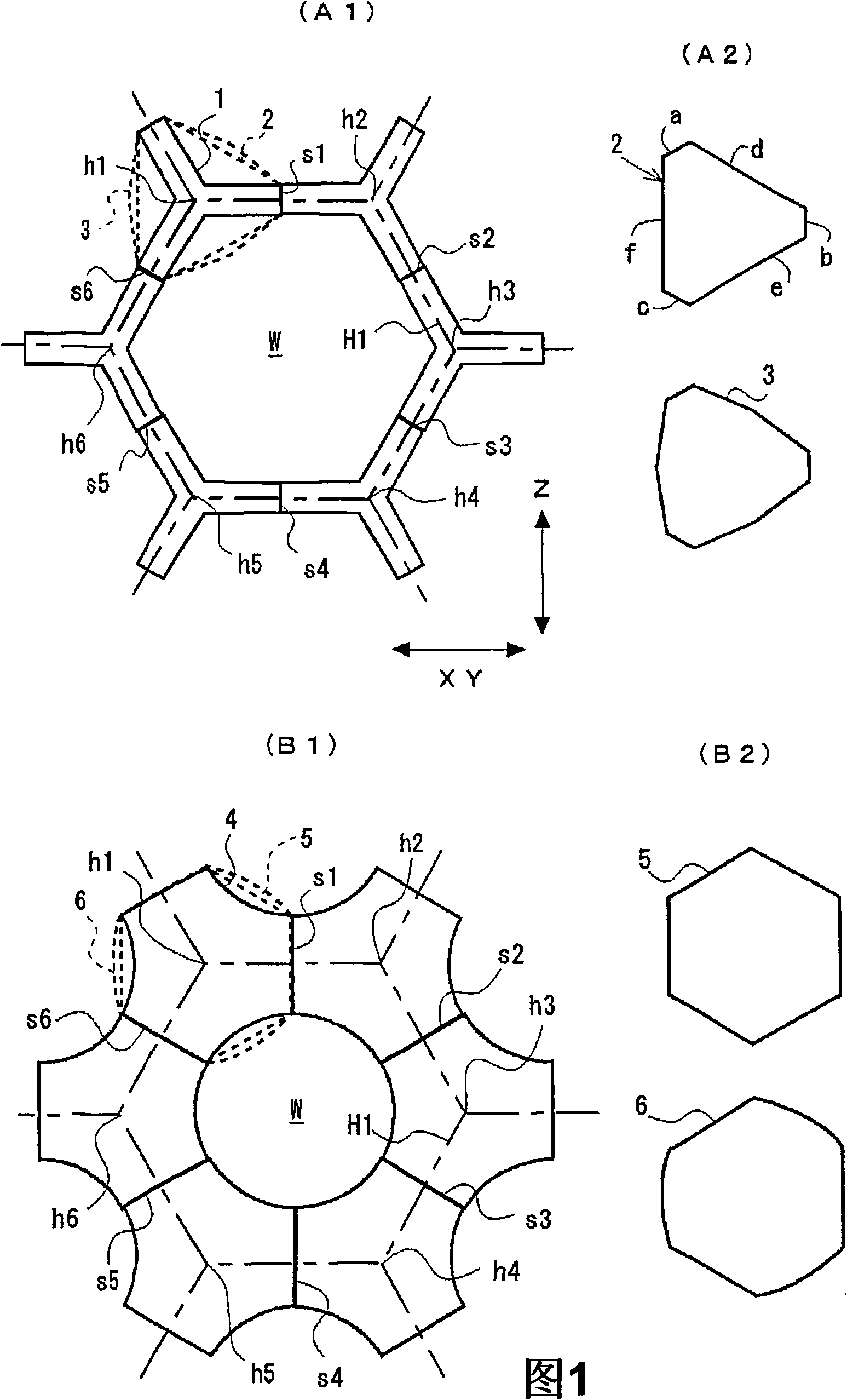

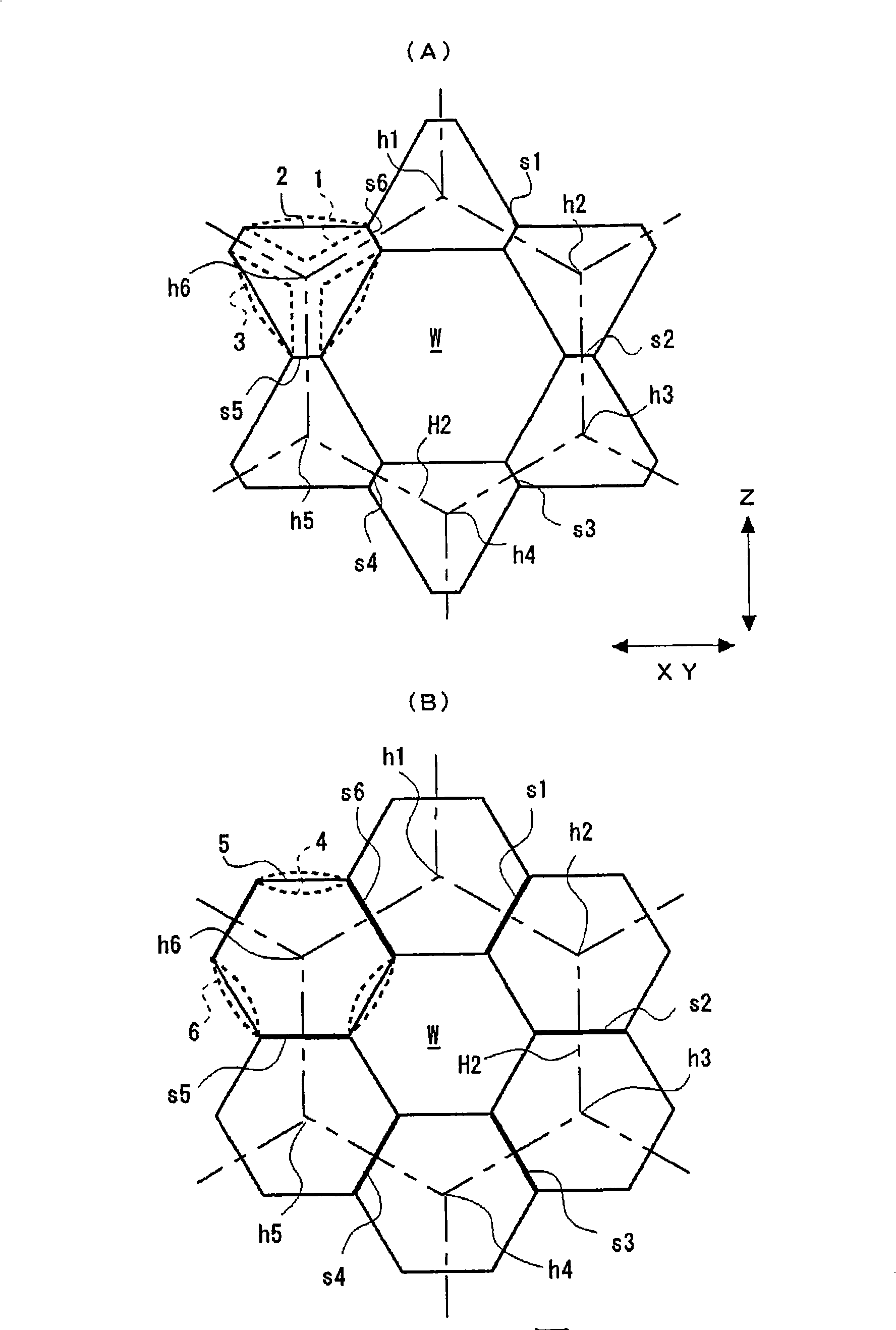

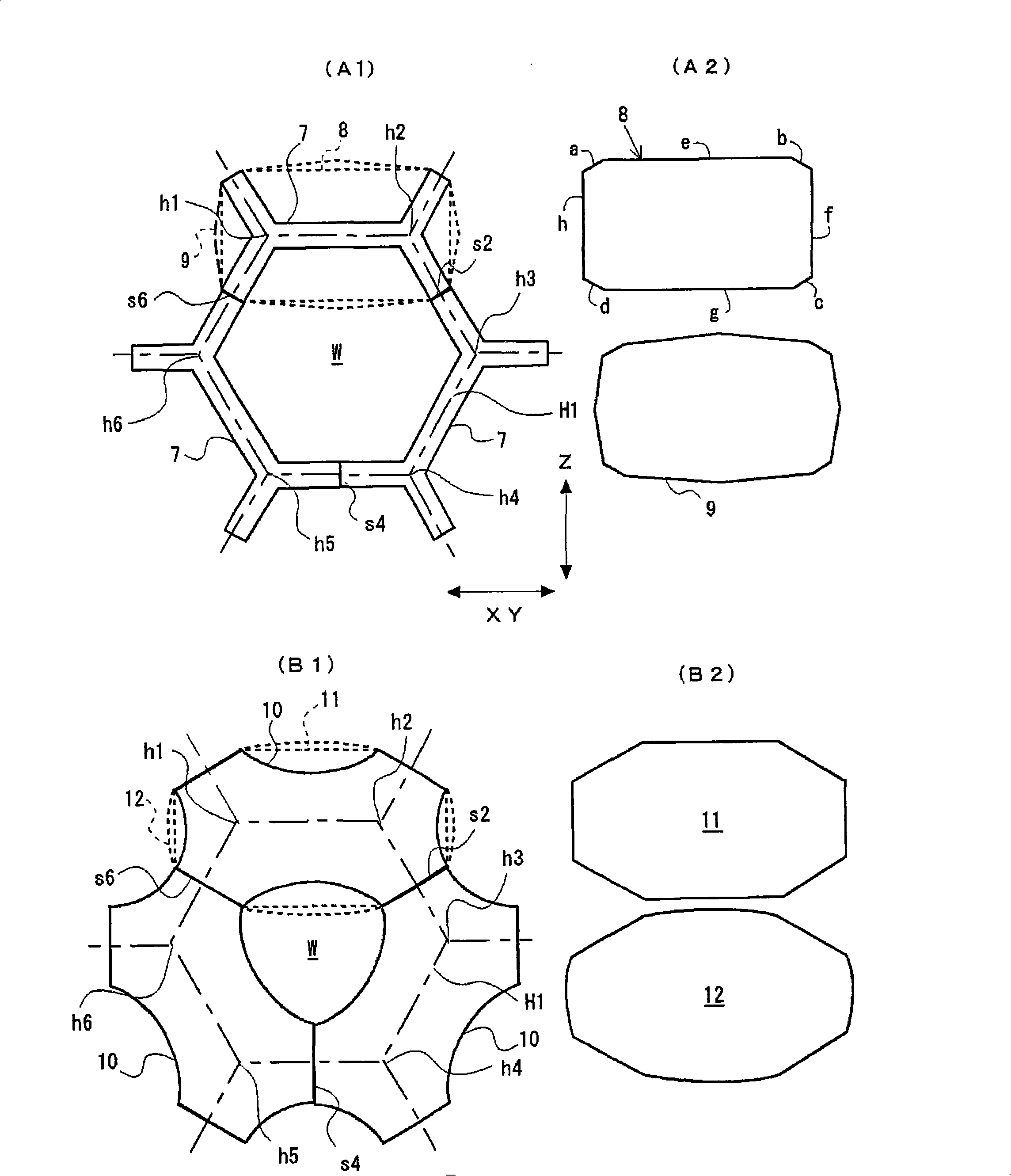

Construction structure body, structure unit, and method for the unit

InactiveCN101316972AValid conversionExtend your lifeExtraordinary structuresClassical mechanicsHoneycomb

The present invention provides a construction structure body having a honeycomb-shaped main frame that is raised and extends in a planar form, a structure unit for the construction structure body, and a method for unit. The construction structure body has the main frame formed by connecting structure units with each other, and an imaginary honeycomb shape is raised and planarly extends in the structure body. In a plan view, structure units (1, 2, 3, 4, 5, 6) are individually placed at positions including vertexes (h1, h2, h3, h4, h5. h6) of a hexagonal grid (H1, H2) as a unit grid of the imaginary honeycomb shape. The construction structure body has means for rigidly joining two structure units with joint surfaces of the two structure units faced to each other, where each of the joint surfaces are formed at a portion on the outer peripheral surface of each of the two adjacent structure units. Each of the rigidly joined surfaces (s1, s2, s3, s4, s5, s6) intersects with one of the sides of the hexagonal grid, an opening (W) is formed at the center of the hexagonal grid, and the opening (W) is surrounded by all the structure units placed on the grid.

Owner:SEKISUI CHEM CO LTD

Display device

ActiveCN112908174AReduce misalignmentReduced risk of breakageIdentification meansDisplay deviceEngineering

The embodiment of the invention discloses a display device. The display device comprises a flexible display body and a first supporting structure. The flexible display body comprises a first plane part, a first bent part, a second plane part, a second bent part and a third plane part which are connected in sequence. The first supporting structure is arranged on the flexible display body and comprises a first supporting part, and the first supporting part corresponds to the second plane part. The first supporting structure is further provided with a first vacant area and a second vacant area. The first vacant area and the second vacant area are arranged on the two sides of the first supporting part. The first vacant area corresponds to the first bent part, and the second vacant area corresponds to the second bent part. The problems that in the prior art, due to the fact that the bending angle of the display screen is too large, the film layer of a bending part is dislocated, the film layer breakage risk is high, and creases are serious are solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

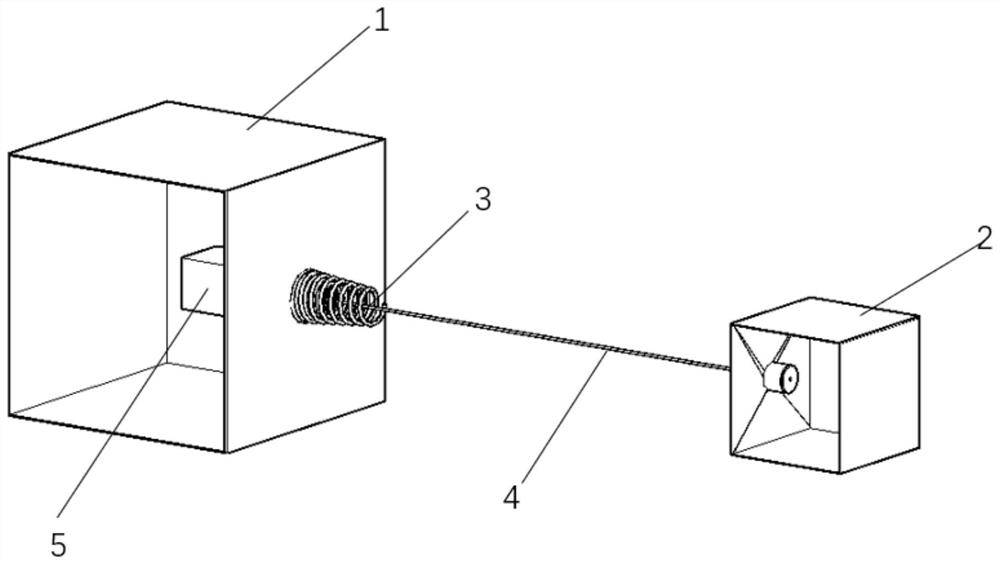

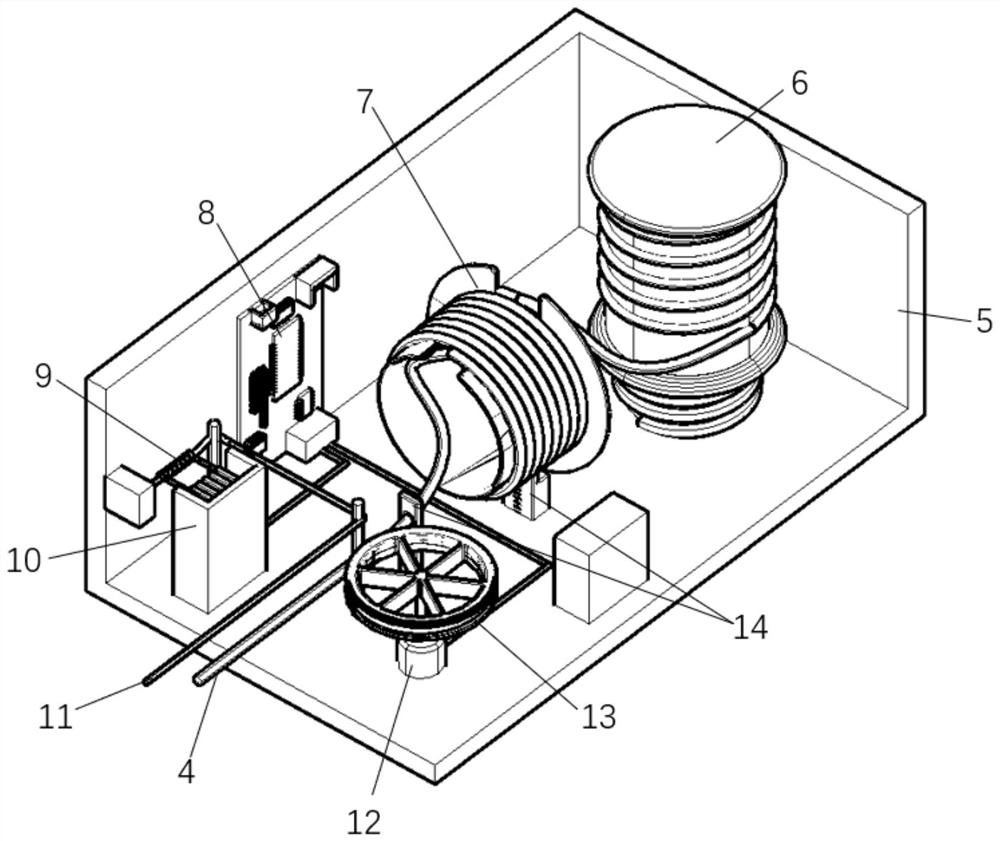

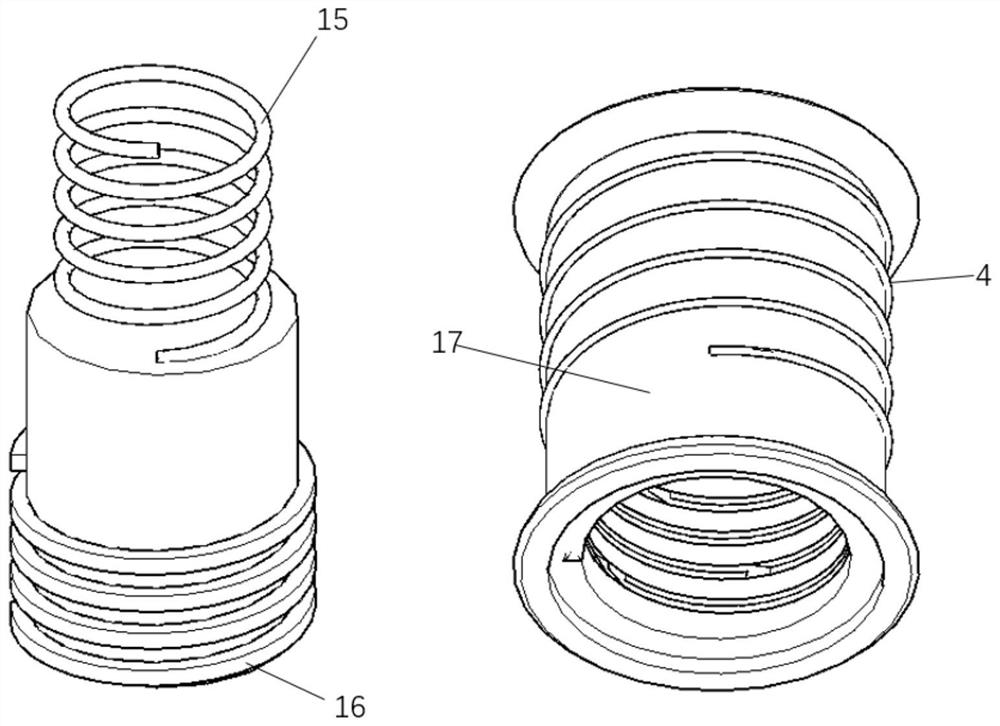

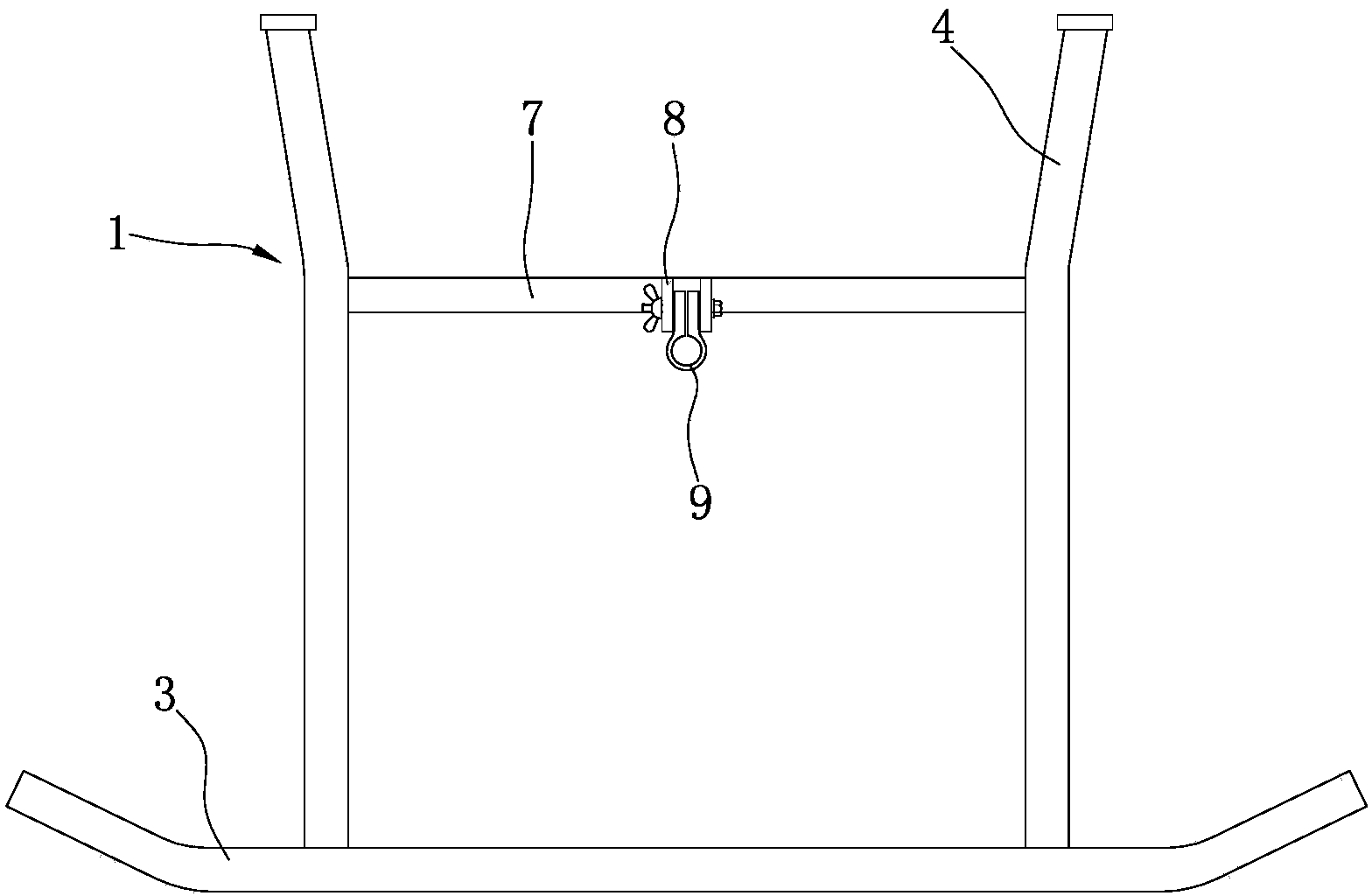

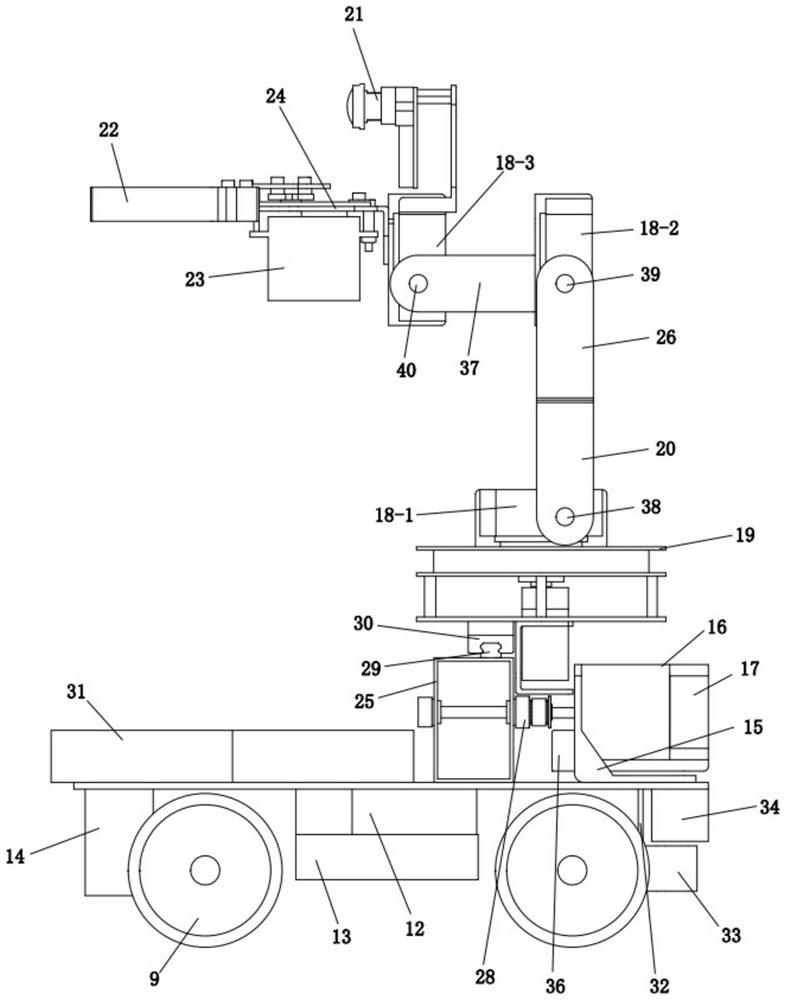

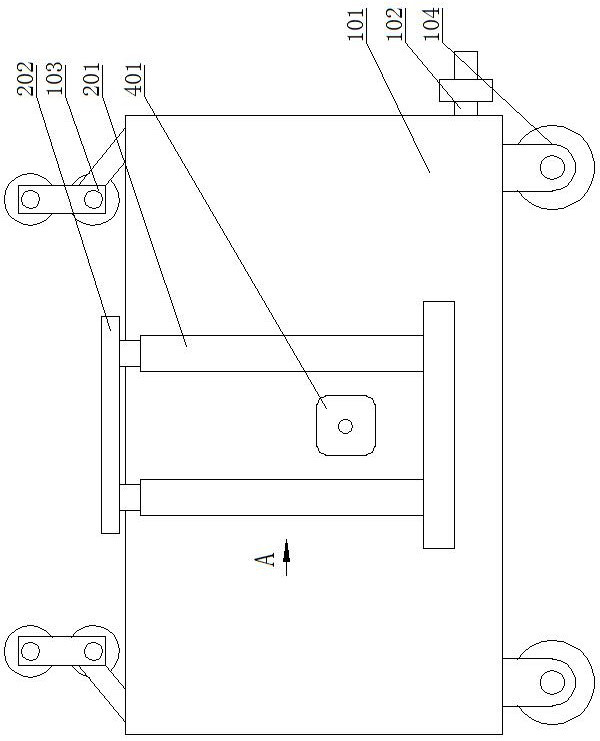

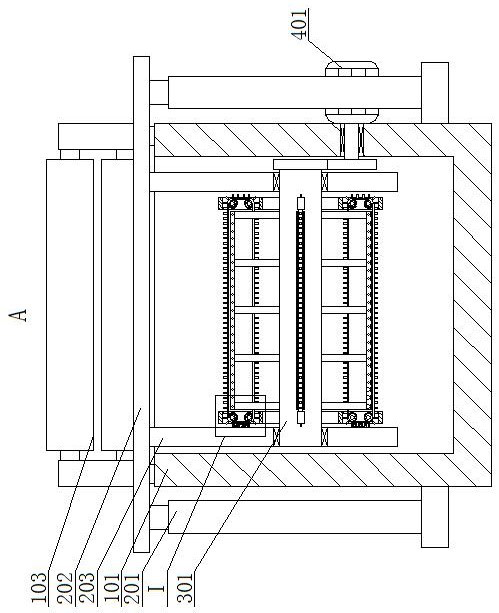

Small space tether system unfolding brake mechanism adopting spinning shaft sleeve

ActiveCN113044248AExpand decelerationEffective damping forceCosmonautic vehiclesCosmonautic component separationAxial displacementSpace tether

The invention discloses a small space tether system unfolding brake mechanism adopting a spinning shaft sleeve, and belongs to the technical field of space tether system equipment. The small space tether system unfolding brake mechanism comprises a small instrument cabin, and a spinning brake, a tether spool core, a tether calibration device, a high-strength tether, an unfolding length measurement module and an ejection module which are arranged in the small instrument cabin, the small instrument cabin is fixed on a mother satellite of the space tether system; the spinning brake restrains the axial displacement of the spinning shaft sleeve through the elastic force of a spring in the spinning brake, so that the unfolding motion of the high-strength tether is braked until the speed is zero; the tether spool core is used for winding a tether, and the unfolding length measuring module is used for guiding the tether and measuring the length and the speed of the tether; and the ejection module is used for control and signal processing of the whole mechanism. The elastic force of the compression spring is changed by changing the thread screwing length of the spinning brake, rotation of the spinning shaft sleeve along threads is restrained, and therefore the braking speed reduction effect of the tether is changed; the braking mechanism is effective in framework damping, low in space occupancy rate and reliable in release.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Cable bending device with adjustable bending degree

ActiveCN107769068AControllable bendingReduce bend angleApparatus for joining/termination cablesEngineering

Owner:烟台中科恩吉科创新产业园管理有限公司

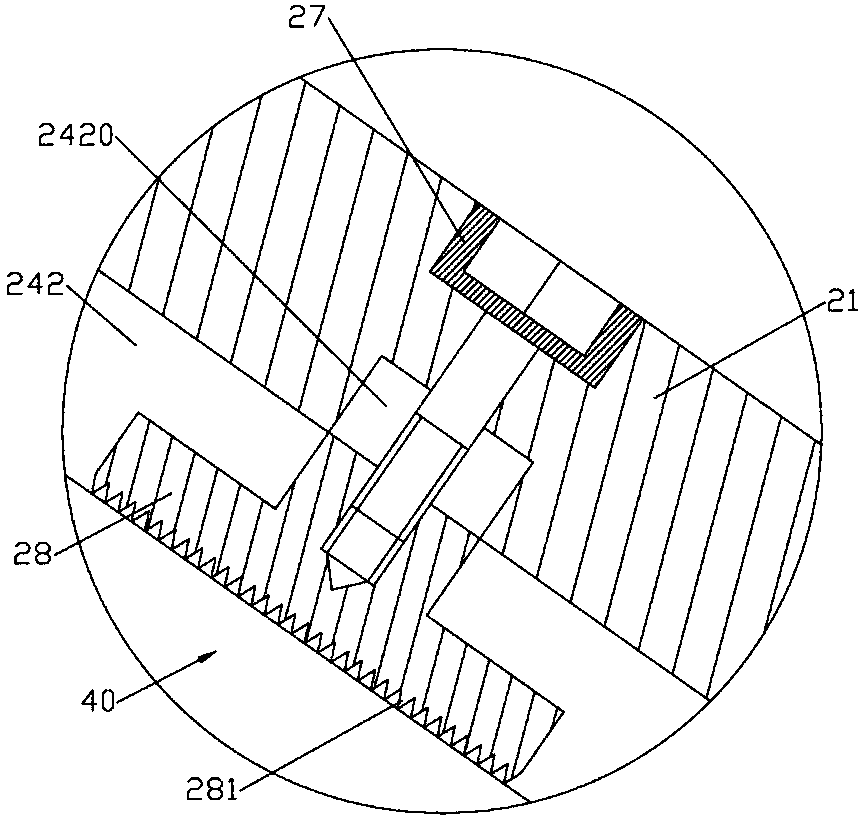

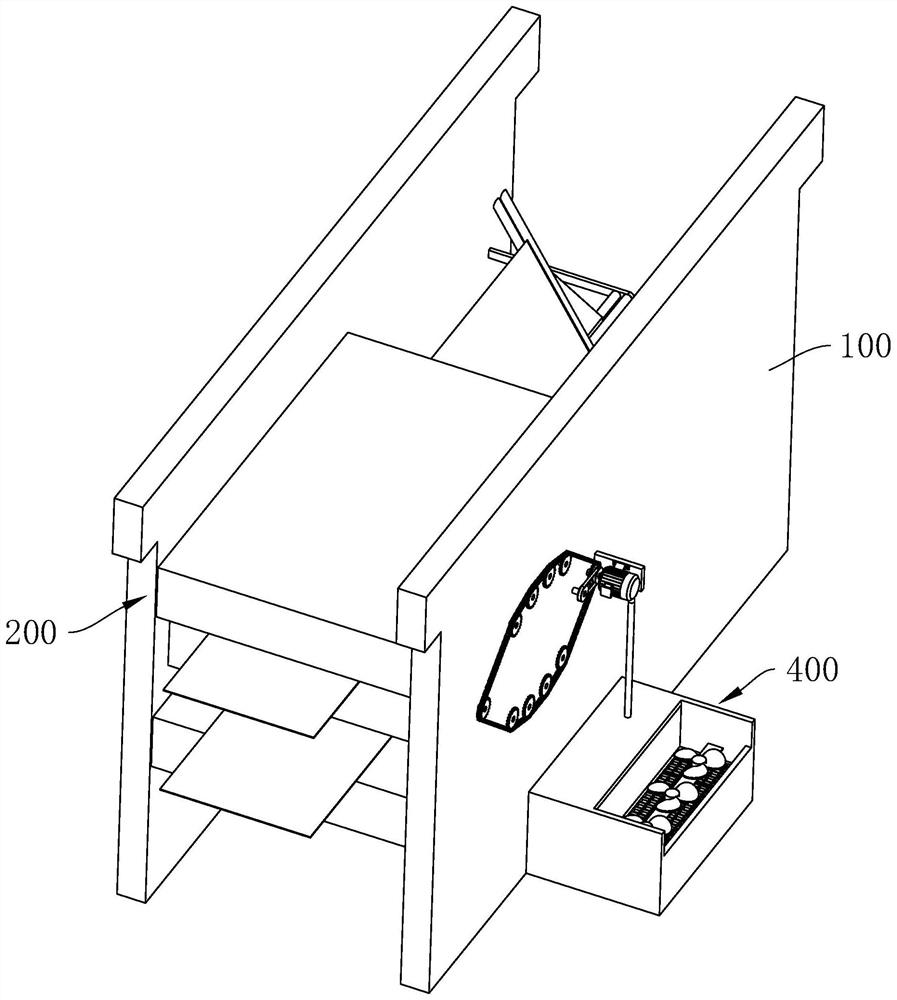

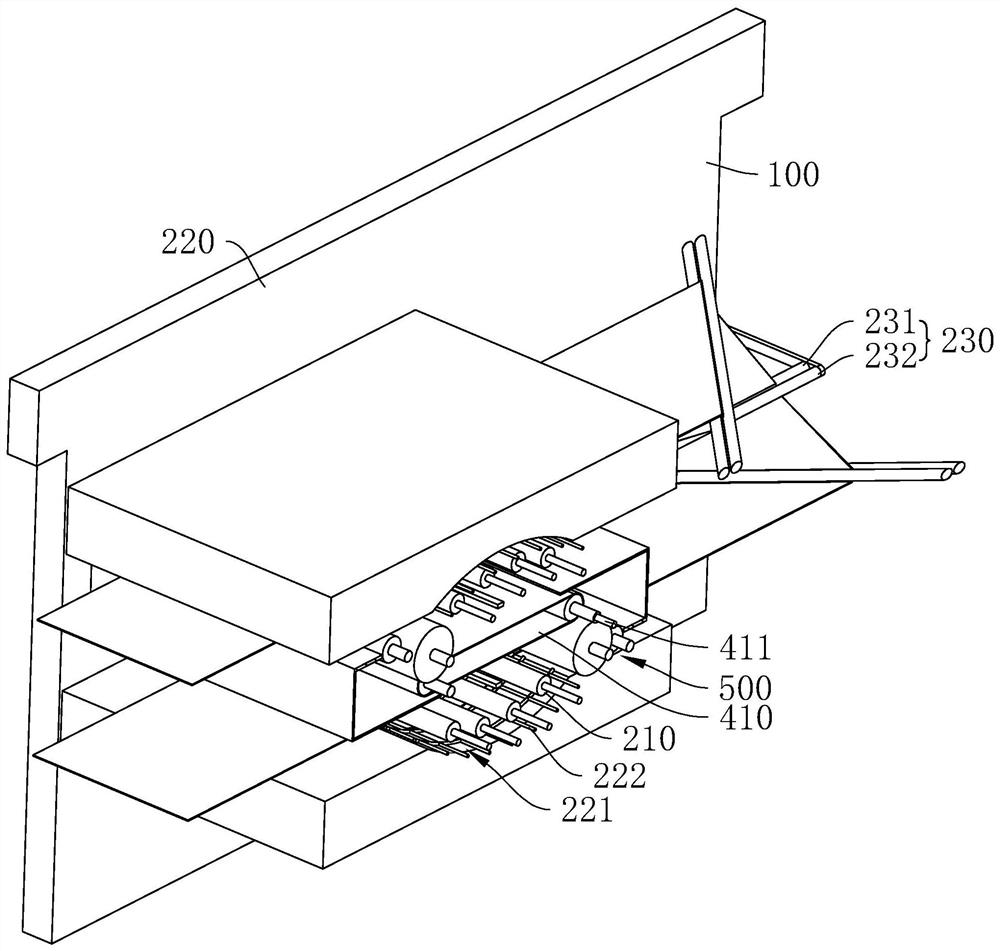

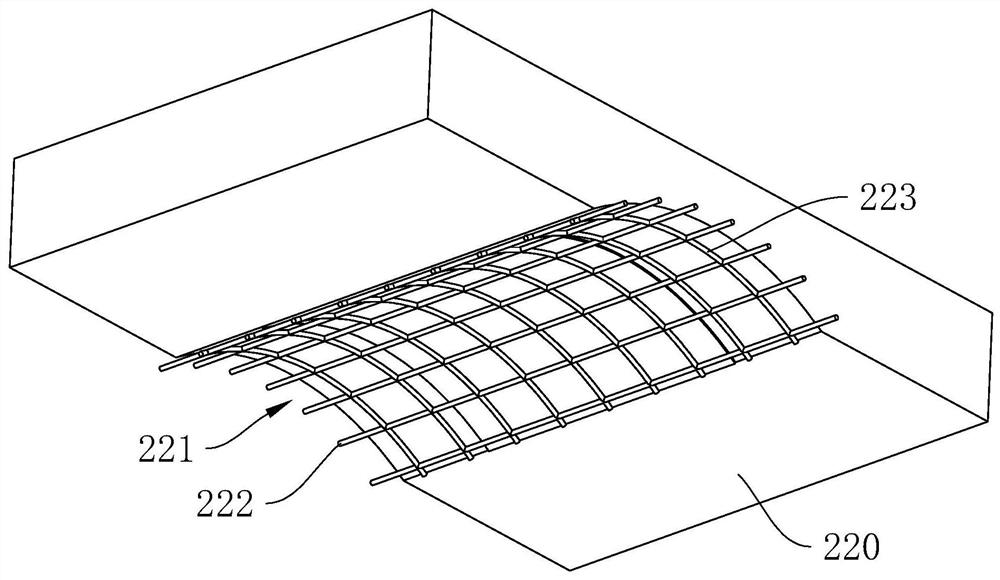

Shearing device and cloth production process using shearing device

ActiveCN113089243AReduce distance variationImprove qualityMechanical cleaningPressure cleaningClassical mechanicsEngineering

The invention relates to a shearing device and a cloth production process using the shearing device. The shearing device comprises a machine frame, a shearing mechanism is arranged on the machine frame, and the shearing mechanism comprises a shearing roller, two limiting blocks, a steering part and a driving assembly. The shearing roller is horizontally and rotatably mounted on the machine frame, and the two limiting blocks are arranged on the machine frame and correspondingly located on the two opposite sides of the shearing roller, the steering part is mounted on the machine frame and used for turning over the fabric, and the driving assembly is mounted on the machine frame and drives the shearing roller to rotate. The shearing device has the effect of reducing the length difference of fluff on two sides of the fabric so as to improve the quality of the fabric.

Owner:绍兴旺埭针纺有限公司

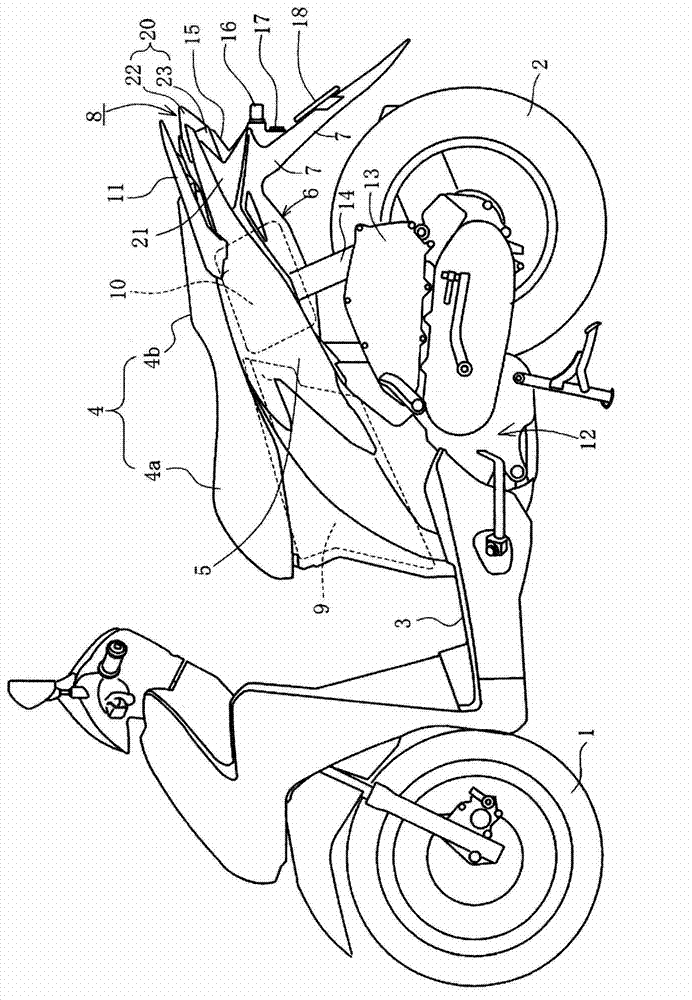

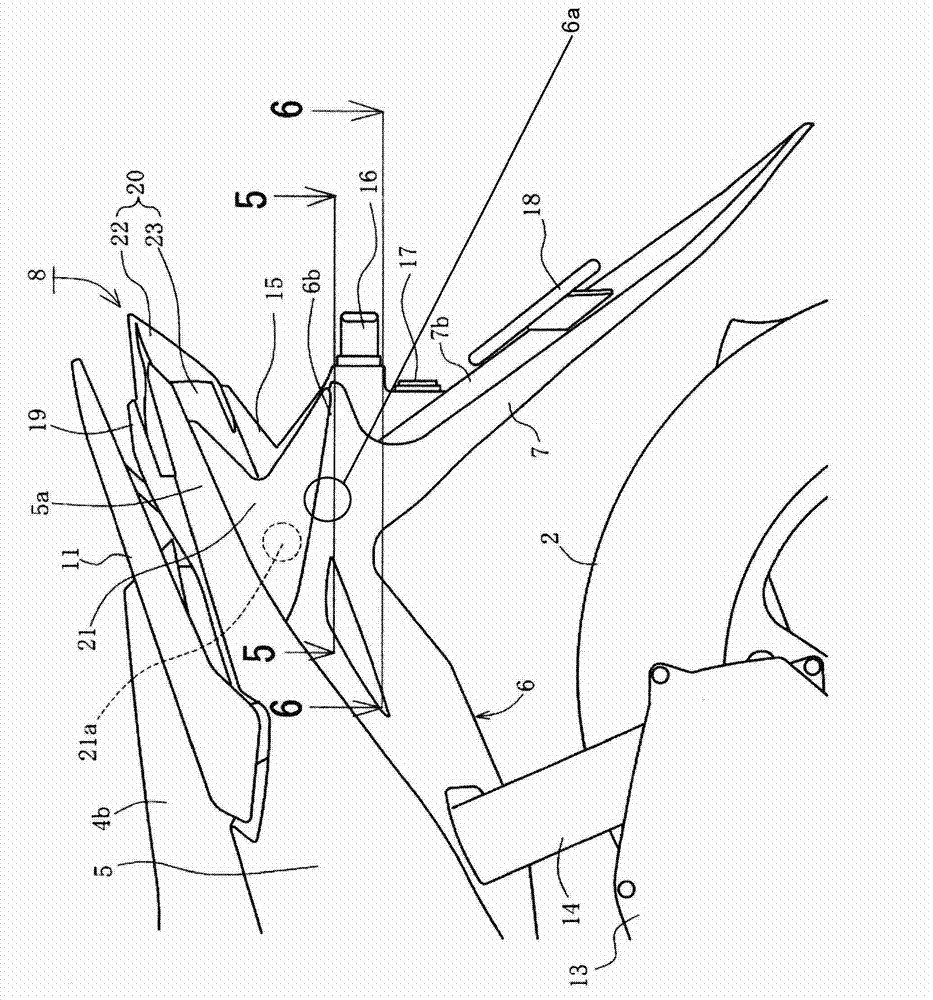

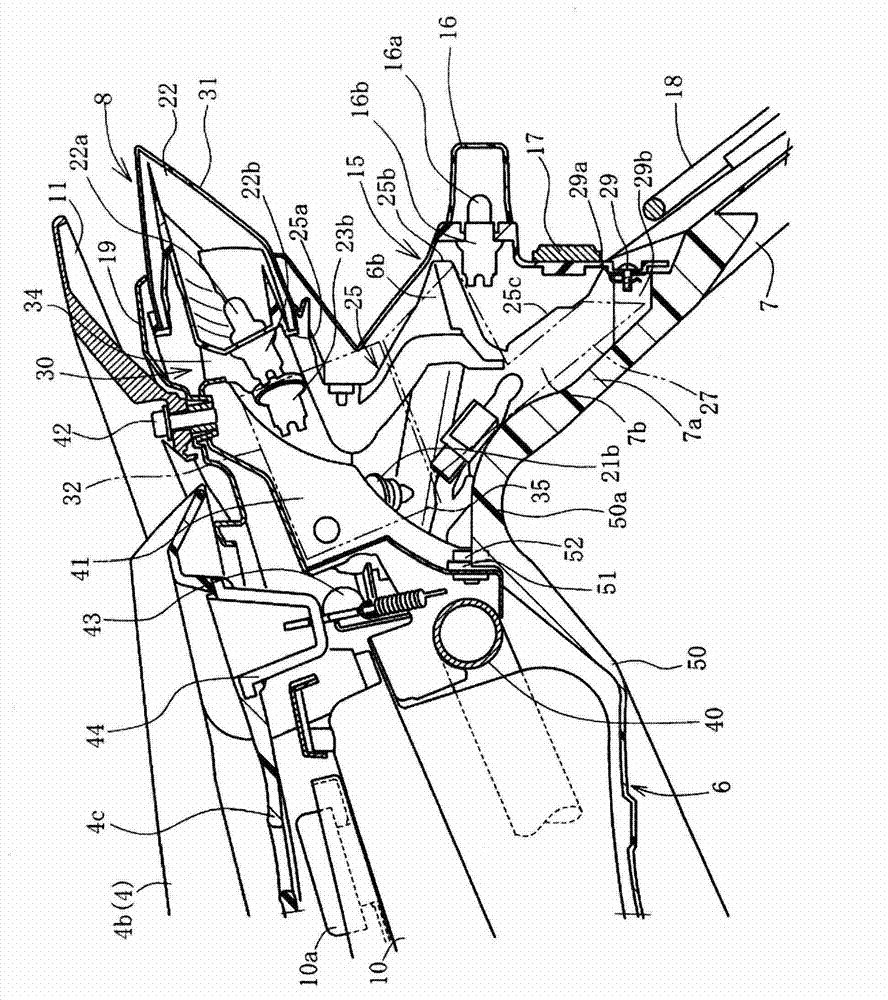

Rear lamp body structure for motorcycle

The invention provides a rear lamp body structure for a motorcycle, which makes it easy to maintain lamps in a rear lamp assembly located above a rear mud guard. The rear mud guard (6) has the rear lamp assembly (8) on the rear end part, and a sagging part (7) on the lower part. A maintaining opening (25) which is formed from the rear lamp assembly (8) and the sagging part is opened or closed through a maintaining cover (15).The sagging part is provided with a maintaining recess (27) which forms a part of the maintaining opening (25) and enters forwards in a recessed way. The recess is communicated with a maintaining space (32) on the inner side of the rear lamp assembly (8). When the maintaining cover is dismounted, a hand (60) is inserted into the maintaining opening from the vehicle rear part. Then the arm is inserted into the maintaining recess and further extends towards the inclined upper part. The hand thus enters the maintaining space. A wrist (61) bends to rotate a lamp seat (22b). A lamp is thus replaced. The bending angle of the wrist is smaller and the operation is easier.

Owner:HONDA MOTOR CO LTD

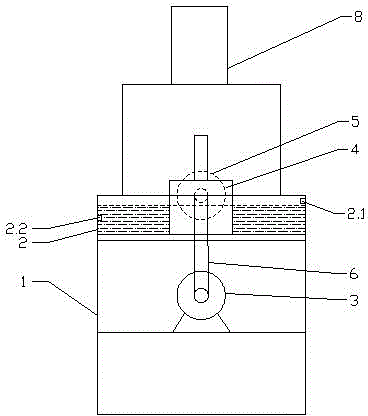

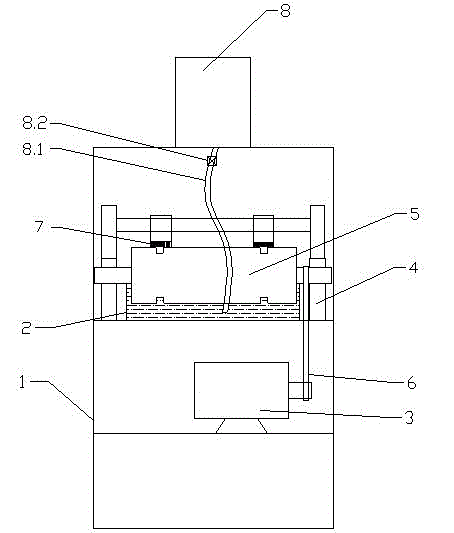

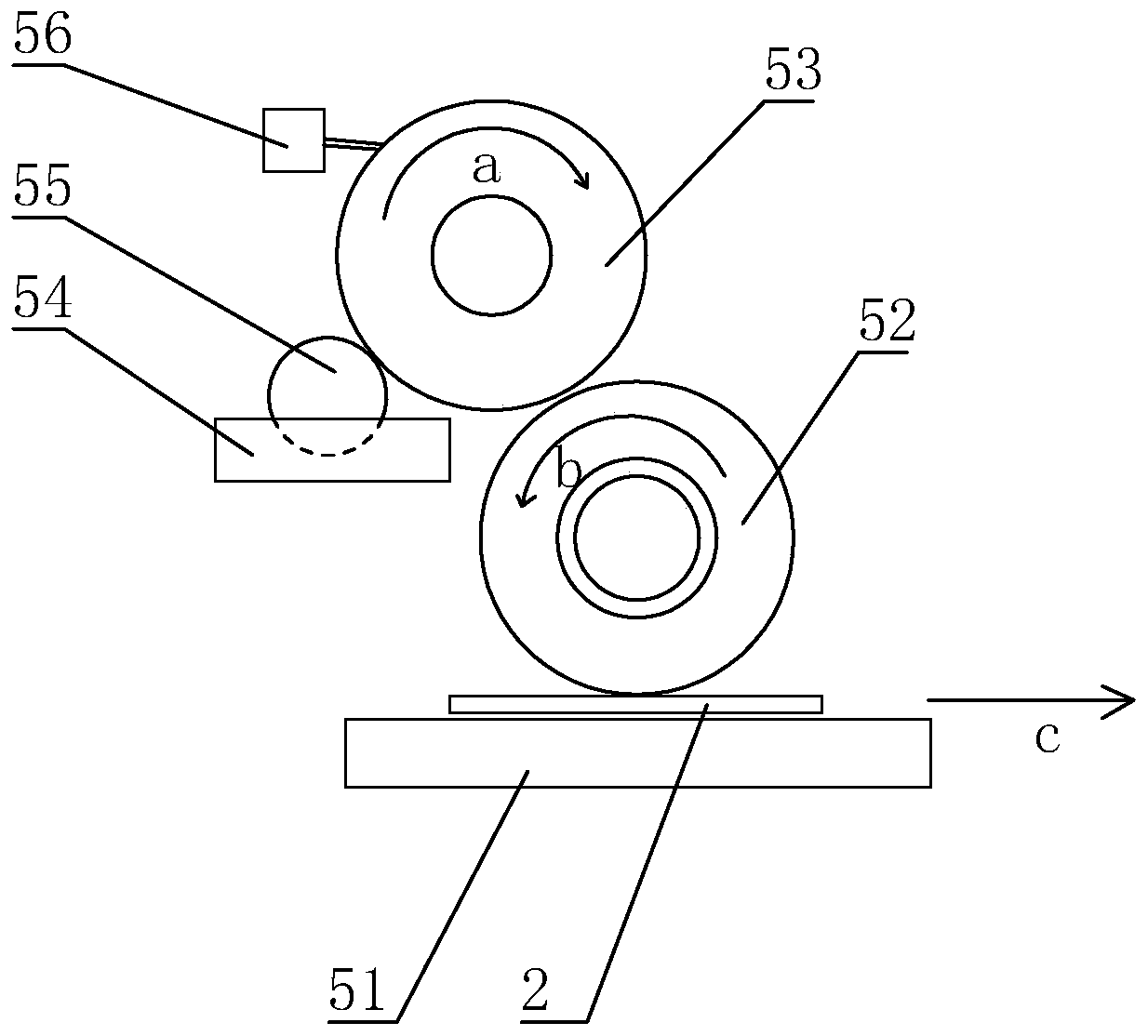

Liquid-level-self-adaptive scaling powder coating device

InactiveCN104907220AReduce labor intensityGuarantee coating qualityLiquid surface applicatorsCoatingsSelf adaptiveElectromagnetic valve

The invention relates to a liquid-level-self-adaptive scaling powder coating device which is characterized by comprising a scaling powder coating rack (1), wherein a scaling powder coating roller (5) is longitudinally erected between the lower sections of a support frame (4) of the scaling powder coating rack (1); the inner wall of a scaling powder tank (2) is provided with a first liquid level meter (2.1) and a second liquid level meter (2.2) which are distributed in an up-down manner; a scaling powder liquid storage barrel (8) is arranged at the top of the scaling powder coating rack (1); the liquid outlet of the scaling powder liquid storage barrel (8) is connected with a liquid outlet pipe (8.1) and is connected into the scaling powder tank (2); an electromagnetic valve (8.2) is arranged on the liquid outlet pipe (8.1); the electromagnetic valve (8.2), the first liquid level meter (2.1) and the second liquid level meter (2.2) are connected with a PLC. The liquid-level-self-adaptive scaling powder coating device has the advantages that the product quality is ensured, and the labor intensity is lowered.

Owner:SHENYU COMM TECH

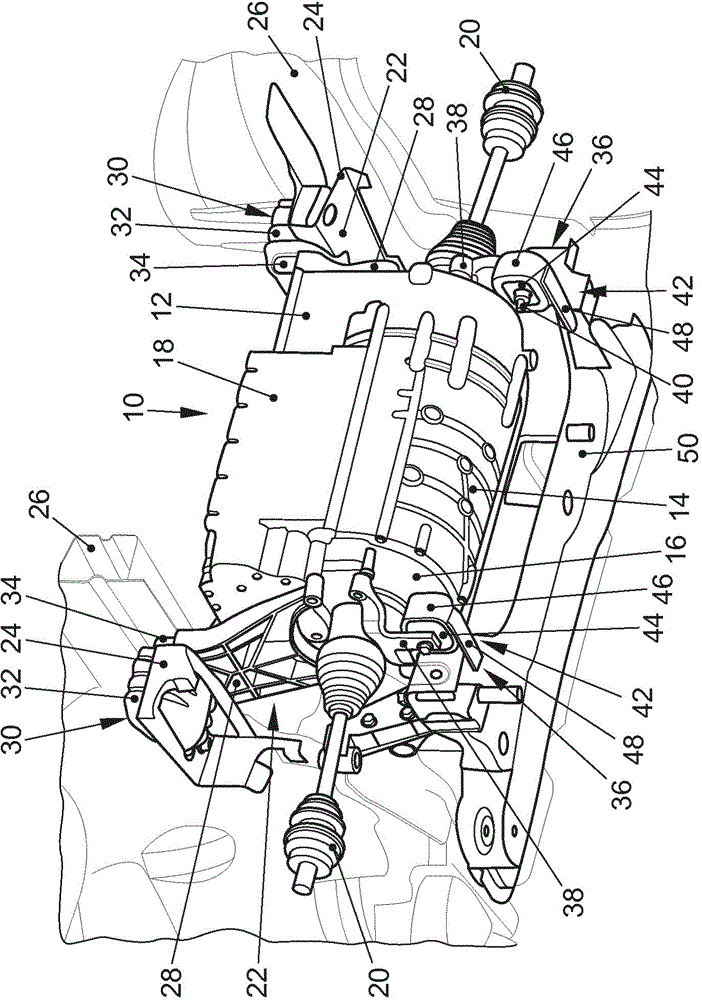

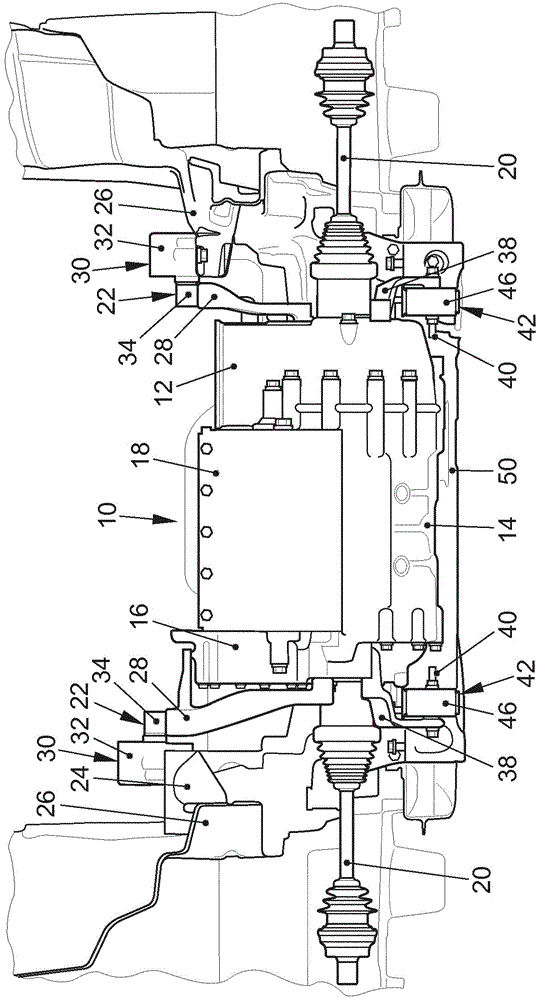

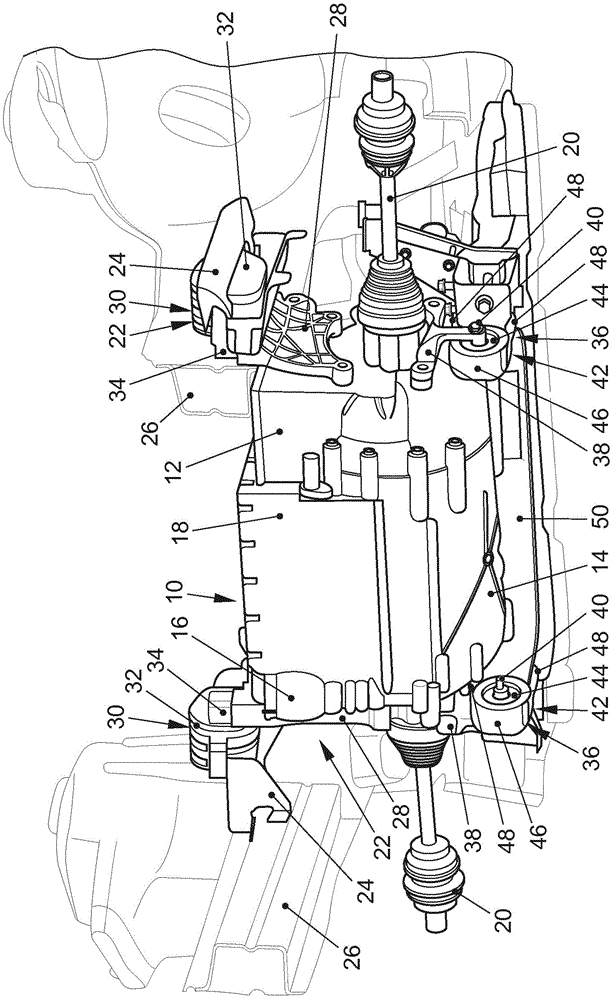

Arrangement of an electric motor unit in the motor compartment of a motor vehicle

ActiveCN104602934AEasy to integrateLower center of gravityElectric propulsion mountingUnderstructuresElectricityElectric drive

The invention relates to an arrangement of an electric motor unit (10) in the motor compartment of a motor vehicle. The electric motor unit (10) comprises an electric drive motor, a housing which surrounds the drive motor, and a transmission (12) which is flange-mounted directly on the drive motor. The electric motor unit (10) is suspended on at least two assembly supports (22), a first assembly support (22) being fixed to the transmission (12) and a second assembly support (22) being fixed to the housing. According to the invention, at least two additional assembly bearings (36) are provided, which connect the electric motor unit (10) to a subframe (50) of the motor vehicle, a first assembly bearing (36) being fixed to the transmission (12) and a second assembly bearing (36) being fixed to the housing.

Owner:VOLKSWAGEN AG

Foldable ultra-thin glass protective cover plate with touch screen function and manufacturing method thereof

InactiveCN110407483AReduce bend angleThickness omittedCoatingsInput/output processes for data processingGlass coverBonding process

The invention discloses a foldable ultra-thin glass protective cover plate with a touch screen function, the foldable ultra-thin glass protective cover plate comprises ultra-thin glass, wherein an inkframe is printed below the ultra-thin glass; an explosion-proof layer is coated below the ink frame; and a touch circuit layer is printed below the explosion-proof layer. The foldable ultra-thin glass protective cover plate has a small thickness, is coated with a functional layer in a printing and coating mode, omits optical glue, not only integrates the functions of a touch screen, but also saves the thickness and bonding process of the optical glue and a PET film, so that the functions of the touch screen and the glass cover plate are integrated, and the glass cover plate with the touch screen function is easier to fold and has no crease.

Owner:AENEQ CO LTD

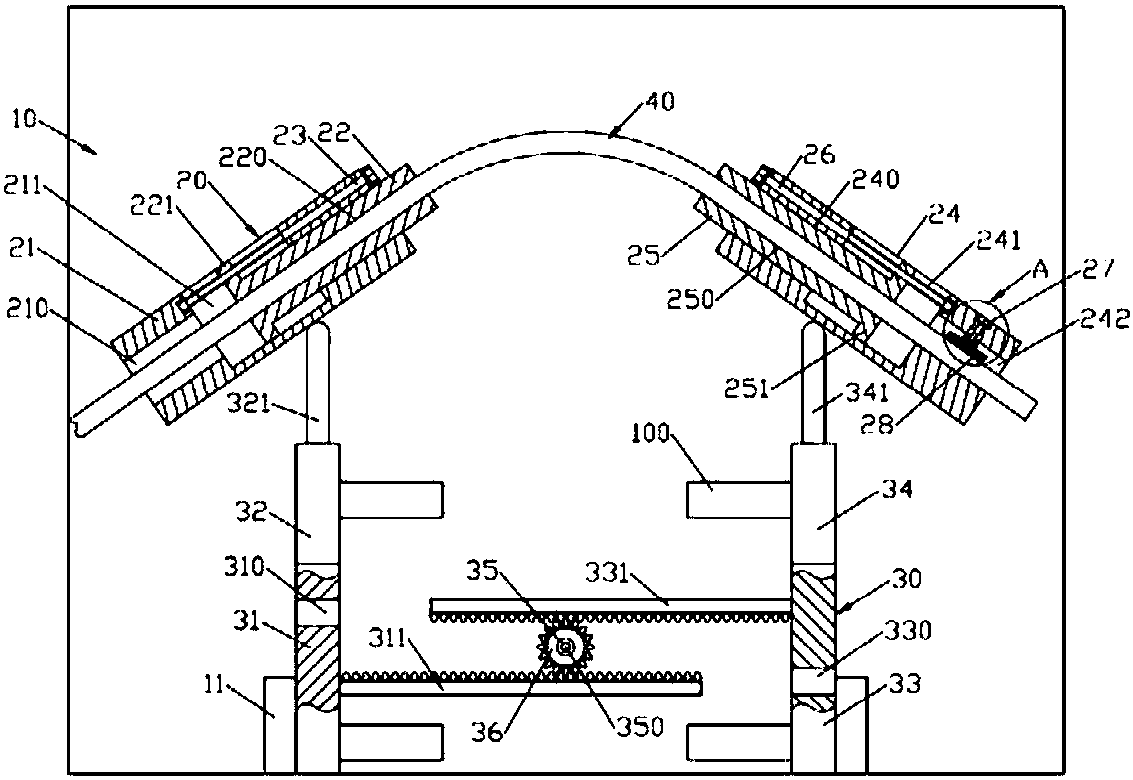

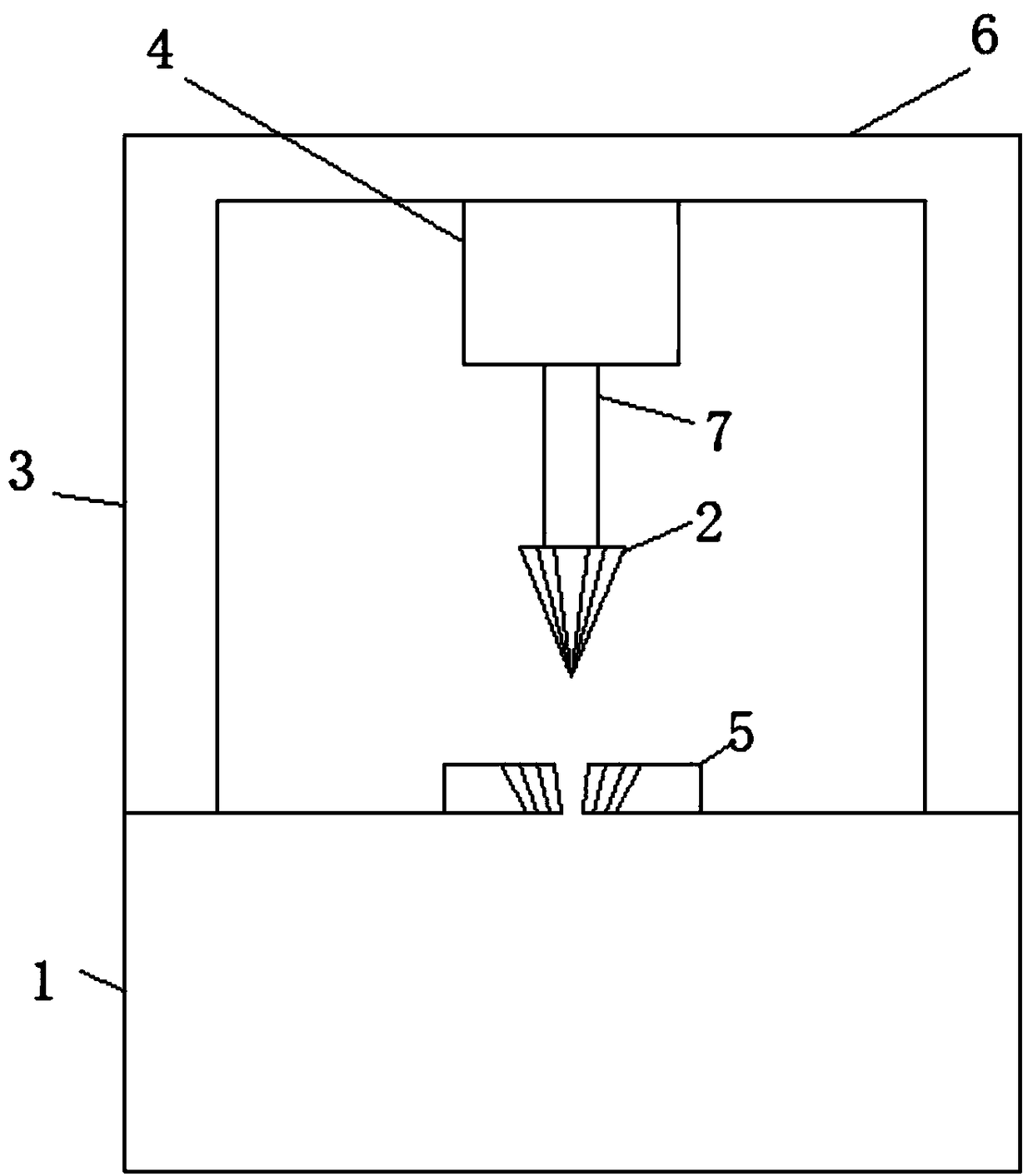

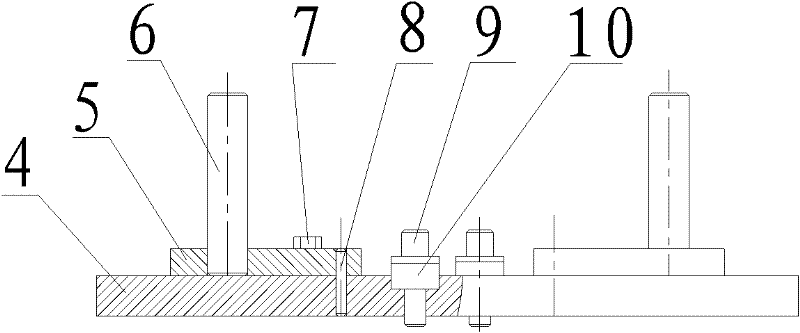

Punching and bending mold with angles convenient to change

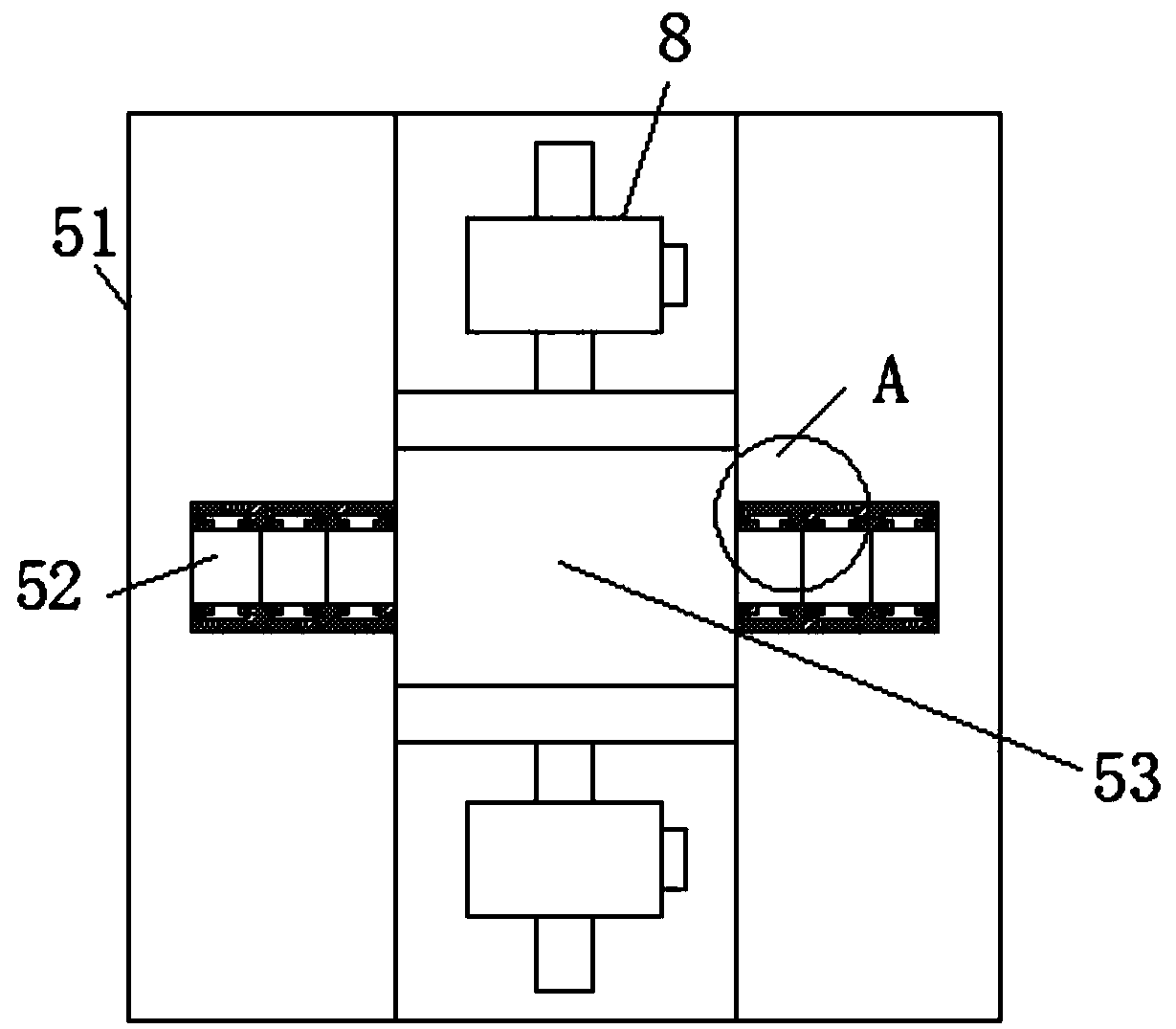

The invention discloses a punching and bending mold with angles convenient to change. The mold comprises a worktable; the worktable is provided with a set of symmetric support frames; a connecting frame is arranged between the two support frames, and is provided with a hydraulic cylinder; an extension rod is arranged at one end of the hydraulic cylinder, and is connected with an upper pressing mold; the worktable is provided with a lower pressing mold; the lower pressing mold comprises a fixed base, a groove, bending grooves and a limiting device; the fixed base is arranged on the worktable; agroove is formed in middle of the fixed base; a set of symmetric limiting devices is arranged in the groove; the bending grooves are formed in the two sides of the groove; the two bending grooves aresymmetrically formed in the fixed base; the bending grooves comprise gaskets, limiting grooves and T-shaped slide plates I; limiting grooves are formed in the fixed base; multiple gaskets are arranged in the limiting grooves; the T-shaped slide plates I are arranged on the two sides of the gaskets; and the limiting grooves are provided with T-shaped chutes I cooperating with the T-shaped slide plates I. Through arrangement of the lower pressing mold, workpieces with different angles can be folded, and use is convenient.

Owner:CHUZHOU MODERN MOLD MFG

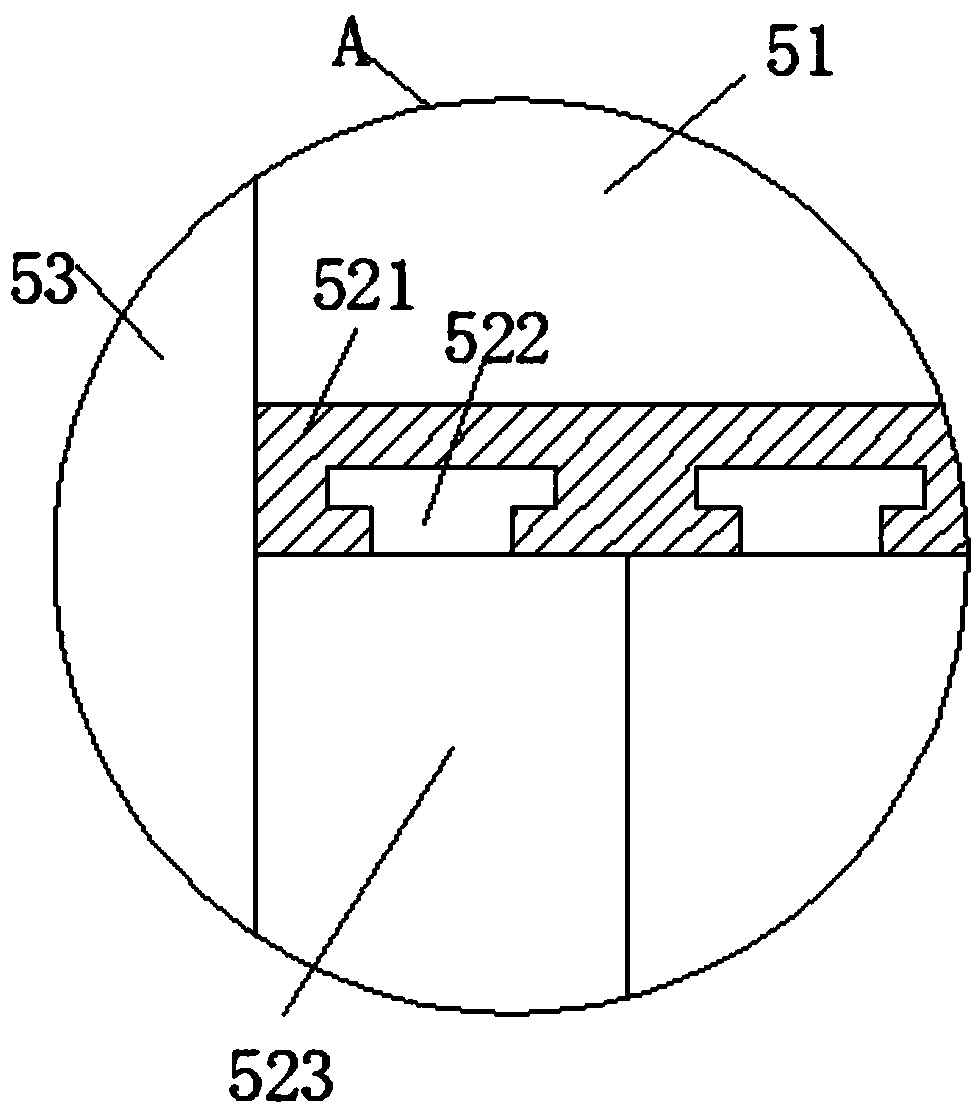

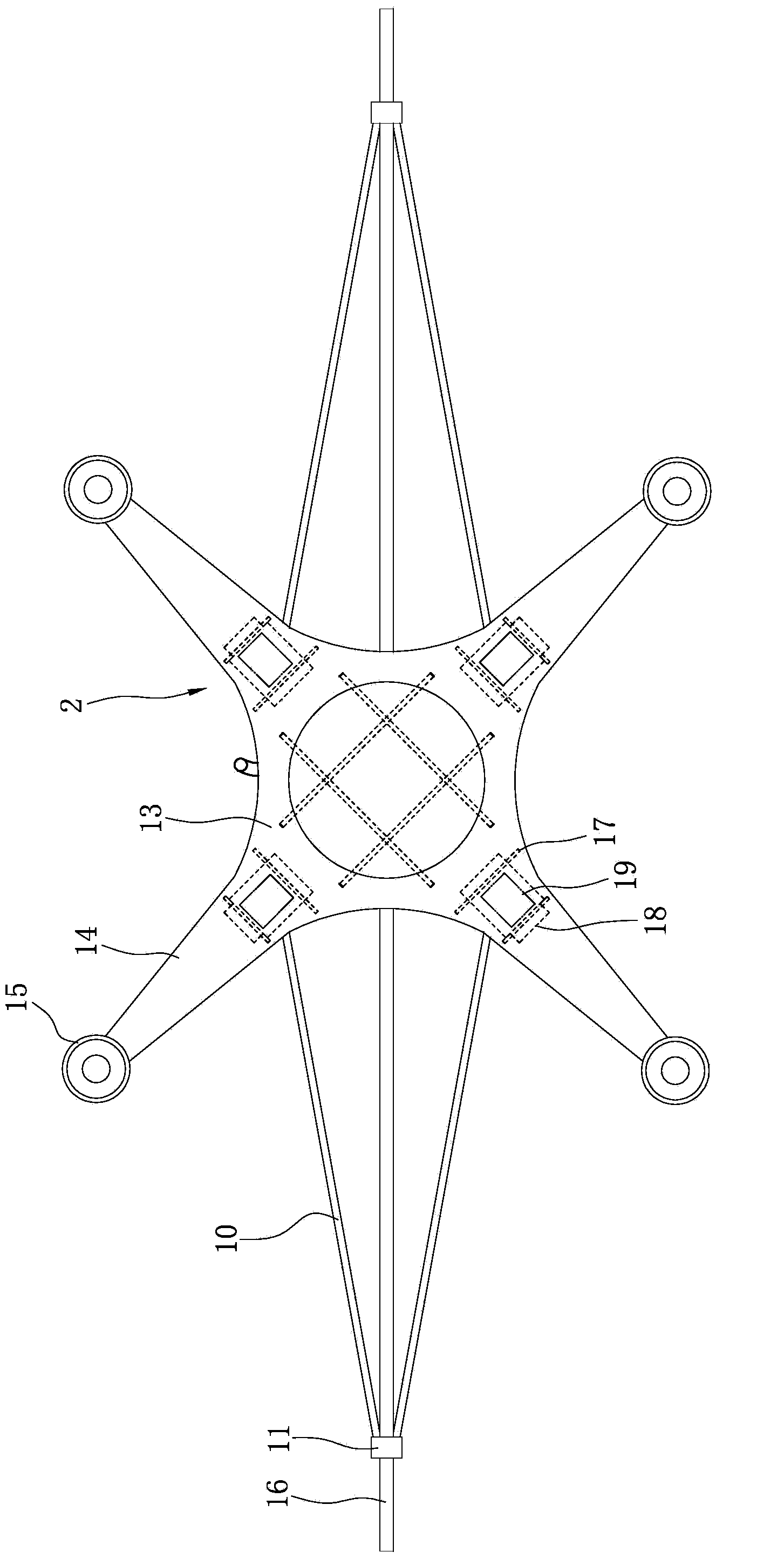

Body supporting assembly for four-axis unmanned aircraft

The invention discloses a body supporting assembly for a four-axis unmanned aircraft. Two positioning frames (17) parallel to each other are arranged at the position, close to an equipment bin (13), inside each cantilever (14); a bottom plate (18) is inserted and fixed into the two positioning frames (17); an electronic speed regulator (19) is arranged on each bottom plate (18); a landing gear (1) comprises a left bottom tube (3) and a right bottom tube (3) which are parallel to each other; supporting tubes (4) are welded at the front and rear parts of each bottom tube (3); a supporting plate (5) is fixed at the top of each supporting tube (4) and is fixedly supported at the position, close to the root, of the bottom surface of the corresponding cantilever (14). The body supporting assembly is simple in structure, convenient and quick to assemble and disassemble, excellent in firmness and high in stability. By arranging the electronic speed regulators inside the cantilevers, the spaces of the cantilevers are fully utilized, and the electronic speed regulators are quite convenient and quick to assemble and disassemble.

Owner:CHONGQING KINGTEC AVIATION IND

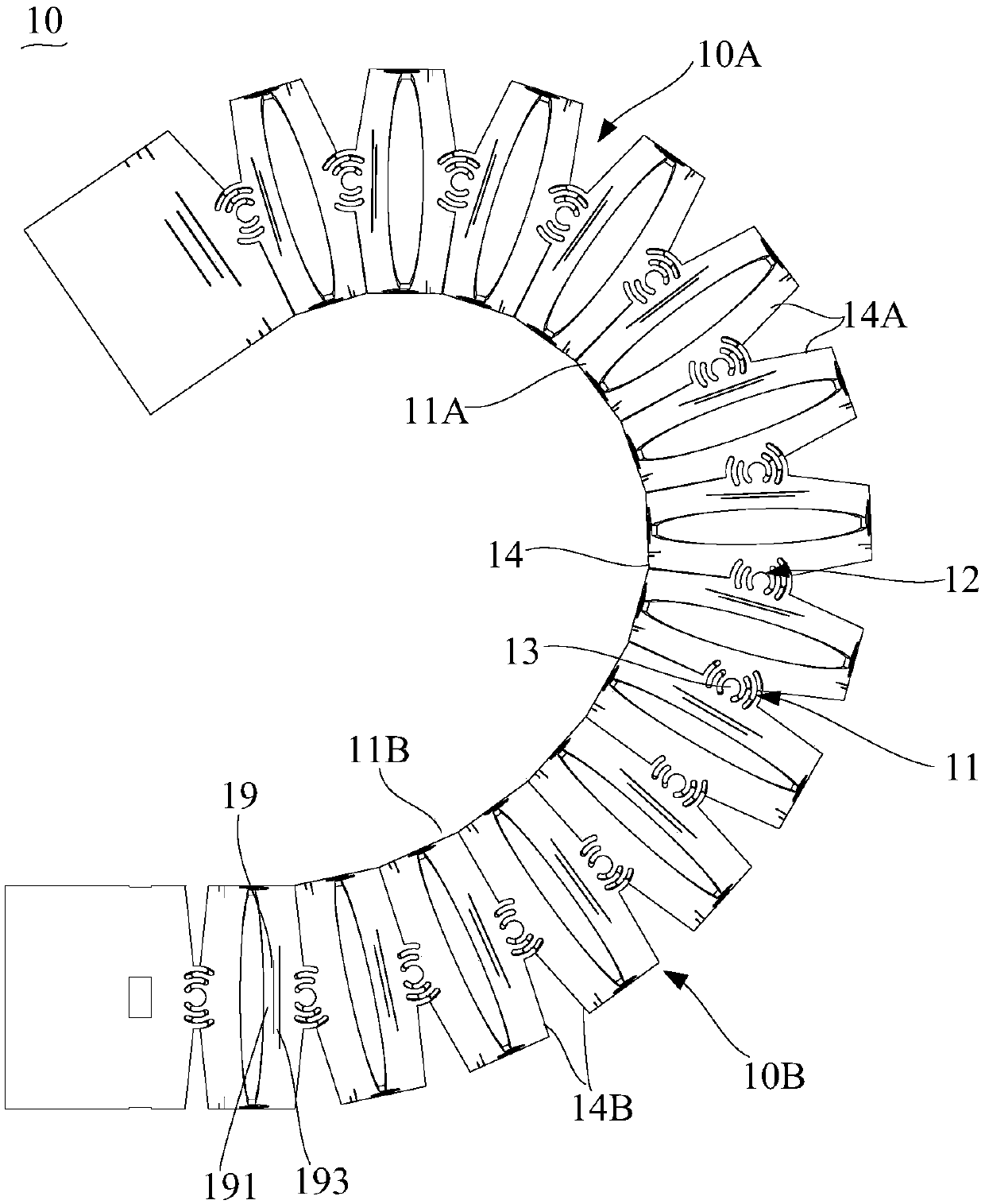

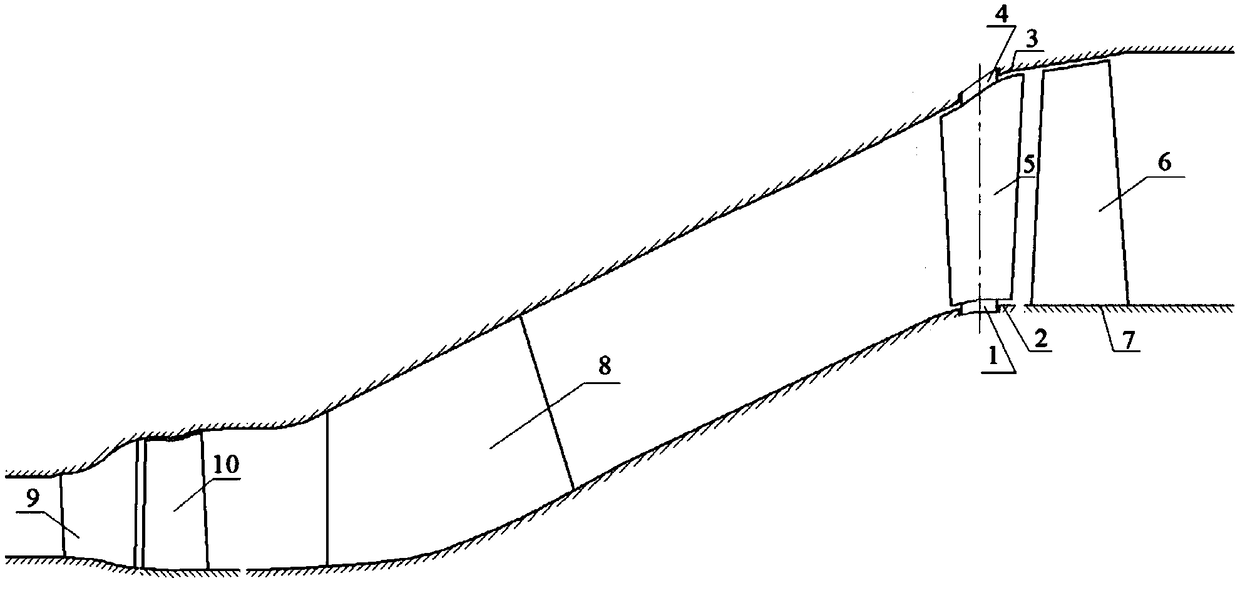

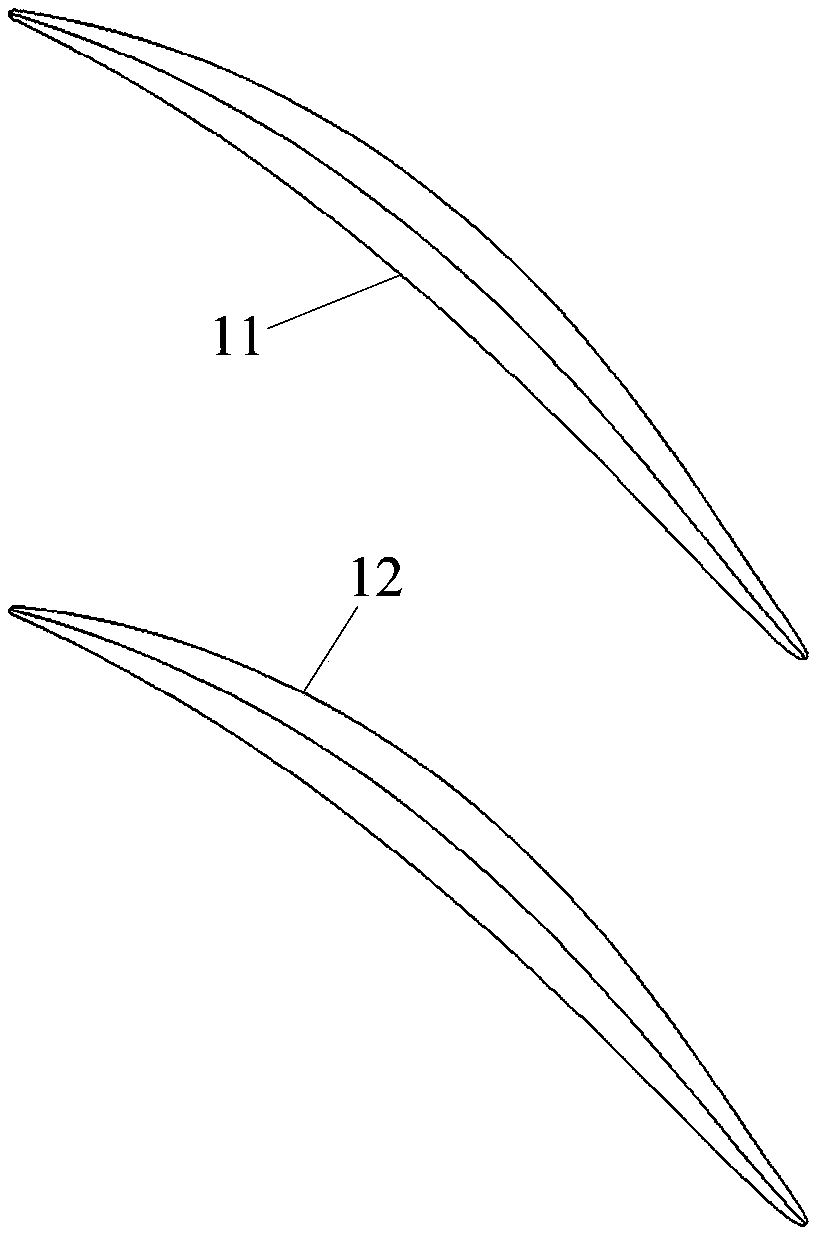

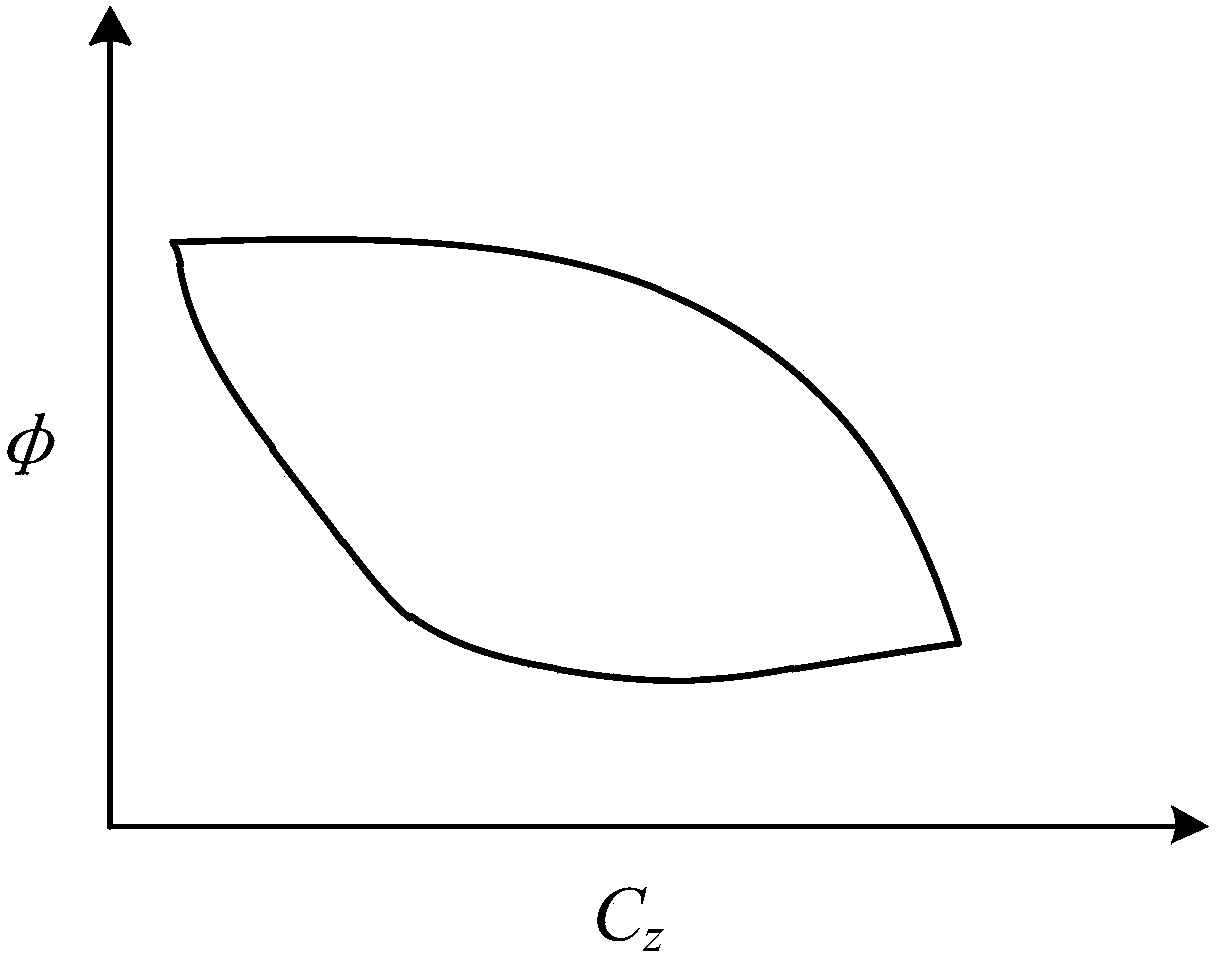

Reverse variable geometric turbine with low-viscosity and no-lift adjustable static blades

InactiveCN108729958AReduce consistencySmall driving forceStatorsNon-positive displacement enginesTurn angleTurbine

The invention provides a reverse variable geometric turbine with low-viscosity and no-lift adjustable static blades. The turbine comprises a cabinet and a hub; the adjustable static blades and movableblades are uniformly mounted between the cabinet and the hub in the peripheral direction; the adjustable static blades are located on the front side, and the movable blades are located on the back side; the movable blades are mounted on the hub; a movable blade hub is arranged beside a static blade hub; a transition section with a support plate and a low-pressure turbine are arranged at the upstream of the adjustable static blades of the variable geometric turbine; static blades of the low-pressure turbine are on the front side, and movable blades of the low-pressure turbine are mounted on the hub; the transition section is positioned between the low-pressure turbine and the variable geometric turbine; the viscosity of the adjustable static blades is lower and within 0.6-1.1; the adjustable static blades are low in blade shape bending degree, and the blade type lift coefficient is as low as 0.15-0.45; and the variable geometric turbine and the low-pressure turbine are opposite in rotating direction. The turbine can effectively reduce the end gaps and the gap leakage quantity of the adjustable static blades, obviously reduces the airflow turning angles of the adjustable static blades, improves the multi-working-condition efficiency of the variable geometric turbine, and achieves excellent working reliability.

Owner:HARBIN ENG UNIV

Rotor winding pole coil and manufacturing die thereof as well as casing copper bar edgewind wrench

InactiveCN102214961AConvenient for heat dissipation and ventilationImprove heat resistanceMagnetic circuit rotating partsManufacturing stator/rotor bodiesHeat resistanceEngineering

The invention relates to a rotor winding pole coil and a manufacturing die thereof as well as a casing copper bar edgewind wrench. The rotor winding pole coil is characterized by comprising an annular coil which is wound by copper bars and arched angles at corners of the annular coil, wherein the annular coil is straight in a length direction and arc-shaped in a width direction; and 0.5mm-thick glass sheets are adhered to the inner diameter of the annular coil. The manufacturing die comprises a baseboard, die cores which are symmetrically arranged on the baseboard and vertical shafts which are vertically arranged on the die cores, wherein the outer side edges of the die cores are arc-shaped in a width direction; and two sides of the baseboard are provided with tension hooks in a length direction. The edgewind wrench comprises tension discs and supporting tube handles which are welded on the tension discs, wherein the tension discs are arc-shaped and the cross sections of the tension discs are T-shaped. According to the invention, the edgewind of a rotor winding pole coil of which the rate of the width and thickness of the cross section of the copper bar is over 15 times for many year is achieved, the efficiency of the winding coil, the radiation and ventilation effects of the rotor winding are improved, and the insulation and heat resistance class as well as electric property of the rotor winding are enhanced.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

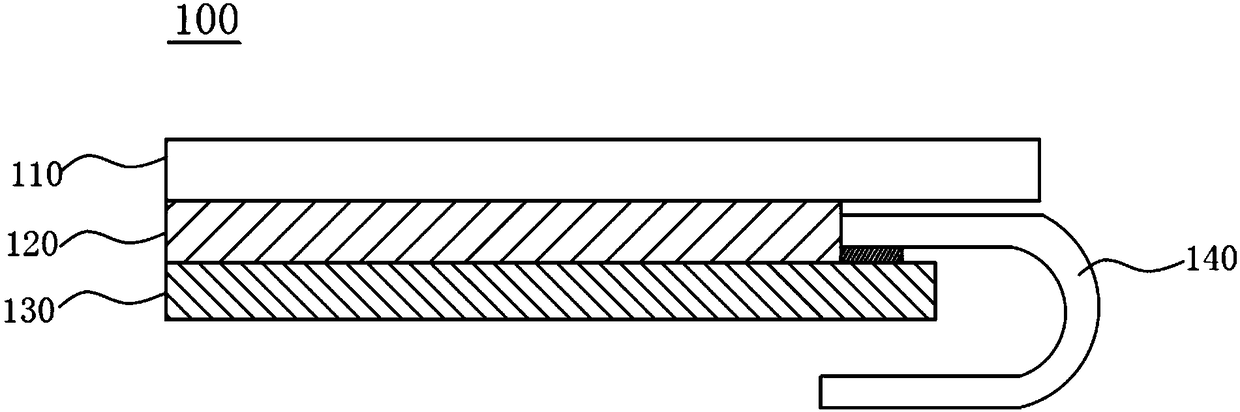

OLED display device

InactiveCN108364996AReduced risk of flakingImprove fit stabilityCasings/cabinets/drawers detailsSolid-state devicesDisplay deviceEngineering

The invention discloses an OLED display device. The OLED display device comprises a bottom plate and a cover plate which are opposite, and the bottom plate is provided with a first surface and a second surface which are opposite. The OLED display device further comprises a display area, a non-display area, an OLED light-emitting assembly, first electrodes, second electrodes, conductive protrusionsand a flexible printed circuit board, wherein the OLED light-emitting assembly is arranged on the first surface of the bottom plate; the first electrodes are arranged on the first surface of the bottom plate and located in the non-display area; the second electrodes are arranged on the cover plate and located in the non-display area; the conductive protrusions are arranged between the bottom plate and the cover plate and are electrically connected with the first electrodes and the second electrodes respectively; the flexible printed circuit board is provided with a first end and a second endwhich are opposite, the first end is electrically connected with the second electrodes, and the second end extends to the side, wherein the second surface is located, of the bottom plate. According tothe OLED display device, the risk that the flexible printed circuit board is peeled off is reduced, and the fitting stability of the flexible printed circuit board is improved.

Owner:AU OPTRONICS CORP

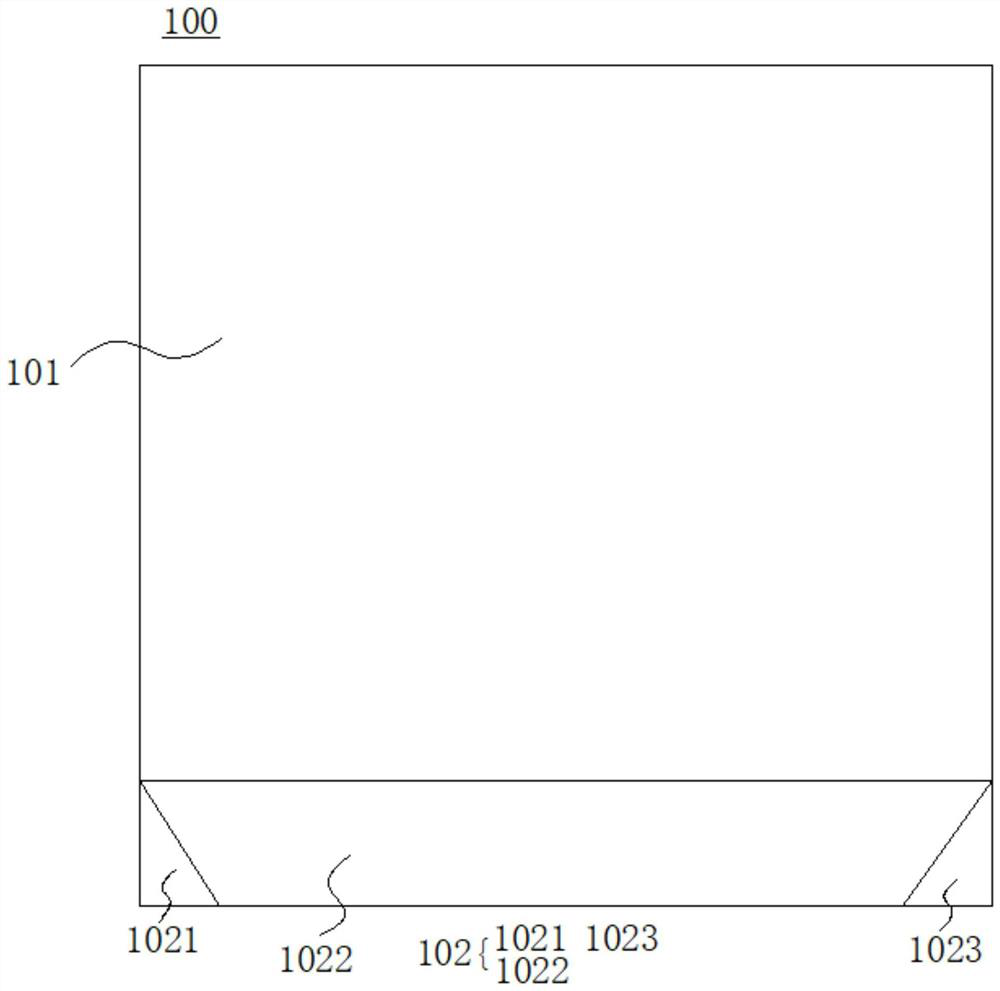

Display panel

ActiveCN111796713ALow costIncrease the overlap areaNon-linear opticsInput/output processes for data processingHemt circuitsEngineering

The invention provides a display panel. The display panel is characterized in that a test module is arranged in a non-display area of the display panel, and the test module at least comprises a test terminal, a test circuit and a test lead for connecting the test terminal and the test circuit, wherein an etching protection layer is formed on a surface of the test terminal, the etching protection layer is positioned between the driving electrode layer and the induction electrode layer of the touch layer, the test terminal is a part, extending to the non-display area, of the induction electrodelayer, the extended part is electrically connected with the etching protection layer, the overlapping area of the test terminals is increased, and the bending angle of a touch electrode in the touch layer is reduced. The display panel is advantaged in that stability of the test lead is improved, reliability and effectiveness of the test of the touch layer of the display panel are improved, and thetest module can be directly measured under the condition that the display panel is not damaged when a user is abnormal in use, so abnormality is analyzed, and maintenance cost of the display panel isreduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

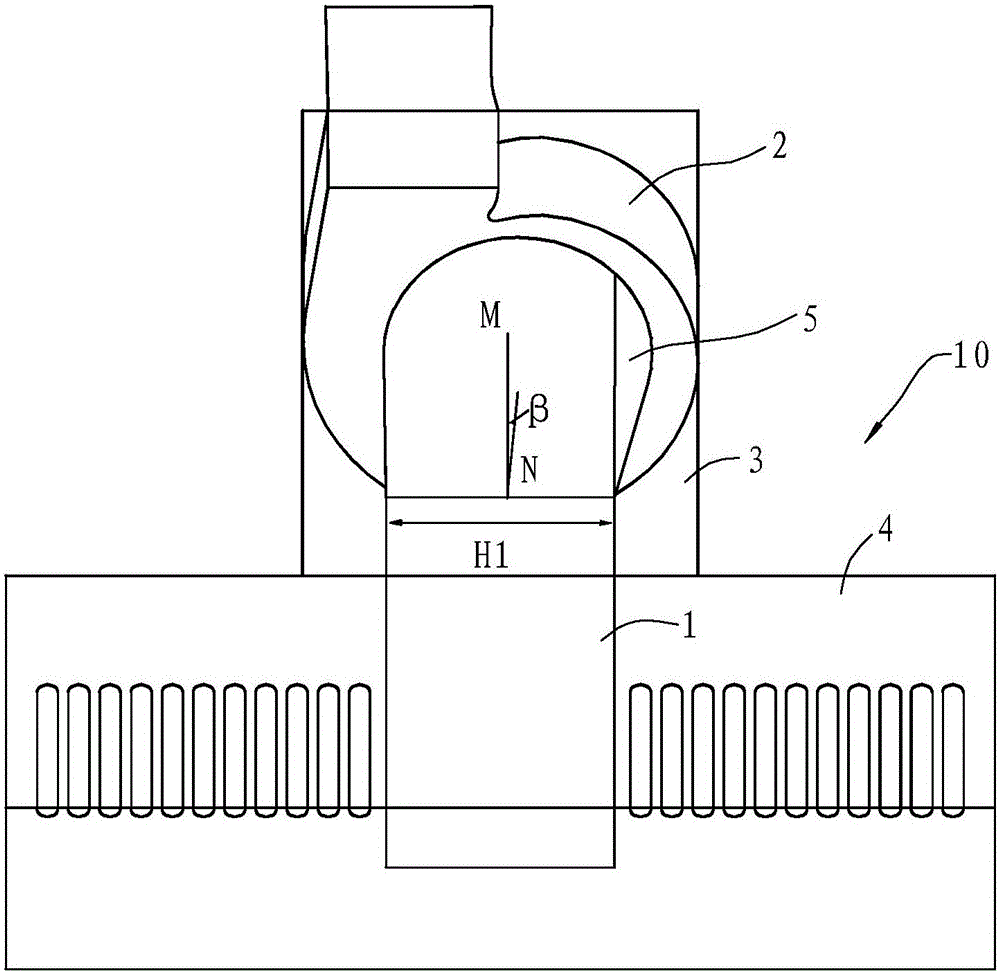

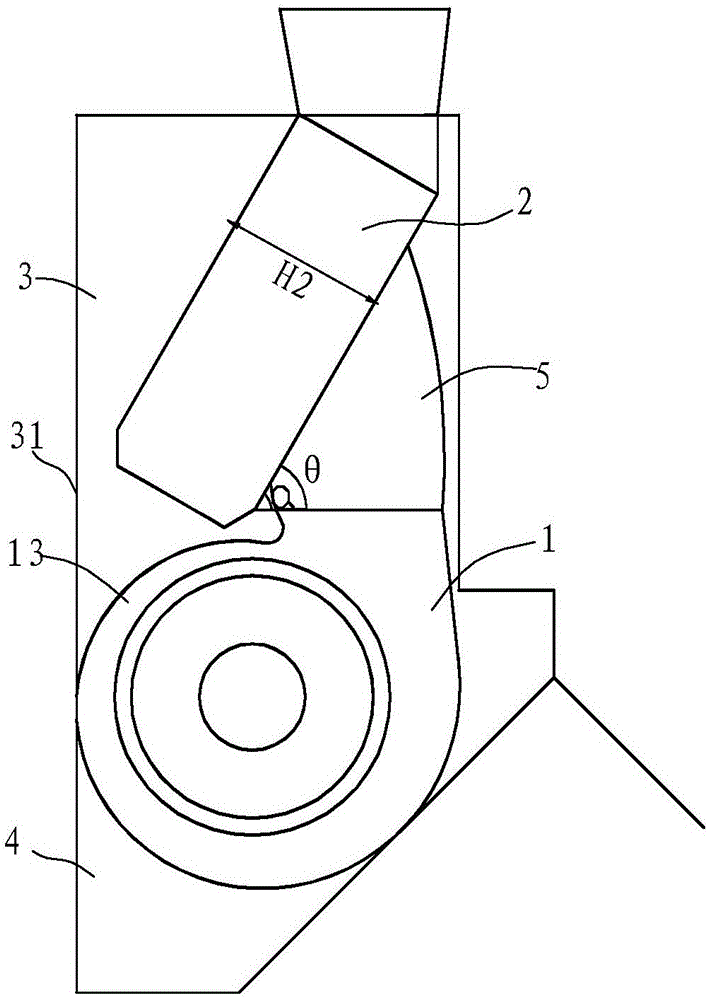

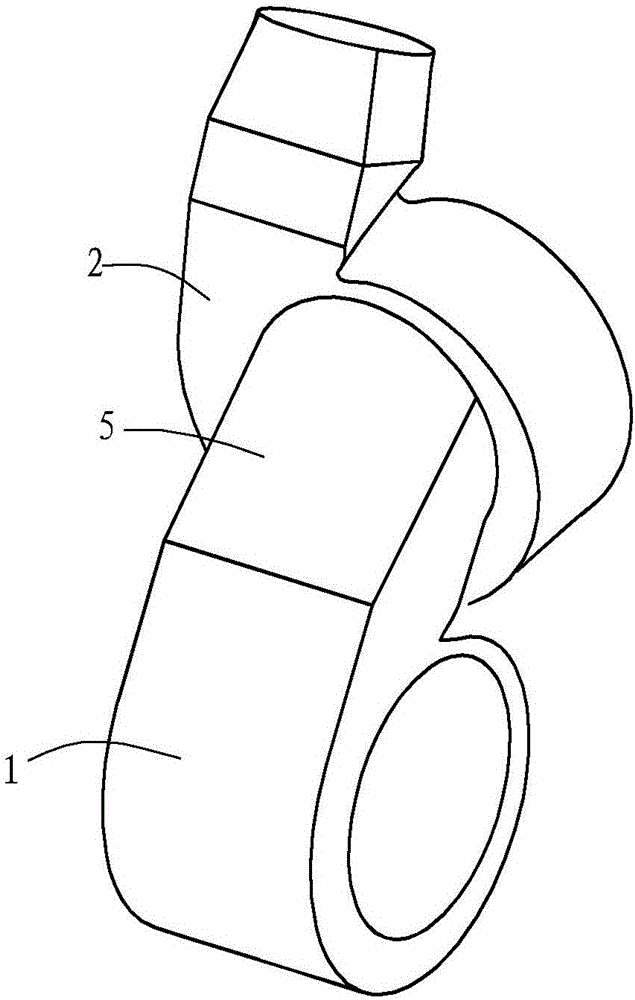

Range hood with double series fans

InactiveCN106524268AIncrease the radius of curvatureReduce lossesDomestic stoves or rangesPump componentsEngineeringCentrifugal fan

The invention discloses a range hood with double series fans. The range hood comprises a fan housing (3), a smoke collection cover (4) arranged at the lower end of the fan housing, and a first-stage centrifugal fan (1) and a second-stage centrifugal fan (2) arranged in the fan housing (3), wherein the second-stage centrifugal fan (2) is located above the first-stage centrifugal fan, an air outlet port of the first-stage centrifugal fan (1) communicates with an air inlet port of the second-stage centrifugal fan, and the orientation of an air inlet port of the first-stage centrifugal fan is vertical to the orientation of an air inlet port of the second-stage centrifugal fan. The range hood is characterized in that the first-stage centrifugal fan (1) is double air-inlet centrifugal fans provided with air inlet ports facing a left direction and a right direction respectively; and the second-stage centrifugal fan (2) is arranged at a position adjacent to the rear sidewall of the fan housing (3), and provided with a forward air inlet port. Compared with the prior art, the range hood disclosed by the invention has the following advantages: a noise can be effectively lowered, and then wind resistance is reduced and a smoke discharge effect is improved; and meanwhile, overall installation is compact, and both height and width are reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

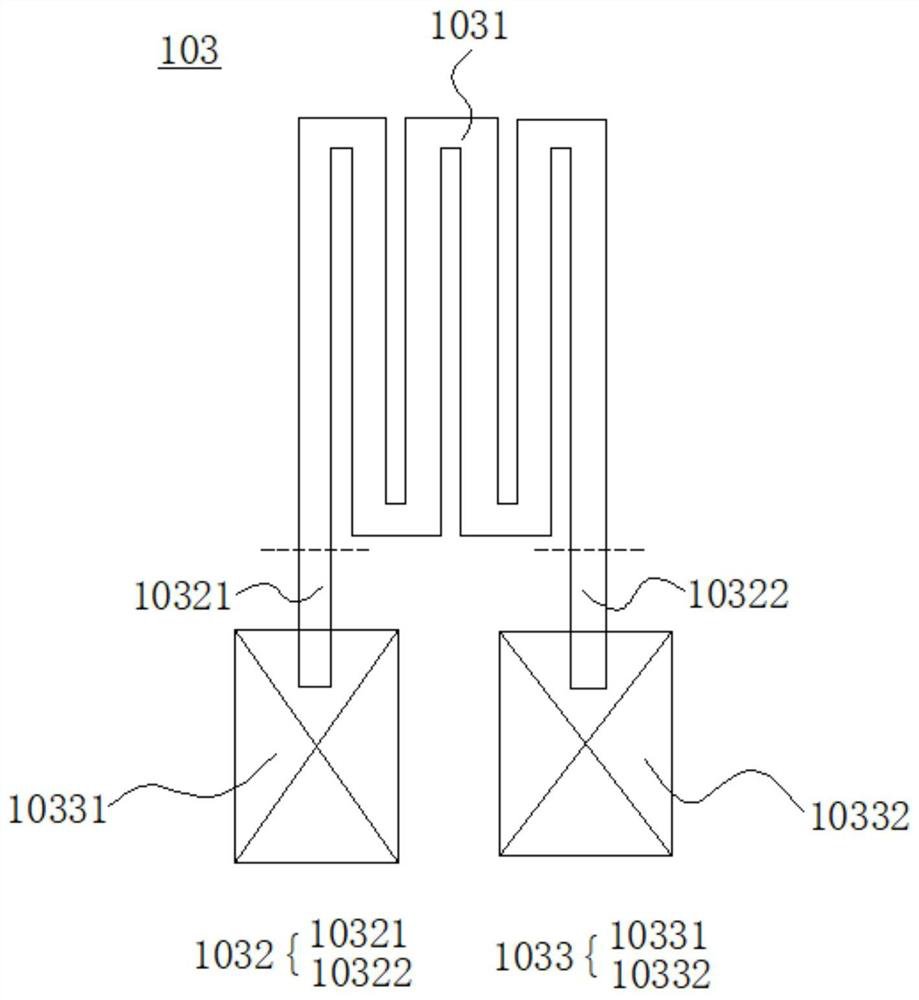

Supporting device and flexible display device

PendingCN112419894ATake full advantage of foldingReduce bend angleIdentification meansComputer hardwareComputer graphics (images)

The invention discloses a supporting device and a flexible display device, and relates to the technical field of display. The flexible display device can be curled in two directions, and the flexibledisplay panel are brought into full play. The flexible display device comprises a flexible display panel and a supporting device which are arranged in a stacked mode. The supporting device comprises aplurality of supporting plates, and the supporting plates are arranged in multiple rows in the first direction and arranged in multiple columns in the second direction. Any two adjacent supporting plates are rotatably connected, the rotating axes between every two adjacent rows of supporting plates are located on the same straight line, and the rotating axes between every two adjacent columns ofsupporting plates are located on the same straight line. The flexible display device is used for visually displaying graphic and text information.

Owner:BOE TECH GRP CO LTD +1

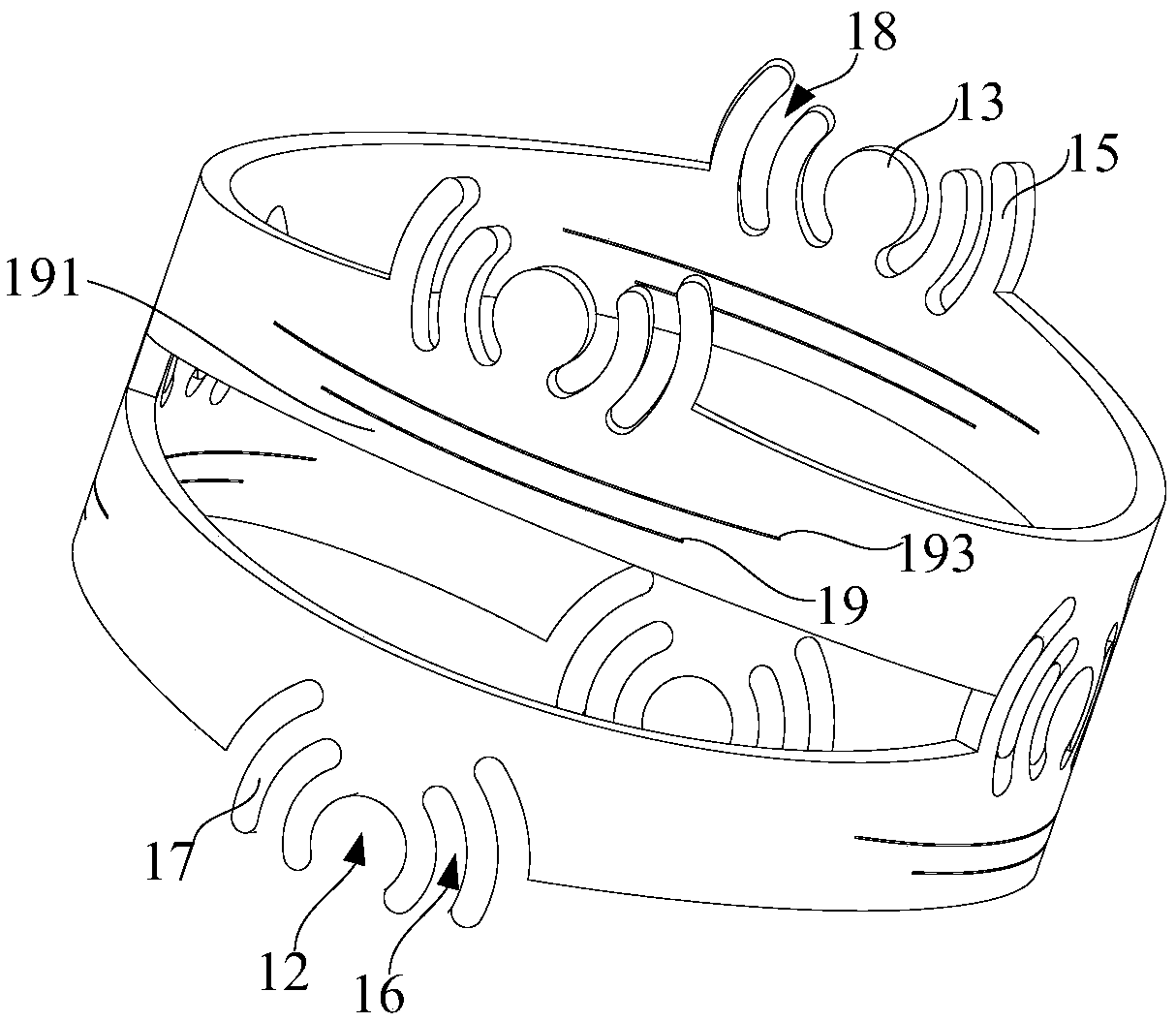

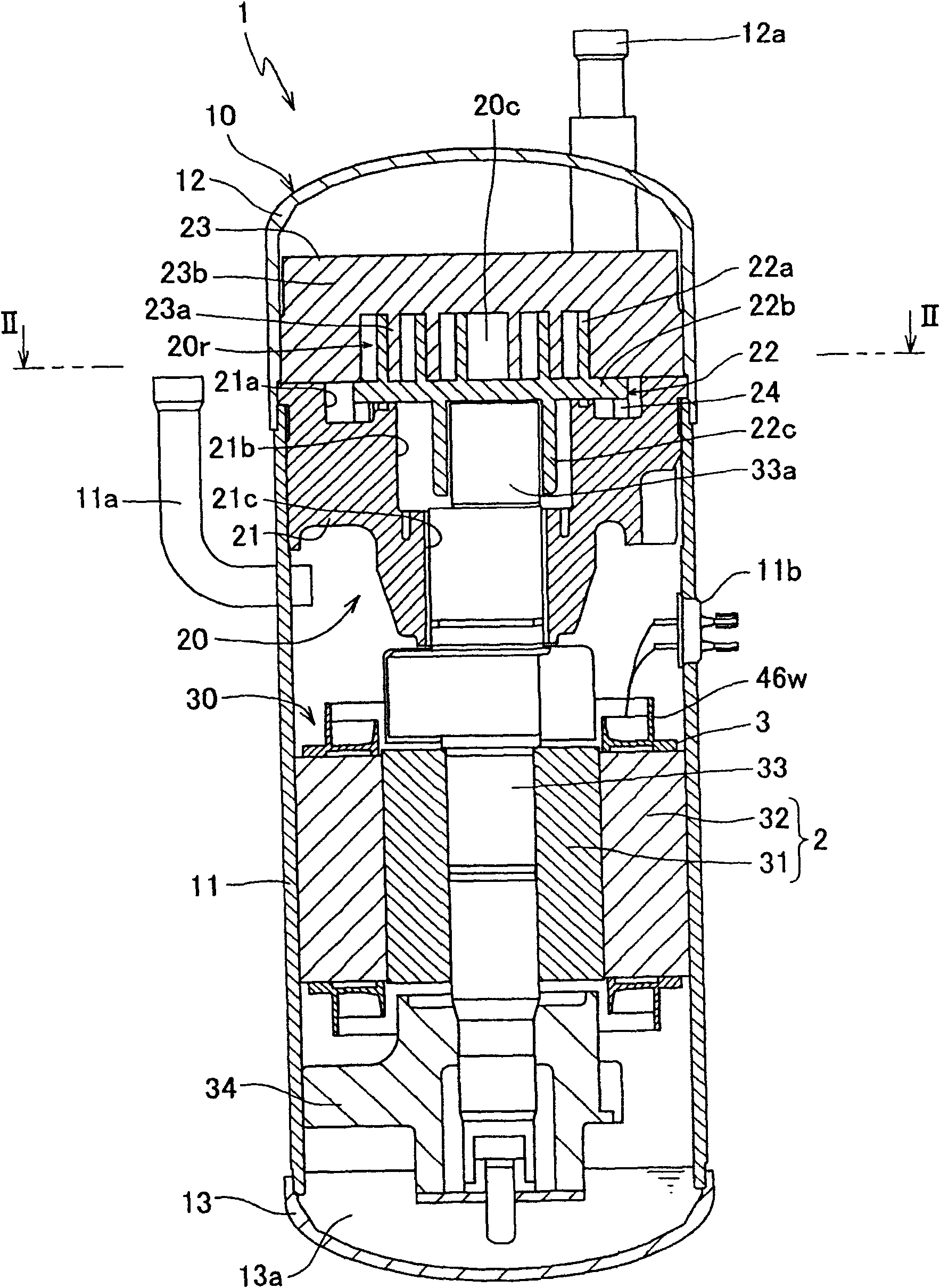

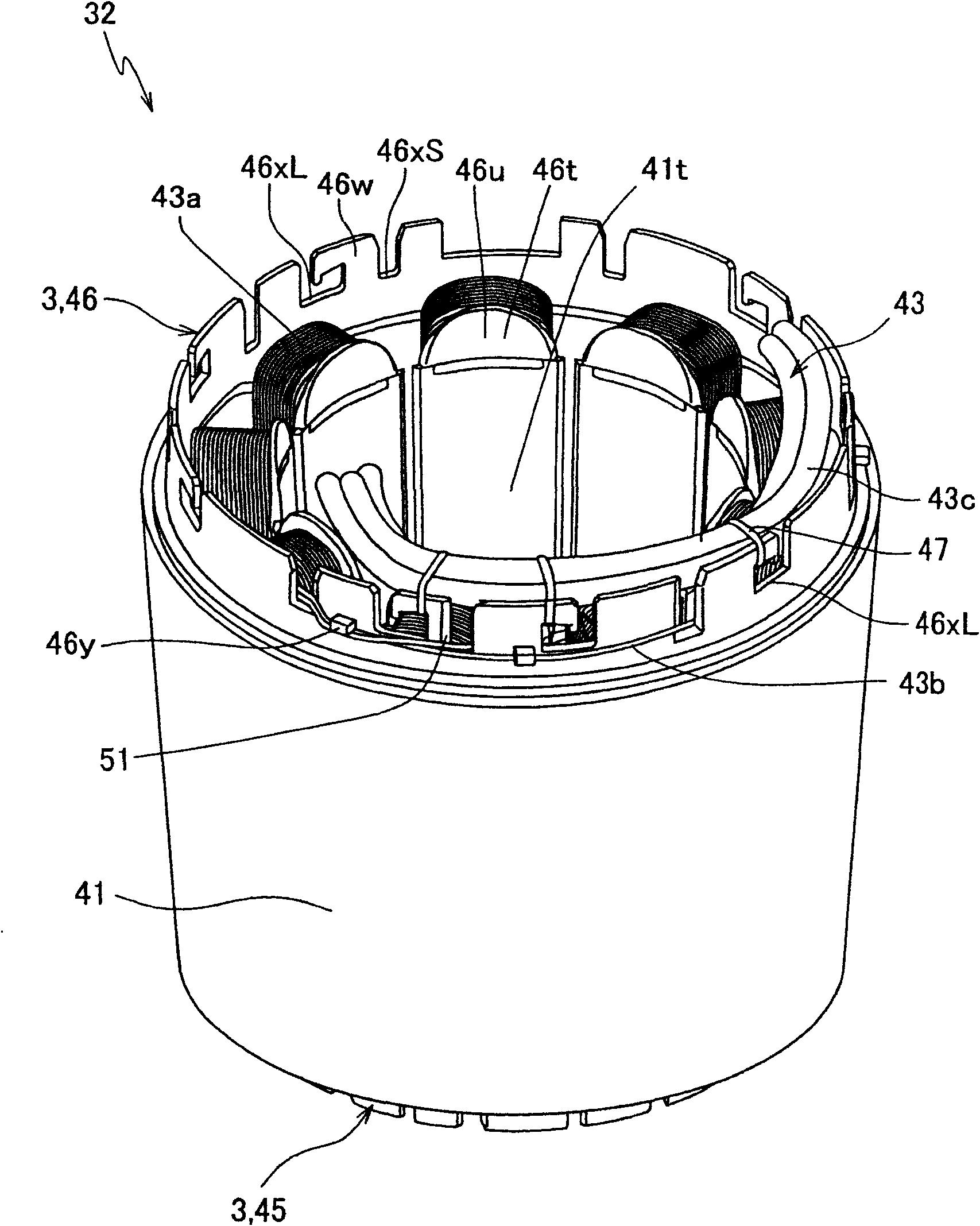

Insulator, motor and compressor

InactiveCN101854091AReduce bend angleStress reliefWindings insulation shape/form/constructionEngineeringElectric wire

The invention provides an insulator, a motor and a compressor, which inhibits stress applied to a wire when equipping wires inside and outside an insulator wall surface of the motor stator and prevents damage owing to press and vibration to an angle portion. The insulator has a circular periphery wall portion (46w) which extends along the shaft direction of a core portion and forms a groove (46xS) allowing the wire (43b) to pass. An inclination surface (51) which is inclined in the racial direction of the core portion relative to the axial direction of the core portion is formed in one wall portion (46wL) in wall portions on two sides of the groove (46xS) in the periphery wall portion (46w) and on the periphery side of the end portion opposite to another wall portion (46wR). The wire (43b) is disposed along the inclined surface (51).

Owner:DAIKIN IND LTD

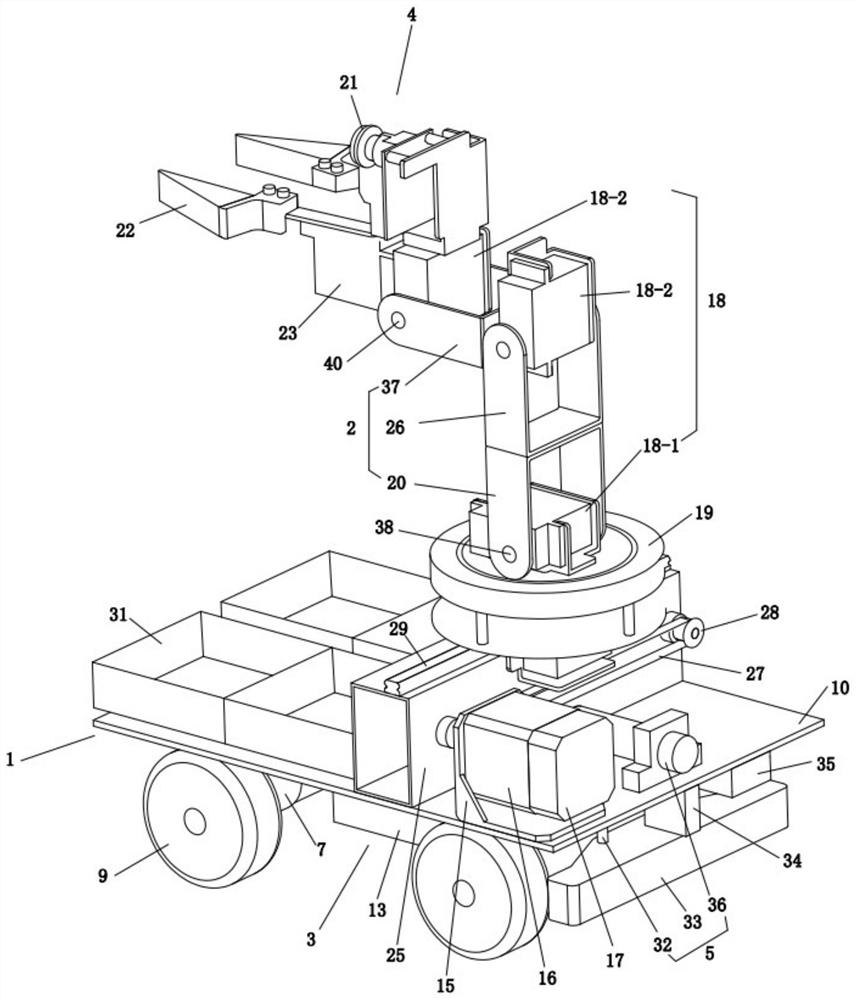

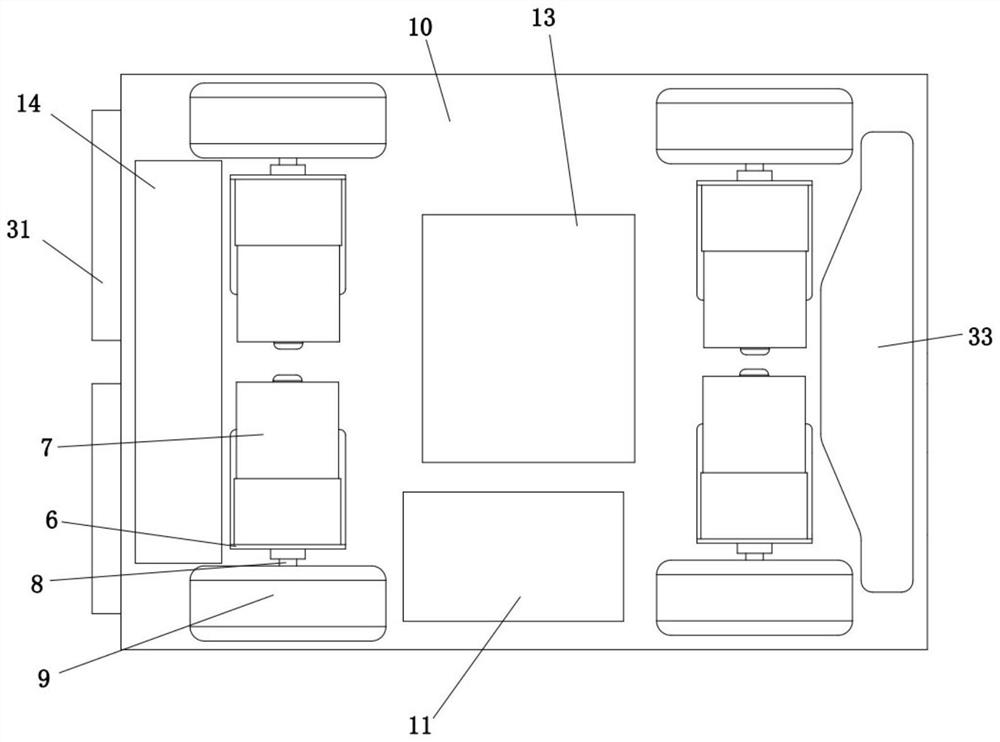

Shopping guide robot for shopping mall

PendingCN114734417AEasy to grabGuaranteed to move normallyProgramme-controlled manipulatorGripping headsRadar systemsControl system

The invention relates to a shopping guide robot for a shopping mall. The shopping guide robot comprises a vehicle body, a mechanical arm system, a motion control system, a visual identification and voice broadcast system and a gray scale and laser radar system, the mechanical arm system comprises a shopping guide mechanical arm, a clamping jaw, a clamping jaw steering engine, a rotating steering engine and a moving device, the clamping jaw is installed at the upper end of the shopping guide mechanical arm and connected with the clamping jaw steering engine, the rotating steering engine is installed at the lower end of the shopping guide mechanical arm, and the moving device is installed on the vehicle body and comprises a stepping motor, a linear guide rail and a sliding block. The output end of the stepping motor is connected with a synchronous wheel, the synchronous wheel is connected with a synchronous belt, the linear guide rail is sleeved with the sliding block in a sliding mode, and the rotary steering engine is installed on the sliding block and the synchronous belt. The sliding block drives the shopping guide mechanical arm to move towards the goods shelf, the distance between the shopping guide mechanical arm and the goods is reduced, under the condition that the length of the shopping guide mechanical arm is not increased, the goods on the goods shelves with different widths are taken and placed, the requirements of people for purchasing different goods are met, and the moving stability of the vehicle body is improved.

Owner:YANTAI UNIV

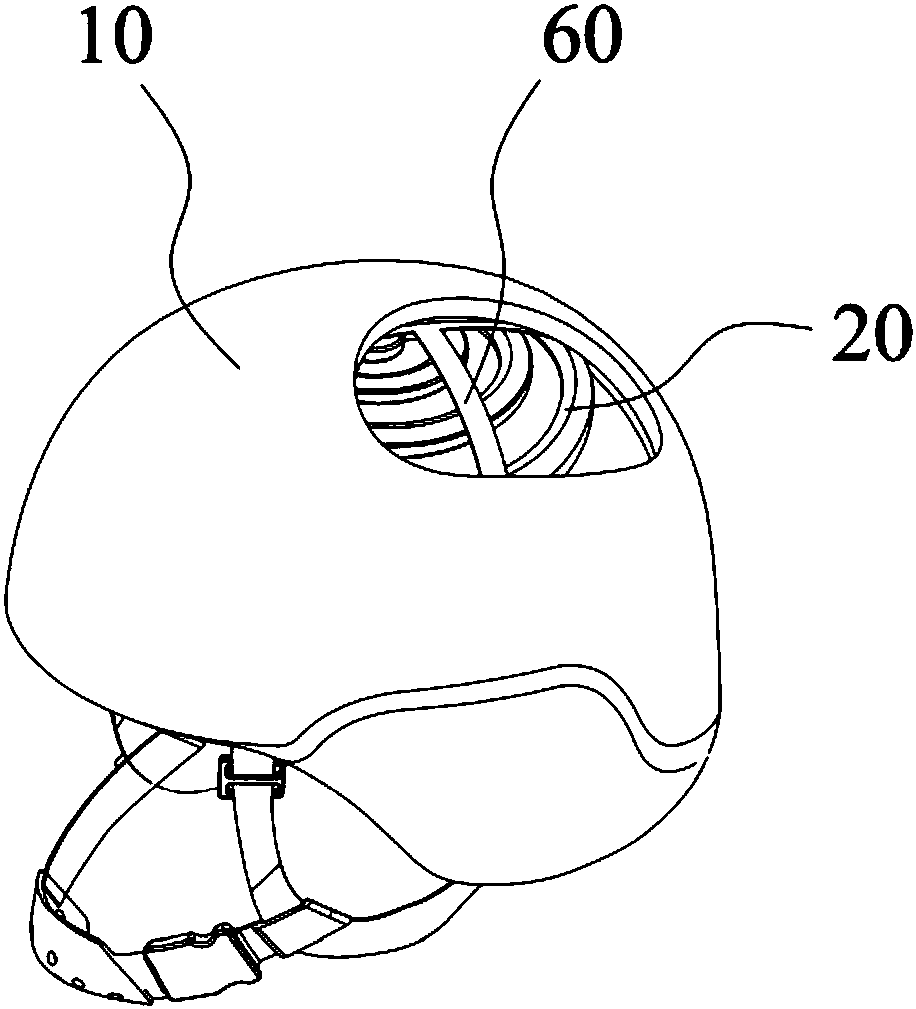

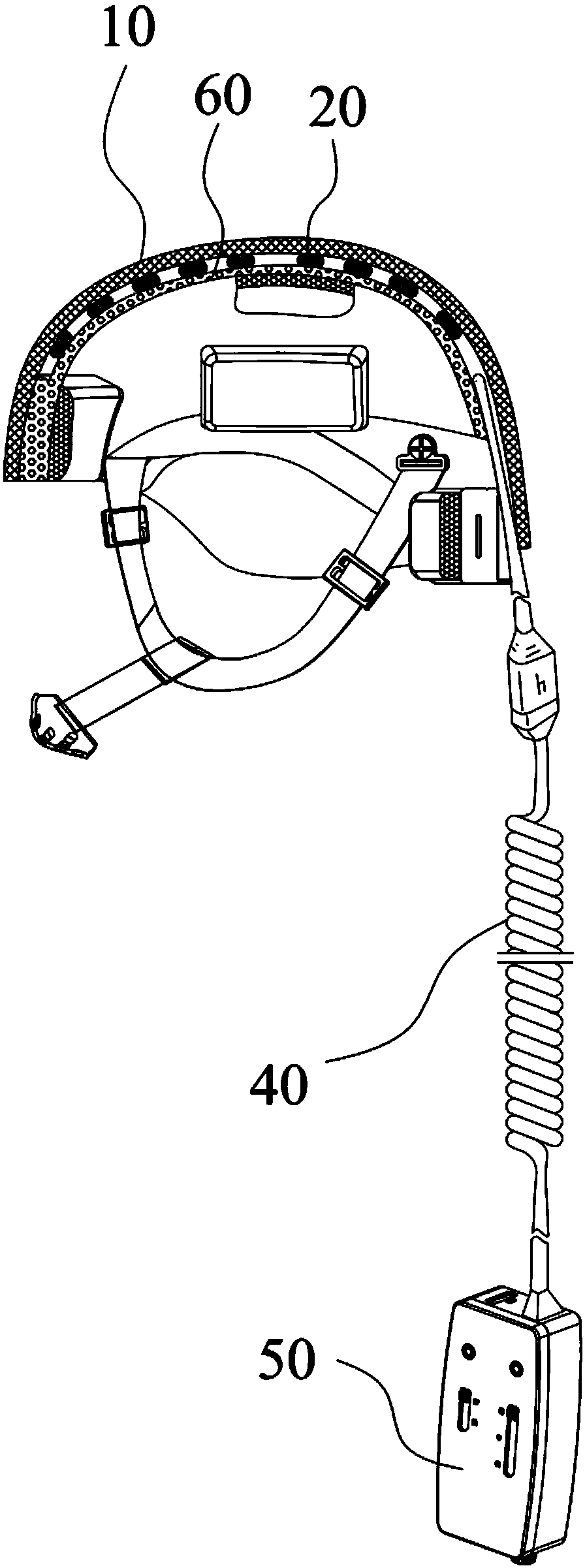

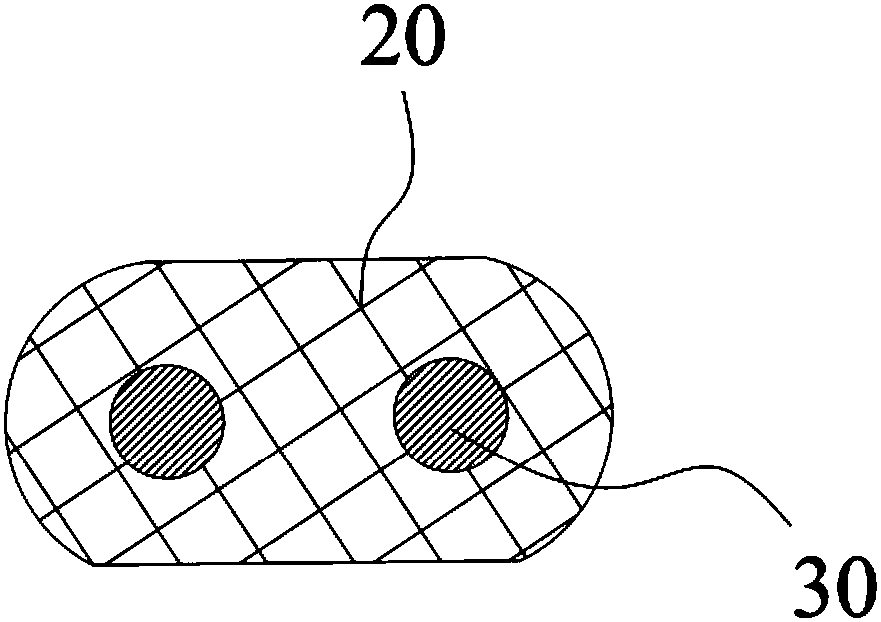

Helmet

PendingCN108185560AReduce bend angleLarge heating areaHelmetsHelmet coversElectric heatingSurface plate

The invention provides a helmet, comprising a helmet body. A flame-retardant acupuncture cotton strip is fixed in the helmet body and is spirally and evenly arranged on the inner wall of the helmet body from top to bottom; an electric heating wire is embedded in the flame-retardant acupuncture cotton strip; a spring cable is connected to the tail end of the electric heating wire and is positionedat the edge of the helmet body; the spring cable is used for being electrically connected to a control box; the front of the control box is provided with an operating panel; a control circuit board and a rechargeable lithium battery pack electrically connected with the control circuit board are arranged in the control box; the control circuit board is used for controlling heating state of the electric heating wire and is electrically connected with the operating panel; the operating panel is provided with a temperature adjusting switch and a power switch. The helmet has large overall heating area, the parts supply heat evenly, and good warmth retention is provided.

Owner:江西联创电声有限公司

Conductor copper bar for bus duct

PendingCN114256672AReduce thicknessIncrease creepage distanceCoupling device detailsElectrical conductorMechanical engineering

The invention relates to the technical field of bus duct accessories, in particular to a conductor copper bar for a bus duct, which comprises an insulating plate and a conducting strip, grooves for reducing the thickness of the insulating plate are formed in the upper end face and the lower end face of the insulating plate, a connecting hole penetrates through a body in the middle of the insulating plate, and the conducting strip is provided with a through hole communicated with the connecting hole. After the conducting strips are pressed in the grooves, the connecting holes are poured to form positioning parts, annular parts abutting against the outer end faces of the conducting strips are formed at the two ends of the positioning parts, the creepage distance is increased, meanwhile, the thickness of the insulating plate is reduced, the production cost is reduced, and meanwhile the safety performance of the bus duct is improved.

Owner:浙江泰昱电气股份有限公司

Biological sample liquid nitrogen tank refrigerator

ActiveCN113714323AReduce bend angleAvoid damageExtrusion cleaning devicesInsulation layerCooling coil

The invention discloses a biological sample liquid nitrogen tank refrigerator which comprises a liquid nitrogen tank refrigerator body and two compressor refrigerating systems. The liquid nitrogen tank refrigerator body comprises an inner tank body, an outer tank body and a vacuum interlayer located between the inner tank body and the outer tank body; the liquid nitrogen tank refrigerator body further comprises a liquid nitrogen filling pipe for filling liquid nitrogen into the inner tank body; and each compressor refrigerating system comprises a condenser, a compressor, a condensation evaporator, a throttling device and an evaporative cooling coil, wherein the two evaporative cooling coils are wound on the inner wall of the inner tank body in a staggered mode. According to the biological sample liquid nitrogen tank refrigerator, liquid nitrogen refrigeration and mechanical compression refrigeration are combined, a vacuum heat insulation layer is used for heat insulation, and therefore the biological sample liquid nitrogen tank refrigerator has the advantages of being good in energy-saving effect and capable of ensuring safety of stored biological samples, the use mode is flexible, and application prospects are wide.

Owner:SHANDONG DAYE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com