Range hood with double series fans

A technology of range hoods and models, which is applied in the direction of removing oil fumes, machines/engines, mechanical equipment, etc. It can solve the problems of large fluid resistance, large installation space, and high noise, and achieves reduced wind resistance, increased air intake area, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

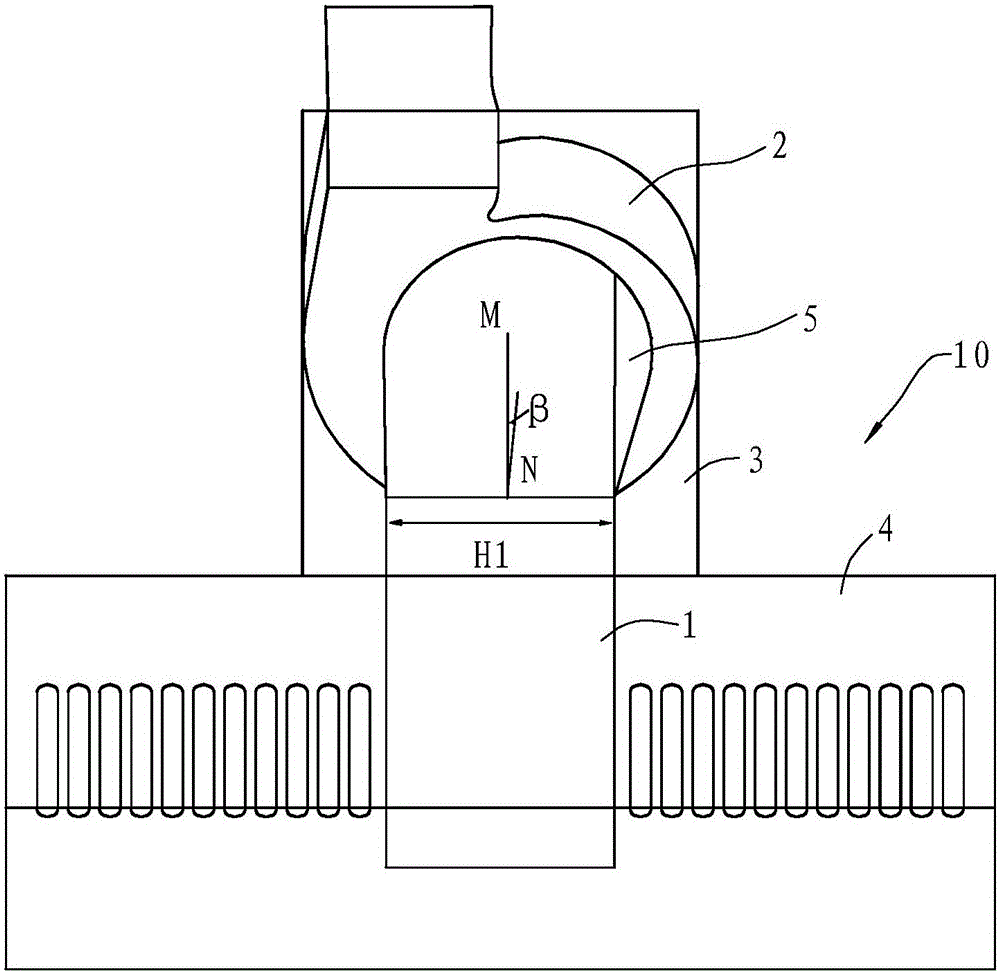

[0029] Example 1, such as figure 1 , figure 2 and image 3 As shown, the tandem double-fan type range hood in this embodiment includes a casing 10 and a first-stage centrifugal fan 1 and a second-stage centrifugal fan 2 arranged in the casing 10, and the casing 10 includes a fan casing 3 and a set The smoke collecting hood 4 at the lower end of the fan cover, the back side of the fan cover 3 is a flat installation surface, and the air inlet of the secondary centrifugal fan 2 is oriented perpendicular to the installation surface 31 . The fume collecting hood 4 is arranged horizontally, and the first-stage centrifugal fan 1 is located in the middle of the fume collecting hood 4 .

[0030] The casing 10 has an oil fume inlet at the lower end and an oil fume outlet at the upper end. The air inlet of the first-stage centrifugal fan 1 communicates with the oil fume inlet, the air outlet of the first-stage centrifugal fan 1 communicates with the air inlet of the second-stage centr...

Embodiment 2

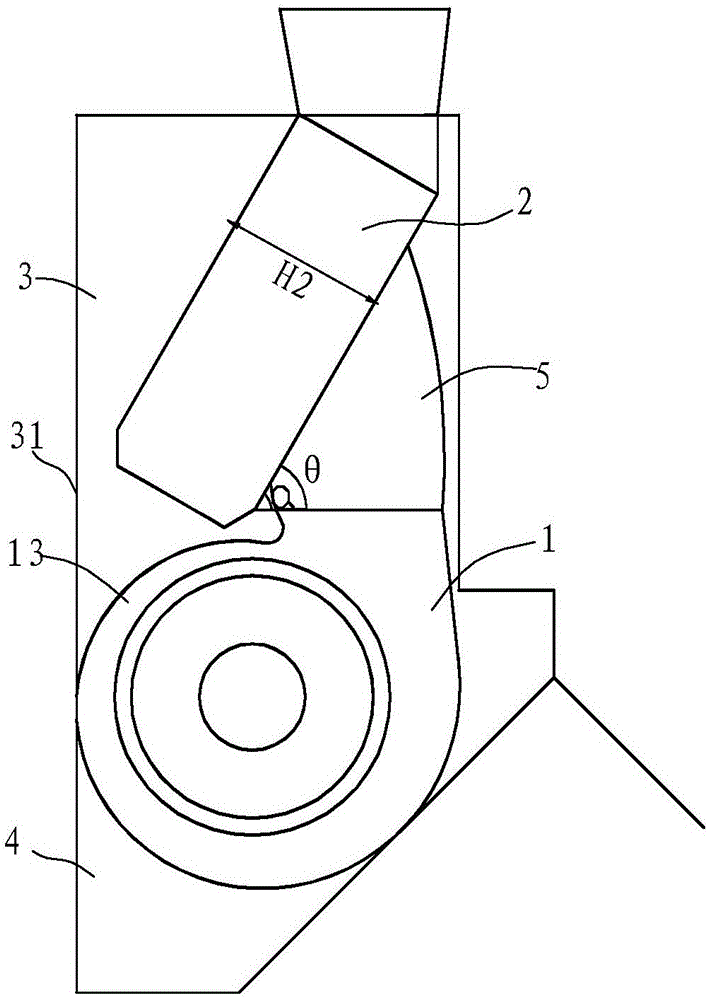

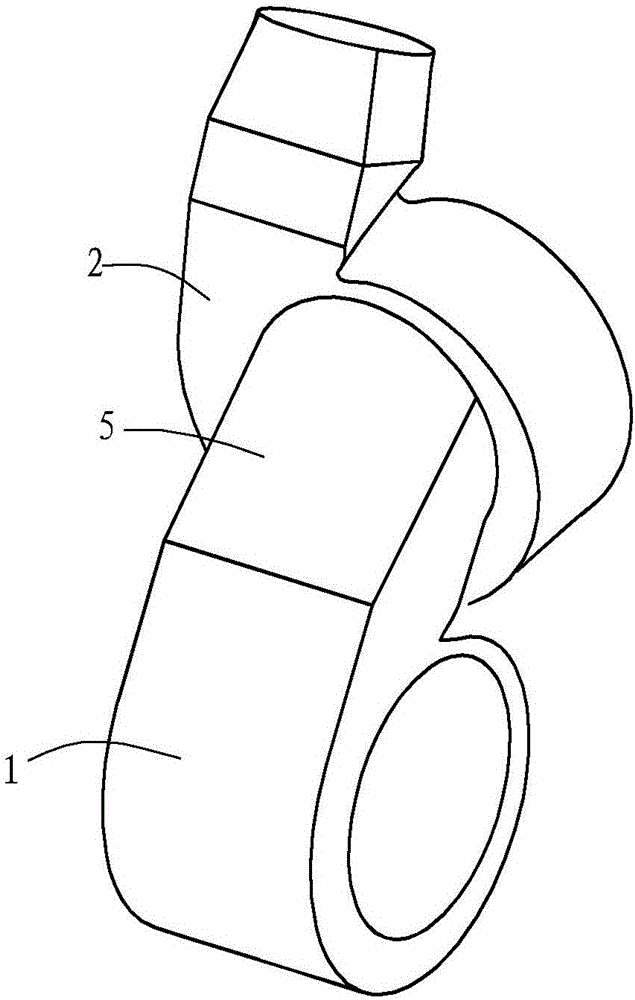

[0037] Example 2, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, in this embodiment, the air outlet of the primary centrifugal fan 1 is connected to the air inlet of the secondary centrifugal fan 2 through the diffuser section 5a. The diffuser section 5a is integrated with the volute of the first-stage centrifugal fan 1 . In order to maintain the centering and airtightness, a mounting plate is designed at the rear end of the diffuser section 5a. The mounting plate can be fixed with the sealing plate 31 and the sealing plate 32 on both sides of the air inlet end face of the secondary centrifugal fan 2. The sealing plate 31 and the sealing plate The plate 32 plays the role of positioning and sealing with the mounting plate. This design eliminates the connecting section between the two-stage centrifugal fans, which can simplify the positioning and installation. Refer to Example 1 for other structures.

[0038] The thickness H1 of the primary centrifugal fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com