Gallium nitride single crystal based on ScAlMgO4 substrate, and preparation method thereof

A gallium nitride single crystal and substrate technology, applied in the field of semiconductors, can solve the problems of complex stripping and dislocation reduction process, high dislocation of gallium nitride crystal, high production cost, etc., to achieve reduced production cost, large radius of curvature , the effect of reducing dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

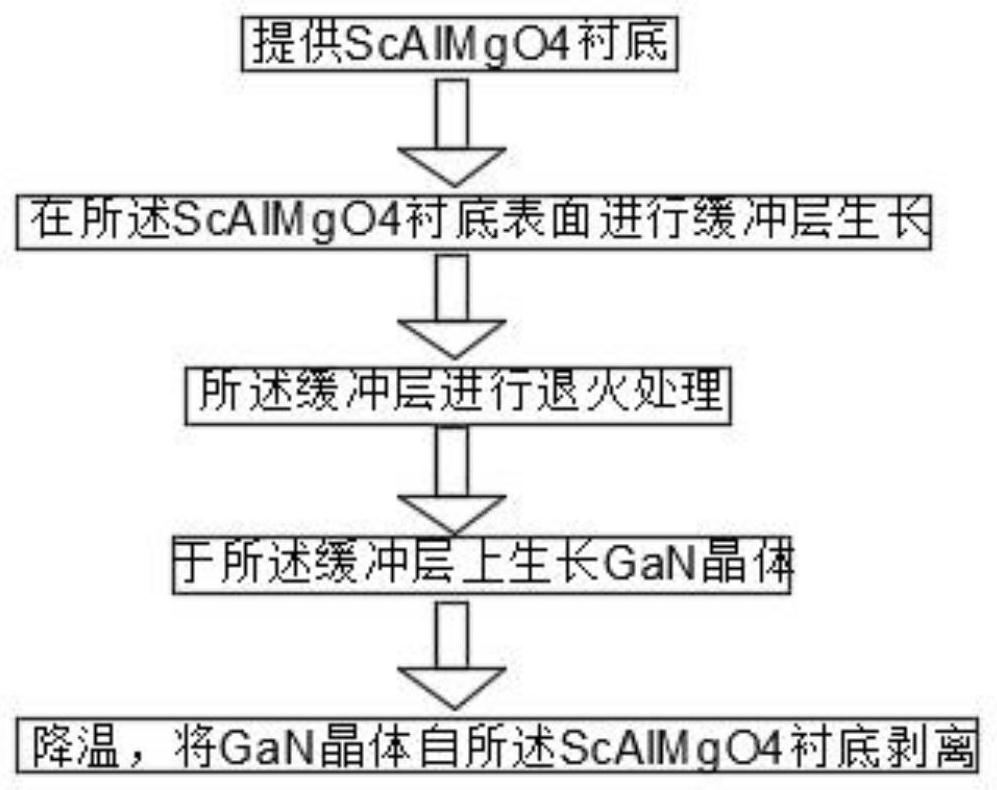

[0029] see figure 1 , the present invention provides a ScAlMgO-based 4 A method for preparing a gallium nitride single crystal of a substrate, comprising the steps of:

[0030] (1) Provide ScAlMgO 4 Substrate;

[0031] (2) In the ScAlMgO 4 Growth of a buffer layer on the surface of the substrate;

[0032] (3) The buffer layer is annealed;

[0033] (4) growing GaN crystals on the buffer layer;

[0034] (5) cooling, the GaN crystal from the ScAlMgO 4 Substrate peeled off.

[0035] see figure 1 and step (1), providing ScAlMgO 4 Substrate 100.

[0036] As a preferred setting of this embodiment, the ScAlMgO 4 The substrate is a circle or a regular polygon; more preferably, the ScAlMgO 4 The substrate is circular or regular hexagonal.

[0037] As a preferred setting of this embodiment, the ScAlMgO 4 Has high crystal quality, its (001) XRDFWHM is generally less than 20 arcsec, preferably less than 10 arcsec; the ScAlMgO 4 The substrate has an atomic layer surface and i...

Embodiment 2

[0046] The present invention also provides a ScAlMgO-based 4 GaN single crystal preparation method of the substrate, described in this example based on ScAlMgO 4 The preparation method of gallium nitride single crystal of the substrate is roughly the same as the preparation method described in other embodiments, the difference is that the growth of the buffer layer described in step (2) of embodiment 2 adopts the MOCVD method to grow the thin film template with a thickness of 1-10um, Its (102)XRDFWHM is less than 320 arcsec, preferably less than 240 arcsec. The MOCVD method is well known to those skilled in the art, and its principle will not be repeated here.

[0047] In step (3), in-situ annealing is performed in an MOCVD furnace, that is, after the low-temperature growth is completed, the temperature is raised to 1000° C. for annealing treatment.

Embodiment 3

[0049] The present invention also provides a ScAlMgO-based 4 GaN single crystal preparation method of the substrate, described in this example based on ScAlMgO 4 The preparation method of the gallium nitride single crystal of the substrate is roughly the same as that described in other embodiments, the difference is that the buffer layer growth in step (2) in this embodiment adopts the high temperature AlNHVPE method. Preferably, under the HVPE process conditions, the temperature is set at 1000-1600°C; more preferably, the temperature is set at 1200-1600°C; more preferably, the temperature is set at 1500-1600°C, and the thickness is 50-3000nm.

[0050] As a preferred setting of Example 3 of the present invention, the buffer layer prepared by the AlNHVPE method may not be annealed, or may be annealed at a high temperature of 1600-1700° C. in a reducing environment in step (3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com