Method for preparing antireflective film of polycrystalline silicon solar cell as well as polycrystalline silicon solar cell

A technology of solar cells and anti-reflection coatings, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of passivating the surface and substrate of silicon wafers, difficult to solve, multiple impurities, dislocations and grain boundaries, etc. Achieve the effect of improving photoelectric conversion efficiency, reducing dislocations and grain boundaries, and increasing maximum power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

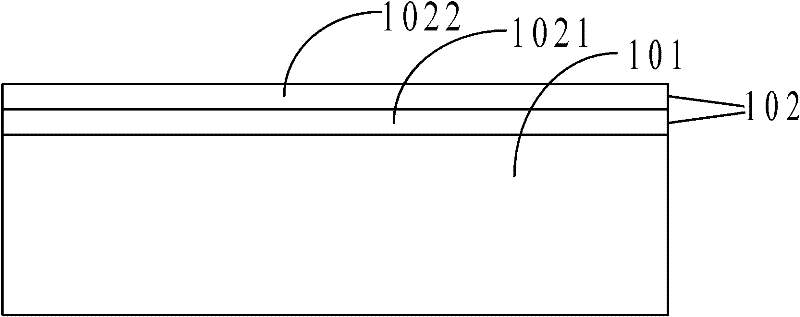

[0032] To this end, an embodiment of the present invention provides a method for preparing an anti-reflection film for a polycrystalline silicon solar cell, which includes:

[0033] The passivation layer deposition step is used to form a passivation layer on the surface of the polysilicon wafer, specifically: feeding ammonia gas with a flow rate of 6000-9000 SCCM and silane gas with a flow rate of 800-1000 SCCM into the deposition chamber, and a radio frequency power of 3000 ~5000W, the duty ratio is 5:50, the pressure is 1500~2000mtor, and the duration is 100~300S;

[0034] The density layer deposition step is used to form a density layer on the surface of the passivation layer, specifically: feeding ammonia gas with a flow rate of 7000-9000 SCCM and silane gas with a flow rate of 400-900 SCCM into the deposition chamber, and a radio frequency power of 4500-900 SCCM 6500W, the duty ratio is 5:50, the pressure is 1500~2000mtor, and the duration is 400~600S.

[0035] The embod...

Embodiment 1

[0039] This embodiment provides a method for preparing an anti-reflection film for a polycrystalline silicon solar cell, which includes:

[0040] The passivation layer deposition step is used to form a passivation layer on the surface of the polysilicon wafer, specifically: feeding ammonia gas with a flow rate of 6000-9000 SCCM and silane gas with a flow rate of 800-1000 SCCM into the deposition chamber, and a radio frequency power of 3000 ~5000W, the duty ratio is 5:50, the pressure is 1500~2000mtor, and the duration is 100~300S.

[0041] In this embodiment, the reaction principle of producing the silicon nitride of the passivation layer is as follows:

[0042] SiH 4 +NH 3 = Si x N y h z +H 2 ;

[0043] In the passivation layer made of silicon nitride, the higher the nitrogen content, the lower the refractive index, but the poorer the passivation effect. The higher the silicon content, the better the passivation effect, but the higher the refractive index, and Light a...

Embodiment 2

[0058] This embodiment provides a specific way to form an anti-reflection film in actual production, including the following steps:

[0059] Put the graphite boat loaded with polysilicon wafers into the furnace tube in the deposition chamber of the PECVD equipment;

[0060] The deposition chamber is evacuated, a pressure test is performed, and the combustion tower is started.

[0061] Ammonia purging step: inject 2-6L of ammonia and 2-4L of nitrogen into the deposition chamber, and control the radio frequency power to 3000-5000W for 100-300S.

[0062] Vacuum the deposition chamber again, conduct a pressure test, and conduct a leak detection of the furnace tube, and wait for the temperature to reach the set value of 450°C.

[0063] Ammonia gas pre-deposition step: inject 3-6L ammonia gas into the deposition chamber, and control the radio frequency power to 3000-5000W for 100-300S.

[0064] Deposition steps of H-containing passivation layer, specific parameters: ammonia gas fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com