Crystalline silicon and preparation method thereof

A technology of crystalline silicon and monocrystalline silicon, which is applied in the field of crystalline silicon and its preparation, can solve the problems of low battery conversion efficiency, affecting the ratio of single crystal, high production cost, etc., and achieve the effect of improving battery conversion efficiency, improving quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing crystalline silicon includes the following steps:

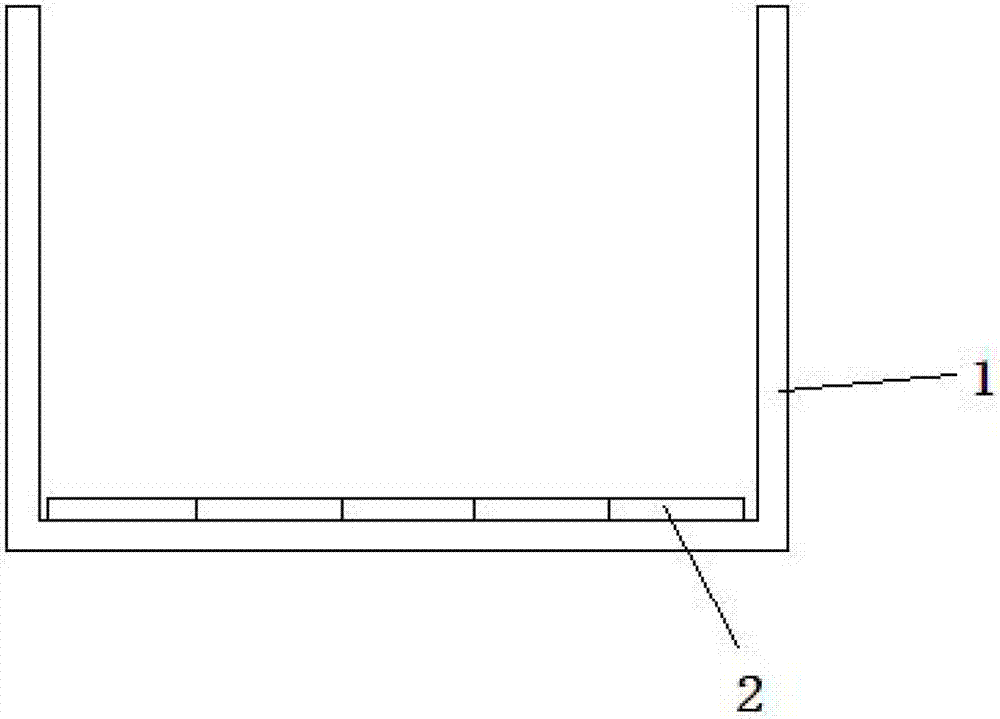

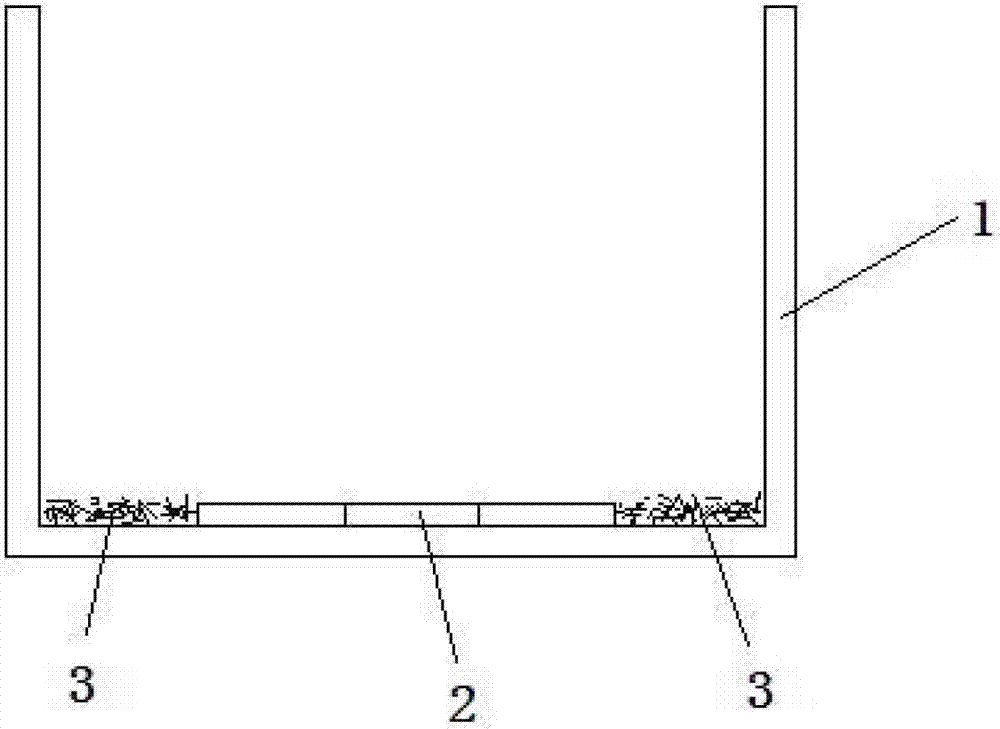

[0037] (1) Randomly lay single crystal silicon seeds at the center of the bottom of the crucible to form a seed layer, and the crystal orientation of the single crystal silicon seeds is not limited; nucleation sources are laid on the rest of the bottom to form a nucleation source layer;

[0038] Among them, the single crystal silicon seed crystal is a square single crystal silicon seed crystal with a thickness of 10 mm, a total of 9 pieces, which are closely arranged at the bottom center of the crucible in the form of 3 rows and 3 columns. The laying of nucleation sources on the rest of the bottom is: lay a 10kg nucleation source evenly on the periphery of the single crystal silicon seed crystal square, and gently flatten to form a nucleation source layer with a thickness of 10mm. The nucleation source is quartz powder with a particle size of 10um.

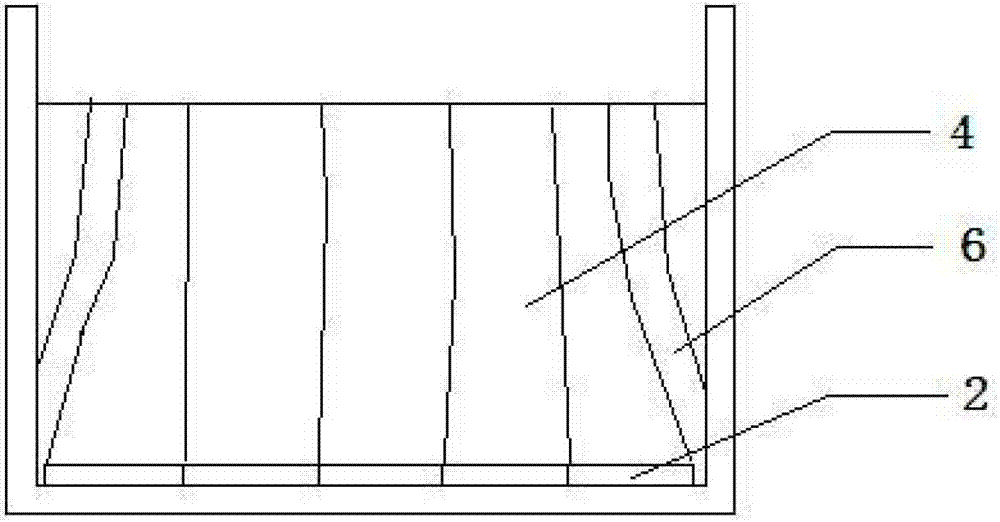

[0039] image 3 It is a schematic diagram of the sing...

Embodiment 2

[0048] A method for preparing crystalline silicon includes the following steps:

[0049] (1) Randomly lay single crystal silicon seeds at the center of the bottom of the crucible to form a seed layer, and the crystal orientation of the single crystal silicon seeds is not limited; nucleation sources are laid on the rest of the bottom to form a nucleation source layer;

[0050] Among them, the single crystal silicon seed crystals are square single crystal silicon seed crystals with a thickness of 5 mm, a total of 16 pieces, which are closely arranged at the bottom center of the crucible in the form of 4 rows and 4 columns. The laying of nucleation sources on the rest of the bottom is: evenly spread 5kg of nucleation sources on the periphery of the single crystal silicon seed crystal square, and gently flatten them to form a nucleation source layer with a thickness of 1mm. The nucleation source is silicon powder with a particle size of 20um.

[0051] (2) A molten silicon material is set...

Embodiment 3

[0058] A method for preparing crystalline silicon includes the following steps:

[0059] (1) Randomly lay single crystal silicon seeds at the center of the bottom of the crucible to form a seed layer, and the crystal orientation of the single crystal silicon seeds is not limited; nucleation sources are laid on the rest of the bottom to form a nucleation source layer;

[0060] Among them, the single crystal silicon seed crystal is a cylindrical single crystal silicon seed crystal with a thickness of 50mm, a total of 1 piece, laid in the center of the bottom of the crucible, and the rest of the bottom is filled with a nucleation source, and the nucleation source layer is gently flattened to make The thickness is about 30mm, and the nucleation source is silicon carbide powder with a particle size of 1cm.

[0061] (2) A molten silicon material is set above the seed crystal layer and the nucleation source layer, and the bottom temperature of the crucible is controlled to be lower than the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com