Method for making selective emitter crystalline silicon solar cell

A solar cell and crystalline silicon technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low battery efficiency, inability to apply, and reduced overall battery performance, avoiding multiple high-temperature damage and high battery conversion efficiency. , the effect of avoiding equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a selective emitter P-type monocrystalline silicon solar cell, comprising the following steps:

[0025] ① Make the P-type monocrystalline silicon wafer suede, then wash and dry it. Suede making and cleaning adopt prior art.

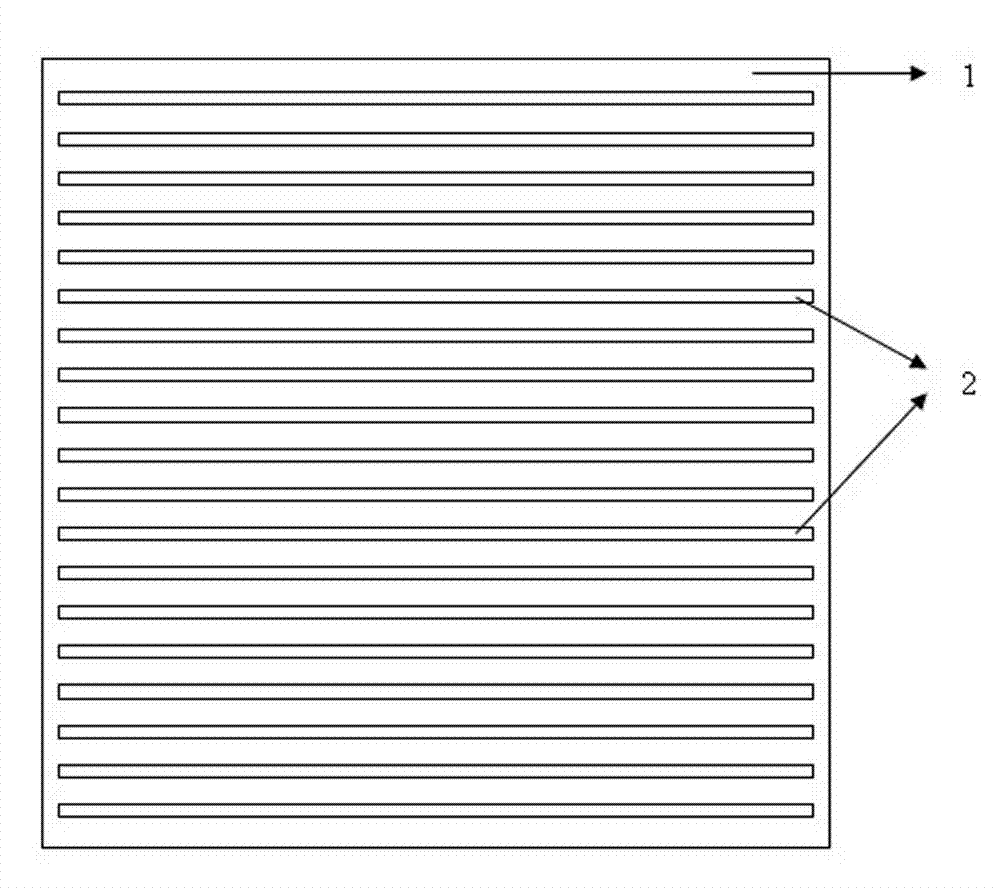

[0026] ②Put the P-type single crystal silicon wafer obtained in step ① on the loading table of the linear magnetron sputtering coating machine, cover the mask plate 1, fix the silicon wafer and the mask plate 1, and then put it into the magnetron sputtering coating machine. In the magnetron sputtering chamber of the sputtering coating machine, the antimony pre-fixed in the magnetron sputtering chamber is used as the target for sputtering. Close the door of the magnetron sputtering chamber, evacuate the magnetron sputtering chamber, set the sputtering pressure to 0.7Pa, the argon flow rate to 15sccm, the substrate temperature to 240°C, and the sputtering time to 25s. The mask plate is removed to realize the antimony film dep...

Embodiment 2

[0030] A method for preparing a selective emitter P-type polycrystalline silicon solar cell, comprising the following steps:

[0031] ① Make the P-type polysilicon wafer suede, then wash and dry it. Suede making and cleaning adopt prior art.

[0032]② Put the P-type polysilicon wafer obtained in step ① on the loading table of the linear magnetron sputtering coating machine, cover the mask plate 1, fix the silicon wafer and the mask plate 1, and then put it into the magnetron sputtering coating machine In the magnetron sputtering chamber of the machine, the antimony pre-fixed in the magnetron sputtering chamber is used as the target for sputtering. Close the door of the magnetron sputtering chamber, evacuate the magnetron sputtering chamber, set the sputtering pressure to 0.9Pa, the argon flow rate to 18sccm, the substrate temperature to 240°C, and the sputtering time to 30s. The mask plate is removed, and the antimony film deposition on the positive electrode gate line regio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com