Patents

Literature

47results about How to "Increase the intake area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

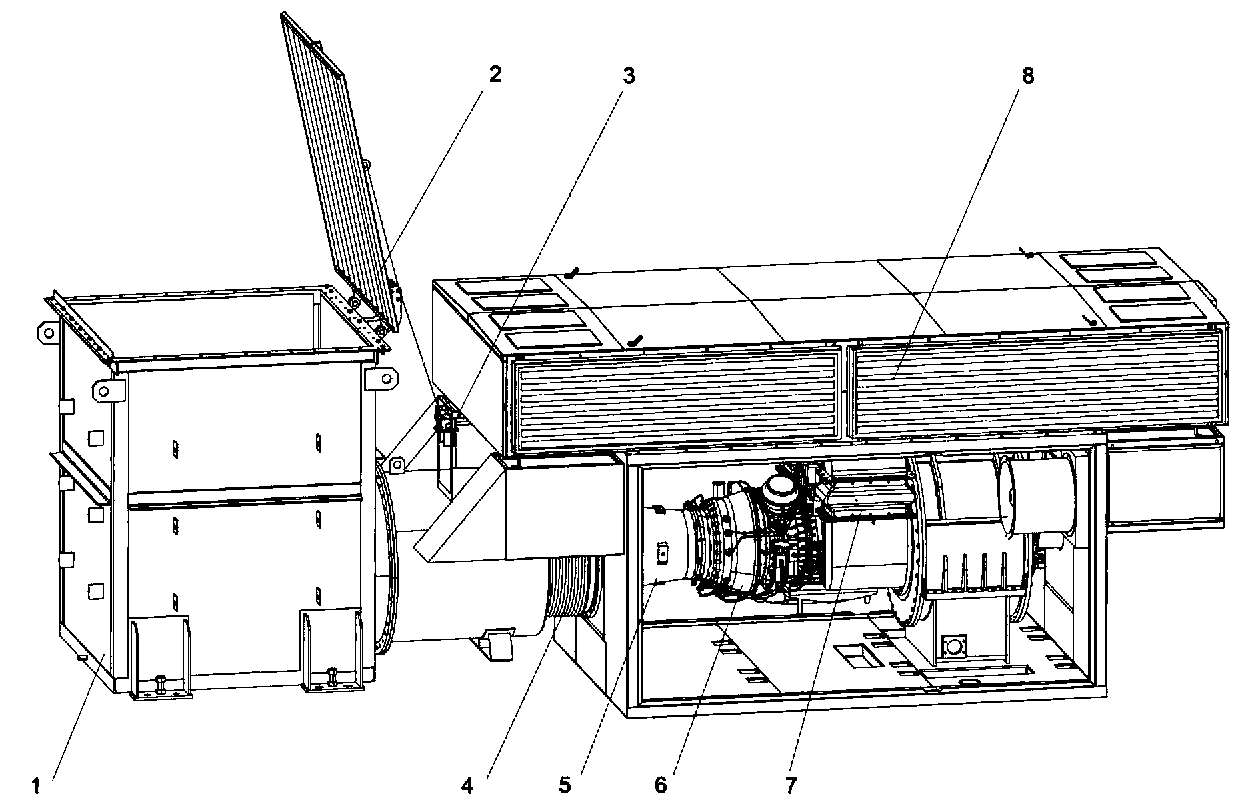

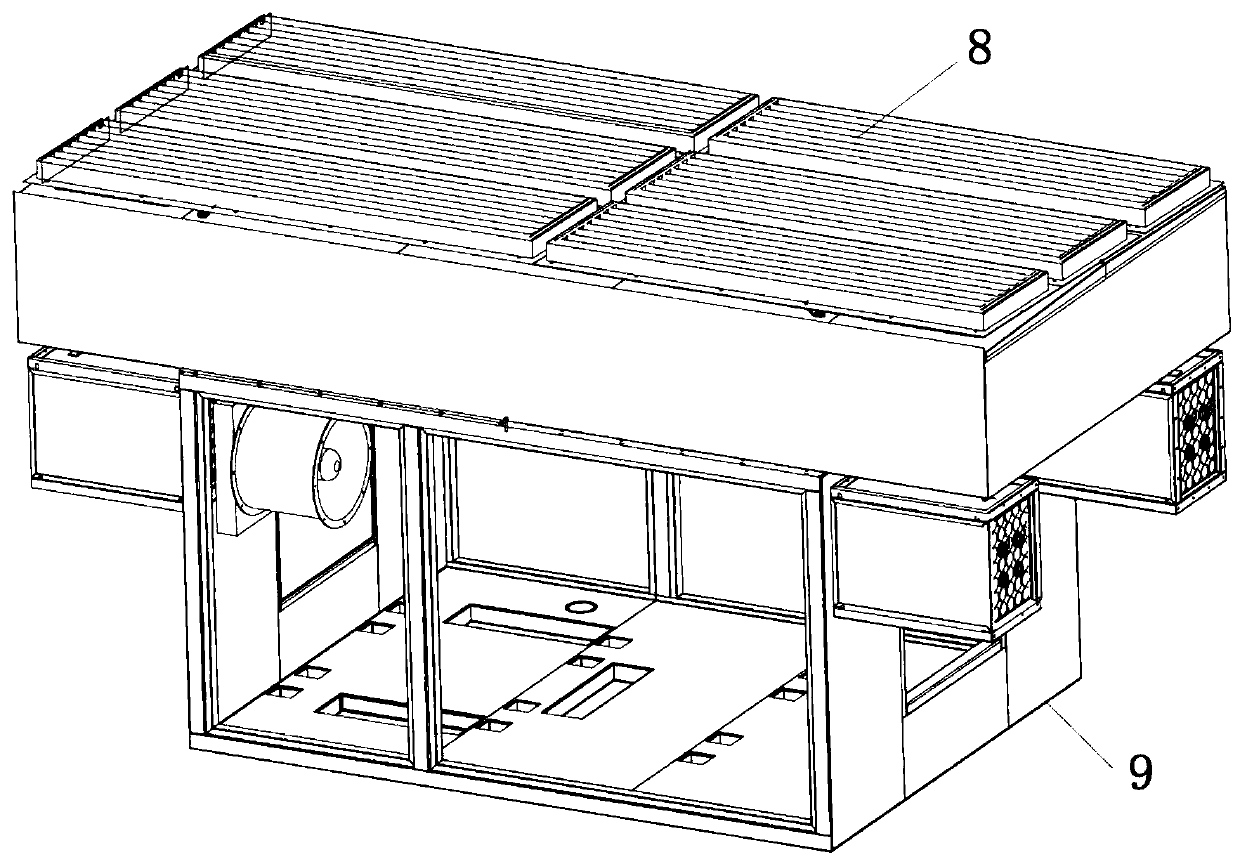

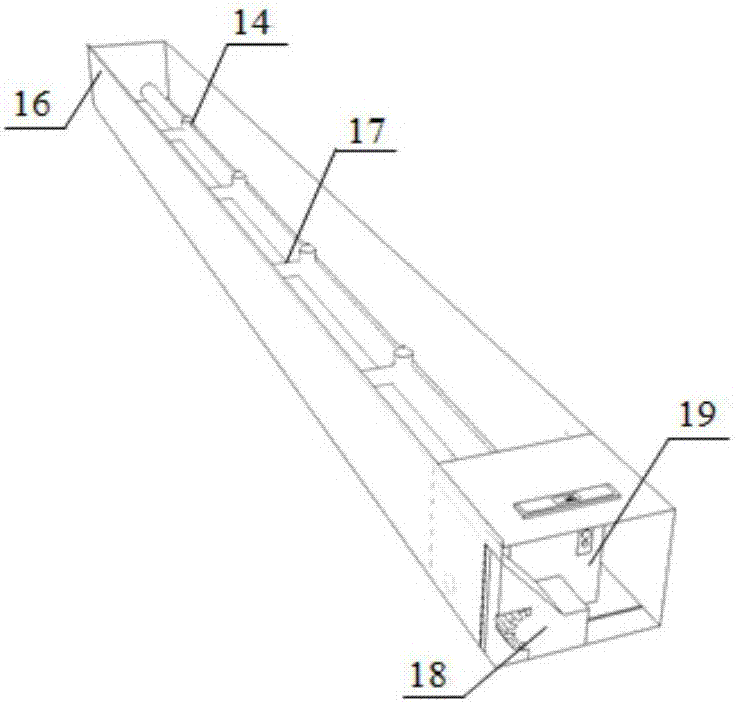

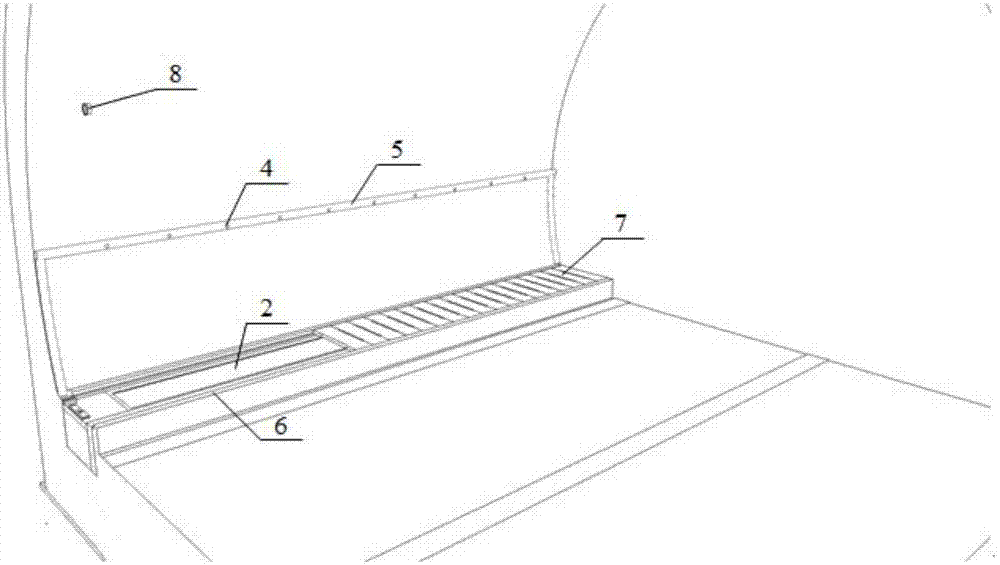

Intake and exhaust system of turbine engine

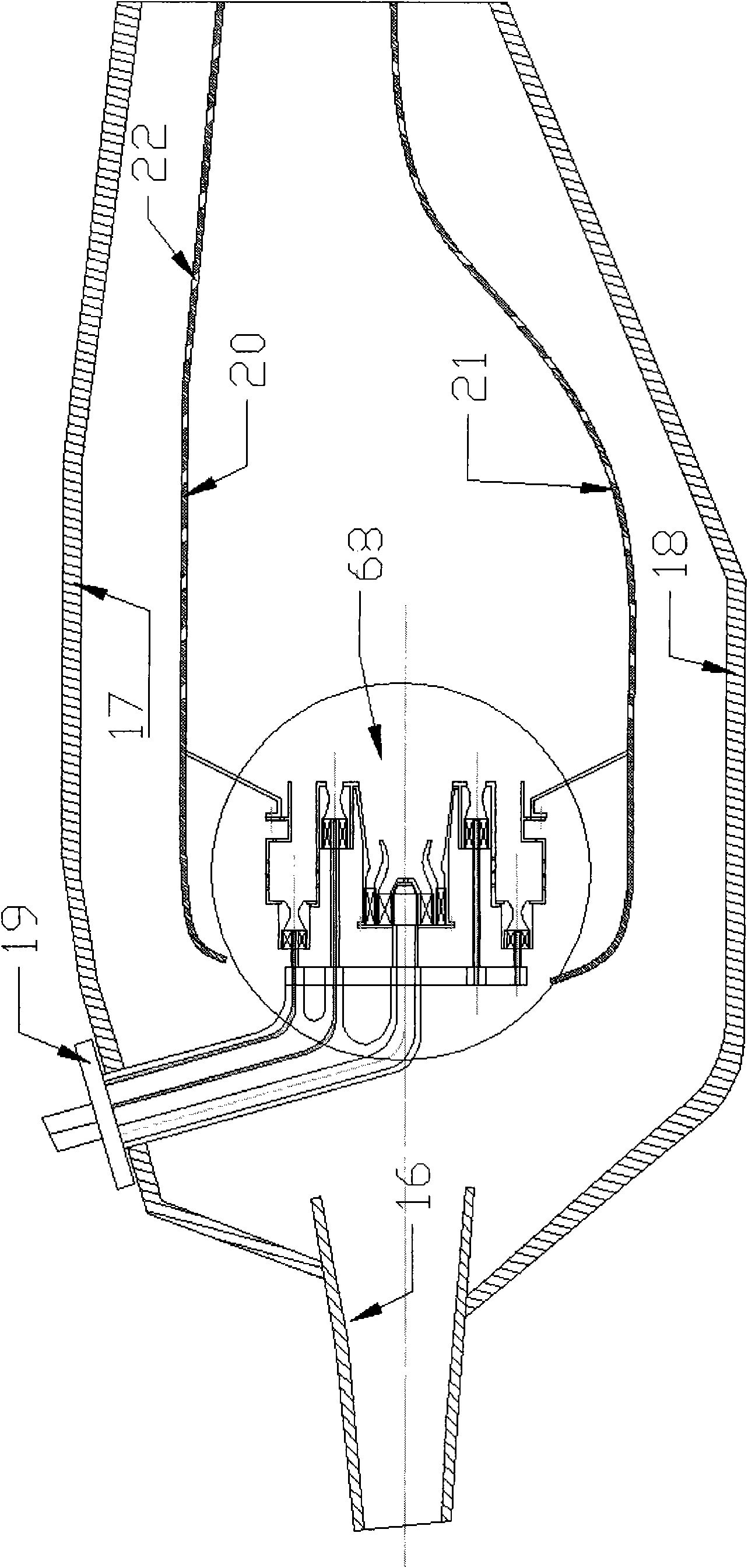

PendingCN111206994AMeet air intake needsAvoid damageGas turbine plantsTurbine/propulsion air intakesAir filterExhaust fumes

The invention discloses an intake and exhaust system of a turbine engine. The intake and exhaust system of the turbine engine comprises an intake system and an exhaust system, wherein the intake system is connected with an intake port of the turbine engine, the exhaust system is connected with an exhaust port of the turbine engine, the intake system comprises an intake filter and an intake pipeline, the intake filter is connected with the intake pipeline, the intake filter adopts a V-shaped structure, and a rain shielding cap is arranged at the exhaust tail end of the exhaust system. The intake and exhaust system of the turbine engine has the beneficial effects that the air inlet area is large, the air inlet flow speed is lower, the service life of an air filter is long, the rain shieldingcap additionally arranged at the exhaust port avoids the rainwater deposition in an exhaust silencer, the condition that rainwater possibly flows backwards is avoided and damages the turbine engine,and an opening of the rain shielding cap is away from the intake port, so that exhausted waste gas is prevented from being sucked by the intake port, and the quality of inlet air is ensured.

Owner:美国杰瑞国际有限公司

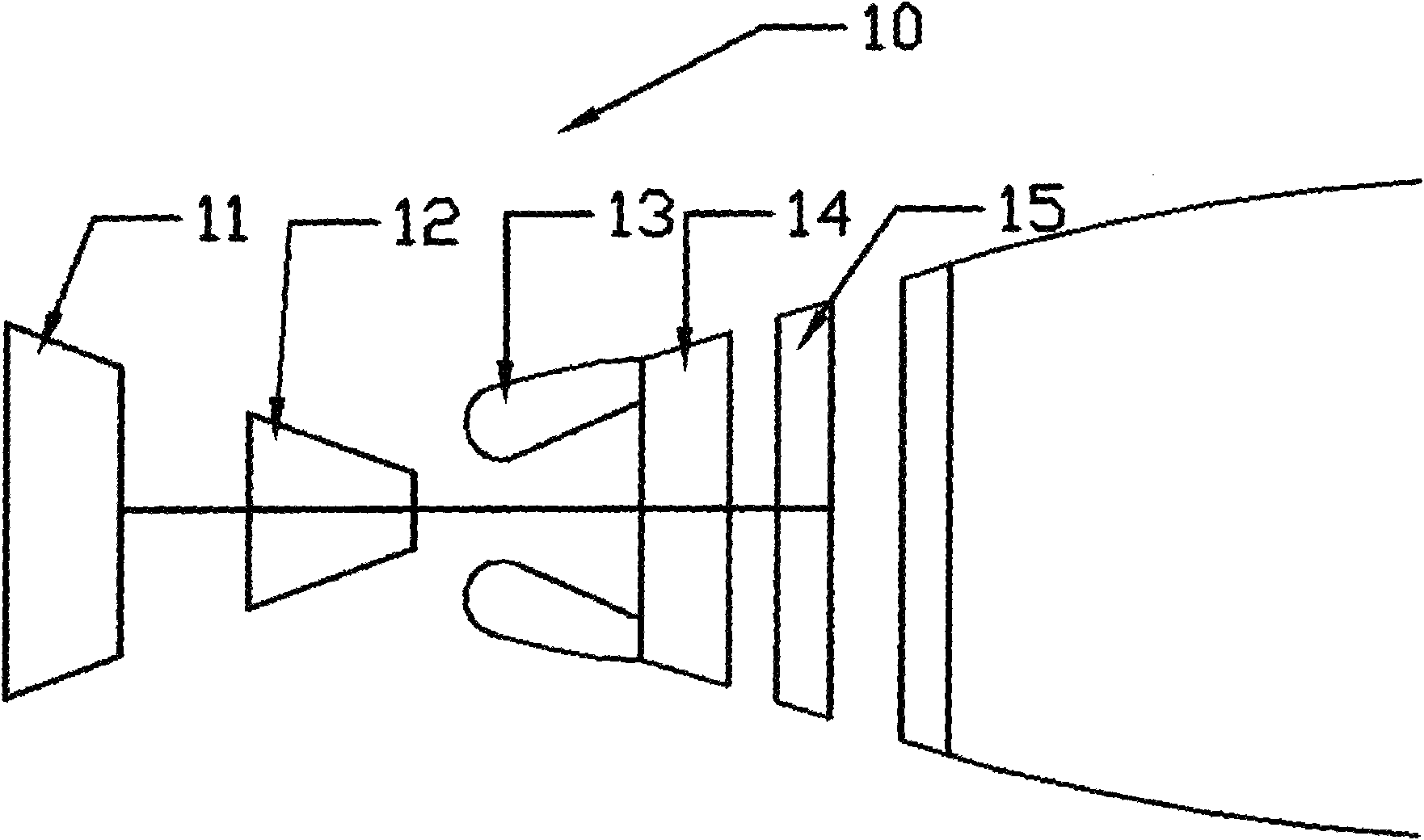

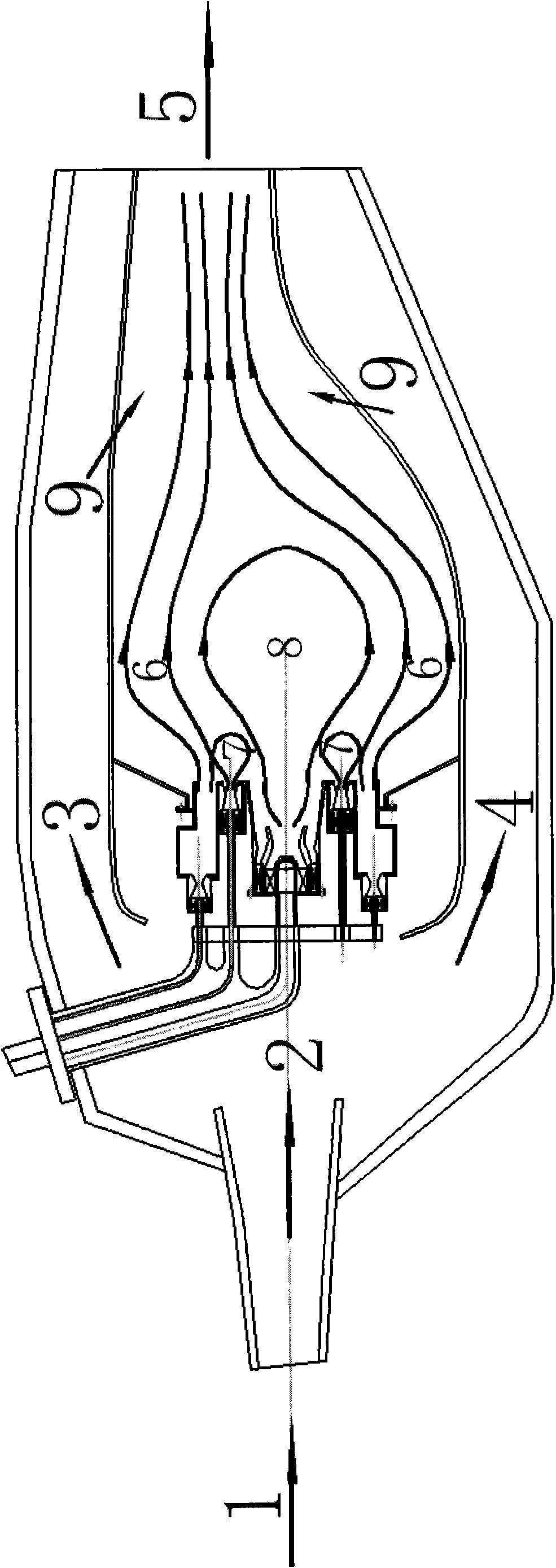

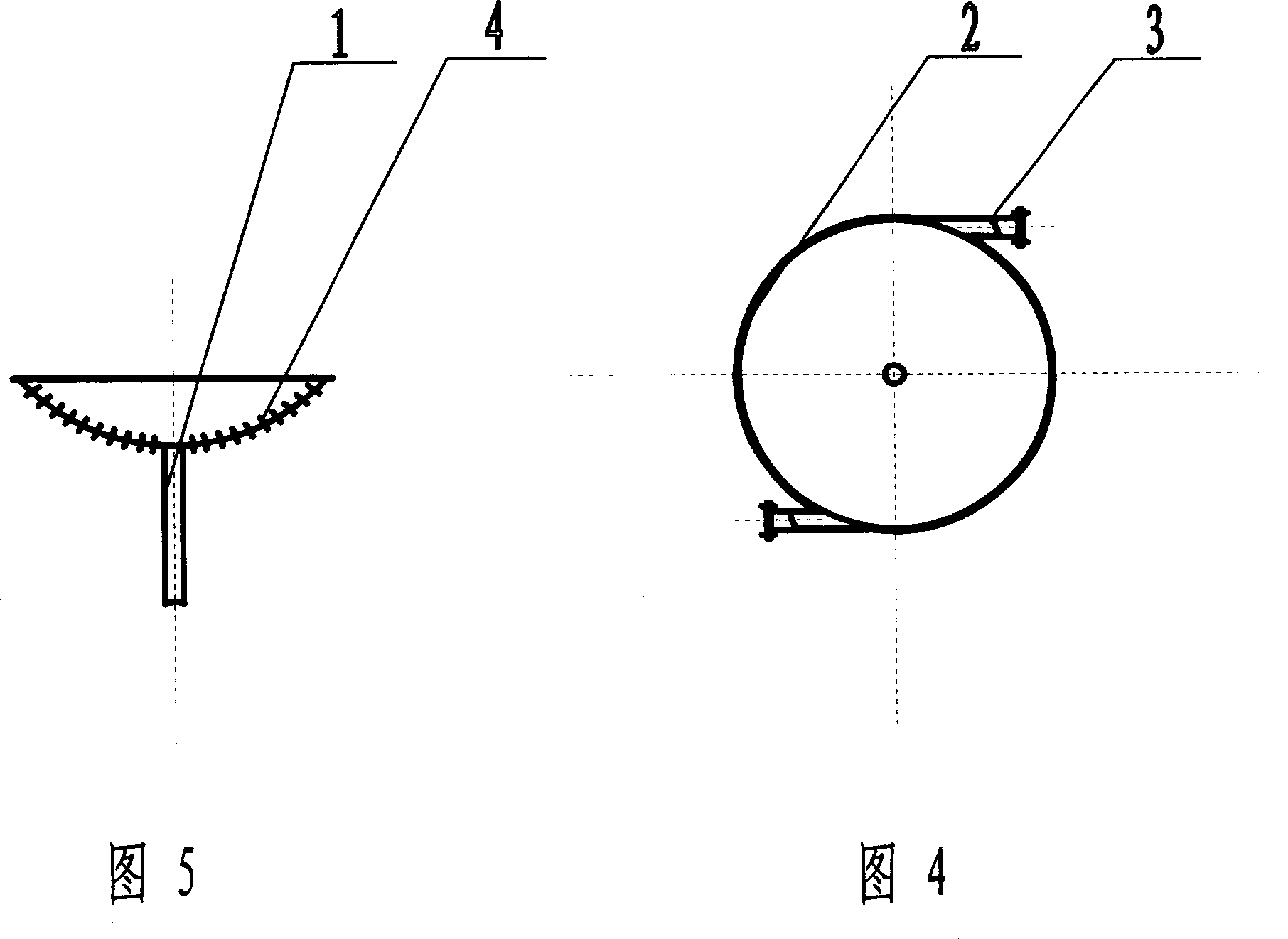

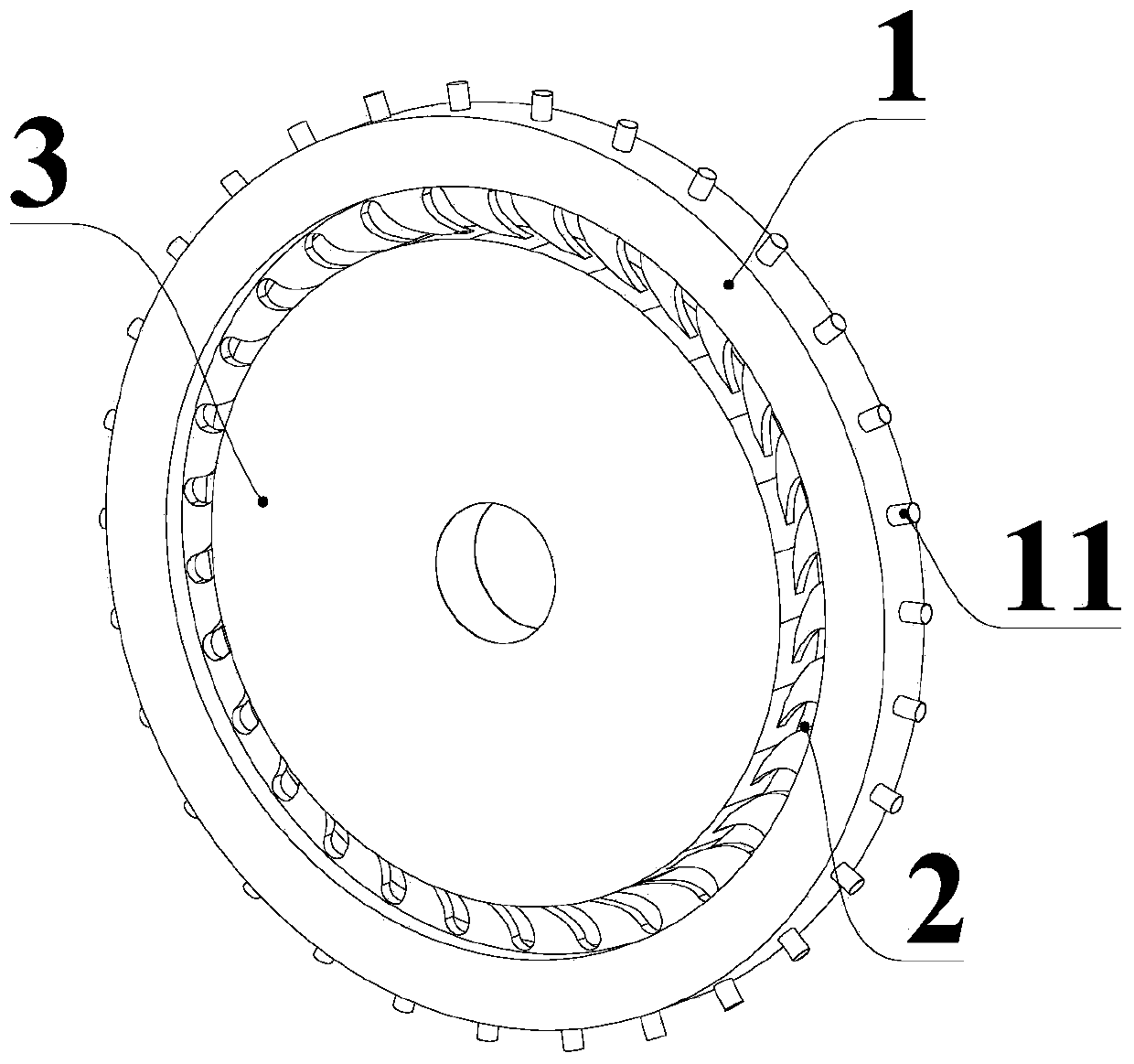

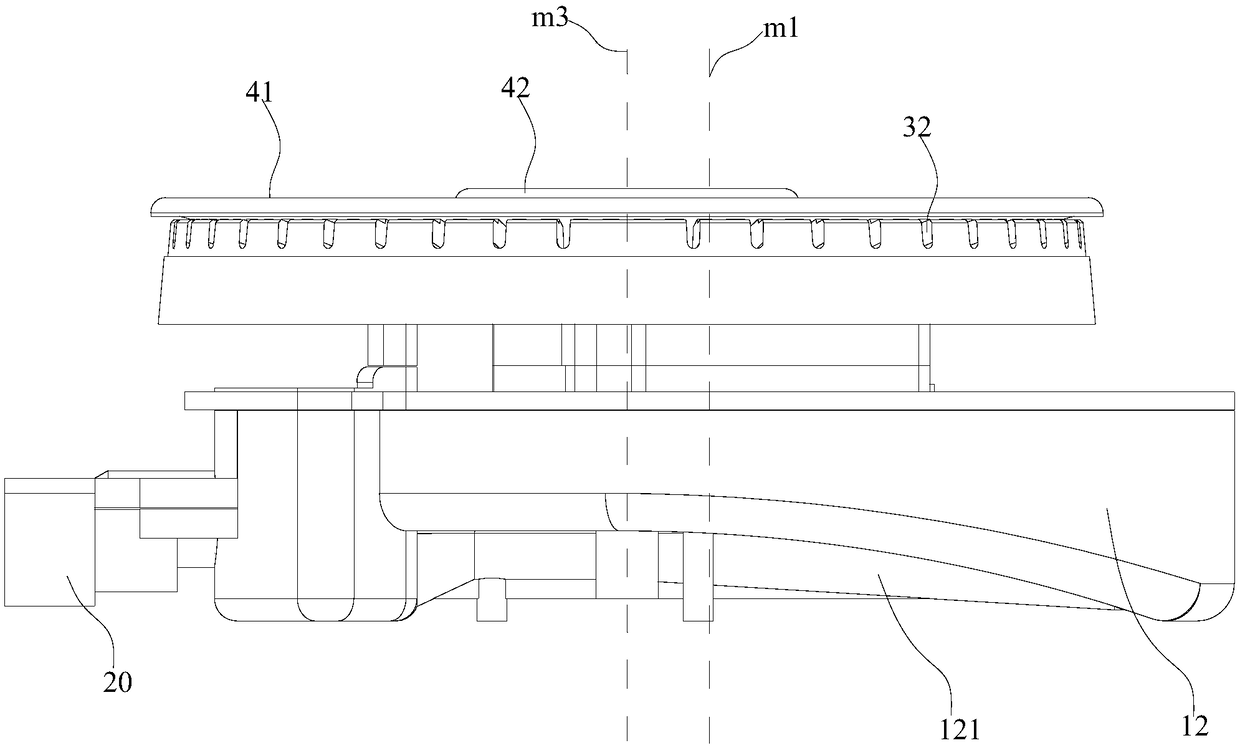

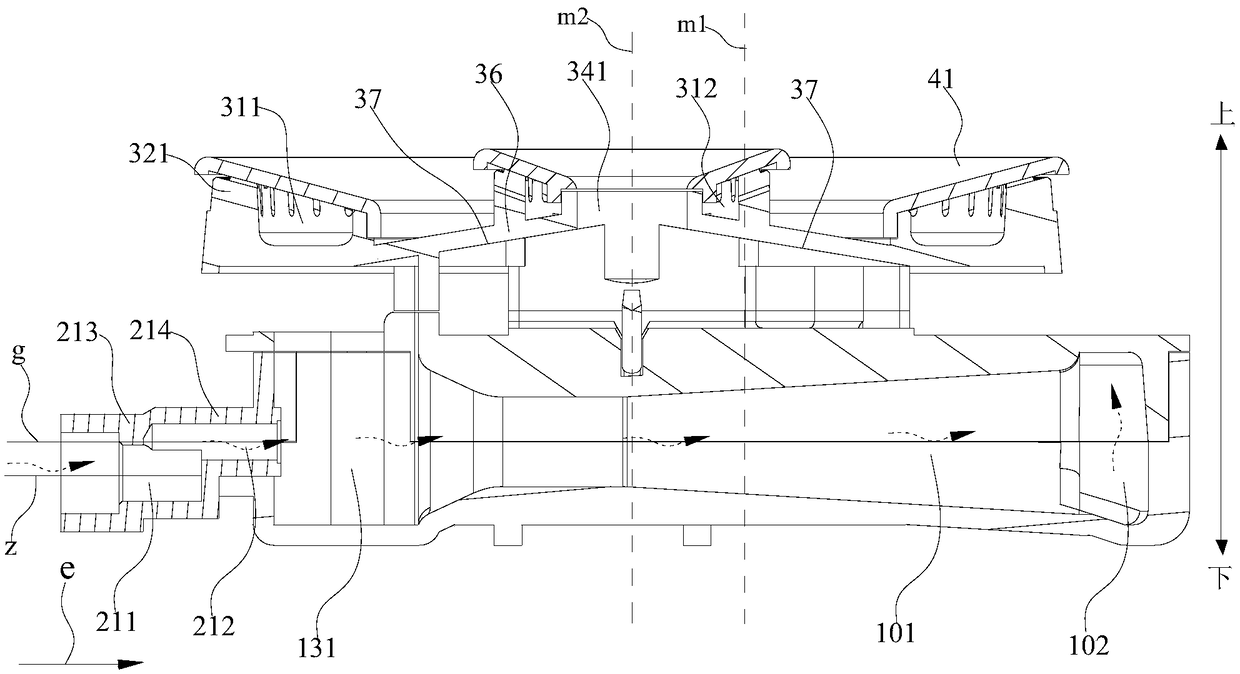

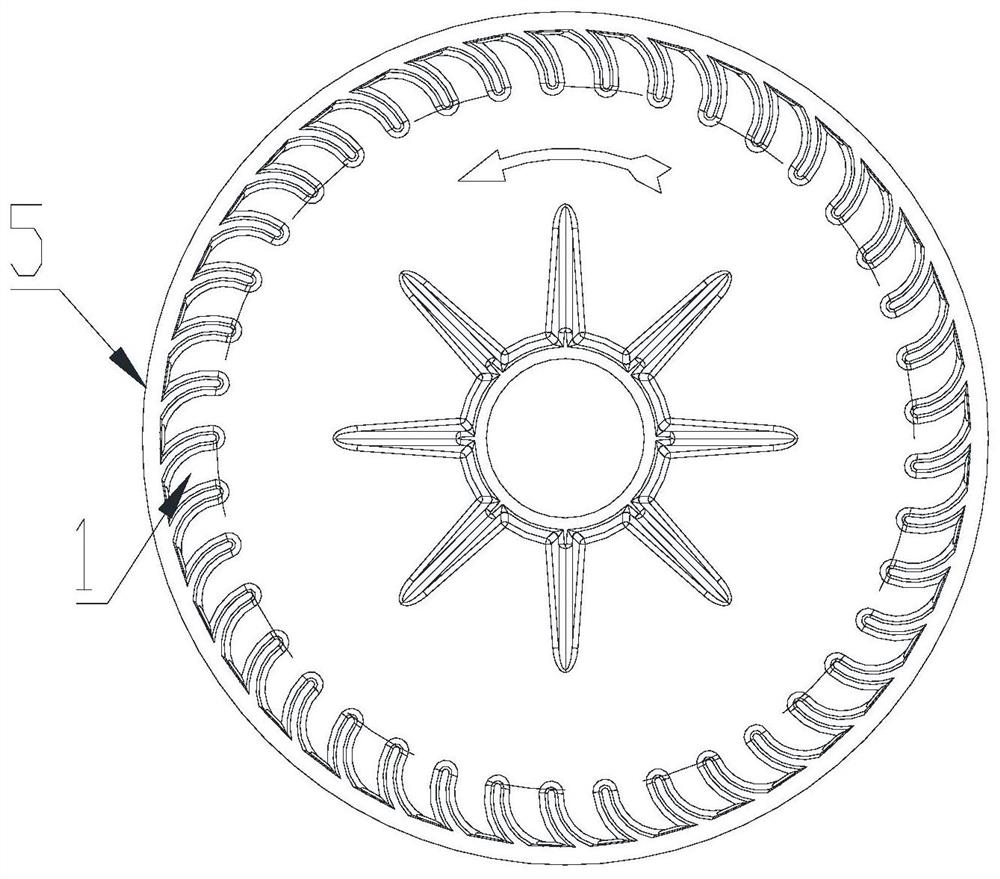

Circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages

InactiveCN102032598AImprove combustion stabilityIncrease the intermediate flame levelContinuous combustion chamberCombustion chamberLow speed

The invention discloses a circumferentially graded low-pollution combustion chamber with multiple middle spiral-flow flame stabilizing stages. The combustion chamber has a single annular cavity structure; a low-pollution combustion organization mode in which air grading is matched with fuel oil grading is adopted; all fuel gas is supplied by a duty stage, a middle stage and a main combustion stage; and fuel oil grading supply proportion is controlled accurately according to the operating condition of an engine and the requirement on stable low-pollution combustion. The duty stage has a combined structure in which two-stage axial spiral flow is matched with a venturi tube, and a formed low-speed reflux region can support stable combustion of the combustion chamber; the middle stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, and a formed middle flame stabilizing stage combustion region is used for intensifying and stabilizing flame in the main combustion stage; and the main combustion stage has a combined structure in which a plurality of single-stage axial spiral flow circumferentially and uniformly distributed on the same circumference in the same axial cross section are matched with the venturi tube, so that an oil and gas mixed poor-oil premixing and pre-evaporation combustion mode is intensified and the emission of pollutants is further reduced greatly.

Owner:BEIHANG UNIV

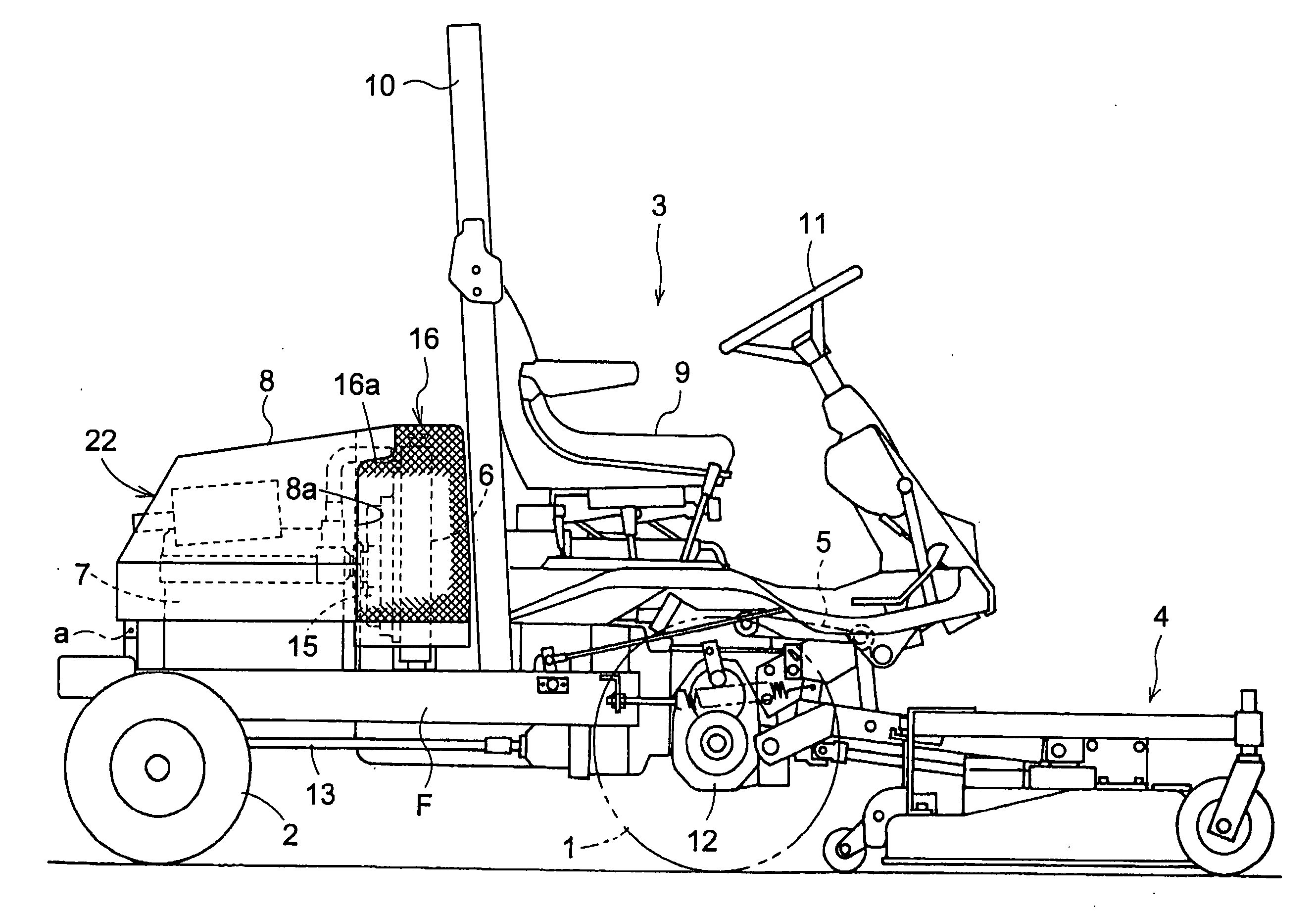

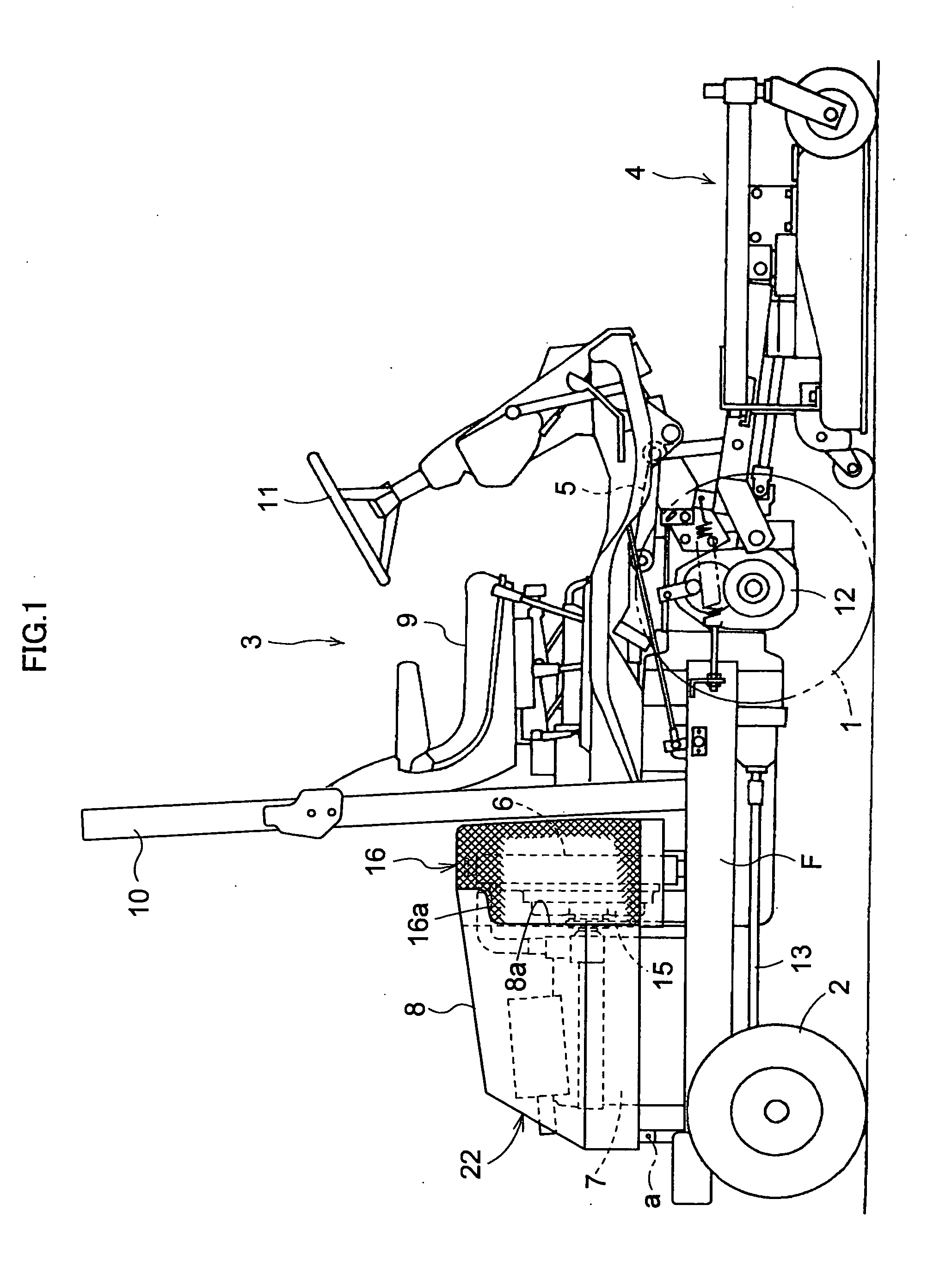

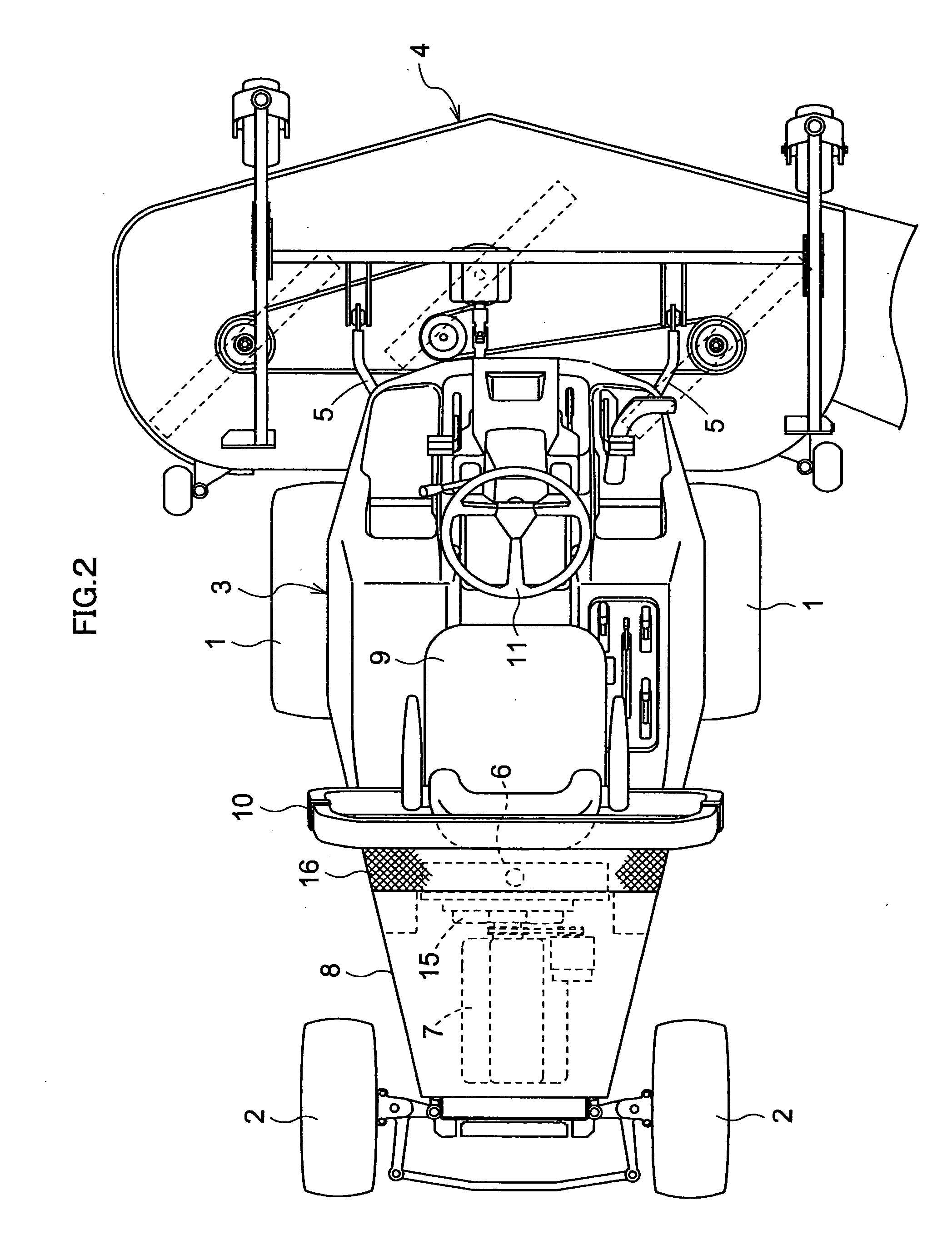

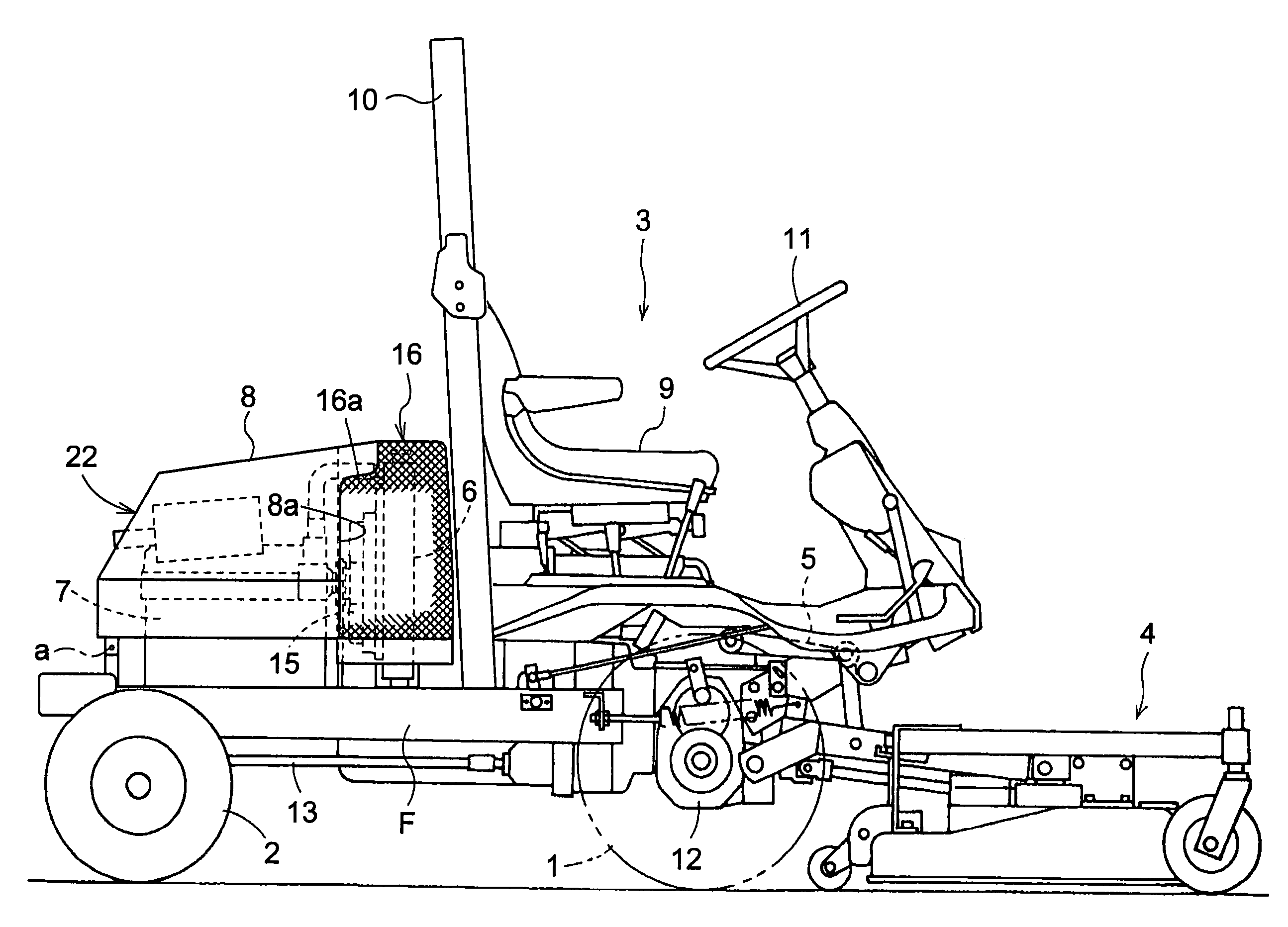

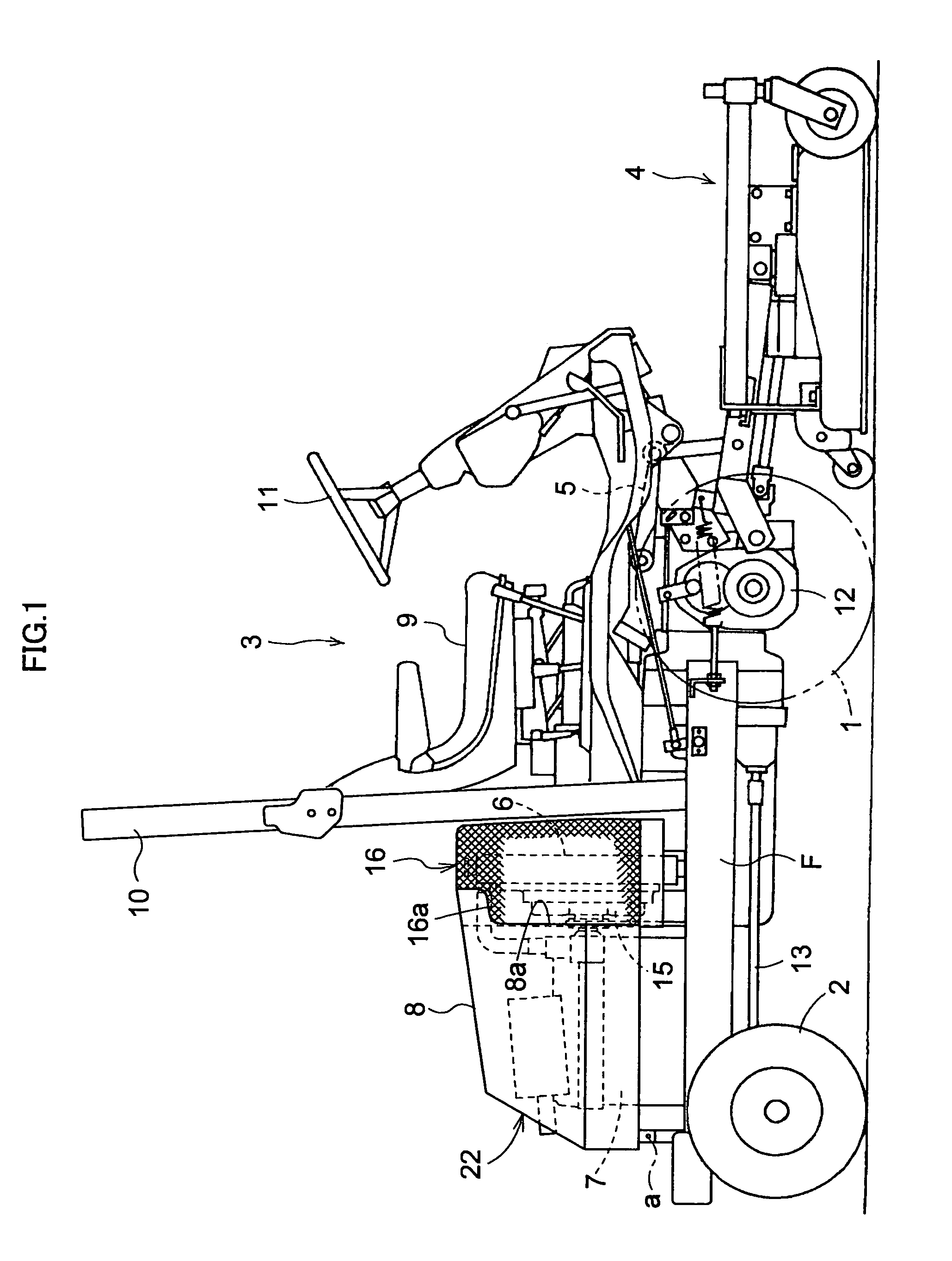

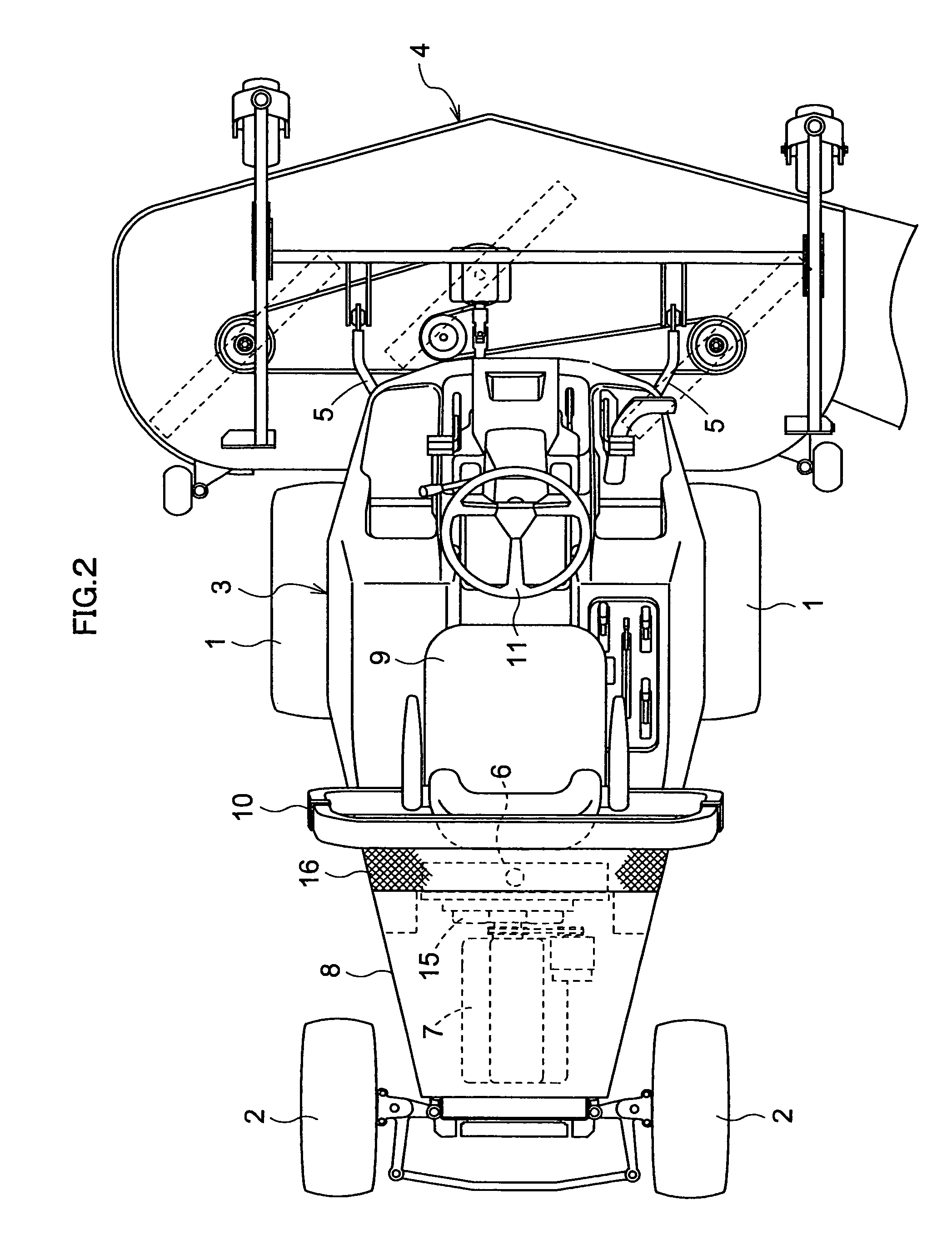

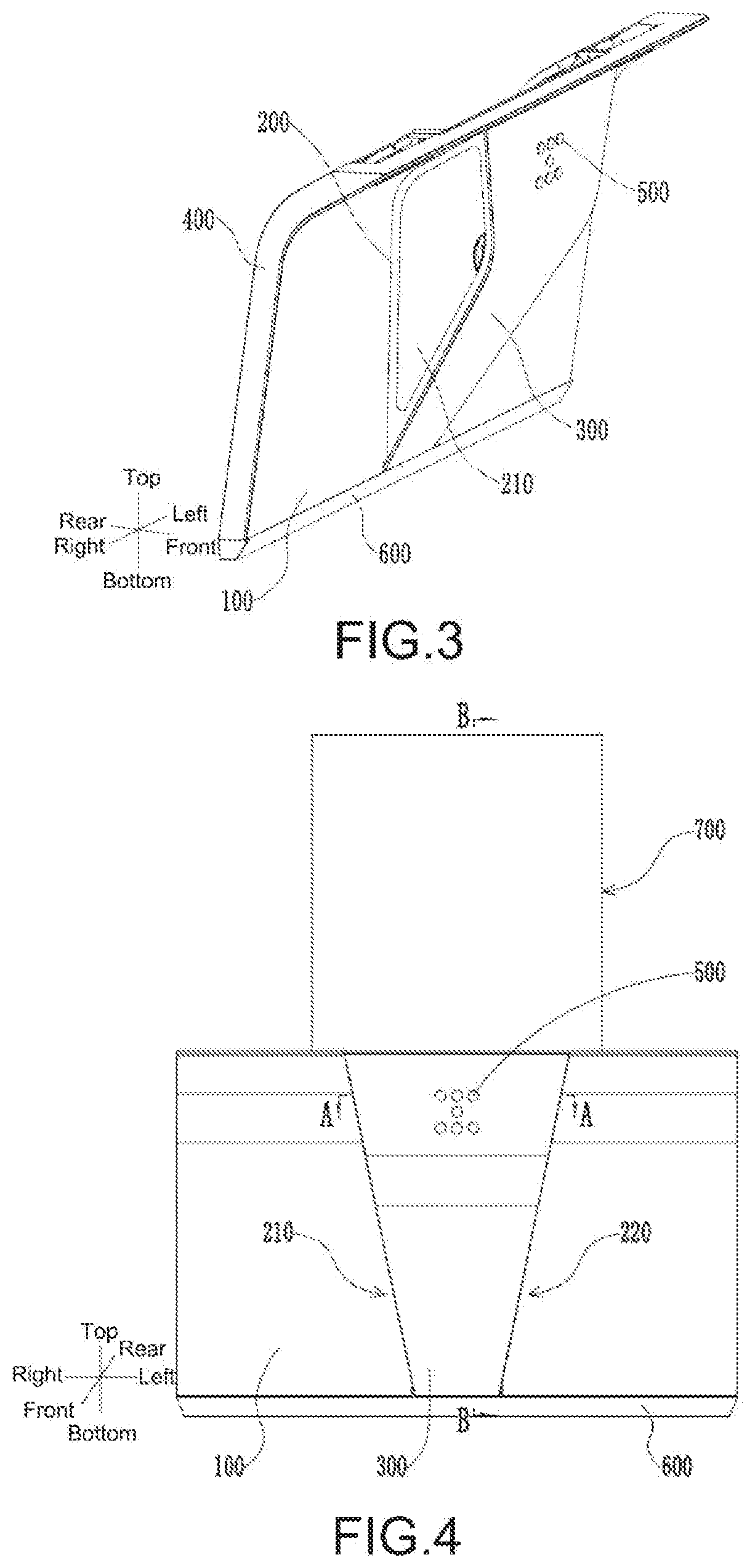

Lawn mower having an engine disposed rearwardly of a driver's seat

ActiveUS20060016632A1Increased air intake areaShorten speedMowersSuperstructure subunitsLawn mowerHeat spreader

A lawn mower comprises: a plurality of wheels; a vehicle body supported by the wheels; a mower unit supported by said vehicle body; a driver's seat supported by said vehicle body; an engine supported by said vehicle body rearwardly of said driver's seat; a radiator disposed between said engine and said driver's seat; a hood for covering said engine; and a dust filtering case disposed at a forward portion of said hood for allowing ambient cooling air to be drawn into said radiator, the dust filtering case surrounding at least a part of the radiator and having a net portion on at least one side thereof, the net portion extending rearwardly beyond a front surface of said radiator.

Owner:KUBOTA LTD

Lawn mower having an engine disposed rearwardly of a driver's seat

ActiveUS7458434B2Shorten speedIncrease the intake areaMowersSuperstructure subunitsLawn mowerHeat spreader

A lawn mower comprises: a plurality of wheels; a vehicle body supported by the wheels; a mower unit supported by said vehicle body; a driver's seat supported by said vehicle body; an engine supported by said vehicle body rearwardly of said driver's seat; a radiator disposed between said engine and said driver's seat; a hood for covering said engine; and a dust filtering case disposed at a forward portion of said hood for allowing ambient cooling air to be drawn into said radiator, the dust filtering case surrounding at least a part of the radiator and having a net portion on at least one side thereof, the net portion extending rearwardly beyond a front surface of said radiator.

Owner:KUBOTA CORP

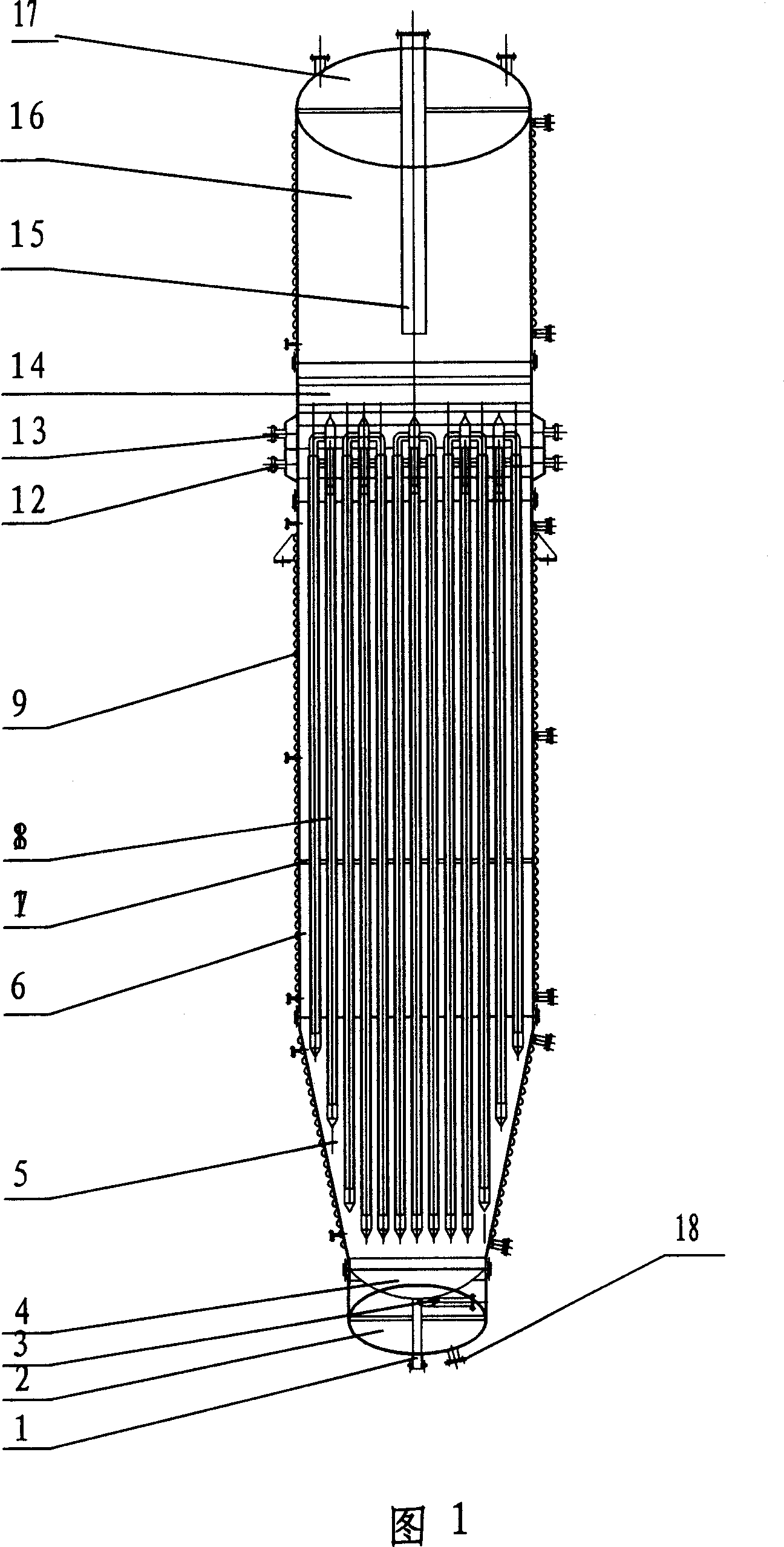

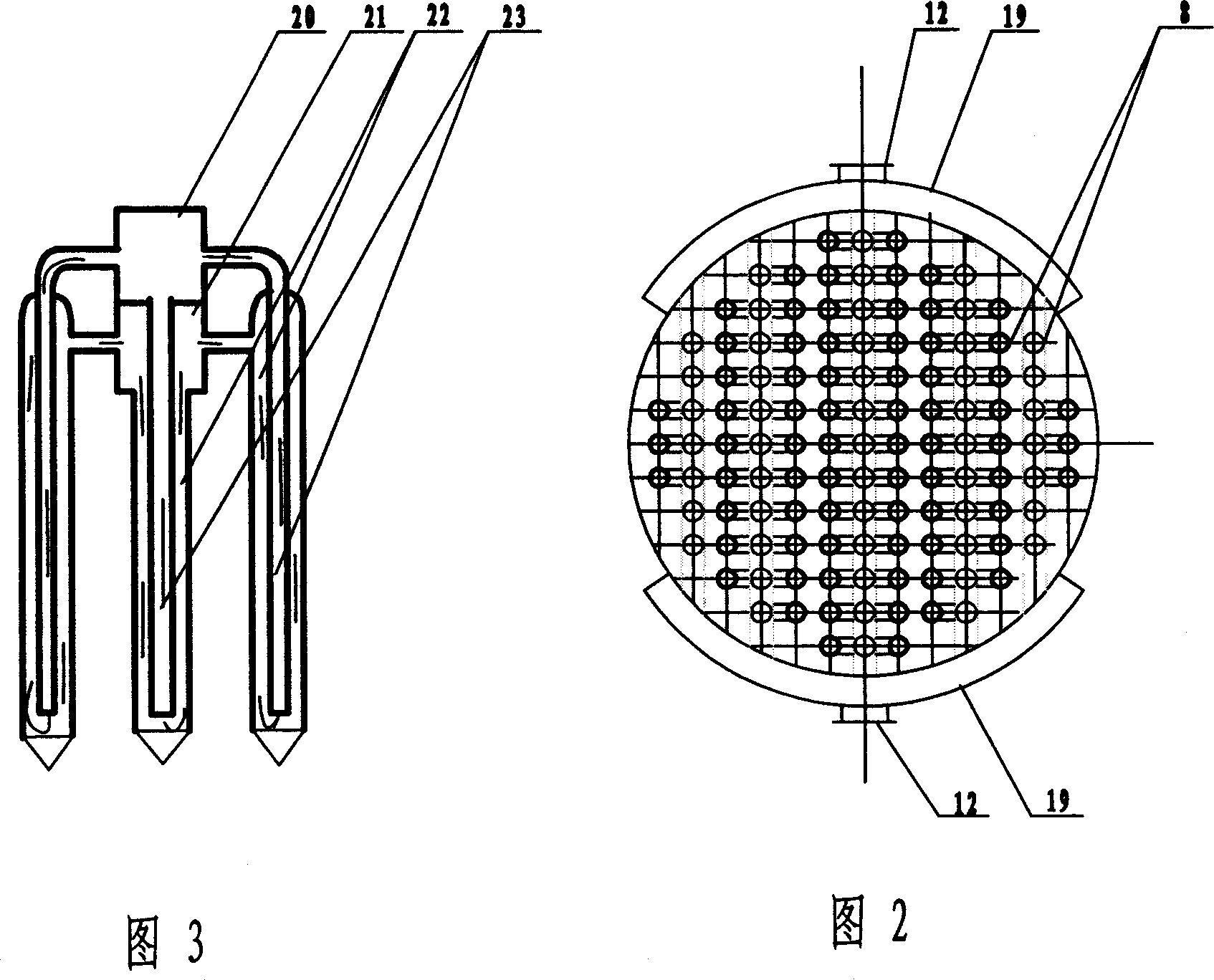

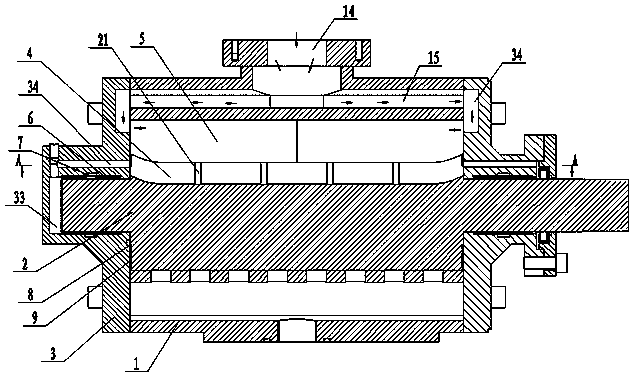

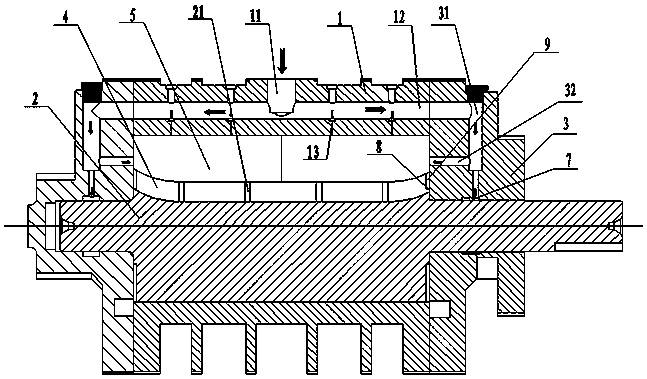

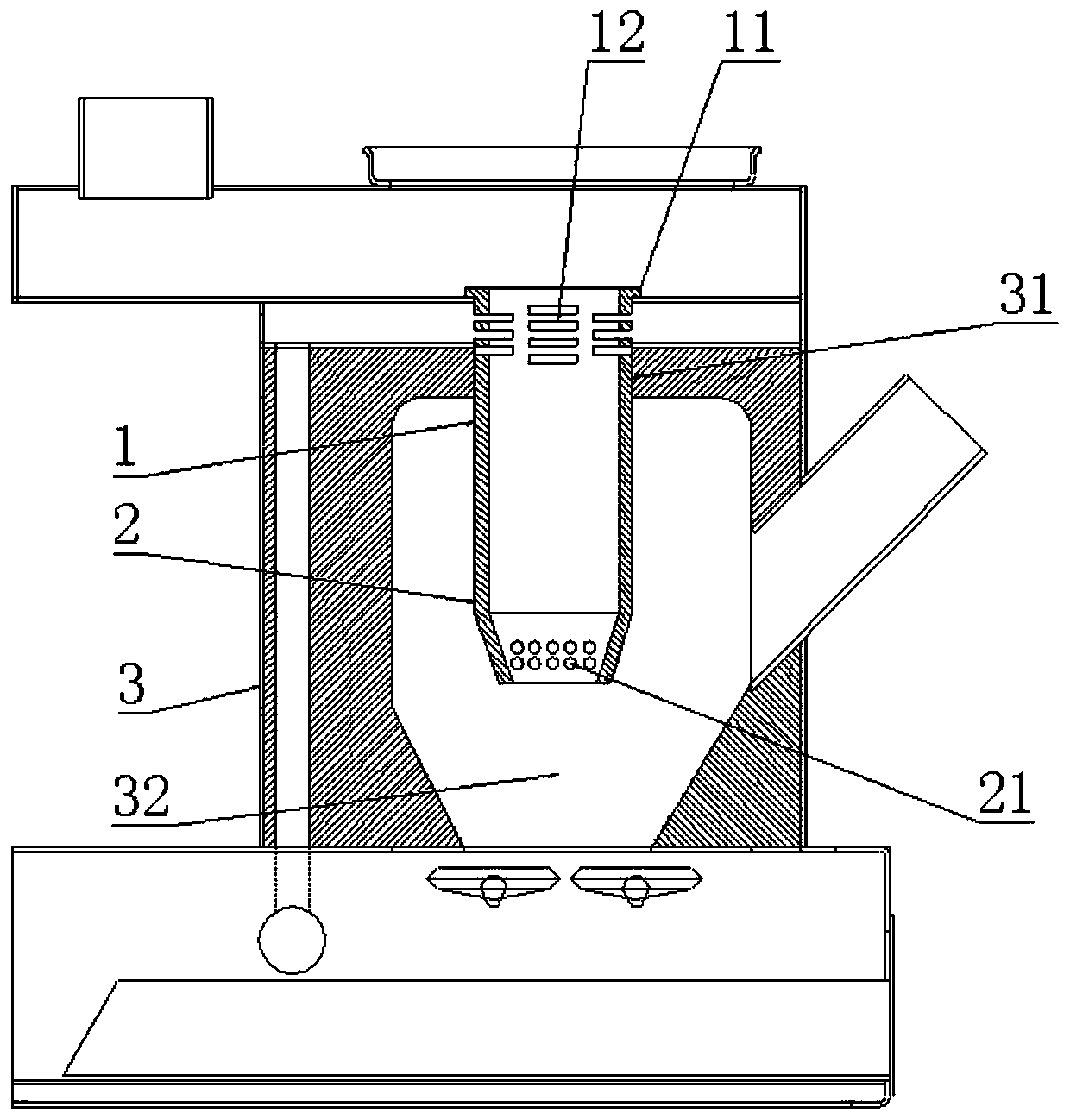

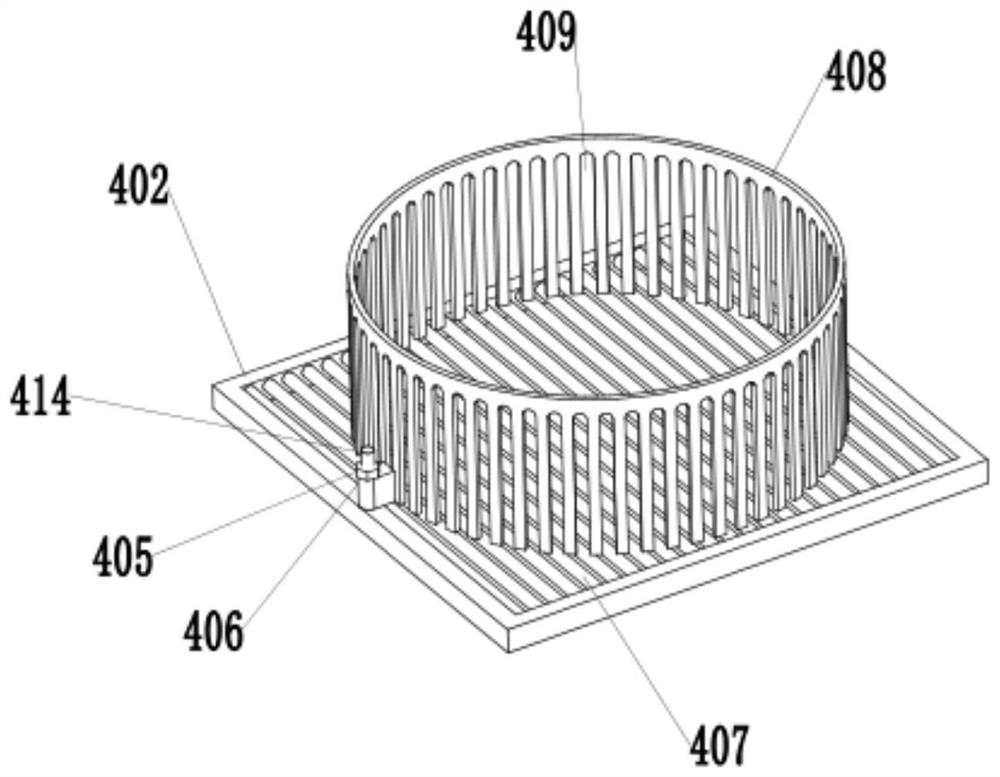

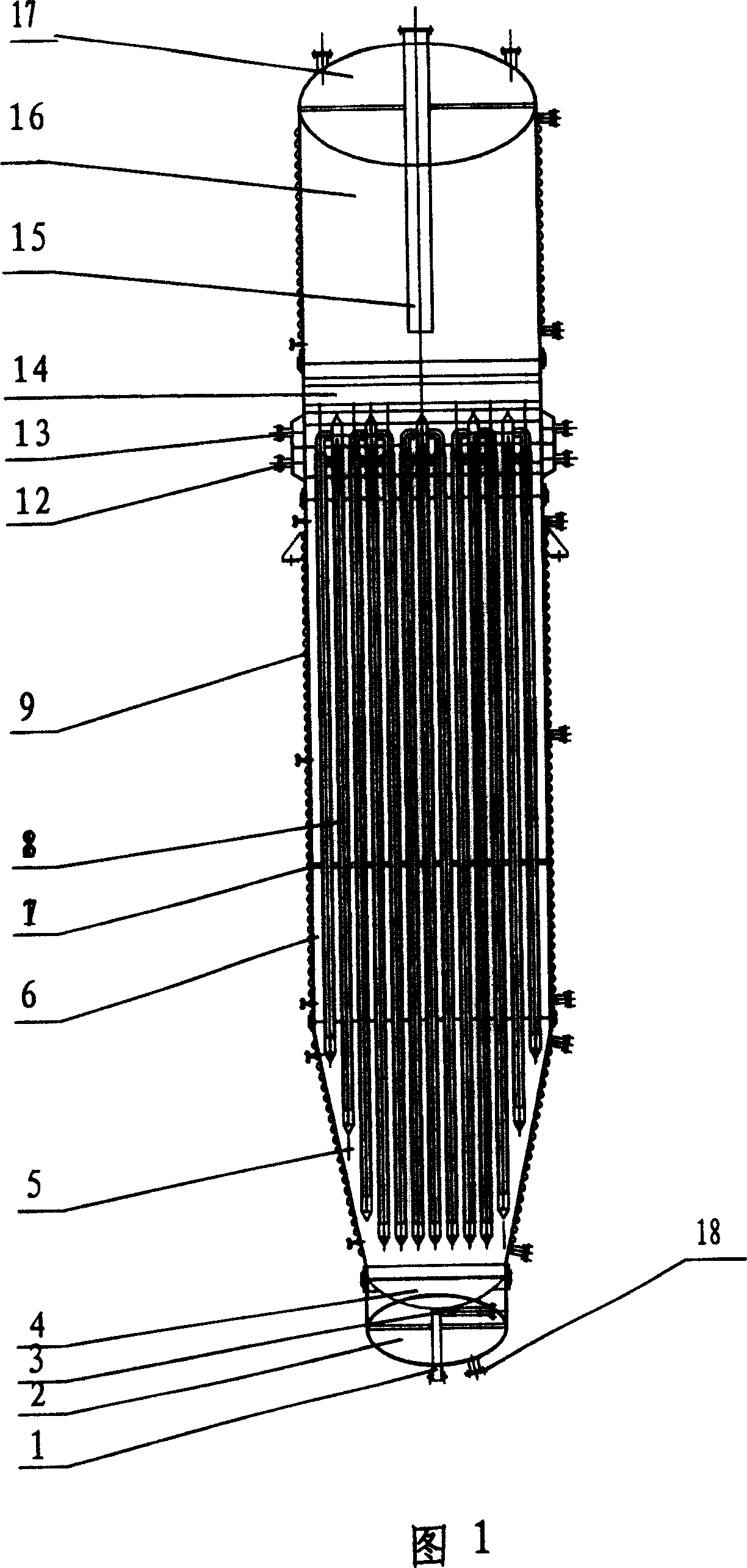

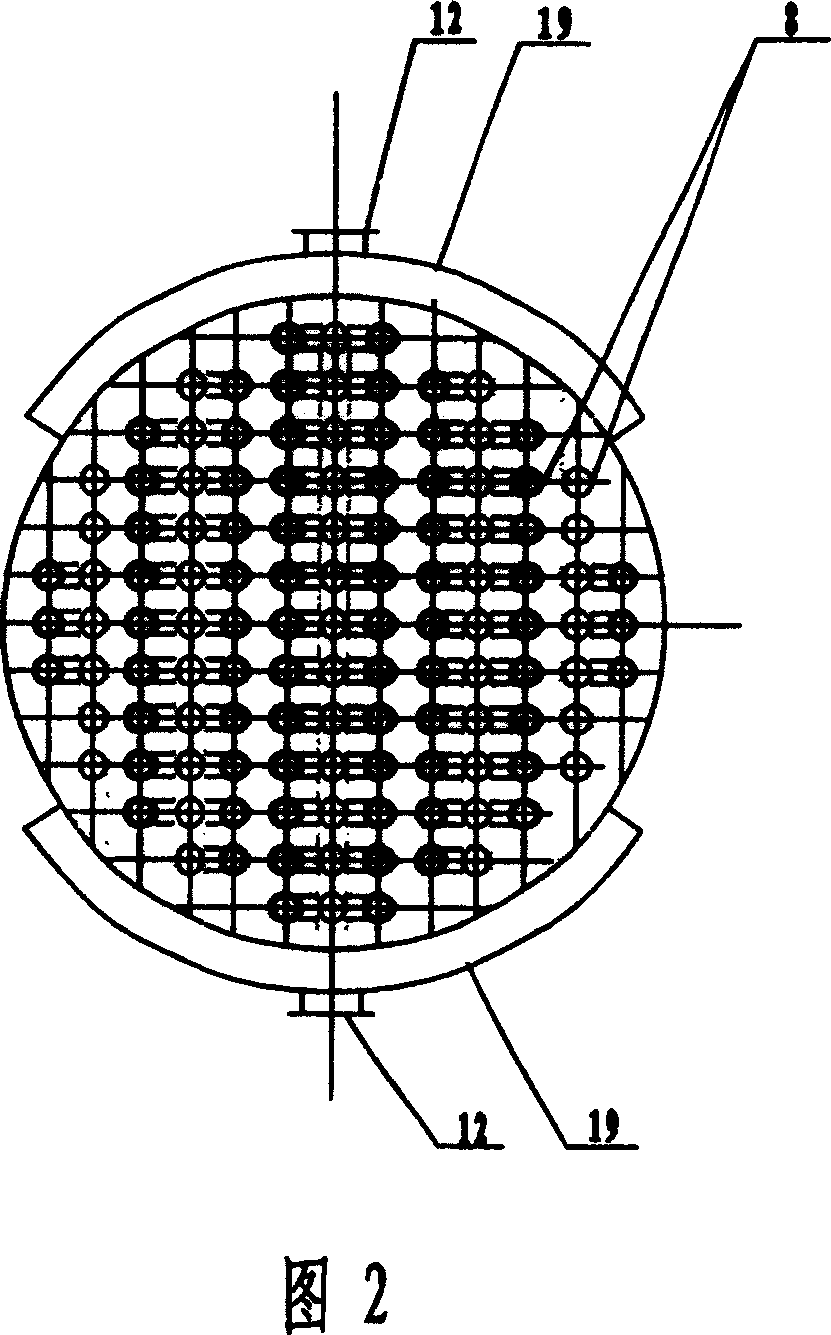

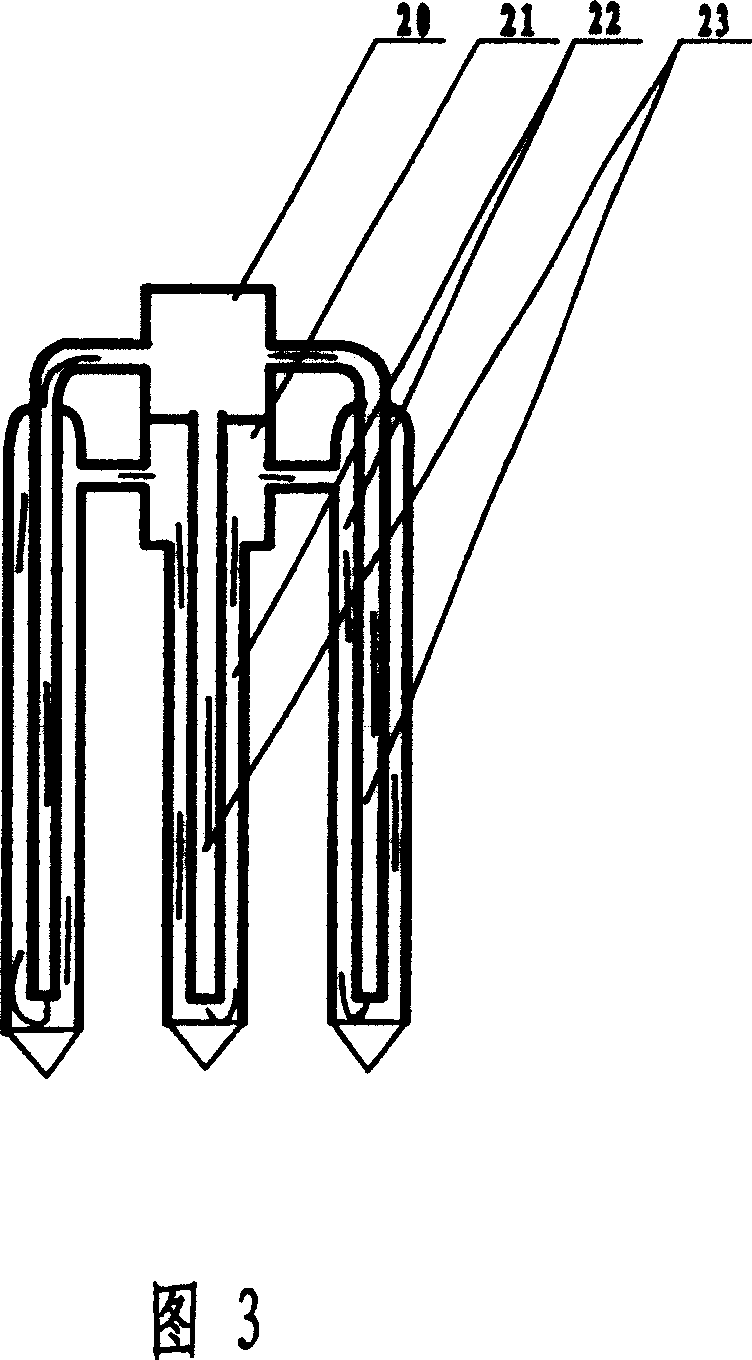

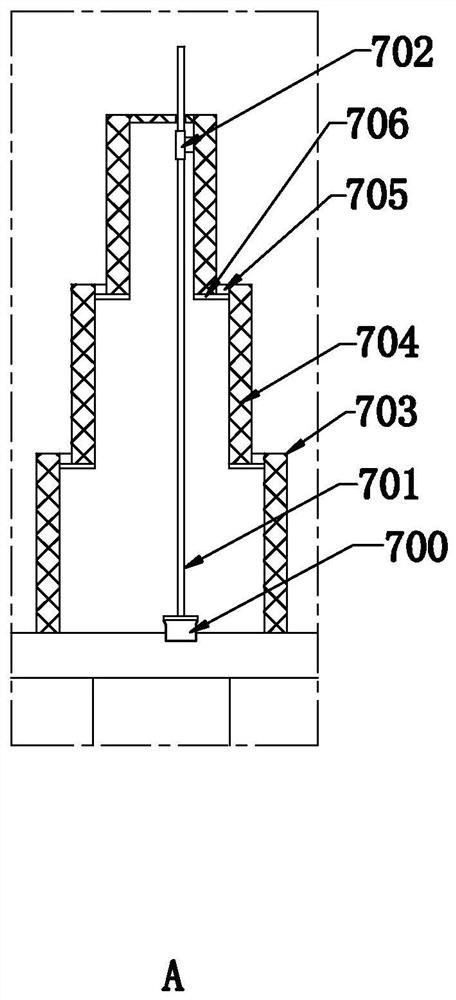

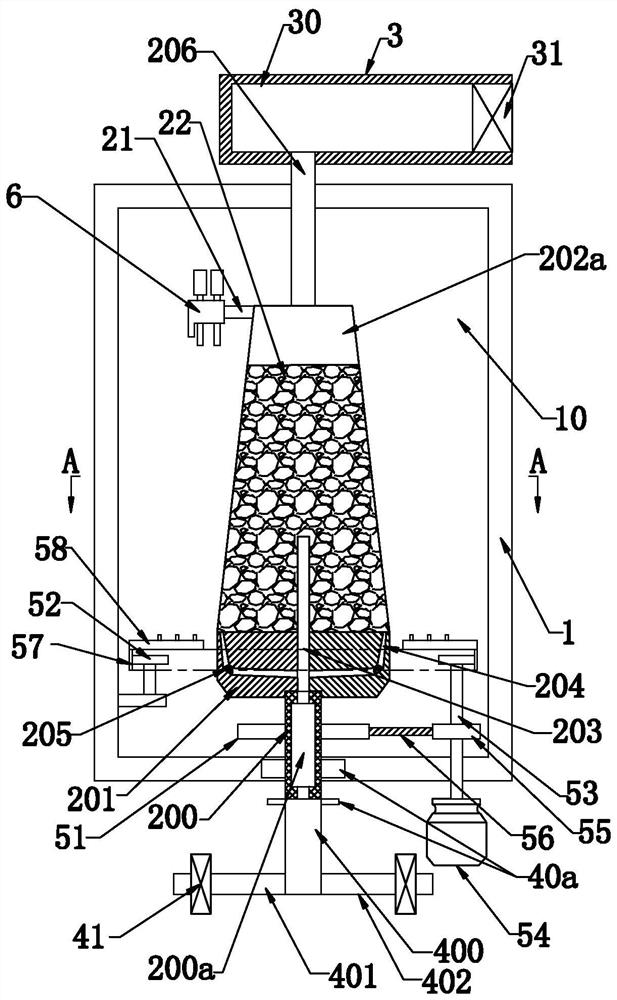

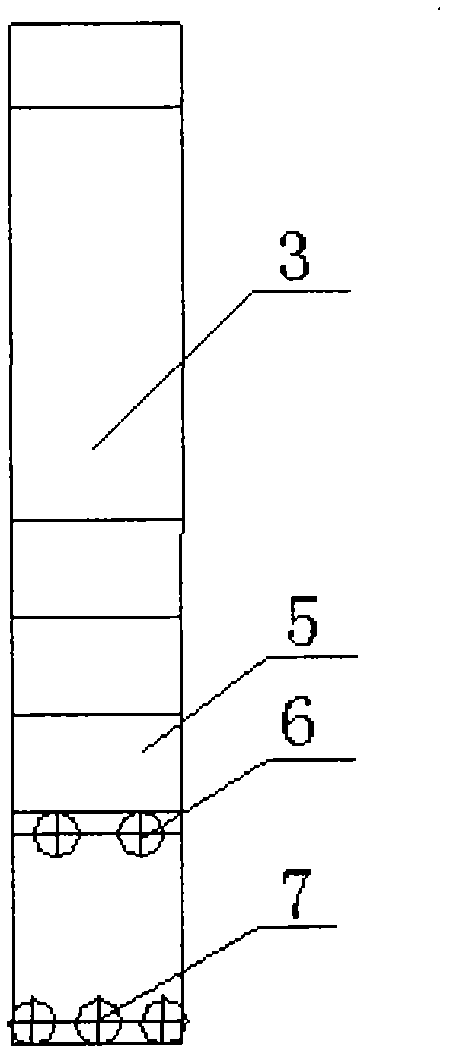

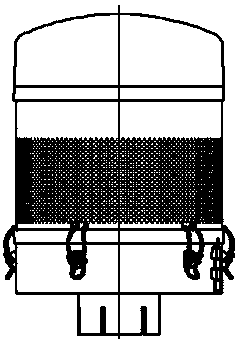

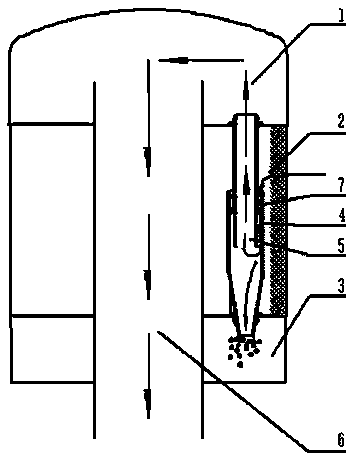

Organosilicon fluidized bed reactor

InactiveCN1935350ALow flow resistanceReduce outputChemical/physical processesHeat conductingFluidized bed

The present invention relates to an organo-silicon fluidized-bed reactor. It includes fluidized-bed body formed from conical cylinder and upper portion cylinder body. In the top portion of bed body an upper shell cover is fixed and in the bottom portion of conical cylinder a lower shell cover is fixed, in the bed body interior a finger-shaped heat exchange tube is hung, the upper portion of said finger-shaped heat extrange tube is connected with a heat-conducting oil distributor, said heat-conducting oil distributor is tubular double-layer structure, its lower layer tube is oil-feeding cavity and its upper layer tube is oil-returning cavity, two ends of said oil-feeding cavity are communicated with inlet of heat-conducting oil, and two ends of said oil-returning cavity are communicated with outlet of heat-conducting oil, the oil-feeding sleeve of finger-shaped heat exchange tube is communicated with lower layer oil-feeding cavity, and the central oil tube is communicated with upper layer oil-returning cavity.

Owner:山西三佳化工新材料有限公司

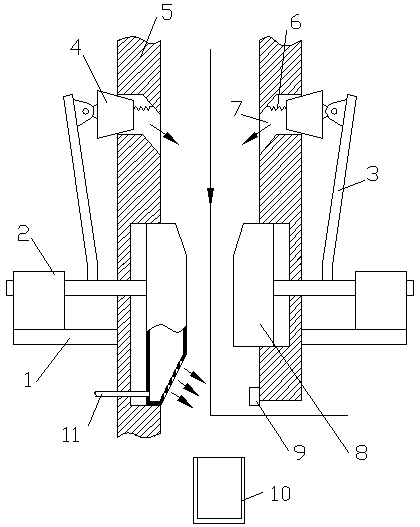

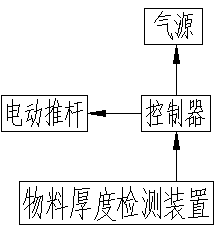

Control system and method for uniformity of nonwoven fabric

PendingCN110409061AIncrease the cross-sectional areaIncrease the intake areaNon-woven fabricsDesign draftsmanControl system

The invention relates to a control system and method for the uniformity of a nonwoven fabric. The control system is located below a slit drafter, mainly compensates for the uneven transverse arrangement of slit type draft fibers, and comprises a channel and an air suction device, wherein the side wall of the channel is provided with air supply holes, the air suction device is located at a discharging end of the channel, the side wall of the channel is slidably connected with two sliding blocks moving oppositely in the transverse direction and located below the air supply holes, a material passing slit with adjustable width is formed between the two sliding blocks, the control system also comprises an electric push rod fixedly arranged at the outer side of the side wall of the channel, anda push rod part of the electric push rod penetrates through the side wall of the channel to be fixedly connected with the sliding blocks. The uniform control system and control method for the nonwovenfabric have the advantages that the sliding blocks move transversely through the electric push rod, thereby achieving the adjustment of the passing cross-sectional area of the material, so that the thickness of the material entering a web former is more uniform, and irregular phenomena such as grooves are avoided; through the linkage of the sliding blocks and taper plugs, the ventilation area ofthe air supply holes is adaptive to the width of the passing slit between the sliding blocks, thereby ensuring the stable transportation of the material.

Owner:SHANDONG TAIPENG ENVIRONMENTAL PROTECTION MATERIAL

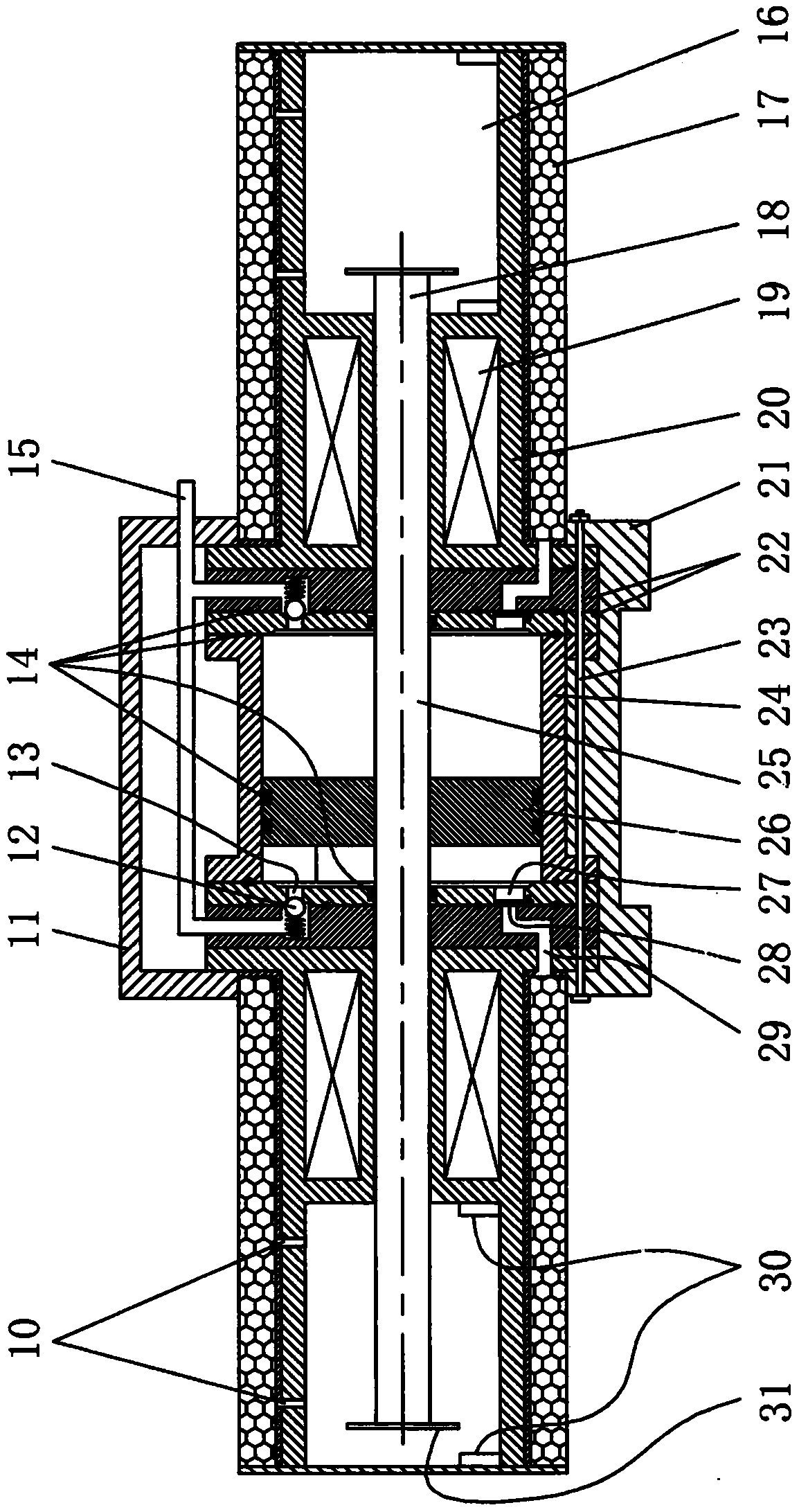

Two-way electromagnetic-driven air compressor

PendingCN110242536AIncrease powerGreat driving forcePositive displacement pump componentsPiston pumpsLow noiseGas compressor

The invention belongs to the technical field of air compressors, and relates to a two-way electromagnetic-driven air compressor. The two-way electromagnetic-driven air compressor comprises a cylindrical cylinder block, and a piston in the cylinder block; cylinder covers are arranged in openings at the two ends of the cylinder block; each cylinder cover is provided with an intake way with an intake one-way valve, an exhaust way with an exhaust one-way valve and an electromagnetic driver; a piston rod connected to the piston extends out from the cylinder covers at the two ends of the cylinder block, and extends into the corresponding electromagnetic drivers; and the electromagnetic drivers on the two sides of the cylinder block are electrified to apply force in the same direction to drive the piston rod and the piston to move back and forth, so that gas is fed from the intake way, and compressed gas is output from the exhaust way. The two-way electromagnetic-driven air compressor has the advantages of high power, high efficiency, low size, low noise and saving of electric energy, and is suitable for providing compressed air to the society.

Owner:赵光天

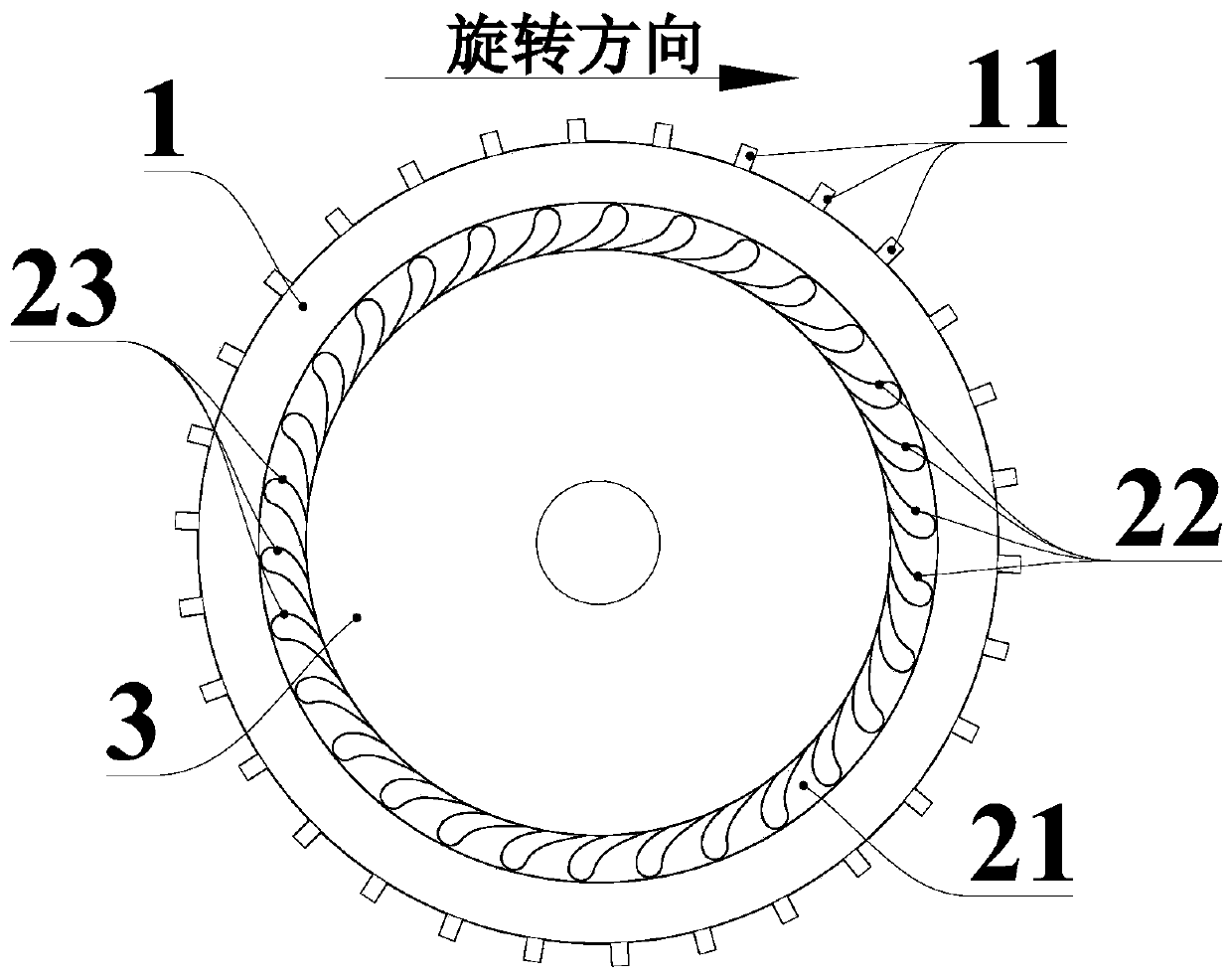

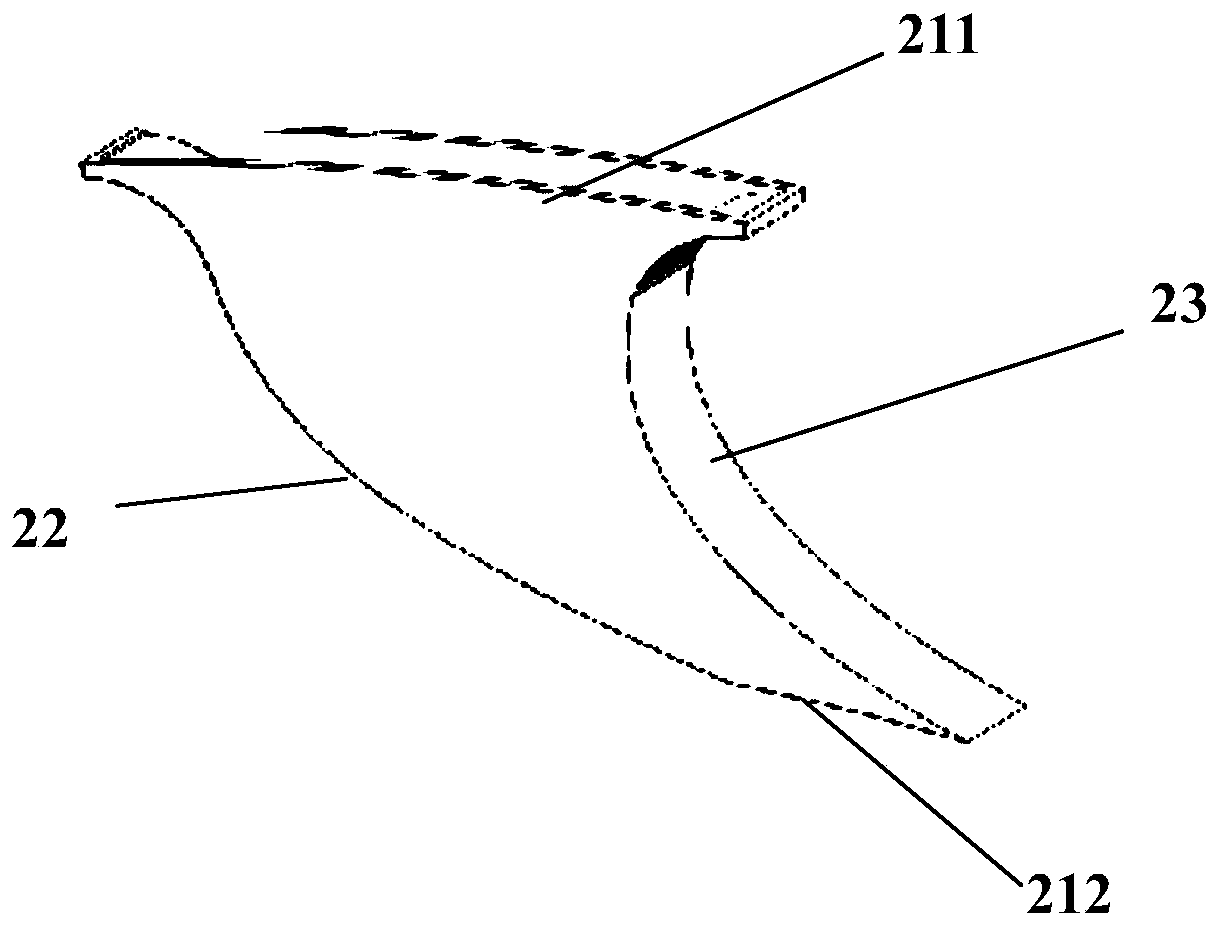

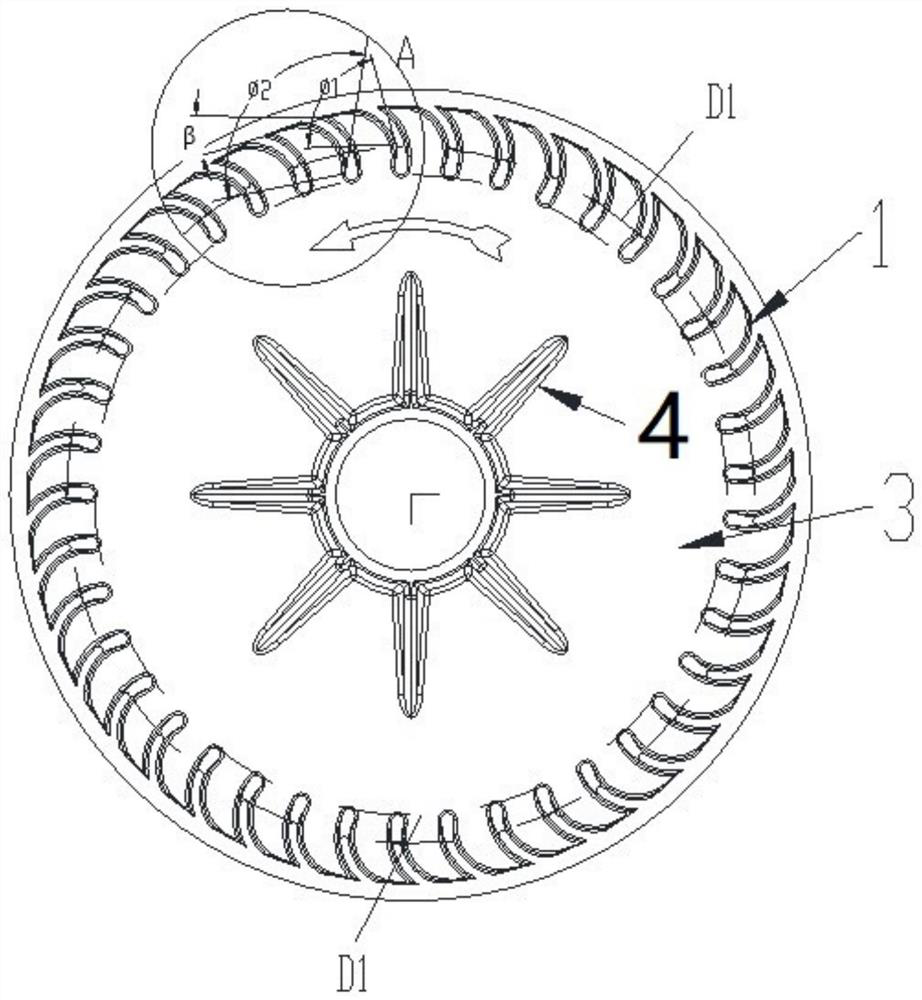

Compressor vortex reducing structure with cascade type de-rotation nozzles

InactiveCN110005525ASmall pressure lossSmooth entryPump componentsGas turbine plantsEngineeringAirflow

The invention provides a compressor vortex reducing structure with cascade type de-rotation nozzles. The compressor vortex reducing structure comprises an upstream disc cavity, a vortex reducing unitand a downstream disc cavity which are sequentially connected from outside to inside and can synchronously rotate, wherein the upstream disc cavity is provided with a plurality of drum holes which areradially fixed along the upstream disc cavity in the circumferential direction; and the vortex reducing unit comprises the plurality of nozzles arranged in the axial direction, the airflow in a compressor enters the upstream disc cavity via the drum holes and then rotates along with the upstream disc cavity and enters the nozzles, and the airflow can move into the downstream disc cavity in the nozzles in the direction opposite to the rotation direction of the upstream disc cavity. The vortex reducing structure with the de-rotation nozzles has the advantages that the air intake area of the nozzles is large, and each inlet is an arc-shaped surface, so that the airflow is able to smoothly enter the nozzles, flow resistance is reduced, and pressure loss is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Host structure of sliding-vane air compressor

PendingCN108980039AFit tightlyImprove sealingSealing arrangement for pumpsRotary piston pumpsLinear compressorPulp and paper industry

The invention discloses an enhanced sealing structure for a sliding-vane air compressor with a simple structure and a good sealing effect. The enhanced sealing structure comprises a rotor arranged ina cylinder block, wherein the cylinder block is taken as a stator; bearing seats are arranged on both sides of the cylinder block; a plurality of sliding chutes are uniformly formed in the middle of the rotor; two sliding vanes are arranged in the sliding chutes matched with the sliding vanes in a sliding way; the two ends of the rotor are rotationally arranged in the bearing seats through slidingbearings respectively; an oil inlet and a main oil inlet passage are formed in the cylinder block; a plurality of oil inlet small passages are uniformly formed in the cylinder block between the mainoil inlet passage and the sliding vanes; lubricating oil is injected directly into the cylinder block through the plurality of oil inlet small passages, so that an oil film layer is formed between therotor and the sliding vanes as well as between the two sliding vanes; the two ends of the main oil inlet passage are provided with sliding bearing lubricating oil supply passages formed in the bearing seats respectively.

Owner:盐城中德劲博机电有限公司

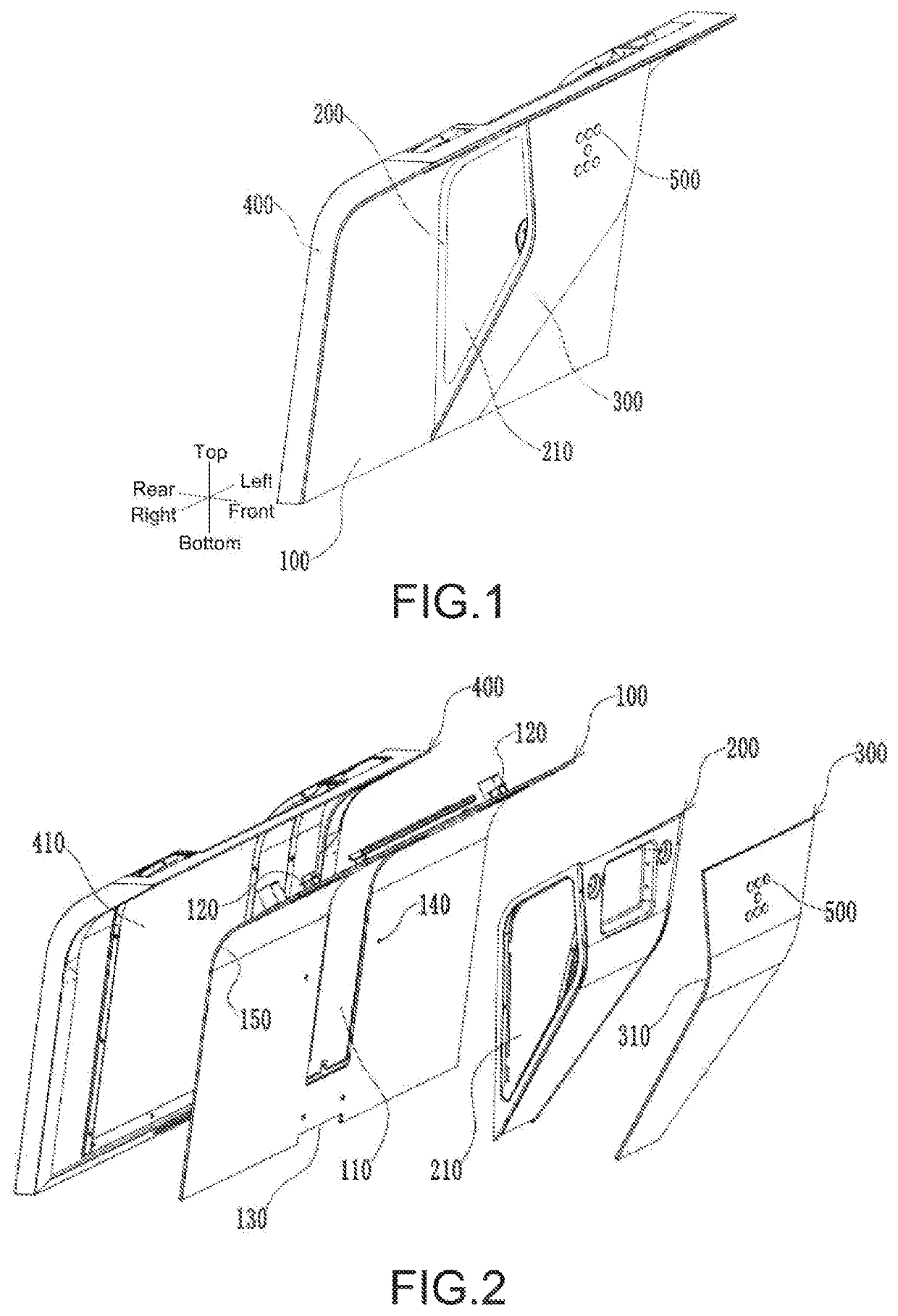

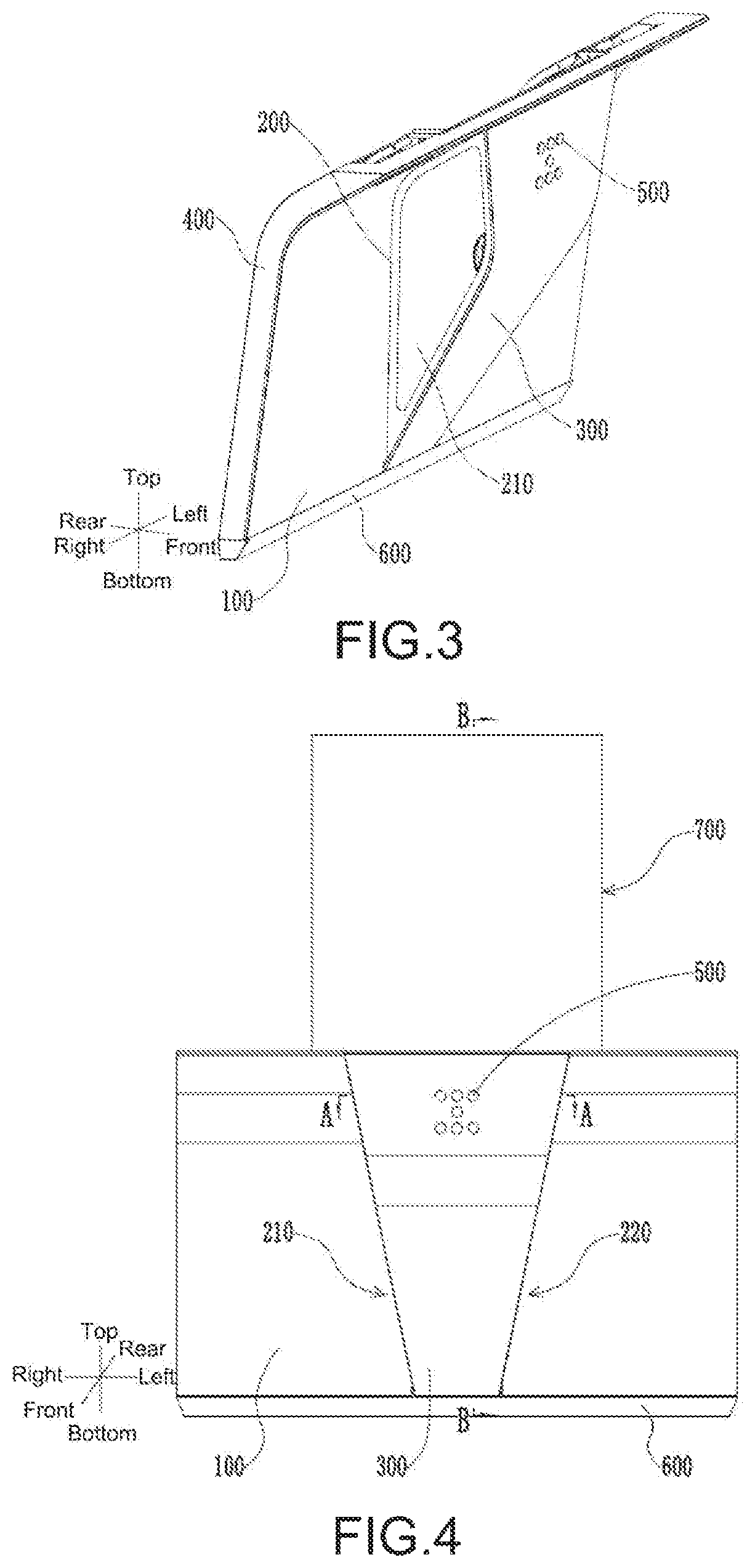

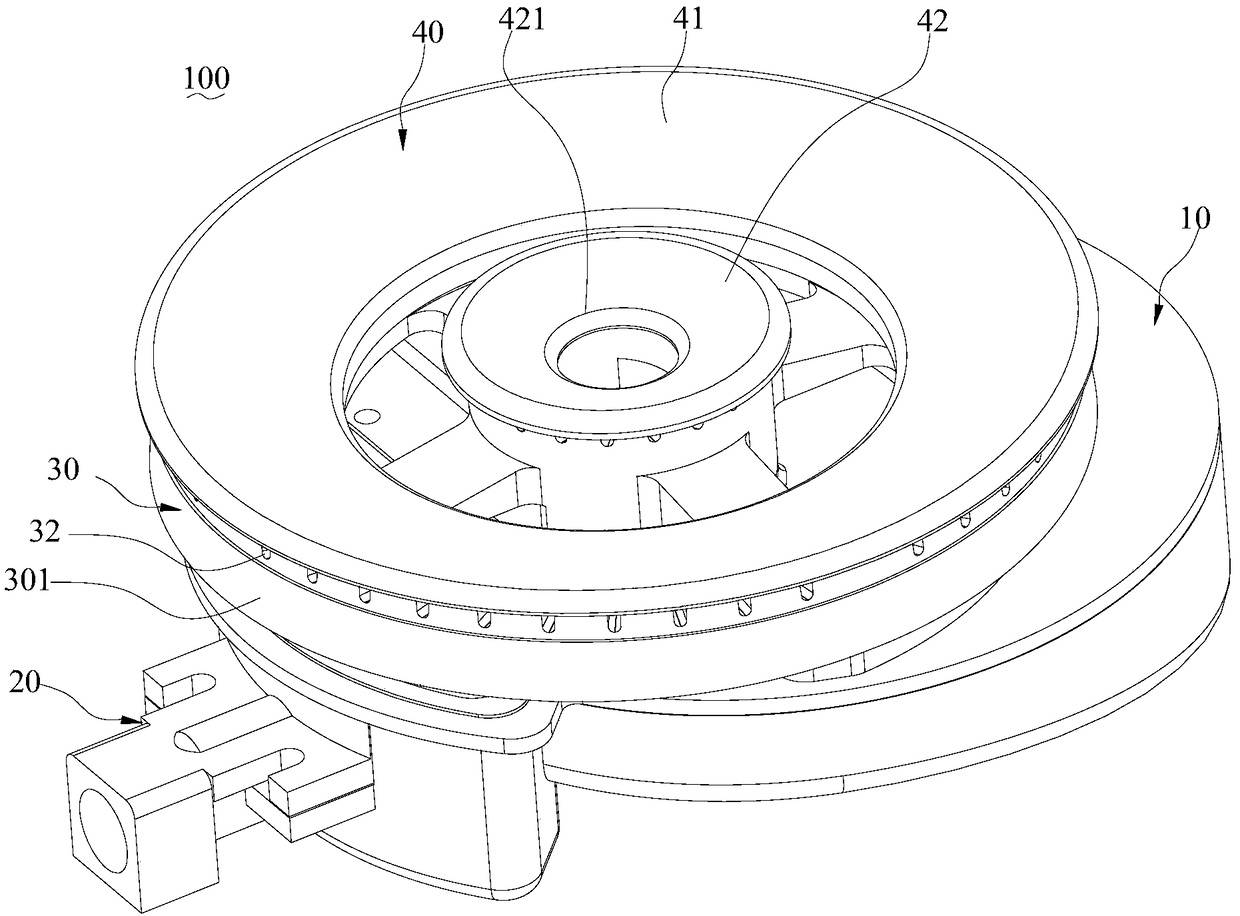

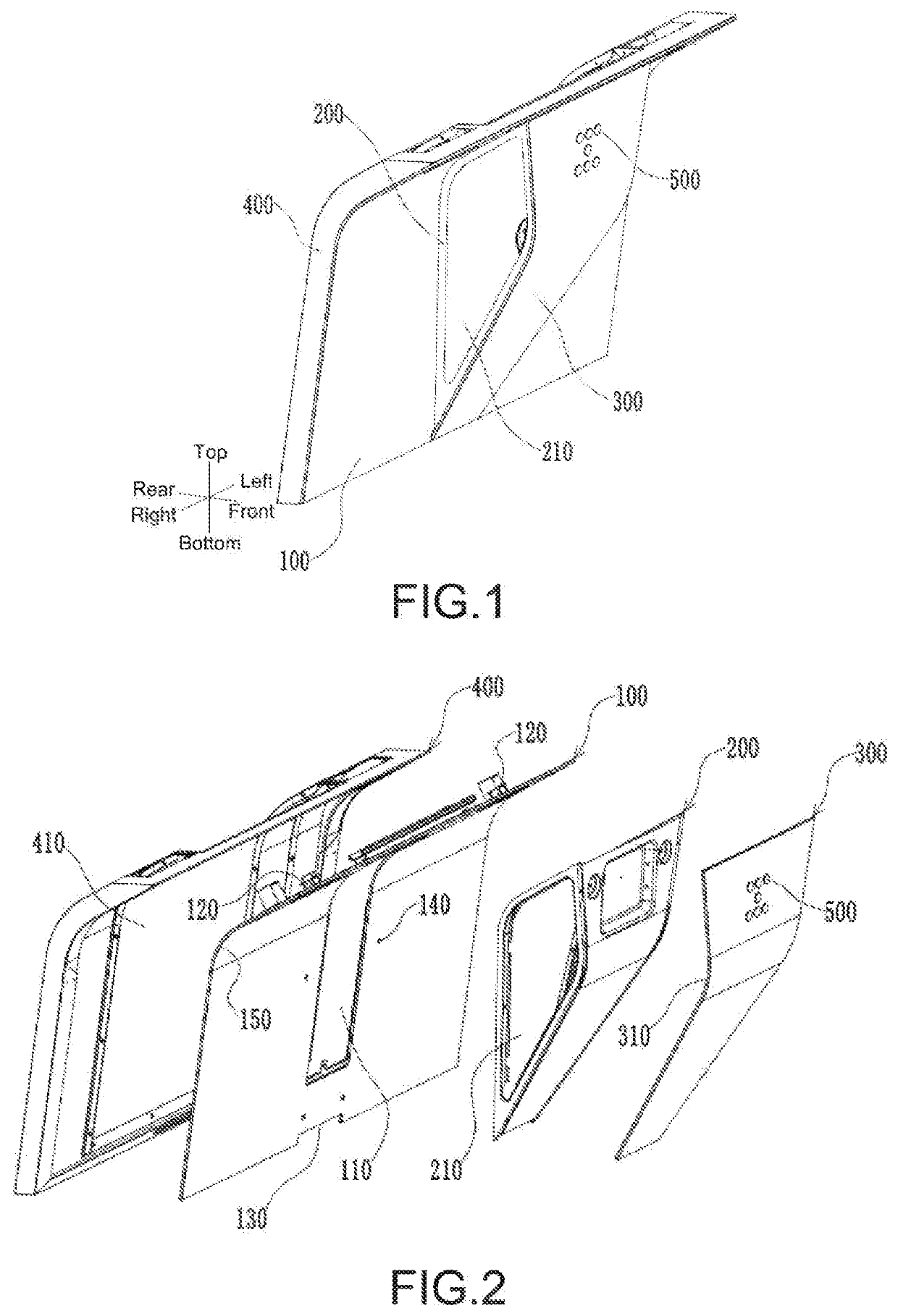

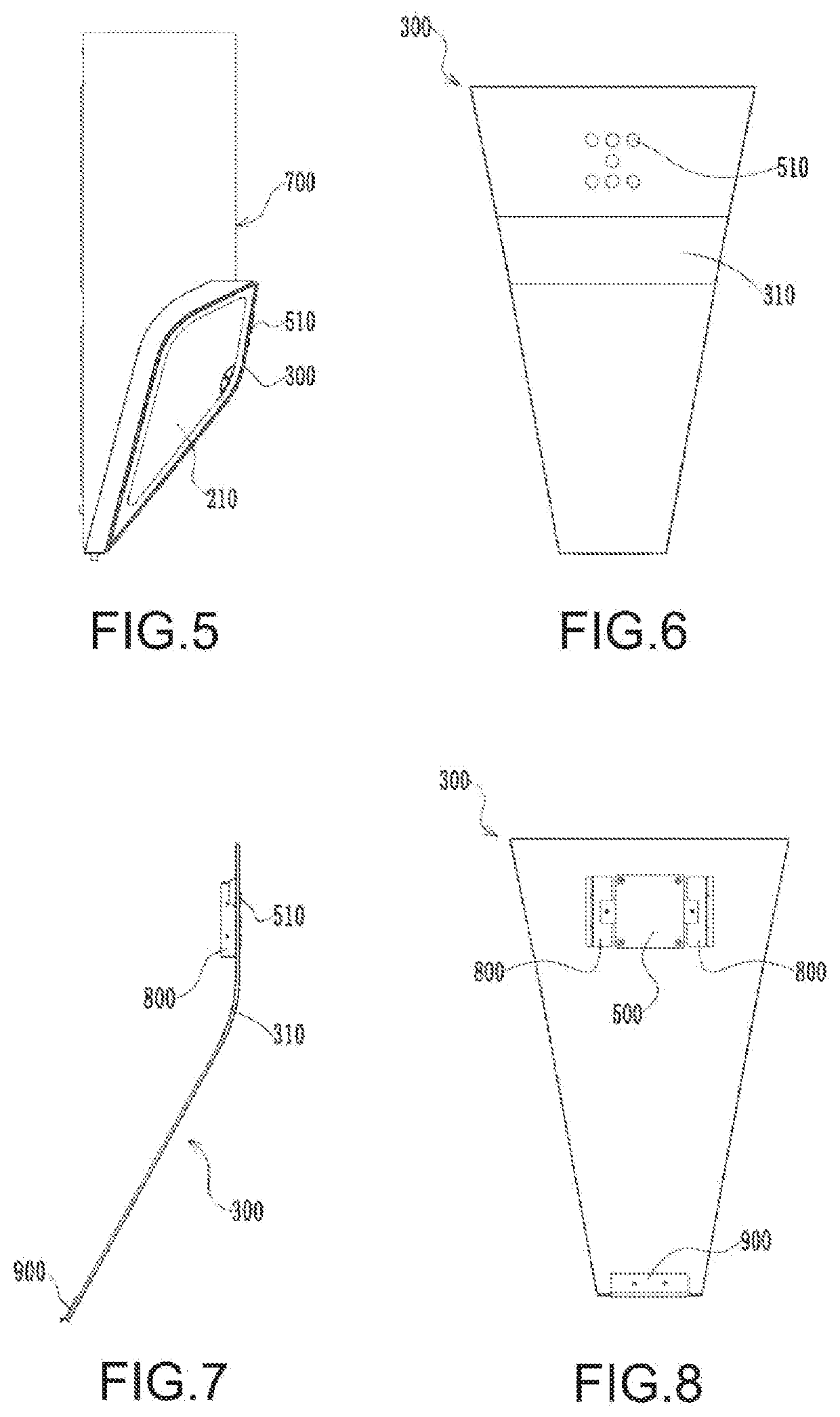

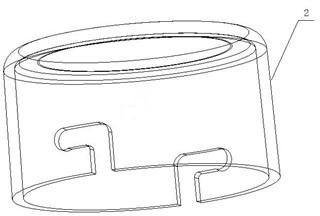

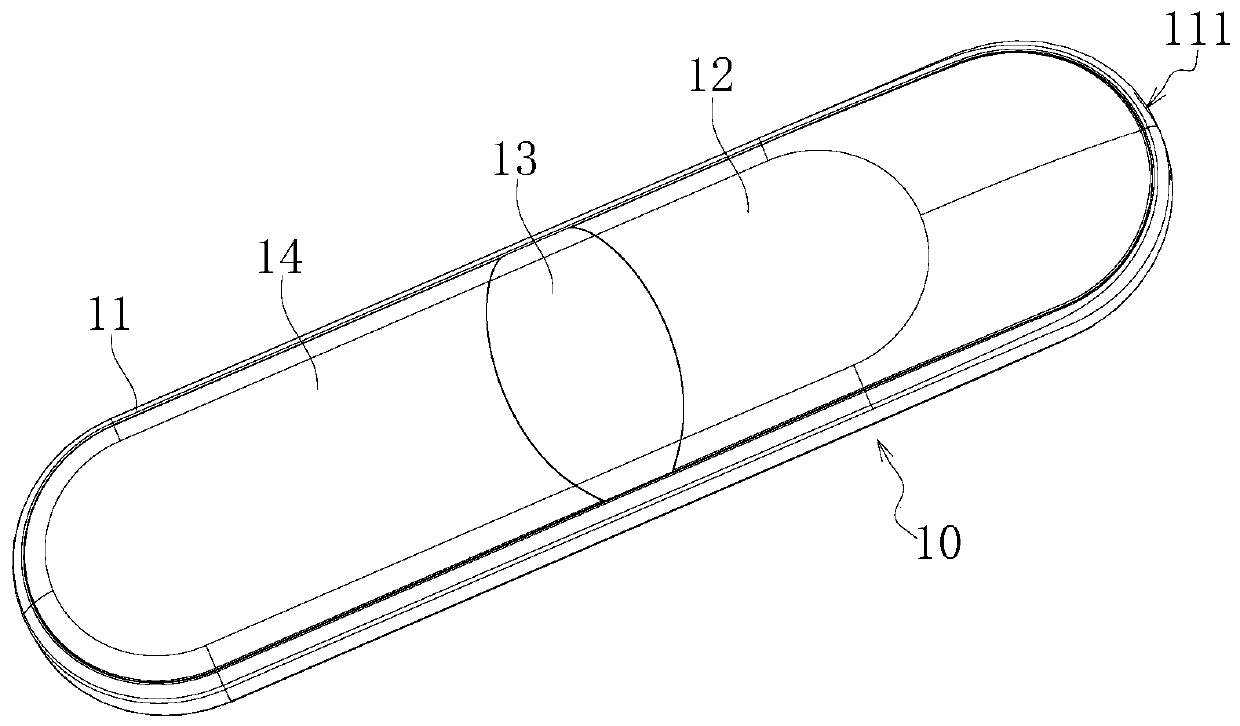

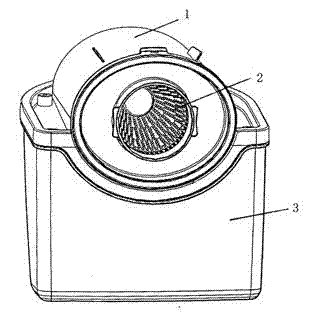

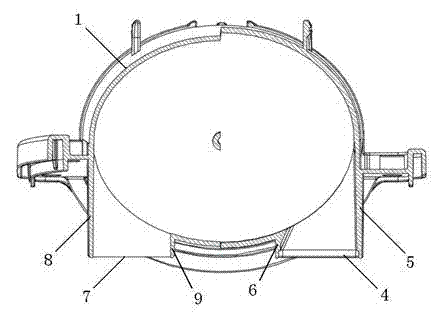

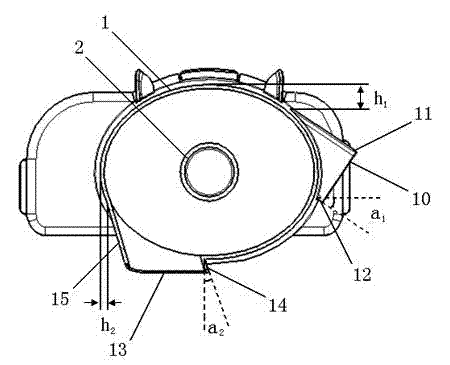

Fume collecting assembly, range hood, side suction range hood, range hood for two-sided fume collection and central air intake, range hood with partition, and central fume purification device

ActiveUS11371718B2Increase the intake areaImprove the smoke effectDomestic stoves or rangesLighting and heating apparatusStructural engineeringMechanical engineering

A fume collecting assembly, a range hood, a side suction range hood, a range hood for two-sided fume collection and central air intake, a range hood with partition, and a central fume purification device are provided. The fume collecting assembly includes a fume collecting panel having curved recessed portion and an air deflector, which has curved protruding portion and is connected to the fume collecting panel, and the curved protruding portion is opposite the curved recessed portion, forming first air inlet and second air inlet spaced apart. The fume collecting panel includes a fume collecting port for discharging fumes into a duct of range hood. The first air inlet and the second air inlet both communicate with the fume collecting port. The range hood, the side suction range hood, the range hood for two-sided fume collection and central air intake, and the range hood with partition include the fume collecting assembly.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

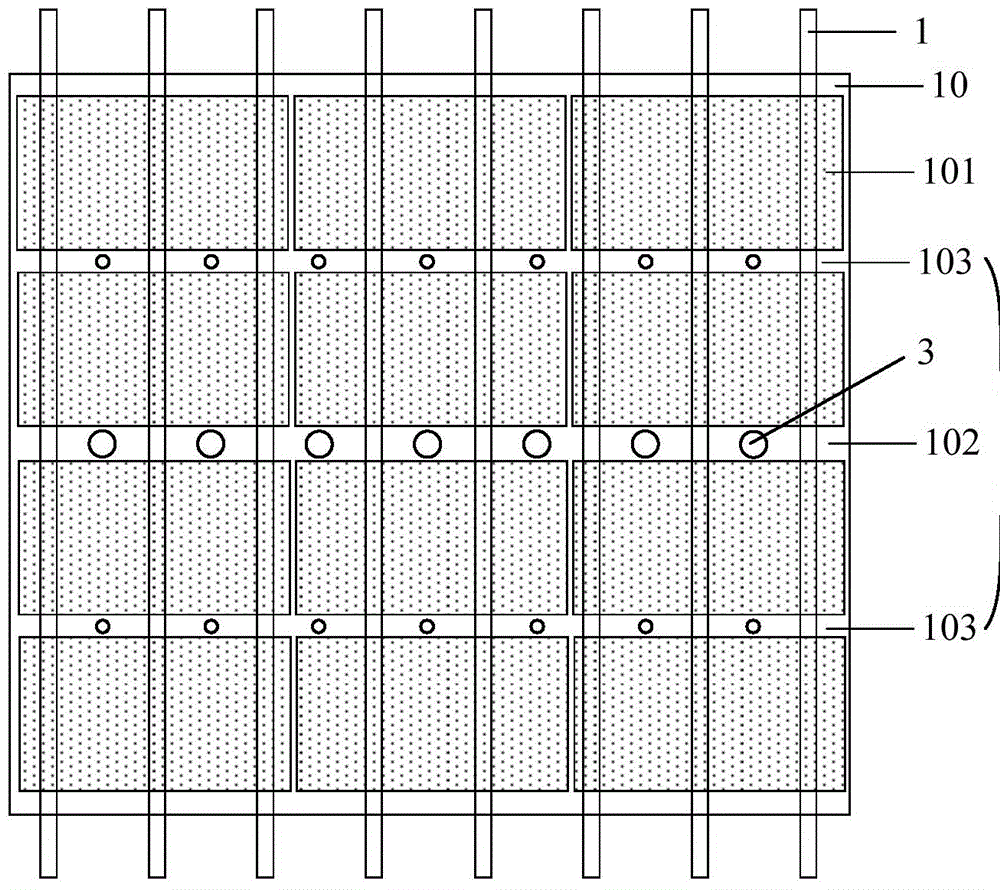

Frame sealing glue solidifying device and mask plate thereof

ActiveCN103984156AReduce loadLoad does not decreasePretreated surfacesCoatingsLiquid-crystal displayEngineering

The invention relates to the technical field of LCD (Liquid Crystal Display), and discloses a frame sealing glue solidifying device and a mask plate thereof. The mask plate comprises a light transmitting zone and a light shielding zone, wherein the light transmitting zone is provided with at least one through hole. In a descending preliminary stage that a liquid crystal panel is far away from the mask plate after exposure solidification of frame sealing glue is finished, due to the arrangement of the through hole, the air inlet area is enlarged, the air inlet amount is enlarged, the air inlet speed is reduced, the pressure difference of the space between the liquid crystal panel and the mask plate and the surrounding environment is lessened, the pressure acting on the mask plate by the pressure difference is lessened under the same action area, and thus the load of absorbing the mask plate by vacuum is reduced; meanwhile, due to the existence of the through hole, the action area of the pressure difference on the mask plate is reduced, and the load of absorbing the mask plate by vacuum is further reduced; therefore, according to the technical scheme of the invention, the risk that the mask plate falls off due to the pressure difference is greatly reduced while the descending speed of the liquid crystal panel is not reduced, and the volume production efficiency is ensured.

Owner:BOE TECH GRP CO LTD +1

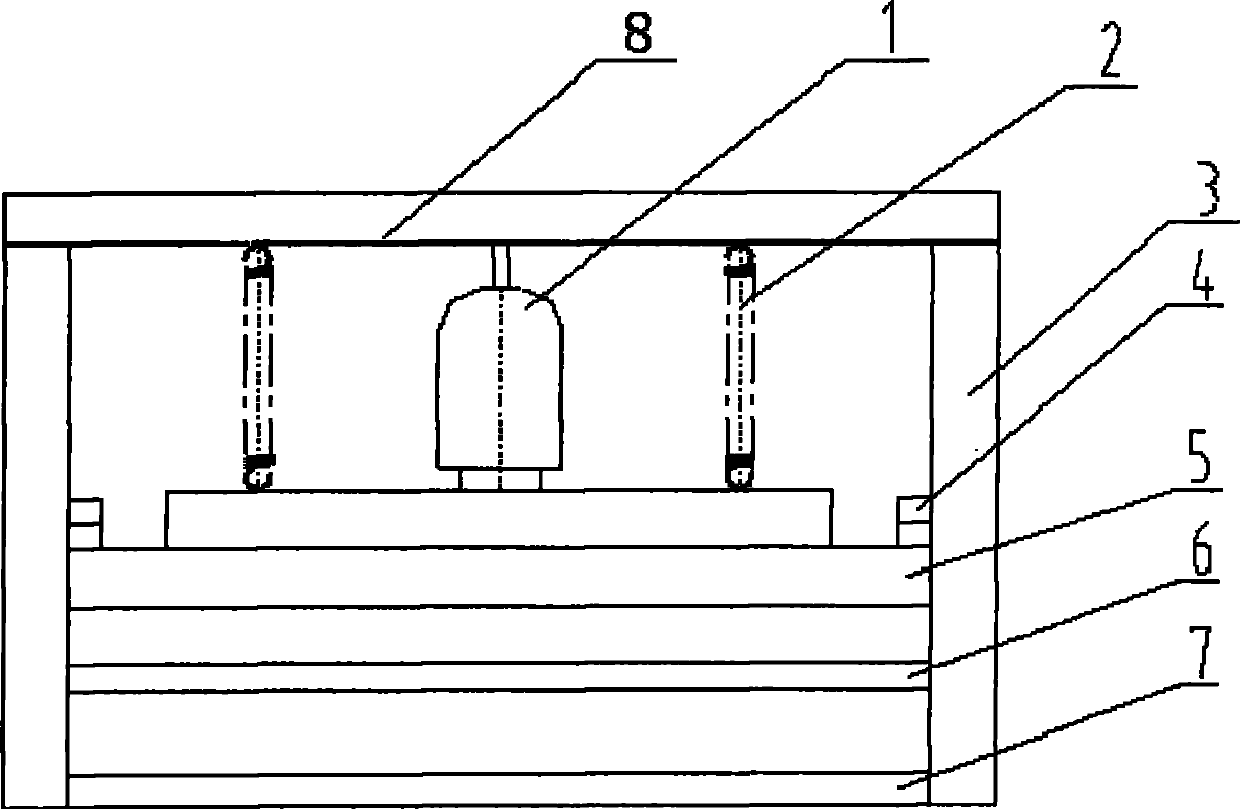

Burner and gas cooker

The invention discloses a burner and a gas cooker. The burner comprises a flamethrower and a bottom cup. The flamethrower comprises an inner ring cavity and an outer ring cavity surrounding the innerring cavity in a spaced mode. The flamethrower comprises an outer gas mixing cavity formed in the outer ring cavity, and an inner gas mixing cavity formed in the inner ring cavity. An ejection channelwith a Venturi effect is formed in the bottom cup. The upper surface of the bottom cup is provided with at least two outer ring gas outlets and at least two inner ring gas outlets, and all the outerring gas outlets and the inner ring gas outlets communicate with the gas outlet end of the ejection channel. At least two outer ring gas outlets are formed in a spaced mode. At least two inner ring gas outlets are formed in a spaced mode. A first secondary air channel is formed in the upper surface, located between the at least two inner ring gas outlets, of the bottom cup. The burner is providedwith a second secondary air channel penetrating through the middle of the inner ring cavity. The first secondary air channel communicates with the second secondary air channel. In the burner, the secondary air inlet area is increased, thus secondary air ability of the inner ring cavity is ensured, and flame stability is ensured.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

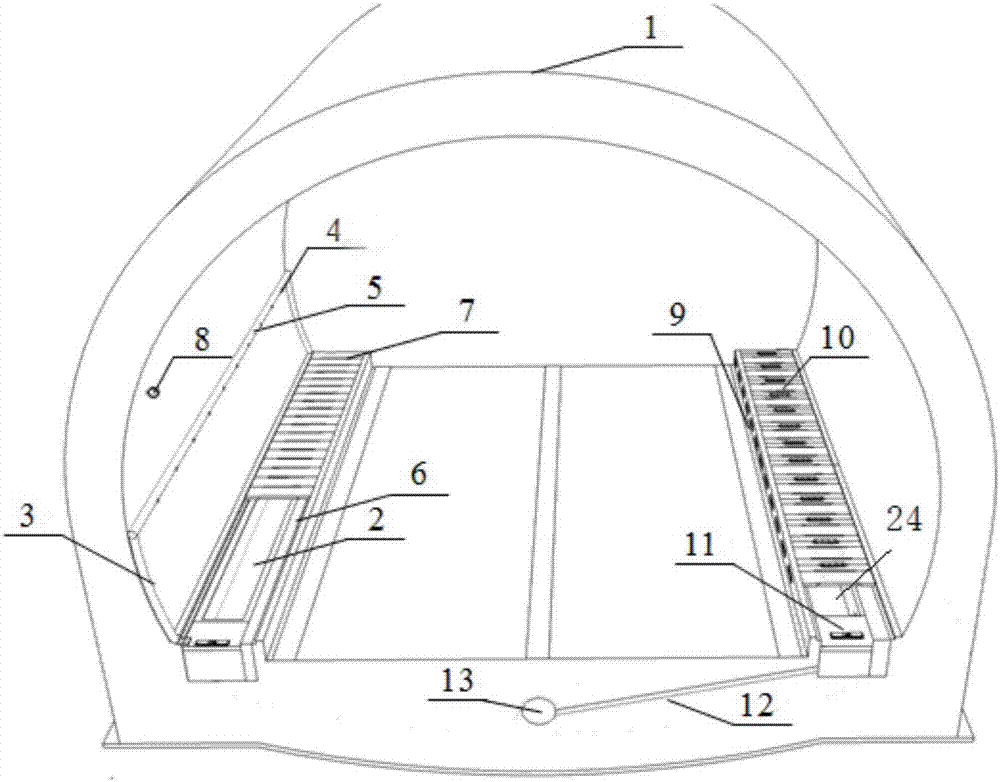

Device for tunnel dedusting, ventilating and purifying on basis of smoke concentration

PendingCN108005702AImprove air qualityProtect healthElectrical apparatusDust removalEngineeringParticulate concentration

A device for tunnel dedusting, ventilating and purifying on the basis of the smoke concentration comprises a smoke concentration detector and an air outlet pipeline which are arranged on the side wallof a tunnel. A first cable trough is formed in one side inside the tunnel, and a second cable trough is formed in the other side inside the tunnel. Slab culvers are arranged above the first cable trough and the second cable trough correspondingly, and an atomization box body is arranged in the first cable trough. An atomization device is arranged in the atomization box body, and an air suction device for purifying air in the tunnel is arranged in the second cable trough and connected with a transverse drainage pipe in the tunnel. In the operating process of the device, the long-time uninterrupted ventilating effect can be achieved, the current situation that the concentration of particles in the tunnel is large is improved, and the quality of the air in the tunnel is improved; and in theoperating process of the device, generated noise is low, the influence on personnel in the tunnel is reduced, and the driving comfort is improved.

Owner:CHANGAN UNIV

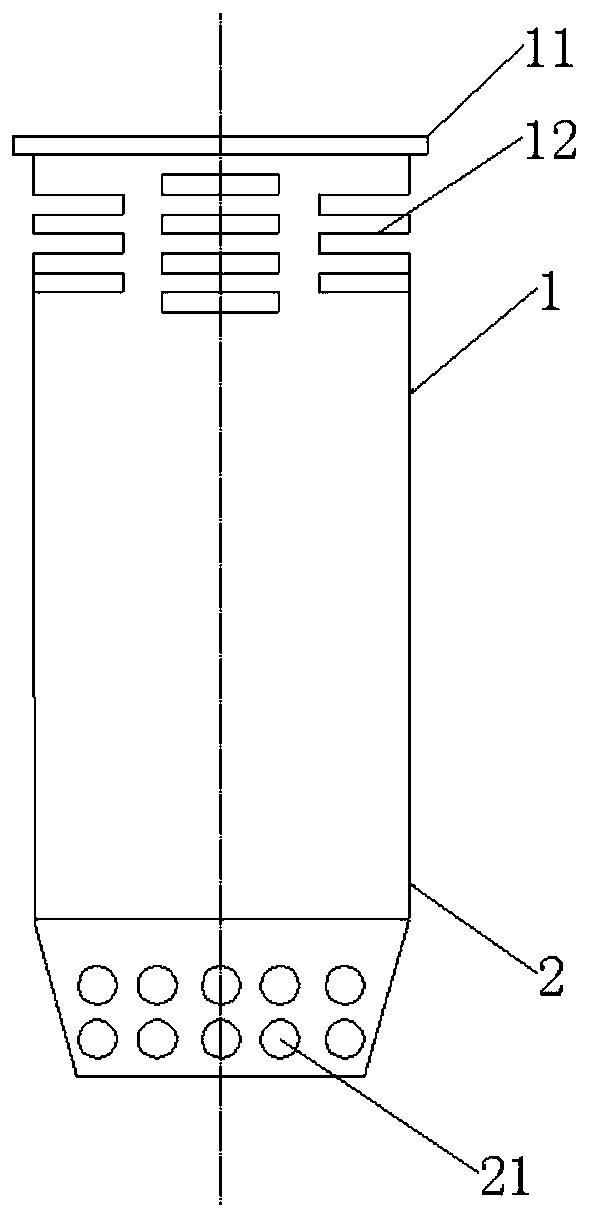

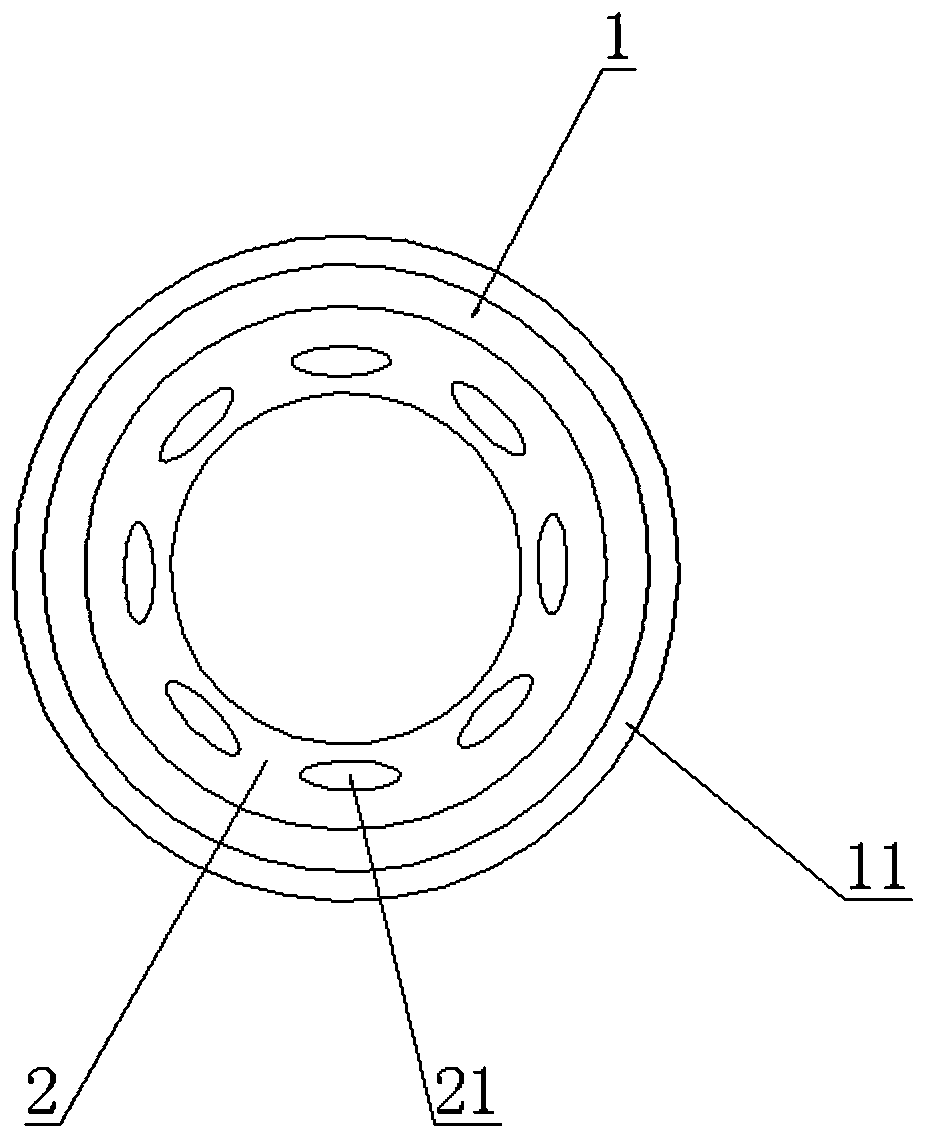

Biomass combustor and biomass fuel furnace

PendingCN109737384ATake up spaceEasy to collectDomestic stoves or rangesSolid fuel combustionCombustorCombustible gas

The invention provides a biomass combustor and a biomass fuel furnace, and belongs to the field of furnace accessories. The biomass combustor comprises a combustion barrel and a gas collection barrel.The combustion barrel is used for being arranged in a furnace opening, and the combustion end is used for combustion of combustible gas in the combustion barrel. The gas outlet end of the gas collection end communicates with the gas inlet end of the combustion barrel, the gas inlet end of the gas collection barrel gradually shrinks from top to bottom and is used for being inserted into a biomassfuel assembly in a hearth, and gas collection holes are formed in the side wall of the gas inlet end. The gas inlet end of the gas collection barrel can be inserted into the biomass fuel assembly moredeeply, meanwhile, the space of biomass fuel in a furnace cavity cannot be occupied too much, combustible gas at the deep position of the biomass fuel assembly can be collected easily, and the gas collection holes formed in the gas inlet end of the gas collection barrel guarantees sufficiency of the collected combustible gas. The biomass combustor is adopted by the biomass fuel furnace, the combustible at the deep position of the biomass fuel assembly in the hearth can be guided out from the combustion barrel, meanwhile, the space of the biomass fuel in the furnace cavity cannot be occupied too much by the gas collection barrel, and it is guaranteed that combustion time is long.

Owner:山东正信德环保科技发展有限公司

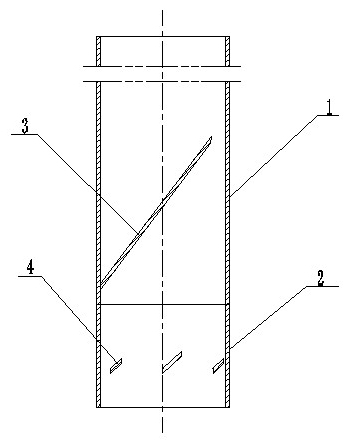

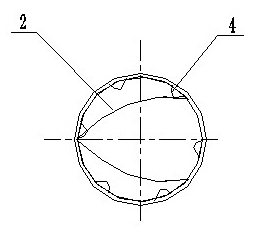

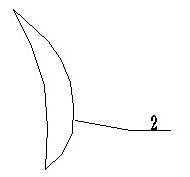

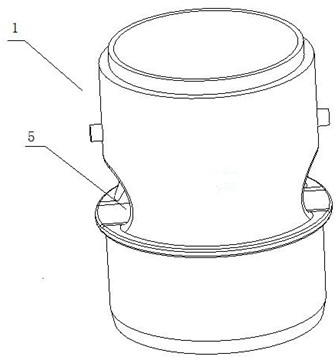

Gas-water separation swirler used in indoor drainage system

InactiveCN101831940AReduce shockSmall footprintDomestic plumbingSewer pipelinesEngineeringConcave surface

The invention discloses a gas-water separation swirler used in an indoor drainage system, relating to a gas-water separation swirler and aiming to solve the problems of great noise, large floor area, easy pressure oscillation inside the pipeline, water seal damage and expensive traditional special pipe units in the indoor drainage system in the current market. In the gas-water separation swirler, each first flow deflector is of a crescent moon shape, two first flow deflectors are arranged vertically along the inner wall of a first pipeline, concave surfaces of the two first flow deflectors are arranged oppositely, the convex surface of each first flow deflector coincides with the inner wall of the first pipeline in a fixed connection way, a set of second flow deflectors are uniformly distributed along the circumference of the inner wall of a second pipeline, each second flow deflector is in a triangular shape, one side of the each second flow deflector is fixedly connected with the inner wall of the second pipeline, and one end of the first pipeline is connected with one end of the second pipeline into a whole. The invention is applied to the indoor drainage system.

Owner:HARBIN INST OF TECH

Fume Collecting Assembly, Range Hood, Side Suction Range Hood, Range Hood for Two-sided Fume Collection and Central Air Intake, Range Hood with Partition, and Central Fume Purification Device

ActiveUS20200232649A1Improve user experienceImprove discharge efficiencyDomestic stoves or rangesLighting and heating apparatusMechanical engineeringEnvironmental engineering

A fume collecting assembly, a range hood, a side suction range hood, a range hood for two-sided fume collection and central air intake, a range hood with partition, and a central fume purification device are provided. The fume collecting assembly includes a fume collecting panel having curved recessed portion and an air deflector, which has curved protruding portion and is connected to the fume collecting panel, and the curved protruding portion is opposite the curved recessed portion, forming first air inlet and second air inlet spaced apart. The fume collecting panel includes a fume collecting port for discharging fumes into a duct of range hood. The first air inlet and the second air inlet both communicate with the fume collecting port. The range hood, the side suction range hood, the range hood for two-sided fume collection and central air intake, and the range hood with partition include the fume collecting assembly.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

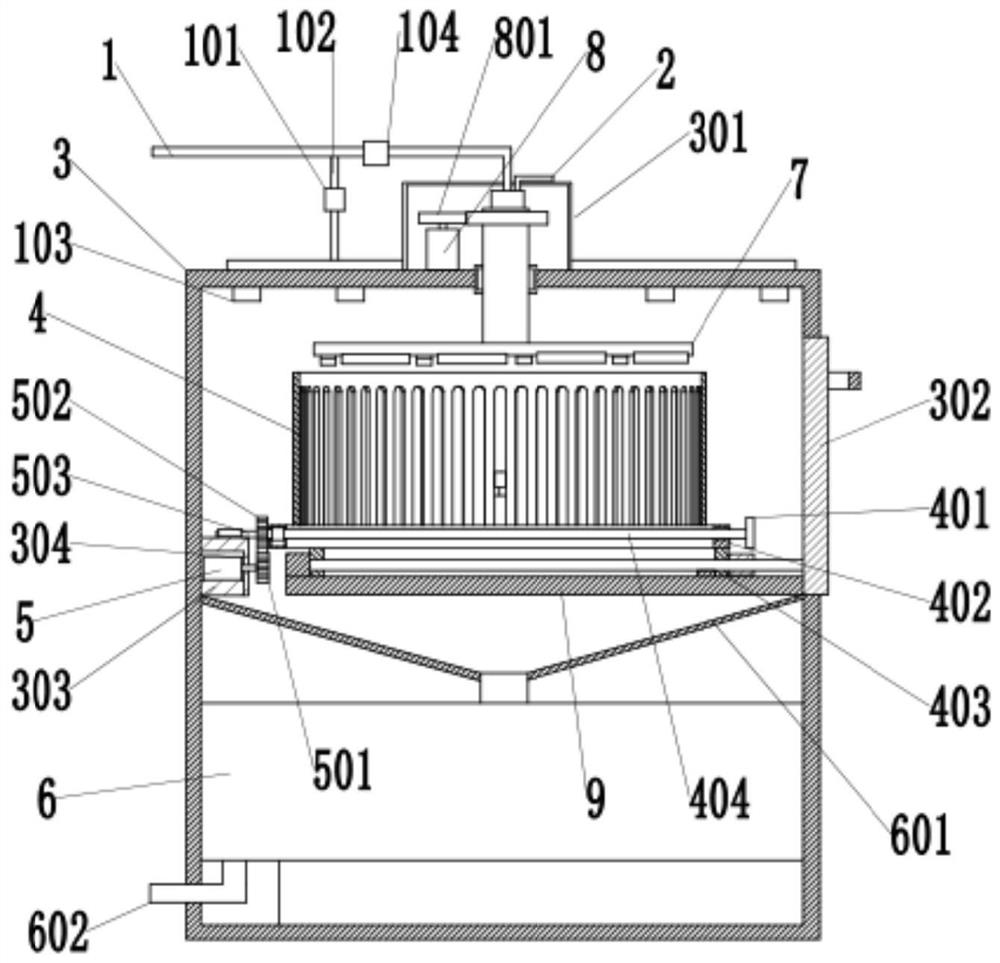

Medical surgical instrument cleaning device

InactiveCN112090829APrevent splashAvoid pollutionDiagnosticsHollow article cleaningWater flowElectric machinery

The invention discloses a medical surgical instrument cleaning device. The device comprises a case, a cleaning basket, a rotating frame and a sewage tank, wherein a slide way is arranged in the case;the cleaning basket is matched with the slide way; a box door corresponding to the cleaning basket in position is arranged on the side wall of the case; the rotating frame comprises a rotary drum anda rotating rod; the lower end of the rotary drum is perpendicularly connected to the rotating rod; the rotary drum is rotatably connected to the upper end of the case; a second motor for driving the rotary drum to rotate is arranged at the upper end of the case; the rotating rod is arranged in the machine box and located above the cleaning basket; a high-pressure spray head and an air knife are arranged on the rotating rod; a sewage tank is arranged below the slide way; a water collecting hopper is connected to the upper end of the sewage tank; the upper end of the water collecting hopper is hermetically connected to the inner wall of the case, and a blow-off pipe is connected to the lower end of the sewage tank. According to the device, closed flushing is adopted in the case, water flow splashing can be prevented, the environment is prevented from being polluted, the rotating frame drives the high-pressure spray head to rotate to conduct rotary comprehensive flushing on medical instruments, and thorough flushing is guaranteed.

Owner:QIANFOSHAN HOSPITAL OF SHANDONG

Organosilicon fluidized bed reactor

InactiveCN100341614CLow flow resistanceReduce outputChemical/physical processesHeat conductingFluidized bed

The present invention relates to an organo-silicon fluidized-bed reactor. It includes fluidized-bed body formed from conical cylinder and upper portion cylinder body. In the top portion of bed body an upper shell cover is fixed and in the bottom portion of conical cylinder a lower shell cover is fixed, in the bed body interior a finger-shaped heat exchange tube is hung, the upper portion of said finger-shaped heat extrange tube is connected with a heat-conducting oil distributor, said heat-conducting oil distributor is tubular double-layer structure, its lower layer tube is oil-feeding cavity and its upper layer tube is oil-returning cavity, two ends of said oil-feeding cavity are communicated with inlet of heat-conducting oil, and two ends of said oil-returning cavity are communicated with outlet of heat-conducting oil, the oil-feeding sleeve of finger-shaped heat exchange tube is communicated with lower layer oil-feeding cavity, and the central oil tube is communicated with upper layer oil-returning cavity.

Owner:山西三佳化工新材料有限公司

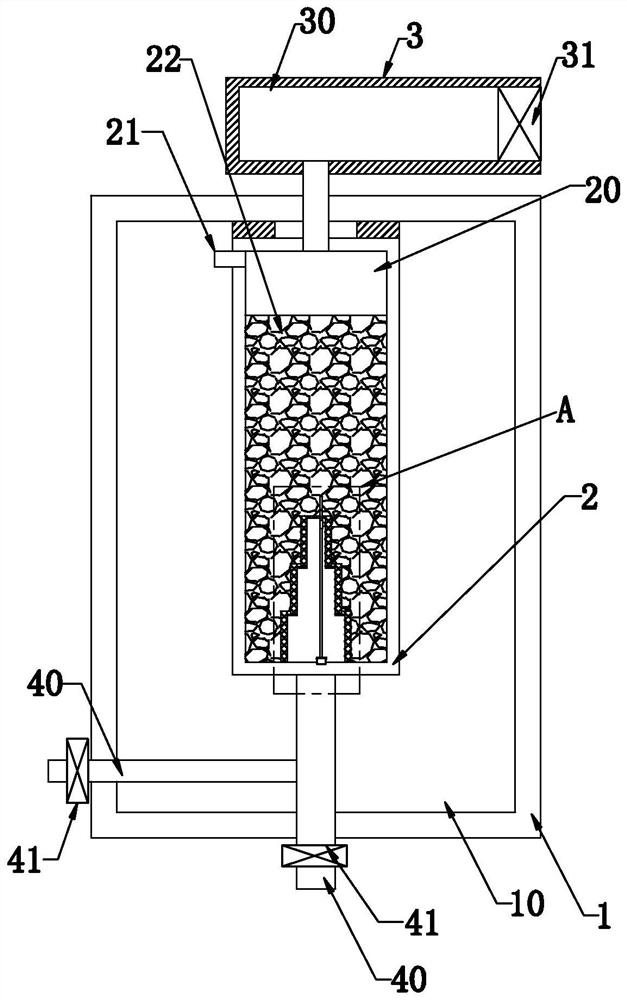

Compressed air drying system and drying method thereof

ActiveCN113069898AReach cleanGuaranteed adsorption effectGas treatmentDispersed particle separationSorbentExhaust fumes

The invention relates to a compressed air drying system and a drying method thereof. The compressed air drying system comprises an outer body provided with a first inner cavity, an inner body arranged in the first inner cavity and provided with a second inner cavity and a discharging part installed on the outer body, the discharging part is at least provided with a discharging cavity communicated with the inner body, a control valve is installed in the discharging cavity, a backflow cavity is formed between the inner body and the outer body, a backflow opening communicated with the backflow cavity is formed in the inner body, the inner body is provided with an air inlet part and a waste airexhaust part, and an adsorbent and a retractable air inlet unit are arranged in the second inner cavity; the air inlet part and the waste air exhaust part respectively comprise an air pipe communicated with the second inner cavity and an electromagnetic valve arranged on the air pipe, the input end of the air inlet unit is communicated with the air pipe, and the air inlet unit can expand when air enters the second inner cavity and is used for enlarging the air outlet surface; the system has the beneficial effects that compressed air can be dried, an adsorbent can be cleaned, and addition of a new adsorbent is completed in the cleaning process.

Owner:SICHUAN DANFU ENVIRONMENT TECH CO LTD

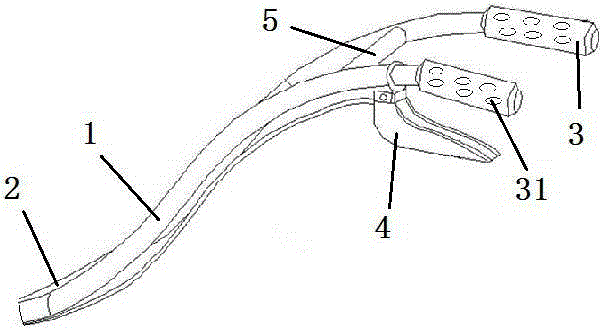

Handrail of walk-behind harvester

InactiveCN105165225AIncrease the intake areaSmall structural changesMowersMetal-working hand toolsEngineeringReaper

The present invention discloses a handrail of a walk-behind harvester. Two handrail branch tubes converge to form a handrail main tube, the handrail branch tubes and the handrail main tube are both hollow tubes, tail ends of the handrail branch tubes are sleeved by handrail sleeves, a handrail seat is disposed on the handrail main tube, end faces and circumferential faces of the handrail sleeves are provided with air inlets, the air inlets and the handrail branch tubes are communicated, and an air inlet corrugated pipe communicated with the handrail main tube is fixed at an end part of the handrail main tube. With arrangement of the air inlets in the handrail sleeve, air enters into the handrail branch tubes and the handrail main tube through the air inlets and then into an engine from the air inlet corrugated pipe through the handrail main tube. Because the walk-behind harvester is originally provided with a handrail, the structure of the handrail is not required for extra addition. By using a hollow structure of the conventional handrail, the handrail main tube and the handrail branch tubes of the overall handrail are used as extra air inlet pipes, the air inlet amount of the engine can be raised, and the problem that an air inlet installation structure of the conventional walk-behind harvester is small in space is solved.

Owner:CHONGQING SHUANGEN AGRI MACHINERY MFG

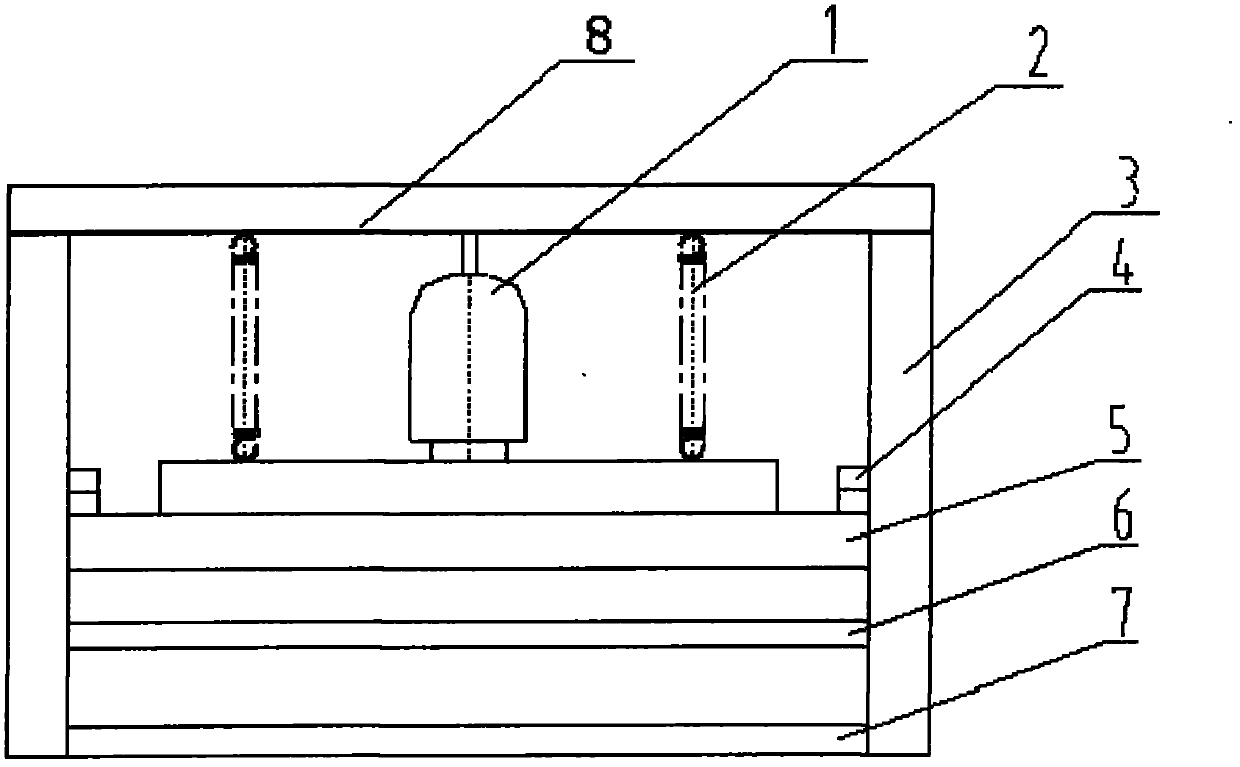

Method for designing moulding press for air-inlet grilles of compartment doors

The invention belongs to the field of moulding presses, and particularly relates to a method for designing a moulding press for air-inlet grilles of compartment doors of highway passenger vehicles. The moulding press comprises a rectangle frame; and the moulding press is characterized in that the rear part of a jack is fixedly connected with the top of the frame, the power output end in the front of the jack is fixedly connected with a pressing plate, a spring is connected between the pressing plate and the top of the frame, a row of upper round steel bars are distributed on the low plane of the pressing plate, a row of lower round steel bars are distributed at the bottom of the frame, and the upper round steel bars and the lower round steel bars are distributed in a parallel and staggered mode; the two sides of the frame are respectively provided with a vertical support, a return limited block is fixed on the inner side of the vertical support, the two sides of the pressing plate and the return limited block are arranged at a same vertical position, and the height of the return limited block is equal to the height of the pressing plate after the jack returns; and the free stroke of the jack is 100 mm. Compared with the existing grille, the air inlet area of an air-inlet grille prepared by using the moulding press is increased, the whole strength of a compartment door can be ensured, and the appearance beauty of the compartment door can be increased; meanwhile, the cost is saved, and the manufacturing efficiency of the compartment door can be improved.

Owner:SHAANXI EUROSTAR AUTOMOBILE

One-way automatic air inlet valve

ActiveCN102182849AEasy to installImprove sealingEqualizing valvesSafety valvesInlet channelInlet valve

The invention relates to a one-way automatic air inlet valve which comprises a valve body and a valve cover, wherein the valve cover is arranged at one end of the valve body, and a sealing cavity is formed between the valve cover and the valve body; the other end of the valve body is provided with an air outlet, the air outlet is used for connecting with a pipeline, and the valve body is hermetically arranged in an air inlet channel communicated with the air; the valve body is provided with an air inlet at one end of the sealing cavity, the air inlet is connected with the air inlet channel, and the air inlet is provided with a floatable sealing assembly; and the sealing assembly comprises a floating pin, a seal ring for sealing the air inlet is arranged on the floating pin, and the sealing cavity is connected with the air outlet through the channel in the valve body. The air inlet valve in the prior art has the technical problem that air inlet sensitivity and air inlet speed can not be guaranteed simultaneously due to the quality of steel balls, and the one-way automatic air inlet valve not only can guarantee air inlet speed but also has better air inlet sensitivity.

Owner:ZHUHAI EDISON ECOTECH CORP CO LTD

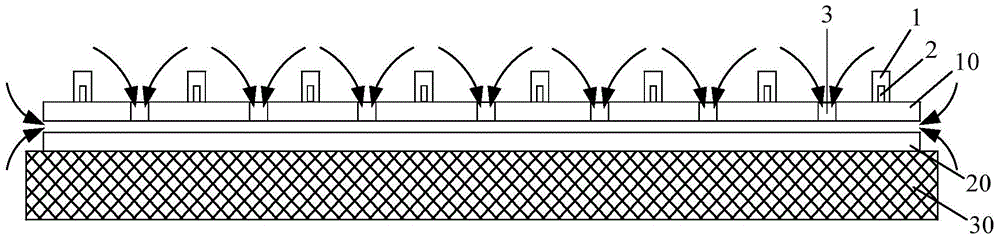

Centrifugal fan blade, fan and air conditioning system comprising fan

PendingCN113550930AIncrease the intake areaReduce intake resistancePump componentsPumpsAir volumeEngineering

The invention provides a centrifugal fan blade, a fan and an air conditioning system, relates to the technical field of air conditioners, and solves the technical problems that a centrifugal fan is small in air volume, high in noise, low in fan efficiency and relatively concentrated in airflow. The centrifugal fan blade comprises blades and a fixed disc, wherein each blade is of a forward bent blade structure and is fixed onto the fixed disc; and the widths of all or part of the blades are gradually increased from an air suction port to the fixed disc in the height direction of the blades, and the air suction port of the fan blade is of a gradually-shrunk trumpet-shaped structure. The fan comprises the centrifugal fan blade and a volute, wherein the two side edges of the volute are inclined. The air conditioning system comprises the fan. According to the centrifugal fan blade, the fan and the air conditioning system provided by the invention, the air suction port of the fan blade is of the trumpet-shaped gradually-shrunk structure, so that under the condition of the same outer diameter and height of the fan blade, the air inlet area of the fan blade is increased, the air inlet resistance is reduced, and the air volume and the fan efficiency are improved; due to the change of the air inlet angles of the blades, air inlet fluid is effectively dispersed, and noise is reduced; and the widths of the blades are gradually increased, and the working capacities of the blades are gradually enhanced, so that the overall working efficiency of the fan is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

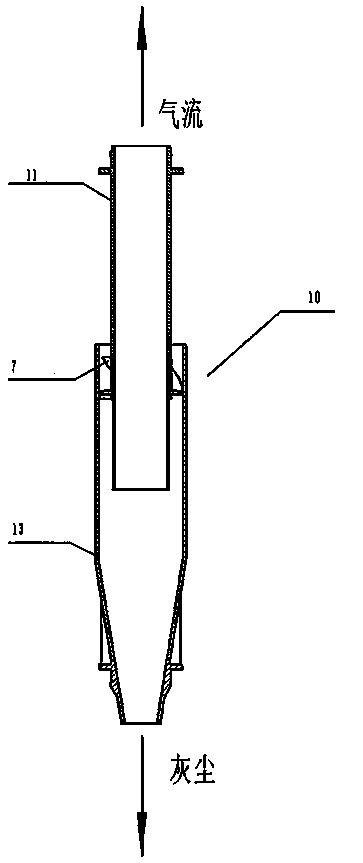

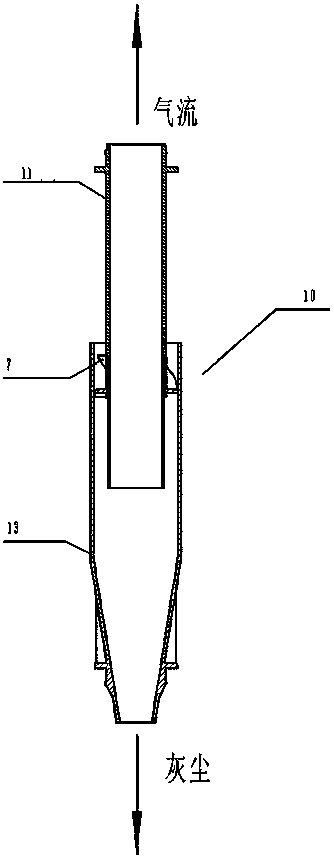

Impurity collecting and discharging device

InactiveCN108905385AReduce volumeSave spaceDispersed particle separationEngineeringMechanical engineering

The present invention discloses an impurity collecting and discharging device which is used in a cyclone pipe type fluid pre-filter. A middle part of a fluid pre-filter shell body is vertically provided with a fluid discharge pipe along an axis direction; a cyclone pipe is arranged between the outer wall of the fluid pre-filter shell body and a fluid discharge pipe; the lower part of the cyclone pipe is provided with an impurity collecting device; an inner annular opening of the impurity collecting device communicates with the fluid discharge pipe; an impurity collecting box with an opening upward; a plurality of impurity-receiving chambers are divided by setting a plurality of vertical partition plates in the impurity collecting box; the impurity collecting box is made from a transparentmaterial; the lower part of the impurity collecting box is provided with an impurity automatic discharging device; the impurity automatic discharging device comprises a plurality of impurity discharging ports and impurity guiding grooves; the number of the impurity discharging ports is the same as the number of the impurity-receiving chambers; and besides, the arranging position of each impurity discharging port corresponds to the position of each impurity-receiving chamber. The provided impurity collecting and discharging device can avoid problems that impurities of separating devices are notdischarged smoothly and installation is inconvenient under a premise of ensuring high-efficiency separation.

Owner:石家庄欧亚惠通滤清器有限公司

Fluid impurity separation device

The invention discloses a fluid impurity separation device. The fluid impurity separation device comprises a first cavity, a second cavity, a third cavity, a fourth cavity, a fifth cavity, a sixth cavity and a cyclone pipe, wherein the first cavity, the second cavity and the third cavity are arranged sequentially from top to bottom; the second cavity is communicated with the outside; an external fluid enters the second cavity firstly and then flows into the fourth cavity; the third cavity is an impurity storage cavity and is provided with an impurity output port; the first cavity is a fluid storage cavity after impurity separation; a to-be-treated impurity-containing fluid enters the second cavity from the outside, is separated by the cyclone pipe, enters the first cavity and then is output to the outside through the sixth cavity; separated impurities enter the third cavity and are discharged timely. With the adoption of the fluid impurity separation device, separation efficiency of the separation device can be increased greatly, and dust removal rate is as high as 98.4% of higher.

Owner:石家庄欧亚惠通滤清器有限公司

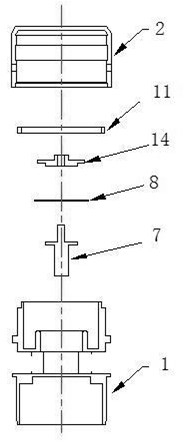

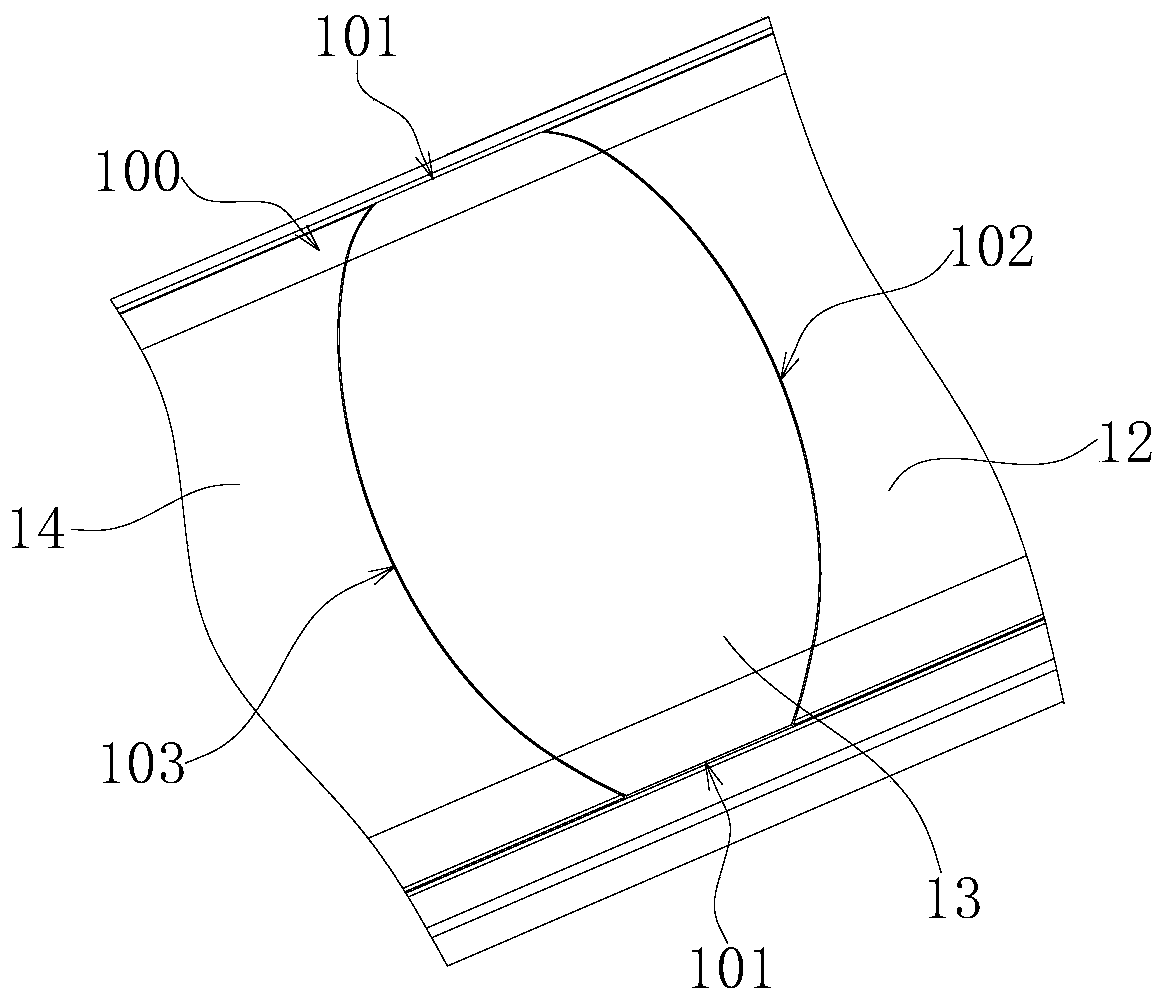

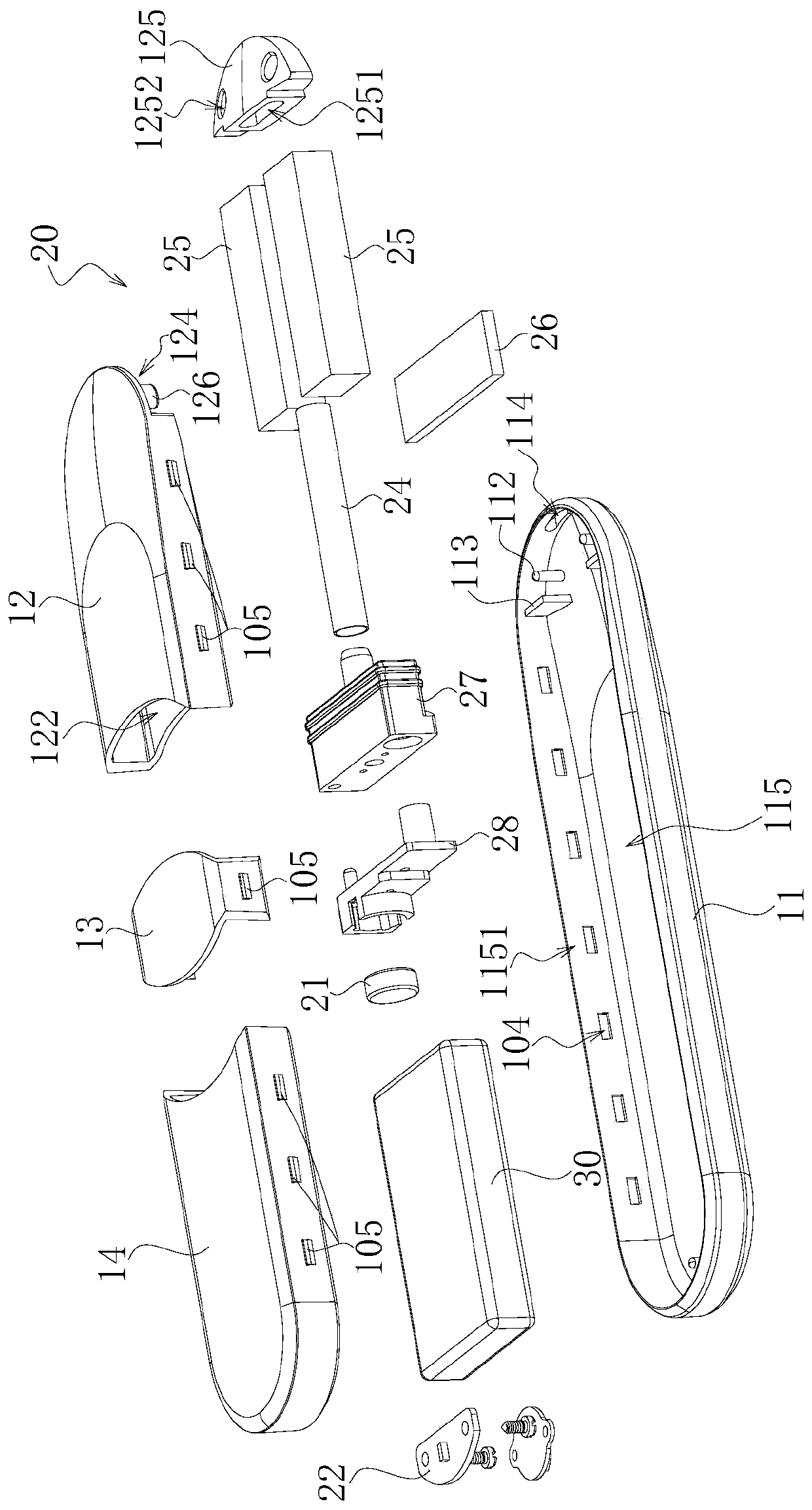

Disposable electronic cigarette

PendingCN110367604AImprove atomization effectImprove the suction experienceTobacco devicesElectronic cigaretteMechanical engineering

The invention belongs to the technical field electronic cigarettes, and particularly relates to a disposable electronic cigarette. The disposable electronic cigarette comprises a shell, an atomizing assembly and a power supply assembly, wherein both the atomizing assembly and the power assembly are arranged in the shell; the shell comprises a bottom shell, a front shell, a middle shell and a backshell; a mounting cavity provided with an opening is formed on one side of the bottom shell; the front shell, the middle shell and the back shell are arranged in the mounting cavity in sequence, and the opening is sealed; a smoking hole and a smoke outlet which communicate with each other are formed at the front end of the bottom shell and the front end of the front shell respectively; the atomizing assembly comprises a microphone positioned in the middle shell; and annular air inlet gaps are formed at the joints between the middle shell and the bottom shell as well as between the front shelland the back shell. According to the disposable electronic cigarette, the air enters from the air inlet gaps, and the air inlet gaps are of annular structures, so that the formed effective air inlet area is larger; the air inlet is not limited to a plurality of pore structures; and the air inlet amount and air inlet efficiency are improved greatly. Thus, the atomizing effect of the electronic cigarette is improved effectively, and the smoking experience of the electronic cigarette is improved for a user.

Owner:中健天和(北京)科技发展有限公司

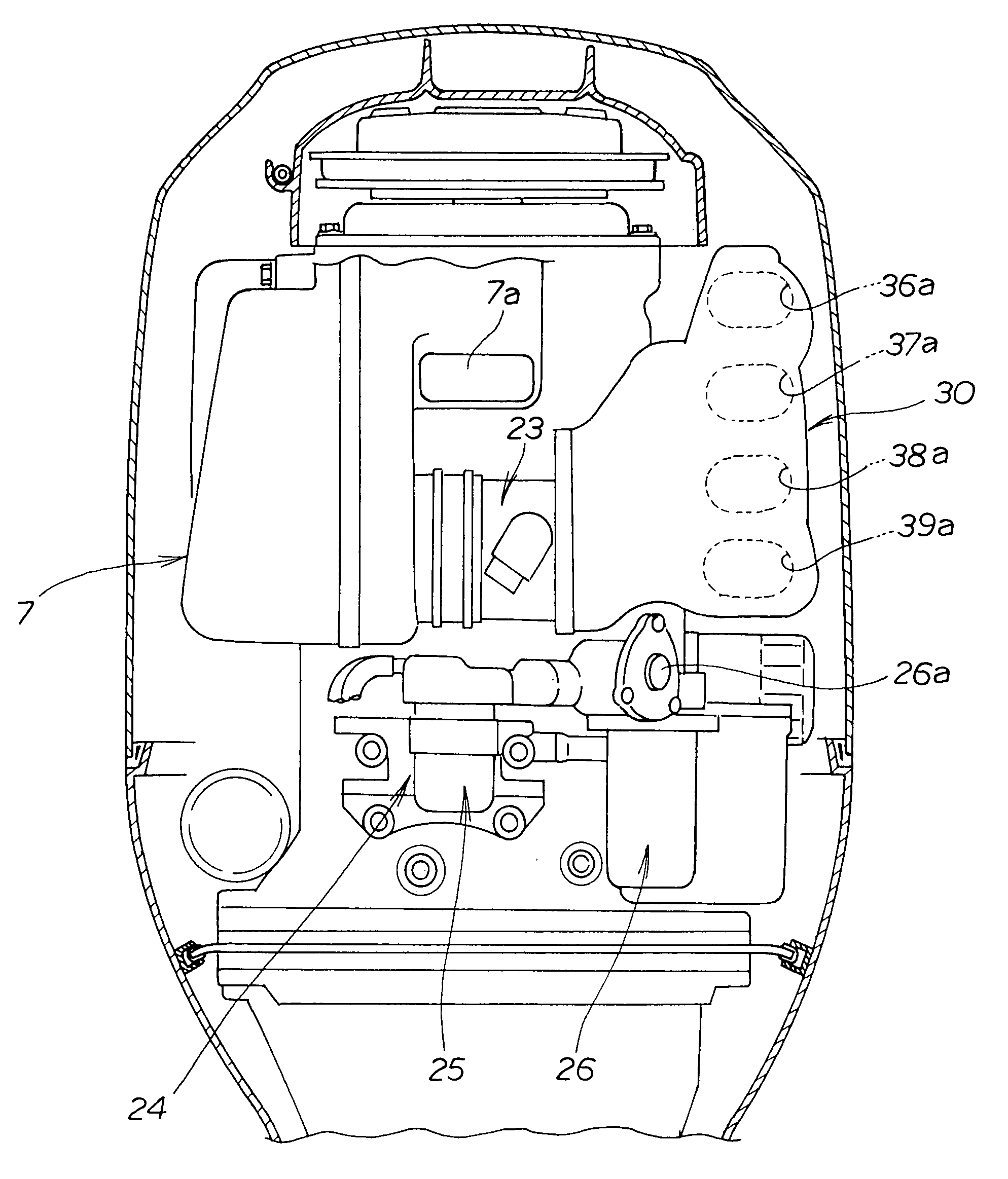

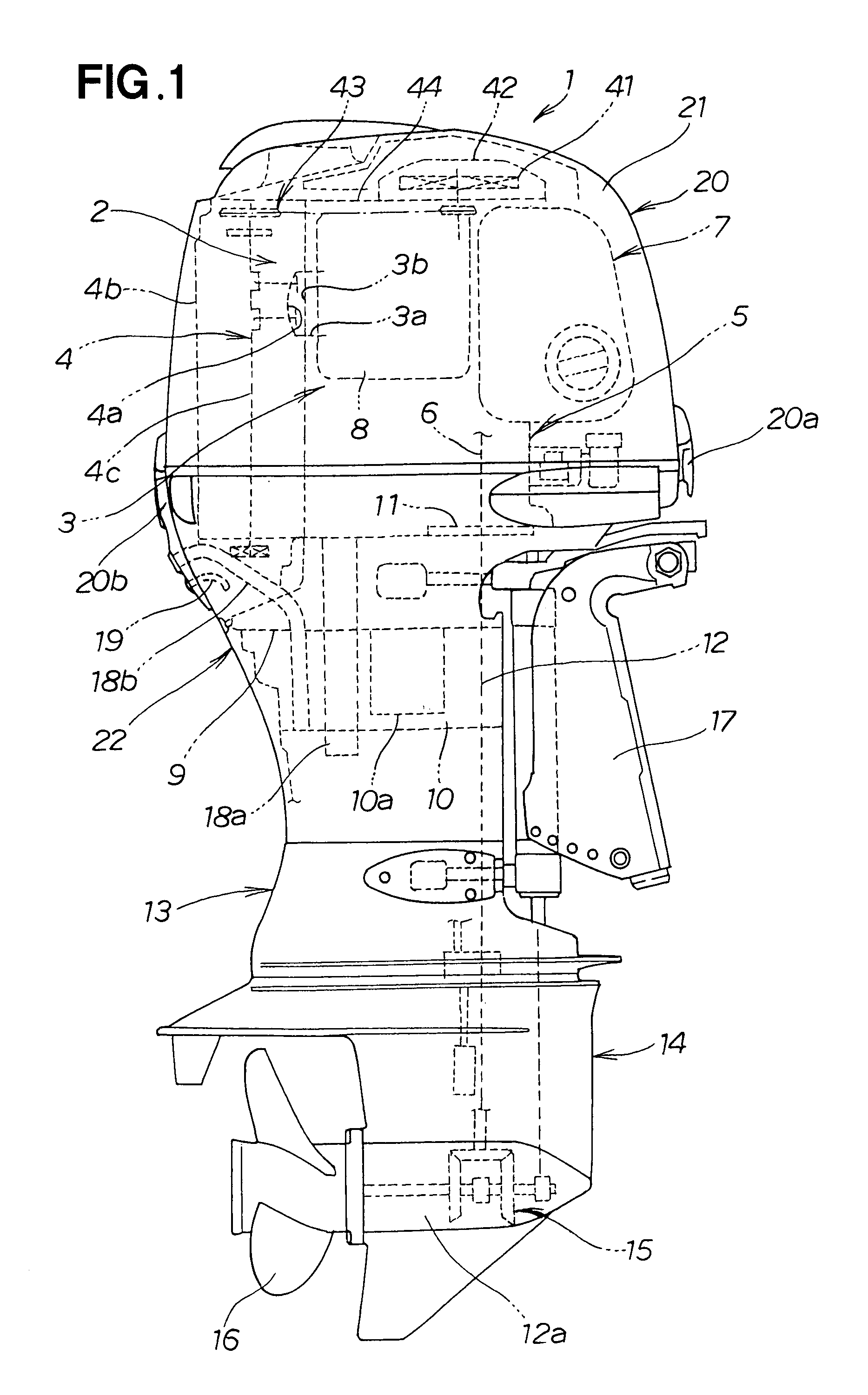

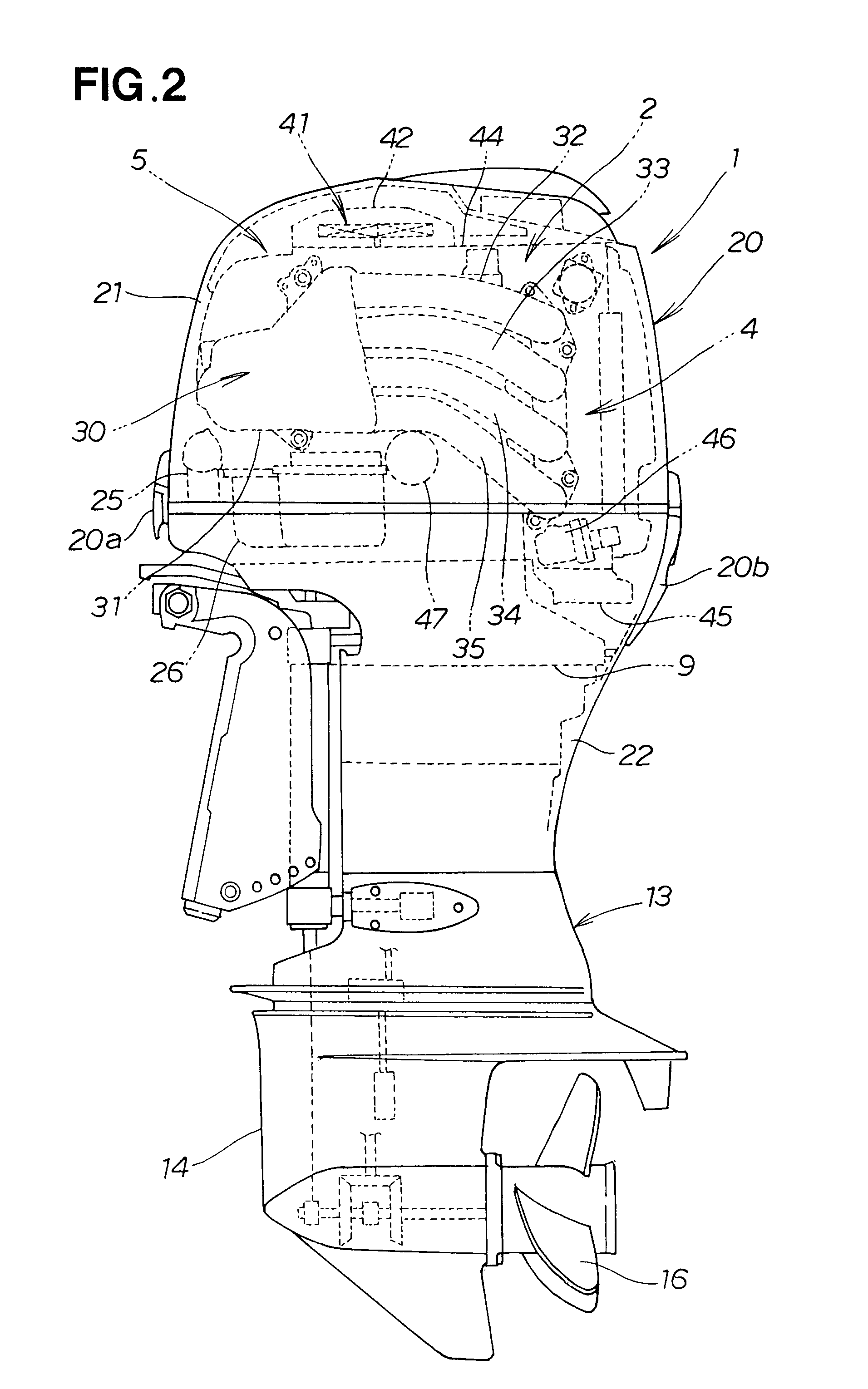

Outboard engine unit

InactiveUS7461623B2Easy to useHigh outputMachines/enginesAir intakes for fuelSurge tankCylinder block

An outboard engine unit has an intake manifold extending in a front-and-rear direction along one side of an engine block and comprised of a surge tank and a plurality of intake tubes communicating with the surge tank. Each of the intake tubes is arranged so as to be separated in a vertical direction. The shape of the channel cross section of each of the intake tubes is a flat shape in which the dimension in the vertical direction is less than the dimension in a crosswise direction.

Owner:HONDA MOTOR CO LTD

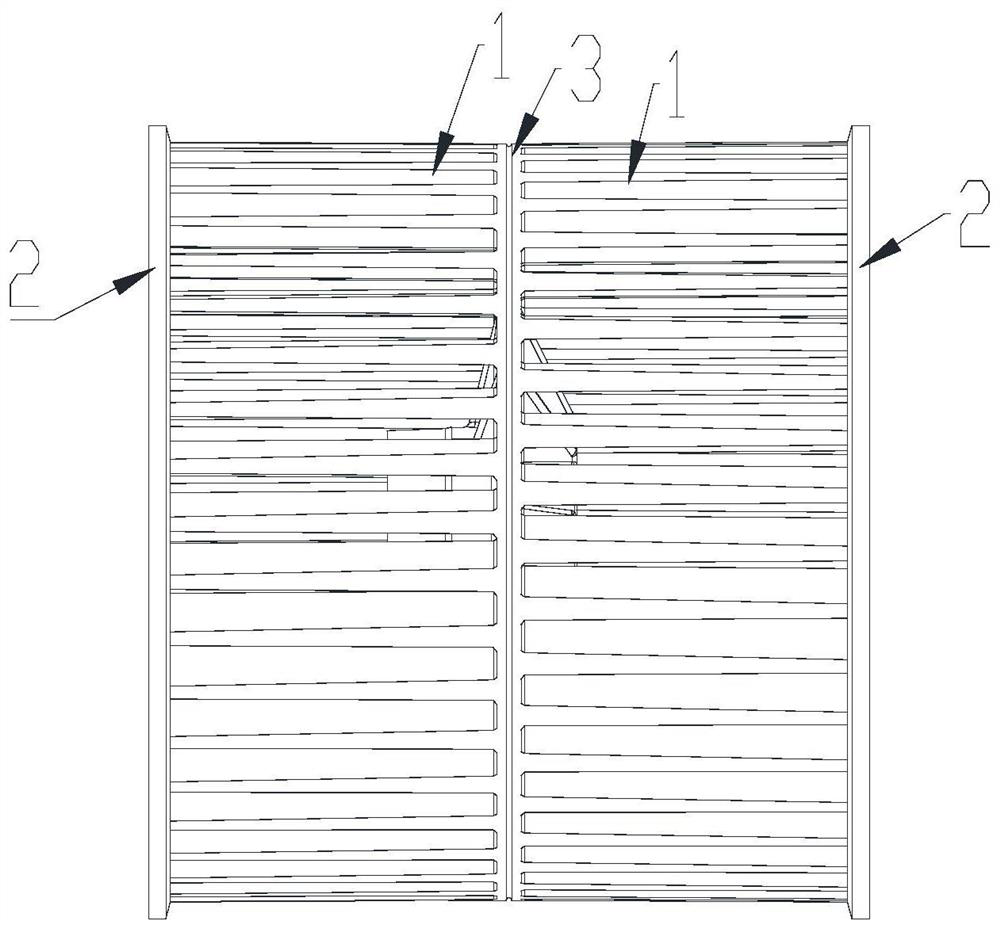

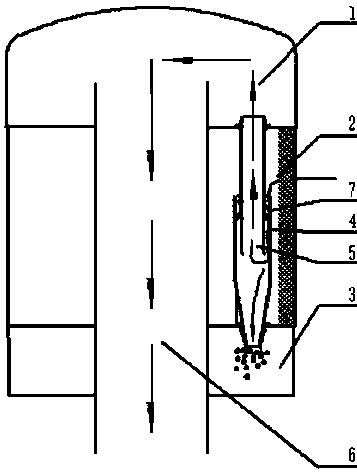

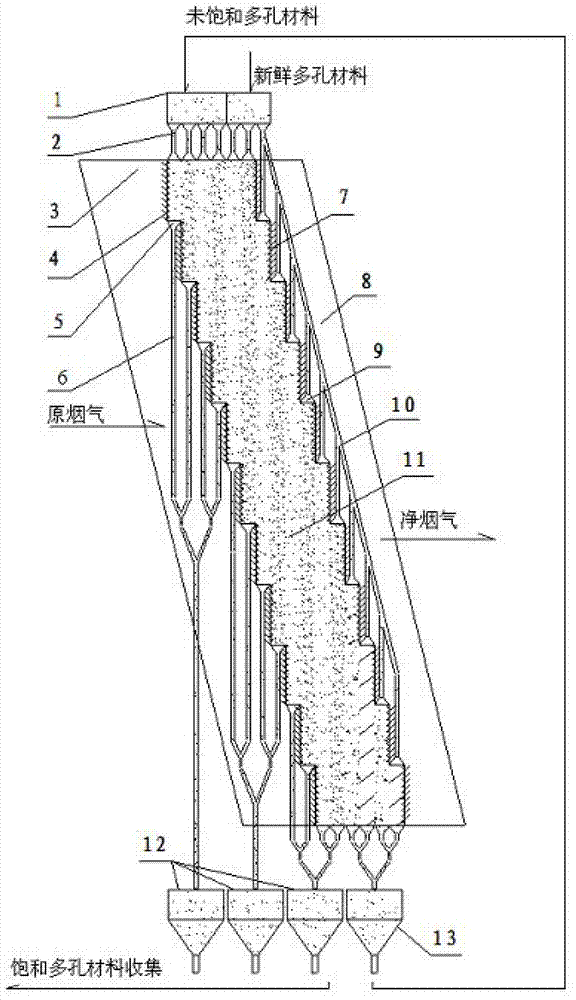

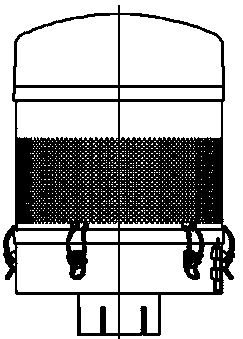

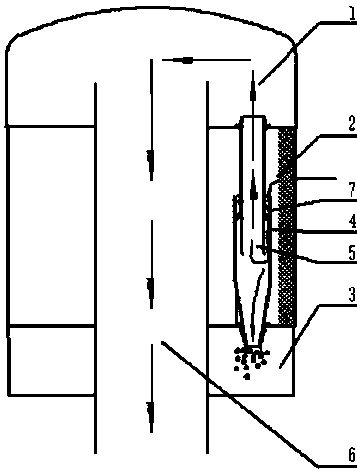

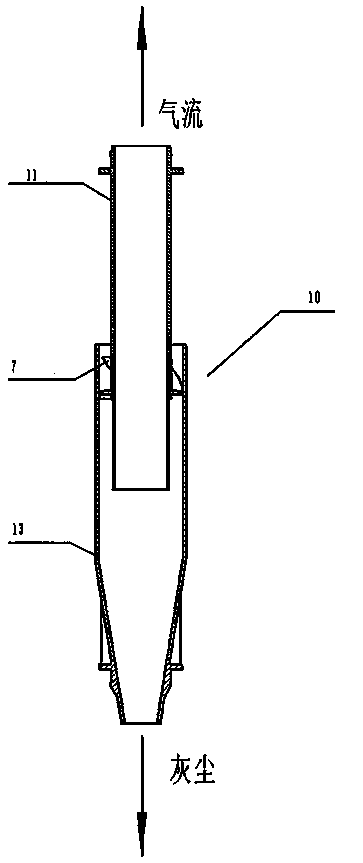

A laminar flow-type stair-shaped porous material adsorption unit and an adsorption method thereof

ActiveCN103386241BReduce construction costsReduce resistanceDispersed particle separationFlue gasEngineering

The present invention provides a laminar flow-type stair-shaped porous material adsorption unit which includes an adsorption tower and is characterized in that a feed hopper (1), an air-inlet grille (4), an air-outlet grille (7), a master feed pipe (10), a saturated material receipt hopper (12), an unsaturated material receipt hopper (13) and multilayer porous material bed layers (11) arranged in a stair-shaped manner are disposed in the adsorption tower; the feed hopper (1) is connected with the porous material bed layers (11) via a feed pipe (2) and the master feed pipe (10); the air-inlet grille (4) is located at the flue gas inlet side of each layer of the porous material bed layers (11), the air-outlet grille (7) is located at the flue gas outlet side of each layer of the porous material bed layers (11); and the porous material bed layers (11) are connected with the material receipt hopper (12) and the material receipt hopper (13) via material receipt pipes (6). The adsorption unit and an adsorption method of the invention have a high contaminant removal efficiency and low operating costs; and the space utilization is high, the construction cost is low, energy consumption is saved.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Impurity collection device

InactiveCN108837605AReduce volumeSave spaceDispersed particle separationPulp and paper industryImpurity

The invention discloses an impurity collection device. The device is used in a cyclone pipe type fluid pre-filter, wherein an impurity discharging pipe is vertically arranged in the middle of a casingof the fluid pre-filter in the axis direction, cyclone pipes are mounted between the outer wall of the casing of the fluid pre-filter and the impurity discharging pipe, impurity collecting units arearranged at the lower parts of the cyclone pipes, each impurity collecting unit comprises an annular impurity collecting box and a control component used for opening or closing a collecting port of each impurity collecting box, an inner annular opening of each impurity collecting unit is communicated with the impurity discharging pipe, the impurity collecting boxes are open upwards, a plurality ofvertical partition boards are arranged in each impurity collecting box to divide each impurity collecting box into multiple impurity accommodating cavities, the impurity collecting boxes are made ofa transparent materials to facilitate observation of the quantity of impurities in the boxes, and the impurity collecting boxes are made through integrated forming with an additive manufacturing process. The provided impurity collecting device can timely observe the impurity stacking condition in the collecting device, dust can be timely and conveniently cleared without dismounting the pre-filterduring dust clearing, and the clearing time is greatly saved.

Owner:石家庄欧亚惠通滤清器有限公司

Cyclone separating device for reducing anticyclone

The invention discloses a cyclone separating device for reducing anticyclone. The cyclone separating device comprises a cyclone separator and a filter horizontally installed in a barrel body of the cyclone separator, wherein an air inlet is arranged at one side of the cyclone separator; the outer wall of the air inlet is formed along a peripheral tangent line of the barrel body of the cyclone separator; an included angle with a certain degree is formed between the outer wall of the air inlet and a parallel line of a peripheral tangent line at the minimum diameter of the cyclone separator; and the inner wall of the air inlet is formed in parallel to the outer wall of the air inlet. According to the cyclone separating device for reducing the anticyclone, an included angle with a certain degree is formed between the outer wall of the air inlet and the parallel line of the peripheral tangent line at the minimum diameter of the cyclone separator, and the outer wall of the air inlet is formed along the peripheral tangent line of the barrel body of the cyclone separator. When air inlet direction is changed for air suction in the tangent line with larger eccentricity, the anticyclone is reduced and resistance of the anticyclone to the air suction is reduced, so that the efficiency of the cyclone separator is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com